Effects of the Application of Lactobacillus plantarum Inoculant and Potassium Sorbate on the Fermentation Quality, In Vitro Digestibility and Aerobic Stability of Total Mixed Ration Silage Based on Alfalfa Silage

Abstract

:Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. Total Mixed Ration (TMR) Silage Preparation

2.2. Chemical and Microbiological Analyses

2.3. In Vitro Incubation and Degradability Measurement

2.4. Aerobic Stability Test

2.5. Statistical Analyses

3. Results

3.1. Fermentation Quality of TMR Silages

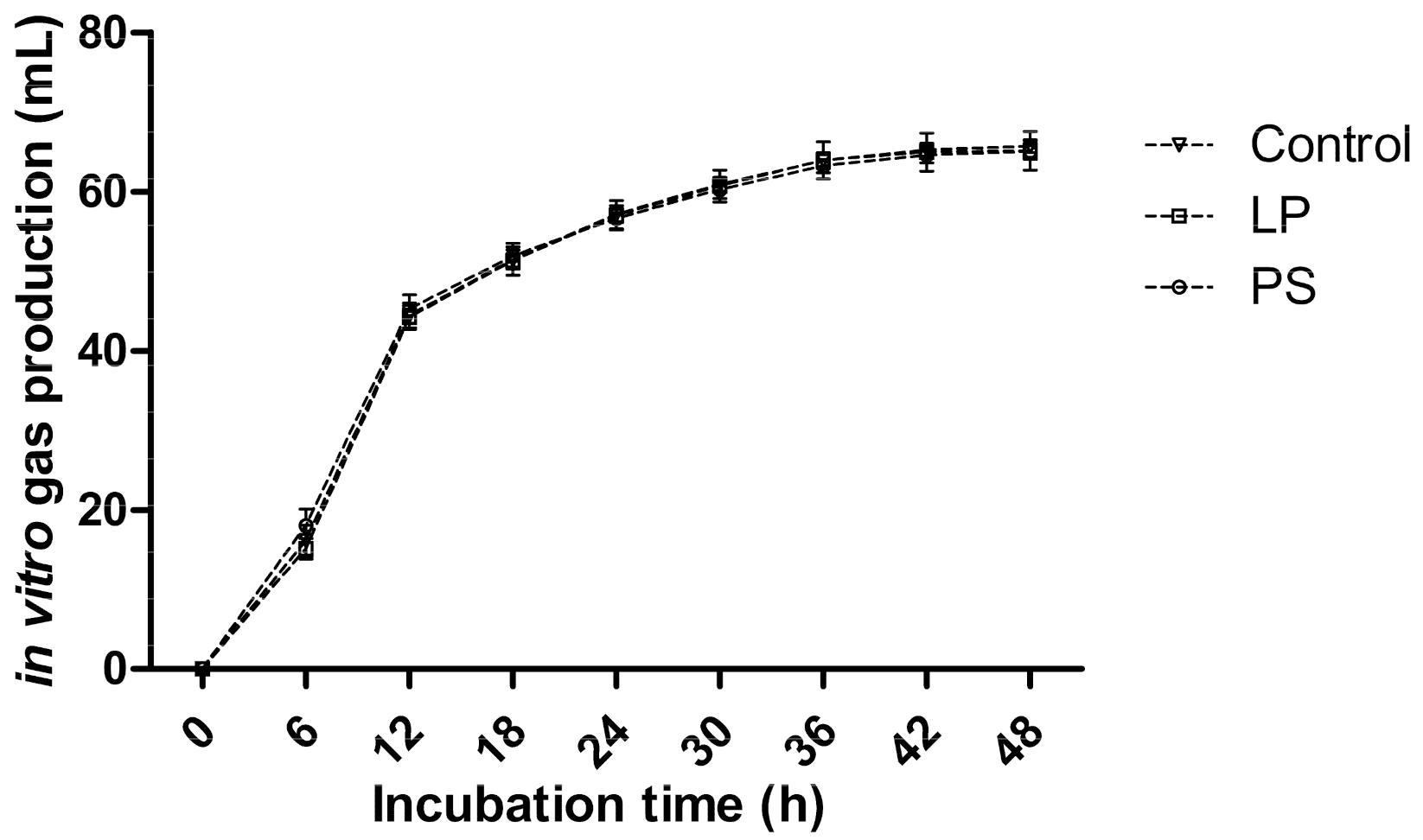

3.2. In Vitro Degradability of TMR Silages

3.3. Aerobic Stability of TMR Silages

4. Discussion

4.1. Effects of Additives on the Fermentation Quality of TMR Silages

4.2. Effects of Additives on the In Vitro Degradability of TMR Silages

4.3. Effects of Additives on the Aerobic Stability of TMR Silages

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Muck, R.E.; Nadeau, E.M.G.; McAllister, T.A.; Contreras-Govea, F.E.; Santos, M.C.; Kung, L. Silage review: Recent advances and future uses of silage additives. J. Dairy Sci. 2018, 101, 3980–4000. [Google Scholar] [CrossRef]

- Zhao, J.; Dong, Z.; Chen, L.; Wang, S.; Shao, T. The replacement of whole-plant corn with bamboo shoot shell on the fermentation quality, chemical composition, aerobic stability and in vitro digestibility of total mixed ration silage. Anim. Feed Sci. Technol. 2020, 259, 114348. [Google Scholar] [CrossRef]

- Nishino, N.; Harada, H.; Sakaguchi, E. Evaluation of fermentation and aerobic stability of wet brewers’ grains ensiled alone or in combination with various feeds as a total mixed ration. J. Sci. Food Agric. 2003, 83, 557–563. [Google Scholar] [CrossRef]

- Yuan, X.; Guo, G.; Wen, A.; Desta, S.T.; Wang, J.; Wang, Y.; Shao, T. The effect of different additives on the fermentation quality, in vitro digestibility and aerobic stability of a total mixed ration silage. Anim. Feed Sci. Technol. 2015, 207, 41–50. [Google Scholar] [CrossRef]

- Bueno, A.V.I.; Lazzari, G.; Jobim, C.C.; Daniel, J.L.P. Ensiling total mixed ration for ruminants: A review. Agronomy 2020, 10, 879. [Google Scholar] [CrossRef]

- Ruppert, L.D.; Drackley, J.K.; Bremmer, D.R.; Clark, J.H. Effects of tallow in diets based on corn silage or alfalfa silage on digestion and nutrient use by lactating dairy cows. J. Dairy Sci. 2003, 86, 593–609. [Google Scholar] [CrossRef]

- Nishino, N.; Ogata, Y.; Han, H.; Yamamoto, Y. Identification of bacteria in total mixed ration silage produced with and without crop silage as an ingredient. Anim. Sci. J. 2015, 86, 45–50. [Google Scholar] [CrossRef]

- Chen, L.; Guo, G.; Yuan, X.; Zhang, J.; Li, J.; Shao, T. Effects of applying molasses, lactic acid bacteria and propionic acid on fermentation quality, aerobic stability and in vitro gas production of total mixed ration silage prepared with oat-common vetch intercrop on the Tibetan Plateau. J. Sci. Food Agric. 2016, 96, 1678–1685. [Google Scholar] [CrossRef]

- Yuan, X.; Wen, A.; Wang, J.; Guo, G.; Desta, S.T.; Shao, T. Effects of ethanol, molasses and Lactobacillus plantarum on the fermentation quality, in vitro digestibility and aerobic stability of total mixed ration silages in the Tibetan plateau of China. Anim. Sci. J. 2016, 87, 681–689. [Google Scholar] [CrossRef]

- Wilkinson, J.M.; Davies, D.R. The aerobic stability of silage: Key findings and recent developments. Grass Forage Sci. 2013, 68, 1–19. [Google Scholar] [CrossRef]

- Seppälä, A.; Heikkilä, T.; Mäki, M.; Rinne, M. Effects of additives on the fermentation and aerobic stability of grass silages and total mixed rations. Grass Forage Sci. 2016, 71, 458–471. [Google Scholar] [CrossRef]

- Zhang, Q.; Yu, Z.; Na, R.S. Effects of different additives on fermentation quality and aerobic stability of Leymus chinensis silage. Grass Forage Sci. 2018, 73, 413–419. [Google Scholar] [CrossRef]

- Kung, L.; Smith, M.L.; Benjamim da Silva, E.; Windle, M.C.; da Silva, T.C.; Polukis, S.A. An evaluation of the effectiveness of a chemical additive based on sodium benzoate, potassium sorbate, and sodium nitrite on the fermentation and aerobic stability of corn silage. J. Dairy Sci. 2018, 101, 5949–5960. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Krishnamoorthy, U.; Muscato, T.V.; Sniffen, C.J.; Van Soest, P.J. Nitrogen fractions in selected feedstuffs. J. Dairy Sci. 1982, 65, 217–225. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis of AOAC International, 17th ed.; Association of Official Analytical Chemists: Gaithersburg, MD, USA, 2005. [Google Scholar]

- McDonald, P.; Henderson, A.R. Determination of water-soluble carbohydrates in grass. J. Sci. Food Agric. 1964, 15, 395–398. [Google Scholar] [CrossRef]

- Van Soest, P.J.; Robertson, J.B.; Lewis, B.A. Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition. J. Dairy Sci. 1991, 74, 3583–3597. [Google Scholar] [CrossRef]

- Broderick, G.A.; Kang, J.H. Automated simultaneous determination of ammonia and total amino acids in ruminal fluid and in vitro media. J. Dairy Sci. 1980, 63, 64–75. [Google Scholar] [CrossRef]

- Tian, J.; Li, Z.; Yu, Z.; Zhang, Q.; Li, X. Interactive effect of inoculant and dried jujube powder on the fermentation quality and nitrogen fraction of alfalfa silage. Anim. Sci. J. 2017, 88, 633–642. [Google Scholar] [CrossRef]

- Takahashi, T.; Horiguchi, K.I.; Goto, M. Effect of crushing unhulled rice and the addition of fermented juice of epiphytic lactic acid bacteria on the fermentation quality of whole crop rice silage, and its digestibility and rumen fermentation status in sheep. Anim. Sci. J. 2005, 76, 353–358. [Google Scholar] [CrossRef]

- Wang, M.; Xu, S.; Wang, T.; Jia, T.; Xu, Z.; Wang, X.; Yu, Z. Effect of inoculants and storage temperature on the microbial, chemical and mycotoxin composition of corn silage. Asian-Australas. J. Anim. Sci. 2018, 31, 1903–1912. [Google Scholar] [CrossRef]

- Benbelkacem, H.; Bayard, R.; Abdelhay, A.; Zhang, Y.; Gourdon, R. Effect of leachate injection modes on municipal solid waste degradation in anaerobic bioreactor. Bioresour. Technol. 2010, 101, 5206–5212. [Google Scholar] [CrossRef] [PubMed]

- Adesogan, A.T.; Salawu, M.B.; Ross, A.B.; Davies, D.R.; Brooks, A.E. Effect of Lactobacillus buchneri, Lactobacillus fermentum, Leuconostoc mesenteroides inoculants, or a chemical additive on the fermentation, aerobic stability, and nutritive value of crimped wheat grains. J. Dairy Sci. 2010, 86, 1789–1796. [Google Scholar] [CrossRef] [Green Version]

- Bal, E.B.B.; Bal, M.A. Effects of chemical additives and ensiling time on whole plant wheat silage microbial profiles inferred by phenotypic and 16S ribosomal DNA analyses. World J. Microbiol. Biotechnol. 2012, 28, 767–776. [Google Scholar] [CrossRef] [PubMed]

- Weinberg, Z.G.; Muck, R.E. New trends and opportunities in the development and use of inoculants for silage. FEMS Microbiol. Rev. 1996, 19, 53–68. [Google Scholar] [CrossRef]

- Su, Z.; Li, Y.; Pan, L.; Xue, F. An investigation on the immunoassays of an ammonia nitrogen-degrading bacterial strain in aquatic water. Aquaculture 2016, 450, 17–22. [Google Scholar] [CrossRef]

- dos Anjos, G.V.S.; Gonçalves, L.C.; Rodrigues, J.A.S.; Keller, K.M.; Coelho, M.M.; Michel, P.H.F.; Ottoni, D.; Jayme, D.G. Effect of re-ensiling on the quality of sorghum silage. J. Dairy Sci. 2018, 101, 6047–6054. [Google Scholar] [CrossRef] [Green Version]

- Yuan, X.; Wen, A.; Dong, Z.; Desta, S.T.; Shao, T. Effects of formic acid and potassium diformate on the fermentation quality, chemical composition and aerobic stability of alfalfa silage. Grass Forage Sci. 2017, 72, 833–839. [Google Scholar] [CrossRef]

- Wen, A.; Yuan, X.; Wang, J.; Desta, S.T.; Shao, T. Effects of four short-chain fatty acids or salts on dynamics of fermentation and microbial characteristics of alfalfa silage. Anim. Feed Sci. Technol. 2017, 223, 141–148. [Google Scholar] [CrossRef]

- Guo, L.; Yao, D.; Li, D.; Lin, Y.; Bureenok, S.; Ni, K.; Yang, F. Effects of lactic acid bacteria isolated from rumen fluid and feces of dairy cows on fermentation quality, microbial community, and in vitro digestibility of alfalfa silage. Front. Microbiol. 2020, 10, 2998. [Google Scholar] [CrossRef]

- Chen, L.; Yuan, X.J.; Li, J.F.; Dong, Z.H.; Wang, S.R.; Guo, G.; Shao, T. Effects of applying lactic acid bacteria and propionic acid on fermentation quality, aerobic stability and in vitro gas production of forage-based total mixed ration silage in Tibet. Anim. Prod. Sci. 2019, 59, 376–383. [Google Scholar] [CrossRef]

- Chen, L.; Yuan, X.; Li, J.; Wang, S.; Dong, Z.; Shao, T. Effect of lactic acid bacteria and propionic acid on conservation characteristics, aerobic stability and in vitro gas production kinetics and digestibility of whole-crop corn based total mixed ration silage. J. Integr. Agric. 2017, 16, 1592–1600. [Google Scholar] [CrossRef] [Green Version]

- Restelatto, R.; Novinski, C.O.; Pereira, L.M.; Silva, E.P.A.; Volpi, D.; Zopollatto, M.; Schmidt, P.; Faciola, A.P. Chemical composition, fermentative losses, and microbial counts of total mixed ration silages inoculated with different Lactobacillus species. J. Anim. Sci. 2019, 97, 1634–1644. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cao, Y.; Takahashi, T.; Horiguchi, K.; Yoshida, N. Effect of adding lactic acid bacteria and molasses on fermentation quality and in vitro ruminal digestion of total mixed ration silage prepared with whole crop rice. Grassl. Sci. 2010, 56, 19–25. [Google Scholar] [CrossRef]

- Filya, I.; Muck, R.E.; Contreras-Govea, F.E. Inoculant effects on alfalfa silage: Fermentation products and nutritive value. J. Dairy Sci. 2007, 90, 5108–5114. [Google Scholar] [CrossRef] [PubMed]

- Contreras-Govea, F.E.; Muck, R.E.; Mertens, D.R.; Weimer, P.J. Microbial inoculant effects on silage and in vitro ruminal fermentation, and microbial biomass estimation for alfalfa, bmr corn, and corn silages. Anim. Feed Sci. Technol. 2011, 163, 2–10. [Google Scholar] [CrossRef]

- Blümmel, M.; Becker, K. The degradability characteristics of fifty-four roughages and roughage neutral-detergent fibres as described by in vitro gas production and their relationship to voluntary feed intake. Br. J. Nutr. 1997, 77, 757–768. [Google Scholar] [CrossRef] [Green Version]

- Blümmel, M.; Makkar, H.P.S.; Becker, K. In vitro gas production: A technique revisited. J. Anim. Physiol. Anim. Nutr. 1997, 77, 24–34. [Google Scholar] [CrossRef]

- Wang, H.; Sun, Q.; Yang, F.; Xu, C. Evaluation of fermentation and aerobic stability of total mixed ration silage containing wet brewers’ grains and corn straw. Adv. Mater. Res. 2012, 347–353, 189–192. [Google Scholar] [CrossRef]

- Wang, F.; Nishino, N. Resistance to aerobic deterioration of total mixed ration silage: Effect of ration formulation, air infiltration and storage period on fermentation characteristics and aerobic stability. J. Sci. Food Agric. 2008, 88, 133–140. [Google Scholar] [CrossRef]

- Jiang, D.; Niu, D.; Zuo, S.; Tian, P.; Zheng, M.; Xu, C. Yeast population dynamics on air exposure in total mixed ration silage with sweet potato residue. Anim. Sci. J. 2020, 91, e13397. [Google Scholar] [CrossRef]

- Fleet, G. Spoilage yeasts. Crit. Rev. Biotechnol. 1992, 12, 1–44. [Google Scholar] [CrossRef] [PubMed]

- Filya, I. The effect of Lactobacillus buchneri and Lactobacillus plantarum on the fermentation, aerobic stability, and ruminal degradability of low dry matter corn and sorghum silages. J. Dairy Sci. 2003, 86, 3575–3581. [Google Scholar] [CrossRef] [Green Version]

- Weinberg, Z.G.; Ashbell, G.; Hen, Y.; Azrieli, A. The effect of applying lactic acid bacteria at ensiling on the aerobic stability of silages. J. Appl. Bacteriol. 1993, 75, 512–518. [Google Scholar] [CrossRef]

- Cai, Y.; Benno, Y.; Ogawa, M.; Kumai, S. Effect of applying lactic acid bacteria isolated from forage crops on fermentation characteristics and aerobic deterioration of silage. J. Dairy Sci. 1999, 82, 520–526. [Google Scholar] [CrossRef]

| Item 1 | Alfalfa Silage | Corn Cob | Corn Grain | Mixed 2 Concentrate |

|---|---|---|---|---|

| Dry matter (g kg−1 FM) | 446.82 | 940.04 | 887.88 | 921.03 |

| Crude protein (g kg−1 DM) | 145.83 | 35.87 | 83.01 | 325.29 |

| Neutral detergent fiber (g kg−1 DM) | 423.30 | 810.26 | 98.50 | 263.31 |

| Acid detergent fiber (g kg−1 DM) | 296.02 | 417.88 | 38.09 | 110.84 |

| Ether extract (g kg−1 DM) | 41.69 | 38.21 | 48.84 | 58.09 |

| Lactic acid (g kg−1 DM) | 42.47 | - | - | - |

| Acetic acid (g kg−1 DM) | 4.56 | - | - | - |

| Propionic acid (g kg−1 DM) | 10.00 | - | - | - |

| Butyric acid (g kg−1 DM) | ND | - | - | - |

| Ammonia nitrogen (g kg−1 TN) | 31.06 | - | - | - |

| Item 1 | TMR |

|---|---|

| Ingredient composition (g kg−1 DM) | |

| Alfalfa silage | 600 |

| Corn cob | 60 |

| Corn grain | 240 |

| Mixed concentrate 2 | 100 |

| Total | 1000 |

| Chemical composition (g kg−1 FM) | |

| Dry matter | 487.51 |

| Crude protein | 146.18 |

| Water soluble carbohydrate | 15.33 |

| Neutral detergent fiber | 349.61 |

| Acid detergent fiber | 231.16 |

| Item 1 | Treatment 2 | Days of Ensiling | SEM | p-Value 3 | |||||

|---|---|---|---|---|---|---|---|---|---|

| 0 | 7 | 14 | 30 | D | T | D × T | |||

| Fermentative Characteristics | |||||||||

| pH | Control | 4.65 A | 4.32 bB | 4.3b B | 4.26 bB | 0.01 | <0.001 | <0.001 | <0.001 |

| LP | 4.70 A | 4.26 bB | 4.24 bB | 4.25 bB | |||||

| PS | 4.67 A | 4.70 aA | 4.72 aA | 4.59 aB | |||||

| LA | Control | 36.12 D | 53.27 aC | 64.43 aB | 75.44 aA | 0.77 | <0.001 | <0.001 | <0.001 |

| LP | 30.05 C | 39.47 bB | 71.91 aA | 69.39 aA | |||||

| PS | 33.47 C | 18.07 cD | 51.05 bB | 56.23 bA | |||||

| AA | Control | 3.56 B | 3.16 aB | 4.09 bB | 12.06 A | 0.10 | <0.001 | 0.230 | 0.009 |

| LP | 3.27 C | 2.39 aC | 5.15 aB | 12.25 A | |||||

| PS | 3.44 B | 1.09 bC | 4.61 abB | 12.39 A | |||||

| PA | Control | 9.83 AB | 8.31 aB | 9.89 bAB | 12.51 A | 0.20 | <0.001 | 0.008 | <0.001 |

| LP | 9.77 B | 5.84 abC | 5.84 cC | 12.40 A | |||||

| PS | 9.51 B | 3.83 bC | 12.86 aA | 12.32 A | |||||

| BA | Control | ND | ND | ND | ND | - | - | - | - |

| LP | ND | ND | ND | ND | |||||

| PS | ND | ND | ND | ND | |||||

| NH3-N | Control | 22.09 C | 5.60 D | 57.44 aA | 42.53 aB | 0.64 | <0.001 | <0.001 | 0.004 |

| LP | 21.80 C | 3.53 D | 41.17 bA | 31.40 bB | |||||

| PS | 19.52 C | 5.08 C | 56.44 aA | 41.14 aB | |||||

| V-score | Control | 91.31 | 92.71 b | 89.51 b | 90.00 | 0.22 | <0.001 | 0.019 | 0.001 |

| LP | 91.50 C | 95.21 abA | 93.09 aB | 90.00 D | |||||

| PS | 91.58 B | 97.76 aA | 88.71 bC | 90.00 BC | |||||

| Item 1 | Treatment 2 | SEM | p-Value | ||

|---|---|---|---|---|---|

| Control | LP | PS | |||

| Chemical compositions | |||||

| Dry matter (g kg−1 FM) | 487.57 | 480.56 | 481.02 | 3.54 | 0.732 |

| Crude protein (g kg−1 DM) | 150.40 | 154.20 | 153.60 | 1.06 | 0.331 |

| Water soluble carbohydrate (g kg−1 DM) | 9.03 B | 7.03 B | 29.01 A | 3.59 | <0.001 |

| Neutral detergent fiber (g/kg (g kg−1 DM) | 366.29 | 347.68 | 342.78 | 8.40 | 0.548 |

| Acid detergent fiber (g kg−1 DM) | 231.43 | 222.87 | 218.45 | 6.91 | 0.789 |

| In vitro degradability | |||||

| DMD (g kg−1) | 579.90 | 606.71 | 608.87 | 6.37 | 0.113 |

| NDFD (g kg−1) | 355.29 | 354.55 | 330.79 | 21.84 | 0.902 |

| In vitro gas production parameters | |||||

| V24h (mL) | 57.15 | 57.01 | 56.57 | 0.72 | 0.957 |

| V48h (mL) | 65.68 | 65.10 | 65.04 | 0.80 | 0.951 |

| V(∞) (mL) | 64.10 | 63.74 | 63.43 | 0.79 | 0.955 |

| k (mL·h−1) | 3.60 | 3.69 | 3.58 | 0.08 | 0.861 |

| Item 1 | Treatment 2 | Days of Air Exposure | SEM | p-Value 3 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 1 | 3 | 5 | 7 | D | T | D × T | |||

| Fermentative characteristics | ||||||||||

| pH | Control | 4.26 bC | 4.28 bC | 4.28 bC | 4.53 B | 7.52 aA | 0.01 | <0.001 | <0.001 | <0.001 |

| LP | 4.25 bC | 4.28 bC | 4.31 bC | 4.56 B | 7.51 aA | |||||

| PS | 4.59 a | 4.63 a | 4.65 a | 4.68 | 4.70 b | |||||

| LA | Control | 75.44 aA | 71.51 A | 71.55 abA | 71.55 A | 42.46 B | 1.17 | 0.006 | 0.001 | 0.178 |

| LP | 69.39 aAB | 67.69 AB | 80.73 aA | 72.89 A | 48.67 B | |||||

| PS | 56.23 b | 56.16 | 44.22 b | 51.16 | 50.84 | |||||

| AA | Control | 12.06 A | 11.20 A | 9.41 A | 4.80 bB | 2.61 B | 0.35 | <0.001 | 0.172 | 0.224 |

| LP | 12.25 A | 10.93 AB | 11.46 A | 5.64 abC | 6.02 BC | |||||

| PS | 12.39 A | 11.45 AB | 7.85 C | 8.73 aBC | 7.47 C | |||||

| PA | Control | 12.51 | 11.91 | 10.82 | 10.75 | 9.48 b | 0.32 | 0.224 | 0.178 | 0.907 |

| LP | 12.41 | 11.20 | 12.63 | 12.30 | 11.19 a | |||||

| PS | 12.32 | 11.37 | 9.47 | 9.74 | 9.28 b | |||||

| BA | Control | ND | ND | ND | ND | ND | - | - | - | - |

| LP | ND | ND | ND | ND | ND | |||||

| PS | ND | ND | ND | ND | ND | |||||

| NH3-N | Control | 42.53 aB | 47.69 abB | 41.71 B | 44.30 B | 135.85 aA | 2.20 | <0.001 | 0.001 | <0.001 |

| LP | 31.40 bB | 39.74 bB | 32.88 B | 53.18 B | 164.96 aA | |||||

| PS | 41.14 a | 52.15 a | 44.24 | 41.51 | 44.04 b | |||||

| V-score | Control | 90.00 A | 89.84 A | 90.65 A | 89.89 A | 67.90 abB | 0.75 | <0.001 | 0.002 | <0.001 |

| LP | 90.00 A | 90.00 A | 90.00 A | 89.37 A | 54.97 bB | |||||

| PS | 90.00 | 89.45 | 90.80 | 90.05 | 89.60 a | |||||

| Chemical compositions | ||||||||||

| DM | Control | 487.57 | 492.51 | 494.73 | 500.26 | 498.86 | 2.33 | 0.466 | 0.058 | 0.918 |

| LP | 480.56 | 483.04 | 489.44 | 482.92 | 476.77 | |||||

| PS | 481.02 | 489.89 | 499.81 | 499.66 | 504.83 | |||||

| CP | Control | 150.40 A | 150.88 A | 152.19 bA | 153.71 A | 144.00 bB | 0.39 | 0.003 | 0.015 | <0.001 |

| LP | 154.20 AB | 151.60 B | 157.18 aA | 155.84 AB | 146.07 bC | |||||

| PS | 153.60 AB | 154.03 AB | 149.20 bC | 151.04 BC | 155.46 aA | |||||

| WSC | Control | 9.03 b | 11.71 b | 8.76 b | 7.92 b | 8.78 c | 0.35 | 0.037 | <0.001 | 0.202 |

| LP | 7.03 bC | 8.11 bBC | 6.91 bC | 10.22 bAB | 11.83 bA | |||||

| PS | 29.01 a | 32.86 a | 27.18 a | 29.34 a | 30.20 a | |||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, Y.; Xu, S.; Li, W.; Wang, M.; Wu, Z.; Bao, J.; Jia, T.; Yu, Z. Effects of the Application of Lactobacillus plantarum Inoculant and Potassium Sorbate on the Fermentation Quality, In Vitro Digestibility and Aerobic Stability of Total Mixed Ration Silage Based on Alfalfa Silage. Animals 2020, 10, 2229. https://doi.org/10.3390/ani10122229

Xie Y, Xu S, Li W, Wang M, Wu Z, Bao J, Jia T, Yu Z. Effects of the Application of Lactobacillus plantarum Inoculant and Potassium Sorbate on the Fermentation Quality, In Vitro Digestibility and Aerobic Stability of Total Mixed Ration Silage Based on Alfalfa Silage. Animals. 2020; 10(12):2229. https://doi.org/10.3390/ani10122229

Chicago/Turabian StyleXie, Yixiao, Shengyang Xu, Wenqi Li, Musen Wang, Zhe Wu, Jinze Bao, Tingting Jia, and Zhu Yu. 2020. "Effects of the Application of Lactobacillus plantarum Inoculant and Potassium Sorbate on the Fermentation Quality, In Vitro Digestibility and Aerobic Stability of Total Mixed Ration Silage Based on Alfalfa Silage" Animals 10, no. 12: 2229. https://doi.org/10.3390/ani10122229

APA StyleXie, Y., Xu, S., Li, W., Wang, M., Wu, Z., Bao, J., Jia, T., & Yu, Z. (2020). Effects of the Application of Lactobacillus plantarum Inoculant and Potassium Sorbate on the Fermentation Quality, In Vitro Digestibility and Aerobic Stability of Total Mixed Ration Silage Based on Alfalfa Silage. Animals, 10(12), 2229. https://doi.org/10.3390/ani10122229