Simple Summary

Oils and fats are relevant sources of energy and functional substances in the animal’s body, ensuring its normal growth and development of laying hens needs. Eggs are rich in proteins, amino acids, and fatty acids, and are considered as ‘the ideal nutrient reservoir for humans’. Adding different types and amounts of oils and fats to feed can affect the production performance and egg quality of laying hens. Therefore, it is particularly relevant to investigate the appropriate type and proportion of oils and fats to be used in egg farming. We studied the effects of different concentrations of soybean oil, lard and mixed oils on the production performance, egg quality, and antioxidant substances of laying hens. The results demonstrated that the type and quantities of oils and fats in the diets of laying hens had significant effects on the parameters studied. Thus, this experiment provides a reference for the selection of different types of oils and fats in the egg production process to improve the quality and economic benefits of eggs.

Abstract

In this study, soybean oil, lard and mixed oils were added to the feed in two concentrations (1.5% and 3% of each), resulting in six experimental groups. The control group was fed with a base diet without additions, and used to compare the effects of feeding on production performance and egg quality of laying hens. The results demonstrated that: (1) the 3% supplemented-oils or lard group showed a decrease in laying rate; (2) 1.5% and 3% added-lard significantly increased the total amount of unsaturated fatty acids in eggs, compared to the control group; (3) 1.5% and 3% soybean oil increased the content of mono/polyunsaturated fatty acids, cholesterol, phospholipids and choline in eggs; (4) glutathione peroxidase (GPx) and superoxide dismutase (SOD) contents were increased in all groups, being the most evident in the lard-treated group; (5) all experimental groups showed an increase in the content of essential and non-essential amino acids in albumen; (6) 3% oils, especially the mixed oils, damaged the structure of globules of cooked egg yolks. Therefore, the use of 1.5% soybean oil in the feed diet of Hyline brown hens resulted in the most adequate oil to ensure animal health and economic significant improvements in this experiment.

1. Introduction

Oils are the most common source of energy in feed diets for laying hens, affecting energy production, absorption of fat-soluble nutrients, resistance to the heat stress, reduction of dust, and improvement of immunity. Moreover, they improve egg production performance and feed intake [1,2,3,4]. Feeding oils are classified into animal, vegetable, and mixed oils. Animal oils are mainly extracted from subcutaneous adipose tissue [5], and the most common types in production are lard and fish oils. Vegetable oils include soybean, rapeseed, and linseed oils, which are obtained from plant seed kernels after pretreatment, including cleaning, removing impurities, dehulling, crushing and softening, followed by extraction by mechanical pressing or solvent leaching. Afterwards, the resultant crude oil is refined [6,7]. The mixed oil includes different oils according to a defined ratio. The effects of oils on the production performance and egg quality of laying hens have been reported several times [8,9,10,11]. Numerous evidence has shown that under high-temperature conditions, the addition of appropriate amounts of soybean oil to the diet of laying hens, alleviated heat stress and improved egg production and feed conversion ratio, without significant adverse effects on egg weight [12,13]. However, it caused oxidative damage to the body and increased serum malondialdehyde (MDA) levels [14]. Other studies have also shown that adding 4.3% of lard to the diet increased egg production and average weight, with a significant improvement in yolk color [15].

Eggs are an excellent source of animal protein for humans, as they are rich in high-quality protein, fat, cholesterol, and other micronutrients [15]. Several studies have demonstrated that the addition of oils to the diet can affect the nutritional composition of eggs [16,17], including the lipid structure of egg yolk. Thus, the addition of moderate amounts of oils, especially vegetable oil, to diets increase the content of unsaturated fatty acid and reduces the cholesterol content of the yolk [18,19]. However, the addition of 2% cottonseed oil to the diet of laying hens increases the hardness of the yolk, resulting in a so-called “rubber egg”, affecting the taste of it [20].

Although oils have been widely used in poultry, there are several drawbacks to the addition of oils to diets [21,22]. Thus, compared with broilers, the addition of oil in laying hens has to be less, because it may lead to excessive fat deposition, decreased meat quality, unbalanced diet nutrition [23], and feed toxin contamination [24]. As a result, fatty liver hemorrhagic syndrome and metabolic disorders leading to decreased performance and increased mortality in laying hens may occur [25,26]. In addition, the rapid oxidation and rancidity of oils loom the safety of livestock and their byproducts, reduce the production performance, alter the antioxidant status of laying hens, and destroy the structure of egg yolk globules [27]. Previous studies have demonstrated the complexity of adding a single type of oil to support the needs of livestock and poultry growth [28,29]. Thus, different proportions and types of oils need to be added to the feed of laying hens. However, the difficulty to control the effect of mixed oils relies on the mutual influence of different types of oils, their mechanism of action not being fully understood. Therefore, the rational and accurate addition of oils to the feed diet is highly relevant, with a comprehensive analysis of the effects of fed oils on egg production performance, quality, nutrient composition, and oxidative properties of laying hens. In this study, we investigated the production performance of different concentrations of soybean oil, lard, and mixed oils in egg feeds for Hyline brown hens during the experimental period, and comprehensively and systematically determined the nutritional composition and conventional egg quality in albumen and yolks, oxidation indexes, textural characteristics, and microstructure of cooked egg yolks. The aim was to provide a reference for the selection of different types of fats and oils in egg rations in order to improve egg quality and economic efficiency of egg production.

2. Materials and Methods

2.1. Experimental Materials and Feeding Management

We conducted the tests at the experimental base of the Poultry Institute of Shandong Academy of Agricultural Sciences. A total of 840 Hyline brown laying hens (40 w of age; 2005 ± 130 g) were housed in cages at 23 ± 2 °C. The pre-feeding period and the experimental period lasted for one and four weeks, respectively. The egg production, feed intake, and general health of the hens was observed during the pre-feeding period. Feed was purchased from Beinongda Technology Co., Ltd. (Jinan, China) and soybean, lard, and mixed oils (soybean, soybean-phospholipid, coconut, rice, and antioxidants) were ordered online. According to NRC feeding standards [30], corn and soybean meal were selected as the main diet components in appropriate proportions to form a corn-soybean meal-based diet. The feeds selected for the experiment were made by a small crushing mixer and were powdered compound feeds with coarser crushed material; the oils and fats used for the experiment were kept in a cool and ventilated place to avoid their oxidation and decay, while the performance of the hens was monitored daily to ensure that they had sufficient water and food everyday and eggs were collected daily. The basic diet formulation for laying hens is shown in Table 1.

Table 1.

Ingredients and composition of the basal diet.

2.2. Experimental Groups and Sampling Time

The experimental hens were randomly divided into seven groups (with 120 animals each, considering three replicates of 40 chickens). The control group was fed with a corn-soybean meal-based diet, and the experimental groups were fed with the same base diet with either 1.5% or 3% of soybean oil, lard, or mixed oils, respectively. Table 2 shows the nutritional composition of the six experimental groups. A sampling of the experimental eggs was carried out on the following day after the end of the experimental period.

Table 2.

Ingredients and composition of the experimental diets (as fed-basis).

2.3. Production Performance and Egg Quality Determination

The number of eggs laid, egg weight (EW), and mortality were recorded daily, while feed conversion ratio (FCR), laying rate, average daily feed intake (ADFI), and average EW (AEW) were calculated weekly.

About forty eggs from each group were randomly selected for egg quality determination, including EW, yolk weight (YW), albumen height (AH), yolk color (YC), and Haugh units (HU). These indicators were measured using the EMT-5200 multifunctional egg tester (Robotmation, Tokyo, Japan). The egg shape index (ESI) was calculated with the formula: ESI = egg length/egg width [31]. Eggshell strength (ESS) was measured by an eggshell strength tester Model-II (Robotmation, Tokyo, Japan), and the eggshell weight (ESW) was obtained with an electronic balance (YP601N, Qinghai Co., Ltd., Shanghai, China) after removing the eggshell membrane. Eggshell thickness (EST) was determined in three zones (at both ends and the equator), calculating the average of the three measurements (Robotmation Co., Ltd., Kyoto, Japan). The yolk ratio was calculated as yolk weight/egg weight × 100% [32].

2.4. Determination of Nutritional Indicators of Eggs

Determination of the nutritional composition of raw egg yolk: nine eggs were selected from each group (three eggs from each replicate). The raw egg yolk was separated and mixed. The nutrient content and moisture (GB 5009.3-2016) of raw egg yolks were determined following the Chinese food safety standards, including fatty acids (GB 5009.168-2016); proteins (GB 5009.5-2016); cholesterol (GB 5009.128-2016); amino acids (GB 5009.124-2016); and using a kit from Qingdao Sci-Tech Quality Co. (Qingdao, China) for phospholipids (PL). Briefly, this kit applies the double antibody sandwich method. A solid antibody phase was made with a purified PL antibody. Samples were added to the microtiter wells coated with the monoclonal antibody and combined with the HRP-labeled PL antibody to form an antibody–antigen–enzyme-labeled antibody complex. The color was developed by adding the tetramethylbenzidine (TMB) substrate and converted to blue and to the final yellow. The color shade is positively correlated with the PL content in the sample. The absorbance was measured at 450 nm using an enzyme standardization instrument. The PL concentration in egg yolk was calculated based on the standard curve. Data from three parallel-samples were obtained for each experimental group.

Determination of the nutritional composition of albumen: nine eggs were selected from each group (three eggs from each replicate). Albumen was mixed, and the nutrient content and moisture were determined according to the Chinese food safety standard, following the guidelines named above. Data from three parallel samples were obtained for each experimental group.

2.5. Determination of Quality Indicators in Cooked Egg Yolk

The textural analysis involved the random selection of 15 to 20 eggs from each experimental group. The freshly collected eggs were refrigerated at −20 °C for one week and pretreated a week later. The pretreatment procedure was as follows: all eggs were boiled for 10 min and cooled to room temperature to prepare cooked yolks. The yolks were manually separated from the shells and albumen and the intact yolks were placed on a test plate for a double compression test. The analysis of the textural parameters of the cooked egg yolks included hardness, springiness, cohesiveness, gumminess, chewiness, and resilience. The SMS P50 probe was used for the texture analyzer with the following parameters set: pre-squeeze rate 0.50 mm/s, test rate 0.50 mm/s, post-test rate 0.50 mm/s, interval time 5 s, and trigger force 5.0 g.

2.6. Sample Preparation for Scanning Electron Microscopy (SEM) Observations

Three eggs were randomly selected from each experimental group and were prepared for microstructure observation according to the method above. The process was as follows: (1) Sample preparation and fixation: the cooked egg yolk was cut into a central slice of 6 mm × 6 mm × 4 mm. The samples were fixed in 2.5% glutaraldehyde (pH 7.2–7.4) for 4–6 h to prevent from disintegration during the experiment. (2) Dehydration: to remove the fixative, samples were washed four times with PBS (25 min each). Samples were dehydrated with different concentrations of ethanol solution in a stepwise manner (20 min each wash), (i) two washes of 30% (v/v), (ii) two washes of 50% (v/v), (iii) one wash of 70% (v/v), (iv) one wash of 90% (v/v), and (v) two washes of 100% (v/v). (3) Drying: the dehydrated cooked egg yolk samples were immersed in isoamyl acetate for 20 min by three times, and transferred to beakers for drying [33]. (4) Spraying: the dried samples placed on a sample table were sprayed with gold using an IB-3 ion-sputtering instrument [34]. (5) On-board observation: the prepared samples were placed into a JEM-840 SEM (JEOL Corporation, Osaka, Japan). The samples were observed and photographed at different magnetization rates (200×, 500×, 1000×).

2.7. Determination of Raw Egg Yolk Oxidation Index

Determination of yolk oxidation index: nine eggs were selected from each group (three eggs from each replicate), and refrigerated at 4°C for one week. Then, the yolks were separated to determine MDA content, and superoxide dismutase (SOD) and glutathione peroxidase (GPx) activities. MDA content was determined according to the Chinese food safety standard (GB 5009.181-2016); SOD activity was determined with a commercial kit from Qingdao Sci-Tech Quality Testing Co., (Qingdao, China); and GPx was determined using the same method as for PL determination.

2.8. Statistical Analysis

In all statistical analyses, each replicate was considered as a test unit. To identify the effects of types and concentrations on production performance and egg properties, data were analyzed using a two-way mixed-design analysis of variance (ANOVA) by using SPSS 20.0 (SPSS, Chicago, IL, USA) [35]. Test data results were expressed as mean ± SD and were considered significantly different at p < 0.05. GraphPad Prism 9 (GraphPad Software Inc., San Diego, CA, USA) was used for graph design.

3. Results

3.1. Performance of Laying Hens

Table 3 shows the results of the performance of laying hens. To test the effects of types and concentrations on production performance, two-way mixed design analysis of variance (ANOVA) revealed a significant effect of types and concentrations on the main and interaction effects of laying rates. The results demonstrated that the laying rate (LR) was significantly lower (p < 0.05) in hens fed with 3% lard, compared to those fed with 1.5% lard. The addition of lard and mixed oils caused a decrease in LR compared to the control group (p < 0.05). Although the addition of 3% mixed oils caused the greatest decrease in LR (p < 0.05), the addition of 1.5% soybean oil showed no significant difference. Moreover, there were no significant differences in FCR, AEW, and ADFI between groups with different content of oils during the experimental period.

Table 3.

Effects of different concentrations of soybean oil, lard, and mixed oils on the production performance of laying hens 1.

3.2. Egg Quality

Table 4 shows the results of egg quality measurements. To test the effects of types and concentrations on egg quality, two-way mixed design analysis of variance (ANOVA) revealed a significant effect of types and concentrations main and interaction effects on HU, YC. The results indicated that there were no significant differences in EW, ESI, ESS, yolk percentage (YP), eggshell thickness (EST), and eggshell weight (ESW) between different experimental groups. However, HU and YC were differentially affected (p < 0.05). Compared to the control group, the addition of soybean oil and lard at different concentrations improved YC (p < 0.05), with 1.5% soybean oil resulting in the highest YC increase (p < 0.05). The addition of lard did not significantly differ (p < 0.05) in protein content and HU, but soybean oil decreased HU, (p < 0.05), compared to the control group.

Table 4.

Effect of different concentrations of soybean oil, lard, and mixed oils on egg quality of laying hens 1.

3.3. Measurement of Nutritional Indicators of Eggs

Table 5 shows the results of fatty acids from raw egg yolks. To test the effects of types and concentrations on the nutrition of raw egg yolk, a two-way mixed design analysis of variance (ANOVA) revealed a significant effect of types on C14:0 and C20:3n6. A significant effect of concentrations on C16:0, C17:0, C18:0, C18:1n9c, C18:3n6, C20:2, and C22:0 and a significant effect of types and concentrations on the main and interaction effects of C15:0, C16:1, C18:2n6c, C18:3n3, C20:1, and UFA.

Table 5.

Effects of different concentrations of soybean oil, lard, and mixed oils on fatty acids of raw egg yolk 1.

Fatty acids content: in raw egg yolk, the saturated fatty acids with the higher contents were C16:0 (palmitic acid) and C18:0 (stearic acid); while the unsaturated fatty acids with the higher contents were C16:1 (palm oleic acid), C18:1n9c (oleic acid), C18:2n6c (linoleic acid), and C20:4n6 (arachidonic acid). Moreover, the saturated fatty acid C14:0 (myristic acid), and the unsaturated fatty acids C16:1, C18:1n9c, C18:2n6c, C18:3n3 (α-linolenic acid), C20:1 (eicosanoic acid), and C20:2 (eicosadienoic acid) were remarkably affected by the addition of oils (p < 0.05).

Compared with the control group, the lard addition significantly increased the content of C18:1n9c, C14:0, C17:0 (margaric acid), C18:3n3, and C20:1 (p < 0.05), while soybean (3%) and mixed oils increased the content of C18:2n6c, C18:3n3, C20:2, and C20:3n6 (methyl linoleate) in yolk (p < 0.05). In summary, while there were no significant differences in the total saturated fatty acid content of egg yolk among all the experimental groups, the addition of lard had significantly increased the content of unsaturated fatty acids in egg yolk.

Table 6 shows the results of amino acids, proteins, moisture, cholesterol, choline, phospholipids from raw egg yolks. The two-way mixed design analysis of variance (ANOVA) revealed a significant effect of types on Cys and phospholipid, as well as a significant effect of concentrations on Thr, Glu, Val, Ile, Tyr, Lys, His, Arg, and cholesterol and a significant effect of types and concentrations of the main and interaction effects of Asp, Ser, Gly, Ala, Met, and choline. Amino acids content in egg yolk: the main amino acids present in raw egg yolk were aspartic acid (Asp), glutamic acid (Glu), leucine (Leu), and methionine (Met), the latter of which was the most variable one. The addition of mixed oils increased the content of cysteine (Cys) compared to the control group (p < 0.05). Meanwhile, 1.5% of mixed oils significantly increased the content of essential amino acids (p < 0.05); the addition of soybean oil significantly increased the content of cholesterol and choline in egg yolk (p < 0.05). The content of PL in egg yolk was increased by the addition of oils in all groups, resulting in the highest content of PL after the addition of mixed oils (p < 0.05). The content of Met was significantly decreased in all experimental groups (p < 0.05).

Table 6.

Effects of different concentrations of soybean oil, lard, and mixed oils on protein, amino acids, moisture, cholesterol, choline, and phospholipids in raw egg yolk 1.

The two-way mixed design analysis of variance (ANOVA) revealed a significant effect of types on Gly, Ala, Ile, Arg, and moisture and a significant effect of types and concentrations on the main and interaction effects of Asp, Thr, Ser, Glu, Cys, Val, Met, Leu, Tyr, Phe, Lys, and Pro. Amino acid content in albumen: Table 7 shows that the most abundant amino acids in raw albumen were Asp, Glu, and Leu. Different diets had distinct effects on the content of amino acids, proteins, water, cholesterol, choline, and PL in raw albumen. We found that the variation in types and amounts of oil had a significant effect, mainly on Thr, Ser, Glu, Val, Ile, and Leu (p < 0.05).

Table 7.

Effects of different concentrations of soybean oil, lard, and mixed oils on amino acids, protein, and moisture of albumen 1.

Essential and non-essential amino acids were significantly increased (p < 0.05) in each experimental group compared to the control. Mainly, 1.5% and 3% lard experimental groups showed the highest increase in the content of essential and non-essential amino acids, which were determined in albumen (p < 0.05).

3.4. Texture Profile Analysis of Cooked Egg Yolk

Table 8 displays the textural parameters of cooked egg yolks. Two-way mixed design analysis of variance (ANOVA) revealed a significant effect of type concentrations on hardness, gumminess, chewiness, and resilience. The addition of 3% soybean oil, 3% lard, and 1.5% mixed oils significantly increased the hardness of cooked egg yolks compared to the control group (p < 0.05). However, the addition of 1.5% soybean oil did not affect the hardness of cooked egg yolks compared to the controls. Compared with the control group, adding different types and concentrations of oils significantly reduced the egg’s resilience. Moreover, 3% soybean oil reduced springiness, and 1.5% of soybean oil significantly increased gumminess.

Table 8.

Effect of different concentrations of soybean oil, lard, and mixed oils on the texture profile analysis of cooked egg yolk 1.

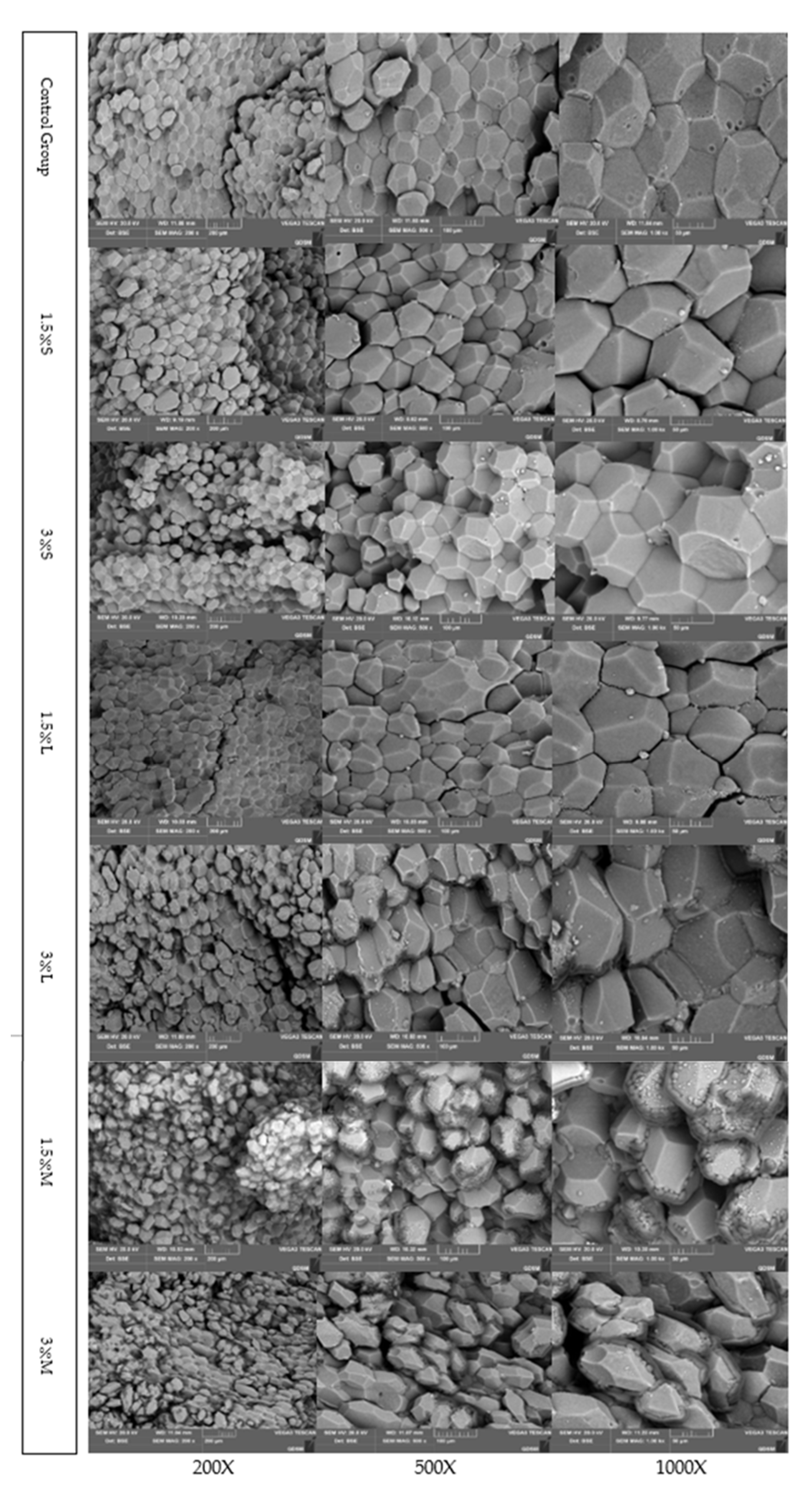

3.5. Microstructure of Cooked Yolk

The microstructure of cooked yolk was observed by SEM, to study the effect of the oils added to the feed on the quality of eggs at the sub-microscopic level. The cooked yolk is composed of polyhedral-shaped yolk balls with a loose texture and a continuous undulating appearance. Under normal conditions, different regions of the yolk spheres were combined without gaps or cross-linking, and the yolk spheres consisted of embedded spheres and holes with uneven and angular surfaces and edges. Figure 1 shows the SEM results. Although the addition of 1.5% oils did not affect the yolk-sphere structure, 3% oil damaged the structure, compared to the control group. Moreover, the addition of mixed oil significantly damaged the structure of the yolk spheres, with evident signs of cross-linking and fragmentation between the yolk spheres. Furthermore, the damage of the yolk spheres increased with the oil concentration.

Figure 1.

Micrographs of cooked yolk observed by JEM-840 at different magnifications. The abscissa indicates the different magnifications. A 1.5% S or 3% addition of 1.5% or 3% of soybean oil to the base diet, respectively. A 1.5% L or 3% addition of 1.5% or 3% of lard to the base diet, respectively. A 1.5% or 3% M: addition of 1.5% or 3% of mixed oils to the base diet, respectively.

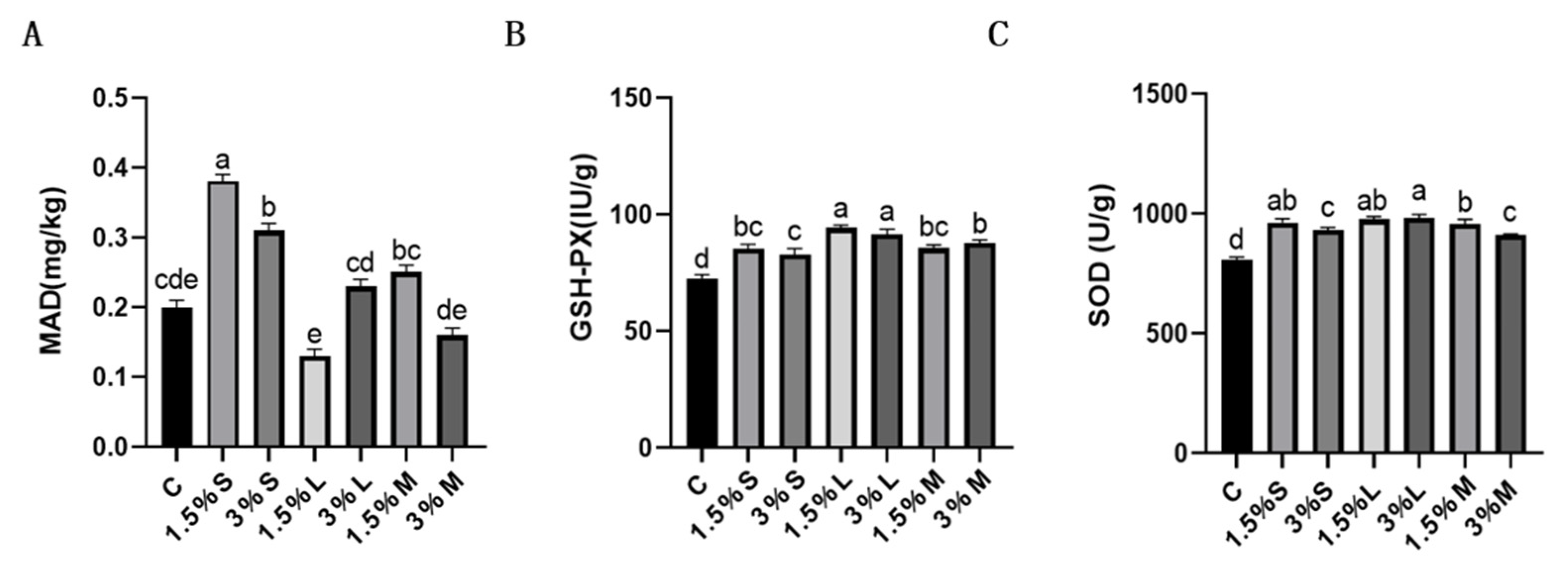

3.6. Oxidative Stability of Egg Yolk

The levels of oxidative indicators, such as MDA, GPx, and SOD were also studied in egg yolk (Figure 2). Although 1.5% and 3% lard diets significantly increased the content of antioxidant enzymes (p < 0.05), the MDA content of the lard and mixed oil groups was similar to that of the control group. However, soybean oil increased the content of MDA (p < 0.05).

Figure 2.

Each value is presented as mean ± SD, different superscript (a–e) indicates significant differences (p < 0.05). The effect of different oils on MDA, SOD, and GPX in egg yolk. C: control group; 1.5% S or 3%: addition of 1.5% or 3% of soybean oil to the base diet, respectively; 1.5% L or 3%: addition of 1.5% or 3% of lard to the base diet, respectively; 1.5% or 3% M: addition of 1.5% or 3% of mixed oils to the base diet, respectively. (A): effect of different oils and fats on MDA in raw egg yolk; (B): effect of different oils and fats on GSH-PX in raw egg yolk; (C): effect of different oils and fats on SOD in raw egg yolk.

4. Discussion

In this study, we found that after four weeks of the consumption of oil-feeding diets, the laying rate of laying hens was affected. At present, it is essential to add 1% of oil to the basic diet of laying hens, to produce energy-rich formulations and nutrient-rich eggs [36]. The effect of oils on the performance of laying hens is influenced by the type of oils, the amount added, and the nutritional level [37,38]. Hence, the addition of different types and quantities of oils to feed have various effects on the production performance and egg quality of laying hens. The addition of oils in high amounts can induce alterations, such as diarrhea, in livestock and poultry; and high quantities of cottonseed oil can significantly reduce the production performance of laying hens and affect their health [39]. Therefore, it is particularly important to add adequate types and amounts of oils to the diet [40].

In the same experimental oil group, the addition of higher levels of oils decreased the laying rate compared to lower levels of oils. In accordance with previous studies, the addition of low amounts of oils had no effect, but a higher oil content considerably affected the laying rate. Moreover, high quantities of fat intake cause metabolic burden with increased fat accumulation in the liver, which leads to a decrease in laying rate [41,42]. Noteworthy, the addition of different types and quantities of vegetable oils reduced the laying rate, but had no effect on FCR, AEW, or ADFI [12]. Additionally, animal oils decreased the laying rate of hens to different extents, as observed previously [12,43]. This may be because vegetable oils or nutrient sources rich in polyunsaturated fatty acids (PUFA) reduce liver fat content or mitigate the effect on fatty liver syndrome in laying hens, whereas animal oils increase liver lipid deposition and aggravate fatty liver syndrome in laying hens, ultimately leading to a decrease in egg production [44,45].

The color of egg yolk depends on the pigment content of the feed for the laying hens [46]. This pigment, which is fat-soluble, is absorbed and transported to the yolk with fat. Thus, the addition of appropriate amounts of oils aids the absorption and transport of pigments [47]. As in previous studies, we found that the addition of different amounts of soybean oil and lard to the diet significantly improved yolk color compared to the control group [15,48]. However, the mixed oils had no effect on yolk color. The differences in EW, ESS, albumen height, YP, EST, and ESW were similar among different oil groups. Noteworthy, the reduction of egg Haugh units in 1.5% and 3% soybean oil groups needs further investigation [49].

Lipids play an essential role in animal growth and are one of the main components of egg yolk in laying hens [50,51]. Lipid metabolism in the body of laying hens is high after the laying starts, in the peak laying period. Forage lipids are introduced into eggs through the ovaries [52]. Thus, the composition and proportion of FA in forage lipids affect the composition and proportion of FA in egg yolk [53]. Fatty acids can be divided into saturated, monounsaturated, and PUFA, the contents of which are relevant to evaluating the nutritional value of poultry eggs [54]. PUFA are divided into n-3 and n-6 PUFA, with n-3 PUFA being the most beneficial to humans. These benefits include maintaining the relative fluidity of cell membranes [55], esterifying cholesterol, reducing cholesterol and triglycerides levels in serum and liver [56], preventing cardiovascular diseases [57], and modulating immunity and gene expression [58]. We found that the addition of different amounts of soybean oil significantly increased the content of certain n-6 PUFA (C18:2n6c, C18:3n6, and C20:3n6) and n-3 PUFA (C18:3n3), and decreased the total content of saturated fatty acid in egg yolk, compared to the control group. The different amounts of lard increased the total unsaturated fatty acid content in egg yolk compared to the other experimental groups. These findings are consistent with other studies [59,60,61]. Moreover, the addition of soybean oil significantly increased the cholesterol content, choline, and PL in egg yolk compared to the other experimental groups. Although cholesterol might be associated with the risk of coronary heart disease (CHD), only one-third of cholesterol is ingested with food. Thus, the consumption of two eggs a day does not increase cholesterol levels, drawing back the conception of eggs and cholesterol content [49].

Eggs contain high-quality proteins and are a source of amino acids, mainly essential ones, which are rapidly digested and absorbed by the body [62]. Amino acids are divided into essential and non-essential ones, the former of which cannot be synthesized and must be obtained with the diet [63]. Non-essential amino acids are synthesized in animals’ bodies [64]. Previous research has been focused on studying the effect of oil additions on the nutrient content of egg yolks [65]. Thus, we studied the content of the main nutrients, including essential and non-essential amino acids, proteins, and water in albumen. The results demonstrated that the addition of different quantities of soybean oil, lard, and mixed oils to the diet increased the total content of both essential and non-essential amino acids in albumen. Further investigations are needed, as the effect of lard was highly evident.

Textural polyhedral analysis (TPA) assay was conducted in equipment that simulates the chewing of food by human teeth and responds to the textural structure of food perceived by the teeth and palate in the mouth according to the pressure detected by the probe [66]. In this study, the TPA test on cooked egg yolks included the following indicators: hardness, springiness, cohesiveness, gumminess, chewiness, and resilience. The results demonstrated that the hardness of cooked egg yolks increased in all experimental groups, but was similar between the 1.5% soybean oil and the control groups. The texture of eggs play a key role in egg processing and pastry making. The greater the value of springiness and resilience, the better the food quality, the refreshing taste, and the non-stickiness, which is positively correlated with the quality of the cake. However, there was a negative correlation between the value of hardness, chewiness, and the lack of springiness with the quality of the cake [67]. Considering the above, 1.5% soybean oil does not affect the characteristics of eggs. Through scanning electron microscopy, we can find that the yolk was composed of spheres, where the main components were low-density lipoprotein (LDL), high-density lipoprotein (HDL), and yolk globular protein [66,68]. The round balls observed on the surface of the yolk spheres have a fibrous network structure, assumed from the shape and size of these balls, resembling grains. The network structure is composed of LDL and yolk globulin. From the results, it is clear that the addition of high concentrations of oils exacerbates the structural damage of cooked egg yolks.

MDA, the end-product of lipid oxidation, is involved in lipid peroxidation [69]. During intensive breeding, lipid oxidation of feed is a common factor generating oxidative stress in animals [12], having a negative effect on the production performance and egg quality of laying hens. However, the organisms have developed systems to cope with oxidative stress, mainly, a group of enzymes, including SOD and GPx. Many studies demonstrated that the addition of different types of oils to feeds improves the antioxidant capacity of laying hens [70,71]. However, the antioxidant properties of oils on eggs need further studies.

Mixed oils are different oils and fats that are mixed in a certain proportion, and are also a new research hotspot in the field of feed oils and fats in recent years [72]. Previous studies have demonstrated that adding a single type of oil or fat to feed is difficult to meet the needs of livestock and poultry for a variety of FAs, especially EFAs. Therefore, some scholars began to study the mixing of different ingredients in a certain proportion, so that different components have complementary effects, and developed new products [58,73,74]. However, due to the interaction of different types of ingredients in mixed oils, its effect becomes difficult to control, and because the study of the relevant mechanism of action is in-depth enough, it is difficult to determine and explain its effect. This study demonstrated that mixed oils produced an evident damage to the structure of egg yolk and reduced the egg production. While the addition of 1.5% soybean oil to the diet increased the content of nutrients and antioxidant enzymes in eggs, the addition of lard caused a reduction in egg production rate and fatty liver formation in hens. In this study, the effects of three different types and concentrations of soybean oil, lard, and mixed oils were compared to provide scientific relevant data for production practices and dietary health guidelines for laying hens.

5. Conclusions

In summary, as the composition of different types of oils is variable, the effects on the production performance, egg quality, and antioxidant capacity in laying hens are diverse and there was also a significant synergistic effect of the concentration and type of oil. Therefore, the choice of oils in the diet feed should be based on studies ascribing the effects and needs of oils in egg production in poultry. Therefore, we recommend adding 1.5% soybean oil to feed diets.

Author Contributions

Conceptualization, Z.G. and G.X.; methodology, Z.G.; software, Z.G.; validation, Z.G., Z.D. and F.L.; formal analysis, Z.G.; investigation, Z.G.; resources, F.L.; data curation, J.Z. (Junnan Zhang); writing—original draft preparation, Z.G.; writing—review and editing, Z.G.; visualization, G.X.; supervision, J.Z. (Jiangxia Zheng) and Z.D.; project administration, Z.D.; funding acquisition, G.X. All authors have read and agreed to the published version of the manuscript.

Funding

This study was supported by the National Key Research and Development Program of China (2021YFD1200803); the China Agriculture Research Systems (CARS-41); the Program for Changjiang Scholars and Innovative Research Team in University (IRT_15R62).

Institutional Review Board Statement

The hens housing conditions were approved and conducted in accordance with the Animal Ethics Committee guidelines of China Agricultural University and national institutes of health guide for the care and use of laboratory animals. The experimental protocols and animal care in this study were approved (Approval date: 11 December 2020) by the guidelines of the Animal Care and Use Committee of China Agricultural University (CAU20160916-2). The experiments were conducted according to the regulations and guidelines established by this committee.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data that support the findings of this study are available on the request from the corresponding author. The data are not publicly available due to privacy or ethical restrictions.

Acknowledgments

We gratefully acknowledge our colleagues at the College of Animal Science and Technology of China Agricultural University for their assistance with sample collection. All the authors acknowledge and thank their respective institutes and universities for providing library facilities.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Baião, N.C.; Lara, L.J.C. Oil and fat in broiler nutrition. Braz. J. Poult. Sci. 2005, 7, 129–141. [Google Scholar] [CrossRef]

- Chwen, L.T.; Foo, H.L.; Thanh, N.T.; Choe, D.W. Growth performance, plasma fatty acids, villous height and crypt depth of preweaning piglets fed with medium chain triacylglycerol. Asian-Australas J. Anim. Sci. 2013, 26, 700–704. [Google Scholar] [CrossRef] [PubMed]

- Stevanović, Z.D.; Bošnjak-Neumüller, J.; Pajić-Lijaković, I.; Raj, J.; Vasiljević, M. Essential oils as feed additives-future perspectives. Molecules 2018, 23, 1717. [Google Scholar] [CrossRef] [PubMed]

- Palmquist, D.L. Omega-3 fatty acids in metabolism, health, and nutrition and for modified animal product foods. Prof. Anim. Sci. 2009, 25, 207–249. [Google Scholar] [CrossRef]

- Lo Fiego, D.P.; Minelli, G.; Volpelli, L.A.; Ulrici, A.; Macchioni, P. Calculating the iodine value for Italian heavy pig subcutaneous adipose tissue from fatty acid methyl ester profiles. Meat Sci. 2016, 122, 132–138. [Google Scholar] [CrossRef]

- Kerr, B.J.; Kellner, T.A.; Shurson, G.C. Characteristics of lipids and their feeding value in swine diets. J. Anim. Sci. Biotechnol. 2016, 6, 30. [Google Scholar] [CrossRef]

- Kilian, L.; Murphy, D.P. The role of inventories and speculative trading in the global market for crude oil. J. Appl. Econom. 2014, 29, 454–478. [Google Scholar] [CrossRef]

- Gao, Z.; Zhang, J.; Li, F.; Zheng, J.; Xu, G. Effect of oils in feed on the production performance and egg quality of laying hens. Animals 2021, 11, 3482. [Google Scholar] [CrossRef]

- Wei, H.; Pan, L.; Li, C.; Zhao, P.; Li, J.; Zhang, R.; Bao, J. Dietary soybean oil supplementation affects keel bone characters and daily feed intake but not egg production and quality in laying hens housed in furnished cages. Front. Vet. Sci. 2021, 8, 657585. [Google Scholar] [CrossRef]

- Lu, Q.; Chen, P.; Chai, Y.; Li, Q.; Mao, H. Effects of dietary rubber seed oil on production performance, egg quality and yolk fatty acid composition of Hy-line Brown layers. Anim. Biosci. 2021, 34, 119–126. [Google Scholar] [CrossRef]

- Kara, Z.; Bülbül, T. The effects of supplementing different vegetable oils in the diet of quails on growth, carcass traits and serum biochemical parameters. Kocatepe Vet. J. 2021, 14, 57–64. [Google Scholar] [CrossRef]

- Dong, X.F.; Liu, S.; Tong, J.M. Comparative effect of dietary soybean oil, fish oil, and coconut oil on performance, egg quality and some blood parameters in laying hens. Poult. Sci. 2018, 97, 2460–2472. [Google Scholar] [CrossRef] [PubMed]

- Daghir, N.J. Nutrient Requirements of Poultry at High Temperatures; CABI: Wallingford, UK, 2008. [Google Scholar]

- Pérez-Bonilla, A.; Frikha, M.; Mirzaie, S.; García, J.; Mateos, G.G. Effects of the main cereal and type of fat of the diet on productive performance and egg quality of Brown-egg laying hens from 22 to 54 weeks of age. Poult. Sci. 2011, 90, 2801–2810. [Google Scholar] [CrossRef] [PubMed]

- Mehta, A.; Guleria, S.; Sharma, R.; Gupta, R. The lipases and their applications with emphasis on food industry. In Microbial Biotechnology in Food and Health; Ray, R.C., Ed.; Academic Press: Cambridge, MA, USA, 2021; pp. 143–164. [Google Scholar]

- Yang, P.; Zheng, Y.; You, M.; Song, H.; Zou, T. Characterization of key aroma-active compounds in four commercial egg flavor Sachimas with differing egg content. J. Food Biochem. 2019, 43, e13040. [Google Scholar] [CrossRef]

- Jamshidi, A.; Amato, M.; Ahmadi, A.; Bochicchio, R.; Rossi, R. Chia (Salvia hispanica L.) as a novel forage and feed source: A review. Ital. J. Agron. 2019, 14, 1–18. [Google Scholar] [CrossRef]

- Liu, Z.; Sun, C.; Yan, Y.; Li, G.; Shi, F.; Wu, G.; Liu, A.; Yang, N. Genetic variations for egg quality of chickens at late laying period revealed by genome-wide association study. Sci. Rep. 2018, 8, 10832. [Google Scholar] [CrossRef]

- Lopez, J.M.M.; Saez, A.C. Fats and Associated Compounds; Royal Society of Chemistry: London, UK, 2021. [Google Scholar]

- Mu, Y.; Zhu, L.Y.; Yang, A.; Gao, X.; Zhang, N.; Sun, L.; Qi, D. The effects of dietary cottonseed meal and oil supplementation on laying performance and egg quality of laying hens. Food Sci. Nutr. 2019, 7, 2436–2447. [Google Scholar] [CrossRef]

- Bacou, E.; Walk, C.; Rider, S.; Litta, G.; Perez-Calvo, E. Dietary oxidative distress: A review of nutritional challenges as models for poultry, swine and fish. Antioxidants 2021, 10, 525. [Google Scholar] [CrossRef]

- Qaisrani, S.N.; Rizwan, M.; Yaseen, G.; Bibi, F.; Sarfraz, M.A.; Khan, N.A.; Naveed, S.; Pasha, T.N. Effects of dietary oxidized oil on growth performance, meat quality and biochemical indices in poultry—A review. Ann. Anim. Sci. 2021, 21, 29–46. [Google Scholar] [CrossRef]

- Jiang, S.; Cheng, H.W.; Cui, L.Y.; Zhou, Z.L.; Hou, J.F. Changes of blood parameters associated with bone remodeling following experimentally induced fatty liver disorder in laying hens. Poult. Sci. 2013, 92, 1443–1453. [Google Scholar] [CrossRef]

- Kan, C.A.; Meijer, G.A.L. The risk of contamination of food with toxic substances present in animal feed. Anim. Feed Sci. Technol. 2007, 133, 84–108. [Google Scholar] [CrossRef]

- Shini, A.; Shini, S.; Bryden, W.L. Fatty liver haemorrhagic syndrome occurrence in laying hens: Impact of production system. Avian Pathol. 2018, 48, 25–34. [Google Scholar] [CrossRef] [PubMed]

- Lee, B.K.; Kim, J.S.; Ahn, H.J.; Hwang, J.H.; Kim, J.M.; Lee, H.T.; An, B.K.; Kang, C.W. Changes in hepatic lipid parameters and hepatic messenger ribonucleic acid expression following estradiol administration in laying hens (Gallus domesticus). Poult. Sci. 2010, 89, 2660–2667. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, J.; Yang, J.; Gong, S.; Zheng, J.; Xu, G. Effects of lard and vegetable oils supplementation quality and concentration on laying performance, egg quality and liver antioxidant genes expression in Hy-line Brown. Animals 2021, 11, 769. [Google Scholar] [CrossRef]

- Pikaar, I.; Matassa, S.; Bodirsky, B.L.; Weindl, I.; Humpenöder, F.; Rabaey, K.; Boon, N.; Bruschi, M.; Yuan, Z.; van Zanten, H.; et al. Decoupling livestock from land use through industrial feed production pathways. Environ. Sci. Technol. 2018, 52, 7351–7359. [Google Scholar] [CrossRef] [PubMed]

- Reda, F.M.; El-Kholy, M.S.; Abd El-Hack, M.E.; Taha, A.E.; Othman, S.I.; Allam, A.A.; Alagawany, M. Does the use of different oil sources in quail diets impact their productive and reproductive performance, egg quality, and blood constituents? Poult. Sci. 2020, 99, 3511–3518. [Google Scholar] [CrossRef]

- Dale, N. National research council nutrient requirements of poultry—Ninth revised edition (1994). J. Appl. Poult. Res. 1994, 3, 101. [Google Scholar] [CrossRef]

- Anderson, K.; Tharrington, J.B.; Curtis, P.A.; Jones, F.T. Shell characteristics of eggs from historic strains of single comb White leghorn chickens and the relationship of egg shape to shell strength. Int. J. Poult. Sci. 2004, 3, 17–19. [Google Scholar] [CrossRef]

- Kaliasheva, K.; Oblakova, M.; Hristakieva, P.; Mincheva, N.; Lalev, M. Comparative study on morphological qualities of eggs from new autosexing layer hybrids for free range poultry farming system. Bulg. J. Agric. Sci. 2017, 23, 609–616. [Google Scholar]

- Erdman, N.; Bell, D.C.; Reichelt, R. Scanning electron microscopy. In Springer Handbook of Microscopy; Hawkes, P.W., Spence, J.C.H., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 229–318. [Google Scholar]

- Liu, J.; Zhang, L.; Zhang, W. Filling technology and disease prevention technology research on highway rock salt embankment. Adv. Mater. Res. 2012, 512–515, 3033–3041. [Google Scholar] [CrossRef]

- Leeson, S.; Summers, J.D. Commercial Poultry Nutrition; Nottingham University Press: Thrumpton, Nottingham, 2008. [Google Scholar]

- Oliveira, D.D.; Baião, N.C.; Cançado, S.V.; Grimaldi, R.; Souza, M.R.; Lara, L.J.; Lana, A.M. Effects of lipid sources in the diet of laying hens on the fatty acid profiles of egg yolks. Poult. Sci. 2010, 89, 2484–2490. [Google Scholar] [CrossRef]

- Jacob, J.P.; Wilson, H.R.; Miles, R.D.; Butcher, G.D.; Mather, F.B. Factors Affecting Egg Production in Backyard Chicken; University of Florida: Gainesville, FL, USA, 2014. [Google Scholar]

- Batkowska, J.; Drabik, K.; Brodacki, A.; Czech, A.; Adamczuk, A. Fatty acids profile, cholesterol level and quality of table eggs from hens fed with the addition of linseed and soybean oil. Food Chem. 2021, 334, 127612. [Google Scholar] [CrossRef] [PubMed]

- Nagalakshmi, D.; Rao, S.V.R.; Panda, A.K.; Sastry, V.R.B. Cottonseed meal in poultry diets: A review. J. Poult. Sci. 2007, 44, 119–134. [Google Scholar] [CrossRef]

- Alagawany, M.; Elnesr, S.S.; Farag, M.R.; Abd El-Hack, M.E.; Khafaga, A.F.; Taha, A.E.; Tiwari, R.; Yatoo, M.I.; Bhatt, P.; Khurana, S.K.; et al. Omega-3 and omega-6 fatty acids in poultry nutrition: Effect on production performance and health. Animals 2019, 9, 573. [Google Scholar] [CrossRef] [PubMed]

- Neijat, M.; Gakhar, N.; Neufeld, J.; House, J.D. Performance, egg quality, and blood plasma chemistry of laying hens fed hempseed and hempseed oil. Poult. Sci. 2014, 93, 2827–2840. [Google Scholar] [CrossRef] [PubMed]

- Küçükersan, K.; Yeşilbağ, D.; Küçükersan, S. Influence of different dietary oil sources on performance and cholesterol content of egg yolk in laying hens. J. Biol. Environ. Sci. 2010, 4, 117–122. [Google Scholar]

- Bozkurt, M.; Cabuk, M.; Alçiçek, A. Effect of dietary fat type on broiler breeder performance and hatching egg characteristics. J. Appl. Poult. Res. 2008, 17, 47–53. [Google Scholar] [CrossRef]

- Trott, K.A.; Giannitti, F.; Rimoldi, G.; Hill, A.; Woods, L.; Barr, B.; Anderson, M.; Mete, A. Fatty liver hemorrhagic syndrome in the backyard chicken: A retrospective histopathologic case series. Vet. Pathol. 2014, 51, 787–795. [Google Scholar] [CrossRef]

- Schumann, B.E.; Squires, E.J.; Leeson, S.; Hunter, B. Effect of hens fed dietary flaxseed with and without a fatty liver supplement on hepatic, plasma and production characteristics relevant to fatty liver haemorrhagic syndrome in laying hens. Br. Poult. Sci. 2003, 44, 234–244. [Google Scholar] [CrossRef]

- Sünder, A.; Wilkens, M.; Böhm, V.; Liebert, F. Egg yolk colour in organic production as affected by feeding—Consequences for farmers and consumers. Food Chem. 2021, 131854. [Google Scholar] [CrossRef]

- Hammershøj, M.; Johansen, N. Review: The effect of grass and herbs in organic egg production on egg fatty acid composition, egg yolk colour and sensory properties. Livest. Sci. 2016, 194, 37–43. [Google Scholar] [CrossRef]

- Cachaldora, P.; García-Rebollar, P.; Alvarez, C.; Blas, J.C.D.; Méndez, J. Effect of type and level of basal fat and level of fish oil supplementation on yolk fat composition and n-3 fatty acids deposition efficiency in laying hens. Anim. Feed Sci. Technol. 2008, 141, 104–114. [Google Scholar] [CrossRef]

- Söderberg, J. Functional Properties of Legume Proteins Compared to Egg Proteins and Their Potential as Egg Replacers in Vegan Food; SLU: St. Louis, MO, USA, 2013. [Google Scholar]

- Gül, M.; Yörük, M.A.; Aksu, T.; Kaya, A.; Kaynar, Ö. The effect of different levels of canola oil on performance, egg shell quality and fatty acid composition of laying hens. Int. J. Poult. Sci. 2012, 11, 769–776. [Google Scholar] [CrossRef]

- Park, J.H.; Kim, Y.M.; Kim, I.H. Egg production, egg quality, blood profiles, cecal microflora, and excreta noxious gas emission in laying hens fed with fenugreek (Trigonella foenum-graecum L.) seed extract. J. Poult. Sci. 2018, 55, 47–53. [Google Scholar] [CrossRef] [PubMed]

- Opachaloemphan, C.; Mancini, G.; Konstantinides, N.; Parikh, A.; Mlejnek, J.; Yan, H.; Reinberg, D.; Desplan, C. Early behavioral and molecular events leading to caste switching in the ant Harpegnathos. Genes Dev. 2021, 35, 410–424. [Google Scholar] [CrossRef]

- Raes, K.; Huyghebaert, G.; De Smet, S.; Nollet, L.; Arnouts, S.; Demeyer, D. The deposition of conjugated linoleic acids in eggs of laying hens fed diets varying in fat level and fatty acid profile. J. Nutr. 2002, 132, 182–189. [Google Scholar] [CrossRef]

- Nimalaratne, C.; Wu, J. Hen egg as an antioxidant food commodity: A review. Nutrients 2015, 7, 8274–8293. [Google Scholar] [CrossRef]

- Kapoor, B.; Kapoor, D.; Gautam, S.; Singh, R.; Bhardwaj, S. Dietary polyunsaturated fatty acids (PUFAs): Uses and potential health benefits. Curr. Nutr. Rep. 2021, 10, 232–242. [Google Scholar] [CrossRef]

- Gonzalez-Esquerra, R.; Leeson, S. Studies on the metabolizable energy content of ground full-fat flaxseed fed in mash, pellet, and crumbled diets assayed with birds of different ages. Poult. Sci. 2000, 79, 1603–1607. [Google Scholar] [CrossRef]

- Harris, W.S.; Poston, W.C.; Haddock, C.K. Tissue n-3 and n-6 fatty acids and risk for coronary heart disease events. Atherosclerosis 2007, 193, 1–10. [Google Scholar] [CrossRef]

- Kralik, G.; Škrtić, Z.; Suchý, P.; Straková, E.; Gajčević, Z. Feeding fish oil and linseed oil to laying hens to increase the n-3 PUFA in egg yolk. Acta Vet. Brno 2008, 77, 561–568. [Google Scholar] [CrossRef]

- Raza, T.; Chand, N.; Khan, R.U.; Shahid, M.S.; Abudabos, A.M. Improving the fatty acid profile in egg yolk through the use of hempseed (Cannabis sativa), ginger (Zingiber officinale), and turmeric (Curcuma longa) in the diet of Hy-line White leghorns. Arch. Anim. Breed. 2016, 59, 183–190. [Google Scholar] [CrossRef]

- Murano, Y.; Funabashi, T.; Sekine, S.; Aoyama, T.; Takeuchi, H. Effect of dietary lard containing higher alpha-linolenic acid on plasma triacylglycerol in rats. J. Oleo Sci. 2007, 56, 361–367. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Nys, Y.; Guyot, N. Improving the Safety and Quality of Eggs and Egg Products; Elseveir: Ansterdam, NL, USA, 2011. [Google Scholar]

- Hou, Y.; Yin, Y.; Wu, G. Dietary essentiality of “nutritionally non-essential amino acids” for animals and humans. Exp. Biol. Med. (Maywood) 2015, 240, 997–1007. [Google Scholar] [CrossRef]

- Talha, N.A.H.; Jeon, Y.; Yu, I.J. Cryopreservation of dog spermatozoa using essential and non-essential amino acids solutions in an egg yolk-free polyvinyl alcohol extender. Cryo Lett. 2021, 42, 44–52. [Google Scholar]

- Mitchell, J. Food texture and viscosity: Concept and measurement. Int. J. Food Sci. Technol. 2003, 38, 839–840. [Google Scholar] [CrossRef]

- Lee, S.H.; Kim, Y.B.; Kim, D.H.; Lee, D.W.; Lee, H.G.; Jha, R.; Lee, K.W. Dietary soluble flaxseed oils as a source of omega-3 polyunsaturated fatty acids for laying hens. Poult. Sci. 2021, 100, 101276. [Google Scholar] [CrossRef]

- Li-Chan, E.C.Y.; Kim, H.O. Structure and chemical compositions of eggs. In Egg Bioscience and Biotechnology; Mine, Y., Ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2008; pp. 1–95. [Google Scholar]

- Ding, S.; Peng, B.; Li, Y.; Yang, J. Evaluation of specific volume, texture, thermal features, water mobility, and inhibitory effect of staling in wheat bread affected by maltitol. Food Chem. 2019, 283, 123–130. [Google Scholar] [CrossRef]

- Woodward, S.A.; Cotterill, O.J. Texture and microstructure of cooked whole egg yolks and heat-formed gels of stirred egg yolk. J. Food Sci. 1987, 52, 63–67. [Google Scholar] [CrossRef]

- Mishra, S.; Mishra, B.B. Study of lipid peroxidation, nitric oxide end product, and trace element status in type 2 diabetes mellitus with and without complications. Int. J. Appl. Basic Med. Res. 2017, 7, 88–93. [Google Scholar] [CrossRef]

- Vlaicu, P.A.; Panaite, T.D.; Turcu, R.P. Enriching laying hens eggs by feeding diets with different fatty acid composition and antioxidants. Sci. Rep. 2021, 11, 20707. [Google Scholar] [CrossRef] [PubMed]

- Torki, M.; Sedgh-Gooya, S.; Mohammadi, H. Effects of adding essential oils of rosemary, dill and chicory extract to diets on performance, egg quality and some blood parameters of laying hens subjected to heat stress. J. Appl. Anim. Res. 2018, 46, 1118–1126. [Google Scholar] [CrossRef]

- Zhang, R.; Ma, S.; Li, L.; Zhang, M.; Tian, S.; Wang, D.; Liu, K.; Liu, H.; Zhu, W.; Wang, X. Comprehensive utilization of corn starch processing by-products: A review. Grain Oil Sci. Technol. 2021, 4, 89–107. [Google Scholar] [CrossRef]

- Ceylan, N.; Ciftci, I.; Mizrak, C.; Kahraman, Z.; Efil, H. Influence of different dietary oil sources on performance and fatty acid profile of egg yolk in laying hens. J. Anim. Feed Sci. 2011, 20, 71–83. [Google Scholar] [CrossRef]

- Lemahieu, C.; Bruneel, C.; Ryckebosch, E.; Muylaert, K.; Buyse, J.; Foubert, I. Impact of different omega-3 polyunsaturated fatty acid (n-3 PUFA) sources (flaxseed, Isochrysis galbana, fish oil and DHA Gold) on n-3 LC-PUFA enrichment (efficiency) in the egg yolk. J. Funct. Foods 2015, 19, 821–827. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).