Effects of Lard and Vegetable Oils Supplementation Quality and Concentration on Laying Performance, Egg Quality and Liver Antioxidant Genes Expression in Hy-Line Brown

Abstract

:Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Design and Diets

2.2. The Production of Oxidized Oil and Measurement of Oil

2.3. Test of Egg Quality

2.4. Determination of Fatty Acids in Raw and Cooked Egg Yolk

2.5. The Sample Preparation for Scanning Electron Microscopy (SEM) Observations

2.6. Tissue Sampling and Preparation

2.7. Total RNA Extraction, Reverse Transcription, and Real-Time Quantitative PCR

2.8. Statistical Analysis

3. Results

3.1. The Indicators of Oil

3.2. Performance of Laying Hens

3.3. Egg Quality

3.4. The Fatty Acid Composition of Raw and Cooked Yolk

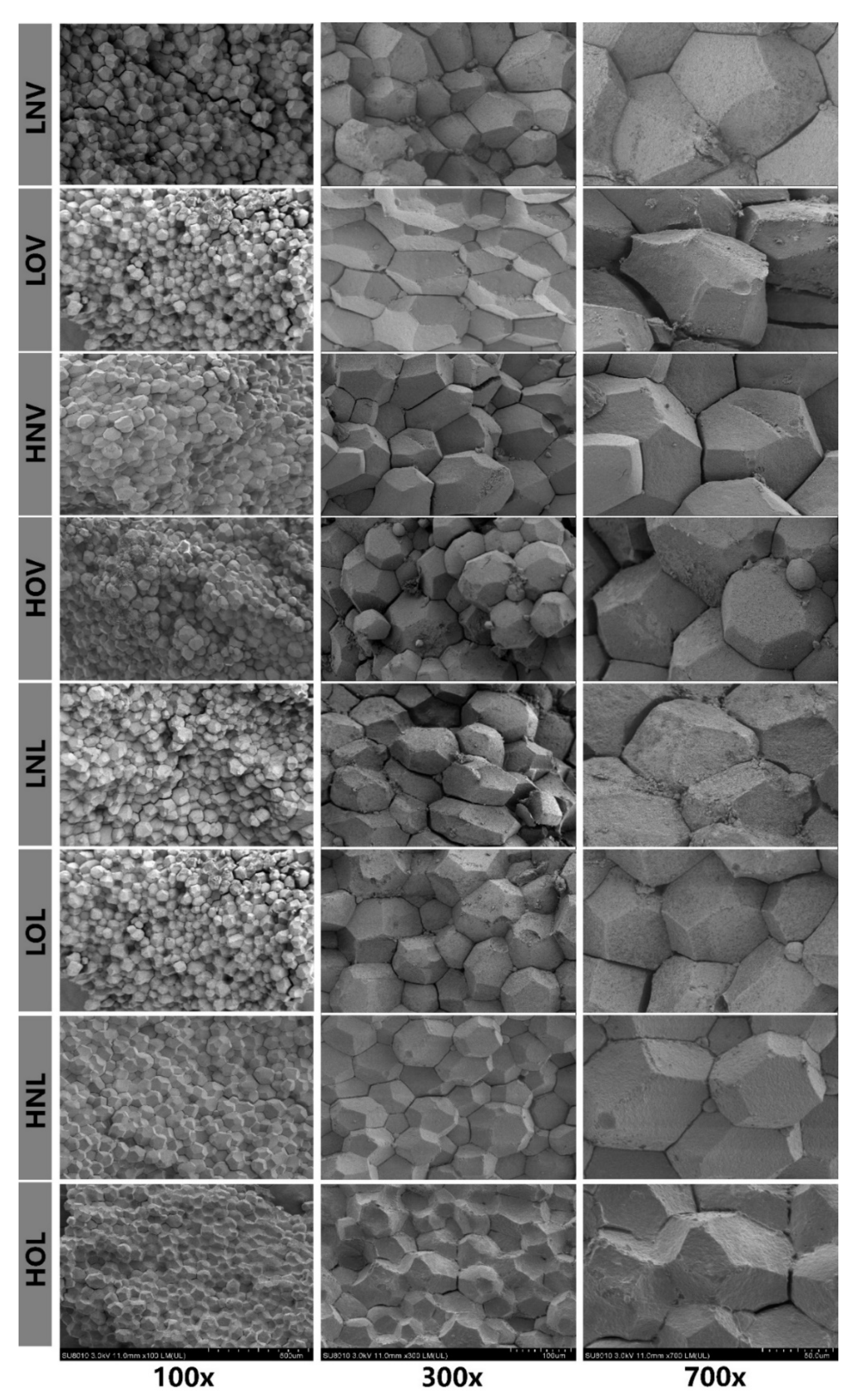

3.5. Microstructure of Cooked Yolk

3.6. Gene Expression of GSTT1, GSTA3, GSTO2, and SOD2

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Stevanović, Z.D.; Bošnjak-Neumüller, J.; Pajić-Lijaković, I.; Raj, J.; Vasiljević, M. Essential Oils as Feed Additives-Future Perspectives. Molecules 2018, 23, 1717. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Palmquist, D.L. Omega-3 Fatty Acids in Metabolism, Health, and Nutrition and for Modified Animal Product Foods. Prof. Anim. Sci. 2009, 25, 207–249. [Google Scholar] [CrossRef]

- Ahmedp, A.; Habibp, A.; Habib, A. Utilization of different peanut oil levels on broiler chickens feed and its effects in their performance. Nova J. Med. Biol. Sci. 2017, 6, 1–9. [Google Scholar] [CrossRef]

- Gul, M.; Yoruk, M.A.; Aksu, T.; Kaya, A.; Kaynar, O. The effect of different levels of canola oil on performance, egg shell quality and fatty acid composition of laying hens. Int. J. Poult. Sci. 2012, 11, 769–776. [Google Scholar] [CrossRef] [Green Version]

- Arab-Tehrany, E.; Jacquot, M.; Gaiani, C.; Imran, M.; Desobry, S.; Linder, M. Beneficial effects and oxidative stability of omega-3 long-chain polyunsaturated fatty acids. Trends Food Sci. Technol. 2012, 25, 24–33. [Google Scholar] [CrossRef]

- Ramírez, M.R.; Estévez, M.; Morcuende, D.; Cava, R. Effect of the Type of Frying Culinary Fat on Volatile Compounds Isolated in Fried Pork Loin Chops by Using SPME-GC-MS. J. Agric. Food Chem. 2004, 52, 7637–7643. [Google Scholar] [CrossRef] [PubMed]

- Varady, J.; Gessner, D.K.; Most, E.; Eder, K.; Ringseis, R. Dietary moderately oxidized oil activates the Nrf2 signaling pathway in the liver of pigs. Lipids Health Dis. 2012, 11, 31. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pizzino, G.; Irrera, N.; Cucinotta, M.; Pallio, G.; Mannino, F.; Arcoraci, V.; Squadrito, F.; Altavilla, D.; Bitto, A. Oxidative Stress: Harms and Benefits for Human Health. Oxid. Med. Cell Longev. 2017, 2017, 8416763. [Google Scholar] [CrossRef]

- Ayala, A.; Muñoz, M.F.; Argüelles, S. Lipid Peroxidation: Production, Metabolism, and Signaling Mechanisms of Malondialdehyde and 4-Hydroxy-2-Nonenal. Oxid. Med. Cell Longev. 2014, 2014, 360438. [Google Scholar] [CrossRef]

- Younus, H. Therapeutic potentials of superoxide dismutase. Int. J. Health Sci. 2018, 12, 88–93. [Google Scholar]

- Kurutas, E.B. The importance of antioxidants which play the role in cellular response against oxidative/nitrosative stress: Current state. Nutr. J. 2016, 15, 71. [Google Scholar] [CrossRef] [Green Version]

- Allocati, N.; Masulli, M.; Di Ilio, C.; Federici, L. Glutathione transferases: Substrates, inihibitors and pro-drugs in cancer and neurodegenerative diseases. Oncogenesis 2018, 7, 8. [Google Scholar] [CrossRef]

- Raza, H. Dual localization of glutathione S-transferase in the cytosol and mitochondria: Implications in oxidative stress, toxicity and disease. FEBS J. 2011, 278, 4243–4251. [Google Scholar] [CrossRef] [Green Version]

- Shahryar, O.; Ardeshir, M.; Navid Ghavi, H.-Z. Effect of dietary fat level and source on performance and immune system response of turkeys. Acta Sci. Anim. Sci. 2019, 42. [Google Scholar] [CrossRef] [Green Version]

- Nikolova, N.; Kocevski, D. Forming egg shape index as influenced by ambient temperatures and age of hens. Biotechnol. Anim. Husb. 2006, 22, 119–125. [Google Scholar] [CrossRef] [Green Version]

- Anderson, K.E.; Tharrington, J.B.; Curtis, P.A.; Jones, F.T. Shell characteristics of eggs from historic strains of Single Comb White Leghorn chickens and the relationship of egg shape to shell strength. Int. J. Poult. Sci. 2004, 3, 17–19. [Google Scholar]

- Doyon, G.; Bernier-Cardou, M.; Hamilton, R.M.G.; Castaigne, F.; Randall, C.J. Egg Quality 2. Albumen Quality of Eggs from Five Commercial Strains of White Leghorn Hens During One Year of Lay. Poult. Sci. 1986, 65, 63–66. [Google Scholar] [CrossRef]

- Eisen, E.J.; Bohren, B.B.; McKean, H.E. Haugh unit as a measure of egg albumen quality. Poult. Sci. 1962, 41, 1461–1468. [Google Scholar] [CrossRef]

- Kaliasheva, K.; Oblakova, M.; Hristakieva, P.; Mincheva, N.; Lalev, M. Comparative study on morphological qualities of eggs from new autosexing layer hybrids for free range poultry farming system. Bulg. J. Agric. Sci. 2017, 23, 609–616. [Google Scholar]

- Hsu, K.-C.; Chung, W.-H.; Lai, K.-M. Histological Structures of Native and Cooked Yolks from Duck Egg Observed by SEM and Cryo-SEM. J. Agric. Food Chem. 2009, 57, 4218–4223. [Google Scholar] [CrossRef]

- Erdman, N.; Bell, D.C.; Reichelt, R. Springer Handbook of Microscopy; Hawkes, P.W., Spence, J.C.H., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 229–318. [Google Scholar] [CrossRef] [Green Version]

- Livak, K.J.; Schmittgen, T.D. Analysis of relative gene expression data using real-time quantitative PCR and the 2(-Delta Delta C(T)) Method. Methods 2001, 25, 402–408. [Google Scholar] [CrossRef] [PubMed]

- Benjamini, Y.; Hochberg, Y. Controlling the False Discovery Rate—A Practical and Powerful Approach to Multiple Testing. J. R. Stat. Soc. Ser. B. Stat. Methodol. 1995, 57, 289–300. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, M.; Mei, J.; Luo, S.; Leng, T.; Chen, Y.; Nie, S.; Xie, M. Comparison of Furans Formation and Volatile Aldehydes Profiles of Four Different Vegetable Oils During Thermal Oxidation. J. Food Sci. 2019, 84, 1966–1978. [Google Scholar] [CrossRef] [PubMed]

- Janero, D.R. Malondialdehyde and thiobarbituric acid-reactivity as diagnostic indices of lipid peroxidation and peroxidative tissue injury. Free Radic. Biol. Med. 1990, 9, 515–540. [Google Scholar] [CrossRef]

- Lee, K.G.; Mitchell, A.E.; Shibamoto, T. Determination of antioxidant properties of aroma extracts from various beans. Agric. Food Chem. 2000, 48, 4817–4820. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.-X.; Guo, L.-Y.; Feng, L.; Jiang, W.-D.; Kuang, S.-Y.; Liu, Y.; Hu, K.; Jiang, J.; Li, S.-H.; Tang, L.; et al. Soybean β-Conglycinin Induces Inflammation and Oxidation and Causes Dysfunction of Intestinal Digestion and Absorption in Fish. PLoS ONE 2013, 8, e58115. [Google Scholar] [CrossRef] [Green Version]

- Liang, F.; Jiang, S.; Mo, Y.; Zhou, G.; Yang, L. Consumption of Oxidized Soybean Oil Increased Intestinal Oxidative Stress and Affected Intestinal Immune Variables in Yellow-feathered Broilers. Asian Australas. J. Anim. Sci. 2015, 28, 1194–1201. [Google Scholar] [CrossRef] [Green Version]

- Li, S.; Tan, H.Y.; Wang, N.; Zhang, Z.J.; Lao, L.; Wong, C.W.; Feng, Y. The Role of Oxidative Stress and Antioxidants in Liver Diseases. Int. J. Mol. Sci. 2015, 16, 26087–26124. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Muramatsu, T.; Hiramoto, K.; Okumura, J. Changes in Ovalbumin and Protein Synthesis in vivo in the Magnum of Laying Hens during the Egg Formation Cycle. Comp. Biochem. Physiol. B Comp. Biochem. 1991, 99, 141–146. [Google Scholar] [CrossRef]

- Rowghani, E.; Arab, M.; Nazifi, S.; Bakhtiari, Z. Effect of canola oil on cholesterol and fatty acid composition of egg-yolk of laying hens. Int. J. Poult. Sci. 2007, 6, 111–114. [Google Scholar]

- Umano, K.; Hagi, Y.; Shoji, A.; Shibamoto, T. Volatile compounds formed from cooked whole egg, egg yolk, and egg white. J. Agric. Food Chem. 1990, 38, 461–464. [Google Scholar] [CrossRef]

- Nebert, D.W.; Vasiliou, V. Analysis of the glutathione S-transferase (GST) gene family. Hum. Genom. 2004, 1, 460–464. [Google Scholar] [CrossRef] [PubMed]

- Josephy, P.D. Genetic variations in human glutathione transferase enzymes: Significance for pharmacology and toxicology. Hum. Genom. Proteom. 2010, 2010, 876940. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sheehan, D.; Meade, G.; Foley, V.M.; Dowd, C.A. Structure, function and evolution of glutathione transferases: Implications for classification of non-mammalian members of an ancient enzyme superfamily. Biochem. J. 2001, 360, 1–16. [Google Scholar] [CrossRef] [PubMed]

- Hassan, H.M. Biosynthesis and regulation of superoxide dismutases. Free Radic. Biol. Med. 1988, 5, 377–385. [Google Scholar] [CrossRef]

- Pias, E.K.; Ekshyyan, O.Y.; Rhoads, C.A.; Fuseler, J.; Harrison, L.; Aw, T.Y. Differential effects of superoxide dismutase isoform expression on hydroperoxide-induced apoptosis in PC-12 cells. J. Biol. Chem. 2003, 278, 13294–13301. [Google Scholar] [CrossRef] [Green Version]

| Items 1 | Groups 2 | |||||||

|---|---|---|---|---|---|---|---|---|

| LNV | HNV | LNL | HNL | LOV | HOV | LOL | HOL | |

| Ingredient, % | ||||||||

| Corn | 63.42 | 60.45 | 60.36 | 60.07 | 63.42 | 60.45 | 63.36 | 60.07 |

| Soybean meal | 24.56 | 25.13 | 24.57 | 25.21 | 24.56 | 25.13 | 24.57 | 25.21 |

| Normal soybean oil | 0.5 | 1.5 | - | - | - | - | - | - |

| Oxidized soybean oil | - | - | - | - | 0.5 | 1.5 | - | - |

| Normal lard | - | - | 0.5 | 1.5 | - | - | - | - |

| Oxidized lard | - | - | - | - | - | - | 0.5 | 1.5 |

| Stone powder | 8.5 | 8.5 | 8.5 | 8.5 | 8.5 | 8.5 | 8.5 | 8.5 |

| Premix 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| Zeolite powder | 0 | 1.4 | 0.05 | 1.7 | 0 | 1.4 | 0.05 | 1.7 |

| Antioxidant 4 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 |

| Total | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Nutrient composition, % | - | - | - | - | - | - | - | - |

| AME, MJ/kg | 11.37 | 11.38 | 11.38 | 11.45 | 11.37 | 11.38 | 11.38 | 11.45 |

| Protein | 17.28 | 17.30 | 17.28 | 16.83 | 17.28 | 17.30 | 17.28 | 16.83 |

| Calcium | 3.14 | 3.14 | 3.14 | 3.06 | 3.14 | 3.14 | 3.14 | 3.06 |

| Phosphorus | 0.33 | 0.32 | 0.33 | 0.32 | 0.33 | 0.32 | 0.33 | 0.32 |

| Lysine | 0.89 | 0.89 | 0.89 | 0.89 | 0.89 | 0.86 | 0.89 | 0.86 |

| Methionine | 0.28 | 0.28 | 0.28 | 0.28 | 0.28 | 0.27 | 0.28 | 0.27 |

| Items 1 | Normal Soybean Oil | Normal Lard | Oxidized Soybean Oil | Oxidized Lard |

|---|---|---|---|---|

| Appearance | The clear, yellow and scented liquid | The pure, white and scented solid | The murky, yellow and odorous liquid | The murky, grey and odorous liquid |

| Acid Value, mg/g | 1.130 | 0.758 | 1.340 | 5.805 |

| Peroxide Value, g/100 g | 0.085 | 0.060 | 0.343 | 0.079 |

| MDA, mg/kg | 0.435 | 0.497 | 1.890 | 3.160 |

| SFA, % | 47.156 | 46.887 | 56.276 | 55.813 |

| UFA, % | 48.347 | 48.002 | 34.778 | 34.539 |

| Item 2 | Groups 3 | |||||||

|---|---|---|---|---|---|---|---|---|

| LNV | HNV | LNL | HNL | LOV | HOV | LOL | HOL | |

| ADFI, g | 115.00 ± 3.77 a | 115.47 ± 4.18 a | 111.78 ± 4.93 ab | 112.93 ± 10.22 ab | 107.16 ± 1.19 ab | 105.44 ± 4.78 b | 102.62 ± 5.10 b | 107.07 ± 1.99 ab |

| FCR, g/g | 2.14 ± 0.12 a | 2.03 ± 0.11 b | 2.14 ± 0.10 a | 1.89 ± 0.15 c | 1.88 ± 0.13 c | 1.93 ± 0.09 bc | 2.01 ± 0.11 b | 1.96 ± 0.07 bc |

| AEW, g | 63.40 ± 0.69 ab | 64.07 ± 0.97 a | 62.83 ± 0.53 b | 63.04 ± 0.61 b | 62.22 ± 2.89 bc | 61.89 ± 1.28 c | 61.93 ± 0.97 c | 61.79 ± 1.40 c |

| LR, % | 87.56 ± 4.03 b | 91.77 ± 4.03 a | 82.03 ± 4.07 c | 92.26 ± 3.79 a | 87.47 ± 4.00 b | 87.46 ± 4.00 b | 82.64 ± 4.10 c | 88.89 ± 4.12 b |

| BWG, g | 40.43 ± 222.70 | 51.64 ± 304.89 | 35.41 ± 302.74 | 52.82 ± 221.38 | 26.99 ± 190.78 | 31.78 ± 282.30 | 30.88 ± 225.8 | 47.52 ± 311.90 |

| Item 2 | Groups 3 | |||||||

|---|---|---|---|---|---|---|---|---|

| LNV | HNV | LNL | HNL | LOV | HOV | LOL | HOL | |

| AH, mm | 4.95 ± 1.11 b | 4.72 ± 1.12 c | 5.26 ± 1.04 a | 4.95 ± 0.96 b | 5.07 ± 1.06 ab | 5.13 ± 1.18 ab | 5.05 ± 1.08 ab | 4.76 ± 1.05 bc |

| YC | 6.36 ± 0.79 ab | 6.21 ± 0.75 b | 6.14 ± 0.65 b | 6.18 ± 0.59 b | 6.32 ± 0.72 ab | 6.26 ± 0.76 b | 6.42 ± 0.60 a | 6.38 ± 0.60 ab |

| HU | 64.58 ± 12.71 b | 63.66 ± 11.13 b | 68.33 ± 10.80 a | 66.05 ± 9.53 ab | 67.38 ± 9.37 ab | 67.89 ± 11.32 a | 66.97 ± 10.25 b | 65.04 ± 9.71 b |

| EW, g | 6.61 ± 1.09 | 6.81 ± 0.54 | 6.80 ± 0.81 | 6.53 ± 0.67 | 6.86 ± 0.78 | 7.19 ± 0.50 | 6.75 ± 0.73 | 6.82 ± 0.55 |

| EST, μm | 373.16 ± 25.5 a | 372.59 ± 32.2 a | 368.33 ± 33.08 ab | 373.74 ± 25.51 a | 368.60 ± 28.83 a | 365.98 ± 27.59 ab | 352.74 ± 36.96 b | 356.20 ± 35.58 b |

| ESS, n/cm2 | 44.34 ± 10.51 | 45.20 ± 9.81 | 44.07 ± 10.05 | 45.34 ± 9.37 | 43.49 ± 10.78 | 43.28 ± 10.57 | 45.25 ± 9.13 | 43.64 ± 10.21 |

| ESI | 1.34 ± 0.05 | 1.35 ± 0.05 | 1.35 ±0.19 | 1.34 ± 0.04 | 1.35 ± 0.05 | 1.35 ± 0.05 | 1.34 ± 0.05 | 1.34 ± 0.05 |

| YP, % | 26.41 ± 1.851 | 26.4 ± 1.576 | 26.35 ± 2.113 | 26.27 ± 3.406 | 26.09 ± 3.763 | 25.83 ± 2.615 | 25.82 ± 3.04 | 25.7 ± 3.804 |

| Item 2 | Groups 3 | |||||||

|---|---|---|---|---|---|---|---|---|

| LNV | HNV | LNL | HNL | LOV | HOV | LOL | HOL | |

| C14:0, mg/g | 0.43 ± 0.027 c | 0.37 ± 0.012 d | 0.27 ± 0.007 e | 0.44 ± 0.027 c | 0.54 ± 0.02 ab | 0.56 ± 0.02 ab | 0.42 ± 0.029 c | 0.6 ± 0.022 a |

| C16:0, mg/g | 34.67 ± 2.348 d | 30.49 ± 0.924 e | 20.65 ± 0.522 f | 31.72 ± 1.442 de | 40.09 ± 1.493 b | 38.09 ± 1.45 c | 32.51 ± 1.659 de | 45.87 ± 2.063 a |

| C16:1, mg/g | 4.64 ± 0.305 ab | 3.63 ± 0.11 b | 2.83 ± 0.071 b | 1.94 ± 2.465 b | 6.18 ± 0.218 a | 5.18 ± 0.218 a | 4.33 ± 0.213 ab | 5.27 ± 0.225 ab |

| C17:0, mg/g | 0.16 ± 0.013 d | 0.19 ± 0.005 bc | 0.09 ± 0.002 e | 0.2 ± 0.008 b | 0.18 ± 0.01 c | 0.18 ± 0.01 c | 0.17 ± 0.009 c | 0.29 ± 0.003 a |

| C18:0, mg/g | 2.9 ± 0.24 b | 2.62 ± 0.253 b | 1.75 ± 0.496 c | 2.69 ± 0.15 b | 2.87 ± 0.32 b | 2.77 ± 0.31 b | 2.58 ± 0.188 b | 4.05 ± 0.334 a |

| C18:1n9c, mg/g | 52.18 ± 3.875 c | 47.24 ± 0.92 c | 32.78 ± 0.885 d | 48.41 ± 2.265 c | 57.7 ± 2.50 b | 52.7 ± 2.4 b | 49.99 ± 2.878 c | 73.54 ± 3.833 a |

| C18:2n6c, mg/g | 15.95 ± 1.143 c | 16.6 ± 0.585 b | 8.12 ± 0.214 d | 15.42 ± 0.687 c | 18.26 ± 0.738 b | 18.28 ± 0.75 b | 14.8 ± 0.769 c | 23.16 ± 1.109 a |

| C18:3n6, mg/g | 0.15 ± 0.008 b | 0.16 ± 0.005 b | 0.09 ± 0.003 c | 0.17 ± 0.012 b | 0.21 ± 0.012 a | 0.20 ± 0.01 a | 0.17 ± 0.008 b | 0.21 ± 0.005 a |

| C20:1, mg/g | 0.31 ± 0.029 bc | 0.27 ± 0.01 c | 0.17 ± 0.005 d | 0.27 ± 0.009 c | 0.32 ± 0.02 b | 0.31 ± 0.02 b | 0.28 ± 0.021 c | 0.43 ± 0.013 a |

| C18:3n3, mg/g | 4.1 ± 0.3 c | 4.5 ± 0.16 bc | 1.6 ± 0.02 e | 3.3 ± 0.11 d | 4.8 ± 0.17 b | 4.6 ± 0.17 b | 3.0 ± 0.22 d | 5.7 ± 0.18 a |

| C20:2, mg/g | 1.7 ± 0.09 b | 1.4 ± 0.43 b | 0.9 ± 0.01 b | 1.7 ± 0.17 b | 1.8 ± 0.07 b | 1.8 ± 0.06 b | 1.7 ± 0.08 b | 2.4 ± 0.12 a |

| C20:3n6, mg/g | 0.23 ± 0.016 d | 0.27 ± 0.008 bc | 0.16 ± 0.004 e | 0.21 ± 0.01 d | 0.29 ± 0.01 b | 0.29 ± 0.02 b | 0.26 ± 0.011 c | 0.33 ± 0.016 a |

| C20:4n6, mg/g | 2.74 ± 0.201 c | 3.11 ± 0.089 b | 1.92 ± 0.051 d | 2.86 ± 0.13 bc | 3.1 ± 0.11 b | 3.1 ± 0.12 b | 3.19 ± 0.157 b | 4.4 ± 0.225 a |

| C22:6n3, mg/g | 0.93 ± 0.071 bc | 1.06 ± 0.031 b | 0.55 ± 0.015 d | 0.88 ± 0.042 c | 0.95 ± 0.045 bc | 0.96 ± 0.05 bc | 0.99 ± 0.126 bc | 1.44 ± 0.076 a |

| SFA, mg/g | 38.3 ± 2.165 c | 33.8 ± 0.677 d | 22.89 ± 0.024 e | 35.18 ± 1.636 cd | 43.84 ± 1.85 b | 41.60 ± 1.86 b | 35.78 ± 1.527 cd | 51.09 ± 1.786 a |

| UFA, mg/g | 78.61 ± 5.748 c | 73.58 ± 1.745 c | 47.58 ± 1.27 d | 71.45 ± 0.738 c | 88.39 ± 3.717 b | 87.42 ± 3.717 b | 75.3 ± 4.265 c | 110.39 ± 5.578 a |

| TFA, mg/g | 116.92 ± 7.913 c | 107.38 ± 2.423 c | 70.47 ± 1.294 d | 106.63 ± 2.374 c | 132.23 ± 5.574 b | 129.02 ± 5.574 b | 111.08 ± 5.793 c | 161.48 ± 7.365 a |

| Item 2 | Groups 3 | |||||||

|---|---|---|---|---|---|---|---|---|

| LNV | HNV | LNL | HNL | LOV | HOV | LOL | HOL | |

| C14:0, mg/g | 0.44 ± 0.02 cd | 0.48 ± 0.03 bc | 0.4 ± 0.023 cd | 0.47 ± 0.05 bc | 0.54 ± 0.04 b | 0.84 ± 0.03 a | 0.47 ± 0.04 bc | 0.35 ± 0.03 d |

| C16:0, mg/g | 36.09 ± 1.76 ab | 37.18 ± 2.14 ab | 31.85 ± 2.54 b | 34.96 ± 3.33 ab | 39.08 ± 1.9 a | 36.14 ± 1.80 ab | 33.66 ± 2.96 ab | 26.5 ± 2.51 b |

| C16:1, mg/g | 3.86 ± 0.18 b | 4.31 ± 0.24 ab | 4.07 ± 0.31 b | 4.9 ± 0.46 a | 4.65 ± 0.23 ab | 3.99 ± 0.24 b | 4.71 ± 0.41 ab | 3.39 ± 0.32 b |

| C17:0, mg/g | 0.19 ± 0.01 | 0.22 ± 0.02 | 0.18 ± 0.02 | 0.17 ± 0.02 | 0.19 ± 0.01 | 0.51 ± 0.01 | 0.18 ± 0.02 | 0.18 ± 0.01 |

| C18:0, mg/g | 2.11 ± 0.13 c | 4.82 ± 0.03 a | 2.94 ± 0.07 bc | 2.54 ± 0.04 c | 2.95 ± 0.16 bc | 3.96 ± 0.17 b | 3.03 ± 0.09 b | 2.58 ± 0.05 c |

| C18:1n9c, mg/g | 54.32 ± 2.81 | 52.95 ± 3.61 | 46.48 ± 3.91 | 55.12 ± 5.48 | 55.6 ± 3.28 | 52.11 ± 2.38 | 46.87 ± 4.40 | 43.28 ± 4.32 |

| C18:2n6c, mg/g | 18.89 ± 0.90 | 23.56 ± 0.16 | 15.67 ± 1.24 | 14.54 ± 1.41 | 19.15 ± 1.07 | 20.21 ± 1.05 | 16.85 ± 1.52 | 12.69 ± 1.21 |

| C18:3n6, mg/g | 0.17 ± 0.01 c | 0.21 ± 0.02 b | 0.2 ± 0.02 bc | 0.16 ± 0.02 cd | 0.44 ± 0.02 a | 0.34 ± 0.01 a | 0.19 ± 0.01 bc | 0.13 ± 0.001 d |

| C20:1, mg/g | 0.32 ± 0.02 | 0.25 ± 0.01 | 0.23 ± 0.02 | 0.32 ± 0.04 | 0.29 ± 0.02 | 0.66 ± 0.01 | 0.28 ± 0.03 | 0.26 ± 0.04 |

| C18:3n3, mg/g | 0.41 ± 0.02 b | 0.67 ± 0.03 a | 0.32 ± 0.02 c | 0.3 ± 0.04 c | 0.44 ± 0.02 b | 0.30 ± 0.01 c | 0.4 ± 0.042 b | 0.25 ± 0.03 c |

| C20:2, mg/g | 0.20 ± 0.01 c | 0.24 ± 0.02 b | 0.15 ± 0.01 d | 0.17 ± 0.02 cd | 0.2 ± 0.01 c | 0.42 ± 0.01 a | 0.18 ± 0.02 cd | 0.15 ± 0.02 d |

| C20:3n6, mg/g | 0.25 ± 0.01 | 0.28 ± 0.02 | 0.25 ± 0.02 | 0.25 ± 0.02 | 0.28 ± 0.02 | 0.46 ± 0.01 | 0.27 ± 0.02 | 0.21 ± 0.01 |

| C20:4n6, mg/g | 0.64 ± 0.01 | 0.61 ± 0.05 | 0.61 ± 0.05 | 0.63 ± 0.09 | 0.62 ± 0.03 | 0.47 ± 0.01 | 0.65 ± 0.05 | 0.68 ± 0.06 |

| C22:6n3, mg/g | 1.21 ± 0.06 b | 1.62 ± 0.12 a | 0.89 ± 0.07 cd | 0.88 ± 0.09 cd | 1.15 ± 0.07 bc | 1.24 ± 0.06 b | 0.99 ± 0.09 c | 0.75 ± 0.01 d |

| SFA, mg/g | 39.02 ± 1.70 ab | 42.87 ± 2.46 a | 35.57 ± 2.54 ab | 38.24 ± 3.48 a | 42.96 ± 1.90 a | 41.45 ± 3.46 ab | 38.00 ± 3.2 ab | 29.78 ± 0.26 b |

| UFA, mg/g | 84.15 ± 4.25 ab | 88.76 ± 5.97 a | 72.23 ± 5.95 b | 80.67 ± 8.01 a | 86.6 ± 4.97 ab | 80.20 ± 3.46 ab | 74.76 ± 6.89 ab | 64.67 ± 6.26 b |

| TFA, mg/g | 123.17 ± 5.95 a | 131.63 ± 8.43 a | 107.8 ± 8.49 ab | 118.91 ± 11.49 a | 129.57 ± 6.88 a | 121.66 ± 7.89 a | 112.76 ± 10.10 ab | 94.45 ± 8.9 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Chen, J.; Yang, J.; Gong, S.; Zheng, J.; Xu, G. Effects of Lard and Vegetable Oils Supplementation Quality and Concentration on Laying Performance, Egg Quality and Liver Antioxidant Genes Expression in Hy-Line Brown. Animals 2021, 11, 769. https://doi.org/10.3390/ani11030769

Zhang J, Chen J, Yang J, Gong S, Zheng J, Xu G. Effects of Lard and Vegetable Oils Supplementation Quality and Concentration on Laying Performance, Egg Quality and Liver Antioxidant Genes Expression in Hy-Line Brown. Animals. 2021; 11(3):769. https://doi.org/10.3390/ani11030769

Chicago/Turabian StyleZhang, Junnan, Jiajing Chen, Jing Yang, Sijia Gong, Jiangxia Zheng, and Guiyun Xu. 2021. "Effects of Lard and Vegetable Oils Supplementation Quality and Concentration on Laying Performance, Egg Quality and Liver Antioxidant Genes Expression in Hy-Line Brown" Animals 11, no. 3: 769. https://doi.org/10.3390/ani11030769

APA StyleZhang, J., Chen, J., Yang, J., Gong, S., Zheng, J., & Xu, G. (2021). Effects of Lard and Vegetable Oils Supplementation Quality and Concentration on Laying Performance, Egg Quality and Liver Antioxidant Genes Expression in Hy-Line Brown. Animals, 11(3), 769. https://doi.org/10.3390/ani11030769