Effects of a Partially Perforated Flooring System on Ammonia Emissions in Broiler Housing—Conflict of Objectives between Animal Welfare and Environment?

Abstract

Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. Animals and Housing

2.2. Floor Design and Litter Management

2.3. Indoor Environmental Factors

2.4. Ammonia Concentration

2.5. Ventilation Rate

2.6. Litter Analysis

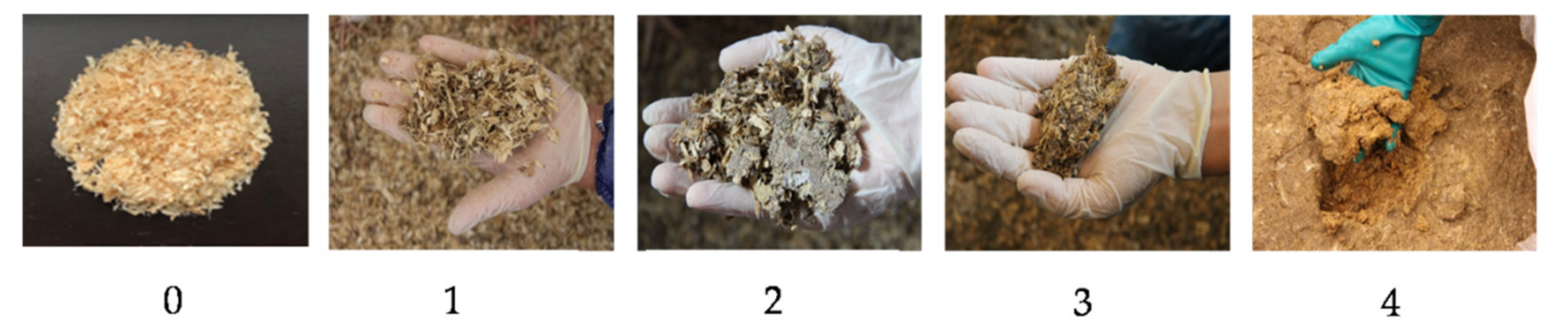

2.7. Litter Quality

2.8. Data Processing and Statistical Analysis

- ER = emission rate (g d−1 bird−1)

- Cinside = inside ammonia concentration (g m−3)

- Coutside = outside ammonia concentration (g m−3)

- VR = ventilation rate (m3 h−1)

- N = actual number of birds per day

3. Results

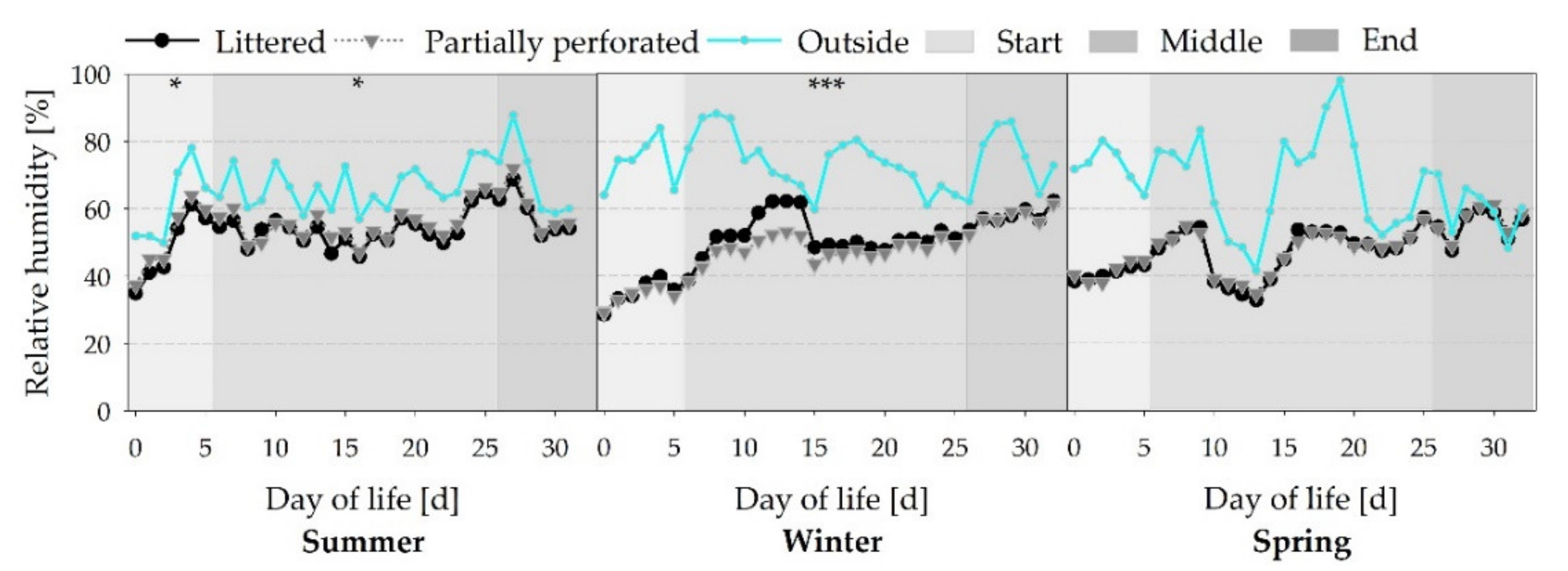

3.1. Indoor Environmental Factors

3.2. Ammonia Concentration

3.3. Ventilation Rate

3.4. Ammonia Emission Rate

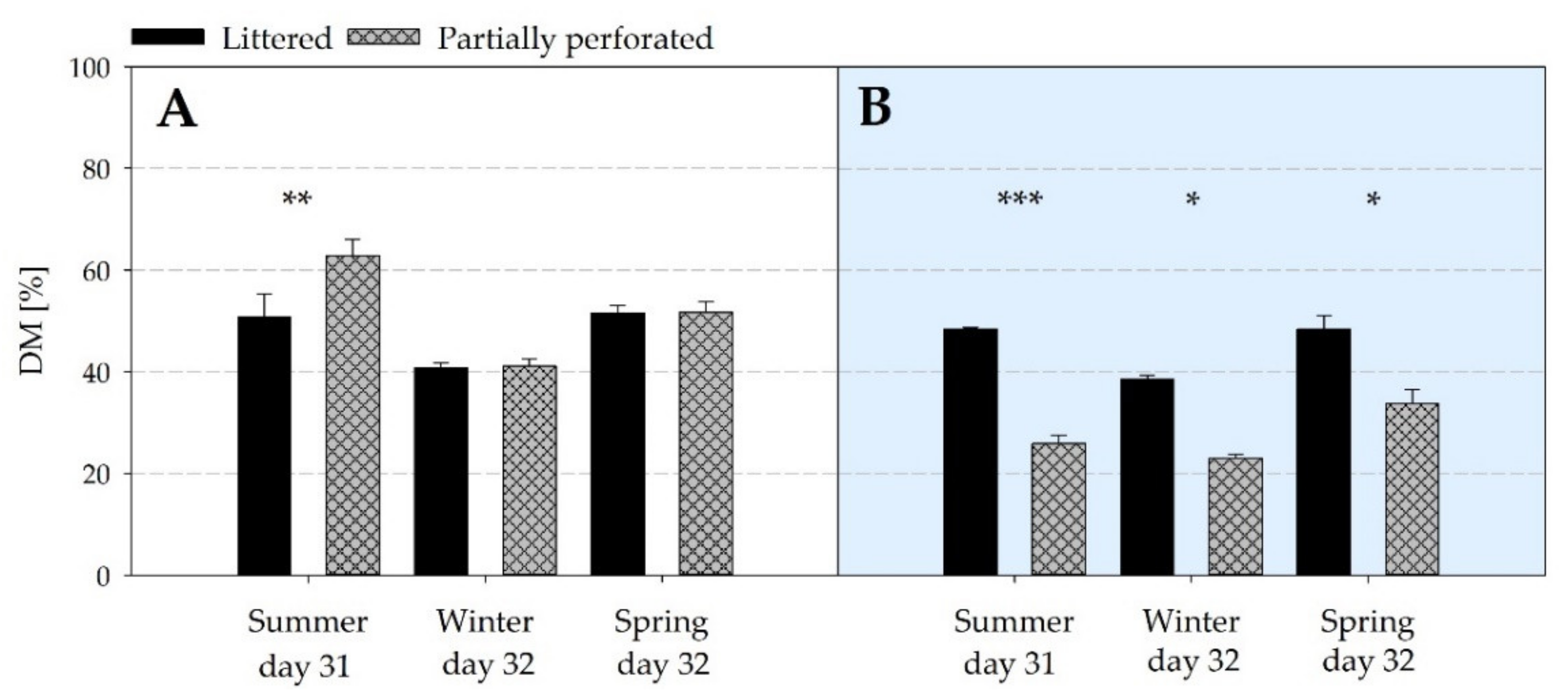

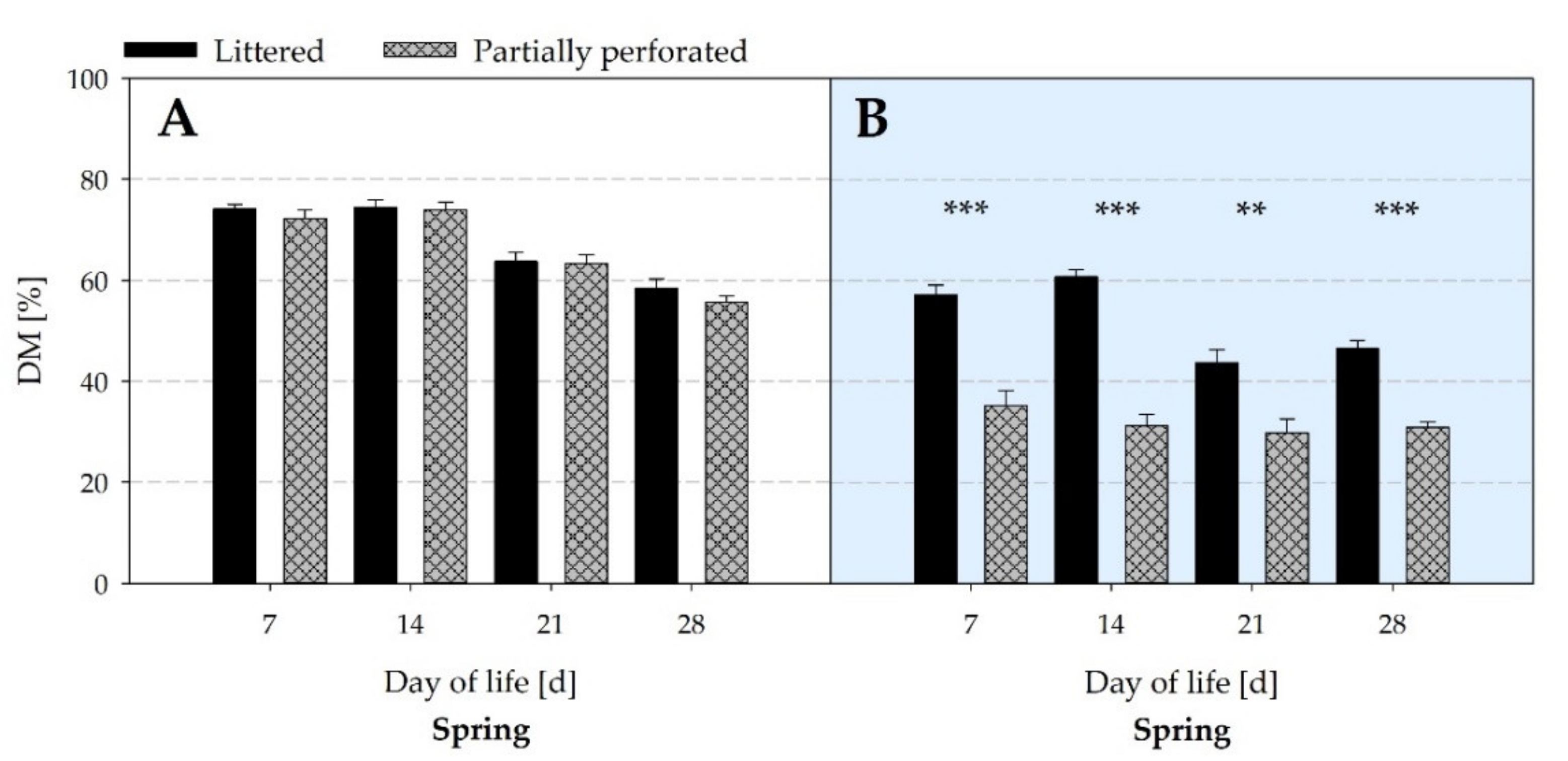

3.5. Litter Analysis

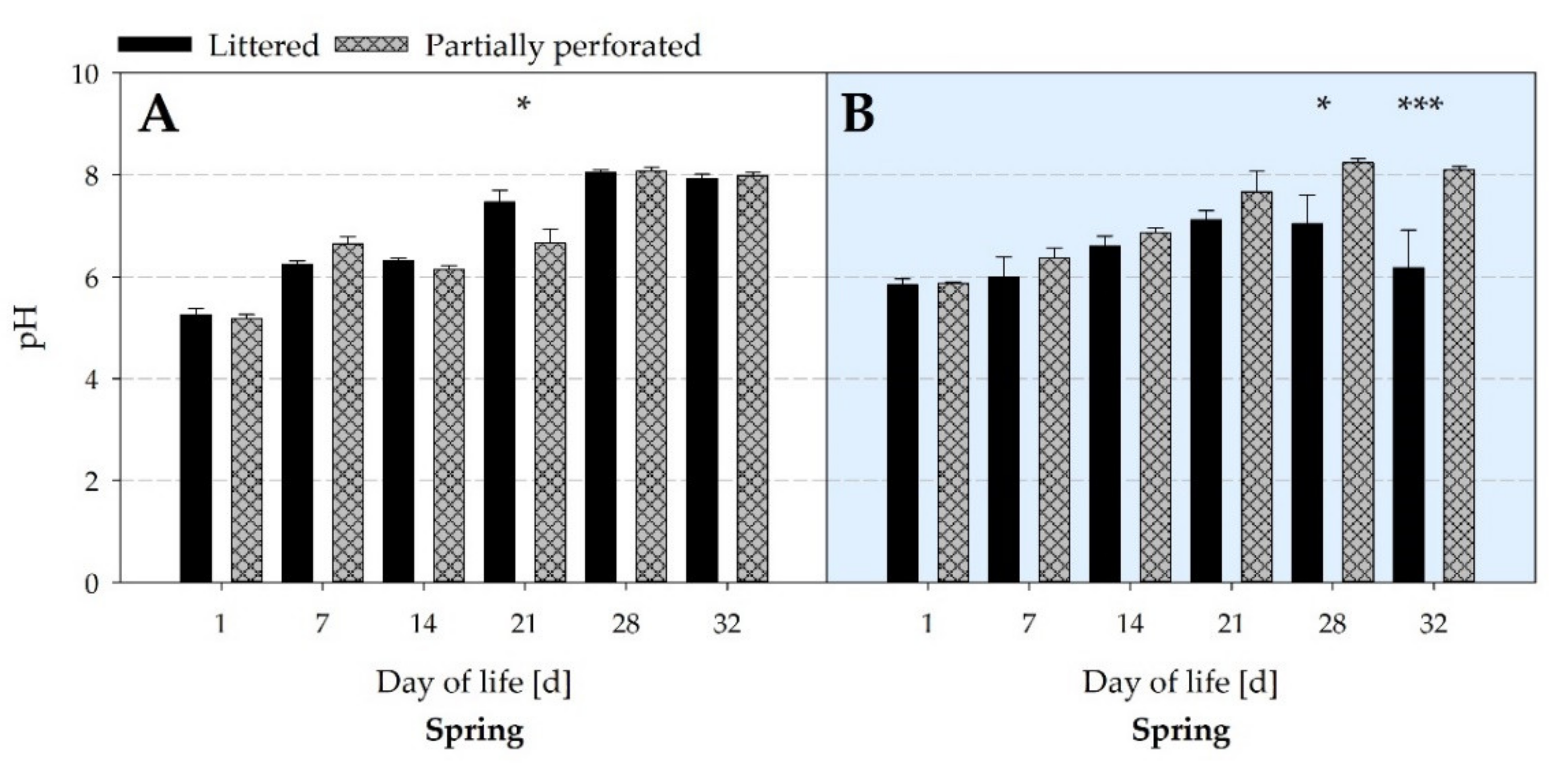

3.6. Litter Quality

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bergmann, S.; Schwarzer, A.; Wilutzky, K.; Louton, H.; Bachmeier, J.; Schmidt, P.; Erhard, M.; Rauch, E. Behavior as welfare indicator for the rearing of broilers in an enriched husbandry environment—A field study. J. Vet. Behav. 2017, 19, 90–101. [Google Scholar] [CrossRef]

- Kamphues, J.; Youssef, A.; Abd El-Wahab, B.; Üffing, B.; Witte, M.; Tost, M. Influence of feeding and housing on foot pad health in hens and turkeys. Übers. Tierernährg. 2011, 39, 147–195. [Google Scholar]

- Youssef, I.M.I.; Beineke, A.; Rohn, K.; Kamphues, J. Experimental study on effects of litter material and its quality on foot pad dermatitis in growing turkeys. Int. J. Poult. Sci. 2010, 9, 1125–1135. [Google Scholar] [CrossRef]

- De Jong, I.C.; van Harn, J.; Gunnink, H.; Hindle, V.A.; Lourens, A. Footpad dermatitis in Dutch broiler flocks: Prevalence and factors of influence. Poult. Sci. 2012, 91, 1569–1574. [Google Scholar] [CrossRef] [PubMed]

- Haslam, S.M.; Knowles, T.G.; Brown, S.N.; Wilkins, L.J.; Kestin, S.C.; Warriss, P.D.; Nicol, C.J. Factors affecting the prevalence of foot pad dermatitis, hock burn and breast burn in broiler chicken. Br. Poult. Sci. 2007, 48, 264–275. [Google Scholar] [CrossRef] [PubMed]

- Martland, M.F. Ulcerative dermatitis dm broiler chickens: The effects of wet litter. Avian Pathol. 1985, 14, 353–364. [Google Scholar] [CrossRef]

- Michel, V.; Prampart, E.; Mirabito, L.; Allain, V.; Arnould, C.; Huonnic, D.; Le Bouquin, S.; Albaric, O. Histologically-validated footpad dermatitis scoring system for use in chicken processing plants. Br. Poult. Sci. 2012, 53, 275–281. [Google Scholar] [CrossRef] [PubMed]

- Bessei, W. Welfare of broilers: A review. Worlds Poult. Sci. J. 2006, 62, 455–466. [Google Scholar] [CrossRef]

- Furtula, V.; Farrell, E.G.; Diarrassouba, F.; Rempel, H.; Pritchard, J.; Diarra, M.S. Veterinary pharmaceuticals and antibiotic resistance of Escherichia coli isolates in poultry litter from commercial farms and controlled feeding trials. Poult. Sci. 2010, 89, 180–188. [Google Scholar] [CrossRef] [PubMed]

- Kemper, N. Veterinary antibiotics and their possible impact on resistant bacteria in the environment. In Antibiotic Resistance: Causes and Risk Factors, Mechanisms and Alternatives, 2nd ed.; Bonilla, A.R., Muniz, K.P., Eds.; Nova Science Publishers, Inc.: New York, NY, USA, 2009; pp. 467–495. ISBN 9781607419730. [Google Scholar]

- Amador, P.; Fernandes, R.; Prudêncio, C.; Duarte, I. Prevalence of antibiotic resistance genes in multidrug-resistant enterobacteriaceae on portuguese livestock manure. Antibiotics 2019, 8, 23. [Google Scholar] [CrossRef] [PubMed]

- Adler, C.; Tiemann, I.; Hillemacher, S.; Schmithausen, A.J.; Müller, U.; Heitmann, S.; Spindler, B.; Kemper, N.; Büscher, W. Effects of a partially perforated flooring system on animal-based welfare indicators in broiler housing. Poult. Sci. 2020, 99, 3343–3354. [Google Scholar] [CrossRef]

- Heitmann, S.; Stracke, J.; Adler, C.; Ahmed, M.F.E.; Schulz, J.; Büscher, W.; Kemper, N.; Spindler, B. Effects of a slatted floor on bacteria and physical parameters in litter in broiler houses. Vet. Anim. Sci. 2020, 9, 100115. [Google Scholar] [CrossRef] [PubMed]

- Wood, D.J.; van Heyst, B.J. A review of ammonia and particulate matter control strategies for poultry housing. Trans. ASAE 2016, 59, 329–344. [Google Scholar] [CrossRef]

- Schrader, L.; Müller, B. Night-time roosting in the domestic fowl: The height matters. Appl. Anim. Behav. Sci. 2009, 121, 179–183. [Google Scholar] [CrossRef]

- Larsen, B.; Vestergaard, K.S.; Hogan, J.A. Development of dustbathing behavior sequences in the domestic fowl: The significance of functional experience. Dev. Psychobiol. 2000, 37, 5–12. [Google Scholar] [CrossRef]

- Blokhuis, H.J. The effect of a sudden change in floor type on pecking behaviour in chicks. Appl. Anim. Behav. Sci. 1989, 22, 65–73. [Google Scholar] [CrossRef]

- Tahamtani, F.M.; Pedersen, I.J.; Toinon, C.; Riber, A.B. Effects of environmental complexity on fearfulness and learning ability in fast growing broiler chickens. Appl. Anim. Behav. Sci. 2018, 207, 49–56. [Google Scholar] [CrossRef]

- Baxter, M.; Bailie, C.L.; O’Connell, N.E. Play behaviour, fear responses and activity levels in commercial broiler chickens provided with preferred environmental enrichments. Animal 2019, 13, 171–179. [Google Scholar] [CrossRef]

- De Jonge, J.; van Trijp, H.C.M. Meeting heterogeneity in consumer demand for animal welfare: A reflection on existing knowledge and implications for the meat sector. J. Agric. Environ. Ethics 2013, 26, 629–661. [Google Scholar] [CrossRef]

- Almuhanna, E.A.; Ahmed, A.S.; Al-Yousif, Y.M. Effect of air contaminants on poultry immunological and production performance. Int. J. Poult. Sci. 2011, 10, 461–470. [Google Scholar] [CrossRef]

- Valentine, H. A study of the effect of different ventilation rates on the ammonia concentrations in the atmosphere of broiler houses. Br. Poult. Sci. 1964, 5, 149–159. [Google Scholar] [CrossRef]

- Ihrig, A.; Hoffmann, J.; Triebig, G. Examination of the influence of personal traits and habituation on the reporting of complaints at experimental exposure to ammonia. Int. Arch. Occup. Environ. Health 2006, 79, 332–338. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.N.; Yan, F.F.; Hu, J.Y.; Chen, H.; Tucker, C.M.; Green, A.R.; Cheng, H.W. The effect of chronic ammonia exposure on acute-phase proteins, immunoglobulin, and cytokines in laying hens. Poult. Sci. 2017, 96, 1524–1530. [Google Scholar] [CrossRef] [PubMed]

- Miles, D.M.; Branton, S.L.; Lott, B.D. Atmospheric ammonia is detrimental to the performance of modern commercial broilers. Poult. Sci. 2004, 83, 1650–1654. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.M.; Meng, Q.P.; Guo, Y.Z.; Wang, Y.Z.; Wang, Z.; Yao, Z.L.; Shan, T.Z. Effect of atmospheric ammonia on growth performance and immunological response of broiler chickens. J. Anim. Vet. Adv. 2010, 22, 2802–2806. [Google Scholar] [CrossRef]

- Xin, H.; Gates, R.S.; Green, A.R.; Mitloehner, F.M.; Moore, P.A.; Wathes, C.M. Environmental impacts and sustainability of egg production systems. Poult. Sci. 2011, 90, 263–277. [Google Scholar] [CrossRef]

- Li, H.; Lin, C.; Collier, S.; Brown, W.; White-Hansen, S. Assessment of frequent litter amendment application on ammonia emission from broilers operations. J. Air Waste Manag. Assoc. 2013, 63, 442–452. [Google Scholar] [CrossRef] [PubMed]

- Van Breemen, N.; van Dijk, H.F.G. Ecosystem effects of atmospheric deposition of nitrogen in The Netherlands. Environ. Pollut. 1988, 54, 249–274. [Google Scholar] [CrossRef]

- Boggia, A.; Paolotti, L.; Antegiovanni, P.; Fagioli, F.F.; Rocchi, L. Managing ammonia emissions using no-litter flooring system for broilers: Environmental and economic analysis. Environ. Sci. Policy 2019, 101, 331–340. [Google Scholar] [CrossRef]

- Almeida, E.A.; Arantes de Souza, L.F.; Sant’Anna, A.C.; Bahiense, R.N.; Macari, M.; Furlan, R.L. Poultry rearing on perforated plastic floors and the effect on air quality, growth performance, and carcass injuries—Experiment 1: Thermal comfort. Poult. Sci. 2017, 96, 3155–3162. [Google Scholar] [CrossRef]

- Li, H.; Wen, X.; Alphin, R.; Zhu, Z.; Zhou, Z. Effects of two different broiler flooring systems on production performances, welfare, and environment under commercial production conditions. Poult. Sci. 2017, 96, 1108–1119. [Google Scholar] [CrossRef]

- Schmithausen, A.J.; Trimborn, M.; Büscher, W. Methodological comparison between a novel automatic sampling system for gas chromatography versus photoacoustic spectroscopy for measuring greenhouse gas emissions under field conditions. Sensors 2016, 16, 1638. [Google Scholar] [CrossRef]

- Schmithausen, A.J.; Schiefler, I.; Trimborn, M.; Gerlach, K.; Südekum, K.-H.; Pries, M.; Büscher, W. Quantification of methane and ammonia emissions in a naturally ventilated barn by using defined criteria to calculate emission rates. Animals 2018, 8, 75. [Google Scholar] [CrossRef]

- Welfare Quality. Welfare Quality® Assessment Protocol for Poultry (Broilers, Laying Hens); Welfare Quality® Consortium: Lelystad, The Netheralands, 2009. [Google Scholar]

- Akpobome, G.O.; Fanguy, R.C. Evaluation of cage floor systems for production of commercial broilers. Poult. Sci. 1992, 71, 274–280. [Google Scholar] [CrossRef]

- Cengiz, Ö.; Hess, J.B.; Bilgili, S.F. Effect of protein source on the development of footpad dermatitis in broiler chickens reared on different flooring types. Arch. Geflügelk. 2013, 77, 166–170. [Google Scholar]

- Çavuşoğlu, E.; Petek, M.; Abdourhamane, İ.M.; Akkoc, A.; Topal, E. Effects of different floor housing systems on the welfare of fast-growing broilers with an extended fattening period. Arch. Anim. Breed. 2018, 61, 9–16. [Google Scholar] [CrossRef]

- Çavuşoğlu, E.; Petek, M. Effects of different floor materials on the welfare and behaviour of slow- and fast-growing broilers. Arch. Anim. Breed. 2019, 62, 335–344. [Google Scholar] [CrossRef]

- Groot Koerkamp, P.W.G. Review on emissions of ammonia from housing systems for laying hens in relation to sources, processes, building design and manure handling. J. Agric. Eng. Res. 1994, 59, 73–87. [Google Scholar] [CrossRef]

- Meda, B.; Hassouna, M.; Aubert, C.; Robin, P.; Dourmad, J.Y. Influence of rearing conditions and manure management practices on ammonia and greenhouse gas emissions from poultry houses. Worlds Poult. Sci. J. 2011, 67, 441–456. [Google Scholar] [CrossRef]

- Ivoš, J.; Asaj, A.; Marjanović, L.; Madžirov, Ž. A contribution to the hygiene of deep litter in the chicken house. Poult. Sci. 1966, 45, 676–683. [Google Scholar] [CrossRef]

- Miles, D.M.; Brooks, J.P.; McLaughlin, M.R.; Rowe, D.E. Broiler litter ammonia emissions near sidewalls, feeders, and waterers. Poult. Sci. 2013, 92, 1693–1698. [Google Scholar] [CrossRef] [PubMed]

- Reece, F.N.; Bates, B.J.; Lott, B.D. Ammonia control in broiler houses. Poult. Sci. 1979, 58, 754–755. [Google Scholar] [CrossRef]

- Xue, S.K.; Chen, S.; Hermanson, R.E. Measuring ammonia and hydrogen sulfide emitted from manure storage facilities. Trans ASAE 1998, 41, 1125–1130. [Google Scholar] [CrossRef]

- Li, H.; Xin, H.; Burns, R.T.; Roberts, S.A.; Li, S.; Kliebenstein, J.; Bregendahl, K. Reducing ammonia emissions from laying-hen houses through dietary manipulation. J. Air Waste Manag. Assoc. 2012, 62, 160–169. [Google Scholar] [CrossRef] [PubMed]

- Hartung, J.; Phillips, V.R. Control of gaseous emissions from livestock buildings and manure stores. J. Agric. Eng. Res. 1994, 57, 173–189. [Google Scholar] [CrossRef]

- Kirchmann, H.; Lundvall, A. Treatment of solid animal manures: Identification of low NH3 emission practices. Nutr. Cycl. Agroecosyst. 1998, 51, 65–71. [Google Scholar] [CrossRef]

- Kirchmann, H.; Witter, E. Ammonia volatilization during aerobic and anaerobic manure decomposition. Plant Soil 1989, 115, 35–41. [Google Scholar] [CrossRef]

- Mahimairaja, S.; Bolan, N.S.; Hedley, M.J.; Macgregor, A.N. Losses and transformation of nitrogen during composting of poultry manure with different amendments: An incubation experiment. Bioresour. Technol. 1994, 47, 265–273. [Google Scholar] [CrossRef]

- Amon, B.; Amon, T.; Boxberger, J.; Alt, C. Emissions of NH3, N2O and CH4 from dairy cows housed in a farmyard manure tying stall (housing, manure storage, manure spreading). Nutr. Cycl. Agroecosyst. 2001, 60, 103–113. [Google Scholar] [CrossRef]

- Acharya, C.N. Studies on the anaerobic decomposition of plant materials. Biochem. J. 1935, 29, 1116–1120. [Google Scholar] [CrossRef]

- Sommer, S.G.; Husted, S. The chemical buffer system in raw and digested animal slurry. J. Agric. Sci. 1995, 124, 45–53. [Google Scholar] [CrossRef]

- Christensen, M.L.; Sommer, S.G. Manure characterization and inorganic chemistry. In Animal Manure Recycling: Treatment and Management, 1st ed.; Sommer, S.G., Christensen, M.L., Schmidt, T., Jensen, L., Eds.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2013; pp. 41–65. [Google Scholar]

- Sistani, K.R.; Brink, G.E.; McGowen, S.L.; Rowe, D.E.; Oldham, J.L. Characterization of broiler cake and broiler litter, the by-products of two management practices. Bioresour. Technol. 2003, 90, 27–32. [Google Scholar] [CrossRef]

- Chadwick, D.R. Emissions of ammonia, nitrous oxide and methane from cattle manure heaps: Effect of compaction and covering. Atmos. Environ. 2005, 39, 787–799. [Google Scholar] [CrossRef]

- Parkinson, R. Effect of turning regime and seasonal weather conditions on nitrogen and phosphorus losses during aerobic composting of cattle manure. Bioresour. Technol. 2004, 91, 171–178. [Google Scholar] [CrossRef]

- Siegford, J.M.; Powers, W.; Grimes-Casey, H.G. Environmental aspects of ethical animal production. Poult. Sci. 2008, 87, 380–386. [Google Scholar] [CrossRef]

- Leinonen, I.; Williams, A.G.; Wiseman, J.; Guy, J.; Kyriazakis, I. Predicting the environmental impacts of chicken systems in the United Kingdom through a life cycle assessment: Broiler production systems. Poult. Sci. 2012, 91, 8–25. [Google Scholar] [CrossRef] [PubMed]

- Schwean-Lardner, K.; Herwig, E. Poultry Welfare: Future Directions and Challenges? Meat Muscle Biol. 2020, 4, 1–5. [Google Scholar] [CrossRef]

- Nicks, B. Ammonia reduction in pigs. In Livestock Production and Society; Geers, R., Madec, F., Eds.; Wageningen Academic Publishers: Wageningen, The Netherlands, 2006; pp. 179–190. ISBN 9789076998893. [Google Scholar]

- Lagadec, S.; Landrain, B.; Landrain, P.; Robin, P.; Hassouna, M. Ammonia and greenhouse gas emissions in pig fattening on slatted floor with excrementdischarge by flat scraping. In Emissions of Gas and Dust from Livestock; IFIP—Institut du Porc: Paris, France, 2013. [Google Scholar]

- Nicholson, F.A.; Chambers, B.J.; Walker, A.W. Ammonia emissions from broiler litter and laying hen manure management systems. Biosyst. Eng. 2004, 89, 175–185. [Google Scholar] [CrossRef]

- Fournel, S.; Pelletier, F.; Godbout, S.; Lagacé, R.; Feddes, J. Odour emissions, hedonic tones and ammonia emissions from three cage layer housing systems. Biosyst. Eng. 2012, 112, 181–191. [Google Scholar] [CrossRef]

- Fangueiro, D.; Hjorth, M.; Gioelli, F. Acidification of animal slurry—A review. J. Environ. Manag. 2015, 149, 46–56. [Google Scholar] [CrossRef] [PubMed]

- Misselbrook, T.; Hunt, J.; Perazzolo, F.; Provolo, G. Greenhouse gas and ammonia emissions from slurry storage: Impacts of temperature and potential mitigation through covering (pig slurry) or acidification (cattle slurry). J. Environ. Qual. 2016, 45, 1520–1530. [Google Scholar] [CrossRef] [PubMed]

- Nahm, K.H. Environmental effects of chemical additives used in poultry litter and swine manure. Crit. Rev. Environ. Sci. Technol. 2005, 35, 487–513. [Google Scholar] [CrossRef]

- Cockerill, S.A.; Gerber, P.F.; Walkden-Brown, S.W.; Dunlop, M.W. Suitability of litter amendments for the Australian chicken meat industry. Anim. Prod. Sci. 2020, 60, 1469. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adler, C.; Schmithausen, A.J.; Trimborn, M.; Heitmann, S.; Spindler, B.; Tiemann, I.; Kemper, N.; Büscher, W. Effects of a Partially Perforated Flooring System on Ammonia Emissions in Broiler Housing—Conflict of Objectives between Animal Welfare and Environment? Animals 2021, 11, 707. https://doi.org/10.3390/ani11030707

Adler C, Schmithausen AJ, Trimborn M, Heitmann S, Spindler B, Tiemann I, Kemper N, Büscher W. Effects of a Partially Perforated Flooring System on Ammonia Emissions in Broiler Housing—Conflict of Objectives between Animal Welfare and Environment? Animals. 2021; 11(3):707. https://doi.org/10.3390/ani11030707

Chicago/Turabian StyleAdler, Carolin, Alexander J. Schmithausen, Manfred Trimborn, Sophia Heitmann, Birgit Spindler, Inga Tiemann, Nicole Kemper, and Wolfgang Büscher. 2021. "Effects of a Partially Perforated Flooring System on Ammonia Emissions in Broiler Housing—Conflict of Objectives between Animal Welfare and Environment?" Animals 11, no. 3: 707. https://doi.org/10.3390/ani11030707

APA StyleAdler, C., Schmithausen, A. J., Trimborn, M., Heitmann, S., Spindler, B., Tiemann, I., Kemper, N., & Büscher, W. (2021). Effects of a Partially Perforated Flooring System on Ammonia Emissions in Broiler Housing—Conflict of Objectives between Animal Welfare and Environment? Animals, 11(3), 707. https://doi.org/10.3390/ani11030707