Reappraisal of the ASTM/AASHTO Standard Rolling Device Method for Plastic Limit Determination of Fine-Grained Soils

Abstract

:1. Introduction

2. Database of PLRT–PLBG Tests

3. Results and Discussion

3.1. Statistical Appraisal of the PLRT–PLBG Relationship

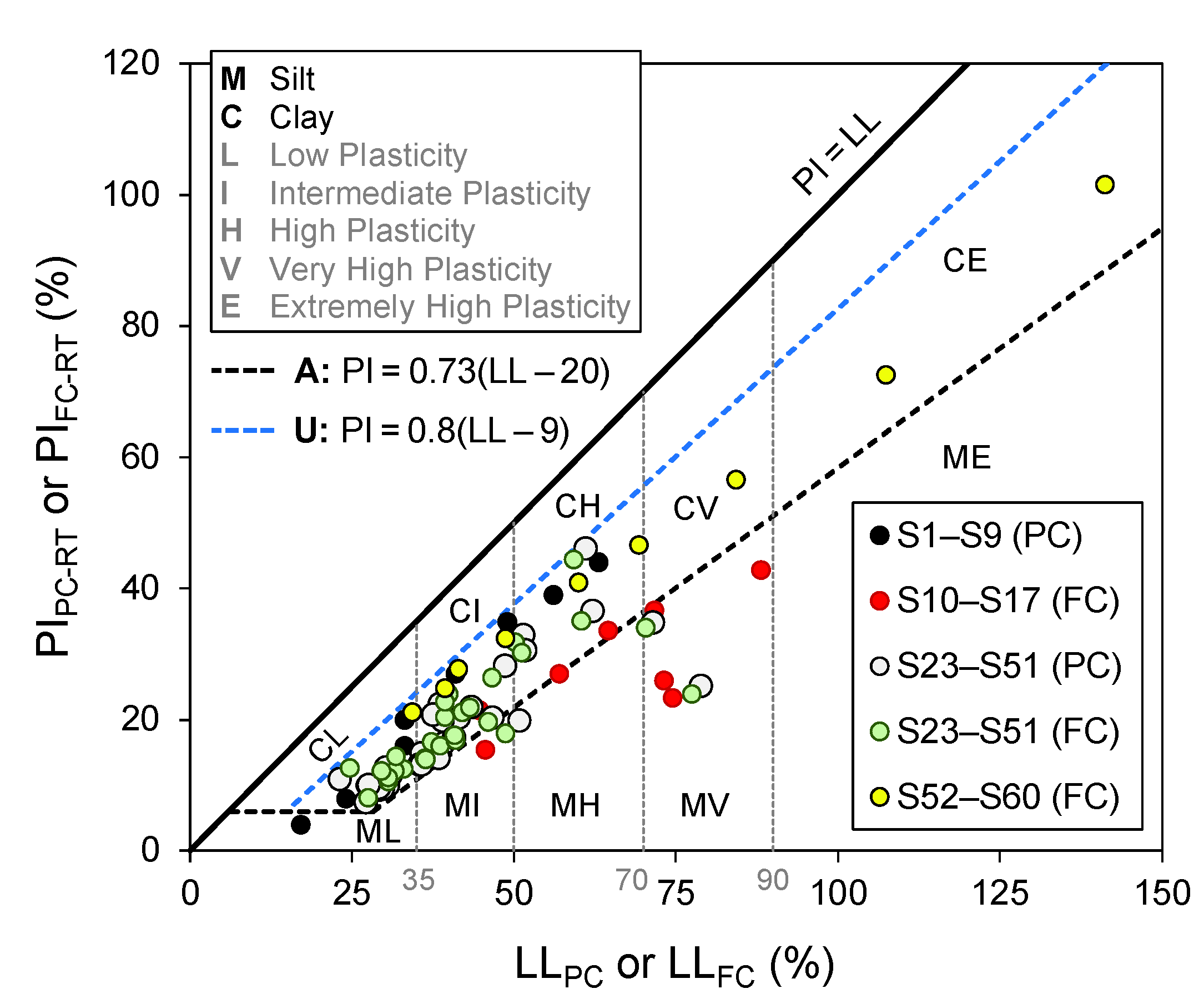

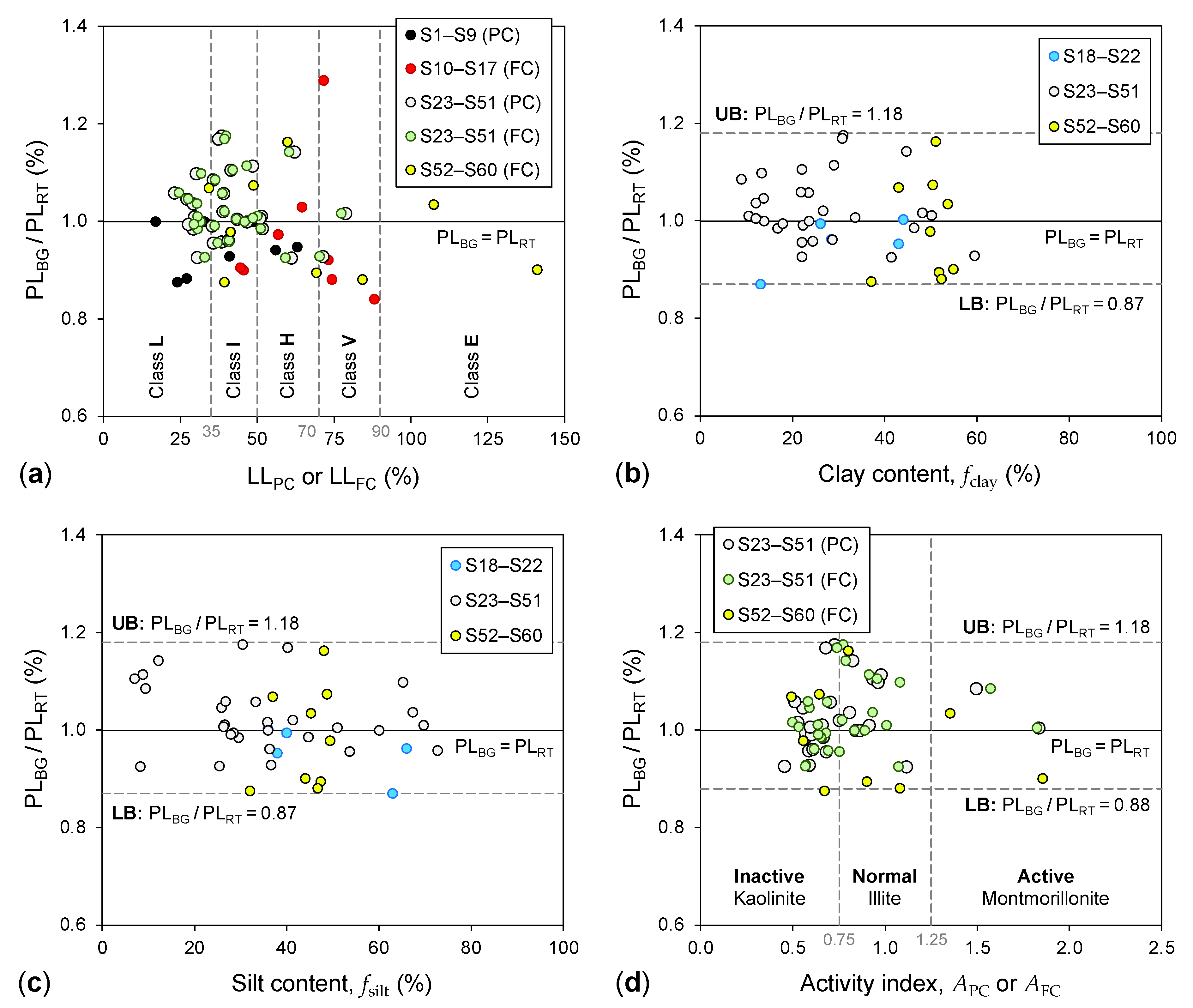

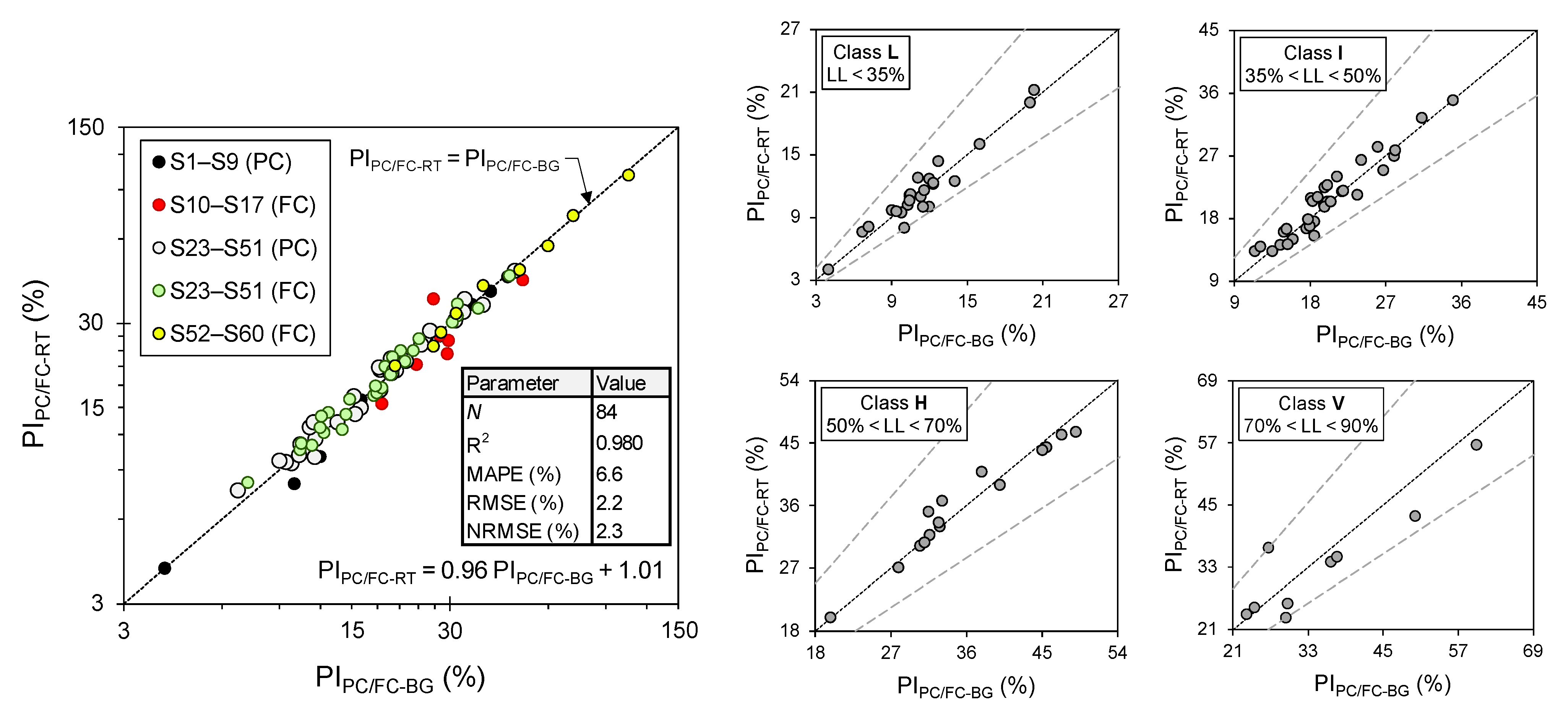

3.2. Use of PLBG for Soil Classification

4. Summary and Conclusions

- Following a comprehensive statistical analysis performed on a large and diverse database of 60 PLRT–PLBG test pairs, it was demonstrated that, under identical testing conditions, the BG-based and RT methods produce essentially similar PL values (i.e., PLRT ≈ PLBG). The 95% lower and upper agreement limits between PLBG and PLRT were obtained as −5.03% and +4.51%, respectively; implying that 95% of the differences between the two PL measurement methods lie between these two small water content limits, both of which can be deemed “statistically insignificant” when compared to the inductively-defined reference limit of ±8% (i.e., the highest possible difference/variation in the PLRT based on its repeatability, as reported in the research literature).

- Further, the likelihoods of underestimating (i.e., PLBG < PLRT) and overestimating (i.e., PLBG > PLRT) the PLRT were obtained as 50% and 40%, respectively; thereby, debunking the notion presented by some researchers that the BG method generally tends to greatly underestimate the PLRT. It was also demonstrated that the degree of underestimation or overestimation does not systematically increase or decrease with changes in fundamental soil properties (i.e., plasticity level class, clay and silt contents, and soil mineralogy); suggesting that the differences between PLBG and PLRT are most likely random in nature.

- Finally, making use of the BS soil plasticity-chart framework, an attempt, for the first time, was made to examine the validity of the PLBG parameter in the context of fine-grained soil classification. Compared to PLRT, the likelihood of achieving consistent soil classifications employing the PLBG (in conjunction with LLPC and/or LLFC) was shown to be 98%, with the classification discrepancies (only two cases out of 84 examined) being soil materials that plot relatively close to the A-Line. This implies that the PLBG parameter, as determined using the ASTM D4318/AASHTO T90 rolling device method, can be used with confidence for routine soil classification purposes.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AASHTO | American Association of State Highway and Transportation Officials |

| ASTM | American Society for Testing and Materials |

| BA | Bland–Altman (analysis/plot) |

| BG | Bobrowski and Griekspoor (method/device) |

| BS | British Standard |

| CE | Clay with extremely high plasticity |

| CH | Clay with high plasticity |

| CI | Clay with intermediate plasticity |

| CL | Clay with low plasticity |

| CV | Clay with very high plasticity |

| FC | Fall-cone (method) |

| ME | Silt with extremely high plasticity |

| MH | Silt with high plasticity |

| MI | Silt with intermediate plasticity |

| ML | Silt with low plasticity |

| MV | Silt with very high plasticity |

| PC | Percussion-cup (method) |

| RT | Rolling-thread (method) |

| USCS | Unified Soil Classification System |

Notations

| AFC | Soil activity index (=PIFC-RT/fclay) |

| APC | Soil activity index (=PIPC-RT/fclay) |

| d | Cone penetration depth (FC test) [mm] |

| DBA | Plastic limit difference, defined as DBA = PLBG − PLRT [%] |

| DA | Actual vertical distance from the A-Line [%] |

| fclay | Clay content [%] |

| fsilt | Silt content [%] |

| LAL | Lower (water content) agreement limit [%] |

| LB | Lower (PLBG-to-PLRT variation) boundary |

| LLFC | Fall-cone liquid limit [%] |

| LLPC | Percussion-cup liquid limit [%] |

| MBA | Plastic limit average, defined as MBA = (PLBG + PLRT)/2 [%] |

| MAPE | Mean absolute percentage error [%] |

| n | Index of summation |

| N | Number of tests/observations |

| Nb | Number of blows (PC test) |

| NRMSE | Normalized root-mean-squared error [%] |

| PIFC-BG | Plasticity index (= LLFC − PLBG) [%] |

| PIFC-RT | Plasticity index (= LLFC − PLRT) [%] |

| PIPC-BG | Plasticity index (= LLPC − PLBG) [%] |

| PIPC-RT | Plasticity index (= LLPC − PLRT) [%] |

| PLBG | Device-rolling plastic limit [%] |

| PLRT | Thread-rolling (by hand) plastic limit [%] |

| PLRT(max) | Maximum of PLRT data [%] |

| PLRT(min) | Minimum of PLRT data [%] |

| R2 | Coefficient of determination |

| RMSE | Root-mean-squared error [% water content] |

| UAL | Upper (water content) agreement limit [%] |

| UB | Upper (PLBG-to-PLRT variation) boundary |

| w | Gravimetric water content [%] |

| μD | Arithmetic mean of DBA (=PLBG − PLRT) data [%] |

| σD | Standard deviation of DBA (=PLBG − PLRT) data [%] |

References

- Atterberg, A. Lerornas forhållande till vatten, deras plasticitetsgränser och plasticitetsgrader. K. Lantbr. Handl. Och Tidskr. 1911, 50, 132–158. (In Swedish) [Google Scholar]

- Atterberg, A. Die plastizität der tone. Int. Mitt. Der Bodenkd. 1911, 1, 4–37. (In German) [Google Scholar]

- Terzaghi, K. Simplified soil tests for subgrades and their physical significance. Public Roads 1926, 7, 153–170. [Google Scholar]

- Terzaghi, K. Principles of final soil classification. Public Roads 1926, 8, 41–53. [Google Scholar]

- Casagrande, A. Research on the Atterberg limits of soils. Public Roads 1932, 13, 121–136. [Google Scholar]

- Casagrande, A. Notes on the design of the liquid limit device. Géotechnique 1958, 8, 84–91. [Google Scholar] [CrossRef]

- AASHTO M145. Standard Specification for Classification of Soils and Soil–Aggregate Mixtures for Highway Construction Purposes; American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 1995. [Google Scholar]

- ASTM D3282. Standard Practice for Classification of Soils and Soil–Aggregate Mixtures for Highway Construction Purposes; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar] [CrossRef]

- BS 5930. Code of Practice for Ground Investigations; British Standards Institution (BSI): London, UK, 2015; ISBN 9780539081350. [Google Scholar]

- ASTM D2487. Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System); ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar] [CrossRef]

- Skemption, A.W.; Northey, R.D. The sensitivity of clays. Géotechnique 1952, 3, 30–53. [Google Scholar] [CrossRef]

- Seed, H.B.; Woodward, R.J.; Lundgren, R. Prediction of swelling potential for compacted clays. J. Soil Mech. Found. Div. 1962, 88, 53–87. [Google Scholar] [CrossRef]

- Nayak, N.V.; Christensen, R.W. Swelling characteristics of compacted, expansive soils. Clays Clay Miner. 1971, 19, 251–261. [Google Scholar] [CrossRef]

- Wroth, C.P.; Wood, D.M. Correlation of index properties with some basic engineering properties of soils. Can. Geotech. J. 1978, 15, 137–145. [Google Scholar] [CrossRef]

- Carrier, W.D. Consolidation parameters derived from index tests. Géotechnique 1985, 35, 211–213. [Google Scholar] [CrossRef]

- Nakase, A.; Kamei, T.; Kusakabe, O. Constitutive parameters estimated by plasticity index. J. Geotech. Eng. 1988, 114, 844–858. [Google Scholar] [CrossRef]

- Nagaraj, T.S.; Pandian, N.S.; Narashimha Raju, P.S.R. Stress state–permeability relationships for fine-grained soils. Géotechnique 1993, 43, 333–336. [Google Scholar] [CrossRef]

- Gurtug, Y.; Sridharan, A. Compaction behaviour and prediction of its characteristics of fine grained soils with particular reference to compaction energy. Soils Found. 2004, 44, 27–36. [Google Scholar] [CrossRef] [Green Version]

- Erzin, Y.; Erol, O. Swell pressure prediction by suction methods. Eng. Geol. 2007, 92, 133–145. [Google Scholar] [CrossRef]

- Dolinar, B. Predicting the hydraulic conductivity of saturated clays using plasticity-value correlations. Appl. Clay Sci. 2009, 45, 90–94. [Google Scholar] [CrossRef]

- Dolinar, B. Predicting the normalized, undrained shear strength of saturated fine-grained soils using plasticity-value correlations. Appl. Clay Sci. 2010, 47, 428–432. [Google Scholar] [CrossRef]

- O’Kelly, B.C. Atterberg limits and remolded shear strength–water content relationships. Geotech. Test. J. 2013, 36, 939–947. [Google Scholar] [CrossRef]

- Vardanega, P.J.; Haigh, S.K. The undrained strength–liquidity index relationship. Can. Geotech. J. 2014, 51, 1073–1086. [Google Scholar] [CrossRef] [Green Version]

- Kootahi, K.; Mayne, P.W. Index test method for estimating the effective preconsolidation stress in clay deposits. J. Geotech. Geoenviron. Eng. 2016, 142, 04016049. [Google Scholar] [CrossRef]

- Soltani, A.; Deng, A.; Taheri, A.; Sridharan, A. Consistency limits and compaction characteristics of clay soils containing rubber waste. Proc. Inst. Civ. Eng. Geotech. Eng. 2019, 172, 174–188. [Google Scholar] [CrossRef] [Green Version]

- Wood, D.M. Soil Behaviour and Critical State Soil Mechanics, 1st ed.; Cambridge University Press: Cambridge, UK, 1991; ISBN 9780521337823. [Google Scholar]

- Dolinar, B.; Trauner, L. Liquid limit and specific surface of clay particles. Geotech. Test. J. 2004, 27, 580–584. [Google Scholar] [CrossRef]

- Trauner, L.; Dolinar, B.; Mišič, M. Relationship between the undrained shear strength, water content, and mineralogical properties of fine-grained soils. Int. J. Geomech. 2005, 5, 350–355. [Google Scholar] [CrossRef]

- AASHTO T89. Standard Method of Test. for Determining the Liquid Limit of Soils; American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2013. [Google Scholar]

- ASTM D4318. Standard Test. Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar] [CrossRef]

- BS 1377–2. Methods of Test. for Soils for Civil. Engineering Purposes—Part. 2: Classification Tests; British Standards Institution (BSI): London, UK, 1990; ISBN 0580178676. [Google Scholar]

- BS EN 1997–2. Eurocode 7—Geotechnical Design—Part. 2: Ground Investigation and Testing; British Standards Institution (BSI): London, UK, 2007; ISBN 9780580718724. [Google Scholar]

- AS 1289.3.9.1. Methods of Testing Soils for Engineering Purposes: Soil Classification Tests—Determination of the Cone Liquid Limit of a Soil; Standards Australia (SA): Sydney, Australia, 2015; ISBN 9781760352974. [Google Scholar]

- O’Kelly, B.C.; Vardanega, P.J.; Haigh, S.K. Use of fall cones to determine Atterberg limits: A review. Géotechnique 2018, 68, 843–856. [Google Scholar] [CrossRef] [Green Version]

- Wood, D.M.; Wroth, C.P. The use of the cone penetrometer to determine the plastic limit of soils. Gr. Eng. 1978, 11, 37. [Google Scholar]

- Haigh, S.K.; Vardanega, P.J.; Bolton, M.D. The plastic limit of clays. Géotechnique 2013, 63, 435–440. [Google Scholar] [CrossRef] [Green Version]

- AS 1289.3.2.1. Methods of Testing Soils for Engineering Purposes: Soil Classification Tests—Determination of the Plastic Limit of a Soil —Standard Method; Standards Australia (SA): Sydney, Australia, 2009; ISBN 0733790054. [Google Scholar]

- AASHTO T90. Standard Method of Test. for Determining the Plastic Limit and Plasticity Index of Soils; American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2020. [Google Scholar]

- Sherwood, P.T.; Ryley, M.D. An investigation of a cone-penetrometer method for the determination of the liquid limit. Géotechnique 1970, 20, 203–208. [Google Scholar] [CrossRef]

- Belviso, R.; Ciampoli, S.; Cotecchia, V.; Federico, A. Use of cone penetrometer to determine consistency limits. Gr. Eng. 1985, 18, 21–22. [Google Scholar]

- Sridharan, A.; Nagaraj, H.B.; Prakash, K. Determination of the plasticity index from flow index. Geotech. Test. J. 1999, 22, 175–181. [Google Scholar] [CrossRef]

- Feng, T.W. Using a small ring and a fall-cone to determine the plastic limit. J. Geotech. Geoenviron. Eng. 2004, 130, 630–635. [Google Scholar] [CrossRef]

- Sivakumar, V.; Glynn, D.; Cairns, P.; Black, J.A. A new method of measuring plastic limit of fine materials. Géotechnique 2009, 59, 813–823. [Google Scholar] [CrossRef]

- Sivakumar, V.; O’Kelly, B.C.; Henderson, L.; Moorhead, C.; Chow, S.H. Measuring the plastic limit of fine soils: An experimental study. Proc. Inst. Civ. Eng. Geotech. Eng. 2015, 168, 53–64. [Google Scholar] [CrossRef]

- Vardanega, P.J.; Haigh, S.K. Some recent developments in the determination of the Atterberg limits. In Advances in Transportation Geotechnics and Materials for Sustainable Infrastructure (GSP 250); Bulut, R., Hsu, S.C., Eds.; American Society of Civil Engineers (ASCE): Reston, VA, USA, 2014; pp. 48–55. ISBN 9780784478509. [Google Scholar] [CrossRef] [Green Version]

- O’Kelly, B.C. Reappraisal of soil extrusion for geomechanical characterisation. Geotech. Res. 2019, 6, 265–287. [Google Scholar] [CrossRef] [Green Version]

- O’Kelly, B.C. Review of recent developments and understanding of Atterberg limits determinations. Geotechnics 2021, 1, 59–75. [Google Scholar] [CrossRef]

- Prakash, K. Discussion of “Plastic limit, liquid limit, and undrained shear strength of soil—reappraisal” by Binu Sharma and Padma K. Bora. J. Geotech. Geoenviron. Eng. 2005, 131, 402. [Google Scholar] [CrossRef]

- Nagaraj, H.B.; Sridharan, A.; Mallikarjuna, H.M. Re-examination of undrained strength at Atterberg limits water contents. Geotech. Geol. Eng. 2012, 30, 727–736. [Google Scholar] [CrossRef]

- O’Kelly, B.C.; Vardanega, P.J.; Haigh, S.K.; Barnes, G.E. Discussion: Use of fall cones to determine Atterberg limits: A review. Géotechnique 2020, 70, 647–651. [Google Scholar] [CrossRef] [Green Version]

- Gay, G.C.W.; Kaiser, W. Mechanization for remolding fine grained soils and for the plastic limit test. J. Test. Eval. 1973, 1, 317–318. [Google Scholar] [CrossRef]

- Bobrowski, L.J.; Griekspoor, D.M. Determination of the plastic limit of a soil by means of a rolling device. Geotech. Test. J. 1992, 15, 284–287. [Google Scholar] [CrossRef]

- Temyingyong, A.; Chantawarangul, K.; Sudasna-na-Ayudthya, P. Statistical analysis of influenced factors affecting the plastic limit of soils. Kasetsart J. Nat. Sci. 2002, 36, 98–102. [Google Scholar]

- Barnes, G.E. An apparatus for the plastic limit and workability of soils. Proc. Inst. Civ. Eng. Geotech. Eng. 2009, 162, 175–185. [Google Scholar] [CrossRef]

- Kayabali, K. Determination of consistency limits: A comparison between –#40 and –#200 materials. Electron. J. Geotech. Eng. 2011, 16, 1547–1561. [Google Scholar]

- Kayabali, K. An alternative testing tool for plastic limit. Electron. J. Geotech. Eng. 2012, 17, 2107–2114. [Google Scholar]

- Barnes, G.E. An apparatus for the determination of the workability and plastic limit of clays. Appl. Clay Sci. 2013, 80–81, 281–290. [Google Scholar] [CrossRef]

- Barnes, G.E. The Plastic Limit and Workability of Soils. Ph.D. Thesis, The University of Manchester, Manchester, UK, 2013. [Google Scholar]

- De Oliveira Modesto, C.; Bernardin, A.M. Determination of clay plasticity: Indentation method versus Pfefferkorn method. Appl. Clay Sci. 2008, 40, 15–19. [Google Scholar] [CrossRef]

- Moreno-Maroto, J.M.; Alonso-Azcárate, J. An accurate, quick and simple method to determine the plastic limit and consistency changes in all types of clay and soil: The thread-bending test. Appl. Clay Sci. 2015, 114, 497–508. [Google Scholar] [CrossRef]

- Moreno-Maroto, J.M.; Alonso-Azcárate, J. A bending test for determining the Atterberg plastic limit in soils. J. Vis. Exp. 2016, 112, e54118. [Google Scholar] [CrossRef]

- Moreno-Maroto, J.M.; Alonso-Azcárate, J. Plastic limit and other consistency parameters by a bending method and interpretation of plasticity classification in soils. Geotech. Test. J. 2017, 40, 467–482. [Google Scholar] [CrossRef]

- Rashid, A.S.A.; Kassim, K.A.; Katimon, A.; Noor, N.M. Determination of plastic limit of soil using modified methods. Malays. J. Civ. Eng. 2008, 20, 295–305. [Google Scholar] [CrossRef]

- Ishaque, F.; Hoque, M.N.; Rashid, M.A. Determination of plastic limit of some selected soils using rolling device. Progress. Agric. 2013, 21, 187–194. [Google Scholar] [CrossRef] [Green Version]

- Rehman, H.U.; Pouladi, N.; Pulido-Moncada, M.; Arthur, E. Repeatability and agreement between methods for determining the Atterberg limits of fine-grained soils. Soil Sci. Soc. Am. J. 2020, 84, 21–30. [Google Scholar] [CrossRef]

- Casagrande, A. Classification and identification of soils. Proc. Am. Soc. Civ. Eng. 1947, 73, 783–810. [Google Scholar]

- Soltani, A.; O’Kelly, B.C. Discussion of “The flow index of clays and its relationship with some basic geotechnical properties” by G. Spagnoli, M. Feinendegen, L. Di Matteo, and D. A. Rubinos, published in Geotechnical Testing Journal 42, No. 6 (2019): 1685–1700. Geotech. Test. J. 2021, 44, 216–219. [Google Scholar] [CrossRef]

- Soltani, A.; Deng, A.; Taheri, A.; Sridharan, A.; Estabragh, A.R. A framework for interpretation of the compressibility behavior of soils. Geotech. Test. J. 2018, 41. [Google Scholar] [CrossRef]

- Bland, J.M.; Altman, D.G. Measuring agreement in method comparison studies. Stat. Methods Med. Res. 1999, 8, 135–160. [Google Scholar] [CrossRef] [PubMed]

| Source | Source ID/Description | New ID | fclay (%) | fsilt (%) | LLPC (%) | LLFC (%) | PLRT (%) | PLBG (%) | PIPC-RT (%) | PIFC-RT (%) | APC | AFC |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [52] | 1 | S1 | — | — | 17.0 | — | 13.0 | 13.0 | 4.0 | — | — | — |

| 2 | S2 | — | — | 24.0 | — | 16.0 | 14.0 | 8.0 | — | — | — | |

| 3 | S3 | — | — | 27.0 | — | 17.0 | 15.0 | 10.0 | — | — | — | |

| 4 | S4 | — | — | 33.0 | — | 17.0 | 17.0 | 16.0 | — | — | — | |

| 5 | S5 | — | — | 33.0 | — | 13.0 | 13.0 | 20.0 | — | — | — | |

| 6 | S6 | — | — | 41.0 | — | 14.0 | 13.0 | 27.0 | — | — | — | |

| 7 | S7 | — | — | 49.0 | — | 14.0 | 14.0 | 35.0 | — | — | — | |

| 8 | S8 | — | — | 56.0 | — | 17.0 | 16.0 | 39.0 | — | — | — | |

| 9 | S9 | — | — | 63.0 | — | 19.0 | 18.0 | 44.0 | — | — | — | |

| [63] | Sample A | S10 | — | — | — | 73.1 | 47.1 | 43.4 | — | 26.0 | — | — |

| Sample B | S11 | — | — | — | 56.9 | 29.8 | 29.0 | — | 27.1 | — | — | |

| Sample C | S12 | — | — | — | 64.5 | 30.9 | 31.8 | — | 33.6 | — | — | |

| Sample D | S13 | — | — | — | 45.5 | 30.0 | 27.0 | — | 15.5 | — | — | |

| Sample E | S14 | — | — | — | 44.6 | 23.2 | 21.0 | — | 21.4 | — | — | |

| Sample F | S15 | — | — | — | 74.4 | 51.1 | 45.0 | — | 23.3 | — | — | |

| Sample G | S16 | — | — | — | 88.1 | 45.2 | 38.0 | — | 42.9 | — | — | |

| Sample H | S17 | — | — | — | 71.6 | 34.9 | 45.0 | — | 36.7 | — | — | |

| [64] | Agronomy Farm | S18 | 13.0 | 63.0 | — | — | 23.0 | 20.0 | — | — | — | — |

| Lalmai | S19 | 26.0 | 40.0 | — | — | 21.1 | 21.0 | — | — | — | — | |

| Gaghra | S20 | 28.4 | 66.0 | — | — | 25.3 | 24.3 | — | — | — | — | |

| Bhaluka | S21 | 43.0 | 38.0 | — | — | 27.8 | 26.5 | — | — | — | — | |

| Bhoraduba | S22 | 44.0 | 36.0 | — | — | 29.9 | 30.0 | — | — | — | — | |

| [65] | DK2 | S23 | 22.0 | 7.0 | 41.4 | 42.0 | 20.9 | 23.1 | 20.5 | 21.1 | 0.93 | 0.96 |

| DK3 | S24 | 28.9 | 8.8 | 48.5 | 46.6 | 20.2 | 22.5 | 28.3 | 26.4 | 0.98 | 0.91 | |

| DK4 | S25 | 44.6 | 12.2 | 62.0 | 60.4 | 25.3 | 28.9 | 36.7 | 35.1 | 0.82 | 0.79 | |

| CH1 | S26 | 22.0 | 53.7 | 35.6 | 37.2 | 20.6 | 19.7 | 15.0 | 16.6 | 0.68 | 0.75 | |

| CH2 | S27 | 48.1 | 35.8 | 78.7 | 77.4 | 53.4 | 54.3 | 25.3 | 24.0 | 0.53 | 0.50 | |

| CH3 | S28 | 59.5 | 36.6 | 71.3 | 70.3 | 36.3 | 33.7 | 35.0 | 34.0 | 0.59 | 0.57 | |

| CH4 | S29 | 16.7 | 29.6 | 29.1 | 30.6 | 19.6 | 19.3 | 9.5 | 11.0 | 0.57 | 0.66 | |

| CH5 | S30 | 26.6 | 41.3 | 38.9 | 39.3 | 18.9 | 19.3 | 20.0 | 20.4 | 0.75 | 0.77 | |

| DE1 | S31 | 22.0 | 25.4 | 30.4 | 32.9 | 20.4 | 18.9 | 10.0 | 12.5 | 0.45 | 0.57 | |

| DE2 | S32 | 13.7 | 25.9 | 27.0 | 27.5 | 19.4 | 20.3 | 7.6 | 8.1 | 0.55 | 0.59 | |

| DE3 | S33 | 50.1 | 26.5 | 51.3 | 50.1 | 18.3 | 18.5 | 33.0 | 31.8 | 0.66 | 0.63 | |

| DE4 | S34 | 23.5 | 33.3 | 39.0 | 38.6 | 22.5 | 23.8 | 16.5 | 16.1 | 0.70 | 0.69 | |

| BE1 | S35 | 13.8 | 60.1 | 30.9 | 31.6 | 19.3 | 19.3 | 11.6 | 12.3 | 0.84 | 0.89 | |

| BE2 | S36 | 13.3 | 65.2 | 30.1 | 31.7 | 17.3 | 19.0 | 12.8 | 14.4 | 0.96 | 1.08 | |

| BE3 | S37 | 10.5 | 69.7 | 29.6 | 30.6 | 20.0 | 20.2 | 9.6 | 10.6 | 0.91 | 1.01 | |

| BE4 | S38 | 12.0 | 67.3 | 29.0 | 30.5 | 19.3 | 20.0 | 9.7 | 11.2 | 0.81 | 0.93 | |

| PK1 | S39 | 17.9 | 28.4 | 27.5 | 29.5 | 17.3 | 17.2 | 10.2 | 12.2 | 0.57 | 0.68 | |

| PK2 | S40 | 24.4 | 72.7 | 38.3 | 40.9 | 24.0 | 23.0 | 14.3 | 16.9 | 0.59 | 0.69 | |

| PK3 | S41 | 46.3 | 44.7 | 51.6 | 51.1 | 20.9 | 20.6 | 30.7 | 30.2 | 0.66 | 0.65 | |

| PK4 | S42 | 21.8 | 26.8 | 23.0 | 24.6 | 11.9 | 12.6 | 11.1 | 12.7 | 0.51 | 0.58 | |

| PK5 | S43 | 31.0 | 30.5 | 38.4 | 39.9 | 15.9 | 18.7 | 22.5 | 24.0 | 0.73 | 0.77 | |

| PK6 | S44 | 30.8 | 40.2 | 37.4 | 39.3 | 16.5 | 19.3 | 20.9 | 22.8 | 0.68 | 0.74 | |

| UA1 | S45 | 22.2 | 27.9 | 35.3 | 36.2 | 22.0 | 21.8 | 13.3 | 14.2 | 0.60 | 0.64 | |

| UA2 | S46 | 8.9 | 9.4 | 35.6 | 36.3 | 22.3 | 24.2 | 13.3 | 14.0 | 1.49 | 1.57 | |

| GH | S47 | 41.4 | 8.3 | 61.0 | 59.2 | 14.8 | 13.7 | 46.2 | 44.4 | 1.12 | 1.07 | |

| CN1 | S48 | 28.6 | 36.3 | 40.6 | 40.8 | 23.2 | 22.3 | 17.4 | 17.6 | 0.61 | 0.62 | |

| CN2 | S49 | 12.0 | 51.0 | 43.3 | 43.2 | 21.3 | 21.4 | 22.0 | 21.9 | 1.83 | 1.83 | |

| NO | S50 | 23.6 | 36.0 | 46.6 | 45.9 | 26.2 | 26.2 | 20.4 | 19.7 | 0.86 | 0.83 | |

| JP | S51 | 33.6 | 26.3 | 50.7 | 48.6 | 30.7 | 30.9 | 20.0 | 17.9 | 0.60 | 0.53 | |

| Present Study | Kilkenny, South Australia | S52 | 43.0 | 37.0 | — | 34.3 | 13.1 | 14.0 | — | 21.2 | — | 0.49 |

| Inkerman, South Australia | S53 | 37.0 | 32.0 | — | 39.3 | 14.4 | 12.6 | — | 24.9 | — | 0.67 | |

| Kaolinite | S54 | 49.8 | 49.4 | — | 41.4 | 13.6 | 13.3 | — | 27.8 | — | 0.56 | |

| Kaolinite + 5% Bentonite | S55 | 50.4 | 48.7 | — | 48.7 | 16.2 | 17.4 | — | 32.5 | — | 0.64 | |

| Kaolinite + 10% Bentonite | S56 | 51.0 | 48.1 | — | 59.9 | 19.0 | 22.1 | — | 40.9 | — | 0.80 | |

| Kaolinite + 15% Bentonite | S57 | 51.7 | 47.4 | — | 69.3 | 22.7 | 20.3 | — | 46.6 | — | 0.90 | |

| Kaolinite + 20% Bentonite | S58 | 52.3 | 46.7 | — | 84.3 | 27.7 | 24.4 | — | 56.6 | — | 1.08 | |

| Kaolinite + 30% Bentonite | S59 | 53.6 | 45.3 | — | 107.4 | 34.8 | 36.0 | — | 72.6 | — | 1.35 | |

| Kaolinite + 40% Bentonite | S60 | 54.8 | 44.0 | — | 141.1 | 39.5 | 35.6 | — | 101.6 | — | 1.85 |

| ID | LLPC (%) | LLFC (%) | PLRT (%) | PLBG (%) | PIPC-RT (%) | PIFC-RT (%) | USCSPC-RT | USCSFC-RT | PIPC-BG (%) | PIFC-BG (%) | USCSPC-BG | USCSFC-BG |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S1 | 17.0 | — | 13.0 | 13.0 | 4.0 | — | ML | — | 4.0 | — | ML | — |

| S2 | 24.0 | — | 16.0 | 14.0 | 8.0 | — | CL | — | 10.0 | — | CL | — |

| S3 | 27.0 | — | 17.0 | 15.0 | 10.0 | — | CL | — | 12.0 | — | CL | — |

| S4 | 33.0 | — | 17.0 | 17.0 | 16.0 | — | CL | — | 16.0 | — | CL | — |

| S5 | 33.0 | — | 13.0 | 13.0 | 20.0 | — | CL | — | 20.0 | — | CL | — |

| S6 | 41.0 | — | 14.0 | 13.0 | 27.0 | — | CI | — | 28.0 | — | CI | — |

| S7 | 49.0 | — | 14.0 | 14.0 | 35.0 | — | CI | — | 35.0 | — | CI | — |

| S8 | 56.0 | — | 17.0 | 16.0 | 39.0 | — | CH | — | 40.0 | — | CH | — |

| S9 | 63.0 | — | 19.0 | 18.0 | 44.0 | — | CH | — | 45.0 | — | CH | — |

| S10 | — | 73.1 | 47.1 | 43.4 | — | 26.0 | — | MV | — | 29.7 | — | MV |

| S11 | — | 56.9 | 29.8 | 29.0 | — | 27.1 | — | CH | — | 27.9 | — | CH |

| S12 | — | 64.5 | 30.9 | 31.8 | — | 33.6 | — | CH | — | 32.7 | — | CH |

| S13 | — | 45.5 | 30.0 | 27.0 | — | 15.5 | — | MI | — | 18.5 | — | MI |

| S14 | — | 44.6 | 23.2 | 21.0 | — | 21.4 | — | CI | — | 23.6 | — | CI |

| S15 | — | 74.4 | 51.1 | 45.0 | — | 23.3 | — | MV | — | 29.4 | — | MV |

| S16 | — | 88.1 | 45.2 | 38.0 | — | 42.9 | — | MV | — | 50.1 | — | CV |

| S17 | — | 71.6 | 34.9 | 45.0 | — | 36.7 | — | MV | — | 26.6 | — | MV |

| S23 | 41.4 | 42.0 | 20.9 | 23.1 | 20.5 | 21.1 | CI | CI | 18.3 | 18.9 | CI | CI |

| S24 | 48.5 | 46.6 | 20.2 | 22.5 | 28.3 | 26.4 | CI | CI | 26.0 | 24.1 | CI | CI |

| S25 | 62.0 | 60.4 | 25.3 | 28.9 | 36.7 | 35.1 | CH | CH | 33.1 | 31.5 | CH | CH |

| S26 | 35.6 | 37.2 | 20.6 | 19.7 | 15.0 | 16.6 | CI | CI | 15.9 | 17.5 | CI | CI |

| S27 | 78.7 | 77.4 | 53.4 | 54.3 | 25.3 | 24.0 | MV | MV | 24.4 | 23.1 | MV | MV |

| S28 | 71.3 | 70.3 | 36.3 | 33.7 | 35.0 | 34.0 | MV | MV | 37.6 | 36.6 | CV | MV |

| S29 | 29.1 | 30.6 | 19.6 | 19.3 | 9.5 | 11.0 | CL | CL | 9.8 | 11.3 | CL | CL |

| S30 | 38.9 | 39.3 | 18.9 | 19.3 | 20.0 | 20.4 | CI | CI | 19.6 | 20.0 | CI | CI |

| S31 | 30.4 | 32.9 | 20.4 | 18.9 | 10.0 | 12.5 | CL | CL | 11.5 | 14.0 | CL | CL |

| S32 | 27.0 | 27.5 | 19.4 | 20.3 | 7.6 | 8.1 | CL | CL | 6.7 | 7.2 | CL | CL |

| S33 | 51.3 | 50.1 | 18.3 | 18.5 | 33.0 | 31.8 | CH | CH | 32.8 | 31.6 | CH | CH |

| S34 | 39.0 | 38.6 | 22.5 | 23.8 | 16.5 | 16.1 | CI | CI | 15.2 | 14.8 | CI | CI |

| S35 | 30.9 | 31.6 | 19.3 | 19.3 | 11.6 | 12.3 | CL | CL | 11.6 | 12.3 | CL | CL |

| S36 | 30.1 | 31.7 | 17.3 | 19.0 | 12.8 | 14.4 | CL | CL | 11.1 | 12.7 | CL | CL |

| S37 | 29.6 | 30.6 | 20.0 | 20.2 | 9.6 | 10.6 | CL | CL | 9.4 | 10.4 | CL | CL |

| S38 | 29.0 | 30.5 | 19.3 | 20.0 | 9.7 | 11.2 | CL | CL | 9.0 | 10.5 | CL | CL |

| S39 | 27.5 | 29.5 | 17.3 | 17.2 | 10.2 | 12.2 | CL | CL | 10.3 | 12.3 | CL | CL |

| S40 | 38.3 | 40.9 | 24.0 | 23.0 | 14.3 | 16.9 | CI | CI | 15.3 | 17.9 | CI | CI |

| S41 | 51.6 | 51.1 | 20.9 | 20.6 | 30.7 | 30.2 | CH | CH | 31.0 | 30.5 | CH | CH |

| S42 | 23.0 | 24.6 | 11.9 | 12.6 | 11.1 | 12.7 | CL | CL | 10.4 | 12.0 | CL | CL |

| S43 | 38.4 | 39.9 | 15.9 | 18.7 | 22.5 | 24.0 | CI | CI | 19.7 | 21.2 | CI | CI |

| S44 | 37.4 | 39.3 | 16.5 | 19.3 | 20.9 | 22.8 | CI | CI | 18.1 | 20.0 | CI | CI |

| S45 | 35.3 | 36.2 | 22.0 | 21.8 | 13.3 | 14.2 | CI | CI | 13.5 | 14.4 | CI | CI |

| S46 | 35.6 | 36.3 | 22.3 | 24.2 | 13.3 | 14.0 | CI | CI | 11.4 | 12.1 | CI | CI |

| S47 | 61.0 | 59.2 | 14.8 | 13.7 | 46.2 | 44.4 | CH | CH | 47.3 | 45.5 | CH | CH |

| S48 | 40.6 | 40.8 | 23.2 | 22.3 | 17.4 | 17.6 | CI | CI | 18.3 | 18.5 | CI | CI |

| S49 | 43.3 | 43.2 | 21.3 | 21.4 | 22.0 | 21.9 | CI | CI | 21.9 | 21.8 | CI | CI |

| S50 | 46.6 | 45.9 | 26.2 | 26.2 | 20.4 | 19.7 | CI | CI | 20.4 | 19.7 | CI | CI |

| S51 | 50.7 | 48.6 | 30.7 | 30.9 | 20.0 | 17.9 | MH | MI | 19.8 | 17.7 | MH | MI |

| S52 | — | 34.3 | 13.1 | 14.0 | — | 21.2 | — | CL | — | 20.3 | — | CL |

| S53 | — | 39.3 | 14.4 | 12.6 | — | 24.9 | — | CI | — | 26.7 | — | CI |

| S54 | — | 41.4 | 13.6 | 13.3 | — | 27.8 | — | CI | — | 28.1 | — | CI |

| S55 | — | 48.7 | 16.2 | 17.4 | — | 32.5 | — | CI | — | 31.3 | — | CI |

| S56 | — | 59.9 | 19.0 | 22.1 | — | 40.9 | — | CH | — | 37.8 | — | CH |

| S57 | — | 69.3 | 22.7 | 20.3 | — | 46.6 | — | CH | — | 49.0 | — | CH |

| S58 | — | 84.3 | 27.7 | 24.4 | — | 56.6 | — | CV | — | 59.9 | — | CV |

| S59 | — | 107.4 | 34.8 | 36.0 | — | 72.6 | — | CE | — | 71.4 | — | CE |

| S60 | — | 141.1 | 39.5 | 35.6 | — | 101.6 | — | CE | — | 105.5 | — | CE |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soltani, A.; O’Kelly, B.C. Reappraisal of the ASTM/AASHTO Standard Rolling Device Method for Plastic Limit Determination of Fine-Grained Soils. Geosciences 2021, 11, 247. https://doi.org/10.3390/geosciences11060247

Soltani A, O’Kelly BC. Reappraisal of the ASTM/AASHTO Standard Rolling Device Method for Plastic Limit Determination of Fine-Grained Soils. Geosciences. 2021; 11(6):247. https://doi.org/10.3390/geosciences11060247

Chicago/Turabian StyleSoltani, Amin, and Brendan C. O’Kelly. 2021. "Reappraisal of the ASTM/AASHTO Standard Rolling Device Method for Plastic Limit Determination of Fine-Grained Soils" Geosciences 11, no. 6: 247. https://doi.org/10.3390/geosciences11060247

APA StyleSoltani, A., & O’Kelly, B. C. (2021). Reappraisal of the ASTM/AASHTO Standard Rolling Device Method for Plastic Limit Determination of Fine-Grained Soils. Geosciences, 11(6), 247. https://doi.org/10.3390/geosciences11060247