Comparison of Cattle Housing Systems Based on the Criterion of Damage to Barn Equipment and Construction Errors

Abstract

Simple Summary

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Leso, L.; Conti, L.; Rossi, G.; Barbari, M. Criteria of design for deconstruction applied to dairy cows housing: A case study in Italy. Agron. Res. 2018, 16, 794–805. [Google Scholar] [CrossRef]

- Von Keyserlingk, M.A.G.; Martin, N.P.; Kebreab, E.; Knowlton, K.F.; Grant, R.J.; Stephenson, M.; Sniffen, C.J.; Harner, J.P.; Wright, A.D.; Smith, S.I. Invited review: Sustainability of the US dairy industry. J. Dairy Sci. 2013, 96, 5405–5425. [Google Scholar] [CrossRef]

- Vasseur, E.; Gibbons, J.; Rushen, J.; Pellerin, D.; Pajor, E.; Lefebvre, D.; de Passillè, A.M. An assessment tool to help producers improve cow comfort on their farms. J. Dairy Sci. 2015, 98, 698–708. [Google Scholar] [CrossRef] [PubMed]

- Hughes, B.O. Behaviour as an index of welfare. In Proceedings of the 5th European Poultry Conference, Valletta, Malta, 5–11 September 1976. [Google Scholar]

- Hurnik, J.F.; Lehman, H. Ethics and farm animal welfare. J. Agric. Ethics 1988, 1, 305–318. [Google Scholar] [CrossRef]

- Fernández, M.E.; Mariño, R.A.; Carreira, X.C. Algorithms for dairy barn design: Resting, feeding, and exercise. J. Dairy Sci. 2006, 89, 2784–2798. [Google Scholar] [CrossRef]

- Fernández, M.E.; Mariño, R.A.; Carreira, X.C. Algorithms for dairy barn design: Maternity and milking areas. J. Dairy Sci. 2009, 92, 2276–2296. [Google Scholar] [CrossRef] [PubMed]

- Fregonesi, J.A.; von Keyserlingk, M.A.G.; Tucker, C.B.; Veira, D.M.; Weary, D.M. Neck-rail position in the free stall affects standing behavior and udder and stall cleanliness. J. Dairy Sci. 2009, 92, 1979–1985. [Google Scholar] [CrossRef]

- Gaworski, M. Free-stall use and preferences in dairy cows: A case study on neck rails covered by foam. Animals 2019, 9, 772. [Google Scholar] [CrossRef]

- Tucker, C.B.; Weary, D.M.; Fraser, D. Influence of neck-rail placement on free-stall preference, use, and cleanliness. J. Dairy Sci. 2005, 88, 2730–2737. [Google Scholar] [CrossRef]

- Tucker, C.B.; Weary, D.M. Bedding on geotextile mattresses: How much is needed to improve cow comfort? J. Dairy Sci. 2004, 87, 2889–2895. [Google Scholar] [CrossRef]

- Bak, A.S.; Herskin, M.S.; Jensen, M.B. Effect of sand and rubber surface on the lying behavior of lame dairy cows in hospital pens. J. Dairy Sci. 2016, 99, 2875–2883. [Google Scholar] [CrossRef]

- Drissler, M.; Gaworski, M.; Tucker, C.B.; Weary, D.M. Freestall maintenance: Effects on lying behavior of dairy cattle. J. Dairy Sci. 2005, 88, 2381–2387. [Google Scholar] [CrossRef]

- Fregonesi, J.A.; Veira, D.M.; von Keyserlingk, M.A.G.; Weary, D.M. Effects of bedding quality on lying behavior of dairy cows. J. Dairy Sci. 2007, 90, 5468–5472. [Google Scholar] [CrossRef] [PubMed]

- Ferreira Ponciano Ferraz, P.; Araújo e Silva Ferraz, G.; Leso, L.; Klopčič, M.; Rossi, G.; Barbari, M. Evaluation of the physical properties of bedding materials for dairy cattle using fuzzy clustering analysis. Animals 2020, 10, 351. [Google Scholar] [CrossRef]

- Ruud, L.E.; Bøe, K.E. Flexible and fixed partitions in freestalls—Effects on lying behavior and cow preference. J. Dairy Sci. 2011, 94, 4856–4862. [Google Scholar] [CrossRef]

- Tucker, C.B.; Zdanowicz, M.; Weary, D.M. Brisket boards reduce freestall use. J. Dairy Sci. 2006, 89, 2603–2607. [Google Scholar] [CrossRef]

- Endres, M.I.; DeVries, T.J.; von Keyserlingk, M.A.G.; Weary, D.M. Short communication: Effect of feed barrier design on the behavior of loose-housed lactating dairy cows. J. Dairy Sci. 2005, 88, 2377–2380. [Google Scholar] [CrossRef]

- Huzzey, J.M.; DeVries, T.J.; Valois, P.; von Keyserlingk, M.A.G. Stocking density and feed barrier design affect the feeding and social behavior of dairy cattle. J. Dairy Sci. 2006, 89, 126–133. [Google Scholar] [CrossRef]

- DeVries, T.J.; von Keyserlingk, M.A.G.; Weary, D.M. Effect of feeding space on the inter-cow distance, aggression, and feeding behavior of free-stall housed lactating dairy cows. J. Dairy Sci. 2004, 87, 1432–1438. [Google Scholar] [CrossRef]

- Machado Filho, L.C.P.; Teixeira, D.L.; Weary, D.M.; von Keyserlingk, M.A.G.; Hötzel, J. Designing better water troughs: Dairy cows prefer and drink more from larger troughs. Appl. Anim. Behav. Sci. 2004, 89, 185–193. [Google Scholar] [CrossRef]

- Teixeira, D.L.; Hötzel, M.J.; Machado Filho, L.C.P. Designing better water troughs: 2. Surface area and height, but not depth, influence dairy cows’ preference. Appl. Anim. Behav. Sci. 2006, 96, 169–175. [Google Scholar] [CrossRef]

- McDonald, P.V.; von Keyserlingk, M.A.G.; Weary, D.M. Hot weather increases competition between dairy cows at the drinker. J. Dairy Sci. 2020, 103, 3447–3458. [Google Scholar] [CrossRef] [PubMed]

- Gaworski, M.; Kamińska, N.; Kic, P. Evaluation and optimization of milking in some Polish dairy farms differed in milking parlours. Agron. Res. 2017, 15, 112–122. [Google Scholar]

- Steeneveld, W.; Tauer, L.W.; Hogeveen, H.; Oude Lansink, A.G.J.M. Comparing technical efficiency of farms with an automatic milking system and a conventional milking system. J. Dairy Sci. 2012, 95, 7391–7398. [Google Scholar] [CrossRef]

- Gaworski, M.; Leola, A.; Kiiman, H.; Sada, O.; Kic, P.; Priekulis, J. Assessment of dairy cow herd indices associated with different milking systems. Agron. Res. 2018, 16, 83–93. [Google Scholar] [CrossRef]

- Jacobs, J.A.; Siegford, J.M. Invited review: The impact of automatic milking systems on dairy cow management, behavior, health, and welfare. J. Dairy Sci. 2012, 95, 2227–2247. [Google Scholar] [CrossRef] [PubMed]

- Pitkäranta, J.; Kurkela, V.; Huotari, V.; Posio, M.; Halbach, C.E. Designing automated milking dairy facilities to maximize labor efficiency. Vet. Clin. N. Am.-Food Anim. Pract. 2019, 35, 175–193. [Google Scholar] [CrossRef] [PubMed]

- Cogato, A.; Brščić, M.; Guo, H.; Marinello, F.; Pezzuolo, A. Challenges and tendencies of automatic milking systems (AMS): A 20-years systematic review of literature and patents. Animals 2021, 11, 356. [Google Scholar] [CrossRef]

- Maller, C.J.; Hemsworth, P.H.; Ng, K.T.; Jongman, E.J.; Coleman, G.J.; Arnold, N.A. The relationships between characteristics of milking sheds and the attitudes to dairy cows, working conditions, and quality of life of dairy farmers. Aust. J. Agric. Res. 2005, 56, 363–372. [Google Scholar] [CrossRef]

- Wagner, A.; Palmer, R.W.; Bewley, J.; Jackson-Smith, D.B. Producer satisfaction, efficiency, and investment cost factors of different milking systems. J. Dairy Sci. 2001, 84, 1890–1898. [Google Scholar] [CrossRef]

- Campler, M.; Munksgaard, L.; Jensen, M.B.; Weary, D.M.; von Keyserlingk, M.A.G. Short communication: Flooring preferences of dairy cows at calving. J. Dairy Sci. 2014, 97, 892–896. [Google Scholar] [CrossRef]

- Haley, D.B.; de Passillè, A.M.; Rushen, J. Assessing cow comfort: Effects of two floor types and two tie stall designs on the behaviour of lactating dairy cows. Appl. Anim. Behav. Sci. 2001, 71, 105–117. [Google Scholar] [CrossRef]

- Platz, S.; Ahrens, F.; Bendel, J.; Meyer, H.H.D.; Erhard, M.H. What happens with cow behavior when replacing concrete slatted floor by rubber coating: A case study. J. Dairy Sci. 2008, 91, 999–1004. [Google Scholar] [CrossRef] [PubMed]

- Telezhenko, E.; Lidfors, L.; Bergsten, C. Dairy cow preferences for soft or hard flooring when standing or walking. J. Dairy Sci. 2007, 90, 3716–3724. [Google Scholar] [CrossRef] [PubMed]

- Gregory, N.G.; Taylor, O.D. Dairy cow preference for a soft track surface. N. Z. Vet. J. 2002, 50, 83. [Google Scholar] [CrossRef] [PubMed]

- Phillips, C.J.C.; Morris, I.D. The locomotion of dairy cows on concrete floors that are dry, wet, or covered with a slurry of excreta. J. Dairy Sci. 2000, 83, 1767–1772. [Google Scholar] [CrossRef]

- Rushen, J.; de Passillé, A.M. Effects of roughness and compressibility of flooring on cow locomotion. J. Dairy Sci. 2006, 89, 2965–2972. [Google Scholar] [CrossRef]

- Stefanowska, J.; Swierstra, D.; van den Berg, J.V.; Metz, J.H.M. Do cows prefer a barn compartment with a grooved or slotted floor? J. Dairy Sci. 2002, 85, 79–88. [Google Scholar] [CrossRef]

- Telezhenko, E.; Magnusson, M.; Bergsten, C. Gait of dairy cows on floors with different slipperiness. J. Dairy Sci. 2017, 100, 6494–6503. [Google Scholar] [CrossRef] [PubMed]

- Jungbluth, T.; Benz, B.; Wandel, H. Soft walking areas in loose housing systems for dairy cows. In Proceedings of the 5th International Dairy Housing Conference, ASAE, Fort Worth, TX, USA, 29–31 January 2003; pp. 171–177. [Google Scholar]

- Weeks, C.A.; McNally, P.W.; Warriss, P.D. Influence of the design of facilities at auction markets and animal handling procedures on bruising in cattle. Vet. Rec. 2002, 150, 743–748. [Google Scholar] [CrossRef] [PubMed]

- Mondaca, M.R.; Cook, N.B. Modeled construction and operating costs of different ventilation systems for lactating dairy cows. J. Dairy Sci. 2019, 102, 896–908. [Google Scholar] [CrossRef] [PubMed]

- Smith, J.F.; Bradford, B.J.; Harner, J.P.; Potts, J.C.; Allen, J.D.; Overton, M.W.; Ortiz, X.A.; Collier, R.J. Effect of cross ventilation with or without evaporative pads on core body temperature and resting time of lactating cows. J. Dairy Sci. 2016, 99, 1495–1500. [Google Scholar] [CrossRef] [PubMed]

- Herbut, P.; Hoffmann, G.; Angrecka, S.; Godyń, D.; Vieira, F.M.C.; Adamczyk, K.; Kupczyński, R. The effects of heat stress on the behaviour of dairy cows—A review. Ann. Anim. Sci. 2021, 21, 385–402. [Google Scholar] [CrossRef]

- Person, H.L.; Jacobson, L.D.; Jordan, K.A. Effect of dirt, louvers and other attachments on fan performance. Trans. Am. Soc. Agric. Eng. 1979, 22, 612–616. [Google Scholar] [CrossRef]

- Leliveld, L.M.C.; Riva, E.; Mattachini, G.; Finzi, A.; Lovarelli, D.; Provolo, G. Dairy cow behavior is affected by period, time of day and housing. Animals 2022, 12, 512. [Google Scholar] [CrossRef] [PubMed]

- Macmillan, K.; Espinoza, O.S.; Oba, M. Case Study: The effects of photoperiod on feeding behavior of lactating dairy cows in tie-stalls. Appl. Anim. Sci. 2018, 34, 103–107. [Google Scholar] [CrossRef]

- Statistics Poland 2022, Warsaw. Available online: https://stat.gov.pl/en/topics/statistical-yearbooks/statistical-yearbooks/statistical-yearbook-of-agriculture-2021,6,16.html (accessed on 10 May 2022).

- Statistics Poland 2021, Warsaw. Available online: https://stat.gov.pl/en/topics/agriculture-forestry/agriculture/agriculture-in-2020,4,17.html (accessed on 10 May 2022).

- Endres, M.I.; Lobeck-Luchterhand, K.M.; Espejo, L.A.; Tucker, C.B. Evaluation of the sample needed to accurately estimate outcome-based measurements of dairy welfare on farm. J. Dairy Sci. 2014, 97, 3523–3530. [Google Scholar] [CrossRef]

- Gaworski, M.; Boćkowski, M. Method for comparing current versus recommended housing conditions in dairy cattle production. Agric. Food Sci. 2018, 27, 17–27. [Google Scholar] [CrossRef]

- Statistica v.13 Software; StatSoft Polska: Cracow, Poland, 2021; Available online: https://www.statsoft.pl/ (accessed on 7 March 2022).

- Food and Agriculture Organization of the United Nations. Tie Stall Housing Systems on Dairy Farms. 2010. Available online: http://www.fao.org/fileadmin/user_upload/animalwelfare/TieStalls.pdf (accessed on 26 May 2022).

- Veissier, I.; Andanson, S.; Dubroeucq, H.; Pomiès, D. The motivation of cows to walk as thwarted by tethering. J. Anim. Sci. 2008, 86, 2723–2729. [Google Scholar] [CrossRef]

- Von Keyserlingk, M.A.G.; Barrientos, A.; Ito, K.; Galo, E.; Weary, D.M. Benchmarking cow comfort on North American freestall dairies: Lameness, leg injuries, lying time, facility design, and management for high-producing Holstein dairy cows. J. Dairy Sci. 2012, 95, 7399–7408. [Google Scholar] [CrossRef]

- De Belie, N.; Lenehan, J.J.; Braam, C.R.; Svennerstedt, B.; Richardson, M.; Sonck, B. Durability of building materials and components in the agricultural environment, Part III: Concrete structures. J. Agric. Eng. Res. 2000, 76, 3–16. [Google Scholar] [CrossRef]

- De Belie, N.; Sonck, B.; Braam, C.R.; Lenehan, J.J.; Svennerstedt, B.; Richardson, M. Durability of building materials and components in the agricultural environment, Part II: Metal structures. J. Agric. Eng. Res. 2000, 75, 333–347. [Google Scholar] [CrossRef]

- Tucker, C.B.; Weary, D.M.; Fraser, D. Effects of three types of free-stall surfaces on preferences and stall usage by dairy cows. J. Dairy Sci. 2003, 86, 521–529. [Google Scholar] [CrossRef]

- Tucker, C.B.; Weary, D.M.; Fraser, D. Free-stall dimensions: Effects on preference and stall usage. J. Dairy Sci. 2004, 87, 1208–1216. [Google Scholar] [CrossRef]

- Hovinen, M.; Rasmussen, M.D.; Pyörälä, S. Udder health of cows changing from tie stalls or free stalls with conventional milking to free stalls with either conventional or automatic milking. J. Dairy Sci. 2009, 92, 3696–3703. [Google Scholar] [CrossRef]

- Deng, Z.; Koop, G.; Lam, T.J.G.M.; van der Lans, I.A.; Vernooij, J.C.M.; Hogeveen, H. Farm-level risk factors for bovine mastitis in Dutch automatic milking dairy herds. J. Dairy Sci. 2019, 102, 4522–4535. [Google Scholar] [CrossRef]

- Ruegg, P.L. A 100-Year Review: Mastitis detection, management, and prevention. J. Dairy Sci. 2017, 100, 10381–10397. [Google Scholar] [CrossRef] [PubMed]

- Seo, T.; Date, K.; Daigo, T.; Kashiwamura, F.; Sato, S. Welfare assessment on Japanese dairy farms using the Animal Needs Index. Anim. Welf. 2007, 16, 221–223. [Google Scholar]

- Beaver, A.; Weary, D.M.; von Keyserlingk, M.A.G. Invited review: The welfare of dairy cattle housed in tiestalls compared to less-restrictive housing types: A systematic review. J. Dairy Sci. 2021, 104, 9383–9417. [Google Scholar] [CrossRef]

- Tarantola, M.; Valle, E.; De Marco, M.; Bergagna, S.; Dezzutto, D.; Gennero, M.S.; Bergero, D.; Schiavone, A.; Prola, L. Effects of abrupt housing changes on the welfare of Piedmontese cows. Ital. J. Anim. Sci. 2016, 15, 103–109. [Google Scholar] [CrossRef]

- Corazzin, M.; Piasentier, E.; Dovier, S.; Bovolenta, S. Effect of summer grazing on welfare of dairy cows reared in mountain tie-stall barns. Ital. J. Anim. Sci. 2010, 9, e59. [Google Scholar] [CrossRef]

- De Boyer des Roches, A.; Lardy, R.; Capdeville, J.; Mounier, L.; Veissier, I. Do International Commission of Agricultural and Biosystems Engineering (CIGR) dimension recommendations for loose housing of cows improve animal welfare? J. Dairy Sci. 2019, 102, 10235–10249. [Google Scholar] [CrossRef] [PubMed]

- Chapinal, N.; Barrientos, A.K.; von Keyserlingk, M.A.G.; Galo, E.; Weary, D.M. Herd-level risk factors for lameness in freestall farms in the northeastern United States and California. J. Dairy Sci. 2013, 96, 318–328. [Google Scholar] [CrossRef]

- Khanal, A.R.; Gillespie, J.; MacDonald, J. Adoption of technology, management practices, and production systems in US milk production. J. Dairy Sci. 2010, 93, 6012–6022. [Google Scholar] [CrossRef] [PubMed]

- DeVries, T.J.; Aarnoudse, M.G.; Barkema, H.W.; Leslie, K.E.; von Keyserlingk, M.A.G. Associations of dairy cow behavior, barn hygiene, cow hygiene, and risk of elevated somatic cell count. J. Dairy Sci. 2012, 95, 5730–5739. [Google Scholar] [CrossRef]

- Cramer, G.; Lissemore, K.D.; Guard, C.L.; Leslie, K.E.; Kelton, D. Herd-level risk factors for seven different foot lesions in Ontario Holstein cattle housed in tie stalls or free stalls. J. Dairy Sci. 2009, 92, 1404–1411. [Google Scholar] [CrossRef] [PubMed]

- Norring, M.; Manninen, E.; de Passillé, A.M.; Rushen, J.; Munksgaard, L.; Saloniemi, H. Effects of sand and straw bedding on the lying behavior, cleanliness, and hoof and hock injuries of dairy cows. J. Dairy Sci. 2008, 91, 570–576. [Google Scholar] [CrossRef] [PubMed]

- Witkowska, D.; Ponieważ, A. The effect of housing system on disease prevalence and productive lifespan of dairy herds—A case study. Animals 2022, 12, 1610. [Google Scholar] [CrossRef] [PubMed]

- Simensen, E.; Østerås, O.; Bøe, K.E.; Kielland, C.; Ruud, L.E.; Næss, G. Housing system and herd size interactions in Norwegian dairy herds; associations with performance and disease incidence. Acta Vet. Scand. 2010, 52, 14. [Google Scholar] [CrossRef]

- Praks, J.; Poikalainen, V.; Vermäe, I.; Sossidou, E. Livestock production systems: Welfare, environment and product quality. Cattle. In Farm Animal Welfare, Environment & Food Quality Interaction Studies; Sossidou, E., Szücs, E., Eds.; National Agricultural Research Foundation: Giannitsa, Greece, 2007; pp. 201–233. [Google Scholar]

- Silva, S.R.; Araujo, J.P.; Guedes, C.; Silva, F.; Almeida, M.; Cerqueira, J.L. Precision technologies to address dairy cattle welfare: Focus on lameness, mastitis and body condition. Animals 2021, 11, 2253. [Google Scholar] [CrossRef] [PubMed]

- Popescu, S.; Borda, C.; Diugan, E.A.; Niculae, M.; Razvan, S.; Sandru, C.D. The effect of the housing system on the welfare quality of dairy cows. Ital. J. Anim. Sci. 2014, 13, 2940. [Google Scholar] [CrossRef]

- Arcidiacono, C.; Barbari, M.; Benni, S.; Carfagna, E.; Cascone, G.; Conti, L.; di Stefano, L.; Guarino, M.; Leso, L.; Lovarelli, D.; et al. Smart Dairy Farming: Innovative Solutions to Improve Herd Productivity. In Innovative Biosystems Engineering for Sustainable Agriculture, Forestry and Food Production; Coppola, A., Di Renzo, G., Altieri, G., D’Antonio, P., Eds.; MID-TERM AIIA 2019; Lecture Notes in Civil Engineering; Springer: Cham, Switzerland, 2020; Volume 67, pp. 265–270. [Google Scholar] [CrossRef]

- Gaworski, M. Implementation of technical and technological progress in dairy production. Processes 2021, 9, 2103. [Google Scholar] [CrossRef]

- Borowski, P.F. Production processes related to conventional and renewable energy in enterprises and in the circular economy. Processes 2022, 10, 521. [Google Scholar] [CrossRef]

- Borowski, P.F. Nexus between water, energy, food and climate change as challenges facing the modern global, European and Polish economy. AIMS Geosci. 2020, 6, 397–421. [Google Scholar] [CrossRef]

| Description | Dairy Farms with Housing System Type: | |

|---|---|---|

| Tie-Stall | Freestall | |

| Number of visited farms | 19 | 19 |

| Average cow herd size ± SD | 29 ± 14 | 85 ± 38 |

| Min./max. cow herd size | 8/60 | 30/150 |

| Average annual milk yield per cow ± SD [kg cow22121 year−1] | 5261 ± 1329 | 6749 ± 1483 |

| Min./max. cow milk yield [kg cow−1 year−1] | 3333/8400 | 3900/9000 |

| Description | Dairy Farms with Housing System Type: | |

|---|---|---|

| Tie-Stall | Freestall | |

| Number of visited farms | 19 | 19 |

| Milking system (m.s.)/ milking parlor (m.p.) used on the farm | bucket m.s. × 6 farms pipeline m.s. × 13 farms | herringbone m.p. × 11 farms side by side m.p. × 5 farms AMS × 3 farms |

| Lying area in the barn | rubber mat × 1 farm shallow straw bedding × 18 farms | rubber mat × 9 farms shallow straw bedding × 10 farms |

| The Zone in the Barn | Technical Equipment Assessed in the Zone | Identified Damage to Barn Equipment | Identified Design and Implementation Errors | |

|---|---|---|---|---|

| Tie-stall housing system | Lying area (LA) | concrete floor, rubber mats, partitions, manure channel, tether | bent metal parts and pipes, damaged chain fastening, defects in concrete in the floor and slurry channel, damaged mats, broken mats | ribbed bar at the front of the stall and its incorrect attachment, no partitions, additional pipe at the front of the stall, incorrect chain length and fastening, no lowering of the manure channel in relation to the stall level, partition with an additional vertical pipe |

| Milking area (MA) | milking pipes and connectors | bent pipes, damaged vacuum gauge, damaged milking cluster fittings | incorrect installation of vacuum and milk lines | |

| Social area (SA) | concrete floor in a walking alley, concrete grid for collecting faeces | concrete damage in the floor and grid | additional concrete threshold in the corridor, pipe installed across the corridor, badly made partitions at the end of the row with stalls | |

| Feeding area (FA) | feeding alley, manger, separating wall, feed ladder, drinking bowl | concrete defects in the manger and fracture, concrete defects in the feeding alley, folded metal parts and pipes, feed ladder defects, drinking bowl defect, damaged drinkers valves | no drinking bowls (water intake from a concrete manger), no running water installation, no level difference between the manger and lying stalls, water pipe on the wall separating the feed alley from the lying stalls, incorrect mounting of the drinkers, metal rod in the feed wall | |

| Freestall housing system | Lying area (LA) | concrete floor, rubber mats, partitions, neck-rails, brisket-boards, curbs | bends of metal elements, no fasteners and securing elements on neck-rails, no fastening elements for partitions, no neck-rails in some lying stalls | additional bars at the pen’s fence, construction posts in the lying area, incorrectly installed rubber mats, the post of the pass gate in the lying area |

| Milking area (MA) | concrete floor in the milking parlor, concrete floor in the waiting area, entrance and exit gates, fencing structure, elements of milking equipment | damaged floor in the milking parlor, broken entrance gate to the milking parlor | too high threshold at the entrance to the milking parlor, improper separation (with a metal pipe) of the entrance to the milking parlor, faulty entrance gate, incorrect width of the entrance to the milking parlor | |

| Social area (SA) | concrete floor in the walking alley, concrete grid for faeces collecting, brush | damaged floor in walking alleys, damaged metal fillings of entry gates, wear and improper operation of the cow brushes | no end caps in the horizontal mounting pipe protruding from the row of stalls into the walking alley, too high threshold at the exit to the external paddock, water system valves not properly secured, improperly mounted brushes | |

| Feeding area (FA) | feeding alley, manger, separating wall, feed ladder, drinking bowl | damaged drinking bowl valve, concrete losses in the feeding alley, losses in the feed ladder | unprotected metal bars and wooden elements at the drinking bowls, sharp drinking bowls’ edges, badly mounted salt licks, protruding metal rods on the feed wall |

| Data | Barns with Tie-Stall Housing System | Barns with Freestall Housing System | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Mean | SD | Skewness | Kurtosis | Mean | SD | Skewness | Kurtosis | ||

| Barn | Barn age (years) | 21.68 | 12.40 | 0.12 | −1.48 | 6.16 | 4.22 | 0.64 | −0.04 |

| Usable area (m2) | 340.26 | 138.35 | 0.17 | −1.03 | 1095.21 | 289.09 | −0.27 | −0.89 | |

| Herd size (cows) | 29.11 | 14.00 | 0.68 | 0.22 | 85.00 | 37.66 | 0.16 | −0.91 | |

| Usable area per cow (m2 cow−1) | 11.69 | 6.40 | 1.69 | 1.77 | 12.89 | 6.13 | 1.39 | 1.78 | |

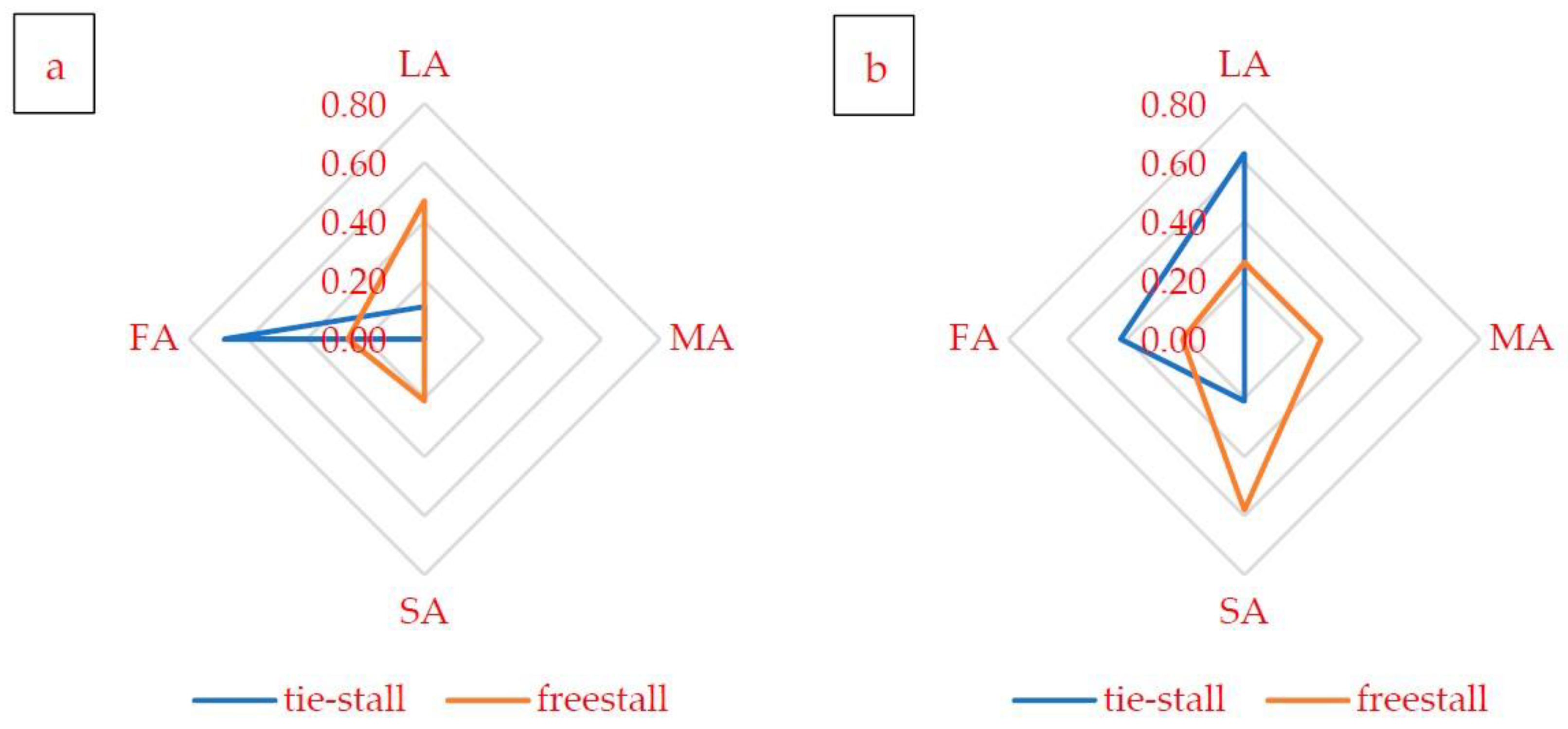

| Technical problems | Problems in LA | 0.74 | 0.81 | 1.25 | 2.17 | 0.74 | 0.93 | 0.59 | −1.68 |

| Problems in MA | 0.00 | 0.00 | − | − | 0.21 | 0.42 | 1.54 | 0.42 | |

| Problems in SA | 0.21 | 0.42 | 1.54 | 0.42 | 0.79 | 0.63 | 0.17 | −0.31 | |

| Problems in FA | 1.11 | 0.74 | −0.17 | −1.00 | 0.47 | 0.51 | 0.11 | −2.24 | |

| Technical problems together | 2.05 | 0.97 | 0.70 | −0.20 | 2.21 | 1.47 | 0.06 | −0.77 | |

| Health Problems | Barns with Tie-Stall Housing System | Barns with Freestall Housing System | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Mean | SD | Skewness | Kurtosis | Mean | SD | Skewness | Kurtosis | ||

| Health problems | Laminitis | 1.05 | 3.42 | 4.18 | 17.82 | 6.26 | 5.16 | 0.93 | 1.13 |

| Other hoof | 0.74 | 2.31 | 4.01 | 16.67 | 5.89 | 7.16 | 0.91 | −0.42 | |

| Mastitis | 14.74 | 7.00 | 0.49 | −1.19 | 11.42 | 11.28 | 0.88 | −0.38 | |

| Other health problems | 1.16 | 3.13 | 2.75 | 6.31 | 0.00 | 0.00 | − | − | |

| Total health problems | 17.68 | 9.62 | 0.58 | −1.09 | 23.58 | 10.55 | 0.27 | −0.15 | |

| Health problems per cow | 0.68 | 0.34 | 0.54 | 0.29 | 0.34 | 0.27 | 0.50 | 1.04 | |

| Barn Age | Usable Area | Herd Size | Problems in: | Laminitis | Other Hoof Probl. | Mastitis | Other Health Probl. | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| LA | MA | SA | FA | ||||||||

| Barn Age | 1.000 | −0.627 | −0.388 | 0.230 | −0.317 | −0.295 | 0.502 | −0.383 | −0.177 | 0.089 | 0.126 |

| Usable Area | −0.627 | 1.000 | 0.849 | −0.013 | 0.289 | 0.390 | −0.338 | 0.638 | 0.400 | −0.182 | −0.123 |

| Herd size | −0.388 | 0.849 | 1.000 | 0.099 | 0.153 | 0.333 | −0.223 | 0.645 | 0.543 | −0.269 | −0.130 |

| Probl. LA | 0.230 | −0.013 | 0.099 | 1.000 | −0.119 | −0.015 | 0.029 | 0.124 | 0.364 | −0.093 | −0.068 |

| Probl. MA | −0.317 | 0.289 | 0.153 | −0.119 | 1.000 | 0.339 | 0.000 | 0.269 | 0.032 | −0.071 | −0.117 |

| Probl. SA | −0.295 | 0.390 | 0.333 | −0.015 | 0.339 | 1.000 | −0.212 | 0.231 | −0.040 | 0.137 | −0.302 |

| Probl. FA | 0.502 | −0.338 | −0.223 | 0.029 | 0.000 | −0.212 | 1.000 | −0.225 | −0.102 | 0.238 | 0.351 |

| Laminitis | −0.383 | 0.638 | 0.645 | 0.124 | 0.269 | 0.231 | −0.225 | 1.000 | 0.591 | −0.351 | −0.165 |

| Other hoof probl. | −0.177 | 0.400 | 0.543 | 0.364 | 0.032 | −0.040 | −0.102 | 0.591 | 1.000 | −0.265 | −0.125 |

| Mastitis | 0.089 | −0.182 | −0.269 | −0.093 | −0.071 | 0.137 | 0.238 | −0.351 | −0.265 | 1.000 | 0.272 |

| Other health probl. | 0.126 | −0.123 | −0.130 | −0.068 | −0.117 | −0.302 | 0.351 | −0.165 | −0.125 | 0.272 | 1.000 |

| Median ts | Median fs | Z | p | |

|---|---|---|---|---|

| Barn age | 16 | 5 | 4.09 | 0.000 |

| Usable area | 325 | 1050 | −5.23 | 0.000 |

| Herd size | 26 | 85 | −4.53 | 0.000 |

| Probl-LA | 1 | 0 | 0.18 | 0.861 |

| Probl-MA | 0 | 0 | −1.09 | 0.274 |

| Probl-SA | 0 | 1 | −2.60 | 0.009 |

| Probl-FA | 1 | 0 | 2.44 | 0.015 |

| Total-tech | 2 | 2 | −0.38 | 0.704 |

| Laminitis | 0 | 5 | −3.91 | 0.000 |

| Other-hoof | 0 | 2 | −2.07 | 0.038 |

| Mastitis | 12 | 8 | 1.65 | 0.099 |

| Other-probl. | 0 | 0 | 1.09 | 0.274 |

| Total-probl. | 13 | 21 | −1.65 | 0.099 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gaworski, M.; Boćkowski, M. Comparison of Cattle Housing Systems Based on the Criterion of Damage to Barn Equipment and Construction Errors. Animals 2022, 12, 2530. https://doi.org/10.3390/ani12192530

Gaworski M, Boćkowski M. Comparison of Cattle Housing Systems Based on the Criterion of Damage to Barn Equipment and Construction Errors. Animals. 2022; 12(19):2530. https://doi.org/10.3390/ani12192530

Chicago/Turabian StyleGaworski, Marek, and Michał Boćkowski. 2022. "Comparison of Cattle Housing Systems Based on the Criterion of Damage to Barn Equipment and Construction Errors" Animals 12, no. 19: 2530. https://doi.org/10.3390/ani12192530

APA StyleGaworski, M., & Boćkowski, M. (2022). Comparison of Cattle Housing Systems Based on the Criterion of Damage to Barn Equipment and Construction Errors. Animals, 12(19), 2530. https://doi.org/10.3390/ani12192530