Effect of Ultraviolet Radiation on Reducing Airborne Escherichia coli Carried by Poultry Litter Particles

Abstract

:Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. Microorganism and System Descriptions

2.1.1. Preparation of E. coli Solution

2.1.2. Litter Preparation

2.1.3. Test Chambers

2.1.4. Aerosolization System

2.1.5. Dust Monitoring

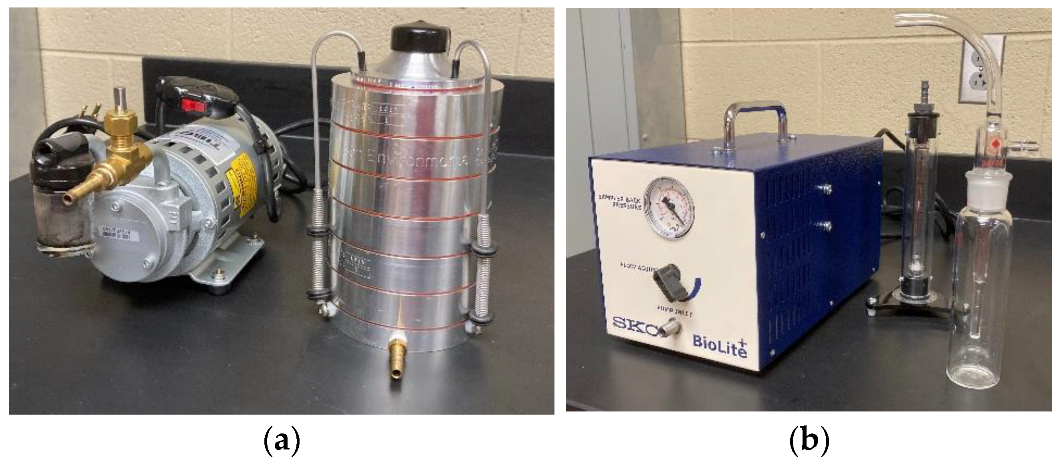

2.1.6. Air Samplers

2.2. Experimental Design and Procedures

2.2.1. System Design

2.2.2. System Setup and Sampling Collection

2.2.3. UV Light Intensity Distribution

2.3. Calculation of E. coli Concentration and Inactivation Rates

2.3.1. Determining Size Distribution of Airborne E. coli Carried by Poultry Dust Particles

2.3.2. Determining Airborne E. coli Concentration

2.3.3. Inactivation Rates

2.3.4. Reynolds Number

2.4. Statistical Analysis

3. Results

3.1. UV Light Intensity Distribution

3.2. Size Distribution of E. coli Attached to Dust Particles and Dust Particles

3.3. Contact Time Effect on Airborne E. coli

3.4. Physical Loss of Testing System

3.5. Inactivation Efficiency of UV Light

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- National Agricultural Statistics Service. Poultry–Production and Value 2020 Summary; U.S. Department of Agriculture, National Agricultural Statistics Service (USDA, NASS): Washington, DC, USA, 2020. [Google Scholar]

- Saif, Y.; Barnes, H.; Glisson, J.; Fadly, A.; McDougald, L.; Swayne, D. Diseases of Poultry, 12th ed.; Blackwell Pub Professional: Ames, IA, USA, 2008; pp. 452–514. [Google Scholar]

- Dho-Moulin, M.; Fairbrother, J.M. Avian pathogenic Escherichia coli (APEC). Vet. Res. 1999, 30, 299–316. [Google Scholar] [PubMed]

- Mellata, M. Human and avian extraintestinal pathogenic Escherichia coli: Infections, zoonotic risks, and antibiotic resistance trends. Foodborne Pathog. Dis. 2013, 10, 916–932. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hasan, B.; Faruque, R.; Drobni, M.; Waldenström, J.; Sadique, A.; Ahmed, K.U.; Islam, Z.; Parvez, M.H.; Olsen, B.; Alam, M. High prevalence of antibiotic resistance in pathogenic Escherichia coli from large-and small-scale poultry farms in Bangladesh. Avian Dis. 2011, 55, 689–692. [Google Scholar] [CrossRef] [PubMed]

- Fancher, C.A.; Zhang, L.; Kiess, A.S.; Adhikari, P.A.; Dinh, T.T.; Sukumaran, A.T. Avian pathogenic Escherichia coli and Clostridium perfringens: Challenges in no antibiotics ever broiler production and potential solutions. Microorganisms 2020, 8, 1533. [Google Scholar] [CrossRef] [PubMed]

- Duan, H.; Chai, T.; Cai, Y.; Zhong, Z.; Yao, M.; Zhang, X. Transmission identification of Escherichia coli aerosol in chicken houses to their environments using ERIC-PCR. Sci. China Ser. C Life Sci. 2008, 51, 164–173. [Google Scholar] [CrossRef]

- Chinivasagam, H.N.; Tran, T.; Maddock, L.; Gale, A.; Blackall, P.J. Mechanically ventilated broiler sheds: A possible source of aerosolized Salmonella, Campylobacter, and Escherichia coli. Appl. Environ. Microbiol. 2009, 75, 7417–7425. [Google Scholar] [CrossRef] [Green Version]

- Lutful Kabir, S.M. Avian colibacillosis and salmonellosis: A closer look at epidemiology, pathogenesis, diagnosis, control and public health concerns. Int. J. Environ. Res. Public Health 2010, 7, 89–114. [Google Scholar] [CrossRef] [Green Version]

- Pourbakhsh, S.A.; Boulianne, M.; Martineau-Doizé, B.; Dozois, C.M.; Desautels, C.; Fairbrother, J.M. Dynamics of Escherichia coli infection in experimentally inoculated chickens. Avian Dis. 1997, 41, 221–233. [Google Scholar] [CrossRef]

- Ochoa-Velasco, C.E.; Ávila-Sosa, R.; Hernández-Carranza, P.; Ruíz-Espinosa, H.; Ruiz-López, I.I.; Guerrero-Beltrán, J.Á. Mathematical modeling used to evaluate the effect of UV-C light treatment on microorganisms in liquid foods. Food Eng. Rev. 2020, 12, 290–308. [Google Scholar] [CrossRef]

- Nguyen, X.D.; Zhao, Y.; Evans, J.D.; Lin, J.; Purswell, J.L. Survival of Escherichia coli in Airborne and Settled Poultry Litter Particles. Animals 2022, 12, 284. [Google Scholar] [CrossRef]

- Zhao, Y.; Aarnink, A.; De Jong, M.; Groot Koerkamp, P.W.G. Airborne Microorganisms From Livestock Production Systems and Their Relation to Dust. Crit. Rev. Environ. Sci. Technol. 2014, 44, 1071–1128. [Google Scholar] [CrossRef]

- Guerrero-Beltrn, J.A.; Barbosa-Cnovas, G.V. Advantages and limitations on processing foods by UV light. Food Sci. Technol. Int. 2004, 10, 137–147. [Google Scholar] [CrossRef]

- Nguyen, X.D.; Zhao, Y.; Evans, J.D.; Lin, J.; Schneider, L.; Voy, B.; Hawkins, S.; Purswell, J.L. Evaluation of Bioaerosol Samplers for Airborne Escherichia coli Carried by Poultry Litter Particles. J. ASABE 2022, 65, 825–833. [Google Scholar] [CrossRef]

- Davis, M.; Morishita, T.Y. Relative ammonia concentrations, dust concentrations, and presence of Salmonella species and Escherichia coli inside and outside commercial layer facilities. Avian Dis. 2005, 49, 30–35. [Google Scholar] [CrossRef]

- Andersen, A.A. New sampler for the collection, sizing, and enumeration of viable airborne particles. J. Bacteriol. 1958, 76, 471–484. [Google Scholar] [CrossRef] [Green Version]

- Yao, Q.; Yang, Z.; Li, H.; Buser, M.D.; Wanjura, J.D.; Downey, P.M.; Zhang, C.; Craige, C.; Torrents, A.; McConnell, L.L. Assessment of particulate matter and ammonia emission concentrations and respective plume profiles from a commercial poultry house. Environ. Pollut. 2018, 238, 10–16. [Google Scholar] [CrossRef]

- Li, M.; Qiang, Z.; Bolton, J.R. In situ detailed fluence rate distributions in a UV reactor with multiple low-pressure lamps: Comparison of experimental and model results. Chem. Eng. J. 2013, 214, 55–62. [Google Scholar] [CrossRef]

- Hijnen, W.; Beerendonk, E.; Medema, G.J. Inactivation credit of UV radiation for viruses, bacteria and protozoan (oo) cysts in water: A review. Water Res. 2006, 40, 3–22. [Google Scholar] [CrossRef]

- Guo, B.; Ghalambor, A. (Eds.) Chapter 11—Transportation. In Natural Gas Engineering Handbook, 2nd ed.; Gulf Publishing Company: Houston, TX, USA, 2005; pp. 219–262. [Google Scholar]

- Zuo, Z.; Kuehn, T.H.; Verma, H.; Kumar, S.; Goyal, S.M.; Appert, J.; Raynor, P.C.; Ge, S.; Pui, D.Y. Association of airborne virus infectivity and survivability with its carrier particle size. Aerosol Sci. Technol. 2013, 47, 373–382. [Google Scholar] [CrossRef]

- Wang, Z.; Gao, T.; Jiang, Z.; Min, Y.; Mo, J.; Gao, Y. Effect of ventilation on distributions, concentrations, and emissions of air pollutants in a manure-belt layer house. J. Appl. Poult. Res. 2014, 23, 763–772. [Google Scholar] [CrossRef]

- Ellen, H.; Bottcher, R.; Von Wachenfelt, E.; Takai, H. Dust levels and control methods in poultry houses. J. Agric. Saf. Health 2000, 6, 275. [Google Scholar] [CrossRef] [PubMed]

- Xu, P.; Kujundzic, E.; Peccia, J.; Schafer, M.P.; Moss, G.; Hernandez, M.; Miller, S.L. Impact of environmental factors on efficacy of upper-room air ultraviolet germicidal irradiation for inactivating airborne mycobacteria. Environ. Sci. Technol. 2005, 39, 9656–9664. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Aarnink, A.J.; Xin, H. Inactivation of airborne Enterococcus faecalis and infectious bursal disease virus using a pilot-scale ultraviolet photocatalytic oxidation scrubber. J. Air Waste Manag. Assoc. 2014, 64, 38–46. [Google Scholar] [CrossRef] [PubMed]

- Rana, M.; Campbell, D.L. Application of ultraviolet light for poultry production: A review of impacts on behavior, physiology, and production. Front. Anim. Sci. 2021, 2, 699262. [Google Scholar] [CrossRef]

| Contact Time (s, Mean ± SD) | Chamber | >7.0 µm (%) | 4.7–7.0 µm (%) | 3.3–4.7 µm (%) | 2.1–3.3 µm (%) | 1.1–2.1 µm (%) | 0.65–1.1 µm (%) |

|---|---|---|---|---|---|---|---|

| 5.62 ± 0.91 | Upstream | 47.52 | 30.60 | 10.05 | 10.64 | 0.23 | 0.96 |

| Downstream | 25.85 | 27.56 | 24.85 | 19.41 | 0.74 | 1.59 | |

| 1.2 ± 0.06 | Upstream | 34.32 | 24.70 | 6.76 | 15.57 | 10.03 | 8.62 |

| Downstream | 31.30 | 29.09 | 7.85 | 24.32 | 5.38 | 2.06 | |

| 0.34 ± 0.01 | Upstream | 34.76 | 20.86 | 9.63 | 9.09 | 19.25 | 6.41 |

| Downstream | 23.74 | 37.40 | 10.78 | 7.98 | 15.88 | 4.22 | |

| 0.23 ± 0.01 | Upstream | 42.75 | 23.64 | 5.72 | 8.86 | 15.25 | 3.78 |

| Downstream | 62.30 | 13.09 | 10.30 | 5.52 | 4.80 | 3.96 |

| Contact Times (s, Mean ± SD) | Number of UV Lamps | Temperature (°C, Mean ± SD) | Relative Humidity (%, Mean ± SD) |

|---|---|---|---|

| 5.62 ± 0.91 | 1 | 23.0 ± 0.7 a | 61 ± 7 a |

| 2 | 23.0 ± 0.7 a | 61 ± 7 a | |

| 1.2 ± 0.06 | 1 | 22.0 ± 1.4 a | 60 ± 2 a |

| 2 | 22.0 ± 1.4 a | 60 ± 2 a | |

| 0.34 ± 0.01 | 1 | 22.5 ± 0.5 a | 61 ± 3 a |

| 2 | 22.5 ± 0.5 a | 61 ± 3 a | |

| 0.23 ± 0.01 | 1 | 22.7 ± 1.3 a | 56 ± 5 b |

| 2 | 22.7 ± 1.3 a | 56 ± 5 b |

| Contact Times (s, Mean ± SD) | Number of UV Lamps | Inactivation Rates (%, Mean ± SD) | Log Reduction (log10) |

|---|---|---|---|

| 5.62 ± 0.91 | 1 | 99.87 ± 0.07 a | 2.9 ± 0.3 |

| 2 | 99.95 ± 0.04 a | 3.5 ± 0.5 | |

| 1.2 ± 0.06 | 1 | 93.97 ± 0.36 b | 1.2 ± 0.0 |

| 2 | 96.85 ± 1.23 c | 1.6 ± 0.2 | |

| 0.34 ± 0.01 | 1 | 92.60 ± 0.63 d | 1.1 ± 0.0 |

| 2 | 95.40 ± 0.59 e | 1.3 ± 0.1 | |

| 0.23 ± 0.01 | 1 | 72.90 ± 2.57 f | 0.6 ± 0.0 |

| 2 | 86.60 ± 1.35 g | 0.9 ± 0.1 |

| Contact Times (s, Mean ± SD) | Number of UV Lamps | k-Values (cm2 mJ−1, Mean ± SD) |

|---|---|---|

| 5.62 ± 0.91 | 1 | 0.300 ± 0.106 a |

| 2 | 0.171 ± 0.059 ab | |

| 1.2 ± 0.06 | 1 | 0.608 ± 0.145 c |

| 2 | 0.378 ± 0.065 a | |

| 0.34 ± 0.01 | 1 | 1.928 ± 0.35 d |

| 2 | 1.136 ± 0.16 e | |

| 0.23 ± 0.01 | 1 | 0.144 ± 0.072 b |

| 2 | 0.114 ± 0.080 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, X.D.; Zhao, Y.; Evans, J.D.; Lin, J.; Voy, B.; Purswell, J.L. Effect of Ultraviolet Radiation on Reducing Airborne Escherichia coli Carried by Poultry Litter Particles. Animals 2022, 12, 3170. https://doi.org/10.3390/ani12223170

Nguyen XD, Zhao Y, Evans JD, Lin J, Voy B, Purswell JL. Effect of Ultraviolet Radiation on Reducing Airborne Escherichia coli Carried by Poultry Litter Particles. Animals. 2022; 12(22):3170. https://doi.org/10.3390/ani12223170

Chicago/Turabian StyleNguyen, Xuan Dung, Yang Zhao, Jeffrey D. Evans, Jun Lin, Brynn Voy, and Joseph L. Purswell. 2022. "Effect of Ultraviolet Radiation on Reducing Airborne Escherichia coli Carried by Poultry Litter Particles" Animals 12, no. 22: 3170. https://doi.org/10.3390/ani12223170