Life Cycle Assessment of an Integrated Membrane Treatment System of Anaerobic-Treated Palm Oil Mill Effluent (POME)

Abstract

:1. Introduction

2. Materials and Methods

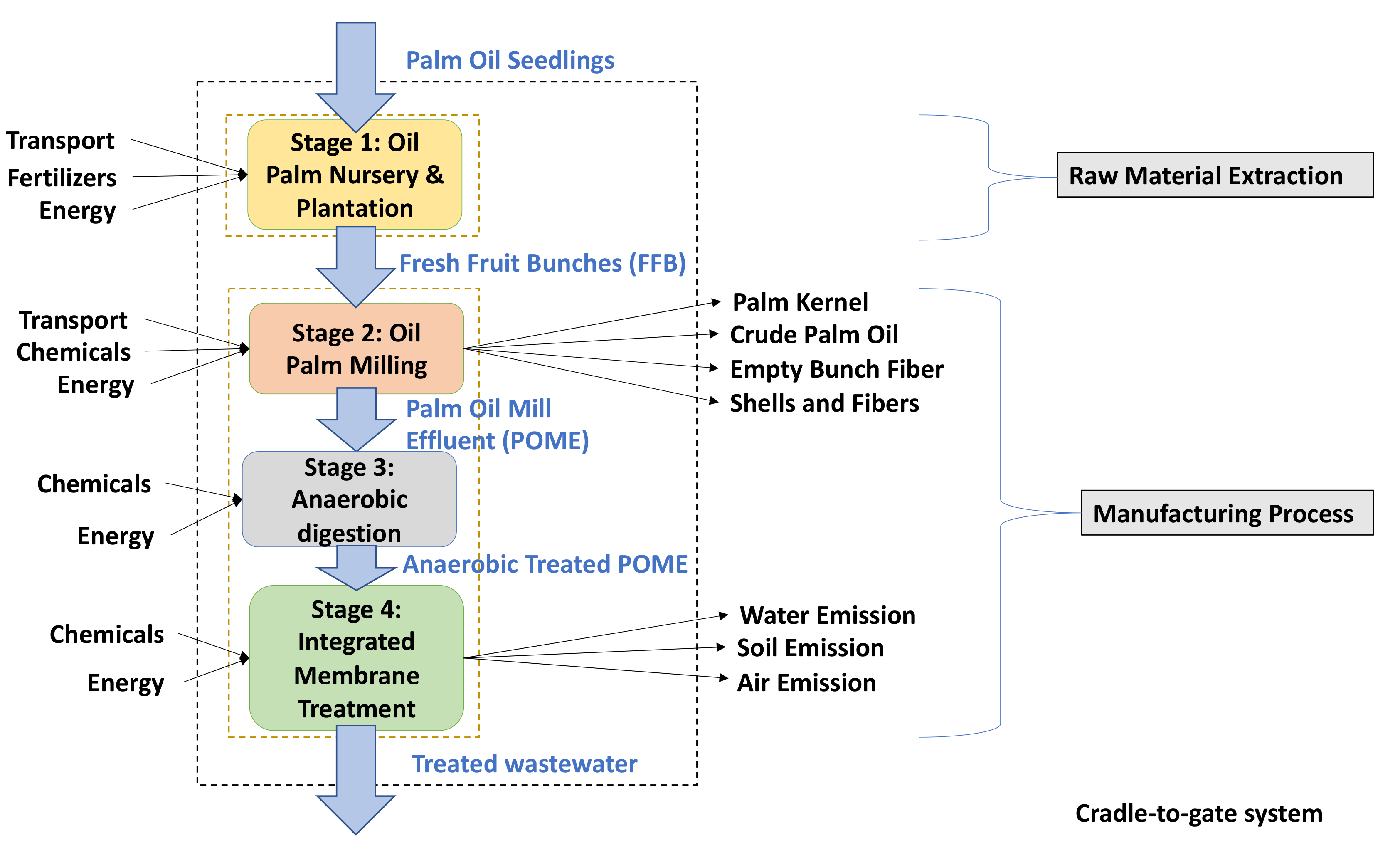

2.1. Goal and Scope Definition

2.2. Life Cycle Inventory

2.2.1. Stage 1—Oil Palm Nursery and Plantation

2.2.2. Stage 2—Oil Palm Milling

2.2.3. Stage 3—Anaerobic Digestion

2.2.4. Stage 4—Integrated Membrane Treatment

Integrated Adsorption-Membrane Process

Integrated Electro-Oxidation Membrane Process

2.3. Life Cycle Impact Assessment

2.4. Interpretation of Scenario and Sensitivity Analysis

3. Results and Discussion

3.1. Environmental Hotspots of Adsorption Integrated Membrane

3.1.1. Midpoint Approach

3.1.2. Endpoint Approach

3.2. Environmental Hotspots of Electro-Oxidation Integrated Membrane

3.2.1. Midpoint Approach

3.2.2. Endpoint Approach

3.2.3. Environmental Impacts between Processes of Integrated Membrane

3.3. Environmental Impacts between Different Sources of Electricity

3.3.1. Adsorption Integrated Membrane

3.3.2. Electro-Oxidation Integrated Membrane

4. Uncertainty Analysis

5. Challenges, Limitations, and Future Directions

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kamyab, H.; Chelliapan, S.; Din, M.F.M.; Rezania, S.; Khademi, T.; Kumar, A. Palm oil mill effluent as an environmental pollutant. Palm Oil 2018, 13, 13–28. [Google Scholar]

- Madaki, Y.S.; Seng, L. Palm Oil Mill Effluent (POME) from Malaysia palm oil mills: Waste or resource. Int. J. Sci. Environ. Technol. 2013, 2, 1138–1155. [Google Scholar]

- Ashraf, M.A.; Hanfiah, M.M. Recent advances in assessment on clear water, soil and air. Environ. Sci. Pollut. Res. 2017, 24, 22753–22754. [Google Scholar] [CrossRef] [Green Version]

- Rupani, P.F.; Singh, R.P.; Ibrahim, M.H.; Esa, N. Review of current Palm Oil Mill Effluent (POME) treatment methods: Vermicomposting as a sustainable practice. World Appl. Sci. J. 2010, 11, 70–81. [Google Scholar]

- Hanafiah, M.M.; Yussof, M.K.M.; Hasan, M.; AbdulHasan, M.J.; Toriman, M.E. Water quality assessment of Tekala River, Selangor, Malaysia. Appl. Ecol. Environ. Res. 2018, 16, 5157–5174. [Google Scholar] [CrossRef]

- David, B.J.; Lalung, J.; Ismail, N. Palm Oil Mill Effluent (POME) treatment “Microbial communities in an anaerobic digester”: A review. Int. J. Sci. Res. Publ. 2014, 4, 1–24. [Google Scholar]

- Qamaruz-Zaman, N.; Yaacof, N.; Faraji, H. Anaerobic digestion of palm oil mill residues for energy generation. In Recycling of Solid Waste for Biofuels and Bio-Chemicals; Springer: Singapore, 2016; pp. 187–210. [Google Scholar]

- Azoddein, A.A.M.; Haris, H.; Azli, F.A.M. Treatment of Palm Oil Mill Effluent (POME) using membrane bioreactor. Malays. J. Anal. Sci. 2015, 19, 463–471. [Google Scholar]

- Abdulsalam, M.; Che Man, H.; Isma Idris, A.; Faezah Yunos, K.; Zainal Abidin, Z. Treatment of palm oil mill effluent using membrane bioreactor: Novel processes and their major drawbacks. Water 2018, 10, 1165. [Google Scholar] [CrossRef] [Green Version]

- Hybat, M.S.; Abdurahman, N.H.; Yasmeen, Z.H.; Jemaat, Z.; Azhari, N.H. Treatment of Palm Oil Mill Effluent (POME) using Membrane Anaerobic System (MAS). In Proceedings of the IOP Conference Series: Materials Science and Engineering, Kuantan, Pahang, Malaysia, 4 September 2019; IOP Publishing: Bristol, UK, 2019; Volume 702, p. 012029. [Google Scholar]

- Wu, T.Y.; Mohammad, A.W.; Jahim, J.M.; Anuar, N. Palm Oil Mill Effluent (POME) treatment and bioresources recovery using ultrafiltration membrane: Effect of pressure on membrane fouling. Biochem. Eng. J. 2007, 35, 309–317. [Google Scholar] [CrossRef]

- Jasney, N.F.; Ahmad, A.L.; Ismail, S. Ultrafiltration membrane for POME treatment: Comparison physical & chemical cleaning process. J. Teknol. 2014, 69, 77–83. [Google Scholar] [CrossRef] [Green Version]

- Azmi, N.S.; Yunos, K.F.M. Wastewater treatment of Palm Oil Mill Effluent (POME) by ultrafiltration membrane separation technique coupled with adsorption treatment as pre-treatment. Agric. Agric. Sci. Proc. 2014, 2, 257–264. [Google Scholar] [CrossRef] [Green Version]

- Warsinger, D.M.; Chakraborty, S.; Tow, E.W.; Plumlee, M.H.; Bellona, C.; Loutatidou, S.; Karimi, L.; Mikelonis, A.; Achilli, A.; Ghassemi, A.; et al. A review of polymeric membranes and processes for potable water reuse. Prog. Polym. Sci. 2018, 81, 209–237. [Google Scholar] [CrossRef] [PubMed]

- Song, W.; Xie, B.; Huang, S.; Zhao, F.; Shi, X. Aerobic membrane bioreactors for industrial wastewater treatment. Curr. Dev. Biotechnol. Bioeng. 2020, 129–145. [Google Scholar] [CrossRef]

- Rongwong, W.; Lee, J.; Goh, K.; Karahan, H.E.; Bae, T.H. Membrane-based technologies for post-treatment of anaerobic effluents. NPJ Clean Water 2018, 1, 1–11. [Google Scholar] [CrossRef]

- Chong, J.W.R.; Chan, Y.J.; Chong, S.; Ho, Y.C.; Mohamad, M.; Tan, W.N.; Cheng, C.K.; Lim, J.W. Simulation and optimization of Integrated Anaerobic-Aerobic Bioreactor (IAAB) for the treatment of palm oil mill effluent. Processes 2021, 9, 1124. [Google Scholar] [CrossRef]

- Kazimierowicz, J. Organic waste used in agricultural biogas plants. J. Ecol. Eng. 2014, 15, 88–92. [Google Scholar]

- Kazimierowicz, J.; Dzienis, L.; Dębowski, M.; Zieliński, M. Optimisation of methane fermentation as a valorisation method for food waste products. Biomass Bioenergy 2021, 144, 105913. [Google Scholar] [CrossRef]

- Abdul Wahid, R.; Ang, W.L.; Mohammad, A.W.; Johnson, D.J.; Hilal, N. Evaluating fertilizer-drawn forward osmosis performance in treating anaerobic palm oil mill effluent. Membranes 2021, 11, 566. [Google Scholar] [CrossRef]

- Ashraf, M.A.; Hanafiah, M.M. Sustaining life on earth system through clean air, pure water, and fertile soil. Environ. Sci. Pollut. Res. 2019, 26, 13679–13680. [Google Scholar] [CrossRef] [Green Version]

- Banch, T.J.; Hanafiah, M.M.; Alkarkhi, A.F.; Abu Amr, S.S. Factorial design and optimization of landfill leachate treatment using tannin-based natural coagulant. Polymers 2019, 11, 1349. [Google Scholar] [CrossRef] [Green Version]

- Hanafiah, M.M.; Leuven, R.S.; Sommerwerk, N.; Tockner, K.; Huijbregts, M.A. Including the introduction of exotic species in life cycle impact assessment: The case of inland shipping. Environ. Sci. Technol. 2013, 47, 13934–13940. [Google Scholar] [CrossRef] [PubMed]

- Hanafiah, M.M.; Huijbregts, M.A.J.; Hendriks, A.J. The influence of nutrients and non-CO2 greenhouse gas emissions on the ecological footprint of products. Sustainability 2010, 2, 963–979. [Google Scholar] [CrossRef] [Green Version]

- Nasution, M.A.; Wibawa, D.S.; Ahamed, T.; Noguchi, R. Comparative environmental impact evaluation of palm oil mill effluent treatment using a life cycle assessment approach: A case study based on composting and a combination for biogas technologies in North Sumatera of Indonesia. J. Clean. Prod. 2018, 184, 1028–1040. [Google Scholar] [CrossRef]

- Sharvini, S.R.; Noor, Z.Z.; Chong, C.S.; Stringer, L.C.; Glew, D. Energy generation from palm oil mill effluent: A life cycle assessment of two biogas technologies. Energy 2020, 191, 116513. [Google Scholar] [CrossRef]

- Ho, K.C.; Teoh, Y.X.; Teow, Y.H.; Mohammad, A.W. Life Cycle Assessment (LCA) of electrically-enhanced POME filtration: Environmental impacts of conductive-membrane formulation and process operating parameters. J. Environ. Manag. 2021, 277, 111434. [Google Scholar] [CrossRef]

- Teow, Y.H.; Chong, M.T.; Ho, K.C.; Mohammad, A.W. Comparative environmental impact evaluation using life cycle assessment approach: A case study of integrated membrane-filtration system for the treatment of aerobically-digested palm oil mill effluent. Sustain. Environ. Res. 2021, 31, 1–14. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organisation for Standardisation (ISO): Geneva, Switzerland, 2006.

- Muñoz, I.; Peral, J.; Antonio Ayllón, J.; Malato, S.; José Martin, M.; Yves Perrot, J.; Vincent, M.; Domènech, X. Life-cycle assessment of a coupled advanced oxidation-biological process for wastewater treatment: Comparison with granular activated carbon adsorption. Environ. Eng. Sci. 2007, 24, 638–651. [Google Scholar] [CrossRef]

- Bonton, A.; Bouchard, C.; Barbeau, B.; Jedrzejak, S. Comparative life cycle assessment of water treatment plants. Desalination 2012, 284, 42–54. [Google Scholar] [CrossRef]

- Surra, E.; Correia, M.; Figueiredo, S.; Silva, J.; Vieira, J.; Jorge, S.; Pazos, M.; Sanromán, M.; Lapa, N.; Delerue-Matos, C. Life cycle and economic analyses of the removal of pesticides and pharmaceuticals from municipal wastewater by anodic oxidation. Sustainability 2021, 13, 3669. [Google Scholar] [CrossRef]

- Aziz, N.I.H.A.; Hanafiah, M.M. Life cycle analysis of biogas production from anaerobic digestion of palm oil mill effluent. Renew. Energy 2020, 145, 847–857. [Google Scholar] [CrossRef]

- Phuang, Z.X.; Woon, K.S.; Wong, K.J.; Liew, P.Y.; Hanafiah, M.M. Unlocking the environmental hotspots of palm biodiesel upstream production in Malaysia via life cycle assessment. Energy 2021, 232, 121206. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Bare, J.C.; Hofstetter, P.; Pennington, D.W.; De Haes, H.A.U. Midpoints versus endpoints: The sacrifices and benefits. Int. J. Life Cycle Assess. 2012, 5, 319–326. [Google Scholar] [CrossRef] [Green Version]

- Yadav, P.; Ismail, N.; Essalhi, M.; Tysklind, M.; Athanassiadis, D.; Tavajohi, N. Assessment of the environmental impact of polymeric membrane production. J. Membr. Sci. 2021, 622, 118987. [Google Scholar] [CrossRef]

- Prézélus, F.; Tiruta-Barna, L.; Guigui, C.; Remigy, J.-C. A generic process modelling–LCA approach for UF membrane fabrication: Application to cellulose acetate membranes. J. Membr. Sci. 2021, 618, 118594. [Google Scholar] [CrossRef]

- Mandal, P.; Dubey, B.K.; Gupta, A.K. Review on landfill leachate treatment by electrochemical oxidation: Drawbacks, challenges and future scope. Waste Manag. 2017, 69, 250–273. [Google Scholar] [CrossRef] [PubMed]

- Chatzisymeon, E.; Foteinis, S.; Mantzavinos, D.; Tsoutsos, T. Life cycle assessment of advanced oxidation processes for olive mill wastewater treatment. J. Clean. Prod. 2013, 54, 229–234. [Google Scholar] [CrossRef] [Green Version]

- Hertwich, E.; Gibon, T.; Bouman, E.A.; Arvesen, A.; Suh, S.; Heath, G.; Bergesen, J.D.; Ramirez, A.; Vega, M.I.; Shi, L. Integrated life-cycle assessment of electricity-supply scenarios confirms global environmental benefit of low-carbon technologies. Proc. Natl. Acad. Sci. USA 2015, 112, 6277–6282. [Google Scholar] [CrossRef] [Green Version]

- Masanet, E.; Chang, Y.; Gopal, A.R.; Larsen, P.; Morrow, W.R., III; Sathre, R.; Shehabi, A.; Zhai, P. Life-cycle assessment of electric power systems. Annu. Rev. Environ. Resour. 2013, 38, 107–136. [Google Scholar] [CrossRef]

| Input from Technosphere | Unit | Amount |

|---|---|---|

| Materials and fuels | ||

| Seed | Seeds | 15.42 |

| Diesel (to run the pump for watering the seedlings) | L | 0.01 |

| Polybag | Kg | 0.017 |

| N Fertilizer, ammonium sulphate | Kg | 0.05 |

| N Fertilizer, urea | Kg | 0.02 |

| P (10%) | Kg | 0.06 |

| K (10%) | Kg | 0.06 |

| Cypermethrin | Kg | 0.01 |

| Dithane (a.i. mancozeb/dithiocarbamates) | Kg | 0.02 |

| Glufosinate ammonium | Kg | 0.03 |

| Energy | ||

| Electricity | kWh | 0.06 |

| MJ | 2.64 | |

| Transport | ||

| Van | Tkm | 3.08 × 10−4 |

| Output to technosphere | ||

| Products and co-products | ||

| Young oil palm | Palms | 8 |

| Input from environment | ||

| Resource | ||

| Water (river) | L | 12 |

| Input from Technosphere | Unit | Amount |

|---|---|---|

| Materials and fuels | ||

| Young oil palm | palms | 8 |

| Land | ha | 0.05 |

| Diesel | MJ | 129.49 |

| N Fertilizer, ammonium sulphate | kg | 5.47 |

| N Fertilizer, urea | kg | 2.02 |

| P Fertilizer | kg | 4.49 |

| K Fertilizer | kg | 13.14 |

| Cypermethrin | kg | 8.20 × 10−3 |

| Carbamate/Carbosulfan | kg | 6.00 × 10−3 |

| Carbamate/Carbofuran | kg | 3.3 × 10−3 |

| Metsulfuron metyl/Sulfonylurea | kg | 4.50 × 10−3 |

| Glufosinate ammonium | kg | 0.05 |

| Glyphosate | kg | 0.04 |

| Paraquat | kg | 0.02 |

| Chlorophacinone | kg | 0.15 |

| Transport | ||

| Lorry 3 t | tkm | 14.32 |

| Energy | ||

| Electricity | MJ | 2.90 × 10−3 |

| Output to technosphere | ||

| Products and co-products | ||

| Fresh fruit bunch | t | 1.43 |

| Input from environment | ||

| Resource | ||

| Water (Rainfall) | m3 | 1511.08 |

| Input from Technosphere | Unit | Amount |

|---|---|---|

| Materials and fuels | ||

| Fresh fruit bunch | t | 1.43 |

| Diesel | L | 0.60 |

| Transport | ||

| Lorry 3t | tkm | 14.32 |

| Energy | ||

| Power consumption from steam turbine | kWh | 5.53 |

| Output to technosphere | ||

| Products and co-products | ||

| Crude palm oil | t | 0.29 |

| Kernel | t | 0.08 |

| Shell | t | 0.06 |

| Mesocarp fibre | t | 0.14 |

| Empty bunch fibre | t | 0.23 |

| Palm oil mill effluent (POME) | t | 1 |

| Input from environment | ||

| Resource | ||

| Water for boiler and processing | m3 | 1.34 |

| Output to environment | ||

| Emissions to air | ||

| Methane | kg | 16.28 |

| Carbon dioxide | kg | 8.76 |

| Boiler ash | kg | 21.61 |

| Input from Technosphere | Unit | Amount |

|---|---|---|

| Materials and fuels | ||

| POME | t | 1 |

| Energy | ||

| Electricity from grid | kWh | 0.02 |

| Output to technosphere | ||

| Products and co-products | ||

| Anaerobic treated POME | m3 | 0.77 |

| Biogas | m3 | 20.79 |

| Electricity | kWh | 0.03 |

| Solid sludge | mt | 0.11 |

| Input from environment | ||

| Resource | ||

| Water | kg | 11 |

| Output to environment | ||

| Emissions to air | ||

| Methane | kg | 8.94 |

| Carbon dioxide | kg | 14.79 |

| Input from Technosphere | Unit | Amount | Source |

|---|---|---|---|

| Materials and fuels | |||

| Pretreated anaerobic POME | m3 | 0.77 | [33] |

| Granular Activated Carbon production | kg | 0.36 | [30] |

| Hollow fiber membrane | p | 1 | |

| Chlorine | kg | 6.00 × 10−4 | [31] |

| Membrane cleaning agent (EDTA/NaOH) | kg | 4.20 × 10−3 | [31] |

| NaHCO3 | kg | 3.4 × 10−3 | [31] |

| Energy | |||

| Pumps | kWh | 0.49 | [31] |

| System cleaning (water heating) | kWh | 4.4 × 10−3 | [31] |

| Prefilter | kWh | 0.04 | [31] |

| Output to Technosphere | Unit | Amount | Source |

| Products and co-products | |||

| Effluent treatment of POME | m3 | 1 | |

| Spent catalyst management | kg | 0.76 | [30] |

| Output to environment | |||

| Emissions to air | |||

| Carbon dioxide, fossil | kg | 2.40 | [30] |

| Nitrogen dioxide | kg | 0.28 | [30] |

| Input from Technosphere | Unit | Amount | Source |

|---|---|---|---|

| Materials and fuels | |||

| Pretreated anaerobic POME | m3 | 0.77 | [33] |

| Water storage | p | 1.20 × 10−7 | [32] |

| Steel, low-alloyed | kg | 9.54 × 10−3 | [32] |

| Chromium steel pipe | kg | 1.76 × 10−4 | [32] |

| Epoxy resin, liquid | kg | 6.86 × 10−4 | [32] |

| Water | m3 | 0.99 | [32] |

| Hollow fiber membrane | p | 1 | |

| Chlorine | kg | 6.00 × 10−4 | [31] |

| Membrane cleaning agent (EDTA/NaOH) | kg | 4.20 × 10−3 | [31] |

| NaHCO3 | kg | 3.40 × 10−3 | [31] |

| Energy | |||

| Electricity, medium voltage | kWh | 3.55 | [32] |

| Pumps | kWh | 0.49 | [31] |

| System cleaning (water heating) | kWh | 4.40 × 10−3 | [31] |

| Prefilter | kWh | 0.04 | [31] |

| Output to technosphere | |||

| Products and co-products | |||

| Treated POME effluent | m3 | 1 |

| Impact Categories | Scenario 1: Grid (Baseline) | Scenario 2: Biogas | Scenario 3: Grid/Solar | |||

|---|---|---|---|---|---|---|

| Adsorption Integrated Membrane | Electro-Oxidation Integrated Membrane | Adsorption Integrated Membrane | Electro-Oxidation Integrated Membrane | Adsorption Integrated Membrane | Electro-Oxidation Integrated Membrane | |

| PMFP (kg PM2.5-eq) | 0.39 (9.89) | 0.37 (10.38) | 0.34 | 0.30 | 0.34 | 0.30 |

| FFP (kg oil-eq) | 57.84 (8.18) | 58.10 (8.17) | 54.82 | 54.16 | 54.82 | 54.19 |

| FETP (kg 1,4-DCB) | 8.97 (26.11) | 8.90 (28.17) | 8.69 | 8.55 | 8.69 | 8.54 |

| FEP (kg P-eq) | 0.07 (47.77) | 0.07 (47.74) | 0.06 | 0.06 | 0.06 | 0.06 |

| GWP (kg CO2-eq) | 583.87 (4.19) | 582.93 (4.37) | 570.15 | 565.08 | 570.15 | 565.12 |

| HTPc (kg 1,4-DCB) | 7.66 (127.22) | 7.80 (102.41) | 6.98 | 6.91 | 6.98 | 6.91 |

| HTPnc (kg 1,4-DCB) | 197.86 (30.47) | 198.54 (33.45) | 185.14 | 182.44 | 185.07 | 181.92 |

| IRP (kBq Co−60-eq) | 15.37 (135.40) | 15.09 (122.35) | 15.35 | 15.07 | 15.35 | 15.07 |

| LUC (m2a crop-eq) | 19.13 (26.62) | 19.06 (25.64) | 18.27 | 19.50 | 18.02 | 17.65 |

| METP (kg 1,4-DCB) | 11.88 (25.76) | 11.80 (27.76) | 11.49 | 11.32 | 11.49 | 11.30 |

| MEP (kg N-eq) | 0.03 (5.33) | 0.03 (5.08) | 0.03 | 0.03 | 0.03 | 0.03 |

| SOP (kg Cu-eq) | 0.73 (24.10) | 0.73 (24.33) | 0.73 | 0.72 | 0.73 | 0.73 |

| HOFP (kg NOx-eq) | 0.66 (5.34) | 0.38 (9.50) | 0.63 | 0.34 | 0.63 | 0.34 |

| EOFP (kg NOx-eq) | 0.67 (5.35) | 0.39 (9.40) | 0.64 | 0.35 | 0.64 | 0.35 |

| ODP (kg CFC11-eq) | 9.89 × 10−5 (13.10) | 9.87 × 10−5 (12.97) | 9.66 × 10−5 | 9.69 × 10−5 | 9.64 × 10−5 | 9.55 × 10−5 |

| TAP (kg SO2-eq) | 0.79 (10.93) | 0.70 (12.59) | 0.73 | 0.62 | 0.73 | 0.62 |

| TETP (kg 1,4-DCB) | 436.32 (40.72) | 430.92 (42.75) | 428.30 | 420.68 | 428.33 | 420.90 |

| WCP (m3) | 2.55 (1061.28) | 2.54 (1233.73) | 2.54 | 2.56 | 2.54 | 2.52 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Razman, K.K.; Hanafiah, M.M.; Mohammad, A.W.; Lun, A.W. Life Cycle Assessment of an Integrated Membrane Treatment System of Anaerobic-Treated Palm Oil Mill Effluent (POME). Membranes 2022, 12, 246. https://doi.org/10.3390/membranes12020246

Razman KK, Hanafiah MM, Mohammad AW, Lun AW. Life Cycle Assessment of an Integrated Membrane Treatment System of Anaerobic-Treated Palm Oil Mill Effluent (POME). Membranes. 2022; 12(2):246. https://doi.org/10.3390/membranes12020246

Chicago/Turabian StyleRazman, Khalisah Khairina, Marlia M. Hanafiah, Abdul Wahab Mohammad, and Ang Wei Lun. 2022. "Life Cycle Assessment of an Integrated Membrane Treatment System of Anaerobic-Treated Palm Oil Mill Effluent (POME)" Membranes 12, no. 2: 246. https://doi.org/10.3390/membranes12020246

APA StyleRazman, K. K., Hanafiah, M. M., Mohammad, A. W., & Lun, A. W. (2022). Life Cycle Assessment of an Integrated Membrane Treatment System of Anaerobic-Treated Palm Oil Mill Effluent (POME). Membranes, 12(2), 246. https://doi.org/10.3390/membranes12020246