Enhancing H2O2 Tolerance and Separation Performance through the Modification of the Polyamide Layer of a Thin-Film Composite Nanofiltration Membrane by Using Graphene Oxide

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals and Reagents

2.2. Preparation of TFC and TFC-GO Membranes

2.3. Filtration Experiments

2.4. Membrane Resistance to H2O2 Oxidation

2.5. Analytical Methods

3. Results and Discussion

3.1. Effects of Modification on the Physicochemical Characteristics of TFC Membrane

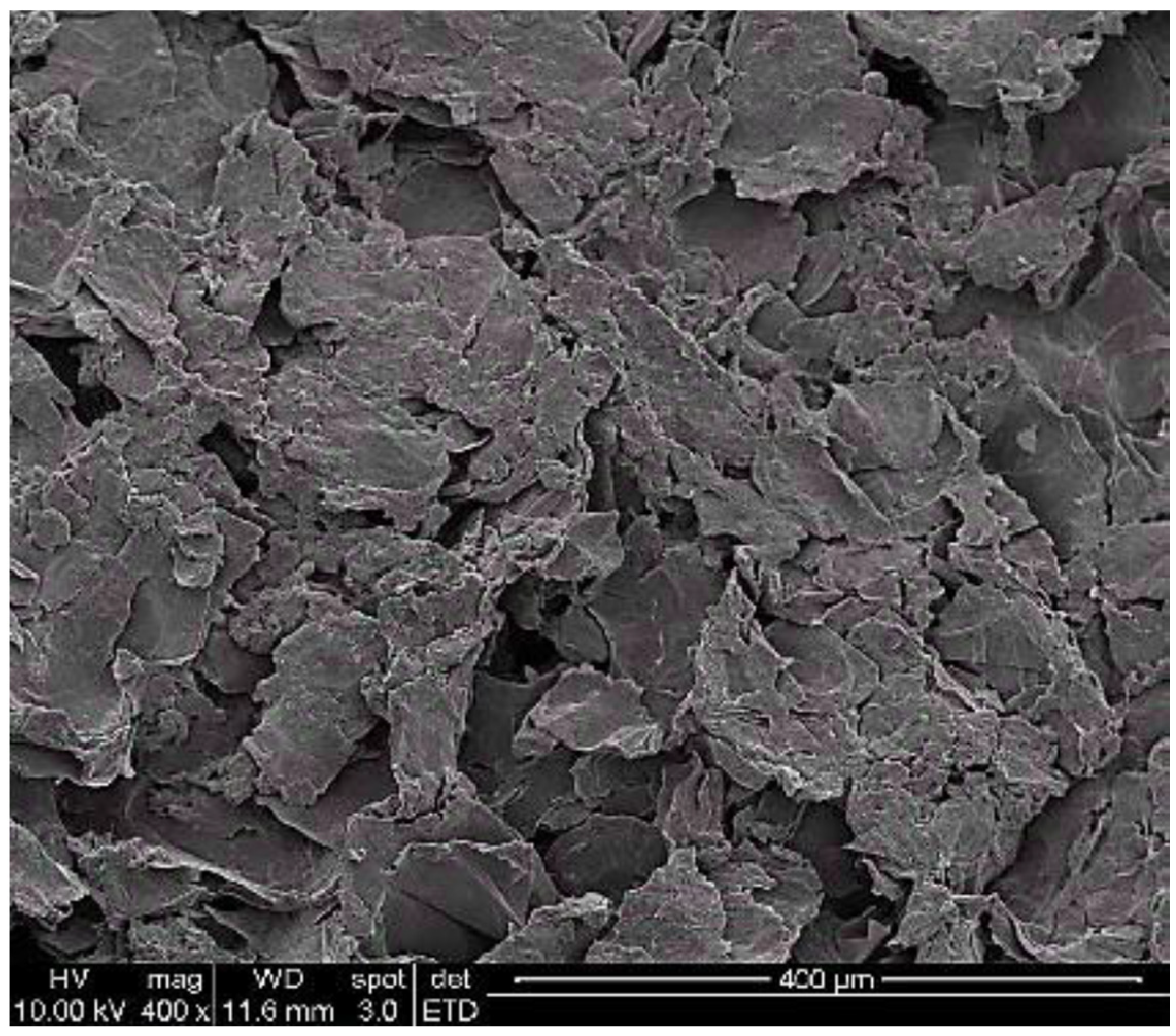

3.1.1. Surface Morphology

3.1.2. Surface Functional Groups

3.1.3. Surface Hydrophilicity

3.2. Effects of Modification on Permeate Flux and Salt Rejection

3.3. Effects of Modification on Permeate PPCP Rejection

3.4. Effects of Modification of PPCP Adsorption on the Membrane Surface

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hu, D.; Xu, Z.-L.; Chen, C. Polypiperazine-amide nanofiltration membrane containing silica nanoparticles prepared by interfacial polymerization. Desalination 2012, 301, 75–81. [Google Scholar] [CrossRef]

- Lin, C.-S.; Tung, K.-L.; Lin, Y.-L.; Dong, C.-D.; Chen, C.-W.; Wu, C.-H. Fabrication and modification of forward osmosis membranes by using graphene oxide for dye rejection and sludge concentration. Process Saf. Environ. Prot. 2020, 144, 225–235. [Google Scholar] [CrossRef]

- Lin, Y.-L. In situ concentration-polarization-enhanced radical graft polymerization of NF270 for mitigating silica fouling and improving pharmaceutical and personal care product rejection. J. Membr. Sci. 2018, 552, 387–395. [Google Scholar] [CrossRef]

- Soroush, A.; Barzin, J.; Barikani, M.; Fathizadeh, M. Interfacially polymerized polyamide thin film composite membranes: Preparation, characterization and performance evaluation. Desalination 2012, 287, 310–316. [Google Scholar] [CrossRef]

- Chae, H.-R.; Lee, C.-H.; Park, P.-K.; Kim, I.-C.; Kim, J.-H. Synergetic effect of graphene oxide nanosheets embedded in the active and support layers on the performance of thin-film composite membranes. J. Membr. Sci. 2017, 525, 99–106. [Google Scholar] [CrossRef]

- Surawanvijit, S.; Rahardianto, A.; Cohen, Y. An Integrated approach for characterization of polyamide reverse osmosis membrane degradation due to exposure to free chlorine. J. Membr. Sci. 2016, 510, 164–173. [Google Scholar] [CrossRef] [Green Version]

- Asadollahi, M.; Bastani, D.; Musavi, S.A. Enhancement of surface properties and performance of reverse osmosis membranes after surface modification: A review. Desalination 2017, 420, 330–383. [Google Scholar] [CrossRef]

- Stankovich, S.; Dikin, D.A.; Piner, R.D.; Kohlhaas, K.A.; Kleinhammes, A.; Jia, Y.; Wu, Y.; Nguyen, S.; Ruoff, R.S. Synthesis of graphene-based nanosheets via chemical reduction of exfoliated graphite oxide. Carbon 2007, 45, 1558–1565. [Google Scholar] [CrossRef]

- Kuila, T.; Bhadra, S.; Yao, D.; Kim, N.H.; Bose, S.; Lee, J.H. Recent advances in graphene based polymer composites. Prog. Polym. Sci. 2010, 35, 1350–1375. [Google Scholar] [CrossRef]

- Yin, J.; Zhu, G.; Deng, B. Graphene oxide (GO) enhanced polyamide (PA) thin-film nanocomposite (TFN) membrane for water purification. Desalination 2016, 379, 93–101. [Google Scholar] [CrossRef]

- Chae, H.-R.; Lee, J.; Lee, C.-H.; Kim, I.-C.; Park, P.-K. Graphene oxide-embedded thin-film composite reverse osmosis membrane with high flux, anti-biofouling, and chlorine resistance. J. Membr. Sci. 2015, 483, 128–135. [Google Scholar] [CrossRef]

- Alammar, A.; Park, S.-H.; Williams, C.J.; Derby, B.; Szekely, G. Oil-in-water separation with graphene-based nanocomposite membranes for produced water treatment. J. Membr. Sci. 2020, 603, 118007. [Google Scholar] [CrossRef]

- Muscatello, J.; Jaeger, F.; Matar, O.K.; Müller, E.A. Optimizing Water Transport through Graphene-Based Membranes: Insights from Nonequilibrium Molecular Dynamics. ACS Appl. Mater. Interfaces 2016, 8, 12330–12336. [Google Scholar] [CrossRef] [Green Version]

- Shi, J.; Wu, W.; Xia, Y.; Li, Z.; Li, W. Confined interfacial polymerization of polyamide-graphene oxide composite membranes for water desalination. Desalination 2018, 441, 77–86. [Google Scholar] [CrossRef]

- Tiraferri, A.; Yip, N.Y.; Phillip, W.A.; Schiffman, J.D.; Elimelech, M. Relating performance of thin-film composite forward osmosis membranes to support layer formation and structure. J. Membr. Sci. 2011, 367, 340–352. [Google Scholar] [CrossRef] [Green Version]

- He, L.; Dumée, L.F.; Feng, C.; Velleman, L.; Reis, R.; She, F.; Gao, W.; Kong, L. Promoted water transport across graphene oxide–poly(amide) thin film composite membranes and their antibacterial activity. Desalination 2015, 365, 126–135. [Google Scholar] [CrossRef]

- Ali, M.E.A.; Wang, L.; Wang, X.; Feng, X. Thin film composite membranes embedded with graphene oxide for water desalination. Desalination 2016, 386, 67–76. [Google Scholar] [CrossRef]

- He, X.; Li, B.; Wang, P.; Ma, J. Novel H2O2–MnO2 system for efficient physico-chemical cleaning of fouled ultrafiltration membranes by simultaneous generation of reactive free radicals and oxygen. Water Res. 2019, 167, 115111. [Google Scholar] [CrossRef] [PubMed]

- Lai, G.S.; Lau, W.J.; Goh, P.S.; Ismail, A.F.; Tan, Y.H.; Chong, C.Y.; Krause-Rehberg, R.; Awad, S. Tailor-made thin film nanocomposite membrane incorporated with graphene oxide using novel interfacial polymerization technique for enhanced water separation. Chem. Eng. J. 2018, 344, 524–534. [Google Scholar] [CrossRef]

- Song, N.; Xie, X.; Chen, D.; Li, G.; Dong, H.; Yu, L.; Dong, L. Tailoring nanofiltration membrane with three-dimensional turing flower protuberances for water purification. J. Membr. Sci. 2021, 621, 118985. [Google Scholar] [CrossRef]

- Yao, Z.; Guo, H.; Yang, Z.; Qing, W.; Tang, C.Y. Preparation of nanocavity-contained thin film composite nanofiltration membranes with enhanced permeability and divalent to monovalent ion selectivity. Desalination 2018, 445, 115–122. [Google Scholar] [CrossRef]

- Lan, H.; Li, P.; Wang, H.; Wang, M.; Jiang, C.; Hou, Y.; Li, P.; Niu, Q.J. Construction of a gelatin scaffold with water channels for preparing a high performance nanofiltration membrane. Sep. Purif. Technol. 2021, 264, 118391. [Google Scholar] [CrossRef]

- Lin, Y.-L. Effects of organic, biological and colloidal fouling on the removal of pharmaceuticals and personal care products by nanofiltration and reverse osmosis membranes. J. Membr. Sci. 2017, 542, 342–351. [Google Scholar] [CrossRef]

- Enick, O.; Moore, M. Assessing the assessments: Pharmaceuticals in the environment. Environ. Impact Assess. Rev. 2007, 27, 707–729. [Google Scholar] [CrossRef]

- Wang, Z.; Ma, J.; Tang, C.Y.; Kimura, K.; Wang, Q.; Han, X. Membrane cleaning in membrane bioreactors: A review. J. Membr. Sci. 2014, 468, 276–307. [Google Scholar] [CrossRef]

- Ling, R.; Yu, L.; Pham, T.P.T.; Shao, J.; Chen, J.P.; Reinhard, M. The tolerance of a thin-film composite polyamide reverse osmo-sis membrane to hydrogen peroxide exposure. J. Membr. Sci. 2017, 524, 529–536. [Google Scholar] [CrossRef]

- Rougé, V.; von Gunten, U.; Allard, S. Efficiency of pre-oxidation of natural organic matter for the mitigation of disinfection byproducts: Electron donating capacity and UV absorbance as surrogate parameters. Water Res. 2020, 187, 116418. [Google Scholar] [CrossRef]

- Korshin, G.; Wu, W.W.; Benjamin, M.M.; Hemingway, O. Correlations between differential absorbance and the formation of individual DBPs. Water Res. 2002, 36, 3273–3282. [Google Scholar] [CrossRef]

- Chen, H.-L. Preparation of GO Modified TFC-PA Membranes to Enhance PPCP Rejection and Chlorine Resistance. Master’s Thesis, National Kaohsiung University of Science and Technology, Kaohsiung, Taiwan, 2018. Available online: https://hdl.handle.net/11296/e748wq (accessed on 1 July 2021).

- Yoon, K.; Kim, K.; Wang, X.; Fang, D.; Hsiao, B.S.; Chu, B. High flux ultrafiltration membranes based on electrospun nanofibrous PAN scaffolds and chitosan coating. Polymer 2006, 47, 2434–2441. [Google Scholar] [CrossRef]

- Cheng, C.; Li, X.; Yu, X.; Wang, M.; Wang, X. Chapter 14—Electrospun Nanofibers for Water Treatment. In Electrospinning: Nanofabrication and Applications; Ding, B., Wang, X., Yu, J., Eds.; William Andrew Publishing: Norwich, NY, USA, 2019; pp. 419–453. [Google Scholar]

- Kwon, Y.-N.; Leckie, J.O. Hypochlorite degradation of crosslinked polyamide membranes: I. Changes in chemical/morphological properties. J. Membr. Sci. 2006, 283, 21–26. [Google Scholar] [CrossRef]

- Cao, S.; Zhang, G.; Xiong, C.; Long, S.; Wang, X.; Yang, J. Preparation and characterization of thin-film-composite reverse-osmosis polyamide membrane with enhanced chlorine resistance by introducing thioether units into polyamide layer. J. Membr. Sci. 2018, 564, 473–482. [Google Scholar] [CrossRef]

- Duan, M.; Wang, Z.; Xu, J.; Wang, J.; Wang, S. Influence of hexamethyl phosphoramide on polyamide composite reverse osmo-sis membrane performance. Sep. Purif. Technol. 2010, 75, 145–155. [Google Scholar] [CrossRef]

- Lin, Y.L.; Tsai, J.Z.; Hung, C.H. Using in situ modification to enhance organic fouling resistance and rejection of pharmaceutical and personal care products in a thin-film composite nanofiltration membrane. Environ. Sci. Pollut. Res. Int. 2019, 26, 34073–34084. [Google Scholar] [CrossRef]

- Lin, Y.-L.; Chiou, J.-H.; Lee, C.-H. Effect of silica fouling on the removal of pharmaceuticals and personal care products by nanofiltration and reverse osmosis membranes. J. Hazard. Mater. 2014, 277, 102–109. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Guo, W.; Jiang, Z.; Pan, F. Reducing active layer thickness of polyamide composite membranes using a covalent organic framework interlayer in interfacial polymerization. Chin. J. Chem. Eng. 2020, 28, 1039–1045. [Google Scholar] [CrossRef]

- Li, D.; Chung, T.-S.; Ren, J.; Wang, R. Thickness Dependence of Macrovoid Evolution in Wet Phase-Inversion Asymmetric Membranes. Ind. Eng. Chem. Res. 2004, 43, 1553–1556. [Google Scholar] [CrossRef]

- Sharabati, J.-A.; Guclu, S.; Ilter, S.E.; Koseoglu-Imer, D.Y.; Unal, S.; Menceloglu, Y.Z.; Ozturk, I.; Koyuncu, I. Interfacially polymerized thin-film composite membranes: Impact of support layer pore size on active layer polymerization and seawater desalination performance. Sep. Purif. Technol. 2019, 212, 438–448. [Google Scholar] [CrossRef]

- Cho, Y.H.; Kim, H.W.; Lee, H.D.; Shin, J.E.; Yoo, B.M.; Park, H.B. Water and ion sorption, diffusion, and transport in graphene oxide membranes revisited. J. Membr. Sci. 2017, 544, 425–435. [Google Scholar] [CrossRef]

- Fei, F.; Cseri, L.; Szekely, G.; Blanford, C.F. Robust Covalently Cross-linked Polybenzimidazole/Graphene Oxide Membranes for High-Flux Organic Solvent Nanofiltration. ACS Appl. Mater. Interfaces 2018, 10, 16140–16147. [Google Scholar] [CrossRef] [Green Version]

- Shao, F.; Dong, L.; Dong, H.; Zhang, Q.; Zhao, M.; Yu, L.; Pang, B.; Chen, Y. Graphene oxide modified polyamide reverse osmosis membranes with enhanced chlorine resistance. J. Membr. Sci. 2017, 525, 9–17. [Google Scholar] [CrossRef]

- Zhang, H.; Quan, X.; Chen, S.; Yu, H.; Niu, J. Electrokinetic Enhancement of Water Flux and Ion Rejection through Graphene Oxide/Carbon Nanotube Membrane. Environ. Sci. Technol. 2020, 54, 15433–15441. [Google Scholar] [CrossRef]

- Goh, P.; Ismail, A. Chemically functionalized polyamide thin film composite membranes: The art of chemistry. Desalination 2020, 495, 114655. [Google Scholar] [CrossRef]

- Kim, T.S.; Nam, J.; Kim, D.W.; Jung, H.-T.; Yeon, K.-M.; Kim, J. Antifouling membranes employing a 2D planar nanobiocatalyst of crosslinked glucose oxidase aggregates wrapping extra-large graphene oxide. Chem. Eng. J. 2021, 424, 130343. [Google Scholar] [CrossRef]

- Khairkar, S.R.; Pansare, A.V.; Shedge, A.A.; Chhatre, S.Y.; Suresh, A.K.; Chakrabarti, S.; Patil, V.R.; Nagarkar, A.A. Hydrophobic interpenetrating polyamide-PDMS membranes for desalination, pesticides removal and enhanced chlorine tolerance. Chemosphere 2020, 258, 127179. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.-H.; Park, P.-K.; Lee, C.-H.; Kwon, H.-H. Surface modification of nanofiltration membranes to improve the removal of organic micro-pollutants (EDCs and PhACs) in drinking water treatment: Graft polymerization and cross-linking followed by functional group substitution. J. Membr. Sci. 2008, 321, 190–198. [Google Scholar] [CrossRef]

| Property | UF |

|---|---|

| Manufacture | A-spring Technology |

| Membrane type | UF |

| Membrane material | Polysulfone |

| Pure water permeability (L/m2 h bar) | 379.2 |

| Contact angle (°) | 60.4 ± 3.3 |

| Average pore size (nm) | 20 |

| The pH range of operation | 2–13 |

| NaCl rejection (%) | 1.4 |

| MgSO4 rejection (%) | 2.2 |

| Membrane | Surface Morphology | Rq a (μm) | Ra b (μm) |

|---|---|---|---|

| TFC before H2O2 | Ridge–valley | 11.2 | 8.9 |

| TFC-GO before H2O2 | Ridge–valley | 17.9 | 14.5 |

| TFC after H2O2 | Ridge–valley | 11.8 | 9.8 |

| TFC-GO after H2O2 | Smooth valley | 5.8 | 4.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, Y.-L.; Zheng, N.-Y.; Chen, Y.-S. Enhancing H2O2 Tolerance and Separation Performance through the Modification of the Polyamide Layer of a Thin-Film Composite Nanofiltration Membrane by Using Graphene Oxide. Membranes 2021, 11, 592. https://doi.org/10.3390/membranes11080592

Lin Y-L, Zheng N-Y, Chen Y-S. Enhancing H2O2 Tolerance and Separation Performance through the Modification of the Polyamide Layer of a Thin-Film Composite Nanofiltration Membrane by Using Graphene Oxide. Membranes. 2021; 11(8):592. https://doi.org/10.3390/membranes11080592

Chicago/Turabian StyleLin, Yi-Li, Nai-Yun Zheng, and Yu-Shen Chen. 2021. "Enhancing H2O2 Tolerance and Separation Performance through the Modification of the Polyamide Layer of a Thin-Film Composite Nanofiltration Membrane by Using Graphene Oxide" Membranes 11, no. 8: 592. https://doi.org/10.3390/membranes11080592