Electrospun PCL Patches with Controlled Fiber Morphology and Mechanical Performance for Skin Moisturization via Long-Term Release of Hemp Oil for Atopic Dermatitis

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Electrospinning

2.2. Scanning Electron Microscopy (SEM) and Mechanical Testing

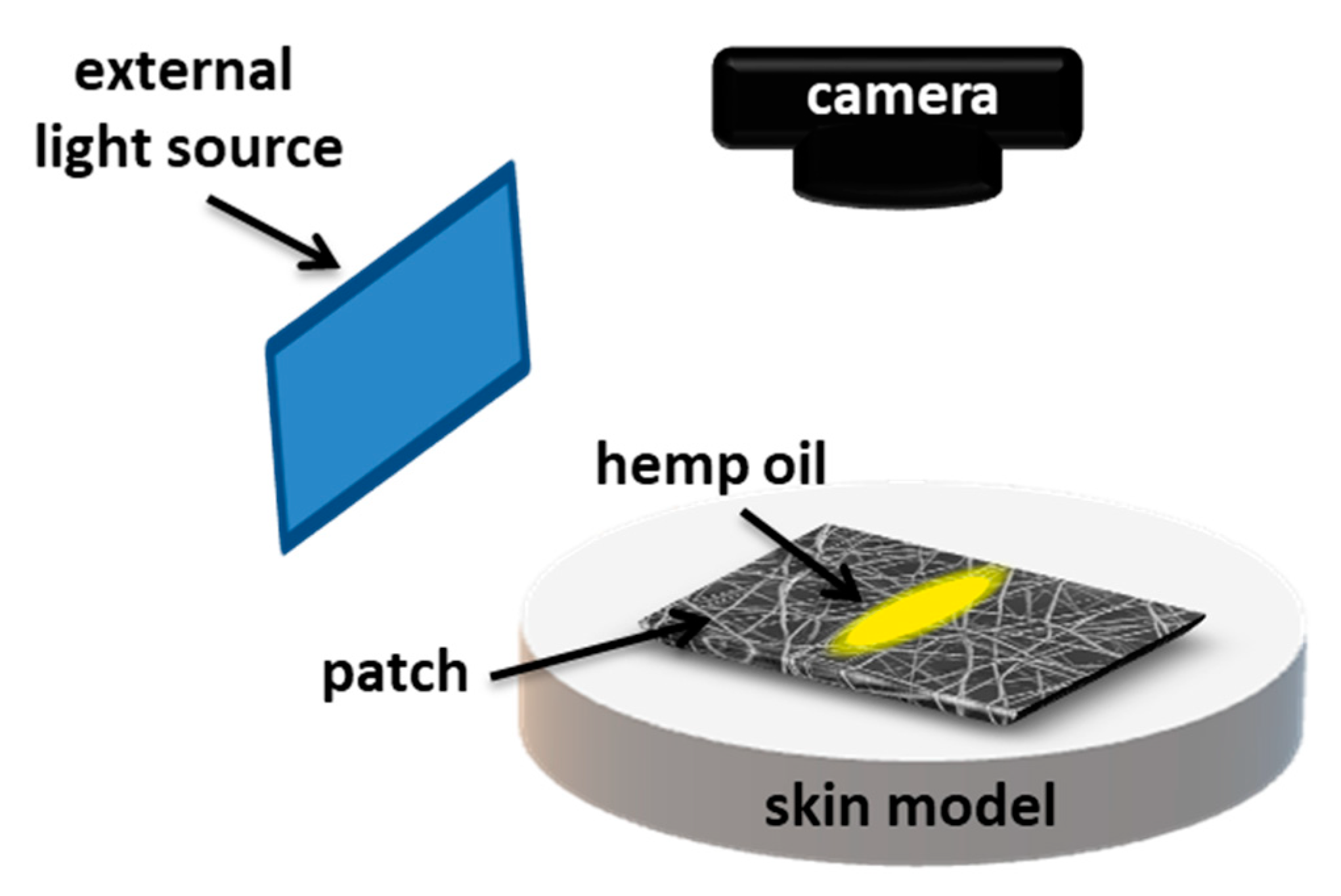

2.3. Skin Model Preparation, Oil Spreading, and Release Tests

2.4. Statistical Analysis

3. Results

3.1. Morphology and Sizes of PCL Fibers

3.2. Mechanical Properties of PCL Fibers

3.3. Oil Spreading and Release

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Sugita, K.; Akdis, C.A. Recent developments and advances in atopic dermatitis and food allergy. Allergol. Int. 2020, 69, 204–214. [Google Scholar] [CrossRef] [PubMed]

- Khalad, M.; Sibbald, C.; Pope, E.; Sibbald, R.G. Diagnosis and Management of Atopic Dermatitis: A Review. Adv. Ski. Wound Care 2019, 31, 538–550. [Google Scholar] [CrossRef]

- Kim, J.; Kim, B.E.; Leung, D.Y.M. Pathophysiology of atopic dermatitis: Clinical implications. Allergy Astma Proc. 2019, 40, 84–92. [Google Scholar] [CrossRef] [PubMed]

- Krasia-Christoforou, T.; Georgiou, T.K. Polymeric theranostics: Using polymer-based systems for simultaneous imaging and therapy. J. Mater. Chem. B 2013, 1, 3002–3025. [Google Scholar] [CrossRef]

- Lalan, M.; Baweja, J.; Misra, A. Atopic Dermatitis: Drug Delivery Approaches in Disease Management. Crit. Rev. Ther. Drug Carrier Syst. 2015, 32, 323–361. [Google Scholar] [CrossRef]

- Nussinovitch, A.; Gal, A.; Padula, C.; Santi, P. Physical Characterization of a New Skin Bioadhesive Film. AAPS PharmSCiTech 2008, 9, 458–463. [Google Scholar] [CrossRef] [Green Version]

- Metwally, S.; Karbowniczek, J.E.; Szewczyk, P.K.; Marzec, M.M.; Gruszczyński, A.; Bernasik, A.; Staczewicz, U. Single-step approach to tailor surface chemistry and potential on electrospun PCL fibers for tissue engineering application. Adv. Mater. Interfaces 2018, 6, 1801211. [Google Scholar] [CrossRef]

- Kaniuk, Ł.; Krysiak, Z.J.; Metwally, S.; Stachewicz, U. Osteoblasts and fibroblasts attachment to poly(3-hydroxybutyric acid-co-3-hydrovaleric acid) (PHBV) film and electrospun scaffolds. Mater. Sci. Eng. C 2020, 110, 110668. [Google Scholar] [CrossRef]

- Metwally, S.; Ferraris, S.; Spriano, S.; Krysiak, Z.J.; Kaniuk, Ł.; Marzec, M.M.; Kim, S.K.; Szewczyk, P.K.; Gruszczynski, A.; Wytrwal-Sarna, M.; et al. Surface potential and roughness controlled cell adhesion and collagen formation in electrospun PCL fibers for bone regeneration. Mater. Des. 2020, 194, 108915. [Google Scholar] [CrossRef]

- Nakielski, P.; Pierini, F. Blood interactions with nano- and microfibers: Recent advances, challenges and applications in nano- and microfibrous hemostatic agents. Acta Biomater. 2018, 84, 63–76. [Google Scholar] [CrossRef]

- Hakimi, O.; Murphy, R.J.; Stachewicz, U. An electrospun polydioxanone patch for the localisation of biological therapies during tendon repair. Eur. Cells Mater. 2012, 24, 344–357. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Cheng, S.; Lu, W.; Wang, Y.; Zhang, P.; Yao, Q. Electrospun fibers and their application in drug controlled release, biological dressings, tissue repair, and enzyme immobilization. RSC Adv. 2019, 9, 25712–25729. [Google Scholar] [CrossRef] [Green Version]

- Chen, S.; Liu, B.; Carlson, M.A.; Adrian, F.; Xie, J. Recent advances in electrospun nanofibers for wound healing. Nanomedicine 2017, 12, 1335–1352. [Google Scholar] [CrossRef] [PubMed]

- Ivanoska-Dacikj, A.; Stachewicz, U. Smart textiles and wearable technologies – opportunities offered in the fight against pandemics in relation to current COVID-19 state. Rev. Adv. Mater. Sci. 2020, 59, 487. [Google Scholar] [CrossRef]

- Tebyetekerwa, M.; Xu, Z.; Yang, S.; Ramakrishna, S. Electrospun Nanofibers-Based Face Masks. Adv. Fiber Mater. 2020, 2, 161–166. [Google Scholar] [CrossRef]

- Augustine, R.; Dominic, E.A.; Reju, I.; Kaimal, B.; Kalarikkal, N.; Thomas, S. Electrospun polycaprolactone-based skin substitutes: In vivo evaluation of wound healing and the mechanism of cell proliferation. J. Biomed. Mater. Res. Part B Appl. Biomater. 2015, 103, 1445–1454. [Google Scholar] [CrossRef]

- Pilehvar-Soltanahmadi, Y.; Akbarzadeh, A.; Moazzez-Lalaklo, N.; Zarghami, N. An update on clinical applications of electrospun nanofibers for skin bioengineering. Artif. Cells Nanomed. Biotechnol. 2016, 44, 1350–1364. [Google Scholar] [CrossRef]

- Venugopal, J.R.; Zhang, Y.; Ramakrishna, S. In Vitro Culture of Human Dermal Fibroblasts on Electrospun Polycaprolactone Collagen Nanofibrous Membrane. Artif. Organs 2006, 30, 440–446. [Google Scholar] [CrossRef]

- Byeon, A.Y.; Cho, M.K.; Shim, K.H.; Kim, H.J.; Song, H.G.; Shin, S.H. Development of a Spirulina Extract/Alginate-Imbedded PCL Nanofibrous Cosmetic Patch. J. Microbiol. Biotechnol 2017, 27, 1657–1663. [Google Scholar] [CrossRef] [Green Version]

- Goddard, A.L.; Lio, P.A. Alternative, Complementary, and Forgotten Remedies for Atopic Dermatitis. Evidence-Based Complement. Altern. Med. 2015, 2015, 676897. [Google Scholar] [CrossRef] [Green Version]

- Callaway, J.C. Hempseed as a nutritional resource: An overview. Euphytica 2004, 140, 65–72. [Google Scholar] [CrossRef]

- Callaway, J.; Schwab, U.; Harvima, I.; Halonen, P.; Ja, T.; Mykka, O. Efficacy of dietary hempseed oil in patients with atopic dermatitis. J. Dermatolog. Treat. 2005, 16, 87–94. [Google Scholar] [CrossRef]

- Grigoriev, O. V Application of Hempseed (Cannabis sativa L.) Oil in the Treatment of Ear, Nose and Throat (ENT) Disorders. J. Ind. Hemp 2002, 7, 5–15. [Google Scholar] [CrossRef]

- Krysiak, Z.J.; Kaniuk, Ł.; Metwally, S.; Szewczyk, P.K.; Sroczyk, E.A.; Peer, P.; Lisiecka-graca, P.; Bailey, R.J.; Bilotti, E.; Stachewicz, U. Nano- and Micro fiber PVB Patches as Natural Oil Carriers for Atopic Skin Treatment. ACS Appl. Bio Mater. 2020. [Google Scholar] [CrossRef]

- Katsogiannis, K.A.G.; Vladisavljević, G.T.; Georgiadou, S. Porous electrospun polycaprolactone (PCL) fibres by phase separation. Eur. Polym. J. 2015, 69, 284–295. [Google Scholar] [CrossRef] [Green Version]

- Nezarati, R.M.; Eifert, M.B.; Cosgriff-hernandez, E. Effects of Humidity and Solution Viscosity on Electrospun Fiber Morphology. Tissue Eng Part C 2013, 19, 810–819. [Google Scholar] [CrossRef] [Green Version]

- Hekmati, A.H.; Rashidi, A.; Ghazisaeidi, R.; Drean, J. Process Optimization for the Electrospinning of Polycaprolactone Nanofibers Using Non-halogenated Solvents. Proc. Int. Conf. New Trends Transp. Phenom. 2014, 1–8. [Google Scholar] [CrossRef]

- Kim, J.I.; Hwang, T.I.; Aguilar, L.E.; Park, C.H.; Kim, C.S. A Controlled Design of Aligned and Random Nanofibers for 3D Bi-functionalized Nerve Conduits Fabricated via a Novel Electrospinning Set-up. Sci. Rep. 2016, 29, 23761. [Google Scholar] [CrossRef] [Green Version]

- Delaine-Smith, R.M.; Green, N.H.; Matcher, S.J.; Macneil, S.; Reilly, G.C. Monitoring Fibrous Scaffold Guidance of Three-Dimensional Collagen Organisation Using Minimally-Invasive Second Harmonic Generation. PLoS ONE 2014, 28, e89761. [Google Scholar] [CrossRef]

- Soliman, S.; Sant, S.; Nichol, J.W.; Khabiry, M.; Traversa, E.; Khademhosseini, A. Controlling the porosity of fibrous scaffolds by modulating the fiber diameter and packing density. J. Biomed. Mater. Res. A 2011, 96, 566–574. [Google Scholar] [CrossRef]

- Kim, J. Biopolymer Composites in Electronics, 1st ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2017; ISBN 9780128092613. [Google Scholar]

- Taylor, P.; Thomas, V.; Jose, M.V.; Chowdhury, S.; Jonathan, F.; Dean, D.R.; Vohra, Y.K. Mechano-morphological studies of aligned nanofibrous scaffolds of polycaprolactone fabricated by electrospinning. J. Biomater. Sci. 2012, 17, 969–984. [Google Scholar] [CrossRef]

- Kiselev, P.; Rosell-llompart, J. Highly Aligned Electrospun Nanofibers by Elimination of the Whipping Motion. Appl. Polym. Sci. 2012, 125, 2433–2441. [Google Scholar] [CrossRef]

- Kim, G.H. Electrospun PCL nanofibers with anisotropic mechanical properties as a biomedical scaffold. Biomed. Mater. 2007, 3, 025010. [Google Scholar] [CrossRef]

- Wong, S.; Baji, A.; Leng, S. Effect of fiber diameter on tensile properties of electrospun poly(3-caprolactone). Polymer 2008, 49, 4713–4722. [Google Scholar] [CrossRef]

- Dwivedi, R.; Kumar, S.; Pandey, R.; Mahajan, A.; Nandana, D.; Katti, D.S.; Mehrotra, D. Polycaprolactone as biomaterial for bone scaffolds: Review of literature. J. Oral Biol. Craniofacial Res. 2019, 10, 381–388. [Google Scholar] [CrossRef]

- Stachewicz, U.; Modaresifar, F.; Bailey, R.J.; Peijs, T.; Barber, A.H. Manufacture of Void-Free Electrospun Polymer Nanofiber Composites with Optimized Mechanical Properties. ACS Appl. Mater. Interfaces 2012, 4, 2577–2582. [Google Scholar] [CrossRef] [PubMed]

- Stachewicz, U.; Peker, I.; Tu, W.; Barber, A.H. Stress delocalization in crack tolerant electrospun nanofiber networks. ACS Appl. Mater. Interfaces 2011, 3, 1991–1996. [Google Scholar] [CrossRef]

- Stachewicz, U.; Hang, F.; Barber, A.H. Adhesion anisotropy between contacting electrospun fibers. Langmuir 2014, 30, 6819–6825. [Google Scholar] [CrossRef]

- Szewczyk, P.K.; Ura, D.P.; Stachewicz, U. Humidity Controlled Mechanical Properties of Electrospun Polyvinylidene Fluoride (PVDF) Fibers. Fibers 2020, 8, 65. [Google Scholar] [CrossRef]

- Ura, D.P.; Rosell-Llompart, J.; Zaszczyńska, A.; Vasilyev, G.; Gradys, A.; Szewczyk, P.K.; Knapczyk-Korczak, J.; Avrahami, R.; Šiškov, A.O.; Arinstein, A.; et al. The Role of Electrical Polarity in Electrospinning and on the Mechanical and Structural Properties of As-Spun Fibers. Materials 2020, 13, 4169. [Google Scholar] [CrossRef]

- Mittal, K.L.; Etzler, F.M. Adhesion in Pharmaceutical, Biomedical, and Dental Fields; Whiley Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

- Demir, M.M.; Horzum, N.; Tasdemerici, A.; Turan, K.; Guden, M. Mechanical Interlocking between Porous Electrospun Polystyrene Fibers and an Epoxy Matrix. ACS Appl. Mater. Interfaces 2014, 6, 21901–21905. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Seuba, J.; Deville, S.; Guizard, C.; Stevenson, A.J. Mechanical properties and failure behavior of unidirectional porous ceramics. Sci. Rep. 2016, 14, 24326. [Google Scholar] [CrossRef] [Green Version]

- Ngoc, D.; Lan, U.; Bakar, A.A.; Azahari, B.; Ariff, Z.M.; Chujo, Y. Effect of interlocking between porous epoxy microparticles and elastomer on mechanical properties and deformation modes. Polym. Test. 2012, 31, 931–937. [Google Scholar] [CrossRef]

- Melnik, B.C.; Plewig, G.; Tschung, T. Disturbances of Essential Fatty Acid- and Prostaglandin E-Mediated Immunoregulation in Atopy. Prostaglandins, Leukot. Essent. Fat. Acids 1991, 42, 125–130. [Google Scholar] [CrossRef]

- Deng, Y.; Winter, G.; Myschik, J. Preparation and validation of a skin model for the evaluation of intradermal powder injection devices. Eur. J. Pharm. Biopharm. 2012, 81, 360–368. [Google Scholar] [CrossRef]

- Dąbrowska, A.K.; Rotaru, G.M.; Derler, S.; Spano, F.; Camenzind, M.; Annaheim, S.; Stampfli, R.; Schmid, M.; Rossi, R.M. Materials used to simulate physical properties of human skin. Ski. Res. Technol. 2016, 22, 3–14. [Google Scholar] [CrossRef]

- Rotaru, G.M.; Spano, F.; Ch, A.; Fortunato, G.; Lehmann, S.; Derler, S.; Spencer, N.D.; Rossi, R.M. A water-responsive, gelatine-based human skin model. Tribol. Int. 2017, 113, 316–322. [Google Scholar] [CrossRef]

- Purnamawati, S.; Indrastuti, N.; Danarti, R.; Saefudin, A. The Role of Moisturizers in Addressing Various Kinds of Dermatitis: A Review. Clin. Med. Res. 2017, 15, 75–87. [Google Scholar] [CrossRef] [Green Version]

- Anderson, C.; Dinulos, J.G. Are the new moisturizers more effective? Curr. Opin. Pediatrics 2009, 21, 486–490. [Google Scholar] [CrossRef]

- Sher, L.; Chang, J.; Patel, I.; Balkrishnan, R.; Fleischer, A.B. Relieving the pruritus of atopic dermatitis: A meta-analysis. Acta Derm. Venereol. 2012, 92, 455–461. [Google Scholar] [CrossRef]

| Sample | Fiber Orientation | Voltage [kV] | Flow Rate [mL·h−1] | Distance between Nozzle and Collector [cm] | T [°C] | RH [%] | Collector Rotation Speed [rpm] |

|---|---|---|---|---|---|---|---|

| sPCL | random | 14 | 0.5 | 15 | 25 | 40 | - |

| sPCL | aligned | 14 | 0.5 | 15 | 25 | 40 | 1500 |

| pPCL | random | 14 | 1 | 20 | 25 | 70 | - |

| pPCL | aligned | 14 | 1 | 20 | 25 | 70 | 2500 |

| Sample | Fiber Orientation | σmax [MPa] | Ɛmax [%] | Ɛf [%] |

|---|---|---|---|---|

| sPCL | random | 0.51 ± 0.1 | 98.36 ± 19.0 | 524.96 ± 154.4 |

| aligned | 0.78 ± 0.2 | 490.28 ± 346.1 | 913.69 ± 109.4 | |

| pPCL | random | 0.16 ± 0.003 | 154.48 ± 50.5 | 395.46 ± 48.5 |

| aligned | 0.16 ± 0.001 | 83.50 ± 35.0 | 238.14 ± 89.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Metwally, S.; Ura, D.P.; Krysiak, Z.J.; Kaniuk, Ł.; Szewczyk, P.K.; Stachewicz, U. Electrospun PCL Patches with Controlled Fiber Morphology and Mechanical Performance for Skin Moisturization via Long-Term Release of Hemp Oil for Atopic Dermatitis. Membranes 2021, 11, 26. https://doi.org/10.3390/membranes11010026

Metwally S, Ura DP, Krysiak ZJ, Kaniuk Ł, Szewczyk PK, Stachewicz U. Electrospun PCL Patches with Controlled Fiber Morphology and Mechanical Performance for Skin Moisturization via Long-Term Release of Hemp Oil for Atopic Dermatitis. Membranes. 2021; 11(1):26. https://doi.org/10.3390/membranes11010026

Chicago/Turabian StyleMetwally, Sara, Daniel P. Ura, Zuzanna J. Krysiak, Łukasz Kaniuk, Piotr K. Szewczyk, and Urszula Stachewicz. 2021. "Electrospun PCL Patches with Controlled Fiber Morphology and Mechanical Performance for Skin Moisturization via Long-Term Release of Hemp Oil for Atopic Dermatitis" Membranes 11, no. 1: 26. https://doi.org/10.3390/membranes11010026