Technological Benefits Associated with the Use of Spray-Dried Animal Plasma in Fish-Based Chunks for Canned Pet Food

Abstract

:Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Formulation of Canned Pet Foods

2.3. Production of Diets

2.4. Nutritional and Viscosity Analyses

2.5. Analysis of Processed Canned Pet Foods

2.6. Statistical Analyses

3. Results and Discussion

3.1. Raw Materials

3.2. Experiment 1

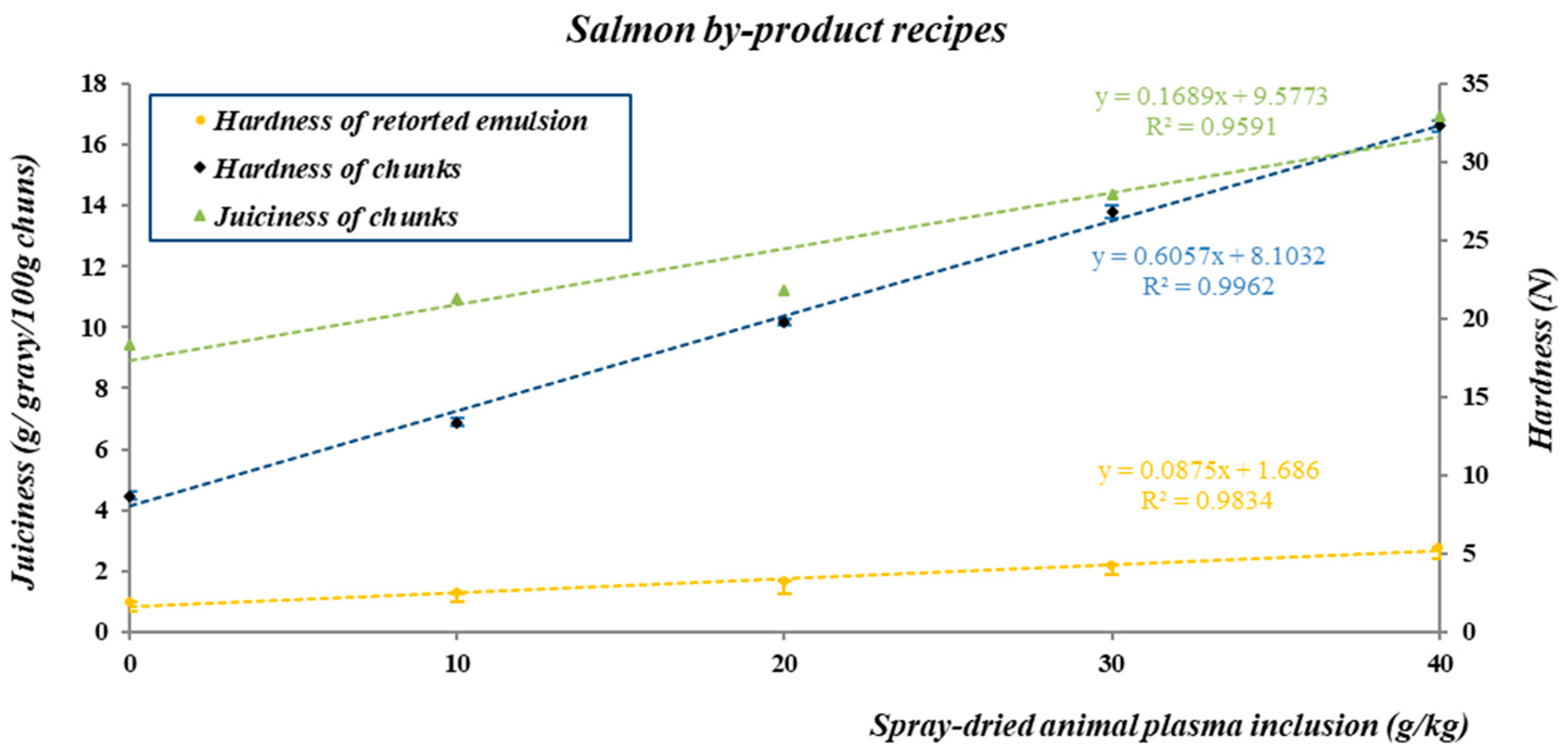

3.3. Experiments 2 and 3

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tybor, P.; Dill, C.; Landmann, W. Functional properties of proteins isolated from bovine by a continuous pilot process. J. Food Sci. 1975, 40, 155–159. [Google Scholar] [CrossRef]

- Etheridge, P.; Hickson, D.; Young, C.; Landmann, W.; Dill, C. Functional and chemical characteristics of bovine plasma proteins isolated as a metaphosphate complex. J. Food Sci. 1981, 46, 1782–1784. [Google Scholar] [CrossRef]

- Howell, N.; Lawrie, R. Functional aspects of blood plasma proteins. II Gelling properties. J. Food Tech. 1984, 19, 289–295. [Google Scholar] [CrossRef]

- Pares, D.; Saguer, E.; Saurina, J.; Suñol, J.J.; Carretero, C. Functional properties of heat induced gels from liquid and spray-dried porcine blood plasma as influenced by pH. J. Food Sci. 1998, 63, 958–961. [Google Scholar] [CrossRef]

- Polo, J.; Rodriguez, C.; Saborido, N.; Rodenas, J. Functional properties of spray-dried animal plasma in canned petfood. Anim. Feed Sci. Technol. 2005, 122, 331–343. [Google Scholar] [CrossRef]

- Polo, J.; Rodriguez, C.; Rodenas, J.; Morera, S.; Saborido, N. Use of spray-dried animal plasma in canned chunk recipes containing excess of added water or chicken fat. Anim. Feed Sci. Technol. 2007, 133, 309–319. [Google Scholar] [CrossRef]

- Polo, J.; Rodriguez, C.; Rodenas, J.; Morera, S.; Saborido, N. The use of spray-dried animal plasma in comparison with other binders in canned pet food recipes. Anim. Feed Sci. Technol. 2009, 154, 241–247. [Google Scholar] [CrossRef]

- Polo, J. Standardizing Quality in Wet Pet food with Plasma; Petfood Industry: Rockford, IL, USA, 2011; pp. 36–40. [Google Scholar]

- Vasconcellos, R.S.; Henriquez, L.B.F.; Lourenço, P.d.S. Spray-Dried Animal Plasma as a Multifaceted Ingredient in Pet Food. Animals 2023, 13, 1773. [Google Scholar] [CrossRef] [PubMed]

- Kazimierska, K.; Biel, W. Chemical composition and functional properties of spray-dried animal plasma and its contribution to livestock and pet health: A review. Animals 2023, 13, 2484. [Google Scholar] [CrossRef] [PubMed]

- Quigley, J.D.; Campbell, J.M.; Polo, J.; Russell, L.E. Effects of spray-dried animal plasma on intake and apparent digestibility in dogs. J. Anim. Sci. 2004, 82, 1685–1692. [Google Scholar] [CrossRef] [PubMed]

- Rodriguez, C.; Saborido, N.; Rodenas, J.; Polo, J. Effects of spray-dried animal plasma on food intake and apparent nutrient digestibility by cats when added to a wet pet food recipe. Anim. Feed. Sci. Tech. 2016, 216, 243–250. [Google Scholar] [CrossRef]

- de Andrade, T.; de Lima, D.C.; Domingues, L.P.; Felix, A.P.; de Oliveira, S.G.; Maiorka, A. Spray-dried porcine plasma in dog foods: Implication on digestibility, palatability and haematology. Semin. Cienc. Agrar. 2019, 40, 1287–1295. [Google Scholar] [CrossRef]

- Miró, L.; Garcia-Just, A.; Amat, C.; Polo, J.; Moretó, M.; Pérez-Bosque, A. Dietary animal plasma proteins improve the intestinal immune response in senescent mice. Nutrients 2017, 9, 1346. [Google Scholar] [CrossRef] [PubMed]

- Balan, P.; Staincliffe, M.; Moughan, P.J. Effects of spray-dried animal plasma on the growth performance of weaned piglets—A review. J. Anim. Phys. Anim. Nutr. 2021, 105, 699–714. [Google Scholar] [CrossRef]

- Moretó, M.; Miró, L.; Amat, C.; Polo, J.; Manichanh, C.; Pérez-Bosque, A. Dietary supplementation with spray-dried porcine plasma has prebiotic effects on gut microbiota in mice. Sci. Rep. 2020, 10, 2926. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Just, A.; Miró, L.; Pérez-Bosque, A.; Amat, C.; Polo, J.; Pallàs, M.; Griñán-Ferré, C.; Moretó, M. Dietary spray-dried porcine plasma prevents cognitive decline in senescent mice and reduces neuroinflammation and oxidative stress. J. Nutr. 2020, 150, 303–311. [Google Scholar] [CrossRef] [PubMed]

- Willard, T. Utilization of marine by-products in pet foods. In Proceedings of the International Conference of Fish By-Products, Anchorage, Alaska, 25–27 April 1990. [Google Scholar]

- Zicker, S.C.; Jewell, D.E.; Yamka, R.M.; Milgram, N.W. Evaluation of cognitive learning, memory, psychomotor, immunologic, and retinal functions in healthy puppies fed foods fortified with docosahexaenoic acid-rich fish oil from 8 to 52 weeks of age. J. Am. Vet. Med. Assoc. 2012, 241, 583–594. [Google Scholar] [CrossRef] [PubMed]

- Biagi, G.; Mordenti, A.L.; Cocchi, M.; Mordenti, A. The role of dietary omega-3 and omega-6 essential fatty acids in the nutrition of dogs and cats: A review. Prog. Nutr. 2004, 6, 97–107. [Google Scholar]

- Dominguez, T.E.; Kaur, K.; Burri, L. Enhanced omega-3 index after long-versus short-chain omega-3 fatty acid supplementation in dogs. Vet. Med. Sci. 2021, 7, 370–377. [Google Scholar] [CrossRef] [PubMed]

- Bauer, J.E. Essential fatty acid metabolism in dogs and cats. R. Bras. Zootec. 2008, 37, 20–27. [Google Scholar] [CrossRef]

- Hielm-Bjorkman, A.; Roine, J.; Elo, K.; Lappalainen, A.; Junnila, J.; Laitinen-Vapaavuori, O. An un-commissioned randomized, placebo controlled double-blind study to test the effect of deep-sea fish oil as a pain reliever for dogs suffering from canine OA. BMC Vet. Res. 2012, 8, 157–169. [Google Scholar] [CrossRef] [PubMed]

- Park, H.J.; Park, J.S.; Hayek, M.G.; Reinhart, G.A.; Chew, B.P. Dietary fish oil and flaxseed oil suppress inflammation and immunity in cats. Vet. Immunol. Immunopathol. 2011, 141, 301–306. [Google Scholar] [CrossRef] [PubMed]

- Houpy, K.A.; Smith, S.L. Taste preferences and their relation to obesity in dogs and cats. Can. Vet. J. 1981, 22, 77–85. [Google Scholar]

- Folador, J.F.; Karr-Lilienthal, L.K.; Parsons, C.M.; Bauer, L.L.; Utterback, P.L.; Schasteen, C.S.; Bechtel, P.J.; Fahey, G.C. Fish meals, fish components, and fish hydrolysates as potential ingredients in pet foods. J. Anim. Sci. 2006, 84, 2752–2765. [Google Scholar] [CrossRef] [PubMed]

- Dunajski, E. Texture of fish muscle. J Text. Stud. 2007, 10, 301–318. [Google Scholar] [CrossRef]

- Rustad, T. Physical and chemical properties of protein seafood by-products. In Maximising the Value of Marine by-Products; Woodhead Publishing: Cambridge, UK, 2007; pp. 3–21. [Google Scholar]

- Official Methods of Analysis of AOAC International, 16th ed.; AOAC International: Gaithersburg, MD, USA, 1999.

- Official Journal of the European Union, First Commission Directive 71/250/EEC (1971); Community methods of analysis for the official control of feeding stuffs. L155; European Union: Brussels, Belgium, 1971; pp. 13–37.

- Bourne, M.C. Texture profile of ripening pears. J. Food Sci. 1968, 33, 223–226. [Google Scholar] [CrossRef]

- Friedman, H.H.; Whitney, J.E.; Szczesnial, A.S. The texturometer—A new instrument for objective texture measurement. J. Food Sci. 1963, 28, 390–396. [Google Scholar] [CrossRef]

- Meullenet, J.; Lyon, B.G.; Carpenter, J.A.; Lyon, C.E. Relationship between sensory and instrumental texture profile attributes. J. Sens. Stud. 1998, 13, 77–93. [Google Scholar] [CrossRef]

- Polo, J.; Rodriguez, C. Improving the Juiciness of Pet Food Chunks and Pouches with Plasma; Petfood Industry: Rockford, IL, USA, 2013; Volume 5, pp. 36–40. [Google Scholar]

| Parameter | Chicken 2 | Tuna 3 | Salmon 4 | p-Value |

|---|---|---|---|---|

| Dry matter (%) | 33.3 ± 0.31 b | 28.96 ± 0.69 a | 37.73 ± 0.23 c | <0.001 |

| Protein (%) | 14.6 ± 0.71 | 14.85 ± 0.31 | 13.44 ± 0.91 | 0.234 |

| Ash (%) | 3.53 ± 0.37 | 3.54 ± 0.05 | 3.51 ± 0.30 | 0.749 |

| Fat 5 (%) | 13.00 | 7.00 | 17.00 | --- |

| Binder | Spray-Dried Animal Plasma 1 | Wheat Gluten 2 |

|---|---|---|

| Dry matter (%) | 91.02 | 90.47 |

| Protein (%) | 72.53 | 80.05 |

| Ash (%) | 14.58 | 1.11 |

| Fat (%) | 2.19 | 5.77 |

| Ingredients (g/kg) | Chicken | Fish | Fish + 20 g/kg SDAP | Fish + 20 g/kg WG |

|---|---|---|---|---|

| Chicken carcass 1 | 711.9 | 0 | 0 | 0 |

| Fish by-product 2 | 0 | 711.9 | 691.9 | 691.9 |

| Wheat flour | 70.0 | 70.0 | 70.0 | 70.0 |

| SDAP 3 | 0 | 0 | 20.0 | 0 |

| WG 4 | 0 | 0 | 0 | 20.0 |

| Locus bean gum | 5.0 | 5.0 | 5.0 | 5.0 |

| Common salt | 5.0 | 5.0 | 5.0 | 5.0 |

| Sodium polyphosphate | 5.0 | 5.0 | 5.0 | 5.0 |

| Sodium bicarbonate | 2.0 | 2.0 | 2.0 | 2.0 |

| Ascorbic acid | 1.0 | 1.0 | 1.0 | 1.0 |

| Sodium nitrite | 0.1 | 0.1 | 0.1 | 0.1 |

| Water | 200 | 200 | 200 | 200 |

| Gravy | 1083 | 1083 | 1083 | 1083 |

| TOTAL | 2083 | 2083 | 2083 | 2083 |

| Ingredients (g/kg) | Control Group (Chicken) | Experimental Group (Salmon) | ||||

|---|---|---|---|---|---|---|

| 0 g/kg SDAP | 10 g/kg SDAP | 20 g/kg SDAP | 30 g/kg SDAP | 40 g/kg SDAP | ||

| Chicken carcass 1 | 411.0 | 326.0 | 316.0 | 306.0 | 296.0 | 286.0 |

| Salmon by-product 2 | 0 | 85.0 | 85.0 | 85.0 | 85.0 | 85.0 |

| Pig lungs and trachea | 186.0 | 186.0 | 186.0 | 186.0 | 186.0 | 186.0 |

| Chicken necks | 92.0 | 92.0 | 92.0 | 92.0 | 92.0 | 92.0 |

| Pig liver | 20.0 | 20.0 | 20.0 | 20.0 | 20.0 | 20.0 |

| Wheat flour | 60.0 | 60.0 | 60.0 | 60.0 | 60.0 | 60.0 |

| SDAP 3 | 0 | 0 | 10.0 | 20.0 | 30.0 | 40.0 |

| Locust bean gum | 4.4 | 4.4 | 4.4 | 4.4 | 4.4 | 4.4 |

| Common salt | 5.0 | 5.0 | 5.0 | 5.0 | 5.0 | 5.0 |

| Sodium polyphosphate | 5.0 | 5.0 | 5.0 | 5.0 | 5.0 | 5.0 |

| Sodium bicarbonate | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 |

| Water | 215 | 215 | 215 | 215 | 215 | 215 |

| Gravy | 1083 | 1083 | 1083 | 1083 | 1083 | 1083 |

| Total | 2083 | 2083 | 2083 | 2083 | 2083 | 2083 |

| Parameter | Measured Variable | Units | Definition |

|---|---|---|---|

| Adhesiveness | Work | N·s | Negative force area of the first compression cycle. It is the work necessary to pull the plunger away from the sample. |

| Chewiness | Work | N·mm | Product of hardness times cohesiveness times springiness. Only applied to solid products. |

| Cohesiveness | Ratio of forces | dimensional | Ratio of the positive force area during the second compression cycle to that during the first cycle. |

| Hardness | Force | N | Peak force during the first compression cycle. |

| Springiness | Distance | mm | Length to which the sample recovers in height during the time elapsed between the end of the first compression cycle and the start of the second cycle. |

| Chicken 2 | Fish 3 | Fish + 20 g/kg SDAP 4 | Fish + 20 g/kg WG 5 | SEM 6 | |

|---|---|---|---|---|---|

| Dry matter (%) | 31.48 | 32.02 | 32.59 | 32.98 | 0.45 |

| Protein (%) | 10.57 | 10.58 | 11.90 | 10.63 | 0.45 |

| Ash (%) | 3.40 | 3.68 | 3.64 | 3.17 | 0.45 |

| Viscosity (Pa.s) | 57.10 | 56.29 | 59.29 | 59.02 | 4.78 |

| Hardness (N) 7 | 3.32 b | 2.49 a | 4.12 c | 2.60 a | 0.16 |

| Chicken 2 | Fish 3 | Fish + 20 g/kg SDAP 4 | Fish + 20 g/kg WG 5 | SEM 6 | |

|---|---|---|---|---|---|

| Juiciness 7 (%) | 11.64 a | 20.59 b | 23.97 d | 21.56 c | 0.26 |

| Hardness (N) | 15.53 b | 10.48 a | 27.92 c | 12.15 ab | 1.50 |

| Adhesiveness (N.s) | −1.42 a | −2.45 b | −3.10 b | −3.02 b | 0.20 |

| Springiness (mm) | 0.77 b | 0.63 a | 0.85 c | 0.63 a | 0.02 |

| Cohesiveness | 0.45 b | 0.34 a | 0.55 c | 0.33 a | 0.02 |

| Chewiness (N.mm) | 5.49 a | 2.28 a | 13.17 b | 2.57 a | 1.01 |

| Chicken 2 | Salmon 3 | SEM 4 | p-Value 5 | |

|---|---|---|---|---|

| Emulsion | ||||

| Dry matter (%) | 31.48 | 29.37 | 0.60 | 0.0692 |

| Protein (%) | 10.57 | 10.12 | 0.22 | 0.2219 |

| Ash (%) | 3.40 | 2.66 | 0.15 | 0.0263 |

| Viscosity (Pa·s) | 57.10 | 51.61 | 3.93 | 0.3786 |

| Hardness (N) | 3.32 | 1.88 | 0.13 | 0.0013 |

| Chunks in gravy | ||||

| Juiciness 6 (%) | 11.64 | 9.45 | 0.81 | 0.1267 |

| Hardness (N) | 15.18 | 8.72 | 0.76 | 0.0038 |

| Adhesiveness (N·s) | −1.53 | −0.99 | 0.16 | 0.0727 |

| Springiness (mm) | 0.76 | 0.65 | 0.03 | 0.0503 |

| Cohesiveness | 0.43 | 0.37 | 0.02 | 0.1392 |

| Chewiness (N·mm) | 5.00 | 2.17 | 0.40 | 0.0077 |

| Dry Matter (%) | Protein (%) | Ash (%) | Viscosity (Pa·s) | Hardness (N) | |

|---|---|---|---|---|---|

| 0 g/kg SDAP 2 | 29.37 | 10.12 | 2.66 | 51.61 | 1.88 |

| 10 g/kg SDAP | 29.70 | 10.71 | 2.86 | 52.98 | 2.46 |

| 20 g/kg SDAP | 30.39 | 11.03 | 2.65 | 53.72 | 3.19 |

| 30 g/kg SDAP | 31.01 | 11.40 | 2.59 | 55.24 | 4.29 |

| 40 g/kg SDAP | 30.85 | 12.45 | 2.90 | 55.68 | 5.36 |

| SEM 3 | 0.53 | 0.17 | 0.12 | 0.44 | 0.13 |

| p-Value | |||||

| Linear | 0.0243 | <0.0001 | 0.5948 | <0.0001 | <0.0001 |

| Quadratic | 0.6064 | 0.1546 | 0.4099 | 0.5228 | 0.0176 |

| Recipes | Juiciness 2 (%) | Hardness (N) | Adhesiveness (N·s) | Springiness (mm) | Cohesiveness | Chewiness (N·mm) |

|---|---|---|---|---|---|---|

| 0 g/kg SDAP 3 | 9.45 | 8.72 | −0.98 | 0.65 | 0.37 | 2.17 |

| 10 g/kg SDAP | 10.98 | 13.41 | −0.76 | 0.76 | 0.45 | 4.62 |

| 20 g/kg SDAP | 11.21 | 19.82 | −0.99 | 0.88 | 0.69 | 10.59 |

| 30 g/kg SDAP | 14.36 | 26.84 | −0.52 | 0.93 | 0.69 | 17.33 |

| 40 g/kg SDAP | 16.93 | 32.30 | −0.49 | 0.95 | 0.74 | 22.60 |

| SEM 4 | 1.25 | 0.76 | 13.4 | 0.02 | 0.05 | 0.70 |

| p-Value | ||||||

| Linear | <0.0001 | <0.0001 | 0.0162 | <0.0001 | <0.0001 | <0.0001 |

| Quadratic | 0.3122 | 0.4706 | 0.5553 | 0.0047 | 0.1054 | 0.0336 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodríguez, M.-C.; Cámara, C.; Morera, S.; Saborido, N.; Polo, J. Technological Benefits Associated with the Use of Spray-Dried Animal Plasma in Fish-Based Chunks for Canned Pet Food. Animals 2023, 13, 3460. https://doi.org/10.3390/ani13223460

Rodríguez M-C, Cámara C, Morera S, Saborido N, Polo J. Technological Benefits Associated with the Use of Spray-Dried Animal Plasma in Fish-Based Chunks for Canned Pet Food. Animals. 2023; 13(22):3460. https://doi.org/10.3390/ani13223460

Chicago/Turabian StyleRodríguez, María-Carmen, Ciro Cámara, Salvador Morera, Neus Saborido, and Javier Polo. 2023. "Technological Benefits Associated with the Use of Spray-Dried Animal Plasma in Fish-Based Chunks for Canned Pet Food" Animals 13, no. 22: 3460. https://doi.org/10.3390/ani13223460

APA StyleRodríguez, M. -C., Cámara, C., Morera, S., Saborido, N., & Polo, J. (2023). Technological Benefits Associated with the Use of Spray-Dried Animal Plasma in Fish-Based Chunks for Canned Pet Food. Animals, 13(22), 3460. https://doi.org/10.3390/ani13223460