CFD Study of a Tunnel-Ventilated Compost-Bedded Pack Barn Integrating an Evaporative Pad Cooling System

Abstract

:Simple Summary

Abstract

1. Introduction

2. Materials and Methods

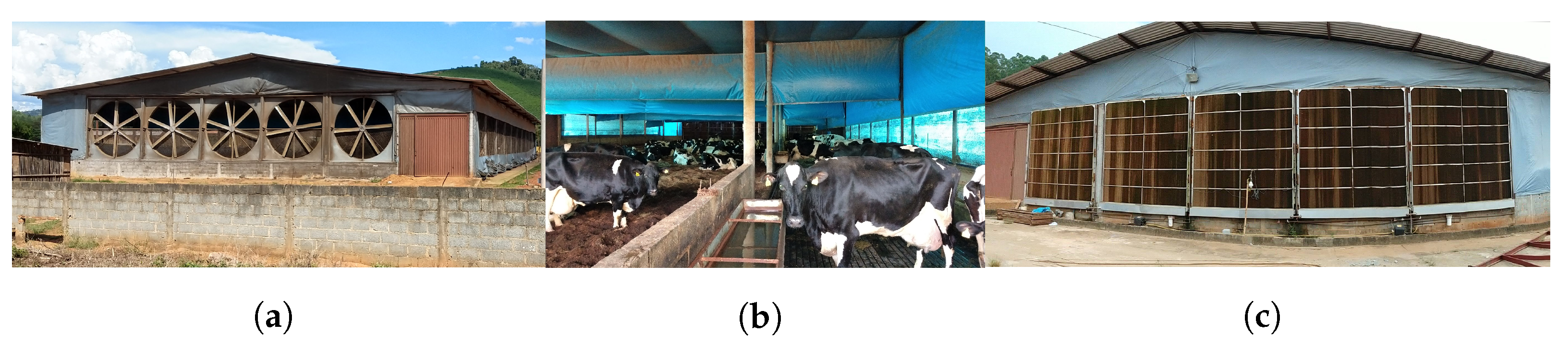

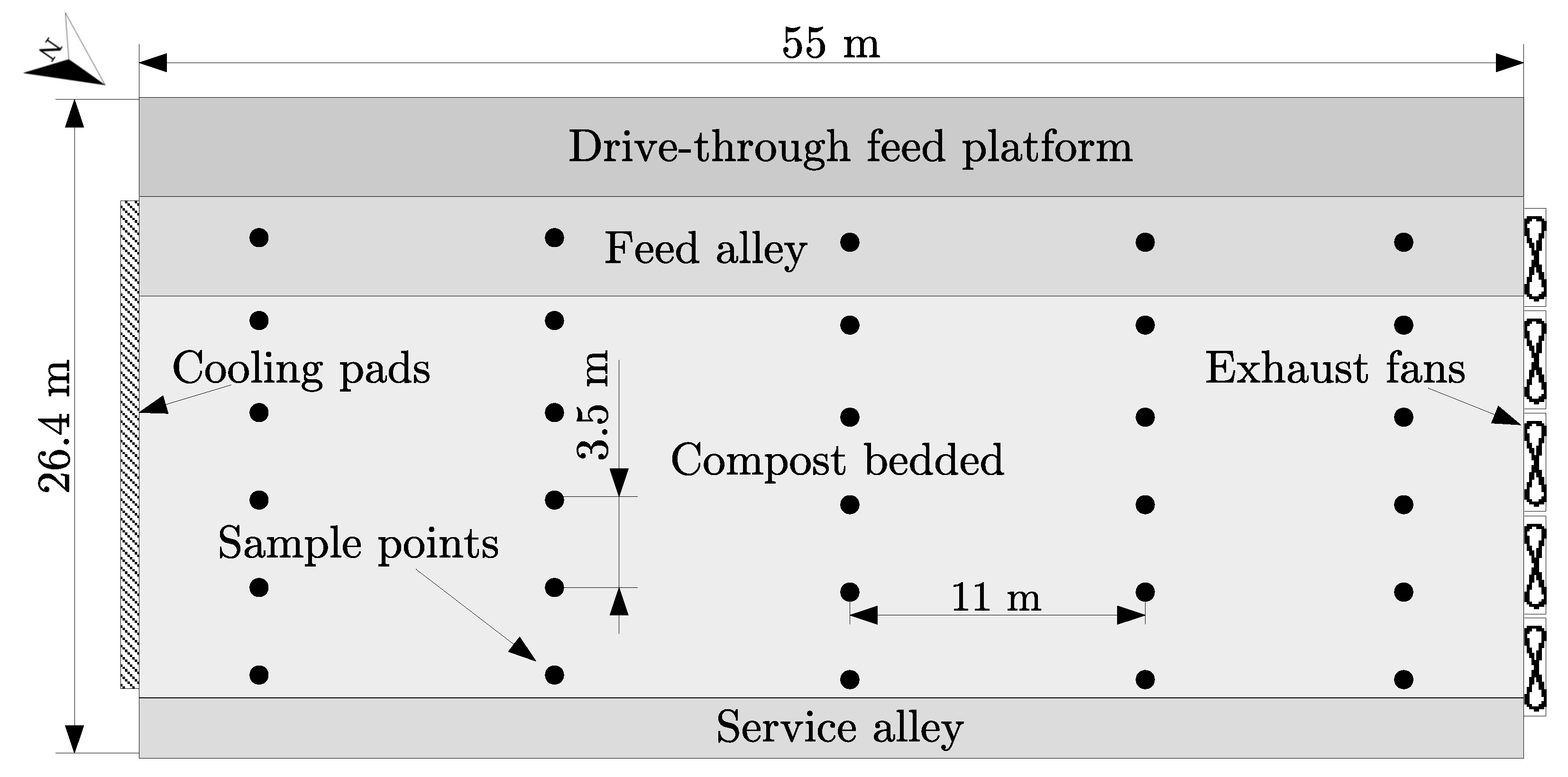

2.1. Experimental Tests in Tunnel-Ventilated Compost-Bedded Pack Barn

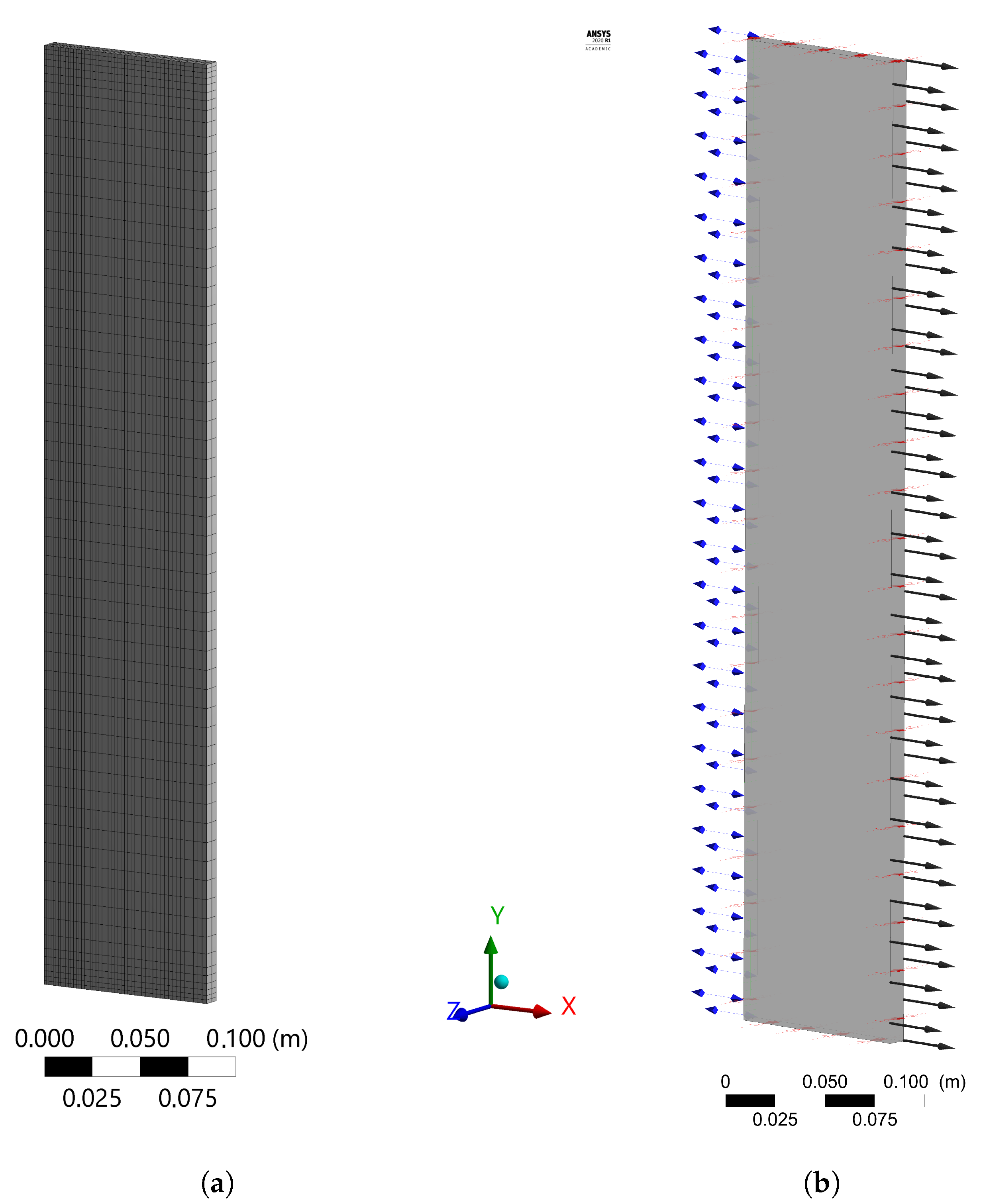

2.2. CFD Model of Evaporative Cooling Pad

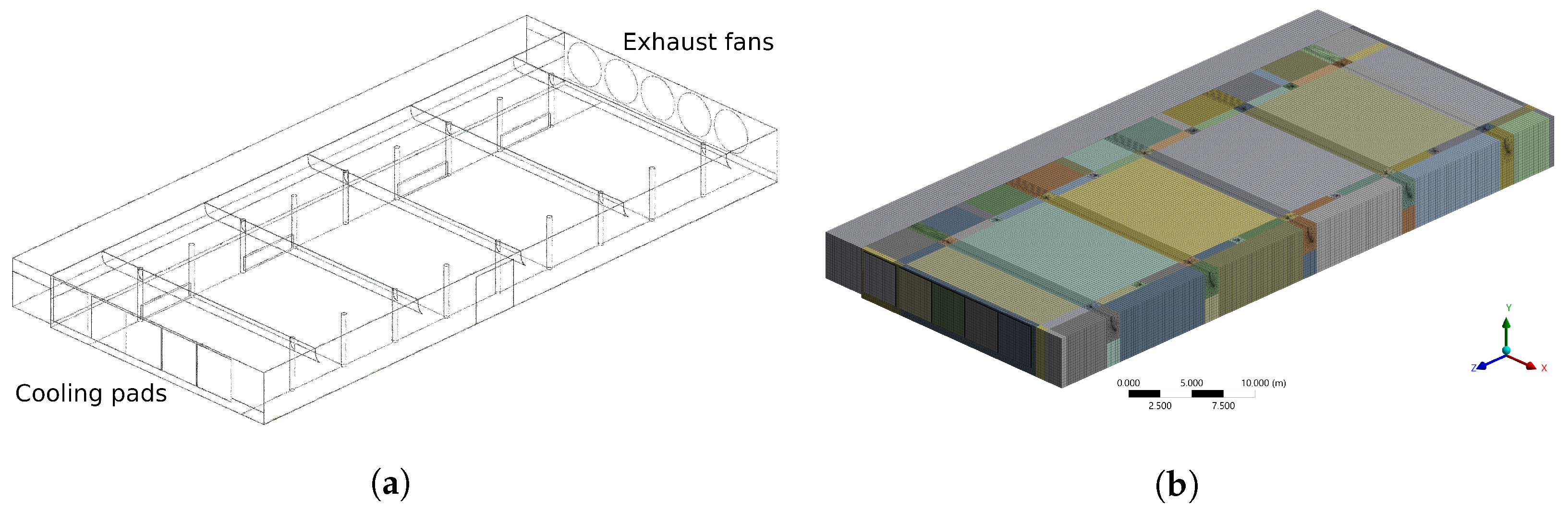

2.3. CFD Model of Tunnel-Ventilated Compost-Bedded Pack Barn

3. Results

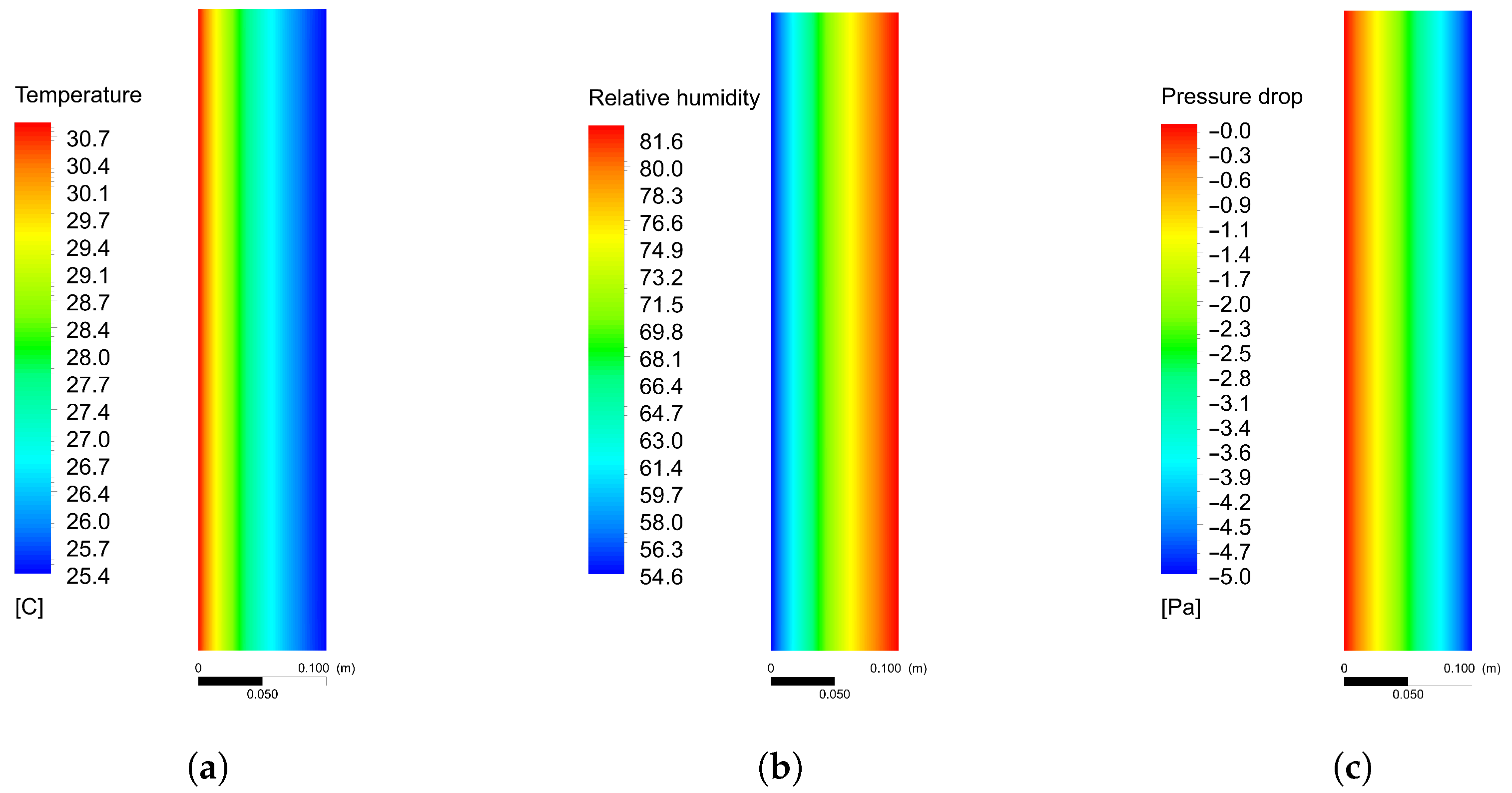

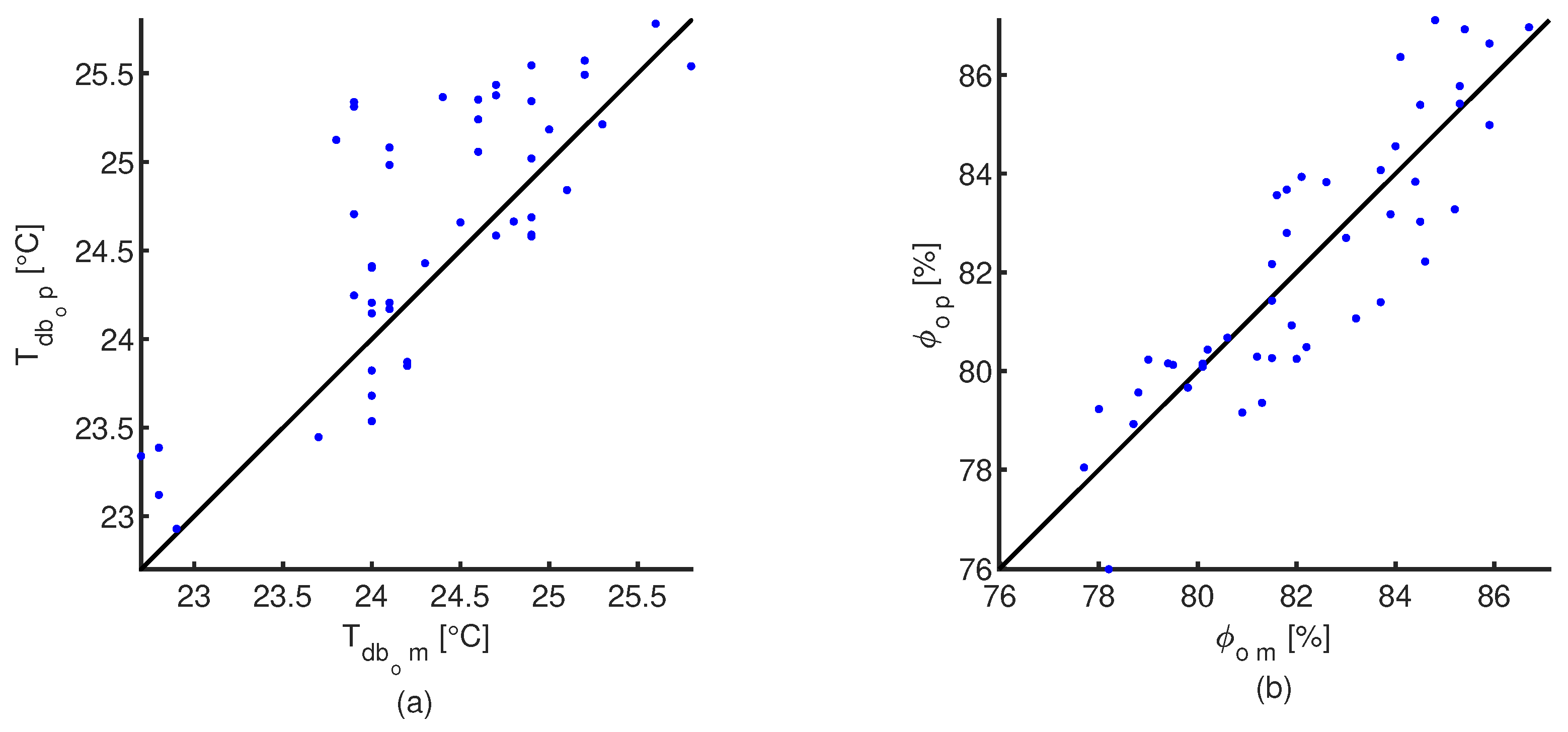

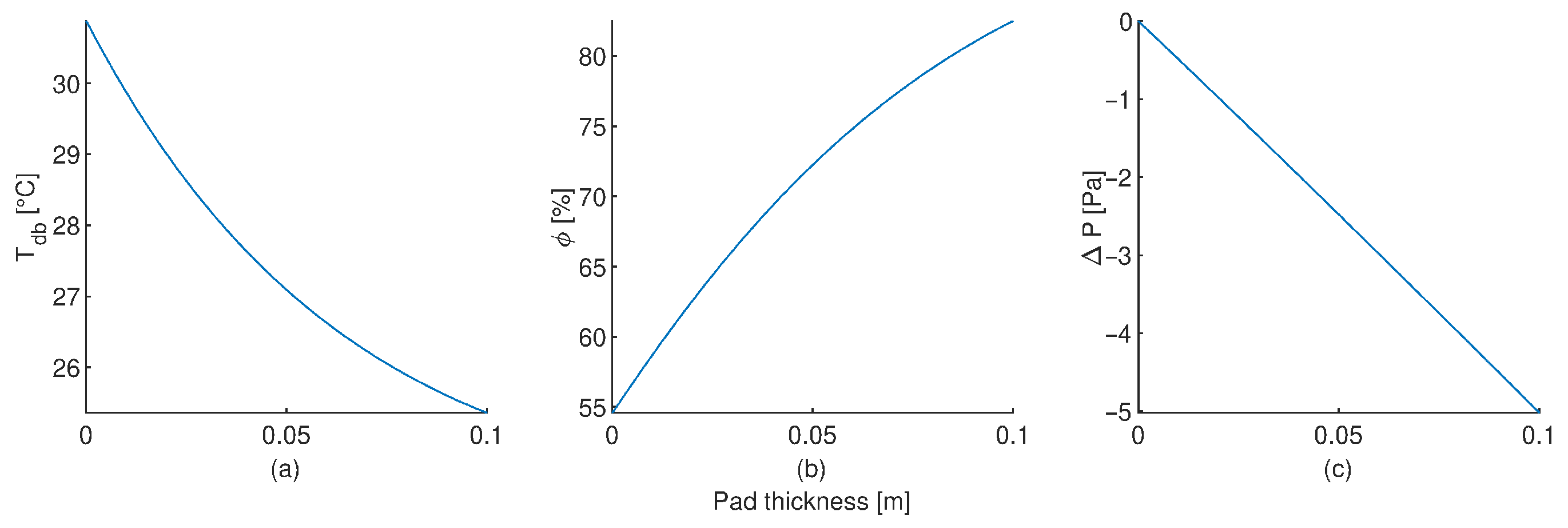

3.1. CFD Modelling of Evaporative Cooling Pad

3.2. CFD Modelling of Tunnel-Ventilate Compost-Bedded Pack Barns

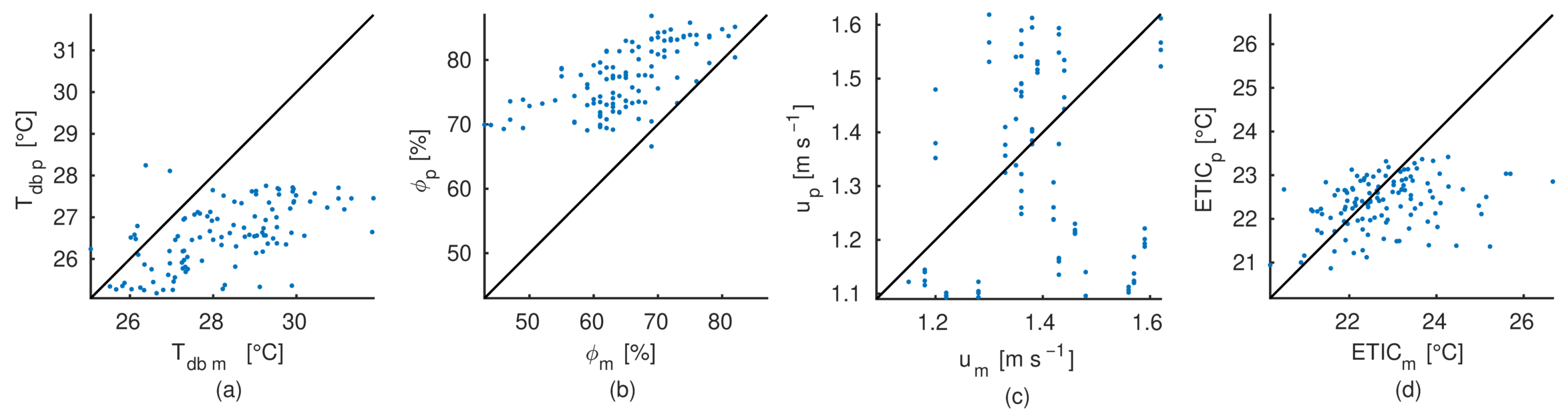

3.2.1. CFD Model Validation

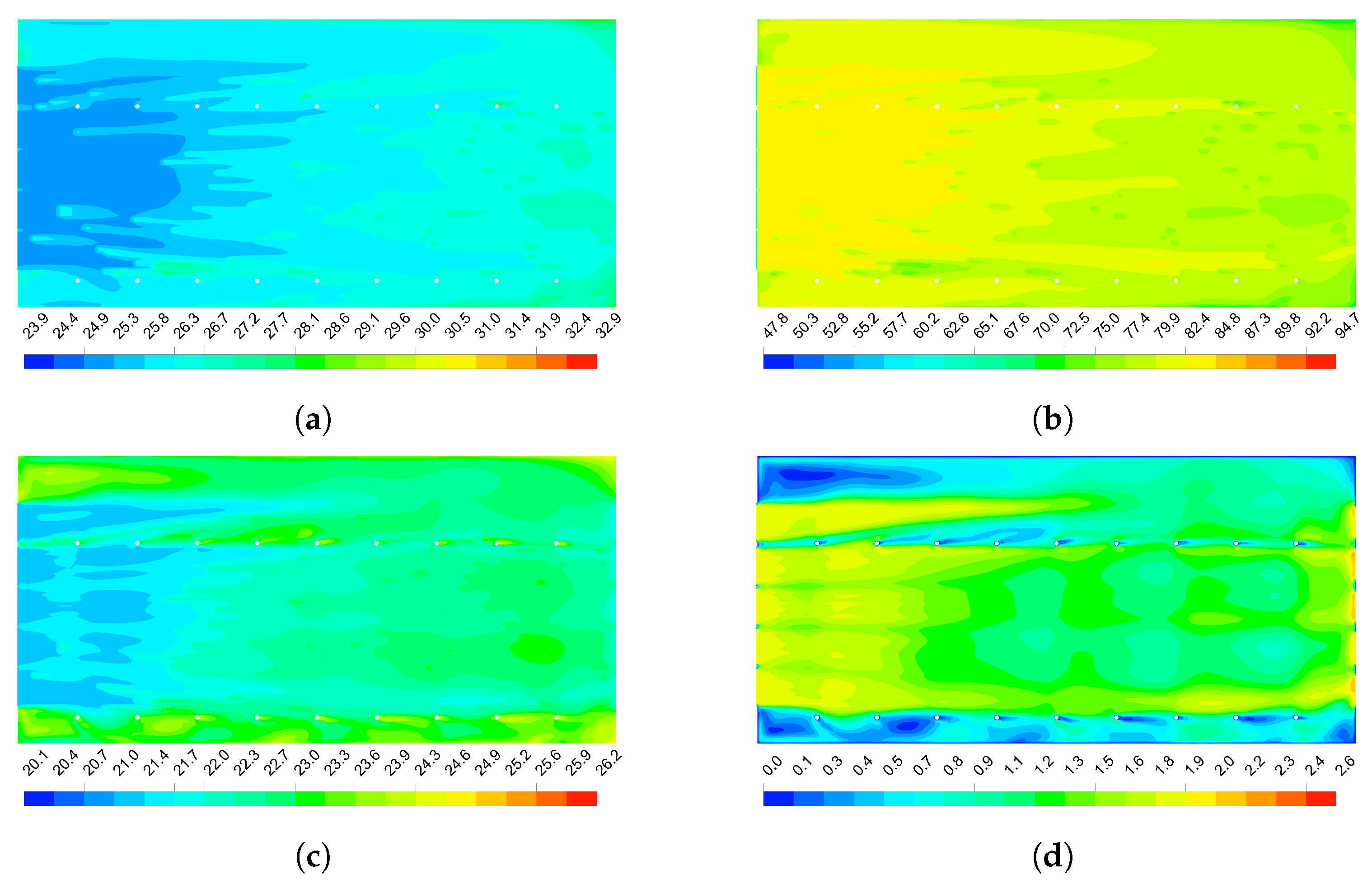

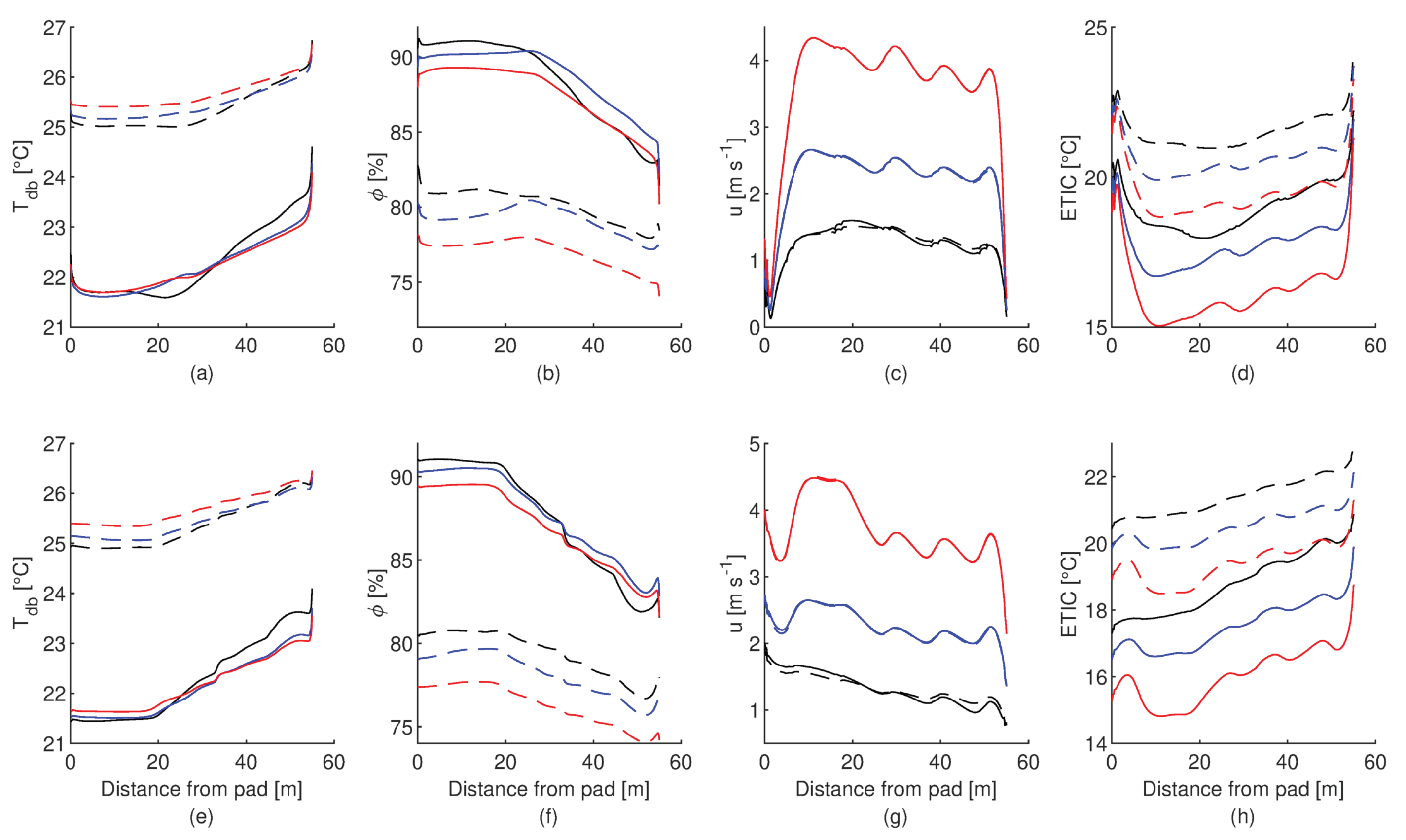

3.2.2. CFD Model Predictions

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Equations Used in the CFD Models

Appendix B. CFD Pad Model Results

Appendix C. Spatial Distribution of Simulated Cows as Point Heat Sources

| Point | x | y | Point | x | y | Point | x | y | Point | x | y |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 11.3 | −18.5 | 21 | 12.7 | −12.5 | 41 | 15.1 | −34.3 | 61 | 15.8 | −51.8 |

| 2 | 14.6 | −22.2 | 22 | 14.4 | −2.1 | 42 | 5.5 | −41.1 | 62 | 10.3 | −49.2 |

| 3 | 16.3 | −7.7 | 23 | 12.7 | −2.6 | 43 | 12.4 | −32.8 | 63 | 14.9 | −54.0 |

| 4 | 9.6 | −15.7 | 24 | 15.5 | −3.2 | 44 | 12.5 | −31.9 | 64 | 15.3 | −49.2 |

| 5 | 14.6 | −10.3 | 25 | 12.4 | −15.9 | 45 | 17.8 | −37.7 | 65 | 11.1 | −41.5 |

| 6 | 10.7 | −19.5 | 26 | 19.9 | −11.6 | 46 | 11.8 | −27.4 | 66 | 4.3 | −42.9 |

| 7 | 17.5 | −18.0 | 27 | 7.5 | −4.4 | 47 | 10.3 | −32.3 | 67 | 9.3 | −53.1 |

| 8 | 17.3 | −3.9 | 28 | 5.7 | −11.6 | 48 | 14.7 | −39.5 | 68 | 10.8 | −47.9 |

| 9 | 8.1 | −20.1 | 29 | 5.8 | −3.5 | 49 | 15.9 | −33.6 | 69 | 8.3 | −52.9 |

| 10 | 13.8 | −23.1 | 30 | 5.0 | −1.3 | 50 | 12.3 | −38.5 | 70 | 7.2 | −44.1 |

| 11 | 13.3 | −12.0 | 31 | 10.5 | −19.9 | 51 | 9.6 | −36.6 | 71 | 17.1 | −48.8 |

| 12 | 12.7 | −20.7 | 32 | 11.2 | −13.1 | 52 | 6.4 | −33.9 | 72 | 10.9 | −49.9 |

| 13 | 17.9 | −13.7 | 33 | 9.9 | −21.7 | 53 | 13.4 | −27.8 | 73 | 18.2 | −41.7 |

| 14 | 8.2 | −3.6 | 34 | 16.2 | −16.3 | 54 | 8.2 | −35.3 | 74 | 10.3 | −49.7 |

| 15 | 9.1 | −4.7 | 35 | 14.0 | −33.8 | 55 | 4.7 | −24.9 | 75 | 18.3 | −46.2 |

| 16 | 5.9 | −9.5 | 36 | 16.4 | −38.0 | 56 | 16.1 | −34.6 | 76 | 10.3 | −41.9 |

| 17 | 19.0 | −17.5 | 37 | 18.9 | −39.1 | 57 | 7.9 | −35.2 | 77 | 16.9 | −48.0 |

| 18 | 14.3 | −19.3 | 38 | 19.6 | −41.1 | 58 | 11.1 | −36.4 | 78 | 16.1 | −43.9 |

| 19 | 11.7 | −18.5 | 39 | 7.1 | −23.4 | 59 | 15.0 | −39.3 | 79 | 10.0 | −42.9 |

| 20 | 14.2 | −7.4 | 40 | 6.2 | −38.8 | 60 | 9.7 | −40.9 | 80 | 7.5 | −44.1 |

Appendix D. Thermal Images

References

- Black, R.A.; Taraba, J.L.; Day, G.B.; Damasceno, F.A.; Bewley, J.M. Compost bedded pack dairy barn management, performance, and producer satisfaction. J. Dairy Sci. 2013, 96, 8060–8074. [Google Scholar] [CrossRef] [PubMed]

- Vinícius da Silva, M.; Pandorfi, H.; Pontes de Almeida, G.; Maniçoba da Rosa Ferraz Jardim, A.; Dias Batista, P.; Batista da Silva, R.; Lopes, I.; Gonçalves de Oliveira, M.; Bezerra da Silva, J.; Moraes, A. Spatial variability and exploratory inference of abiotic factors in barn compost confinement for cattle in the semiarid. J. Therm. Biol. 2020, 94, 102782. [Google Scholar] [CrossRef] [PubMed]

- Leso, L.; Barbari, M.; Lopes, M.A.; Damasceno, F.A.; Galama, P.; Taraba, J.L.; Kuipers, A. Invited review: Compost-bedded pack barns for dairy cows. J. Dairy Sci. 2020, 103, 1072–1099. [Google Scholar] [CrossRef] [PubMed]

- Bewley, J.M.; Robertson, L.M.; Eckelkamp, E.A. A 100-Year Review: Lactating dairy cattle housing management. J. Dairy Sci. 2017, 100, 10418–10431. [Google Scholar] [CrossRef] [PubMed]

- Biasato, I.; D’Angelo, A.; Bertone, I.; Odore, R.; Bellino, C. Compost bedded-pack barn as an alternative housing system for dairy cattle in Italy: Effects on animal health and welfare and milk and milk product quality. Ital. J. Anim. Sci. 2019, 18, 1142–1153. [Google Scholar] [CrossRef]

- Galama, P.J.; Ouweltjes, W.; Endres, M.I.; Sprecher, J.R.; Leso, L.; Kuipers, A.; Klopčič, M. Symposium review: Future of housing for dairy cattle. J. Dairy Sci. 2020, 103, 5759–5772. [Google Scholar] [CrossRef]

- Herbut, P.; Angrecka, S.; Nawalany, G. Influence of wind on air movement in a free-stall barn during the summer period. Ann. Anim. Sci. 2013, 13, 109–119. [Google Scholar] [CrossRef] [Green Version]

- Zhou, B.; Wang, X.; Mondaca, M.R.; Rong, L.; Choi, C.Y. Assessment of optimal airflow baffle locations and angles in mechanically-ventilated dairy houses using computational fluid dynamics. Comput. Electron. Agric. 2019, 165, 104930. [Google Scholar] [CrossRef]

- Damasceno, F.A.; Taraba, J.L.; Day, G.B.; Vega, F.A.; Rocha, K.S.; Black, R.A.; Bewley, J.M.; Oliveira, C.E.; Barbari, M. 3D Cfd Analysis of Natural Ventilation in Reduced Scale Model of Compost Bedded Pack Barn for Dairy Cows. Appl. Sci. 2020, 10, 8112. [Google Scholar] [CrossRef]

- Mondaca, M.R.; Cook, N.B. Modeled construction and operating costs of different ventilation systems for lactating dairy cows. J. Dairy Sci. 2019, 102, 896–908. [Google Scholar] [CrossRef] [Green Version]

- Mondaca, M.R.; Choi, C.Y.; Cook, N.B. Understanding microenvironments within tunnel-ventilated dairy cow freestall facilities: Examination using computational fluid dynamics and experimental validation. Biosyst. Eng. 2019, 183, 70–84. [Google Scholar] [CrossRef]

- Dikmen, S.; Larson, C.C.; De Vries, A.; Hansen, P.J. Effectiveness of tunnel ventilation as dairy cow housing in hot climates: Rectal temperatures during heat stress and seasonal variation in milk yield. Trop. Anim. Health Prod. 2020, 52, 2687–2693. [Google Scholar] [CrossRef] [PubMed]

- Fournel, S.; Ouellet, V.; Charbonneau, É. Practices for alleviating heat stress of dairy cows in humid continental climates: A literature review. Animals 2017, 7, 37. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tao, S.; Orellana Rivas, R.M.; Marins, T.N.; Chen, Y.C.; Gao, J.; Bernard, J.K. Impact of heat stress on lactational performance of dairy cows. Theriogenology 2020, 150, 437–444. [Google Scholar] [CrossRef]

- Orellana Rivas, R.M.; Bernard, J.K.; Tao, S. Case study: Evaluation of cooling in 3 grazing dairy farms in Georgia, USA. Appl. Anim. Sci. 2019, 35, 634–640. [Google Scholar] [CrossRef]

- Chaiyabutr, N.; Chanpongsang, S.; Suadsong, S. Effects of evaporative cooling on the regulation of body water and milk production in crossbred Holstein cattle in a tropical environment. Int. J. Biometeorol. 2008, 52, 575–585. [Google Scholar] [CrossRef]

- Shiao, T.F.; Chen, J.C.; Yang, D.W.; Lee, S.N.; Lee, C.F.; Cheng, W.T. Feasibility assessment of a tunnel-ventilated, water-padded barn on alleviation of heat stress for lactating Holstein cows in a humid area. J. Dairy Sci. 2011, 94, 5393–5404. [Google Scholar] [CrossRef]

- Smith, T.R.; Chapa, A.; Willard, S.; Herndon, C.; Williams, R.J.; Crouch, J.; Riley, T.; Pogue, D. Evaporative tunnel cooling of dairy cows in the southeast. I: Effect on body temperature and respiration rate. J. Dairy Sci. 2006, 89, 3904–3914. [Google Scholar] [CrossRef] [Green Version]

- Smith, T.R.; Chapa, A.; Willard, S.; Herndon, C.; Williams, R.J.; Crouch, J.; Riley, T.; Pogue, D. Evaporative tunnel cooling of dairy cows in the southeast. II: Impact on lactation performance. J. Dairy Sci. 2006, 89, 3915–3923. [Google Scholar] [CrossRef] [Green Version]

- Smith, J.F.; Bradford, B.J.; Harner, J.P.; Potts, J.C.; Allen, J.D.; Overton, M.W.; Ortiz, X.A.; Collier, R.J. Short communication: Effect of cross ventilation with or without evaporative pads on core body temperature and resting time of lactating cows. J. Dairy Sci. 2016, 99, 1495–1500. [Google Scholar] [CrossRef]

- Brouk, M.J.; Smith, J.F.; Harner, J.P. Effect of tunnel ventilation and evaporative cooling on the barn environment and cow comfort in midwest dairy facilities. Kans. Agric. Exp. Stn. Res. Rep. 2002, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Tyson, J.T.; Mcfarland, D.F.; Graves, R.E. Tunnel Ventilation for Tie Stall Dairy Barns; Technical Report; Penn State Extension: State College, PA, USA, 2014. [Google Scholar]

- Kaufman, J.D.; Saxton, A.M.; Ríus, A.G. Short communication: Relationships among temperature–Humidity index with rectal, udder surface, and vaginal temperatures in lactating dairy cows experiencing heat stress. J. Dairy Sci. 2018, 101, 6424–6429. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mylostyvyi, R.; Izhboldina, O.; Chernenko, O.; Khramkova, O.; Kapshuk, N.; Hoffmann, G. Microclimate modeling in naturally ventilated dairy barns during the hot season: Checking the accuracy of forecasts. J. Therm. Biol. 2020, 93, 102720. [Google Scholar] [CrossRef] [PubMed]

- Herbut, P.; Angrecka, S.; Walczak, J. Environmental parameters to assessing of heat stress in dairy cattle—A review. Int. J. Biometeorol. 2018, 62, 2089–2097. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Gao, H.; Gebremedhin, K.G.; Bjerg, B.S.; Van Os, J.; Tucker, C.B.; Zhang, G. A predictive model of equivalent temperature index for dairy cattle (ETIC). J. Therm. Biol. 2018, 76, 165–170, Corrigendum in J. Therm. Biol. 2019, 82, 252–253. [Google Scholar] [CrossRef]

- Angrecka, S.; Herbut, P.; Godyn, D.; Corrêa Vieira, F.M.; Zwolenik, M. Dynamics of microclimate conditions in freestall barns during winter—A case study from Poland. J. Ecol. Eng. 2020, 21, 129–136. [Google Scholar] [CrossRef]

- Herbut, P. Temperature, humidity and air movement variations inside a free-stall barn during heavy frost. Ann. Anim. Sci. 2013, 13, 587–596. [Google Scholar] [CrossRef] [Green Version]

- Pinto, S.; Hoffmann, G.; Ammon, C.; Amon, B.; Heuwieser, W.; Halachmi, I.; Banhazi, T.; Amon, T. Influence of barn climate, body postures and milk yield on the respiration rate of dairy cows. Ann. Anim. Sci. 2019, 19, 469–481. [Google Scholar] [CrossRef] [Green Version]

- Polsky, L.B.; Madureira, A.M.; Filho, E.L.; Soriano, S.; Sica, A.F.; Vasconcelos, J.L.; Cerri, R.L. Association between ambient temperature and humidity, vaginal temperature, and automatic activity monitoring on induced estrus in lactating cows. J. Dairy Sci. 2017, 100, 8590–8601. [Google Scholar] [CrossRef] [Green Version]

- Rong, L.; Nielsen, P.V.; Bjerg, B.; Zhang, G. Summary of best guidelines and validation of CFD modeling in livestock buildings to ensure prediction quality. Comput. Electron. Agric. 2016, 121, 180–190. [Google Scholar] [CrossRef]

- Obando, F.A.; Montoya, A.P.; Osorio, J.A.; Damasceno, F.A.; Norton, T. Evaporative pad cooling model validation in a closed dairy cattle building. Biosyst. Eng. 2020, 198, 147–162. [Google Scholar] [CrossRef]

- ASHRAE. Fundamental Handbook SI; ASHRAE: Atlanta, GA, USA, 2017; p. 1013. [Google Scholar]

- Liao, C.M.; Singh, S.; Wang, T.S. Characterizing the performance of alternative evaporative cooling pad media in thermal environmental control applications. J. Environ. Sci. Health Part A 1998, 33, 1391–1417. [Google Scholar] [CrossRef]

- Incropera, F.P.; Dewitt, D.P.; Lavine, A.S.; Bergman, T.L. Fundamentals of Heat and Mass Transfer, 7th ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2011; p. 1076. [Google Scholar]

- Tu, J.; Yeoh, G.H.; Liu, C. CFD Mesh Generation: A Practical Guideline. In Computational Fluid Dynamics, 3rd ed.; Elsevier: Amsterdam, The Netherlands, 2018; Chapter 4; pp. 125–154. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, G.; Choi, C.Y. Effect of airflow speed and direction on convective heat transfer of standing and reclining cows. Biosyst. Eng. 2018, 167, 87–98. [Google Scholar] [CrossRef]

- Heinrichs, A.J.; Rogers, G.W.; Cooper, J.B. Predicting Body Weight and Wither Height in Holstein Heifers Using Body Measurements. J. Dairy Sci. 1992, 75, 3576–3581. [Google Scholar] [CrossRef]

- Heinrichs, A.J.; Heinrichs, B.S.; Jones, C.M.; Erickson, P.S.; Kalscheur, K.F.; Nennich, T.D.; Heins, B.J.; Cardoso, F.C. Short communication: Verifying Holstein heifer heart girth to body weight prediction equations. J. Dairy Sci. 2017, 100, 8451–8454. [Google Scholar] [CrossRef] [Green Version]

- Berman, A. Effects of body surface area estimates on predicted energy requirements and heat stress. J. Dairy Sci. 2003, 86, 3605–3610. [Google Scholar] [CrossRef]

- Bjerg, B.; Klaas, I. Water and ammonia evaporation in a compost bedded pack dairy barn with under floor aeration. In Proceedings of the ASABE 2014, Montreal, QC, Canada, 13–16 July 2014; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2014; Volume 4, pp. 2435–2442. [Google Scholar] [CrossRef] [Green Version]

- Yao, C.; Shi, Z.; Zhao, Y.; Ding, T. Effect of mixed-flow fans with a newly shaped diffuser on heat stress of dairy cows based on CFD. Energies 2019, 12, 4315. [Google Scholar] [CrossRef] [Green Version]

- Palmer, J.D. Evaporative Cooling Design Guidelines Manual for New Mexico Schools and Commercial Buildings; Technical Report; NRG Engineering: Albuquerque, NM, USA, 2002. [Google Scholar]

- Mondaca, M.; Choi, C.Y. An evaluation of simplifying assumptions in dairy cow computational fluid dynamics models. Trans. ASABE 2016, 59, 1575–1584. [Google Scholar] [CrossRef]

- Stull, R. Wet-bulb temperature from relative humidity and air temperature. J. Appl. Meteorol. Climatol. 2011, 50, 2267–2269. [Google Scholar] [CrossRef] [Green Version]

- Cengel, Y.A.; Cimbala, J.M. Fluid Mechanics: Fundamentals and Applications; McGrawHill: New York, NY, USA, 2005. [Google Scholar]

- Cengel, Y.A.; Boles, M.A. Thermodynamics: An Engineering Approach, 8th ed.; McGrawHill: New York, NY, USA, 2015. [Google Scholar]

- ASHRAE. Handbook: Fundamentals; ASHRAE: Atlanta, GA, USA, 2009. [Google Scholar]

| Location | Boundary Type | Mass and Momentum | Thermal Condition | Value |

|---|---|---|---|---|

| Roof ceiling | Wall | No slip wall—Smooth wall roughness | Isothermal | 34 °C |

| Lateral curtains | Isothermal | 34 °C | ||

| Baffles | Adiabatic | 0 | ||

| Columns | Adiabatic | 0 | ||

| Walls between columns | Adiabatic | 0 | ||

| Doors | Isothermal | 32 °C | ||

| Drive-through alley floor | Isothermal | 27 °C | ||

| Feed alley floor | Isothermal | 27.5 °C | ||

| Compost bedded | Variable temperature | °C * | ||

| Service floor | Isothermal | 28 °C | ||

| Fans support wall | Isothermal | 30 °C | ||

| Laterals of pad cooling | Adiabatic | 0 | ||

| Pad cooling input | Opening | Entrainment: 95,320 Pa | Isothermal | 29.7 °C |

| Fans | Outlet | Normal speed: 1.2 m s | - | - |

| Dry-Bulb Temperature | Relative Humidity | |||||

|---|---|---|---|---|---|---|

| [°C] | [°C] | [°C] | [%] | [%] | [%] | |

| Inlet | 29.7 | 29.9 | 1.1 | 57.8 | 56.2 | 4.1 |

| Outlet | 24.4 | 24.4 | 0.7 | 82.1 | 81.8 | 2.4 |

| (24.6) | (24.7) | (0.7) | (82.1) | (81.4) | (2.6) | |

| Mesh Properties | Mesh Sizes | ||||

|---|---|---|---|---|---|

| Coarse | Medium | Fine | Fine | ||

| Number of elements | 331,386 | 796,694 | 1,358,107 | 2,989,746 | |

| Number of nodes | 1,048,893 | 2,675,770 | 4,655,442 | 10,236,714 | |

| Maximum element size | 0.4 m | 0.25 m | 0.2 m | 0.15 m | |

| Skewness | Average | 0.19631 | 0.14428 | 0.11884 | 0.10174 |

| Standard deviation | 0.23201 | 0.20251 | 0.18236 | 0.16896 | |

| Orthogonal quality | Average | 0.81062 | 0.86484 | 0.8893 | 0.90426 |

| Standard deviation | 0.23101 | 0.19997 | 0.18057 | 0.16633 | |

| Aspect ratio | Average | 22.041 | 10.007 | 6.4221 | 3.6717 |

| Standard deviation | 44.33 | 30.339 | 23.628 | 16.129 | |

| Hour Interval | Outside | Inside | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 10–11 | 27.5 | 27.4 | 0.2 | 26.3 | 25.4 | 26.4 | 25.4 | 0.8 | 0.6 | |

| 12–13 | 29.6 | 29.5 | 0.3 | 28.2 | 26.0 | 28.4 | 26.1 | 1.1 | 0.5 | |

| 14–15 | 32.2 | 32.3 | 0.4 | 28.9 | 27.1 | 29.3 | 27.2 | 1.4 | 0.5 | |

| 16–17 | 33.0 | 33.0 | 0.2 | 29.0 | 27.2 | 29.0 | 27.2 | 1.5 | 0.5 | |

| 10-11 | 72.8 | 73.0 | 1.6 | 74.1 | 84.9 | 73.5 | 84.3 | 6.5 | 2.3 | |

| 12–13 | 62.6 | 62.5 | 1.2 | 67.3 | 80.5 | 68.0 | 79.9 | 7.2 | 2.4 | |

| 14–15 | 52.7 | 52.6 | 1.9 | 62.3 | 75.0 | 63.0 | 74.7 | 6.1 | 1.9 | |

| 16–17 | 47.5 | 47.4 | 1.6 | 59.8 | 71.2 | 61.0 | 71.0 | 7.5 | 1.8 | |

| ETIC * | 10-11 | 24.6 | 24.6 | 0.1 | 21.8 | 22.0 | 21.9 | 22.2 | 0.7 | 0.6 |

| 12–13 | 25.1 | 25.3 | 1.0 | 23.1 | 22.2 | 22.8 | 22.4 | 0.9 | 0.5 | |

| 14–15 | 26.1 | 26.4 | 1.2 | 23.3 | 22.8 | 23.2 | 23.0 | 1.1 | 0.4 | |

| 15–16 | 26.4 | 26.4 | 0.2 | 23.0 | 22.5 | 23.0 | 22.6 | 1.0 | 0.4 | |

| u | - | - | - | - | 1.4 | 1.3 | 1.4 | 1.3 | 0.1 | 0.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Obando Vega, F.A.; Montoya Ríos, A.P.; Osorio Saraz, J.A.; Andrade, R.R.; Damasceno, F.A.; Barbari, M. CFD Study of a Tunnel-Ventilated Compost-Bedded Pack Barn Integrating an Evaporative Pad Cooling System. Animals 2022, 12, 1776. https://doi.org/10.3390/ani12141776

Obando Vega FA, Montoya Ríos AP, Osorio Saraz JA, Andrade RR, Damasceno FA, Barbari M. CFD Study of a Tunnel-Ventilated Compost-Bedded Pack Barn Integrating an Evaporative Pad Cooling System. Animals. 2022; 12(14):1776. https://doi.org/10.3390/ani12141776

Chicago/Turabian StyleObando Vega, Felipe Andrés, Ana Paola Montoya Ríos, Jairo Alexander Osorio Saraz, Rafaella Resende Andrade, Flávio Alves Damasceno, and Matteo Barbari. 2022. "CFD Study of a Tunnel-Ventilated Compost-Bedded Pack Barn Integrating an Evaporative Pad Cooling System" Animals 12, no. 14: 1776. https://doi.org/10.3390/ani12141776

APA StyleObando Vega, F. A., Montoya Ríos, A. P., Osorio Saraz, J. A., Andrade, R. R., Damasceno, F. A., & Barbari, M. (2022). CFD Study of a Tunnel-Ventilated Compost-Bedded Pack Barn Integrating an Evaporative Pad Cooling System. Animals, 12(14), 1776. https://doi.org/10.3390/ani12141776