Spanish Fuet Sausages Fat-Reduced to Diminish Boar Taint: Sensory and Technological Quality

Abstract

:Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. Ingredients

2.2. Fuet Preparation

2.3. Colour Measurement

2.4. Moisture and Fat Determination

2.5. Texture Profile Analysis (TPA)

2.6. Sensory Analyses

2.7. Statistics

3. Results and Discussion

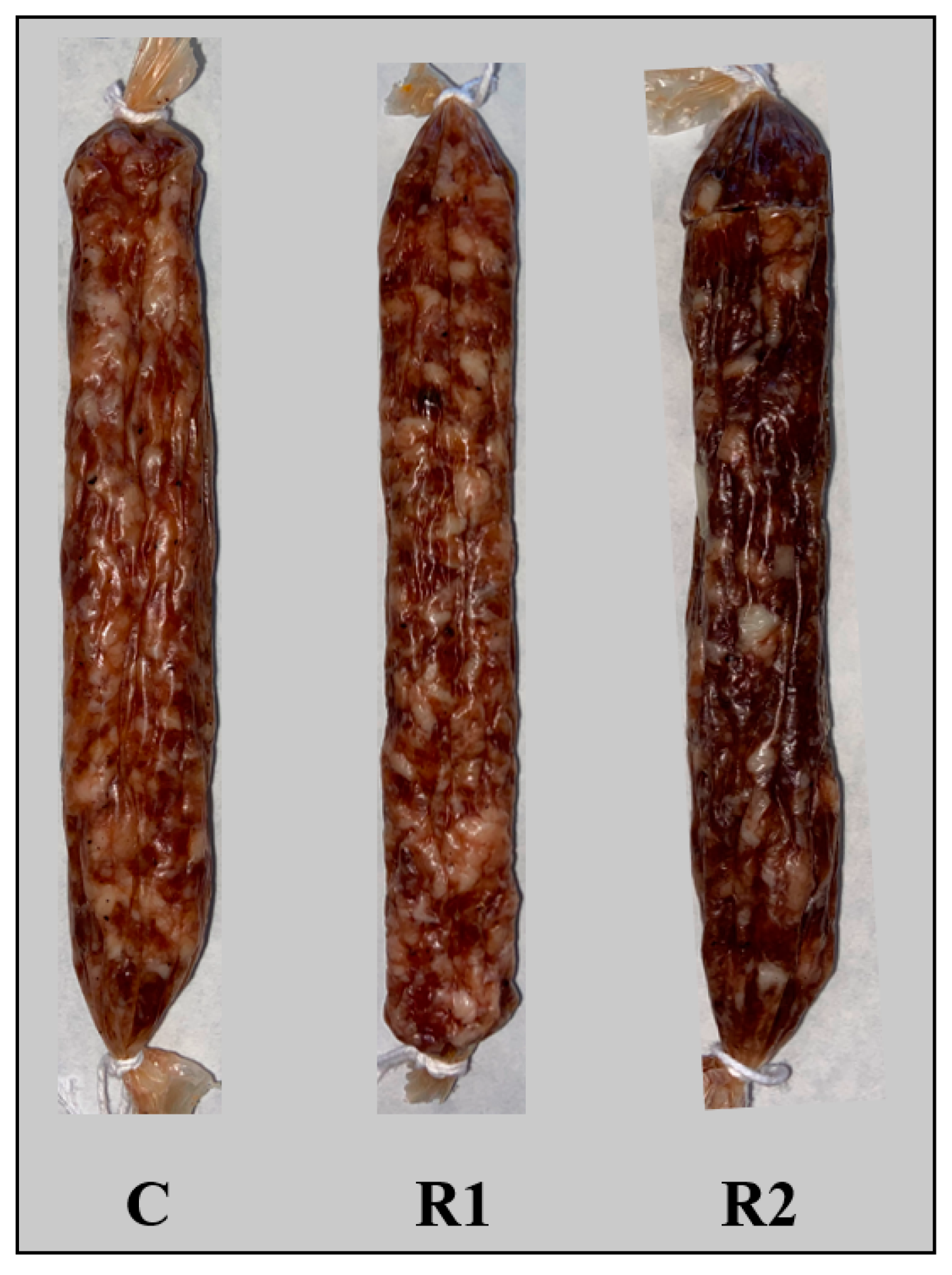

3.1. Composition and Instrumental Colour

3.2. Instrumental Texture

3.3. Sensory Analyses

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- European Declaration on Alternatives to Surgical Castration of Pigs. 2010. Available online: https://food.ec.europa.eu/system/files/2016-10/aw_prac_farm_pigs_cast-alt_declaration_en.pdf (accessed on 15 July 2021).

- Bonneau, M.; Weiler, U. Pros and cons of alternatives to piglet castration: Welfare, boar taint, and other meat quality traits. Animals 2019, 9, 884. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Borrisser-Pairó, F.; Panella-Riera, N.; Zammerini, D.; Olivares, A.; Garrido, M.D.; Martínez, B.; Gil, M.; García-Regueiro, M.J.; Oliver, M.A. Prevalence of boar taint in commercial pigs from Spanish farms. Meat Sci. 2016, 111, 177–182. [Google Scholar] [CrossRef] [PubMed]

- Font-i-Furnols, M. Consumer studies on sensory acceptability of boar taint: A review. Meat Sci. 2012, 92, 319–329. [Google Scholar] [CrossRef]

- Lunde, K.; Egelandsdal, B.; Choinski, J.; Mielnik, M.; Flåtten, A.; Kubberød, E. Marinating as a technology to shift sensory thresholds in ready-to-eat entire male pork meat. Meat Sci. 2008, 80, 1264–1272. [Google Scholar] [CrossRef] [PubMed]

- Egea, M.; Linares, M.B.; Gil, M.; López, M.B.; Garrido, M.D. Reduction of androstenone perception in pan-fried boar meat by different masking strategies. J. Sci. Food Agric. 2018, 98, 2251–2257. [Google Scholar] [CrossRef] [PubMed]

- Martínez, B.; Vieira, C.; Rubio, B.; Garrido, M.D.; Egea, M.; Linares, M.B.; Riera, N.P. Effect of androstenone level in characteristics of dry fermented sausage manufactured with meat from entire male pigs. Arch. Zootec. 2018, 1, 213–216. [Google Scholar]

- Mörlein, J.; Meier-Dinkel, L.; Gertheiss, J.; Schnäckel, W.; Mörlein, D. Sustainable use of tainted boar meat: Blending is a strategy for processed products. Meat Sci. 2019, 152, 65–72. [Google Scholar] [CrossRef]

- Peñaranda, I.; Garrido, M.D.; Moumeh, B.; Linares, M.B. Use of masking strategies to avoid the boar taint perception in chorizo: Consumers’ acceptability. Meat Sci. 2020, 169, 108223. [Google Scholar] [CrossRef]

- Garrido, M.D.; Egea, M.; Linares, M.B.; Martínez, B.; Viera, C.; Rubio, B.; Borrisser-Pairó, F. A procedure for sensory detection of androstenone in meat and meat products from entire male pigs: Development of a panel training. Meat Sci. 2016, 122, 60–67. [Google Scholar] [CrossRef]

- Bis-Souza, C.V.; Ozaki, M.M.; Vidal, V.A.S.; Pollonio, M.A.R.; Penna, A.L.B.; Barretto, A.C.S. Can dietary fiber improve the technological characteristics and sensory acceptance of low-fat Italian type salami? J. Food Sci. Technol. 2020, 57, 1003–1012. [Google Scholar] [CrossRef]

- Bis-Souza, C.V.; Pateiro, M.; Domínguez, R.; Penna, A.L.; Lorenzo, J.M.; Barretto, A.C.S. Impact of fructo-oligosaccharides and probiotic strains on the quality parameters of low-fat Spanish Salchichón. Meat Sci. 2020, 159, 107936. [Google Scholar] [CrossRef] [PubMed]

- Ruiz-Aceituno, L.; Hernandez-Hernandez, O.; Kolida, S.; Moreno, F.J.; Methven, L. Sweetness and sensory properties of commercial and novel oligosaccharides +of prebiotic potential. LWT—Food Sci. Technol. 2018, 97, 476–482. [Google Scholar] [CrossRef] [Green Version]

- Öztürk, B.; Serdaroğlu, M. A rising star prebiotic dietary fiber: Inulin and recent applications in meat products. Food Health 2017, 3, 12–20. [Google Scholar] [CrossRef]

- Álvarez, D.; Barbut, S. Effect of inulin, β-glucan and their mixtures on emulsion stability, color and textural parameters of cooked meat batters. Meat Sci. 2013, 94, 320–327. [Google Scholar] [CrossRef] [PubMed]

- Egea, M.; Álvarez, D.; Peñaranda, I.; Panella-Riera, N.; Linares, M.B.; Garrido, M.D. Fat Replacement by Vegetal Fibres to Improve the Quality of Sausages Elaborated with Non-Castrated Male Pork. Animals 2020, 10, 1872. [Google Scholar] [CrossRef] [PubMed]

- Choe, J.H.; Kim, H.Y.; Lee, J.M.; Kim, Y.J.; Kim, C.J. Quality of frankfurter-type sausages with added pig skin and wheat fiber mixture as fat replacers. Meat Sci. 2013, 93, 849–854. [Google Scholar] [CrossRef]

- Yalınkılıç, B.; Kaban, G.; Kaya, M. The effects of different levels of orange fiber and fat on microbiological, physical, chemical and sensorial properties of sucuk. Food Microbiol. 2012, 29, 255–259. [Google Scholar] [CrossRef]

- Fernández-Diez, A.; Caro, I.; Castro, A.; Salvá, B.K.; Ramos, D.D.; Mateo, J. Partial fat replacement by boiled quinoa on the quality characteristics of a dry-cured sausage. J. Food Sci. 2016, 81, C1891–C1898. [Google Scholar] [CrossRef]

- Lorenzo, J.M.; Franco, D. Fat effect on physico-chemical, microbial and textural changes through the manufactured of dry-cured foal sausage lipolysis, proteolysis and sensory properties. Meat Sci. 2012, 92, 704–714. [Google Scholar] [CrossRef]

- Directive 2010/63/EU of the European Parliament and of the Council, of 22 September 2010, on the protection of animals used for scientific purposes. Off. J. Eur. Union 2010, L 276/33, 33–79.

- Rius, M.A.; García-Regueiro, J.A. Analysis of androstenone in pig back fat by solid-phase extraction and GC-MS. In Proceedings of the 44th International Congress of Meat Science and Technology 1998, Barcelona, Spain, 30 August–4 September 1998. [Google Scholar]

- Garcia-Regueiro, J.A.; Rius, M.A. Rapid determination of skatole and indole in pig back fat by normal-phase liquid chromatography. J. Chromatogr. A 1998, 809, 246–251. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis, 15th ed.; Analytical Chemists; Association of Official: Washington, DC, USA, 1996. [Google Scholar]

- ISO 1442; Meat and Meat Products—Determination of Moisture Content (Reference Method). International Organization for Standardization Publications: Genève, Switzerland, 1997.

- ISO 1443; Meat and Meat Products—Determination of Total Fat Content (Reference Method). International Organization for Standardization Publications: Genève, Switzerland, 1973.

- Garcia-Santos, M.D.S.L.; Conceicao, F.S.; Villas Boas, F.; Salotti De Souza, B.M.; Barretto, A.C.D.S. Effect of the addition of resistant starch in sausage with fat reduction on the physicochemical and sensory properties. Food Sci. Technol. 2019, 39, 491–497. [Google Scholar] [CrossRef] [Green Version]

- ISO 8586; General Guidelines for the Selection, Training and Monitoring of Selected Assessors and Expert Sensory Assessors. International Organization for Standardization Publications: Genève, Switzerland, 2012.

- ISO 4121; Meat and Meat Products. Evaluation of Food Products by Methods Using Scales. Sensory Analysis. International Organization for Standardization Publications: Genève, Switzerland, 2003.

- ISO 8589; Sensory Analysis—General Guidance for the Design of Test Rooms. International Organization for Standardization Publications: Genève, Switzerland, 2007.

- MacFie, H.J.; Bratchell, N.; Greenhoff, K.; Vallis, L.V. Designs to balance the effect of order of presentation and first-order carry-over effects in hall tests. J. Sens. Stud. 1989, 4, 129–148. [Google Scholar] [CrossRef]

- IBM Corp. SPSS Statistic for Windows Version 24.0; IBM Corp: Armonk, NY, USA, 2019. [Google Scholar]

- Regulation (EC) No 1924/2006 of the European Parliament and of the Council of 20 December 2006 on nutrition and health claims made on foods. Off. J. Eur. Union 2006, L 404, 9–25.

- Beriain, M.J.; Gómez, I.; Petri, E.; Insausti, K.; Sarriés, M.V. The effects of olive oil emulsified alginate on the physico-chemical, sensory, microbial, and fatty acid profiles of low-salt, inulin-enriched sausages. Meat Sci. 2011, 88, 189–197. [Google Scholar] [CrossRef] [PubMed]

- Glisic, M.; Baltic, M.; Glisic, M.; Trbovic, D.; Jokanovic, M.; Parunovic, N.; Dimitrijevic, M.; Suvajdzic, B.; Boskovic, M.; Vasilev, D. Inulin-based emulsion-filled gel as a fat replacer in prebiotic-and PUFA-enriched dry fermented sausages. Int. J. Food Sci. Technol. 2019, 54, 787–797. [Google Scholar] [CrossRef]

- Choi, Y.S.; Choi, J.H.; Han, D.J.; Kim, H.Y.; Lee, M.A.; Kim, H.W.; Ju-Woon Lee, J.W.; Hai-Jung Chung, H.J.; Kim, C.J. Optimization of replacing pork back fat with grape seed oil and rice bran fiber for reduced-fat meat emulsion systems. Meat Sci. 2010, 84, 212–218. [Google Scholar] [CrossRef]

- Ryu, K.S.; Shim, K.S.; Shin, D. Effect of grape pomace powder addition on TBARS and color of cooked pork sausages during storage. Korean J. Food Sci. Anim. Resour. 2014, 34, 200. [Google Scholar] [CrossRef] [Green Version]

- Riazi, F.; Zeynali, F.; Hoseini, E.; Behmadi, H.; Savadkoohi, S. Oxidation phenomena and color properties of grape pomace on nitrite-reduced meat emulsion systems. Meat Sci. 2016, 121, 350–358. [Google Scholar] [CrossRef]

- Mainente, F.; Menin, A.; Alberton, A.; Zoccatelli, G.; Rizzi, C. Evaluation of the sensory and physical properties of meat and fish derivatives containing grape pomace powders. Int. J. Food Sci. Technol. 2019, 54, 952–958. [Google Scholar] [CrossRef]

- Jongberg, S.; Skov, S.H.; Tørngren, M.A.; Skibsted, L.H.; Lund, M.N. Effect of white grape extract and modified atmosphere packaging on lipid and protein oxidation in chill stored beef patties. Food Chem. 2011, 128, 276–283. [Google Scholar] [CrossRef] [PubMed]

- Menegas, L.Z.; Pimentel, T.C.; Garcia, S.; Prudencio, S.H. Dry-fermented chicken sausage produced with inulin and corn oil: Physicochemical, microbiological, and textural characteristics and acceptability during storage. Meat Sci. 2013, 93, 501–506. [Google Scholar] [CrossRef] [PubMed]

- Keenan, D.F.; Resconi, V.C.; Kerry, J.P.; Hamill, R.M. Modelling the influence of inulin as a fat substitute in comminuted meat products on their physico-chemical characteristics and eating quality using a mixture design approach. Meat Sci. 2014, 96, 1384–1394. [Google Scholar] [CrossRef] [PubMed]

- Triki, M.; Herrero, A.M.; Rodríguez-Salas, L.; Jiménez-Colmenero, F.; Ruiz-Capillas, C. Chilled storage characteristics of low-fat, n-3 PUFA-enriched dry fermented sausage reformulated with a healthy oil combination stabilized in a konjac matrix. Food Control 2013, 31, 158–165. [Google Scholar] [CrossRef]

- Han, M.; Bertram, H.C. Designing healthier comminuted meat products: Effect of dietary fibers on water distribution and texture of a fat-reduced meat model system. Meat Sci. 2017, 133, 159–165. [Google Scholar] [CrossRef] [PubMed]

- Mariezcurrena-Berasain, M.A.; Braña-Varela, D.; Mariezcurrena-Berasain, M.D.; Domínguez-Vara, I.A.; Méndez-Medina, D.; Rubio-Lozano, M.S. Chemical and sensory characteristics of pork meat as a function of consumption of diets with ractopamine and different concentrations of lysine. Rev. Mex. Cienc. Pecu. 2012, 3, 427–438. [Google Scholar] [CrossRef] [Green Version]

- Wauters, J.; Verplanken, K.; Vercruysse, V.; Ampe, B.; Aluwé, M.; Vanhaecke, L. Sensory evaluation of boar meat products by trained experts. Food Chem. 2017, 237, 516–524. [Google Scholar] [CrossRef]

- Škrlep, M.; Tomašević, I.; Mörlein, D.; Novaković, S.; Egea, M.; Garrido, M.D.; Linares, M.B.; Peñaranda, I.; Font-i-Furnols, M. The use of pork from entire male and immunocastrated pigs for meat products—An overview with recommendations. Animals 2020, 10, 1754. [Google Scholar] [CrossRef]

- Verplanken, K.; Wauters, J.; Vercruysse, V.; Aluwé, M.; Vanhaecke, L. Sensory evaluation of boar-taint-containing minced meat, dry-cured ham and dry fermented sausage by a trained expert panel and consumers. Food Chem. 2017, 233, 247–255. [Google Scholar] [CrossRef]

- Hemeryck, L.; Wauters, J.L.; Dewulf, L.; Decloedt, A.I.; Aluwe, M.; De Smet, S.; Fraeye, I.; Vanhaecke, L. Valorisation of tainted boar meat in patties, frankfurter sausages and cooked ham by means of targeted dilution, cooking and smoking. Food Chem. 2020, 330, 126887. [Google Scholar] [CrossRef]

| Formulation (%fat) | Lean | Fat * | Inulin | Grape Skin | β-Glucan | Salt | Mix | Water |

|---|---|---|---|---|---|---|---|---|

| C (25) | 60 | 33.69 | 1 | 4 | 1.31 | |||

| R1 (16) | 60 | 21.19 | 6 | 0.5 | 1 | 4 | 7.31 | |

| R2 (16) | 60 | 21.19 | 3 | 0.5 | 1 | 1 | 4 | 9.31 |

| Parameters | C | R1 | R2 | p-Value |

|---|---|---|---|---|

| Moisture (%) | 21.4 ± 0.00 b | 19.5 ± 1.43 a | 21.3 ± 0.36 b | 0.002 |

| Fat (% MM) | 35.2 ± 2.65 b | 26.9 ± 1.93 a | 26.2 ± 1.93 a | 0.000 |

| CIELAB colour | ||||

| L* | 48.4 ± 1.83 c | 45.1 ± 1.38 b | 41.7 ± 1.17 a | 0.000 |

| a* | 11.6 ± 1.78 b | 11.7 ± 1.68 b | 9.1 ± 1.22 a | 0.004 |

| b* | 6.3 ± 0.53 b | 5.9 ± 0.94 ab | 5.2 ± 0.27 a | 0.008 |

| Parameters | C | R1 | R2 | p-Value |

|---|---|---|---|---|

| Hardness (g) | 9418.3 ± 464.24 | 10,069.0 ± 1146.32 | 10,206.0 ± 1007.07 | 0.212 |

| Gumminess (g) | 2907.2 ± 140.90 a | 3348.7 ± 172.03 b | 3341.6 ± 398.36 b | 0.004 |

| Chewiness (mJ) | 147.8 ± 13.10 a | 178.8 ± 24.99 ab | 202.0 ± 36.04 b | 0.002 |

| Adhesiveness (mJ) | 4.4 ± 0.43 b | 3.9 ± 0.60 ab | 3.6 ± 0.49 a | 0.014 |

| Resilience | 1.5 ± 0.19 c | 1.4 ± 0.06 b | 1.2 ± 0.09 a | 0.000 |

| Extensibility | 21.5 ± 5.47 a | 18.0 ± 3.84 a | 29.0 ± 5.22 b | 0.001 |

| Cohesiveness | 0.3 ± 0.02 | 0.3 ± 0.02 | 0.3 ± 0.03 | 0.718 |

| Elasticity (mm) | 5.2 ± 0.29 a | 5.4 ± 0.76 ab | 5.9 ± 0.36 b | 0.039 |

| Attributes | C | R1 | R2 | p-Value |

|---|---|---|---|---|

| Colour | 5.6 ± 0.80 a | 6.4 ± 0.56 b | 8.3 ± 0.72 c | 0.000 |

| Brightness | 4.8 ± 0.70 b | 4.9 ± 1.01 b | 3.6 ± 0.88 a | 0.000 |

| Homogeneity | 9.9 ± 0.43 | 9.9 ± 0.46 | 9.7 ± 0.63 | 0.390 |

| Sausage odour | 4.9 ± 0.69 a | 5.7 ± 1.41 a | 6.8 ± 1.82 b | 0.000 |

| Acid odour | 0.9 ± 0.58 | 0.7 ± 0.76 | 0.8 ± 0.75 | 0.469 |

| Off odour | 0.0 ± 0.00 a | 0.0 ± 0.00 a | 0.2 ± 0.37 b | 0.007 |

| Boar taint odour | 4.3 ± 1.32 c | 2.8 ± 1.08 b | 1.0 ± 0.53 a | 0.000 |

| Acid | 1.1 ± 0.88 | 1.0 ± 0.98 | 1.1 ± 1.04 | 0.938 |

| Salty | 5.4 ± 0.46 a | 5.6 ± 0.44 ab | 5.9 ± 0.70 b | 0.021 |

| Bitter | 0.2 ± 0.56 | 0.2 ± 0.57 | 0.2 ± 0.39 | 0.986 |

| Sausage flavour | 4.9 ± 0.92 a | 5.9 ± 0.78 b | 7.0 ± 1.23 c | 0.000 |

| Off flavour | 0.0 ± 0.00 a | 0.0 ± 0.00 a | 0.3 ± 0.52 b | 0.000 |

| Boar taint flavour | 5.3 ± 1.95 c | 3.1 ± 1.38 b | 1.0 ± 0.64 a | 0.000 |

| Hardness | 5.7 ± 0.61 a | 6.0 ± 0.66 ab | 6.5 ± 1.15 b | 0.016 |

| Cohesiveness | 5.9 ± 1.63 | 5.8 ± 0.59 | 6.1 ± 0.87 | 0.627 |

| Chewiness | 5.3 ± 0.50 a | 5.9 ± 0.49 b | 5.9 ± 1.16 b | 0.016 |

| Juiciness | 5.0 ± 0.75 | 4.5 ± 0.93 | 4.6 ± 1.50 | 0.366 |

| Overall rating | 4.1 ± 1.57 a | 5.8 ± 1.19 b | 8.0 ± 1.58 c | 0.000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peñaranda, I.; Egea, M.; Álvarez, D.; Garrido, M.D.; Linares, M.B. Spanish Fuet Sausages Fat-Reduced to Diminish Boar Taint: Sensory and Technological Quality. Animals 2023, 13, 912. https://doi.org/10.3390/ani13050912

Peñaranda I, Egea M, Álvarez D, Garrido MD, Linares MB. Spanish Fuet Sausages Fat-Reduced to Diminish Boar Taint: Sensory and Technological Quality. Animals. 2023; 13(5):912. https://doi.org/10.3390/ani13050912

Chicago/Turabian StylePeñaranda, Irene, Macarena Egea, Daniel Álvarez, María Dolores Garrido, and María Belén Linares. 2023. "Spanish Fuet Sausages Fat-Reduced to Diminish Boar Taint: Sensory and Technological Quality" Animals 13, no. 5: 912. https://doi.org/10.3390/ani13050912

APA StylePeñaranda, I., Egea, M., Álvarez, D., Garrido, M. D., & Linares, M. B. (2023). Spanish Fuet Sausages Fat-Reduced to Diminish Boar Taint: Sensory and Technological Quality. Animals, 13(5), 912. https://doi.org/10.3390/ani13050912