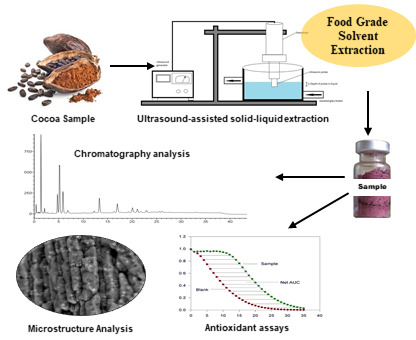

Food-Safe Process for High Recovery of Flavonoids from Cocoa Beans: Antioxidant and HPLC-DAD-ESI-MS/MS Analysis

Abstract

:1. Introduction

2. Material and Methods

2.1. Reagents

2.2. Pre-Treatment of Cocoa Beans

2.2.1. Drying and Milling Process

- (a)

- Drying: Beans after polyphenol oxidase (PPO) inactivation were used immediately to evaluate the effect of drying technology on the total polyphenol content. To do so, beans were chopped (cross section of 50 × 30 mm2). Then, beans were a) oven dried (FD 23, Binder, Germany) at both 50 °C and 70 °C at atmospheric pressure, and b) freeze-dried (Labconco Corp., Kansas City, MO, USA) at −84 °C processing temperature and 13 Pa constant pressure in the drying chamber to obtain final humidity < 4%. The moisture content was evaluated by AOAC method 931.04 (AOAC, 1990).

- (b)

- Milling: As a strategy to avoid the use of a non-GRAS (Generally Recognized as Safe) solvent for removing the fat from cocoa beans, different particle size distributions and ultrasound time were evaluated as a function of total phenol content. Dried beans were milled at max speed at −20 °C in N2 environment for 30 s during three cycles (Grindomix GM 200, Retsch, Haan, Germany). The milled samples were sieved through steel mesh (W.S. Tyler, Mentor, OH, USA) with a sieve shaker (Gilson, Screen Co., USA) and fractionated in three groups: sieved and retained on 20 to 40-mesh (sample 1); 40 to 80-mesh (sample 2); and 80 to 200-mesh (sample 3). After that, the powdered sample was immersed in 50% aqueous ethanol and ultrasonicated (35 kHz, ice bath at 4 °C, Elma, Ultrasonic LC20H, Germany) for several intervals of time. A defatted cocoa sample (<5 wt.%) was employed as a control sample. To do so, the cocoa bean powder (1.0 g) was three times defatted with n-hexane (10 mL, extraction in an ultrasonic bath at 25 °C for 15 min). The resulting powder was dried overnight at room temperature.

2.2.2. Scanning Electron Microscopy

2.3. Solid–Liquid Extraction of Polyphenols

2.4. Determination of Total Polyphenol, Total Flavonoids, and Total Flavan-3-ols Content

2.4.1. Total Polyphenol Content by Folin-Ciocalteu

2.4.2. Total Flavonoid Assay

2.4.3. Total Flavan-3-Ol Assay

2.5. Kinetic of Solid–Liquid (S-L) Extraction of Polyphenols

2.6. Characterization by HPLC-DAD-ESI-MS/MS

2.7. Antioxidant Assays

2.8. Statistical Analysis

3. Results and Discussion

3.1. Effect of Drying Temperature, Particle Size and Non-Degreasing Process on the Concentration of Total Phenols

3.1.1. Drying Technology

3.1.2. Impact of Particle Size on Extraction Yield

3.1.3. Conditions to Avoid the Degreasing Process

3.1.4. Microscopy Analysis

3.2. Solid–Liquid Extraction of Polyphenols from Cocoa Beans

Effect of Independent Factors on the Recovery of Total Polyphenols and Total Flavonoids

3.3. Extraction Kinetics Parameters

3.4. Chromatographic and Antioxidant Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Pedan, V.; Fischer, N.; Rohn, S. An online NP-HPLC-DPPH method for the determination of the antioxidant activity of condensed polyphenols in cocoa. Food Res. Int. 2016, 89, 890–900. [Google Scholar] [CrossRef] [Green Version]

- Batista, N.N.; de Andrade, D.P.; Ramos, C.L.; Dias, D.R.; Schwan, R.F. Antioxidant capacity of cocoa beans and chocolate assessed by FTIR. Food Res. Int. 2016, 90, 313–319. [Google Scholar] [CrossRef] [PubMed]

- Toro-Uribe, S.; Montero, L.; López-Giraldo, L.; Ibáñez, E.; Herrero, M. Characterization of secondary metabolites from green cocoa beans using focusing-modulated comprehensive two-dimensional liquid chromatography coupled to tandem mass spectrometry. Anal. Chim. Acta 2018, 1036, 204–213. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pérez-Jiménez, J.; Neveu, V.; Vos, F.; Scalbert, A. Identification of the 100 richest dietary sources of polyphenols: An application of the Phenol-Explorer database. Eur. J. Clin. Nutr. 2010, 64, S112–S120. [Google Scholar] [CrossRef] [PubMed]

- Presidencia de la República de Colombia Decreto Ley 896 de 2017 “Programa Nacional Integral de Sustitución de Cultivos de uso ilícito PNIS”. Available online: http://www.indepaz.org.co/wp-content/uploads/2017/05/Decreto-896-del-29-de-Mayo-de-2017-1.pdf (accessed on 3 August 2018).

- Quiroz-Reyes, C.N.; Aguilar-Mendez, M.A.; Ramírez-Ortíz, M.E.; Ronquillo-De Jesus, E. Comparative study of ultrasound and maceration techniques for the extraction of polyphenols from cocoa beans (Theobroma cacao L.). Rev. Mex. Ing. Química 2013, 12, 11–18. [Google Scholar]

- Routray, W.; Orsat, V. Microwave-Assisted Extraction of Flavonoids: A Review. Food Bioprocess Technol. 2012, 5, 409–424. [Google Scholar] [CrossRef]

- Okiyama, D.C.G.; Soares, I.D.; Cuevas, M.S.; Crevelin, E.J.; Moraes, L.A.B.; Melo, M.P.; Oliveira, A.L.; Rodrigues, C.E.C. Pressurized liquid extraction of flavanols and alkaloids from cocoa bean shell using ethanol as solvent. Food Res. Int. 2018, 114, 20–29. [Google Scholar] [CrossRef]

- Servent, A.; Boulanger, R.; Davrieux, F.; Pinot, M.N.; Tardan, E.; Forestier-Chiron, N.; Hue, C. Assessment of cocoa (Theobroma cacao L.) butter content and composition throughout fermentations. Food Res. Int. 2018, 107, 675–682. [Google Scholar] [CrossRef]

- Rodríguez-Carrasco, Y.; Gaspari, A.; Graziani, G.; Sandini, A.; Ritieni, A. Fast analysis of polyphenols and alkaloids in cocoa-based products by ultra-high performance liquid chromatography and Orbitrap high resolution mass spectrometry (UHPLC-Q-Orbitrap-MS/MS). Food Res. Int. 2018, 111, 229–236. [Google Scholar] [CrossRef]

- Żyżelewicz, D.; Budryn, G.; Oracz, J.; Antolak, H.; Kręgiel, D.; Kaczmarska, M. The effect on bioactive components and characteristics of chocolate by functionalization with raw cocoa beans. Food Res. Int. 2018, 113, 234–244. [Google Scholar] [CrossRef]

- Schinella, G.; Mosca, S.; Cienfuegos-Jovellanos, E.; Pasamar, M.Á.; Muguerza, B.; Ramón, D.; Ríos, J.L. Antioxidant properties of polyphenol-rich cocoa products industrially processed. Food Res. Int. 2010, 43, 1614–1623. [Google Scholar] [CrossRef] [Green Version]

- Pons-Andreu, J.-V.; Cienfuegos-Jovellanos, E.; Ibarra, A. Process for Producing Cocoa Polyphenol Concentrate. U.S. Patent 0193629 A1, 14 August 2008. [Google Scholar]

- Pinelo, M.; Sineiro, J.; Núñez, M.J. Mass transfer during continuous solid-liquid extraction of antioxidants from grape byproducts. J. Food Eng. 2006, 77, 57–63. [Google Scholar] [CrossRef]

- Carrillo, L.C.; Londoño-Londoño, J.; Gil, A. Comparison of polyphenol, methylxanthines and antioxidant activity in Theobroma cacao beans from different cocoa-growing areas in Colombia. Food Res. Int. 2014, 60, 273–280. [Google Scholar] [CrossRef]

- Ioannone, F.; Di Mattia, C.D.; De Gregorio, M.; Sergi, M.; Serafini, M.; Sacchetti, G. Flavanols, proanthocyanidins and antioxidant activity changes during cocoa (Theobroma cacao L.) roasting as affected by temperature and time of processing. Food Chem. 2015, 174, 256–262. [Google Scholar] [CrossRef]

- Patras, M.A.; Milev, B.P.; Vrancken, G.; Kuhnert, N. Identification of novel cocoa flavonoids from raw fermented cocoa beans by HPLC-MSn. Food Res. Int. 2014, 63, 353–359. [Google Scholar] [CrossRef]

- Chew, K.K.; Khoo, M.Z.; Ng, S.Y.; Thoo, Y.Y.; Aida, W.M.W.; Ho, C.W. Effect of ethanol concentration, extraction time and extraction temperature on the recovery of phenolic compounds and antioxidant capacity of Orthosiphon stamineus extracts. Int. Food Res. J. 2011, 18, 1427–1435. [Google Scholar]

- Singleton, V.L.; Orthofer, R.; Lamuela-Raventós, R.M. Analysis of total phenols and other oxidation substrates and antioxidants by means of folin-ciocalteu reagent. Methods Enzymol. 1998, 299, 152–178. [Google Scholar]

- Zhishen, J.; Mengcheng, T.; Jianming, W. The determination of flavonoid contents in mulberry and their scavenging effects on superoxide radicals. Food Chem. 1999, 64, 555–559. [Google Scholar] [CrossRef]

- Sun, B.; Ricardo-da-Silva, J.M.; Spranger, I. Critical Factors of Vanillin Assay for Catechins and Proanthocyanidins. J. Agric. Food Chem. 1998, 46, 4267–4274. [Google Scholar] [CrossRef]

- Amendola, D.; De Faveri, D.M.; Spigno, G. Grape marc phenolics: Extraction kinetics, quality and stability of extracts. J. Food Eng. 2010, 97, 384–392. [Google Scholar] [CrossRef]

- Doymaz, İ.; İsmail, O. Drying characteristics of sweet cherry. Food Bioprod. Process. 2011, 89, 31–38. [Google Scholar] [CrossRef]

- Peleg, M. An Empirical Model for the Description of Moisture Sorption Curves. J. Food Sci. 1988, 53, 1216–1217. [Google Scholar] [CrossRef]

- Spiro, M.; Jago, D.S. Kinetics and equilibria of tea infu- sion. Part 3. Rotating disc experiments interpreted by a steady state model. J. Chem. Soc. Faraday Trans. 1 1982, 78, 295–305. [Google Scholar] [CrossRef]

- Sant’Anna, V.; Brandelli, A.; Marczak, L.D.F.; Tessaro, I.C. Kinetic modeling of total polyphenol extraction from grape marc and characterization of the extracts. Sep. Purif. Technol. 2012, 100, 82–87. [Google Scholar] [CrossRef]

- Toro-Uribe, S.; López-Giraldo, L.J.; Decker, E.A. Relationship between the physiochemical properties of cocoa procyanidins and their ability to inhibit lipid oxidation in liposomes. J. Agric. Food Chem. 2018, 66, 4490–4502. [Google Scholar] [CrossRef] [PubMed]

- Huang, D.; Ou, B.; Hampsch-Woodill, M.; Flanagan, J.A.; Prior, R.L. High-throughput assay of oxygen radical absorbance capacity (ORAC) using a multichannel liquid handling system coupled with a microplate fluorescence reader in 96-well format. J. Agric. Food Chem. 2002, 50, 4437–4444. [Google Scholar] [CrossRef]

- Brand-Williams, W.; Cuvelier, M.E.; Berset, C. Use of a free radical method to evaluate antioxidant activity. LWT Food Sci. Technol. 1995, 28, 25–30. [Google Scholar] [CrossRef]

- Kothe, L.; Zimmermann, B.F.; Galensa, R. Temperature influences epimerization and composition of flavanol monomers, dimers and trimers during cocoa bean roasting. Food Chem. 2013, 141, 3656–3663. [Google Scholar] [CrossRef]

- Sun, Y.; Liu, D.; Chen, J.; Ye, X.; Yu, D. Effects of different factors of ultrasound treatment on the extraction yield of the all-trans-B-carotene from citrus peels. Ultrason. Sonochem. 2011, 18, 243–249. [Google Scholar] [CrossRef]

- Goula, A.M. Ultrasound-assisted extraction of pomegranate seed oil—Kinetic modeling. J. Food Eng. 2013, 117, 492–498. [Google Scholar] [CrossRef]

- Hoskin, J.M.; Dimick, P.S.; Daniels, R.R. Scanning Electron Microscopy of the Theobroma cacao Seed. J. Food Sci. 1980, 45, 1538–1540. [Google Scholar] [CrossRef]

- Lopez, A.S.; Dimick, P.S.; Walsh, R.M. Scanning Electron Microscopy Studies of the Cellular Changes in Raw, Fermented and Dried Cocoa. Food Struct. 1987, 6, 9–16. [Google Scholar]

- Rostagno, M.A.; Palma, M.; Barroso, C.G. Ultrasound-assisted extraction of soy isoflavones. J. Chromatogr. A 2003, 1012, 119–128. [Google Scholar] [CrossRef]

- Cacace, J.E.; Mazza, G. Mass transfer process during extraction of phenolic compounds from milled berries. J. Food Eng. 2003, 59, 379–389. [Google Scholar] [CrossRef]

- Mokrani, A.; Madani, K. Effect of solvent, time and temperature on the extraction of phenolic compounds and antioxidant capacity of peach (Prunus persica L.) fruit. Sep. Purif. Technol. 2016, 162, 68–76. [Google Scholar] [CrossRef]

- Rakotondramasy-Rabesiaka, L.; Havet, J. Estimation of effective diffusion and transfer rate during the protopine extraction process from Fumaria officinalis L. Sep. Purif. Technol. 2010, 76, 126–131. [Google Scholar] [CrossRef]

- Datta, C.; Dutta, A.; Dutta, D.; Chaudhuri, S. Adsorption of polyphenols from ginger rhizomes on an anion exchange resin Amberlite IR-400—Study on effect of pH and temperature. Procedia Food Sci. 2011, 1, 893–899. [Google Scholar] [CrossRef] [Green Version]

- Galvan D’Alessandro, L.; Kriaa, K.; Nikov, I.; Dimitrov, K. Ultrasound assisted extraction of polyphenols from black chokeberry. Sep. Purif. Technol. 2012, 93, 42–47. [Google Scholar] [CrossRef]

- Othman, S.N.S.; Mustapa, A.N.; Ku Hamid, K.H. Extraction of polyphenols from Clinacanthus nutans Lindau (C. nutans) by vacuum solvent-free microwave extraction (V-SFME). Chem. Eng. Commun. 2020. [Google Scholar] [CrossRef]

- Bucić-Kojić, A.; Planinić, M.; Tomas, S.; Bilić, M.; Velić, D. Study of solid-liquid extraction kinectics of total polyphenols from grape seeds. J. Food Eng. 2007, 81, 236–242. [Google Scholar] [CrossRef]

- Tomas-Barberán, F.A.; Cienfuegos-Jovellanos, E.; Marín, A.; Muguerza, B.; Gil-Izquierdo, A.; Cerdá, B.; Zafrilla, P.; Morillas, J.; Mulero, J.; Ibarra, A.; et al. A new process to develop a cocoa powder with higher flavonoid monomer content and enhanced bioavailability in healthy humans. J. Agric. Food Chem. 2007, 55, 3926–3935. [Google Scholar] [CrossRef] [PubMed]

- Maisuthisakul, P. Antioxidant Potential and Phenolic Constituents of Mango Seed. Kasetsart J. Nat. Sci. 2009, 297, 290–297. [Google Scholar]

- Crozier, S.J.; Hurst, W.J. Cocoa Polyphenols and Cardiovascular Health. In Polyphenols in Human Health and Disease; Watson, R.R., Preedy, V.R., Zibadi, S., Eds.; Elsevier Inc.: Amsterdam, The Netherlands, 2013; Volume 2, pp. 1077–1085. ISBN 9780123984562. [Google Scholar]

- Racine, K.C.; Wiersema, B.D.; Griffin, L.E.; Essenmacher, L.A.; Lee, A.H.; Hopfer, H.; Lambert, J.D.; Stewart, A.C.; Neilson, A.P. Flavanol polymerization is a superior predictor of α-glucosidase inhibitory activity compared to flavanol or total polyphenol concentrations in cocoas prepared by variations in controlled fermentation and roasting of the same raw cocoa beans. Antioxidants 2019, 8, 635. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hasing, M.H. Estudio de la Variación en los Contenidos de Polifenoles y Alcaloides, en Almendras de Cacao por Efecto de los Procesos de Fermentación y Tostado. Ph.D. Thesis, Escuela Superior Politécnica de Chimborazo, Facultad de Ciencias, Escuela de Bioquímica y Farmacia, Riobamba, Ecuador, 2004. [Google Scholar]

- Fernández-Romero, E.; Chavez-Quintana, S.G.; Siche, R.; Castro-Alayo, E.M.; Cardenas-Toro, F.P. The kinetics of total phenolic content and monomeric Flavan-3-ols during the roasting process of Criollo Cocoa. Antioxidants 2020, 9, 7–10. [Google Scholar] [CrossRef] [Green Version]

- Niemenak, N.; Rohsius, C.; Elwers, S.; Ndoumou, D.; Liebereri, R. Comparative study of different cocoa (Theobroma cacao L.) clones in terms of their phenolics and anthocyanins contents. J. Food Compos. Anal. 2006, 19, 612–619. [Google Scholar] [CrossRef]

- Rockenbach, I.I.; Jungfer, E.; Ritter, C.; Santiago-Schübel, B.; Thiele, B.; Fett, R.; Galensa, R. Characterization of flavan-3-ols in seeds of grape pomace by CE, HPLC-DAD-MS n and LC-ESI-FTICR-MS. Food Res. Int. 2012, 48, 848–855. [Google Scholar] [CrossRef] [Green Version]

- Hurst, W.J.; Payne, M.J.; Miller, K.B.; Stuart, D.A. Stability of cocoa antioxidants and flavan-3-ols over time. J. Agric. Food Chem. 2009, 57, 9547–9550. [Google Scholar] [CrossRef] [PubMed]

- Summa, C.; Raposo, F.C.; McCourt, J.; Scalzo, R.L.; Wagner, K.H.; Elmadfa, I.; Anklam, E. Effect of roasting on the radical scavenging activity of cocoa beans. Eur. Food Res. Technol. 2006, 222, 368–375. [Google Scholar] [CrossRef]

| Drying Method | Enthalpy of Sublimation (kJ/mol) * | Time (h) | Total Polyphenol Content (mgGAE/g) |

|---|---|---|---|

| Freeze Drying | 51.00 | 48 | 43.99 ± 0.25 a |

| Oven-air (50 °C) | 41.69 | 20 | 38.96 ± 1.47 b |

| Oven-air (70 °C) | 40.84 | 3 | 43.20 ± 0.73 a |

| T (°C) | SS (w/v) | EW (v/v) | pH | TP (mgGAE/g) | TF (mgECE/g) | TF3 (mgECE/g) |

|---|---|---|---|---|---|---|

| 60 | 1/30 | 25 | 5 | 78.22 ± 1.17 | 62.30 ± 1.75 | 35.07 ± 0.14 |

| 50 | 1/24 | 50 | 4 | 94.15 ± 0.50 | 79.64 ± 1.88 | 48.62 ± 0.59 |

| 50 | 1/40 | 50 | 2 | 98.86 ± 0.52 | 55.87 ± 2.60 | 39.46 ± 0.25 |

| 60 | 1/60 | 75 | 3 | 103.57 ± 1.25 | 57.48 ± 0.39 | 43.78 ± 0.90 |

| 40 | 1/30 | 75 | 3 | 92.23 ± 1.79 | 77.30 ±4.10 | 42.89 ± 0.27 |

| 60 | 1/60 | 25 | 3 | 91.59 ± 1.30 | 52.36 ± 0.39 | 40.74 ± 0.98 |

| 50 | 1/40 | 50 | 2 | 98.17 ± 1.10 | 53.84 ± 2.34 | 38.01 ± 0.13 |

| 40 | 1/30 | 75 | 3 | 95.81 ± 0.07 | 68.77 ± 3.51 | 40.75 ± 0.24 |

| 50 | 1/40 | 50 | 6 | 98.85 ± 0.65 | 66.45 ± 2.08 | 59.28 ± 0.98 |

| 50 | 1/40 | 50 | 4 | 95.96 ± 0.82 | 67.97 ± 4.16 | 51.26 ± 0.09 |

| 50 | 1/120 | 50 | 4 | 107.59 ± 0.52 | 53.74 ±0.77 | 55.21 ± 1.39 |

| 50 | 1/40 | 50 | 6 | 97.53 ± 0.26 | 64.31 ± 0.26 | 59.78 ± 1.54 |

| 60 | 1/30 | 75 | 3 | 97.90 ± 0.93 | 73.11 ± 2.35 | 47.46 ± 0.04 |

| 50 | 1/40 | 50 | 4 | 95.52 ± 0.61 | 63.01 ± 3.38 | 47.38 ± 0.93 |

| 40 | 1/30 | 75 | 5 | 81.23 ± 0.23 | 76.18 ± 4.30 | 50.28 ± 1.40 |

| 40 | 1/30 | 25 | 5 | 76.97 ± 1.29 | 61.21 ± 0.96 | 42.77 ± 0.28 |

| 40 | 1/60 | 75 | 5 | 91.56 ± 0.19 | 49.34 ± 2.72 | 42.19 ± 0.63 |

| 60 | 1/30 | 25 | 3 | 82.64 ± 0.13 | 59.53 ± 0.59 | 39.84 ± 0.07 |

| 60 | 1/60 | 75 | 5 | 89.26 ± 0.45 | 57.78 ± 0.39 | 58.68 ± 1.12 |

| 50 | 1/40 | 100 | 4 | 46.79 ± 0.44 | 15.18 ± 1.30 | 22.72 ± 0.37 |

| 40 | 1/60 | 25 | 3 | 84.58 ± 0.19 | 50.93 ± 3.12 | 38.83 ± 0.99 |

| 40 | 1/30 | 25 | 3 | 76.06 ± 0.69 | 55.74 ± 2.91 | 43.87 ± 0.21 |

| 40 | 1/60 | 25 | 3 | 84.45 ± 0.99 | 51.83 ± 3.52 | 40.37 ± 1.28 |

| 30 | 1/40 | 50 | 4 | 88.59 ± 0.13 | 74.73 ± 1.56 | 42.52 ± 0.14 |

| 70 | 1/40 | 50 | 4 | 100.04 ± 0.69 | 79.73 ± 4.14 | 58.04 ± 0.51 |

| 60 | 1/60 | 25 | 3 | 82.98 ± 2.23 | 55.26 ± 1.16 | 39.85 ± 0.85 |

| 40 | 1/30 | 25 | 5 | 78.95 ± 1.03 | 59.04 ± 3.69 | 46.46 ± 0.21 |

| 40 | 1/60 | 75 | 3 | 102.28 ± 2.25 | 46.02 ± 3.91 | 29.49 ± 0.61 |

| 60 | 1/30 | 25 | 5 | 81.21 ± 0.45 | 64.10 ± 3.88 | 38.59 ± 0.36 |

| 50 | 1/120 | 50 | 4 | 104.96 ± 0.91 | 55.91 ± 1.56 | 55.57 ± 0.56 |

| 60 | 1/30 | 75 | 5 | 83.48 ± 0.58 | 74.43 ± 4.27 | 55.98 ± 0.52 |

| 50 | 1/40 | 0 | 4 | 43.45 ± 1.22 | 22.40 ± 1.56 | 21.73 ± 0.09 |

| 40 | 1/60 | 25 | 5 | 76.43 ± 1.17 | 56.35 ± 2.34 | 41.86 ± 0.42 |

| 50 | 1/40 | 0 | 4 | 41.32 ± 0.22 | 17.09 ± 0.26 | 25.81 ± 0.65 |

| 30 | 1/40 | 50 | 4 | 89.97 ± 0.91 | 77.91 ± 2.60 | 41.31 ± 0.23 |

| 40 | 1/30 | 25 | 3 | 79.12 ± 0.67 | 58.51 ± 0.39 | 39.37 ± 0.25 |

| 60 | 1/30 | 75 | 5 | 84.29 ± 0.39 | 75.47 ± 4.26 | 52.63 ± 1.39 |

| 60 | 1/30 | 25 | 3 | 82.19 ± 0.39 | 59.47 ± 3.50 | 36.21 ± 0.39 |

| 60 | 1/60 | 75 | 5 | 89.01 ± 1.36 | 57.96 ± 1.16 | 54.35 ± 1.74 |

| 50 | 1/40 | 50 | 4 | 90.36 ± 0.48 | 69.19 ± 4.17 | 44.92 ± 0.84 |

| 60 | 1/60 | 25 | 5 | 85.11 ± 0.33 | 59.55 ± 1.95 | 44.08 ± 0.35 |

| 50 | 1/24 | 50 | 4 | 100.27 ± 0.05 | 86.05 ± 4.53 | 53.69 ± 0.25 |

| 70 | 1/40 | 50 | 4 | 97.97 ± 0.26 | 82.05 ± 2.08 | 58.80 ± 0.84 |

| 60 | 1/60 | 75 | 3 | 95.49 ± 2.51 | 53.52 ± 0.78 | 46.89 ± 1.50 |

| 60 | 1/30 | 75 | 3 | 98.69 ± 0.57 | 72.95 ± 3.50 | 49.99 ± 1.22 |

| 50 | 1/40 | 50 | 4 | 93.54 ± 1.13 | 64.19 ± 1.30 | 45.78 ± 0.77 |

| 40 | 1/30 | 75 | 5 | 81.22 ± 0.49 | 70.55 ± 2.15 | 47.68 ± 0.77 |

| 50 | 1/40 | 50 | 4 | 90.52 ± 0.30 | 65.81 ± 4.16 | 50.50 ± 0.79 |

| 50 | 1/40 | 50 | 4 | 91.27 ± 0.17 | 64.09 ± 3.90 | 50.16 ± 0.19 |

| 40 | 1/60 | 25 | 5 | 77.75 ± 0.91 | 51.53 ± 0.39 | 41.35 ± 1.01 |

| 40 | 1/60 | 75 | 3 | 99.96 ± 1.39 | 45.00 ± 1.55 | 32.91 ± 1.12 |

| 60 | 1/60 | 25 | 5 | 87.44 ± 1.25 | 56.65 ± 2.73 | 41.67 ± 0.85 |

| 50 | 1/40 | 100 | 4 | 47.40 ± 0.35 | 15.19 ± 0.78 | 23.69 ± 0.28 |

| 40 | 1/60 | 75 | 5 | 92.33 ± 0.32 | 48.27 ± .50 | 46.59 ± 0.14 |

| Control by S-L extraction (Yield = 14.9%) | 49.35 ± 2.06 a | 35.71 ± 0.19 a | 26.41 ± 1.88 a | |||

| Optimum by S-L Extract. (Yield = 16.8%) | 122.34 ± 2.35 b | 88.86 ± 0.78 b | 62.57 ± 3.37 b | |||

| Model | Parameters for TP | Parameters for TF | Parameters for TF3 | Ref. | |

|---|---|---|---|---|---|

| nth order (1) | [26] | ||||

| r RMSE | 0.93 8.23 | 0.90 5.46 | 0.90 4.19 | ||

| Page (2) | [23] | ||||

| r RMSE | 0.93 8.52 | 0.89 5.55 | 0.89 4.22 | ||

| Peleg (3) | [24] | ||||

| r RMSE | 0.98 0.71 | 0.99 0.62 | 0.99 0.67 | ||

| Weibull-type (4) | [22] | ||||

| r RMSE | 0.93 8.33 | 0.89 5.51 | 0.90 4.32 | ||

| Mincher and Minkov (5) | [26] | ||||

| r RMSE | 0.64 22.06 | 0.68 12.47 | 0.71 8.35 | ||

| Pseudo first order (6) | [25] | ||||

| r RMSE | 0.98 6.49 | 0.98 5.59 | 0.99 2.29 | ||

| Compound | Reverse Phase | Ionization | Predicted Mass (mau) | Observed Mass (mau) | Error (mau) | HPLC-ESI-MSn | |

|---|---|---|---|---|---|---|---|

| Retention Time (min) | Concentration * (ppm) | MS2 Fragment (m/z) | |||||

| Theobromine | 1.42 | 7.78 ± 0.01 | [M + H]+ | 181.07 | 181.8 | 0.73 | 137.5, 110.5 |

| Caffeine | 5.01 | 2.65 ± 0.02 | [M + H]+ | 195.08 | 195.5 | 0.42 | 158.4, 138.7 |

| Catechin | 2.16 | 0.62 ± 0.01 | [M − H]+ | 291.08 | 292.3 | 1.22 | 273.3, 165.3, 139.4, 123.7 |

| Epicatechin | 5.46 | 7.30 ± 0.10 | [M − H]+ | 291.08 | 292.3 | 1.22 | 273.3, 165.3, 139.3, 123.6 |

| Dimer B2 | 6.22 | 4.06 ± 0.03 | [M − H]− | 577.14 | 577.4 | 0.26 | 451.2, 425.1, 289.1, 271.1 |

| Trimer C1 | 12.91 | 11.99 ± 0.25 | [M − H]− | 865.19 | 865.4 | 0.21 | 695.2, 577.2, 451.0, 289.0 |

| Tetramer D | 16.81 | 9.33 ± 0.40 | [M − H]− | 1153.26 | 1153.6 | 0.34 | 1027.3, 865.3, 739.2, 577.1 |

| Pentamer | 19.91 | 6.81 ± 0.52 | [M − H]− | 1441.33 | 1441.3 | 0.03 | 1153.3, 865.2, 691.6, 574.3 |

| Hexamer | 20.85 | 1.81 ± 0.01 | [M − H]− | 1729.38 | 1729.3 | 0.08 | 1534.0, 1153.3, 865.2, 574.2 |

| Heptamer | 22.51 | ND | [M − H]− | 2017.45 | 2019.3 | 1.85 | 1153.4, 995.3,851.3, 574.3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Toro-Uribe, S.; Ibañez, E.; Decker, E.A.; Villamizar-Jaimes, A.R.; López-Giraldo, L.J. Food-Safe Process for High Recovery of Flavonoids from Cocoa Beans: Antioxidant and HPLC-DAD-ESI-MS/MS Analysis. Antioxidants 2020, 9, 364. https://doi.org/10.3390/antiox9050364

Toro-Uribe S, Ibañez E, Decker EA, Villamizar-Jaimes AR, López-Giraldo LJ. Food-Safe Process for High Recovery of Flavonoids from Cocoa Beans: Antioxidant and HPLC-DAD-ESI-MS/MS Analysis. Antioxidants. 2020; 9(5):364. https://doi.org/10.3390/antiox9050364

Chicago/Turabian StyleToro-Uribe, Said, Elena Ibañez, Eric A. Decker, Arley René Villamizar-Jaimes, and Luis Javier López-Giraldo. 2020. "Food-Safe Process for High Recovery of Flavonoids from Cocoa Beans: Antioxidant and HPLC-DAD-ESI-MS/MS Analysis" Antioxidants 9, no. 5: 364. https://doi.org/10.3390/antiox9050364

APA StyleToro-Uribe, S., Ibañez, E., Decker, E. A., Villamizar-Jaimes, A. R., & López-Giraldo, L. J. (2020). Food-Safe Process for High Recovery of Flavonoids from Cocoa Beans: Antioxidant and HPLC-DAD-ESI-MS/MS Analysis. Antioxidants, 9(5), 364. https://doi.org/10.3390/antiox9050364