Efficacy of Salvia officinalis Shrub as a Sustainable Feed Additive for Reducing Ruminal Methane Production and Enhancing Fermentation in Ruminants

Abstract

:Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. Ingredients and Treatments

2.2. In Vitro Fermentation and Biodegradation

2.3. Sampling and Analysis of Fermentation Variables

2.4. Chemical Analysis

2.5. Calculations and Statistical Analyses

3. Results

3.1. Salvia Officinalis

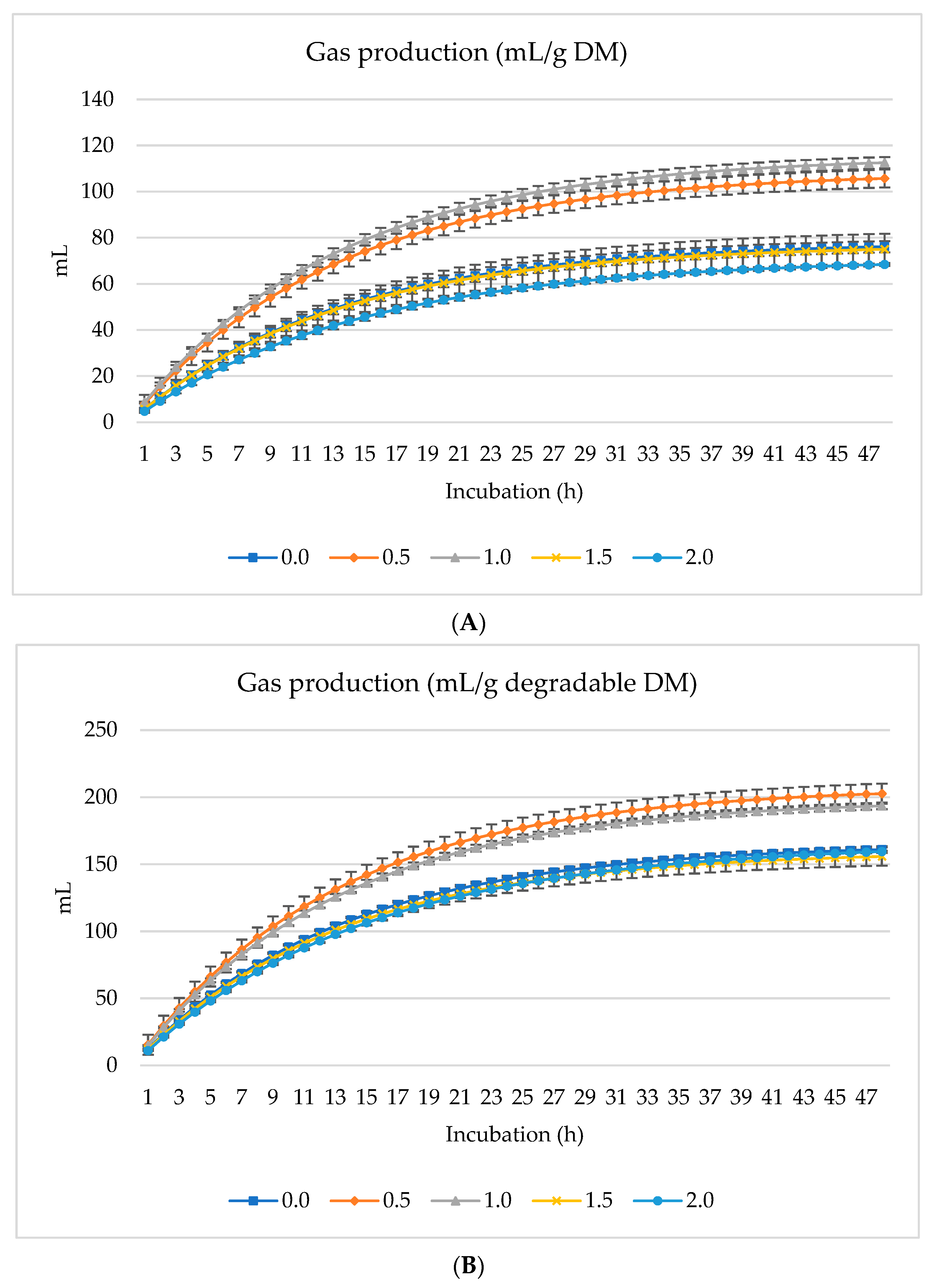

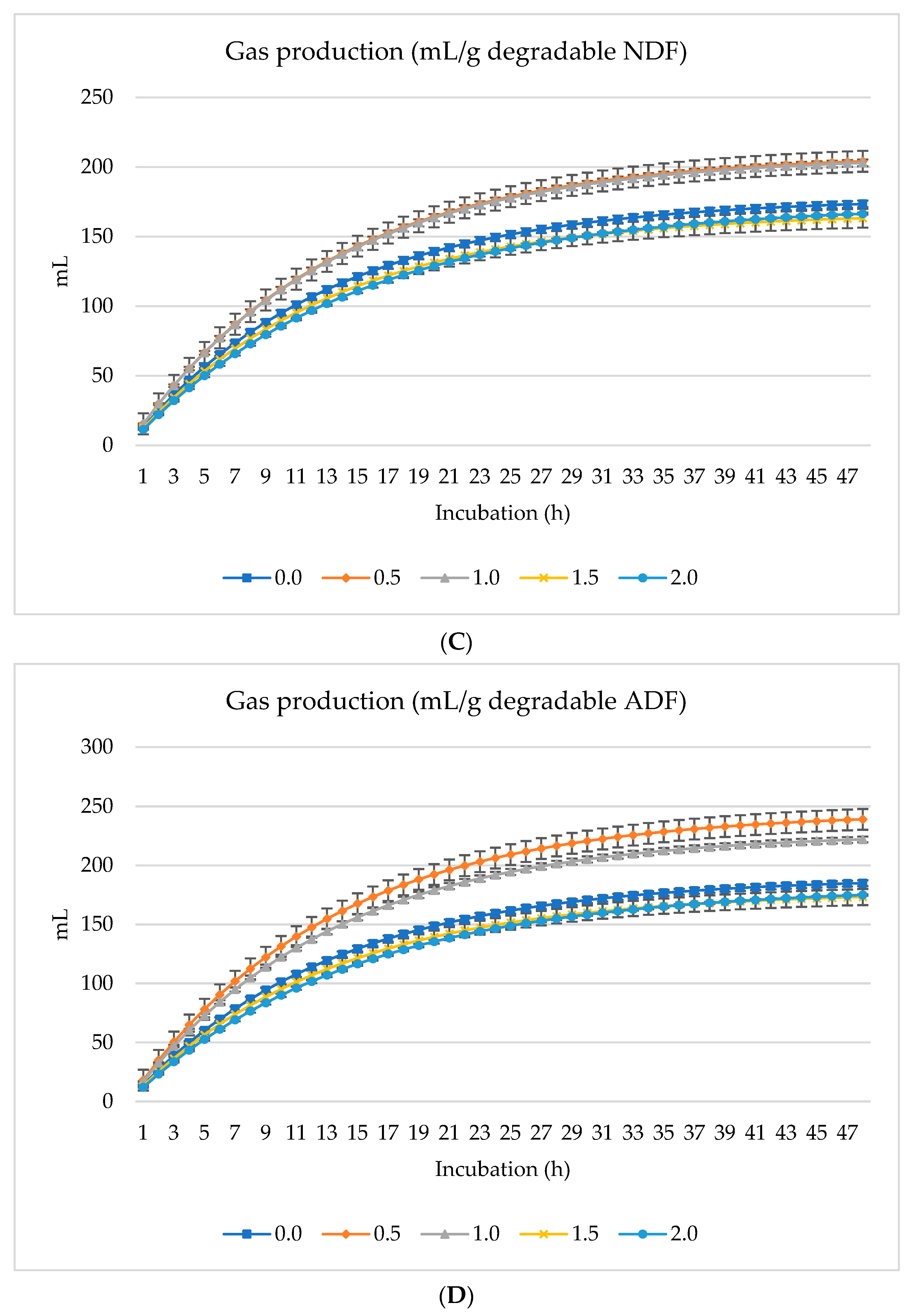

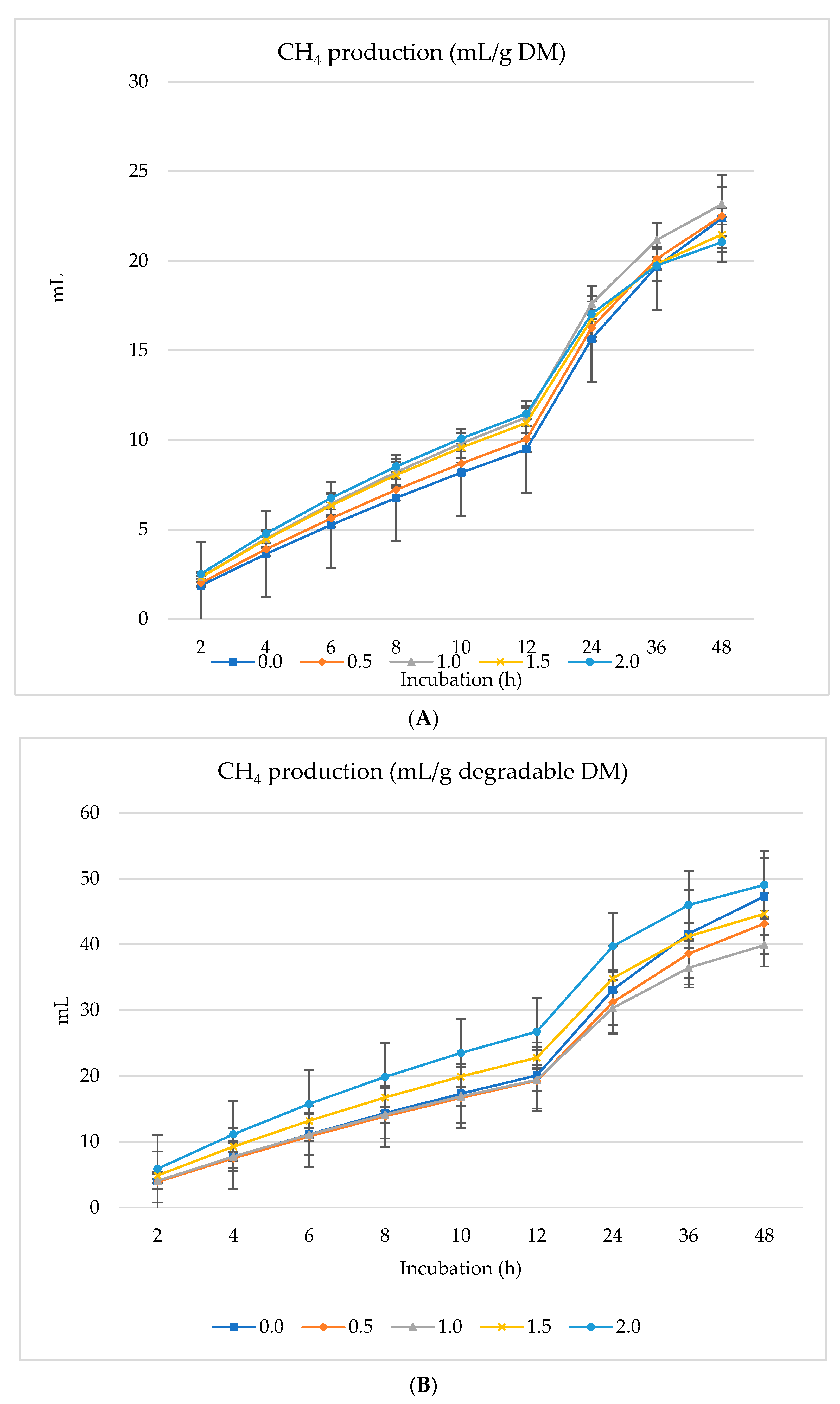

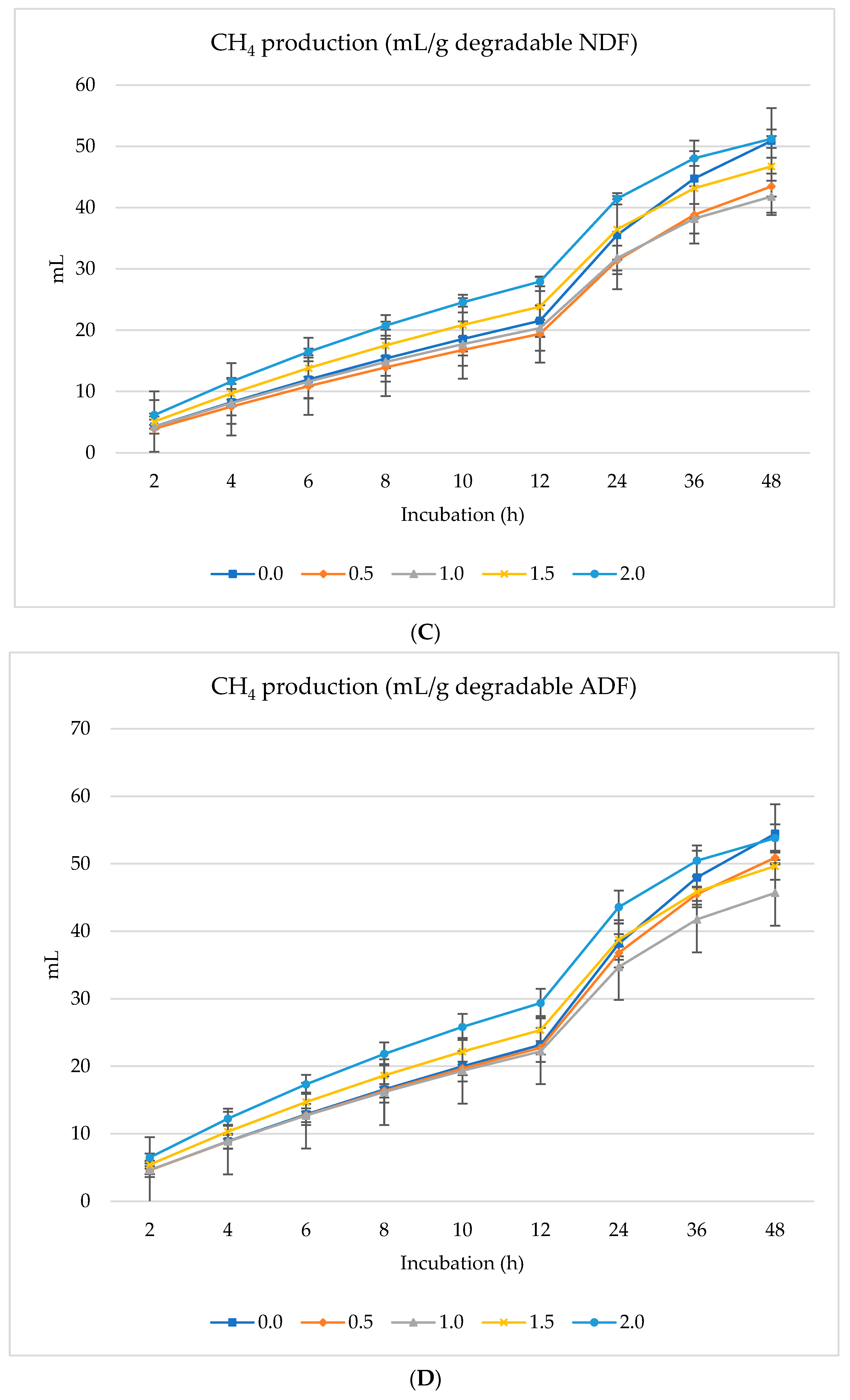

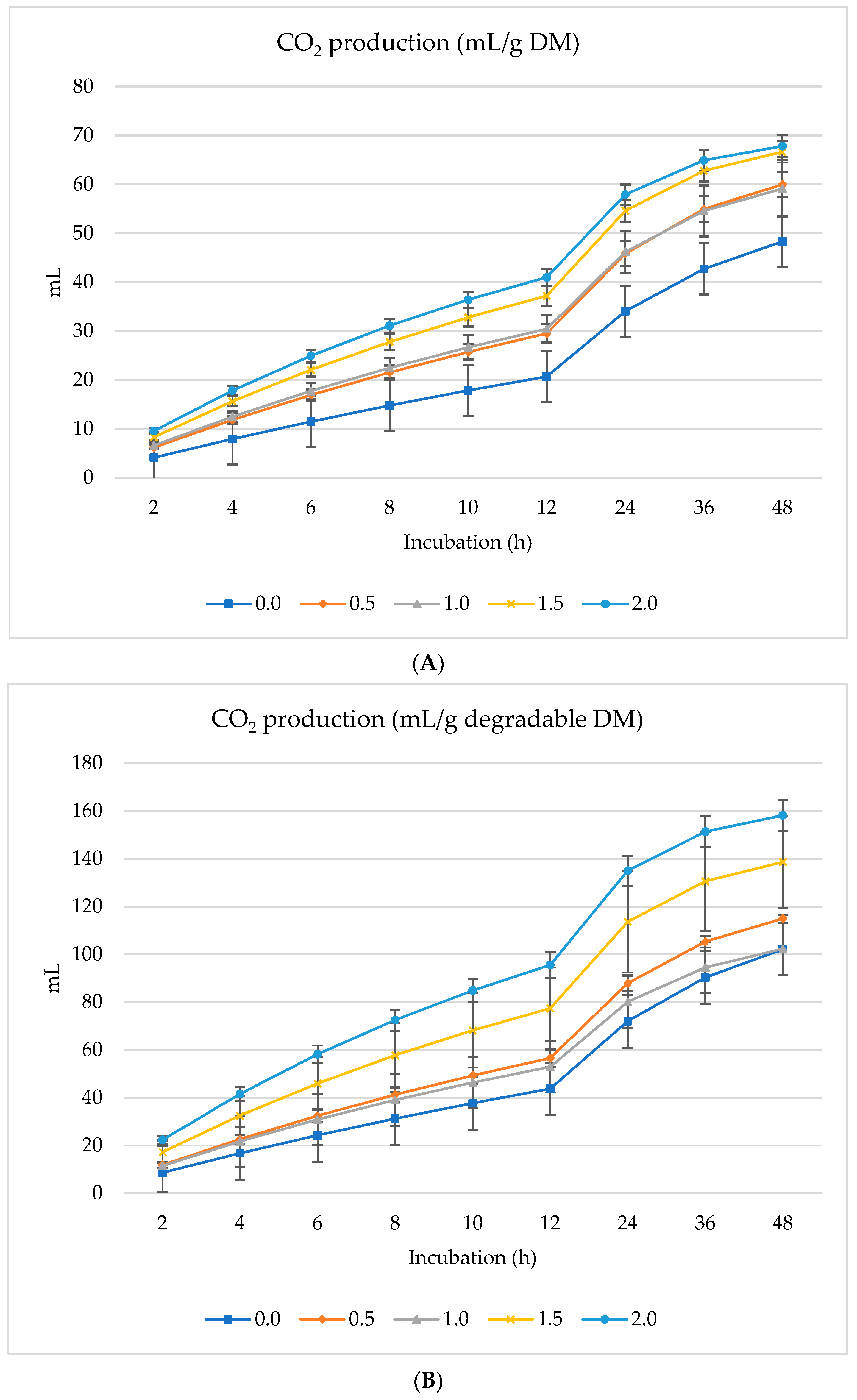

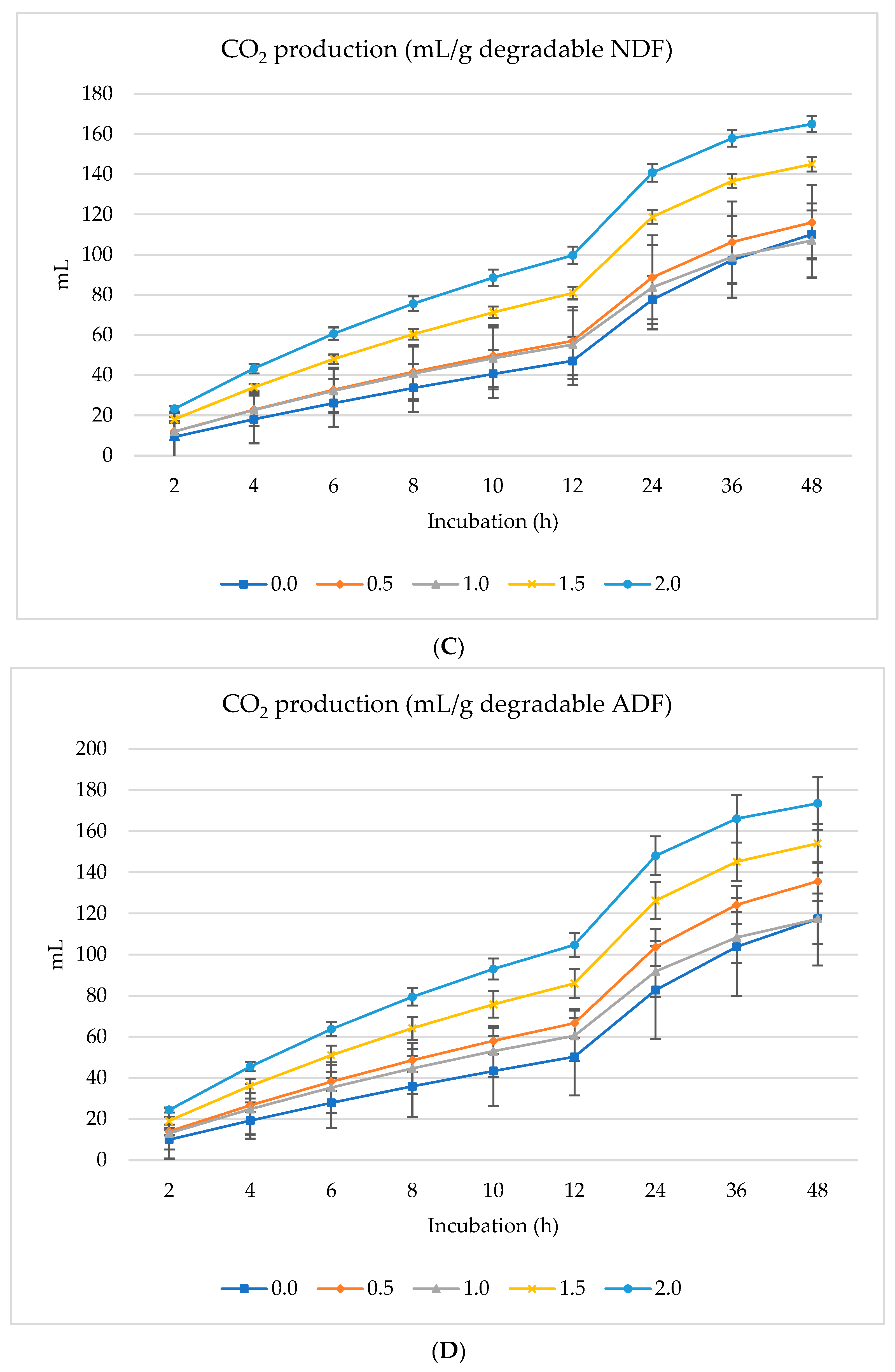

3.2. Biogases Production

3.3. Degradability and Fermentation

4. Discussion

4.1. Salvia Officinalis

4.2. Gas Production

4.3. Methane and Carbon Dioxide Production

4.4. Degradability and Fermentation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gerber, P.J.; Steinfeld, H.; Henderson, B.; Mottet, A.; Opio, C.; Dijkman, J.; Falcucci, A.; Tempio, G. Tackling Climate Change through Livestock—A Global Assessment of Emissions and Mitigation Opportunities; Food and Agriculture Organization of the United Nations (FAO): Rome, Italy, 2013; ISBN 978-92-5-107920-1. [Google Scholar]

- Johannisson, J. Prospective Environmental Assessment of Technologies for Mitigating Methane Emissions. Doctoral Dissertation, Universität Ulm, Ulm, Germany, 2023. [Google Scholar]

- Niu, M.; Kebreab, E.; Hristov, A.N.; Oh, J.; Arndt, C.; Bannink, A.; Bayat, A.R.; Brito, A.F.; Boland, T.; Casper, D.; et al. Prediction of Enteric Methane Production, Yield, and Intensity in Dairy Cattle Using an Intercontinental Database. Glob. Chang. Biol. 2018, 24, 3368–3389. [Google Scholar] [CrossRef] [PubMed]

- Opio, C.; Gerber, P.; Mottet, A.; Falcucci, A.; Tempio, G.; MacLeod, M.; Vellinga, T.; Henderson, B.; Steinfeld, H. Greenhouse Gas Emissions from Ruminant Supply Chains—A Global Life Cycle Assessment; Food and Agriculture Organization of the United Nations (FAO): Rome, Italy, 2013. [Google Scholar]

- Beauchemin, K.A.; Ungerfeld, E.M.; Eckard, R.J.; Wang, M. Review: Fifty Years of Research on Rumen Methanogenesis: Lessons Learned and Future Challenges for Mitigation. Animal 2020, 14, S2–S16. [Google Scholar] [CrossRef] [PubMed]

- Gomaa, A.S.; Kholif, A.E.; Kholif, A.M.; Salama, R.; El-Alamy, H.A.; Olafadehan, O.A. Sunflower Oil and Nannochloropsis oculata Microalgae as Sources of Unsaturated Fatty Acids for Mitigation of Methane Production and Enhancing Diets’ Nutritive Value. J. Agric. Food Chem. 2018, 66, 1751–1759. [Google Scholar] [CrossRef] [PubMed]

- El-Zaiat, H.M.; Kholif, A.E.; Moharam, M.S.; Attia, M.F.; Abdalla, A.L.; Sallam, S.M.A. The Ability of Tanniniferous Legumes to Reduce Methane Production and Enhance Feed Utilization in Barki Rams: In Vitro and In Vivo Evaluation. Small Rumin. Res. 2020, 193, 106259. [Google Scholar] [CrossRef]

- Morsy, T.A.; Gouda, G.A.G.A.; Kholif, A.E. In Vitro Fermentation and Production of Methane and Carbon Dioxide from Rations Containing Moringa oleifera Leave Silage as a Replacement of Soybean Meal: In Vitro Assessment. Environ. Sci. Pollut. Res. 2022, 29, 69743–69752. [Google Scholar] [CrossRef] [PubMed]

- Zmora, P.; Cieślak, A.; Pers-Kamczyc, E.; Szyszka, P.; Szumacher-Strabel, M. An In Vitro Study on the Effect of Sage, Salvia officinalis L., on Rumen Fermentation. J. Anim. Feed Sci. 2012, 21, 613–623. [Google Scholar] [CrossRef]

- Hosseini, S.M.; Rezaei, J.; Rouzbehan, Y. Nutritive Value of Adiantum Capillus-Veneris and Salvia officinalis L. Forages and the Effect of Their Dietary Levels on In Vitro Digestibility, Methane Production, Antioxidant Capacity, and Fermentation Parameters. Anim. Prod. Res. 2022, 11, 1–15. [Google Scholar] [CrossRef]

- Benchaar, C.; Calsamiglia, S.; Chaves, A.V.; Fraser, G.R.; Colombatto, D.; McAllister, T.A.; Beauchemin, K.A. A Review of Plant-Derived Essential Oils in Ruminant Nutrition and Production. Anim. Feed Sci. Technol. 2008, 145, 209–228. [Google Scholar] [CrossRef]

- Kahvand, M.; Malecky, M. Dose-Response Effects of Sage (Salvia officinalis) and Yarrow (Achillea millefolium) Essential Oils on Rumen Fermentation In Vitro. Ann. Anim. Sci. 2018, 18, 125–142. [Google Scholar] [CrossRef]

- Kholif, A.E.; Hassan, A.A.; El Ashry, G.M.; Bakr, M.H.; El-Zaiat, H.M.; Olafadehan, O.A.; Matloup, O.H.; Sallam, S.M.A. Phytogenic Feed Additives Mixture Enhances the Lactational Performance, Feed Utilization and Ruminal Fermentation of Friesian Cows. Anim. Biotechnol. 2021, 32, 708–718. [Google Scholar] [CrossRef]

- Ghazy, O.A.; Fouad, M.T.; Morsy, T.A.; Kholif, A.E. Nanoemulsion Formulation of Lawsonia inermis Extract and Its Potential Antimicrobial and Preservative Efficacy against Foodborne Pathogens. Food Control 2023, 145, 109458. [Google Scholar] [CrossRef]

- Ghazy, O.A.; Fouad, M.T.; Saleh, H.H.; Kholif, A.E.; Morsy, T.A. Ultrasound-Assisted Preparation of Anise Extract Nanoemulsion and Its Bioactivity against Different Pathogenic Bacteria. Food Chem. 2021, 341, 128259. [Google Scholar] [CrossRef] [PubMed]

- Kholif, A.E.; Olafadehan, O.A. Essential Oils and Phytogenic Feed Additives in Ruminant Diet: Chemistry, Ruminal Microbiota and Fermentation, Feed Utilization and Productive Performance. Phytochem. Rev. 2021, 20, 1087–1108. [Google Scholar] [CrossRef]

- Broudiscou, L.P.; Papon, Y.; Broudiscou, A.F. Effects of Dry Plant Extracts on Fermentation and Methanogenesis in Continuous Culture of Rumen Microbes. Anim. Feed Sci. Technol. 2000, 87, 263–277. [Google Scholar] [CrossRef]

- Bokharaeian, M.; Ghoorchi, T.; Toghdory, A.; Esfahani, I.J. The Dose-Dependent Role of Sage, Clove, and Pine Essential Oils in Modulating Ruminal Fermentation and Biohydrogenation of Polyunsaturated Fatty Acids: A Promising Strategy to Reduce Methane Emissions and Enhance the Nutritional Profile of Ruminant Produc. Appl. Sci. 2023, 13, 11605. [Google Scholar] [CrossRef]

- Kholif, A.E. A Review of Effect of Saponins on Ruminal Fermentation, Health and Performance of Ruminants. Vet. Sci. 2023, 10, 450. [Google Scholar] [CrossRef] [PubMed]

- Goering, H.K.; Van Soest, P.J. Forage Fiber Analyses; ARS-USDA: Washington, DC, USA, 1975.

- Fortina, R.; Glorio Patrucco, S.; Barbera, S.; Tassone, S. Rumen Fluid from Slaughtered Animals: A Standardized Procedure for Sampling, Storage and Use in Digestibility Trials. Methods Protoc. 2022, 5, 59. [Google Scholar] [CrossRef] [PubMed]

- AOAC. Official Methods of Analysis of AOAC International, 16th ed.; AOAC International: Washington DC, USA, 1997; ISBN 9780935584547. [Google Scholar]

- Van Soest, P.J.; Robertson, J.B.; Lewis, B.A. Methods for Dietary Fiber, Neutral Detergent Fiber, and Nonstarch Polysaccharides in Relation to Animal Nutrition. J. Dairy Sci. 1991, 74, 3583–3597. [Google Scholar] [CrossRef] [PubMed]

- France, J.; Dijkstra, J.; Dhanoa, M.S.; Lopez, S.; Bannink, A. Estimating the Extent of Degradation of Ruminant Feeds from a Description of Their Gas Production Profiles Observed In Vitro: Derivation of Models and Other Mathematical Considerations. Br. J. Nutr. 2000, 83, 143–150. [Google Scholar] [CrossRef]

- Blümmel, M.; Steingaβ, H.; Becker, K. The Relationship between In Vitro Gas Production, In Vitro Microbial Biomass Yield and 15 N Incorporation and Its Implications for the Prediction of Voluntary Feed Intake of Roughages. Br. J. Nutr. 1997, 77, 911–921. [Google Scholar] [CrossRef]

- Menke, K.H.; Raab, L.; Salewski, A.; Steingass, H.; Fritz, D.; Schneider, W. The Estimation of the Digestibility and Metabolizable Energy Content of Ruminant Feedingstuffs from the Gas Production When They Are Incubated with Rumen Liquor In Vitro. J. Agric. Sci. 1979, 93, 217–222. [Google Scholar] [CrossRef]

- Sharma, Y.; Velamuri, R.; Fagan, J.; Schaefer, J.; Streicher, C.; Stimson, J. Identification and Characterization of Polyphenols and Volatile Terpenoid Compounds in Different Extracts of Garden Sage (Salvia officinalis L.). Pharmacogn. Res. 2020, 12, 149. [Google Scholar] [CrossRef]

- Baranauskiene, R.; Dambrauskiene, E.; Venskutonis, P.R.; Viskelis, P. Influence of Harvesting Time on the Yield and Chemical Composition of Sage (Salvia officinalis L.). In Proceedings of the 6th Baltic Conference on Food Science and Technology: Innovations for Food Science and Production, FOODBALT-2011—Conference Proceedings, Jelgava, Latvia, 5–6 May 2011; pp. 104–109. [Google Scholar]

- de Sousa, D.P.; Damasceno, R.O.S.; Amorati, R.; Elshabrawy, H.A.; de Castro, R.D.; Bezerra, D.P.; Nunes, V.R.V.; Gomes, R.C.; Lima, T.C. Essential Oils: Chemistry and Pharmacological Activities. Biomolecules 2023, 13, 1144. [Google Scholar] [CrossRef] [PubMed]

- Woodward, S.L.; Waghorn, G.C.; Ulyatt, M.J.; Lassey, K.R. Early Indications That Feeding Lotus Will Reduce Methane Emissions from Ruminants. Proc. N. Z. Soc. Anim. Prod. 2001, 61, 23–26. [Google Scholar]

- Ebeid, H.M.; Mengwei, L.; Kholif, A.E.; ul Hassan, F.; Lijuan, P.; Xin, L.; Chengjian, Y. Moringa oleifera Oil Modulates Rumen Microflora to Mediate In Vitro Fermentation Kinetics and Methanogenesis in Total Mix Rations. Curr. Microbiol. 2020, 77, 1271–1282. [Google Scholar] [CrossRef] [PubMed]

- Ammar, H.; Kholif, A.E.; Soltan, Y.A.; Almadani, M.I.; Soufan, W.; Morsy, A.S.; Ouerghemmi, S.; Chahine, M.; de Haro Marti, M.E.; Hassan, S.; et al. Nutritive Value of Ajuga iva as a Pastoral Plant for Ruminants: Plant Phytochemicals and In Vitro Gas Production and Digestibility. Agriculture 2022, 12, 1199. [Google Scholar] [CrossRef]

- Hart, K.J.; Yáñez-Ruiz, D.R.; Duval, S.M.; McEwan, N.R.; Newbold, C.J. Plant Extracts to Manipulate Rumen Fermentation. Anim. Feed Sci. Technol. 2008, 147, 8–35. [Google Scholar] [CrossRef]

- Calsamiglia, S.; Busquet, M.; Cardozo, P.W.; Castillejos, L.; Ferret, A. Invited Review: Essential Oils as Modifiers of Rumen Microbial Fermentation. J. Dairy Sci. 2007, 90, 2580–2595. [Google Scholar] [CrossRef]

- Macheboeuf, D.; Morgavi, D.P.; Papon, Y.; Mousset, J.-L.; Arturo-Schaan, M. Dose–Response Effects of Essential Oils on In Vitro Fermentation Activity of the Rumen Microbial Population. Anim. Feed Sci. Technol. 2008, 145, 335–350. [Google Scholar] [CrossRef]

- Kholif, A.E.; Gouda, G.A.; Morsy, T.A.; Matloup, O.H.; Fahmy, M.; Gomaa, A.S.; Patra, A.K. Dietary Date Palm Leaves Ensiled with Fibrolytic Enzymes Decreased Methane Production, and Improved Feed Degradability and Fermentation Kinetics in a Ruminal In Vitro System. Waste Biomass Valori. 2022, 13, 3475–3488. [Google Scholar] [CrossRef]

- Kholif, A.E.; Gouda, G.A.; Morsy, T.A.; Matloup, O.H.; Sallam, S.M.; Patra, A.K. Associative Effects between Chlorella vulgaris Microalgae and Moringa oleifera Leaf Silage Used at Different Levels Decreased In Vitro Ruminal Greenhouse Gas Production and Altered Ruminal Fermentation. Environ. Sci. Pollut. Res. 2023, 30, 6001–6020. [Google Scholar] [CrossRef] [PubMed]

- Gunal, M.; Ishlak, A.; Abughazaleh, A.A. Evaluating the Effects of Six Essential Oils on Fermentation and Biohydrogenation in In Vitro Rumen Batch Cultures. Czech J. Anim. Sci. 2013, 58, 243–252. [Google Scholar] [CrossRef]

- Patra, A.K.; Saxena, J. A New Perspective on the Use of Plant Secondary Metabolites to Inhibit Methanogenesis in the Rumen. Phytochemistry 2010, 71, 1198–1222. [Google Scholar] [CrossRef]

- Wang, K.; Xiong, B.; Zhao, X. Could Propionate Formation Be Used to Reduce Enteric Methane Emission in Ruminants? Sci. Total Environ. 2023, 855, 158867. [Google Scholar] [CrossRef] [PubMed]

- Kamra, D.N.; Patra, A.K.; Chatterjee, P.N.; Kumar, R.; Agarwal, N.; Chaudhary, L.C. Effect of Plant Extracts on Methanogenesis and Microbial Profile of the Rumen of Buffalo: A Brief Overview. Aust. J. Exp. Agric. 2008, 48, 175–178. [Google Scholar] [CrossRef]

- Pinski, B.; Günal, M.; Abughazaleh, A.A. The Effects of Essential Oil and Condensed Tannin on Fermentation and Methane Production under In Vitro Conditions. Anim. Prod. Sci. 2016, 56, 1707–1713. [Google Scholar] [CrossRef]

- Haisan, J.; Sun, Y.; Guan, L.L.; Beauchemin, K.A.; Iwaasa, A.; Duval, S.; Barreda, D.R.; Oba, M. The Effects of Feeding 3-Nitrooxypropanol on Methane Emissions and Productivity of Holstein Cows in Mid Lactation. J. Dairy Sci. 2014, 97, 3110–3119. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Dagar, S.S.; Sirohi, S.K.; Upadhyay, R.C.; Puniya, A.K. Microbial Profiles, In Vitro Gas Production and Dry Matter Digestibility Based on Various Ratios of Roughage to Concentrate. Ann. Microbiol. 2013, 63, 541–545. [Google Scholar] [CrossRef]

- Kazana, P.; Siachos, N.; Panousis, N.; Petridou, A.; Mougios, V.; Valergakis, G.E. Phenotypical Variation of Ruminal Volatile Fatty Acids and PH during the Peri-Weaning Period in Holstein Calves and Factors Affecting Them. Animals 2022, 12, 894. [Google Scholar] [CrossRef]

- Castillejos, L.; Calsamiglia, S.; Ferret, A. Effect of Essential Oil Active Compounds on Rumen Microbial Fermentation and Nutrient Flow in In Vitro Systems. J. Dairy Sci. 2006, 89, 2649–2658. [Google Scholar] [CrossRef]

- Castillejos, L.; Calsamiglia, S.; Martín-Tereso, J.; Ter Wijlen, H. In Vitro Evaluation of Effects of Ten Essential Oils at Three Doses on Ruminal Fermentation of High Concentrate Feedlot-Type Diets. Anim. Feed Sci. Technol. 2008, 145, 259–270. [Google Scholar] [CrossRef]

- Nolan, J.V.; Dobos, R.C. Nitrogen Transactions in Ruminants. In Quantitative Aspects of Ruminant Digestion and Metabolism; CABI Publishing: Cambridge, UK, 2005; pp. 177–206. [Google Scholar]

- Hailemariam, S.; Zhao, S.; He, Y.; Wang, J. Urea Transport and Hydrolysis in the Rumen: A Review. Anim. Nutr. 2021, 7, 989–996. [Google Scholar] [CrossRef] [PubMed]

- Kholif, A.E.; Gouda, G.A.; Fahmy, M.; Morsy, T.A.; Abdelsattar, M.M.; Vargas-Bello-Pérez, E. Fennel Seeds Dietary Inclusion as a Sustainable Approach to Reduce Methane Production and Improve Nutrient Utilization and Ruminal Fermentation. Anim. Sci. J. 2024, 95, e13910. [Google Scholar] [CrossRef] [PubMed]

- Mandal, S.M.; Chakraborty, D.; Dey, S. Phenolic Acids Act as Signaling Molecules in Plant-Microbe Symbioses. Plant Signal. Behav. 2010, 5, 359–368. [Google Scholar] [CrossRef] [PubMed]

- Boucher, S.E.; Ordway, R.S.; Whitehouse, N.L.; Lundy, F.P.; Kononoff, P.J.; Schwab, C.G. Effect of Incremental Urea Supplementation of a Conventional Corn Silage-Based Diet on Ruminal Ammonia Concentration and Synthesis of Microbial Protein. J. Dairy Sci. 2007, 90, 5619–5633. [Google Scholar] [CrossRef] [PubMed]

- Agarwal, N.; Shekhar, C.; Kumar, R.; Chaudhary, L.C.; Kamra, D.N. Effect of Peppermint (Mentha piperita) Oil on In Vitro Methanogenesis and Fermentation of Feed with Buffalo Rumen Liquor. Anim. Feed Sci. Technol. 2009, 148, 321–327. [Google Scholar] [CrossRef]

- Patra, A.K.; Kamra, D.N.; Agarwal, N. Effect of Plant Extracts on In Vitro Methanogenesis, Enzyme Activities and Fermentation of Feed in Rumen Liquor of Buffalo. Anim. Feed Sci. Technol. 2006, 128, 276–291. [Google Scholar] [CrossRef]

| Salvia officinalis | CGM 1 | Berseem Hay | Rice Straw | Diet 2 | |

|---|---|---|---|---|---|

| Dry matter | 931 | 903 | 890 | 940 | 893 |

| Organic matter | 821 | 923 | 884 | 851 | 819 |

| Crude protein | 56 | 165 | 128 | 42 | 136 |

| Ether extract | 94 | 47 | 54 | 19 | 62 |

| Nonstructural carbohydrates | 306 | 414 | 224 | 166 | 359 |

| Neutral detergent fiber | 365 | 297 | 478 | 624 | 379 |

| Acid detergent fiber | 177 | 175 | 381 | 394 | 240 |

| Compound 1 | Concentration 2 (%) |

|---|---|

| α-Pinene | 15.85 |

| α-Thujone | 15.62 |

| Camphor | 15.20 |

| 1,8-cineole | 13.20 |

| β-Pinene | 10.84 |

| Camphene | 6.86 |

| Limonene | 5.22 |

| β-Thujone | 3.90 |

| Borneol | 2.55 |

| Borneol | 2.30 |

| β-Caryophyllene | 2.20 |

| p-Cymene | 2.00 |

| β-Myrcene | 1.52 |

| α-Terpineol | 0.76 |

| Thujone | 0.50 |

| Verbenol | 0.37 |

| L-Fenchone | 0.35 |

| Estragole | 0.31 |

| Linalool | 0.28 |

| Tricyclene | 0.17 |

| GP Parameters 1 | CH4 Parameters 2 | CO2 Parameters 3 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Level | A | c | Lag | A | c | Lag | A | c | Lag | ||

| 0 | 78b | 0.076ab | 1.55bc | 29a | 0.035b | 1.42c | 59b | 0.036c | 2.47 | ||

| 0.5 | 108a | 0.077a | 1.43c | 27ab | 0.040b | 1.56bc | 66ab | 0.049bc | 1.87 | ||

| 1 | 115a | 0.077a | 1.33c | 26abc | 0.048ab | 1.62abc | 65ab | 0.053abc | 1.70 | ||

| 1.5 | 77b | 0.076ab | 1.89ab | 23bc | 0.053ab | 1.78ab | 70a | 0.063ab | 1.90 | ||

| 2 | 71b | 0.069b | 2.08a | 22c | 0.060a | 1.87a | 70a | 0.074a | 2.11 | ||

| SEM | 2.4b | 0.0017 | 0.076 | 0.8 | 0.0041 | 0.057 | 2.3 | 0.0049 | 0.229 | ||

| p value | |||||||||||

| Treatment | <0.001 | 0.022 | <0.001 | 0.003 | 0.009 | 0.002 | 0.035 | 0.003 | 0.232 | ||

| Linear | 0.001 | 0.017 | 0.001 | 0.002 | 0.006 | <0.001 | 0.005 | 0.002 | 0.360 | ||

| Quadratic | <0.001 | 0.015 | 0.002 | 0.902 | 0.950 | 0.988 | 0.279 | 0.901 | 0.042 | ||

| Degradability 1 | SCFA 2 | Fermentation 3 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Level | dDM | dNDF | dADF | Total | C2 | C3 | C4 | pH | NH3-N | ME | PF24 | MCP | ||

| 0 | 0.473ab | 0.439bc | 0.412b | 23.4c | 11.4b | 7.9b | 4.1 | 6.27a | 10.4 | 4.68b | 7.22a | 328a | ||

| 0.5 | 0.521b | 0.519a | 0.444ab | 25.0b | 12.5ab | 8.7ab | 3.8 | 6.27a | 11.8 | 5.00a | 5.72b | 321b | ||

| 1 | 0.582a | 0.555a | 0.508a | 28.5a | 14.0a | 9.6a | 4.9 | 6.10b | 12.7 | 5.17a | 5.98b | 368a | ||

| 1.5 | 0.481b | 0.459b | 0.433b | 23.1c | 11.3bc | 7.7b | 4.0 | 6.33a | 11.6 | 4.28c | 7.46a | 338ab | ||

| 2 | 0.429c | 0.411c | 0.392b | 21.2d | 9.7c | 7.5b | 4.0 | 6.37a | 11.4 | 4.08c | 7.49a | 303b | ||

| SEM | 0.0107 | 0.0095 | 0.0146 | 0.29 | 0.36 | 0.27 | 0.28 | 0.030 | 0.50 | 0.06 | 0.19 | 8.6 | ||

| p value | ||||||||||||||

| Treatment | <0.001 | <0.001 | 0.002 | <0.001 | <0.001 | 0.002 | 0.121 | 0.008 | 0.102 | <0.001 | <0.001 | 0.004 | ||

| Linear | 0.004 | 0.004 | 0.293 | <0.001 | 0.002 | 0.069 | 0.944 | 0.018 | 0.326 | <0.001 | 0.003 | 0.254 | ||

| Quadratic | <0.001 | <0.001 | 0.004 | <0.001 | <0.001 | 0.008 | 0.212 | 0.002 | 0.021 | <0.001 | 0.001 | 0.002 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kholif, A.E.; Rahman, M.A.; Abo El-Nor, S.A.H.; Morsy, T.A.; Gouda, G.A.; Fahmy, M.; Chahine, M. Efficacy of Salvia officinalis Shrub as a Sustainable Feed Additive for Reducing Ruminal Methane Production and Enhancing Fermentation in Ruminants. Animals 2024, 14, 1648. https://doi.org/10.3390/ani14111648

Kholif AE, Rahman MA, Abo El-Nor SAH, Morsy TA, Gouda GA, Fahmy M, Chahine M. Efficacy of Salvia officinalis Shrub as a Sustainable Feed Additive for Reducing Ruminal Methane Production and Enhancing Fermentation in Ruminants. Animals. 2024; 14(11):1648. https://doi.org/10.3390/ani14111648

Chicago/Turabian StyleKholif, Ahmed E., Md Atikur Rahman, Salah A. H. Abo El-Nor, Tarek A. Morsy, Gouda A. Gouda, Mahmoud Fahmy, and Mireille Chahine. 2024. "Efficacy of Salvia officinalis Shrub as a Sustainable Feed Additive for Reducing Ruminal Methane Production and Enhancing Fermentation in Ruminants" Animals 14, no. 11: 1648. https://doi.org/10.3390/ani14111648