Conceptual and Applied Aspects of Water Retention Tests on Tailings Using Columns

Abstract

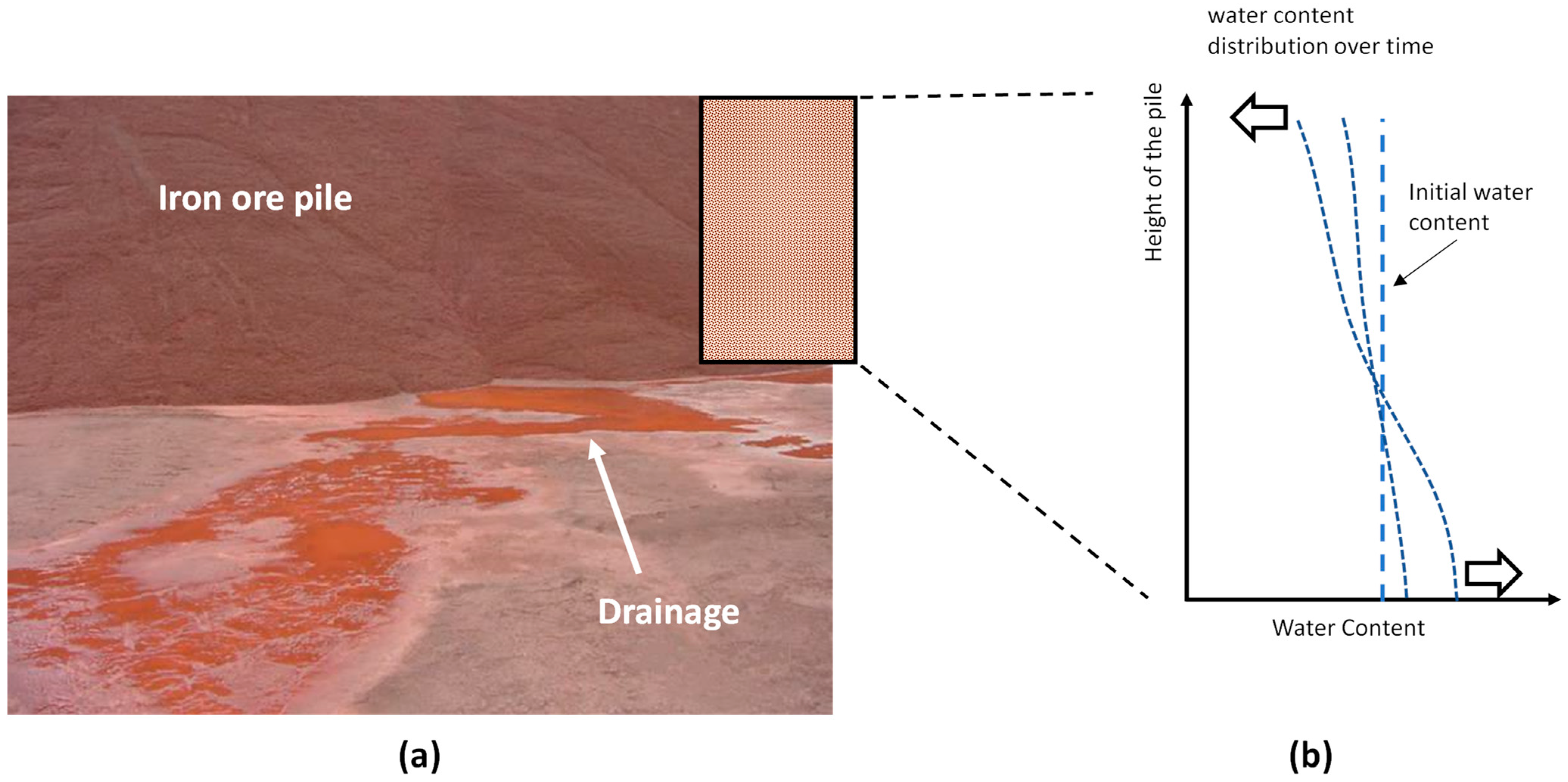

1. Introduction

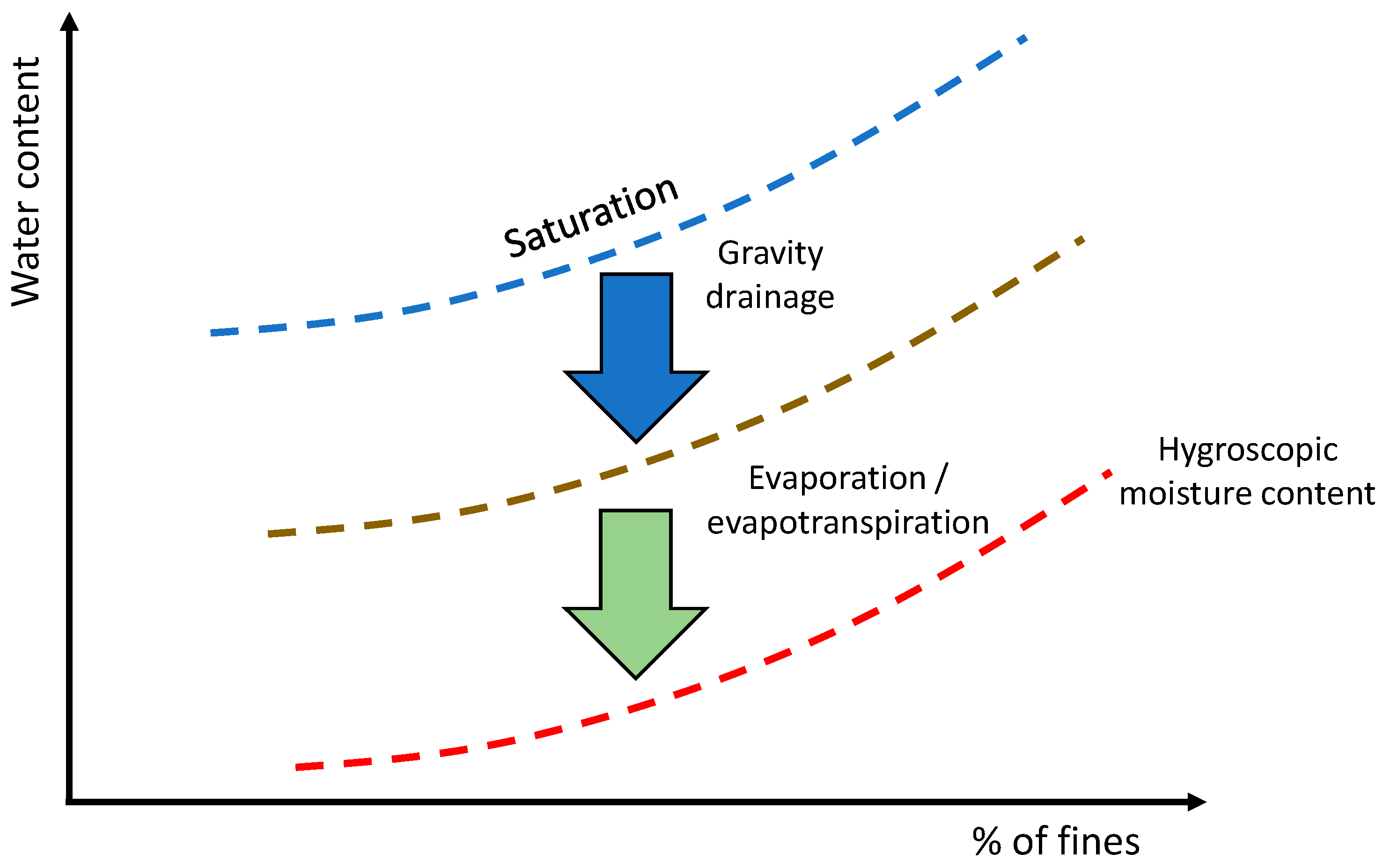

2. Water Retention in Porous Media

Water Retention Curves in Porous Media

3. Use of Columns for Water Retention Studies

4. Columns with Compacted Iron Ore Tailings

4.1. Materials

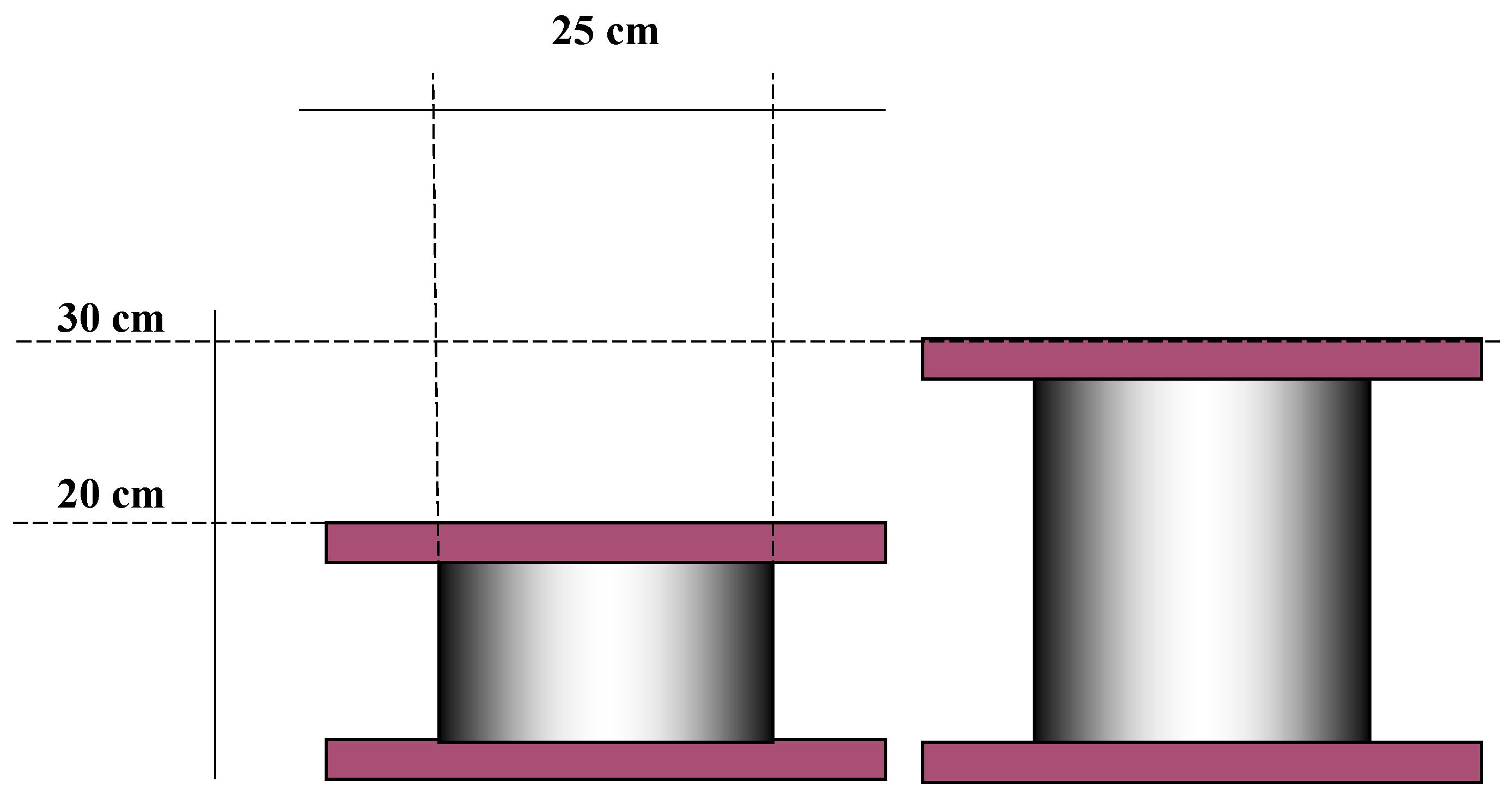

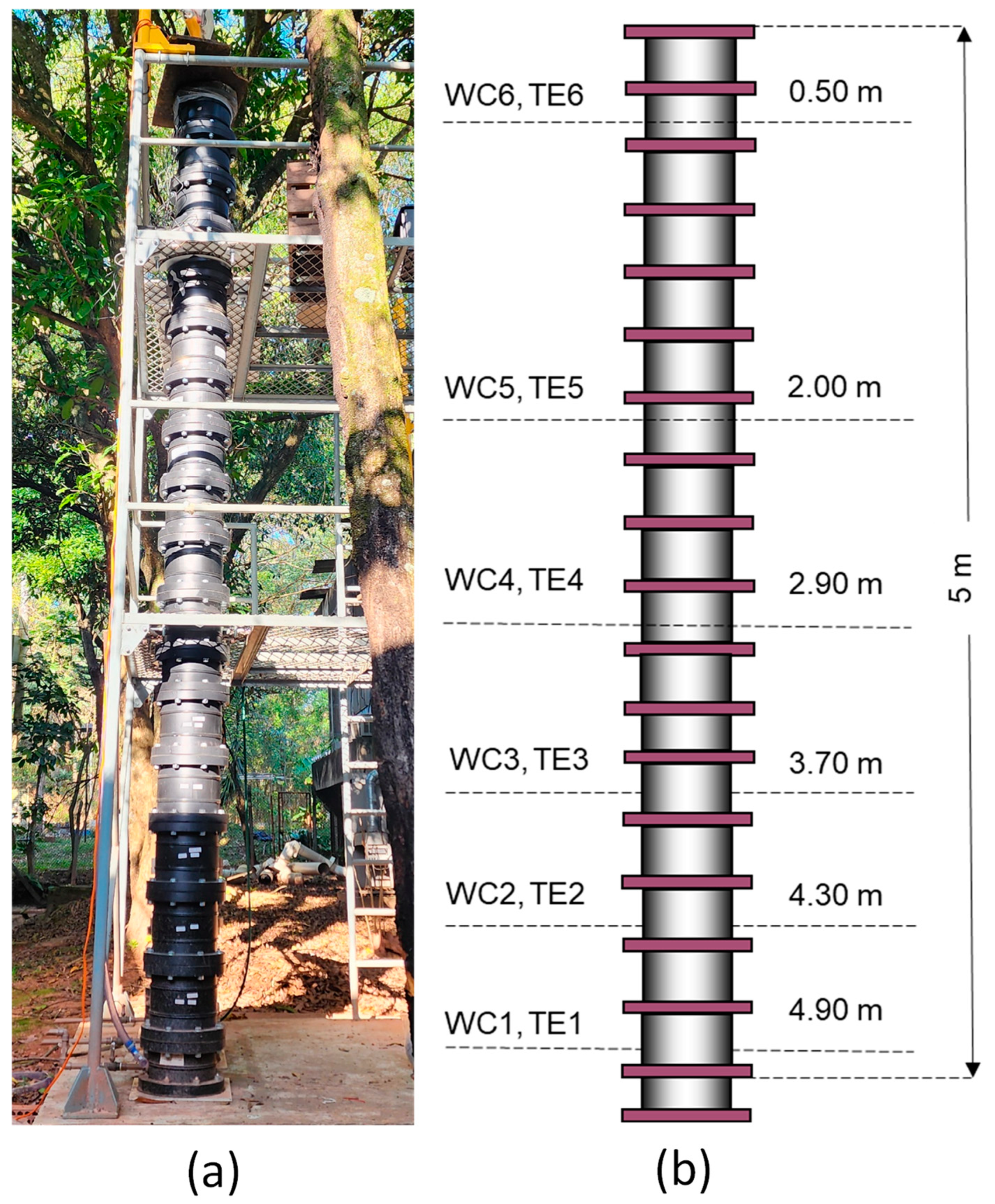

4.2. Column Assembly

4.3. Material Preparation and Compaction

4.4. Sensors and Installation

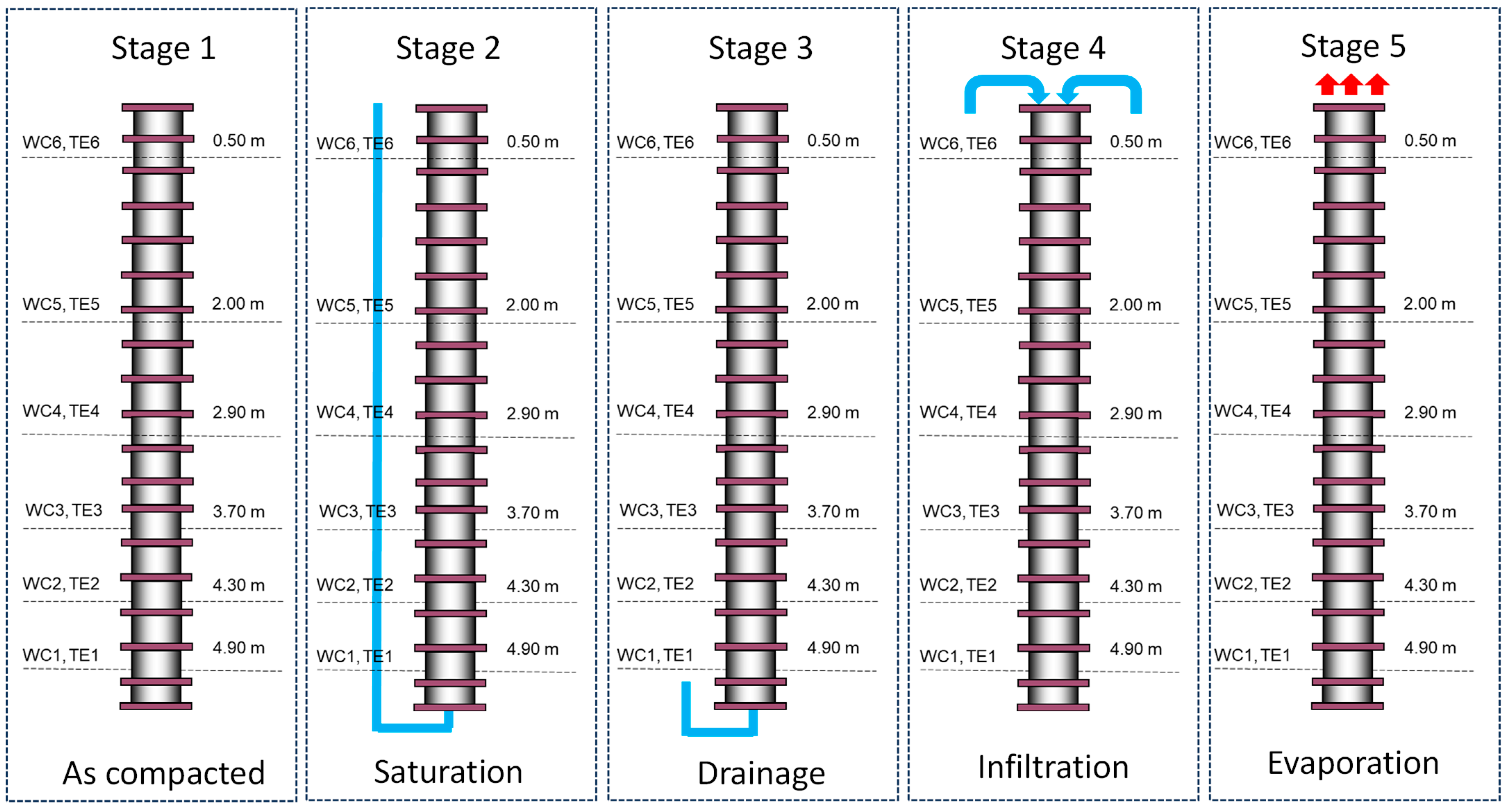

5. Experiments

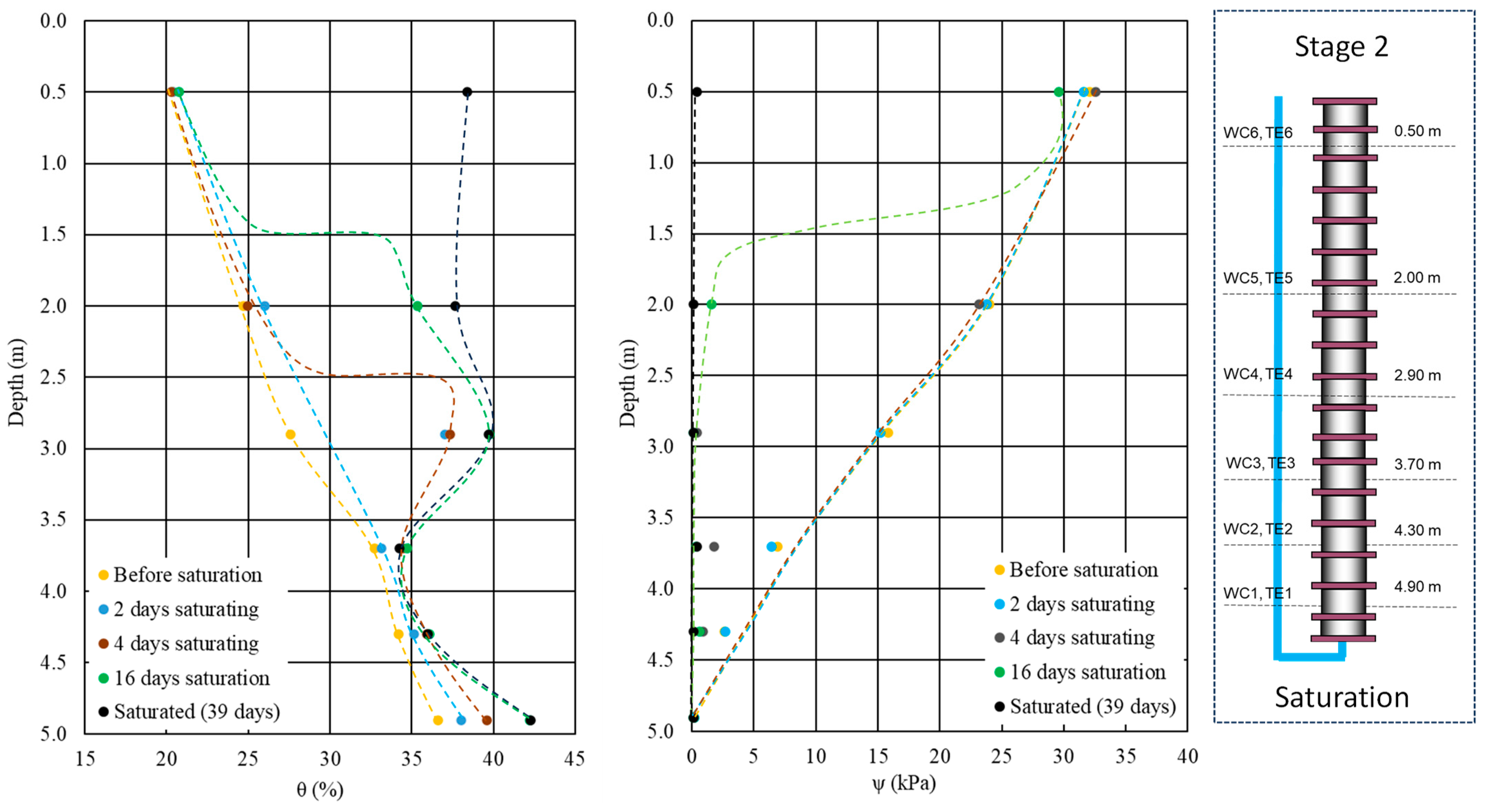

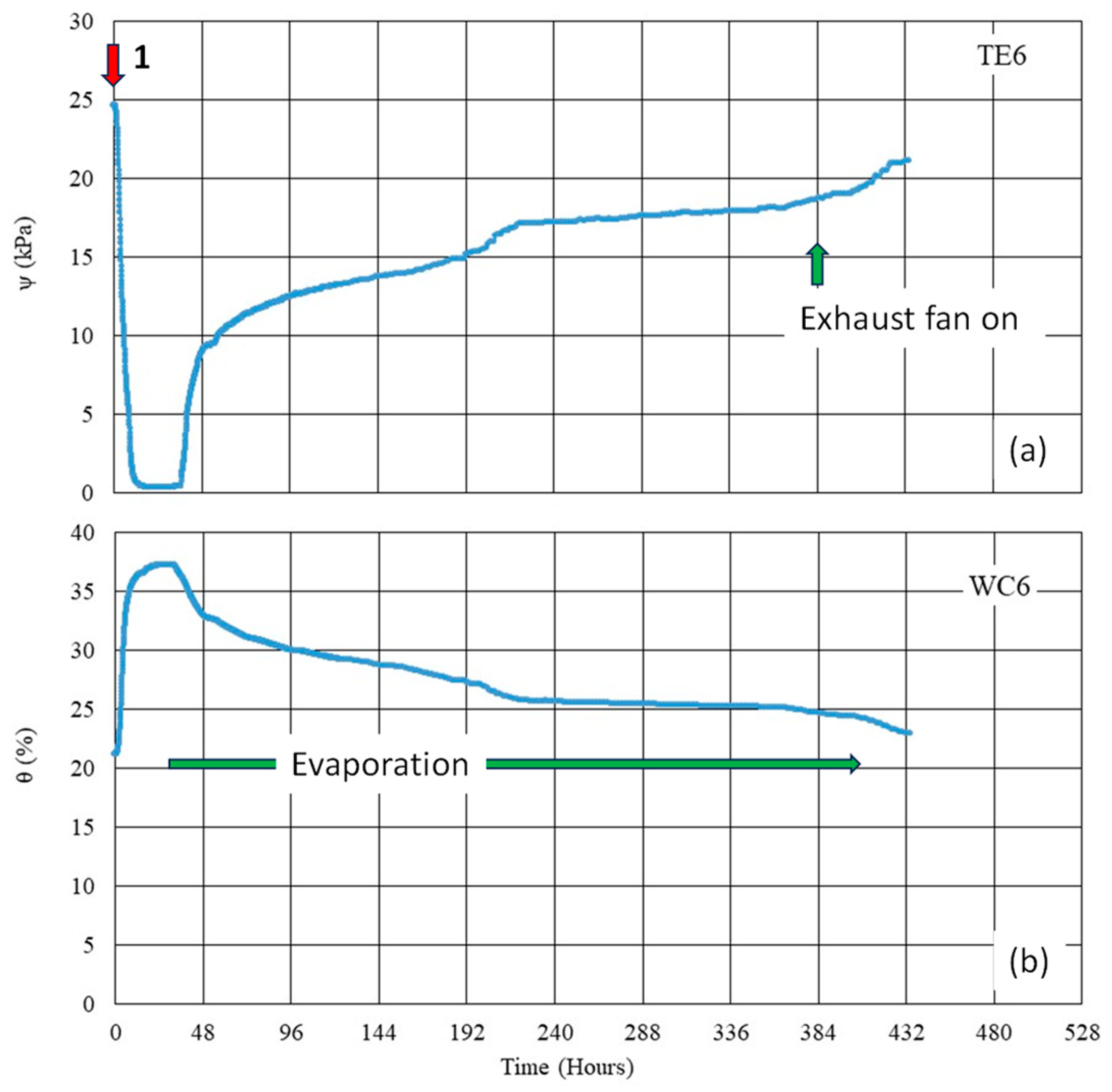

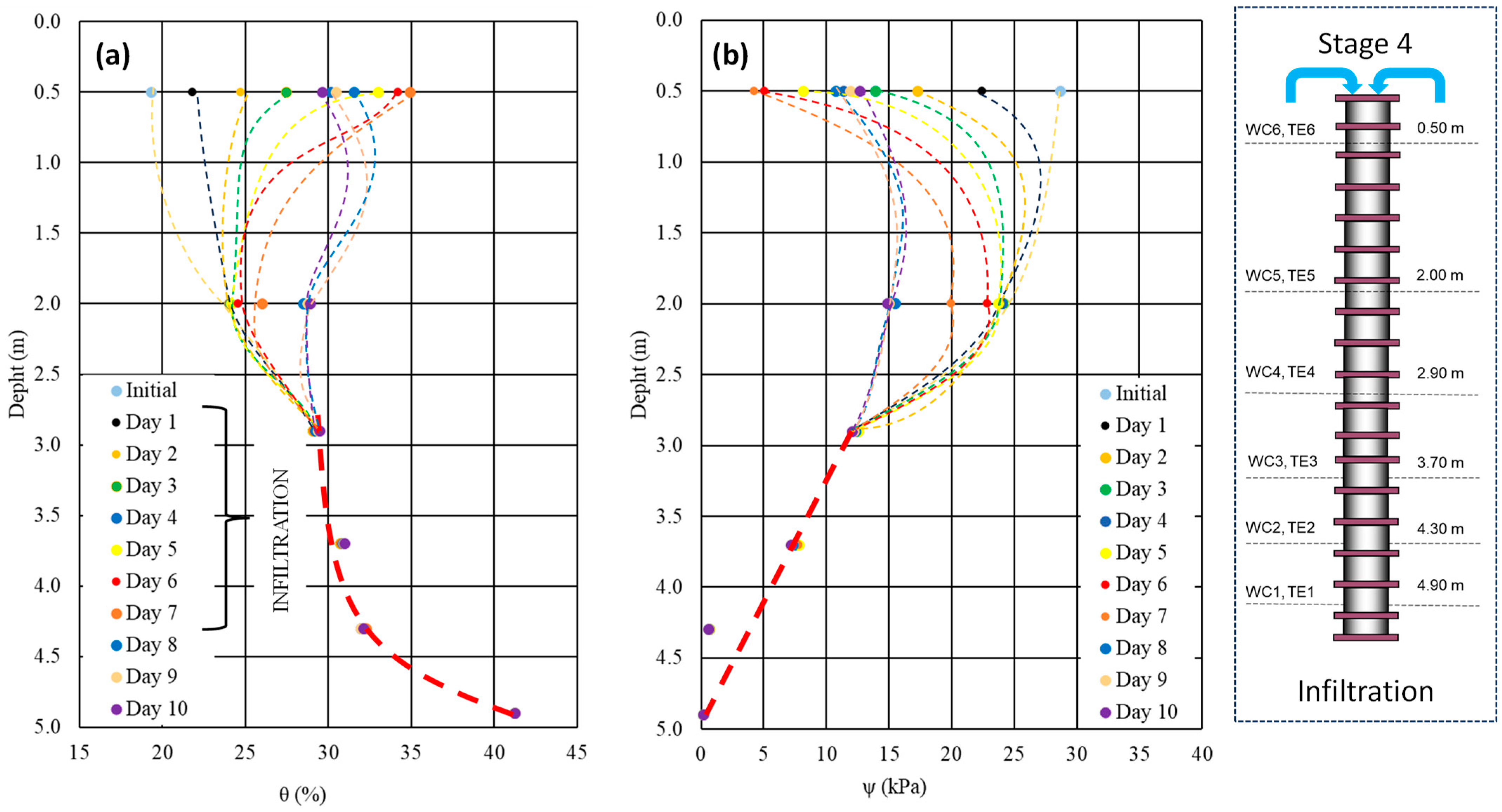

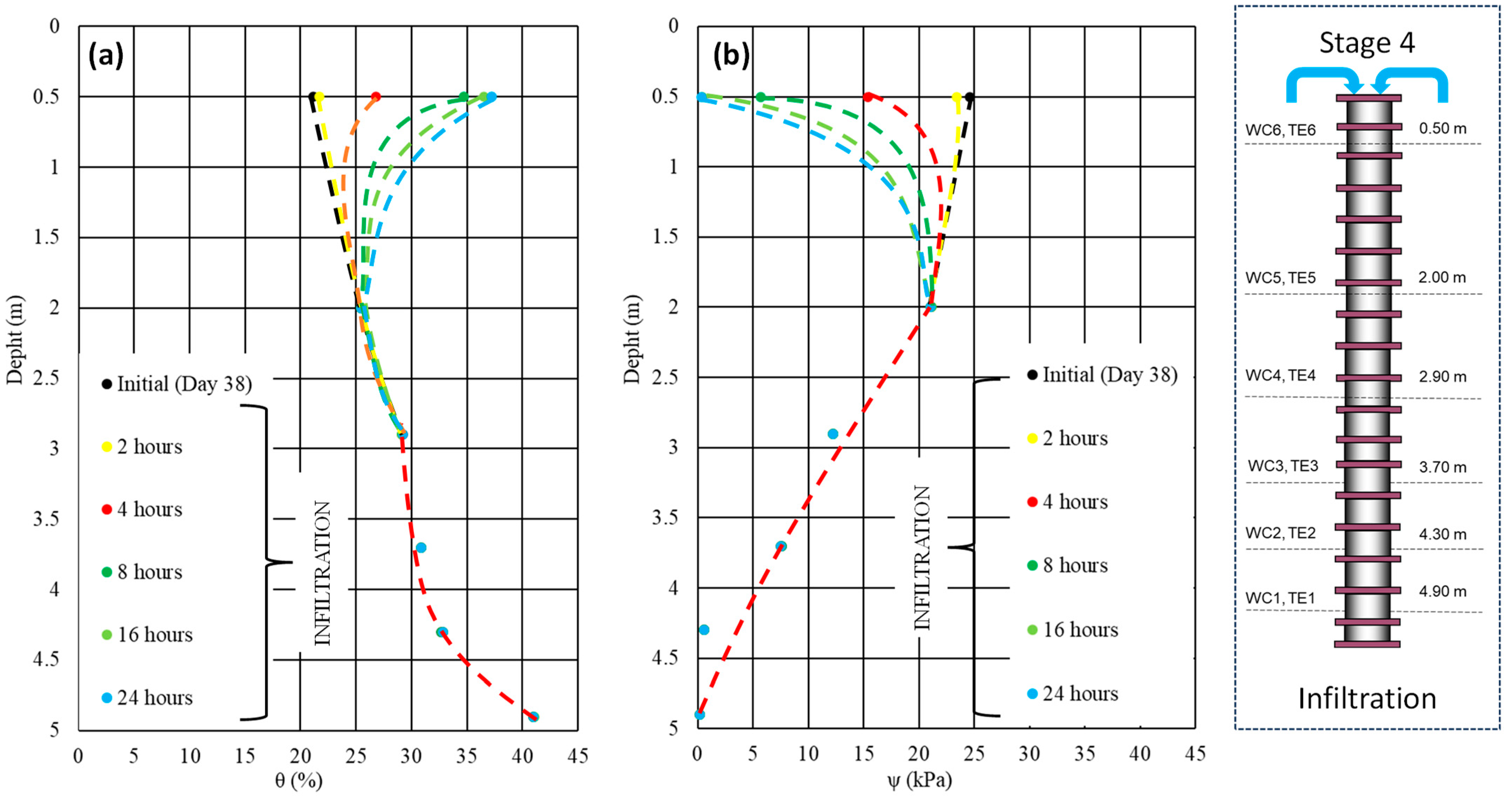

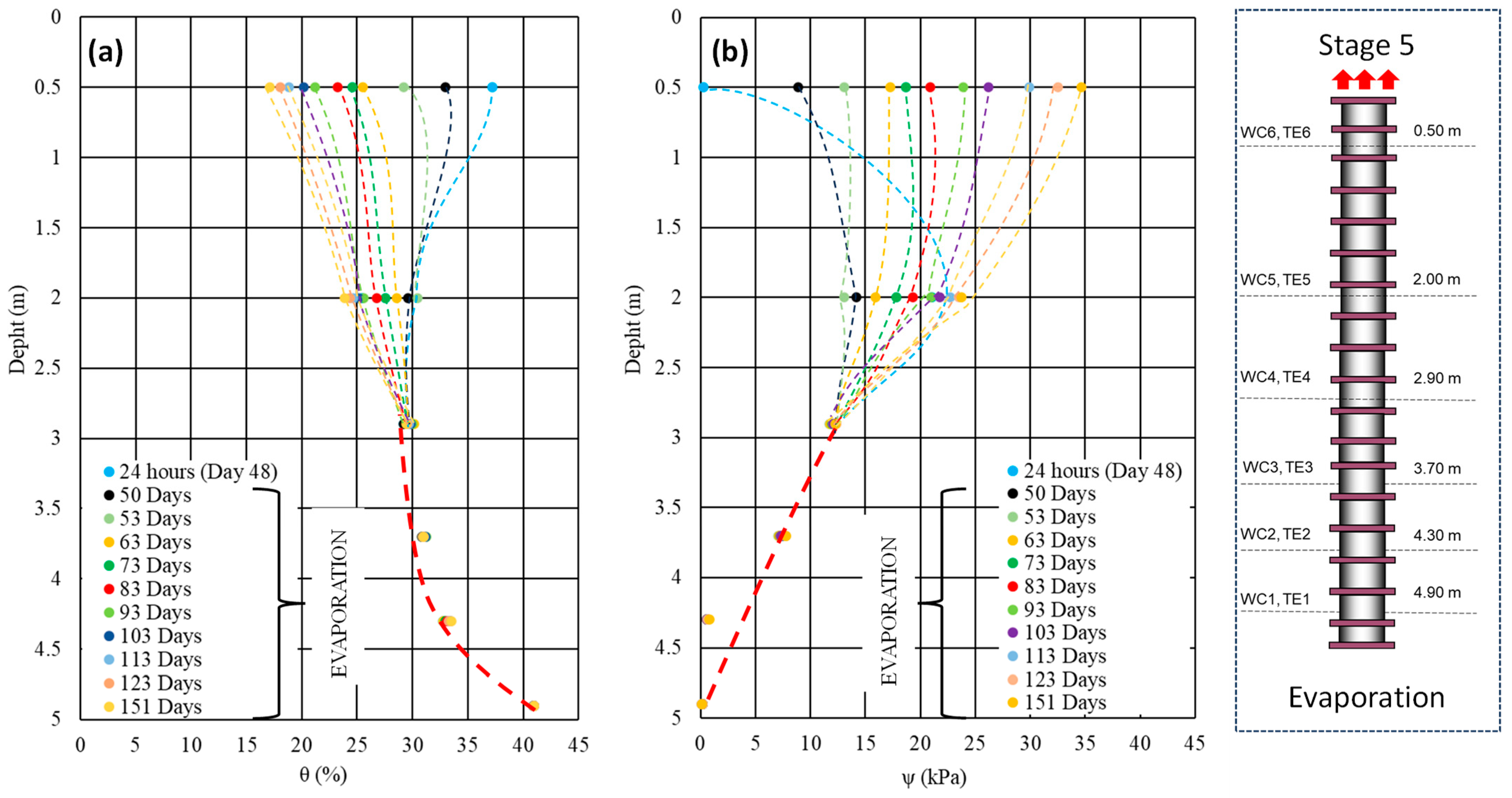

5.1. Profiles at Different Stages

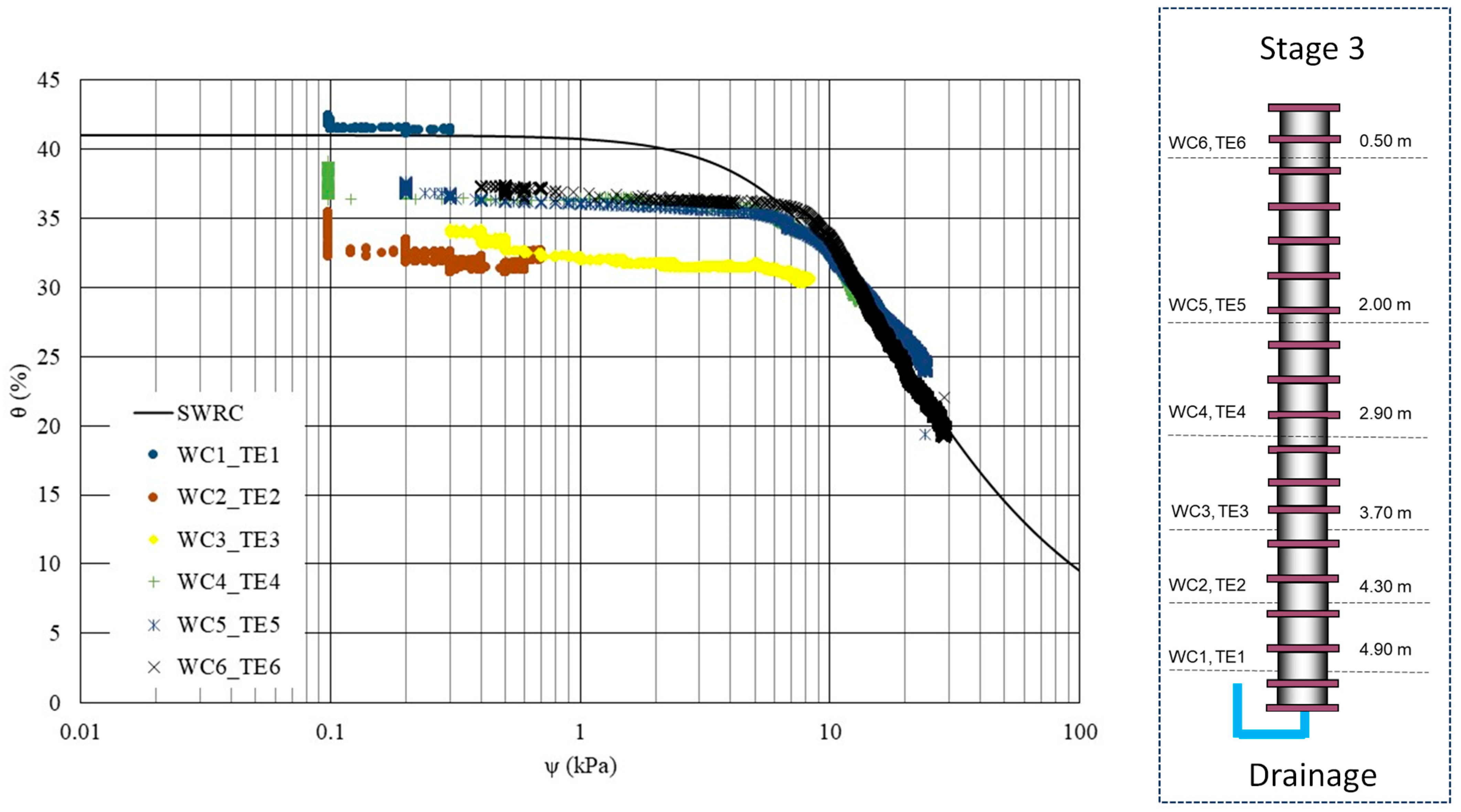

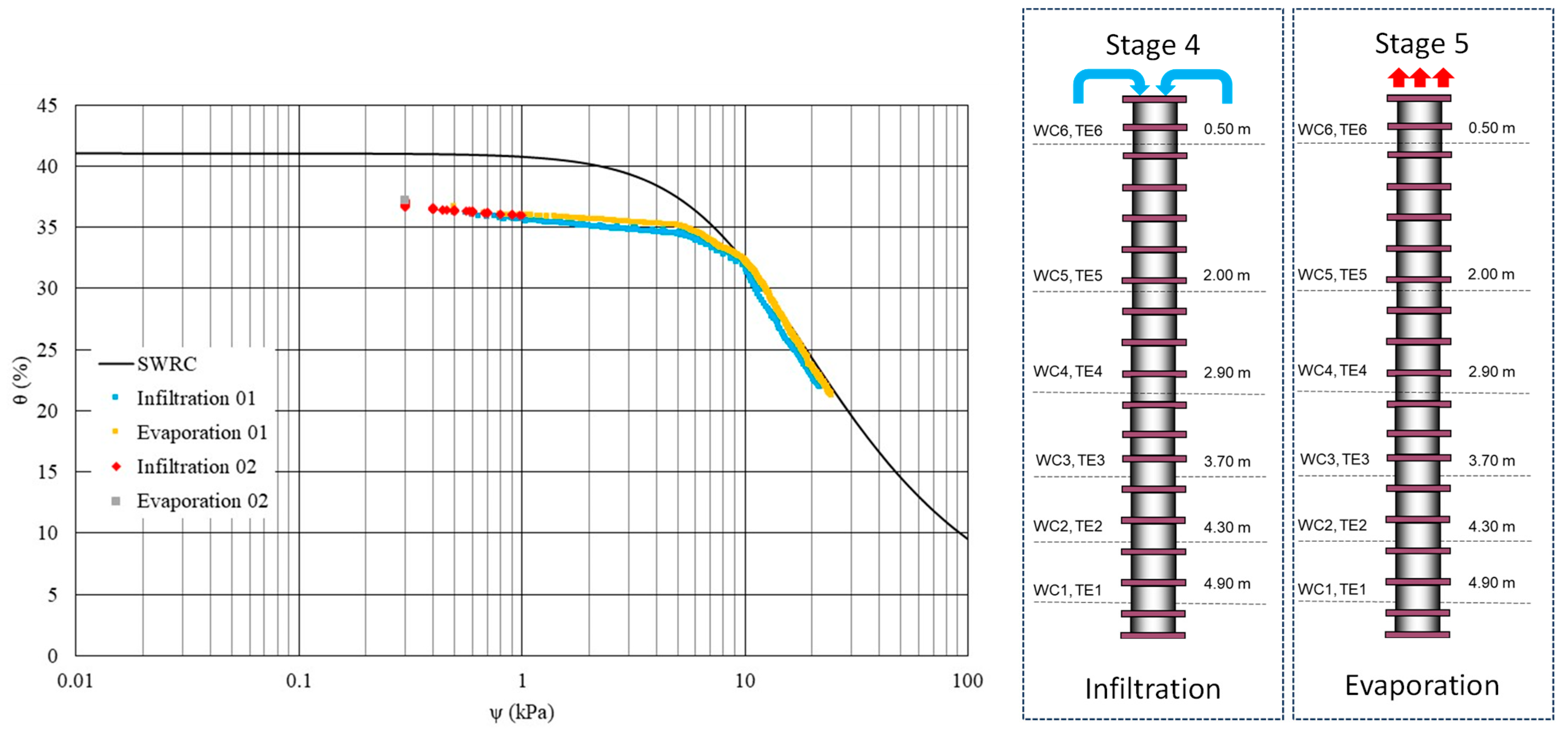

5.2. Results After Drainage

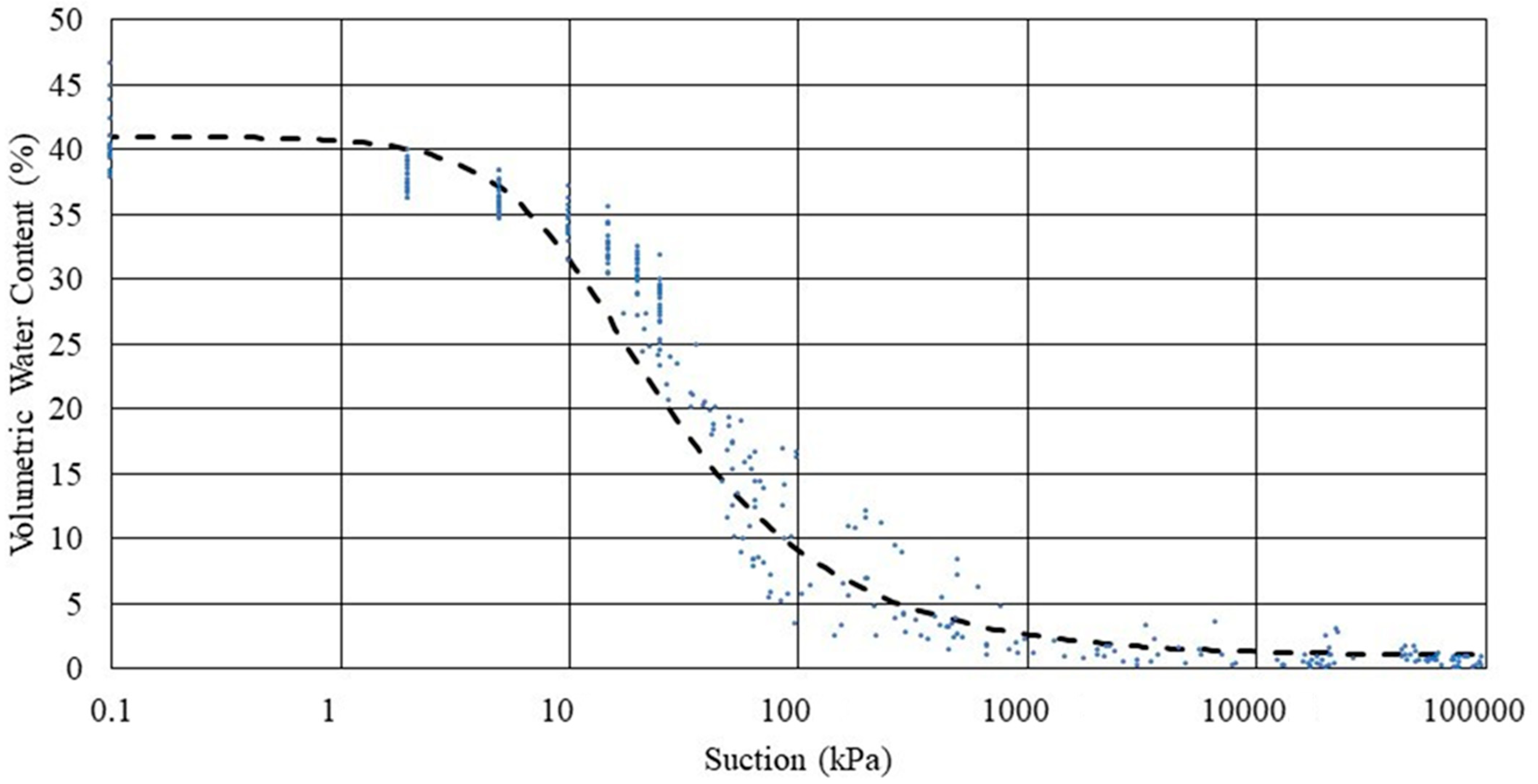

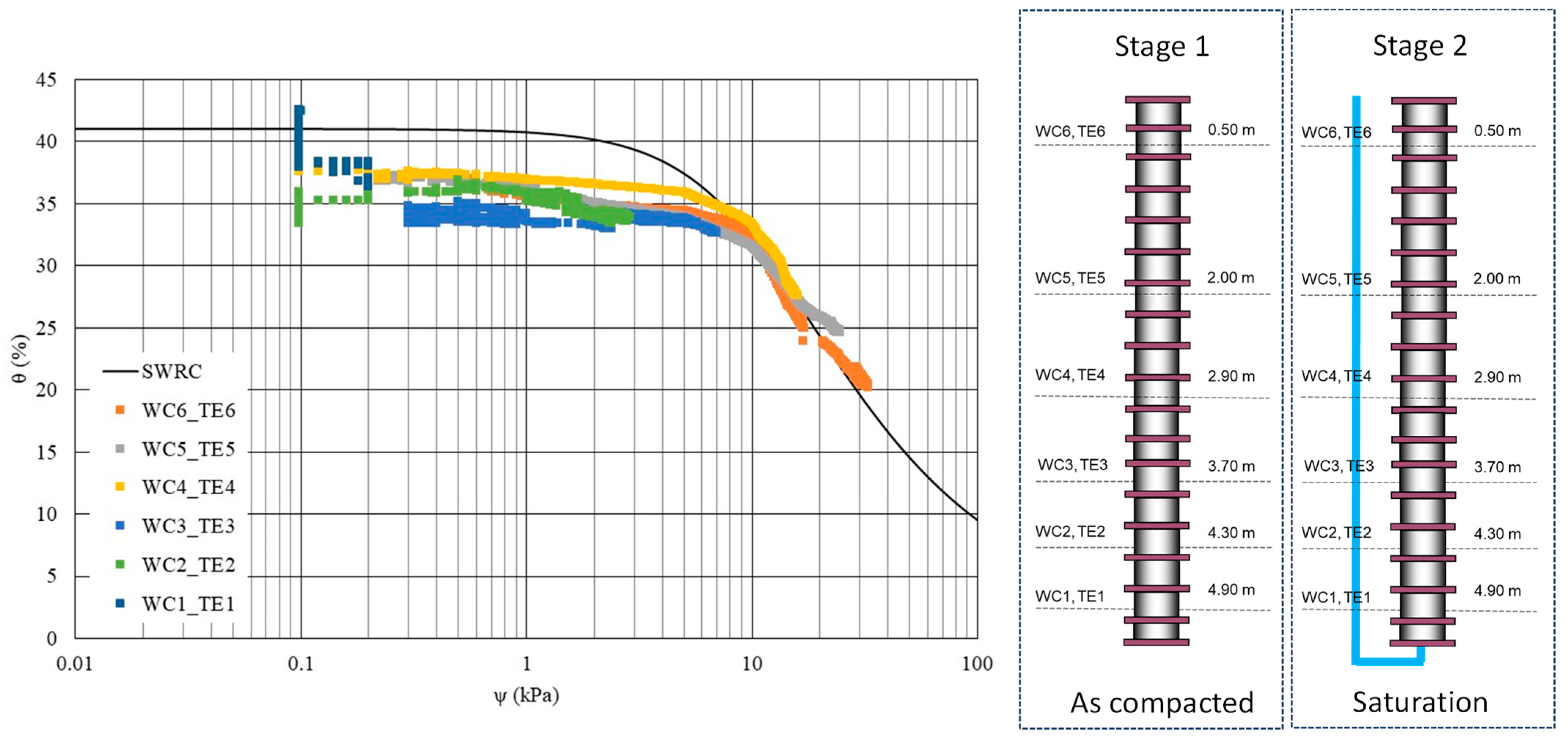

5.3. Soil Water Retention Curve and Column Data

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rico, M.; Benito, G.; Salgueiro, A.R.; Díez-Herrero, A.; Pereira, H.G. Reported tailings dam failures: A review of the European incidents in the worldwide context. J. Hazard. Mater. 2008, 152, 846–852. [Google Scholar] [CrossRef] [PubMed]

- Santamarina, J.C.; Torres-Cruz, L.A.; Bachus, R.C. Why coal ash and tailings dam disasters occur. Science 2019, 364, 526–528. [Google Scholar] [CrossRef] [PubMed]

- Koppe, J.C. Lessons learned from the two major tailings dam accidents in Brazil. Mine Water Environ. 2021, 40, 166–173. [Google Scholar] [CrossRef]

- Nwigwe, T.; Minami, K. Assessment of factors contributing to the risks of cargo liquefication accident in bulk carriers (a qualitative approach). TransNav Int. J. Mar. Navig. Saf. Sea Transp. 2022, 16, 149–152. [Google Scholar] [CrossRef]

- Marshall, T.J.; Holmes, J.W.; Rose, C.W. Soil Physics; Cambridge University Press: Cambridge, UK, 1996. [Google Scholar]

- Murray, E.J.; Sivakumar, V. Unsaturated Soils: A Fundamental Interpretation of Soil Behaviour; John Wiley & Sons: New York, NY, USA, 2010. [Google Scholar]

- Edlefsen, N.; Anderson, A. Thermodynamics of soil moisture. Hilgardia 1943, 15, 31–298. [Google Scholar] [CrossRef]

- Nelson, J.D.; Miller, D.J. Expansive Soils; Wiley: New York, NY, USA, 1992. [Google Scholar]

- Blight, G.E. Unsaturated Soil Mechanics in Geotechnical Practice; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Goss, M.J.; Ehlers, W. The role of lysimeters in the development of our understanding of soil water and nutrient dynamics in ecosystems. Soil Use Manag. 2009, 25, 213–223. [Google Scholar] [CrossRef]

- Lewis, J.; Sjöstrom, J. Optimizing the experimental design of soil columns in saturated and unsaturated transport experiments. J. Contam. Hydrol. 2010, 115, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Pütz, T.; Fank, J.; Flury, M. Lysimeters in vadose zone research. Vadose Zone J. 2018, 17, 180035. [Google Scholar] [CrossRef]

- Buckingham, E. Studies on the Movement of Soil Moisture; US Department of Agriculture, Bureau of Soils: Washington, DC, USA, 1907. [Google Scholar]

- Marinho, F.A.M.; Stuermer, M.M. Aspects of the storage capacity of a compacted residual soil. In Proceedings of the Second International Conference on Unsaturated Soils Beijing, Beijing, China, 27–30 August 1998; International Academic Publishers: Beijing, China, 1998; pp. 581–585. [Google Scholar]

- Marinho, F.A.M.; Pinto, C.D.S. Investigating the water retention in iron ore. In Proceeding of the 3rd International Conference on Unsaturated Soils, Recife, Brazil, 10–13 March 2002; CRC Press: Boca Raton, FL, USA, 2004; pp. 1143–1146. [Google Scholar]

- Oliveira, O.M.; Marinho, F.A.M. Simulação de chuva em coluna de solo residual compactado. In Proceedings of the VI Simpósio Brasileiro de Solos Não Saturados, Salvador, Brazil, 1–3 November 2007; pp. 291–297. [Google Scholar]

- Teixeira, P.F.; Marinho, F.A.; Oliveira, O.M.D. Efeito do fluxo de ar no perfil de umidade de uma areia. In Proceedings of the XIV Congresso Brasileiro de Mecânica dos Solos e Engenharia Geotécnia, Búzios, Brazil, 23–26 August 2008. [Google Scholar]

- Reinert, D.J.; Reichert, J.M. Coluna de areia para medir a retenção de água no solo: Protótipos e teste. Ciênc. Rural 2006, 36, 1931–1935. [Google Scholar] [CrossRef]

- McCartney, J.S.; Zornberg, J.G. Effects of infiltration and evaporation on geosynthetic capillary barrier performance. Can. Geotech. J. 2010, 47, 1201–1213. [Google Scholar] [CrossRef]

- Ng, C.W.W.; Leung, A.K. Measurements of drying and wetting permeability functions using a new stress-controllable soil column. J. Geotech. Geoenviron. Eng. 2012, 138, 58–68. [Google Scholar] [CrossRef]

- Crystal, C.; Hore, C.; Ezama, I. Filter-pressed dry stacking: Design considerations based on practical experience. In Proceedings of the Tailings and Mine Waste, Brisbane, Australia, 23–24 July 2018; pp. 209–219. [Google Scholar]

- Jesus, M.H.; Silva, J.P.D.S.; Marinho, F.A.M. Soil water retention curve of a compacted iron ore tailing obtained by various methods. In Proceedings of the 17th Pan-American Conference on Soil Mechanics and Geotechnical Engineering (XVII PCSMGE), La Serena, Chile, 12–17 November 2024. [Google Scholar]

- Van Genuchten, M.T. A closed-form equation for predicting the hydraulic conductivity of unsaturated soils. Soil Sci. Soc. Am. J. 1980, 44, 892–898. [Google Scholar] [CrossRef]

- De Sá Landim, A.; Corrêa, Y.; Silva, J.P.; Marinho, A.M.F. Evaluation a volumetric water content sensor to be used for compacted filtered iron ore tailings. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2023; p. 16003. [Google Scholar]

- Nguyen, B.T.; Ishikawa, T.; Zhu, Y.; Subramanian, S.S.; Nguyen, T.T. New simplified transient method for determining the coefficient of permeability of unsaturated soil. Eng. Geol. 2022, 300, 106564. [Google Scholar] [CrossRef]

| θ= | nS | ||

| w= | |||

| S= | |||

| hw= |

| Specific gravity (Gs) | 3.35 |

| Fine sand | 13.5% |

| Silt | 83.7% |

| % < 2 mm | 2.8% |

| wopt | 11.9% |

| θopt | 24.0% |

| Sopt | 58.0% |

| Maximum dry unit weight | 19.77 kN/m3 |

| θsat | 40% |

| Quartz | 89.1% |

| Fe2O3 | 10.9% |

| a | 0.09 |

| n | 1.7 |

| m = (1-1/n) | 0.4118 |

| θsat | 41% |

| θresidual | 1% |

| Description | Volume (Litres) |

|---|---|

| Theoretical pore saturation volume | 103.1 |

| Sensor-estimated saturation volume | 93.3 |

| Volume of water drained after 190 days | 42 |

| Estimated volume for initial drainage (hyperbolic fitting) | 43.5 |

| Volume of water in the first infiltration | 12.6 |

| Volume of water in the second infiltration | 12.6 |

| Drainage after the first infiltration (47 days) | 10.3 |

| Drainage after the second infiltration (103 days) | 14.7 |

| Total volume of water present in the column since the start | 118.5 |

| Total increase in drained water after induced infiltrations | 23.6 |

| Volume to be drained over time | 0.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marinho, F.A.M.; Corrêa, Y.; Soares, R.; Carvalho, I.D.; de Sousa Silva, J.P. Conceptual and Applied Aspects of Water Retention Tests on Tailings Using Columns. Geosciences 2024, 14, 273. https://doi.org/10.3390/geosciences14100273

Marinho FAM, Corrêa Y, Soares R, Carvalho ID, de Sousa Silva JP. Conceptual and Applied Aspects of Water Retention Tests on Tailings Using Columns. Geosciences. 2024; 14(10):273. https://doi.org/10.3390/geosciences14100273

Chicago/Turabian StyleMarinho, Fernando A. M., Yuri Corrêa, Rosiane Soares, Inácio Diniz Carvalho, and João Paulo de Sousa Silva. 2024. "Conceptual and Applied Aspects of Water Retention Tests on Tailings Using Columns" Geosciences 14, no. 10: 273. https://doi.org/10.3390/geosciences14100273

APA StyleMarinho, F. A. M., Corrêa, Y., Soares, R., Carvalho, I. D., & de Sousa Silva, J. P. (2024). Conceptual and Applied Aspects of Water Retention Tests on Tailings Using Columns. Geosciences, 14(10), 273. https://doi.org/10.3390/geosciences14100273