Properties and Uses of Biochars Incorporated into Mortars

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials for Carbonization

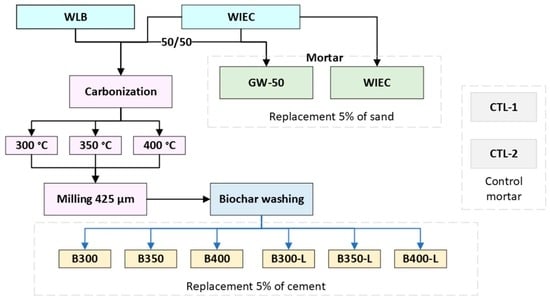

2.2. Carbonization Experiments

2.3. Biochar Washing for the Removal of Water-Soluble Compounds

2.4. Characterization of Biochars

2.5. Row Materials for Cement Mortar

2.6. Experimental Procedure

2.7. Compression Tests

2.8. Immersion Water Absorption Tests

3. Results and Discussion

3.1. Raw Material Characterization

3.2. Mechanical Compression Properties

3.3. Water Absorption by Immersion

4. Conclusions

- With regard to compressive strength and the incorporation of biochars, unwashed biochars showed better results than those that were subjected to the washing process; however, in both situations, there is a loss of compressive strength at 28 days, which for biochar produced at 400 °C, this was a loss of around 24% for the unwashed biochars and around 50% for the washed biochars.

- Mortars produced with biochar present higher percentages of water absorption than control (current) mortars; this effect is amplified in the case of washed biochar.

- Water absorption is proportional to the increase in biochar production temperature; however, with washed biochars, this difference is relatively smaller, varying by 1% between the three biochars.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Scrivener, K.L.; John, V.M.; Gartner, E.M. Eco-efficient cements: Potential economically viable solutions for a low-CO2 cement-based materials industry. Cem. Concr. Res. 2016, 114, 2–26. [Google Scholar] [CrossRef]

- Szabó, L.; Hidalgo, I.; Císcar, J.C.; Soria, A.; Russ, P. Energy Consumption and CO2 Emissions from the World Cement Industry; European Commission Joint Research Centre: Brussels, Belgium, 2003. [Google Scholar]

- Fu, B.; Cheng, Z.; Wang, D.; Li, N. Investigation on the utilization of coal gasification slag in Portland cement: Reaction kinetics and microstructure. Constr. Build. Mater. 2022, 323, 126587. [Google Scholar] [CrossRef]

- Klee, H. Briefing: The Cement Sustainability Initiative. Proc. Inst. Civ. Eng. Eng. Sustain. 2004, 157, 9–11. [Google Scholar] [CrossRef]

- IEA Paris. Cement. 2021. Available online: https://www.iea.org/reports/cement (accessed on 25 September 2022).

- Müller, D.B.; Liu, G.; Løvik, A.N.; Modaresi, R.; Pauliuk, S.; Steinhoff, F.S.; Brattebø, H. Carbon Emissions of Infrastructure Development. Environ. Sci. Technol. 2013, 47, 11739–11746. [Google Scholar] [CrossRef]

- Summerbell, D.L.; Barlow, C.Y.; Cullen, J.M. Potential reduction of carbon emissions by performance improvement: A cement industry case study. J. Clean. Prod. 2016, 135, 1327–1339. [Google Scholar] [CrossRef]

- Schneider, M.; Romer, M.; Tschudin, M.; Bolio, H. Sustainable cement production-present and future. Cem. Concr. Res. 2011, 41, 642–650. [Google Scholar] [CrossRef]

- Iacobescu, R.I.; Angelopoulos, G.N.; Jones, P.T.; Blanpain, B.; Pontikes, Y. Ladle metallurgy stainless steel slag as a raw material in Ordinary Portland Cement production: A possibility for industrial symbiosis. J. Clean. Prod. 2015, 112, 872–881. [Google Scholar] [CrossRef]

- Thomas, B.S.; Yang, J.; Mo, K.H.; Abdalla, J.A.; Hawileh, R.A.; Ariyachandra, E. Biomass ashes from agricultural wastes as supplementary cementitious materials or aggregate replacement in cement/geopolymer concrete: A comprehensive review. J. Build. Eng. 2021, 40, 102332. [Google Scholar] [CrossRef]

- Bartoli, M.; Giorcelli, M.; Jagdale, P.; Rovere, M.; Tagliaferro, A. A Review of Non-Soil Biochar Applications. Materials 2020, 13, 261. [Google Scholar] [CrossRef] [Green Version]

- Mota-Panizio, R.; Hermoso-Orzáez, M.; Carmo-Calado, L.; Calado, H.; Goncalves, M.; Brito, P. Co-carbonization of a mixture of waste insulation electric cables (WIEC) and lignocellulosic waste, for the removal of chlorine: Biochar properties and their behaviors. Fuel 2022, 320, 123932. [Google Scholar] [CrossRef]

- Vochozka, M.; Maroušková, A.; Váchal, J.; Straková, J. Biochar pricing hampers biochar farming. Clean Technol. Environ. Policy 2016, 18, 1225–1231. [Google Scholar] [CrossRef]

- Sohi, S.P.; Krull, E.; Lopez-Capel, E.; Bol, R. A review of biochar and its use and function in soil. In Advances in Agronomy; Elsevier: Amsterdam, The Netherlands, 2010; Volume 105, pp. 47–82. [Google Scholar] [CrossRef]

- Xiao, L.; Feng, L.; Yuan, G.; Wei, J. Low-cost field production of biochars and their properties. Environ. Geochem. Health 2019, 42, 1569–1578. [Google Scholar] [CrossRef]

- Torsello, D.; Ghigo, G.; Giorcelli, M.; Bartoli, M.; Rovere, M.; Tagliaferro, A. Tuning the microwave electromagnetic properties of biochar-based composites by annealing. Carbon Trends 2021, 4, 100062. [Google Scholar] [CrossRef]

- Akhtar, A.; Sarmah, A.K. Novel biochar-concrete composites: Manufacturing, characterization and evaluation of the mechanical properties. Sci. Total Environ. 2018, 616–617, 408–416. [Google Scholar] [CrossRef]

- Cuthbertson, D.; Berardi, U.; Briens, C.; Berruti, F. Biochar from residual biomass as a concrete filler for improved thermal and acoustic properties. Biomass Bioenergy 2019, 120, 77–83. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.W.; Pang, S.D. Effect of biochar on mechanical and permeability properties of concrete exposed to elevated temperature. Constr. Build. Mater. 2019, 234, 117338. [Google Scholar] [CrossRef]

- Javed, M.H.; Sikandar, M.A.; Ahmad, W.; Bashir, M.T.; Alrowais, R.; Wadud, M.B. Effect of various biochars on physical, mechanical, and microstructural characteristics of cement pastes and mortars. J. Build. Eng. 2022, 57, 104850. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.W. Factors Determining the Potential of Biochar as a Carbon Capturing and Sequestering Construction Material: Critical Review. J. Mater. Civ. Eng. 2017, 29, 04017086. [Google Scholar] [CrossRef]

- Berardi, U.; Naldi, M. The impact of the temperature dependent thermal conductivity of insulating materials on the effective building envelope performance. Energy Build. 2017, 144, 262–275. [Google Scholar] [CrossRef]

- Zhao, C.; Wang, P.; Wang, L.; Liu, D. Reducing Railway Noise with Porous Sound-Absorbing Concrete Slabs. Adv. Mater. Sci. Eng. 2014, 2014, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Berardi, U.; Iannace, G. Acoustic characterization of natural fibers for sound absorption applications. Build. Environ. 2015, 94, 840–852. [Google Scholar] [CrossRef]

- Choi, W.C.; Yun, H.D.; Lee, J.Y. Mechanical Properties of Mortar Containing Bio-Char From Pyrolysis. J. Korea Inst. Struct. Maint. Insp. 2012, 16, 67–74. [Google Scholar] [CrossRef] [Green Version]

- Restuccia, L.; Ferro, G.A. Promising low cost carbon-based materials to improve strength and toughness in cement composites. Constr. Build. Mater. 2016, 126, 1034–1043. [Google Scholar] [CrossRef]

- Jindal, B.B.; Sharma, R. The effect of nanomaterials on properties of geopolymers derived from industrial by-products: A state-of-the-art review. Constr. Build. Mater. 2020, 252, 119028. [Google Scholar] [CrossRef]

- Calvino, M.M.; Lisuzzo, L.; Cavallaro, G.; Lazzara, G.; Milioto, S. Halloysite based geopolymers filled with wax microparticles as sustainable building materials with enhanced thermo-mechanical performances. J. Environ. Chem. Eng. 2022, 10, 108594. [Google Scholar] [CrossRef]

- Temuujin, J.; Minjigmaa, A.; Lee, M.; Chen-Tan, N.; van Riessen, A. Characterisation of class F fly ash geopolymer pastes immersed in acid and alkaline solutions. Cem. Concr. Compos. 2011, 33, 1086–1091. [Google Scholar] [CrossRef]

- Aneja, A.; Sharma, R.; Singh, H. Mechanical and durability properties of biochar concrete. Mater. Today Proc. 2022, 65, 3724–3730. [Google Scholar] [CrossRef]

- Nobre, C.; Vilarinho, C.; Alves, O.; Mendes, B.; Gonçalves, M. Upgrading of refuse derived fuel through torrefaction and carbonization: Evaluation of RDF char fuel properties. Energy 2019, 181, 66–76. [Google Scholar] [CrossRef]

- Guo, S.; Yang, J.; Liu, Z. The Fate of Fluorine and Chlorine during Thermal Treatment of Coals. Environ. Sci. Technol. 2006, 40, 7886–7889. [Google Scholar] [CrossRef]

- Longo, A.; Nobre, C.; Sen, A.; Panizio, R.; Brito, P.; Gonçalves, M. Torrefaction Upgrading of Heterogenous Wastes Containing Cork and Chlorinated Polymers. Environments 2022, 9, 99. [Google Scholar] [CrossRef]

- Weber, K.; Quicker, P. Properties of biochar. Fuel 2018, 217, 240–261. [Google Scholar] [CrossRef]

- CIMPOR. Ficha Técnica CEM I 42,5R. Cimento Portland 2019. Available online: https://www.cimpor.com/documents/20124/34187/FICHA+T%C3%89CNICA_CEM_I_42%2C5R_DEZEMBRO_2022.pdf/46777337-6efe-c1df-9d72-b9ee01f8d6f5?t=1669714554188 (accessed on 25 September 2022).

- Salih, A.; Rafiq, S.; Sihag, P.; Ghafor, K.; Mahmood, W.; Sarwar, W. Systematic multiscale models to predict the effect of high-volume fly ash on the maximum compression stress of cement-based mortar at various water/cement ratios and curing times. Measurement 2020, 171, 108819. [Google Scholar] [CrossRef]

- Chaidachatorn, K.; Suebsuk, J.; Horpibulsuk, S.; Arulrajah, A. Extended water/cement ratio law for cement mortar containing recycled asphalt pavement. Constr. Build. Mater. 2019, 196, 457–467. [Google Scholar] [CrossRef]

- EN 1015-11:2019; Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar. European Committee for Standardization: Brussels, Belgium, 2019.

- LNEC E394:1993; Concrete. Determination of Water Absorption by Immersion. Laboratório Nacional de Engenharia Civil (LNEC): Lisboa, Portugal, 1993.

- Al-Wabel, M.I.; Al-Omran, A.; El-Naggar, A.H.; Nadeem, M.; Usman, A.R. Pyrolysis temperature induced changes in characteristics and chemical composition of biochar produced from conocarpus wastes. Bioresour. Technol. 2013, 131, 374–379. [Google Scholar] [CrossRef] [PubMed]

- Windeatt, J.H.; Ross, A.B.; Williams, P.T.; Forster, P.M.; Nahil, M.A.; Singh, S. Characteristics of biochars from crop residues: Potential for carbon sequestration and soil amendment. J. Environ. Manag. 2014, 146, 189–197. [Google Scholar] [CrossRef] [PubMed]

- Gupta, S.; Kua, H.W. Carbonaceous micro-filler for cement: Effect of particle size and dosage of biochar on fresh and hardened properties of cement mortar. Sci. Total. Environ. 2019, 662, 952–962. [Google Scholar] [CrossRef]

- Khushnood, R.A.; Ahmad, S.; Restuccia, L.; Spoto, C.; Jagdale, P.V.; Tulliani, J.-M.; Ferro, G.A. Carbonized nano/microparticles for enhanced mechanical properties and electromagnetic interference shielding of cementitious materials. Front. Struct. Civ. Eng. 2016, 10, 209–213. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.W.; Low, C.Y. Use of biochar as carbon sequestering additive in cement mortar. Cem. Concr. Compos. 2018, 87, 110–129. [Google Scholar] [CrossRef]

- Moosberg-Bustnes, H.; Lagerblad, B.; Forssberg, E. The function of fillers in concrete. Mater. Struct. 2004, 37, 74–81. [Google Scholar] [CrossRef]

- Mrad, R.; Chehab, G. Mechanical and Microstructure Properties of Biochar-Based Mortar: An Internal Curing Agent for PCC. Sustainability 2019, 11, 2491. [Google Scholar] [CrossRef] [Green Version]

- Horsakulthai, V. Effect of recycled concrete powder on strength, electrical resistivity, and water absorption of self-compacting mortars. Case Stud. Constr. Mater. 2021, 15, e00725. [Google Scholar] [CrossRef]

- Song, W.; Wang, Q.; Qu, L.; Li, X.; Xu, S. Study of water absorption and corrosion resistance of the mortar with waste marble powder. Constr. Build. Mater. 2022, 345, 128235. [Google Scholar] [CrossRef]

- Chen, B.; Zhou, D.; Zhu, L. Transitional adsorption and partition of nonpolar and polar aromatic contaminants by biochars of pine needles with different pyrolytic temperatures. Environ. Sci. Technol. 2008, 42, 5137–5143. [Google Scholar] [CrossRef] [PubMed]

- Gray, M.; Johnson, M.G.; Dragila, M.I.; Kleber, M. Water uptake in biochars: The roles of porosity and hydrophobicity. Biomass Bioenergy 2014, 61, 196–205. [Google Scholar] [CrossRef]

- Sasanipour, H.; Aslani, F. Durability properties evaluation of self-compacting concrete prepared with waste fine and coarse recycled concrete aggregates. Constr. Build. Mater. 2019, 236, 117540. [Google Scholar] [CrossRef]

- Kaya, T.I.; Karakuzu, K.; Özen, S.; Doğangün, A.; Aghabaglou, A.M. Effect of polypropylene fiber and shrinkage reducing admixture utilization on water absorption of Khorasan mortar. Mater. Today Proc. 2022, 57, 730–733. [Google Scholar] [CrossRef]

| Characteristics | Property | Specific Value |

|---|---|---|

| Chemicals | Loss on fire (P.F.) | ≤5.0% |

| Insoluble residue (I.R.) | ≤5.0% | |

| Sulfates (SO3) | ≤4.0% | |

| Chlorides (Cl−) | ≤0.10% | |

| Physics | Start of prey | (min) ≥60 |

| Expandability | (mm) ≤10 | |

| Mechanics | Compressive strength | |

| 2 days | 20 MPa | |

| 28 days | 42.5 MPa | |

| Reference | Description | Cement (g) | Sand (g) | Water (g) | Waste (g) | Biochar (g) | Ratio W/B |

|---|---|---|---|---|---|---|---|

| CTL | Control mortar | 2000 | 6000 | 1100 | 0 | 0 | 0.55 |

| GW-50 | Mortar with 10% incorporation in place of sand | 2000 | 5400 | 1100 | 600 | 0 | 0.55 |

| WIEC | 2000 | 5400 | 1100 | 600 | 0 | 0.55 | |

| B300 | Mortar with 5% biochar incorporation in place of cement | 1900 | 6000 | 1100 | 0 | 100 | 0.58 |

| B350 | 1900 | 6000 | 1100 | 0 | 100 | 0.58 | |

| B400 | 1900 | 6000 | 1100 | 0 | 100 | 0.58 | |

| B300-L | Mortar with the incorporation of 5% of washed biochars in place of cement | 1900 | 6000 | 1100 | 0 | 100 | 0.58 |

| B350-L | 1900 | 6000 | 1100 | 0 | 100 | 0.58 | |

| B400-L | 1900 | 6000 | 1100 | 0 | 100 | 0.58 |

| Parameters | WLB | WIEC | B300 | B350 | B400 | B300-L | B350-L | B400-L |

|---|---|---|---|---|---|---|---|---|

| Moisture (wt.% a.r.) | 7.73 | 0.79 | 8.83 | 6.65 | 4.87 | 6.22 | 6.17 | 3.69 |

| Ash (wt.% d.b) | 23.55 | 33.20 | 43.26 | 39.1 | 33.85 | 33.4 | 33.6 | 34 |

| Elemental composition (wt.% d.b.) | ||||||||

| C | 37.52 | 52.3 | 40.77 | 42.64 | 43.95 | 42.38 | 43.06 | 43.14 |

| H | 7.9 | 2.5 | 4.02 | 3.74 | 2.83 | 2.81 | 3.33 | 3.76 |

| N | 2.29 | 0.2 | 5.08 | 4.24 | 4.01 | 12.9 | 11.38 | 10.41 |

| S | <d.l. | <d.l. | <d.l. | <d.l. | <d.l. | <d.l. | <d.l. | <d.l. |

| O | 47.02 | 42.7 | 6.87 | 10.28 | 15.36 | 8.51 | 8.63 | 8.69 |

| Atomic composition (% at.) | ||||||||

| C | 36.58 | 52.19 | 67.15 | 66.01 | 63.73 | 61.07 | 61.78 | 61.88 |

| H | 15.3 | 4.95 | 13.15 | 11.49 | 8.15 | 8.04 | 9.49 | 10.71 |

| N | 2.23 | 0.21 | 8.37 | 6.57 | 5.82 | 18.61 | 16.34 | 14.94 |

| S | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| O | 45.89 | 42.65 | 11.33 | 15.93 | 22.3 | 12.28 | 12.39 | 12.47 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mota-Panizio, R.; Carmo-Calado, L.; Assis, A.C.; Matos, V.; Hermoso-Orzáez, M.J.; Romano, P.; Gonçalves, M.; Brito, P. Properties and Uses of Biochars Incorporated into Mortars. Environments 2023, 10, 47. https://doi.org/10.3390/environments10030047

Mota-Panizio R, Carmo-Calado L, Assis AC, Matos V, Hermoso-Orzáez MJ, Romano P, Gonçalves M, Brito P. Properties and Uses of Biochars Incorporated into Mortars. Environments. 2023; 10(3):47. https://doi.org/10.3390/environments10030047

Chicago/Turabian StyleMota-Panizio, Roberta, Luís Carmo-Calado, Ana Carolina Assis, Vitor Matos, Manuel Jesus Hermoso-Orzáez, Pedro Romano, Margarida Gonçalves, and Paulo Brito. 2023. "Properties and Uses of Biochars Incorporated into Mortars" Environments 10, no. 3: 47. https://doi.org/10.3390/environments10030047

APA StyleMota-Panizio, R., Carmo-Calado, L., Assis, A. C., Matos, V., Hermoso-Orzáez, M. J., Romano, P., Gonçalves, M., & Brito, P. (2023). Properties and Uses of Biochars Incorporated into Mortars. Environments, 10(3), 47. https://doi.org/10.3390/environments10030047