Three-Dimensional Simulation of the Temperature Distribution in a Commercial Broiler House

Abstract

Simple Summary

Abstract

1. Introduction

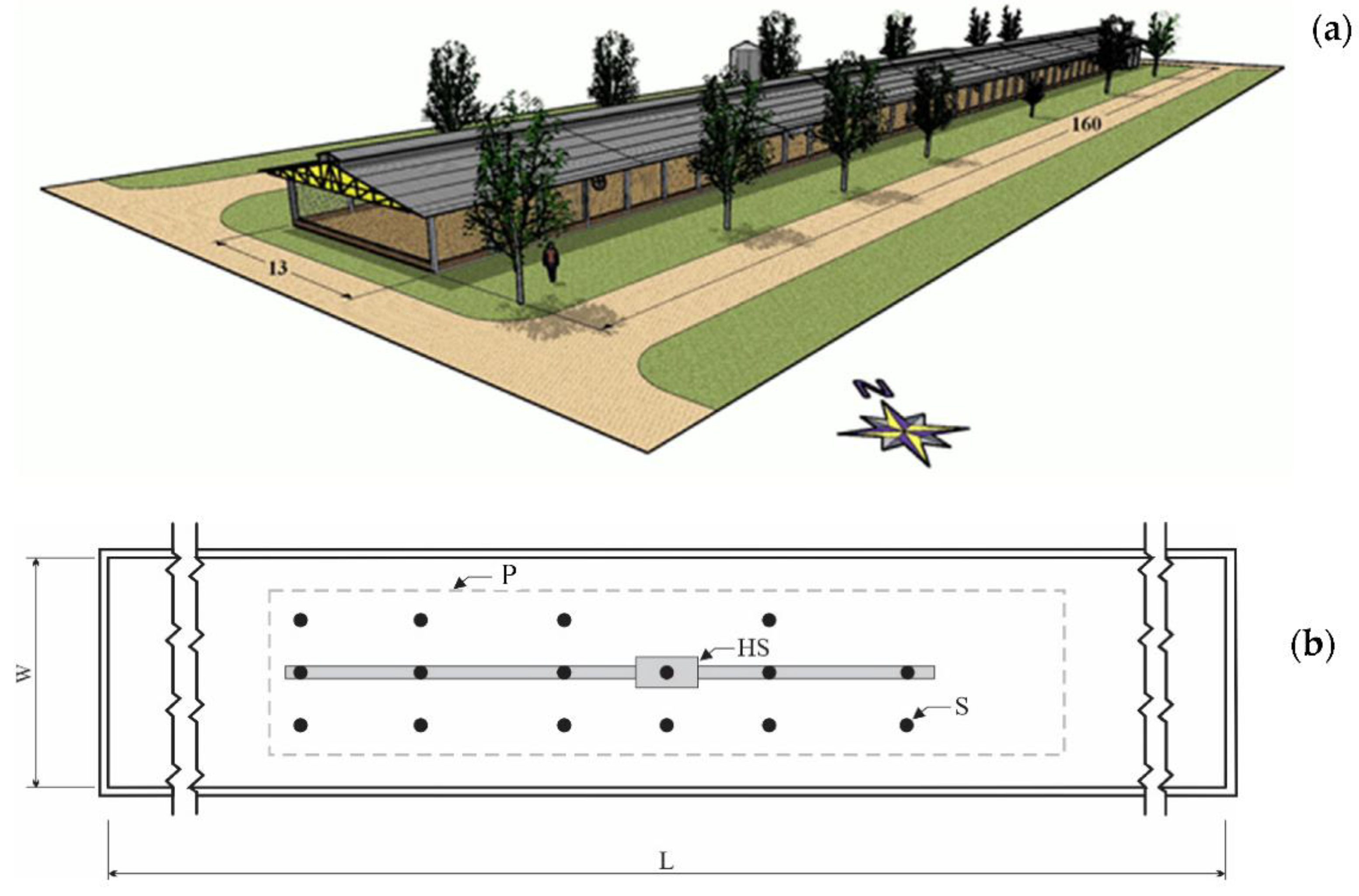

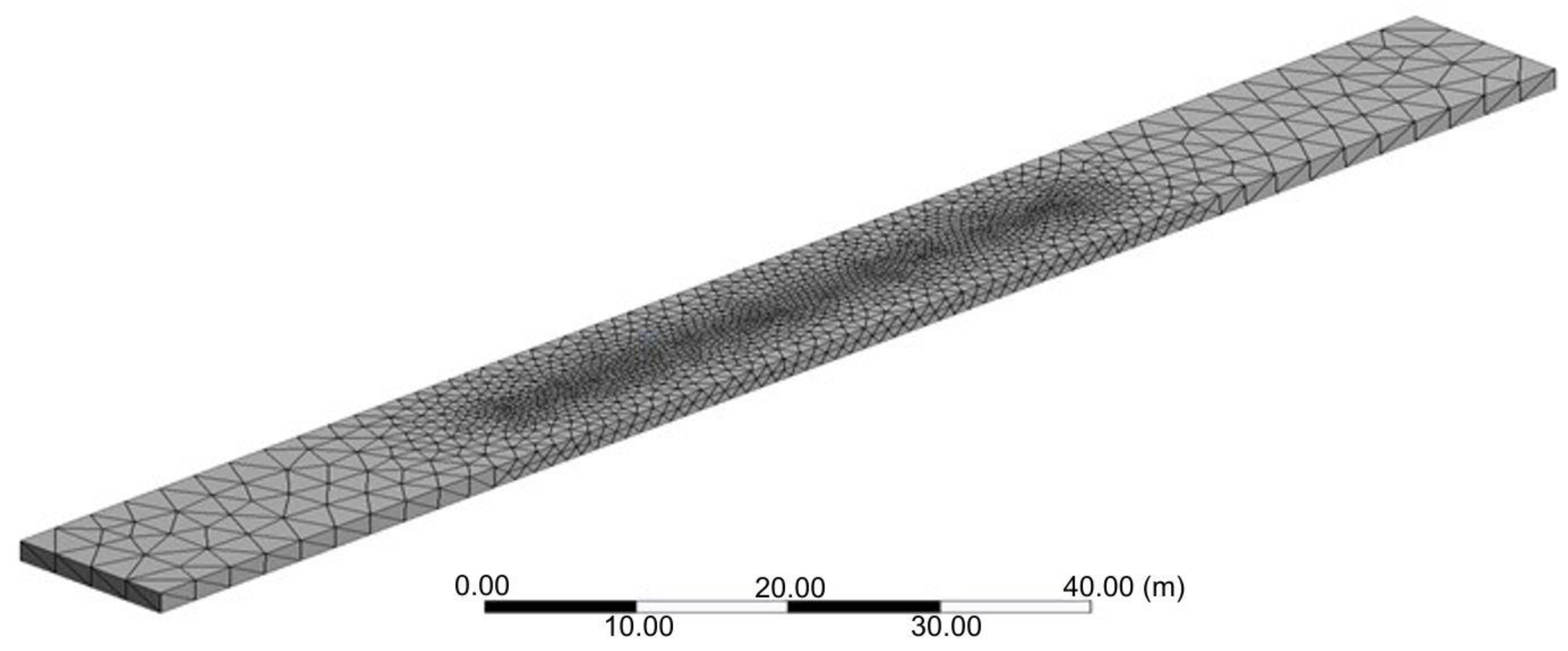

2. Materials and Methods

Conservation Equations

- —fluid density (kg m−3);

- t—time (s);

- —length of the components (m);

- —velocity of the components (m s−1);

- P—pressure (Pa);

- —tension (Pa);

- —gravitational acceleration (m s−2); and

- —direction of external forces (N m−3).

- A—approximate bird area (m2);

- w—body weight (g). It was considered the body weight of 194 g according to [19].

- Qt—heat produced (W);

- w—body weight (kg).

- Y—value observed experimentally, dimensionless;

- Y0—value calculated by the model, dimensionless;

- n—number of experimental observations;

- DF—degrees of freedom of the model.

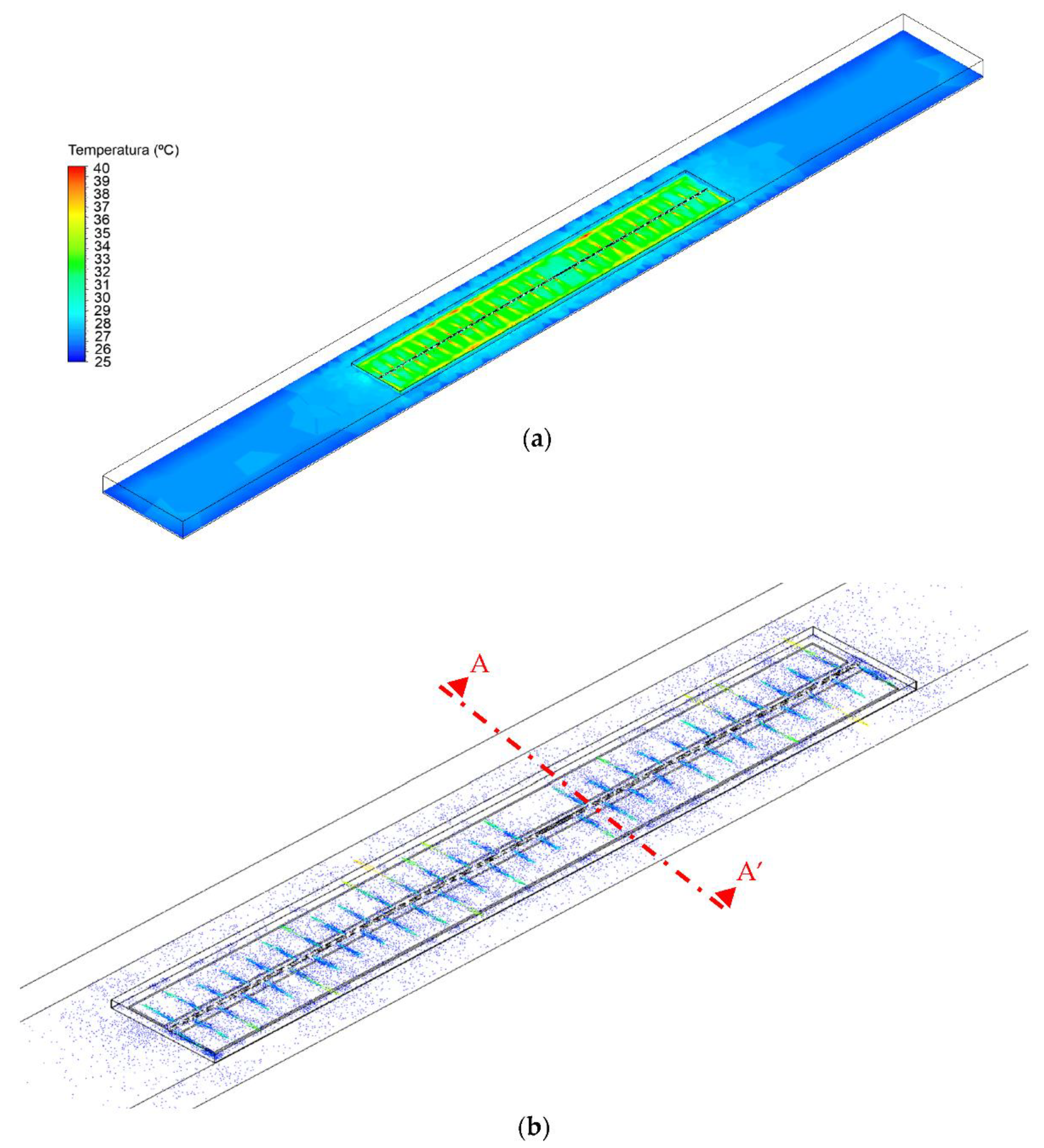

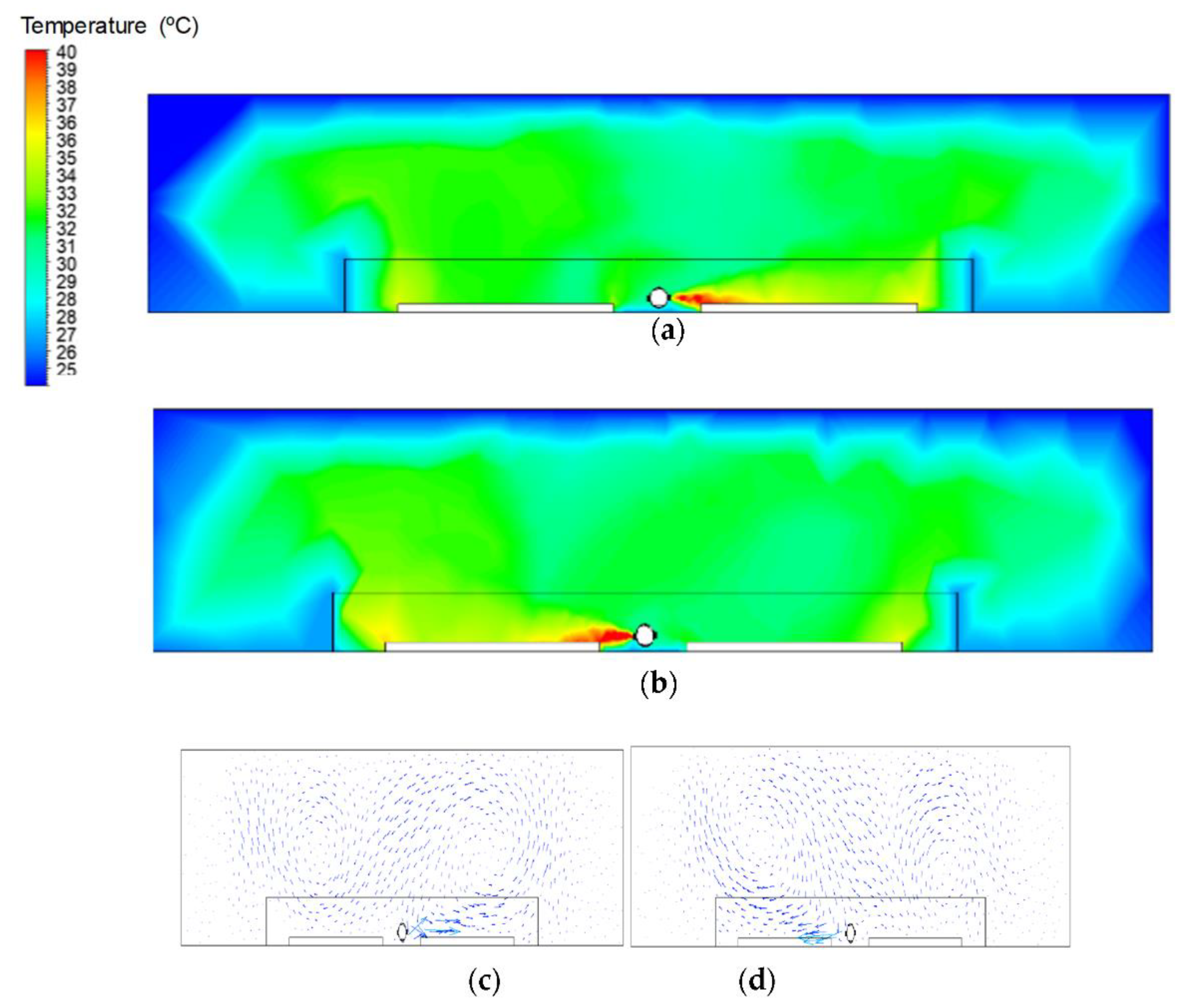

3. Results

Validation of the Model

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fidaros, D.; Baxevanou, C.; Bartzanas, T.; Kittas, C. Numerical study of mechanically ventilated broiler house equipped with evaporative pads. Comput. Electron. Agric. 2018, 149, 101–109. [Google Scholar] [CrossRef]

- Nawalany, G.; Sokołowski, P. Improved Energy Management in an Intermittently Heated Building Using a Large Broiler House in Central Europe as an Example. Energies 2020, 13, 1371. [Google Scholar] [CrossRef]

- Vandana, G.D.; Sejian, V.; Lees, A.M.; Pragna, P.; Silpa, M.V.; Maloney, S.K. Heat stress and poultry production: Impact and amelioration. Int. J. Biometeorol. 2021, 65, 163–179. [Google Scholar] [CrossRef] [PubMed]

- Ferraz, P.F.P.; Yanagi, T.; Lima, R.R.D.; Ferraz, G.A.; Xin, H. Performance of chicks subjected to thermal challenge. Pesqui. Agropecuária Bras. 2017, 52, 113–120. [Google Scholar] [CrossRef]

- Nawab, A.; Ibtisham, F.; Li, G.; Kieser, B.; Wu, J.; Liu, W.; An, L. Heat stress in poultry production: Mitigation strategies to overcome the future challenges facing the global poultry industry. J. Therm. Biol. 2018, 78, 131–139. [Google Scholar] [CrossRef] [PubMed]

- Olfati, A.; Mojtahedin, A.; Sadeghi, T.; Akbari, M.; Martínez-Pastor, F. Comparison of growth performance and immune responses of broiler chicks reared under heat stress, cold stress and thermoneutral conditions. Span. J. Agric. Res. 2018, 16, e0505. [Google Scholar] [CrossRef]

- Cordeiro, M.B.; Tinôco, I.D.F.F.; Silva, J.N.D.; Vigoderis, R.B.; Pinto, F.D.A.D.C.; Cecon, P.R. Conforto térmico e desempenho de pintos de corte submetidos a diferentes sistemas de aquecimento no período de inverno. Rev. Bras. De Zootec. 2010, 39, 217–224. [Google Scholar] [CrossRef][Green Version]

- Houndonougbo, F.M.; Tona, K.; Kpomasse, C.C.; Oke, O.E. Broiler production challenges in the tropics: A review. Vet. Med. Sci. 2021, 7, 831–842. [Google Scholar]

- Nawalany, G.; Lendelova, J.; Sokołowski, P.; Zitnak, M. Numerical Analysis of the Impact of the Location of a Commercial Broiler House on Its Energy Management and Heat Exchange with the Ground. Energies 2021, 14, 8565. [Google Scholar] [CrossRef]

- Goel, A.; Ncho, C.M.; Choi, Y.H. Regulation of gene expression in chickens by heat stress. J. Anim. Sci. Biotechnol. 2021, 12, 11. [Google Scholar] [CrossRef]

- Norton, T.; Sun, D.W.; Grant, J.; Fallon, R.; Dodd, V. Applications of computational fluid dynamics (CFD) in the modelling and design of ventilation systems in the agricultural industry: A review. Bioresour. Technol. 2007, 98, 2386–2414. [Google Scholar] [CrossRef] [PubMed]

- Seo, I.H.; Lee, I.B.; Moon, O.K.; Kim, H.T.; Hwang, H.S.; Hong, S.W.; Han, J.W. Improvement of the ventilation system of a naturally ventilated broiler house in the cold season using computational simulations. Biosyst. Eng. 2009, 104, 106–117. [Google Scholar] [CrossRef]

- Bates, P.D.; Lane, S.N.; Ferguson, R.I. Computational Fluid Dynamics: Applications in Environmental Hydraulics; John Wiley & Sons Ltd.: West Sussex, UK, 2005. [Google Scholar]

- Saraz, J.A.O.; Martins, M.A.; Marín, O.L.Z.; Damasceno, F.A.; Velasquéz, H.J.C. Una revisión acerca de la dinamica de fluidos computacionales (CFD) en instalaciones avícolas. Dyna 2012, 79, 142–149. [Google Scholar]

- Coulombe, F.; Rousse, D.R.; Paradis, P.L. CFD simulations to improve air distribution inside cold climate broiler houses involving heat exchangers. Biosyst. Eng. 2020, 198, 105–118. [Google Scholar] [CrossRef]

- AutoCAD, version R.14. [S.l.]; Autodesk: San Rafael, CA, USA; Available online: https://knowledge.autodesk.com/support/autocad (accessed on 20 January 2022).

- ANSYS Fluent, version 14.0.; Users’ Guide ANSYS, Release 14.0 Incorporated; Southpointe 275 Technology Drive: Canonsburg, PA, USA, 2011.

- Saraz, J.A.O.; Martins, M.A.; Rocha, K.S.O.; Machado, N.S.; Velasques, H.J.C. Use of computational fluid dynamics to simulate temperature distribution in broiler houses with negative and positive tunnel type ventilation systems. Rev. UDCA Actual. Divulg. Científica 2013, 16, 159–166. [Google Scholar]

- Cobb-Vantress, Suplemento: Desempenho e Nutrição para Frangos de Corte Cobb 500, 2018. p. 14. Available online: https://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&cad=rja&uact=8&ved=2ahUKEwis5Jf_g-T3AhXSIbkGHS8dDl8QFnoECAcQAQ&url=https%3A%2F%2Fwww.cobb-vantress.com%2Fassets%2FCobb-Files%2F99b0cf062c%2F61bd2490-56d1-11e9-bfbd-7963ec6b06e5.pdf&usg=AOvVaw0W-7Z3zftzKpy_-MCiVSxy (accessed on 16 March 2022).

- Pedersen, S.; Thomsen, G.M. Heat and Moisture Production of Broilers kept on Straw Bedding. J. Agric. Eng. Res. 2000, 75, 177–187. [Google Scholar] [CrossRef]

- Ryan, T. Estatística Moderna Para Engenharia; Elsevier Editora Ltd.: Rio de Janeiro, Brazil, 2009; Volume 1, p. 344. [Google Scholar]

- Mostafa, E.; Lee, I.B.; Song, S.H.; Kwon, K.S.; Seo, I.H.; Hong, S.W.; Han, H.T. Computational fluid dynamics simulation of air temperature distribution inside broiler building fitted with duct ventilation system. Biosyst. Eng. 2012, 112, 293–303. [Google Scholar] [CrossRef]

- Blanes-Vidal, V.; Guijarro, E.; Balasch, S.; Torres, A.G. Application of computational fluid dynamics to the prediction of airflow in a mechanically ventilated commercial poultry building. Biosyst. Eng. 2008, 100, 105–116. [Google Scholar] [CrossRef]

- Menegali, I.; Tinôco, I.F.F.; Baêta, F.C.; Cecon, P.R.; Guimarães, M.C.C.; Cordeiro, M.B. Ambiente térmico e concentração de gases em instalações para frangos de corte no período de aquecimento. Rev. Bras. De Eng. Agrícola E Ambient. 2009, 13, 984–990. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, W.; Zhai, Z.J.; Chen, Q.Y. Evaluation of various turbulence models in predicting airflow and turbulence in enclosed environments by CFD: Part 2-comparison with experimental data from literature. HVAC R Res. 2007, 13, 871–886. [Google Scholar] [CrossRef]

- Küçüktopcu, E.; Cemek, B.; Simsek, H.; Ni, J.-Q. Computational Fluid Dynamics Modeling of a Broiler House Microclimate in Summer and Winter. Animals 2022, 12, 867. [Google Scholar] [CrossRef] [PubMed]

- Küçüktopcu, E.; Cemek, B. Evaluating the influence of turbulence models used in computational fluid dynamics for the prediction of airflows inside poultry houses. Biosyst. Eng. 2019, 183, 1–12. [Google Scholar] [CrossRef]

- Nääs, I.A.; Miragliotta, M.Y.; Aradas, M.E.C.; Silva, I.J.O.; Baracho, M.S. Controle e sistematização em ambientes de produção. In Ambiência Na Produção de Aves em Clima Tropical, 1st ed.; Silva, I.J.O., Ed.; FUNEP: Piracicaba, Brazil, 2001; Volume 1, pp. 165–200. [Google Scholar]

| X | Y | Experimental Air Temperature (°C) | Simulated Air Temperature (°C) | Mean Error | |

|---|---|---|---|---|---|

| 1 | 110.7 | 6.5 | 28.7 | 28.45 | 0.87 |

| 2 | 110.7 | 3.0 | 27.5 | 27.45 | 0.18 |

| 3 | 73.4 | 3.0 | 29.3 | 28.75 | 1.88 |

| 4 | 73.4 | 6.5 | 28.2 | 27.55 | 2.30 |

| 5 | 73.4 | 9.9 | 29.9 | 29.25 | 2.17 |

| 6 | 99.2 | 9.9 | 28.7 | 28.55 | 0.52 |

| 7 | 99.2 | 6.5 | 28.3 | 28.55 | 0.88 |

| 8 | 99.2 | 3.0 | 28.6 | 28.55 | 0.17 |

| 9 | 86.4 | 6.5 | 29.4 | 29.45 | 0.17 |

| 10 | 86.4 | 3.0 | 29.8 | 29.15 | 2.18 |

| 11 | 60.3 | 9.9 | 28.9 | 28.55 | 1.21 |

| 12 | 60.3 | 6.5 | 29.9 | 29.55 | 1.17 |

| 13 | 60.3 | 3.0 | 28.9 | 29.15 | 0.87 |

| 14 | 48.5 | 9.9 | 28.9 | 28.05 | 2.94 |

| 15 | 48.5 | 6.5 | 28.7 | 27.95 | 2.61 |

| 16 | 48.5 | 3.0 | 26.7 | 27.25 | 2.06 |

| P (%) | 1.49 | ||||

| SE (decimal) | 1.35 | ||||

| χ2 (decimal) | 1.81 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferraz, P.F.P.; Andrade, E.T.d.; Vilas Boas, R.B.; Rezende, R.P.; Yanagi Junior, T.; Barbari, M. Three-Dimensional Simulation of the Temperature Distribution in a Commercial Broiler House. Animals 2022, 12, 1278. https://doi.org/10.3390/ani12101278

Ferraz PFP, Andrade ETd, Vilas Boas RB, Rezende RP, Yanagi Junior T, Barbari M. Three-Dimensional Simulation of the Temperature Distribution in a Commercial Broiler House. Animals. 2022; 12(10):1278. https://doi.org/10.3390/ani12101278

Chicago/Turabian StyleFerraz, Patrícia Ferreira Ponciano, Ednilton Tavares de Andrade, Regina Batista Vilas Boas, Renan Pereira Rezende, Tadayuki Yanagi Junior, and Matteo Barbari. 2022. "Three-Dimensional Simulation of the Temperature Distribution in a Commercial Broiler House" Animals 12, no. 10: 1278. https://doi.org/10.3390/ani12101278

APA StyleFerraz, P. F. P., Andrade, E. T. d., Vilas Boas, R. B., Rezende, R. P., Yanagi Junior, T., & Barbari, M. (2022). Three-Dimensional Simulation of the Temperature Distribution in a Commercial Broiler House. Animals, 12(10), 1278. https://doi.org/10.3390/ani12101278