Fabrication of PS/PVDF-HFP Multi-Level Structured Micro/Nano Fiber Membranes by One-Step Electrospinning

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals and Materials

2.2. Preparation of PS/PVDF-HFP Nanofibers Membranes

2.3. Characterizations of Membranes

2.4. Direct Contact Membrane Distillation Performance Test

3. Results and Discussion

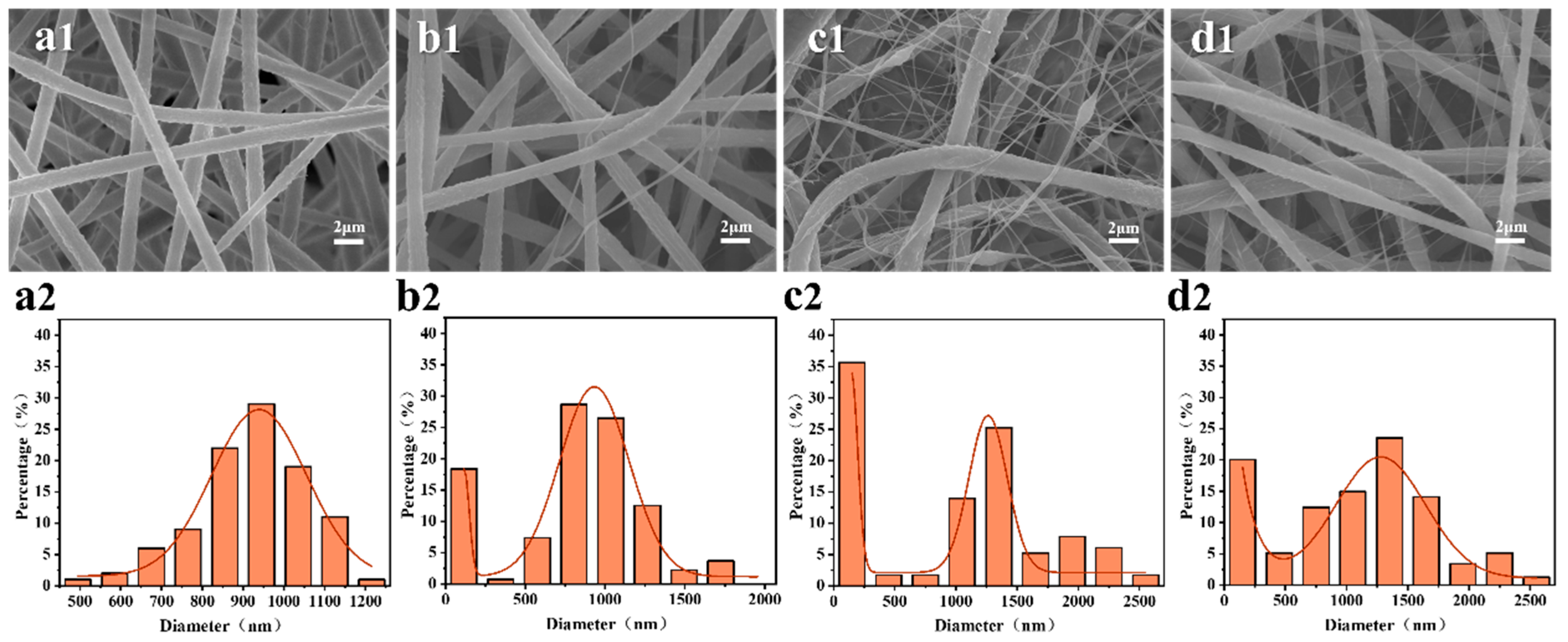

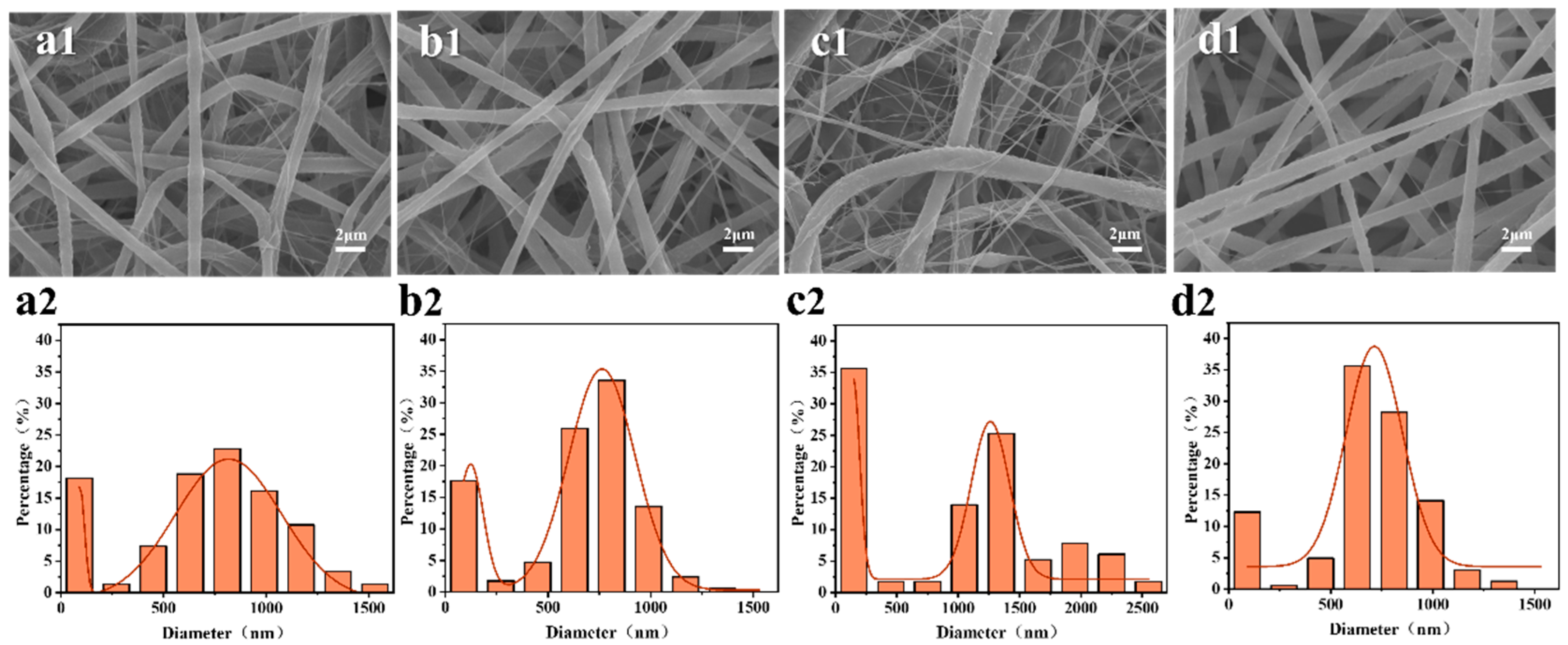

3.1. Effect on Fiber Membrane Morphology

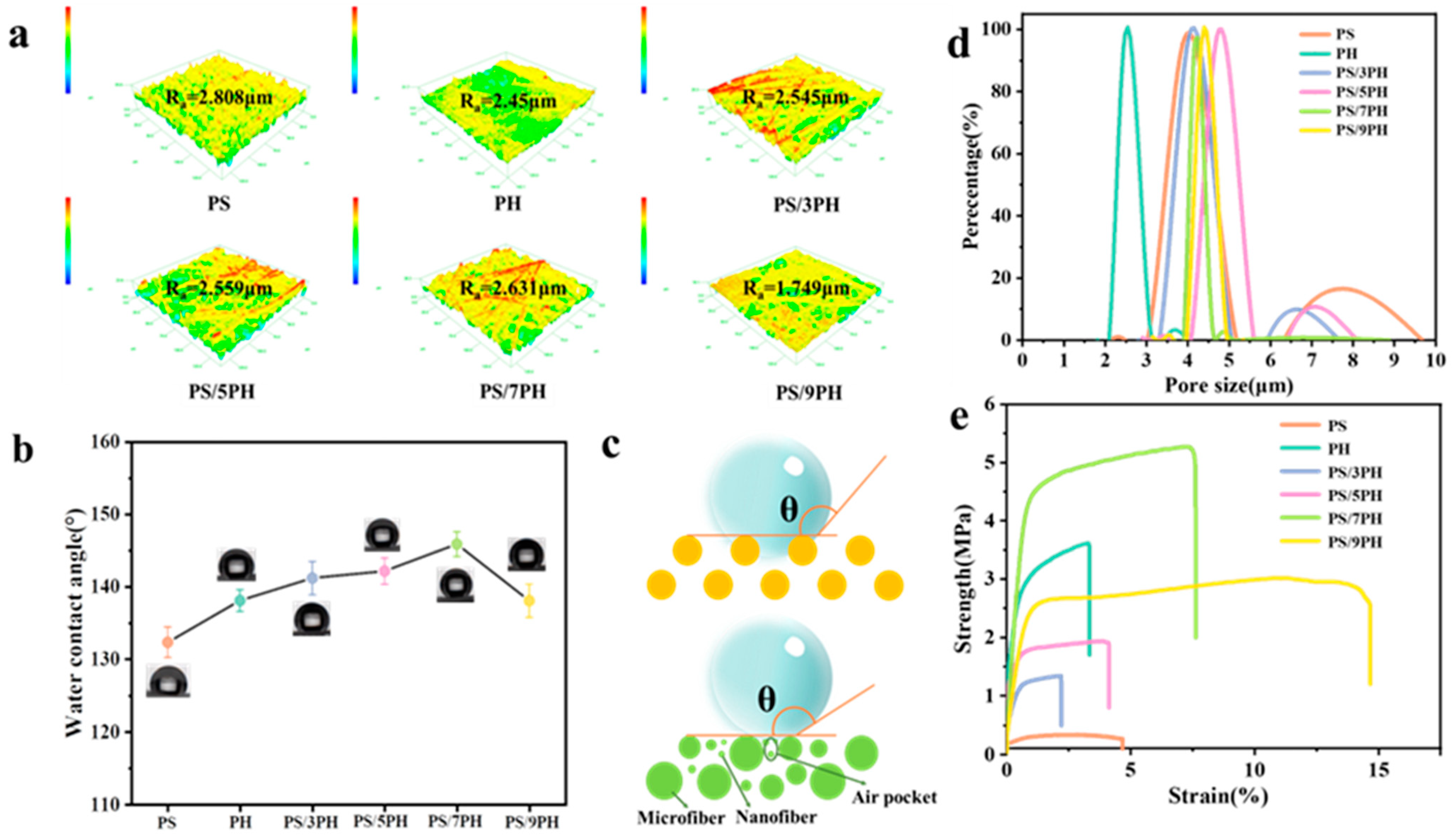

3.2. Properties of PS/PVDF-HFP Nanofiber Membrane

3.3. Study of Multi-Level Structured Forming Mechanism

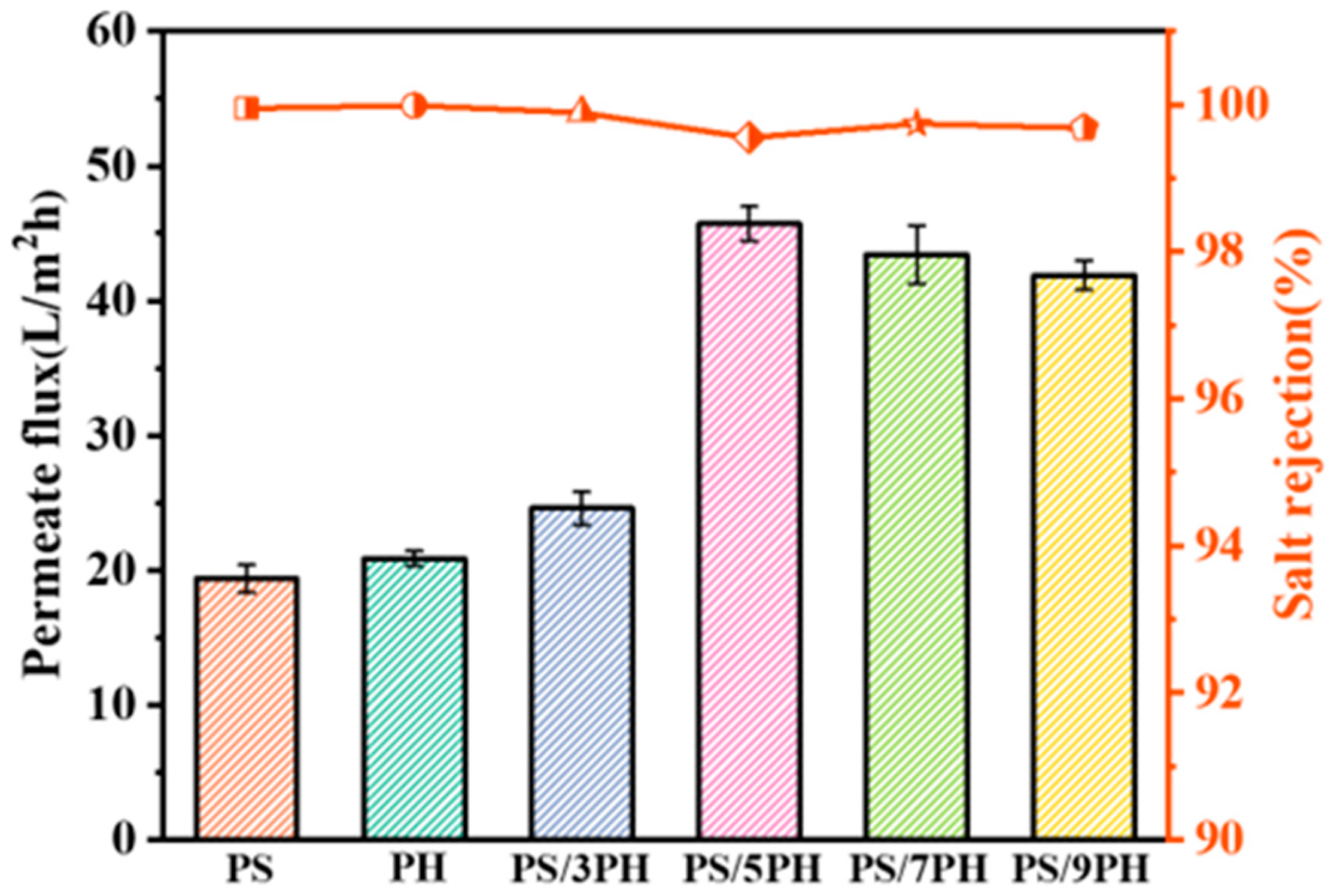

3.4. Direct Contact Membrane Distillation Performance Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Huang, Y.; Xiao, C.; Huang, Q.; Liu, H.; Zhao, J. Progress on polymeric hollow fiber membrane preparation technique from the perspective of green and sustainable development. Chem. Eng. J. 2020, 403, 126295. [Google Scholar] [CrossRef]

- Zhang, J.; Xue, Q.; Pan, X.; Jin, Y.; Lu, W.; Ding, D.; Guo, Q. Graphene oxide/polyacrylonitrile fiber hierarchical-structured membrane for ultra-fast microfiltration of oil-water emulsion. Chem. Eng. J. 2017, 307, 643–649. [Google Scholar] [CrossRef]

- Haase, M.F.; Jeon, H.; Hough, N.; Kim, J.H.; Stebe, K.J.; Lee, D. Multifunctional nanocomposite hollow fiber membranes by solvent transfer induced phase separation. Nat. Commun. 2017, 8, 1234. [Google Scholar] [CrossRef] [PubMed]

- Hatat-Fraile, M.; Liang, R.; Arlos, M.J.; He, R.X.; Peng, P.; Servos, M.R.; Zhou, Y.N. Concurrent photocatalytic and filtration processes using doped TiO2 coated quartz fiber membranes in a photocatalytic membrane reactor. Chem. Eng. J. 2017, 330, 531–540. [Google Scholar] [CrossRef]

- Yang, S.; Shi, X.; Li, X.; Wang, J.; Wang, Y.; Luo, Y. Oriented collagen fiber membranes formed through counter-rotating extrusion and their application in tendon regeneration. Biomaterials 2019, 207, 61–75. [Google Scholar] [CrossRef] [PubMed]

- Feng, X.; Li, J.; Zhang, X.; Liu, T.; Ding, J.; Chen, X. Electrospun polymer micro/nanofibers as pharmaceutical repositories for healthcare. J. Control. Release 2019, 302, 19–41. [Google Scholar] [CrossRef] [PubMed]

- Ji, K.; Liu, C.; He, H.; Mao, X.; Wei, L.; Zhou, F.; Sun, R. Green-solvent-processable composite micro/nanofiber membrane with gradient asymmetric structure for efficient microfiltration. Small 2023, 19, e2207330. [Google Scholar] [CrossRef]

- Ding, R.; Chen, S.; Xuan, H.; Li, B.; Rui, Y. Green-solvent-processed amphiphobic polyurethane nanofiber membranes with mechanically stable hierarchical structures for seawater desalination by membrane distillation. Desalination 2021, 516, 115223. [Google Scholar] [CrossRef]

- Xu, Y.; Cui, W.; Zhang, Y.; Zhou, P.; Gu, Y.; Shen, X.; Li, B.; Chen, L. Hierarchical micro/nanofibrous bioscaffolds for structural tissue regeneration. Adv. Healthc. Mater. 2017, 6, 1601457. [Google Scholar] [CrossRef]

- Zhang, Y.; Nishi, N.; Amano, K.I.; Sakka, T. One-dimensional Pt nanofibers formed by the redox reaction at the ionic liquid|water interface. Electrochim. Acta 2018, 282, 886–891. [Google Scholar] [CrossRef]

- Ji, D.; Xiao, C.; An, S.; Chen, K.; Gao, Y.; Zhou, F.; Zhang, T. Completely green and sustainable preparation of PVDF hollow fiber membranes via melt-spinning and stretching method. J. Hazard. Mater. 2020, 398, 122823. [Google Scholar] [CrossRef]

- Meng, Z.-C.; Gao, L.-Y.; Liu, Z.-Q. Synthesis of Sn nanowire by template electrodeposition and its conversion into Sn nanosolder. Mater. Charact. 2020, 163, 110278. [Google Scholar] [CrossRef]

- Hou, L.; Wang, N.; Wu, J.; Cui, Z.; Jiang, L.; Zhao, Y. Bioinspired Superwettability Electrospun Micro/Nanofibers and Their Applications. Adv. Funct. Mater. 2018, 28, 1801114. [Google Scholar] [CrossRef]

- Hadia, N.; Alzaid, M.; Mohamed, W. Tailoring the physical properties of low dimensional MgO nanostructures using vapor transport deposition. Mater. Charact. 2020, 165, 110392. [Google Scholar] [CrossRef]

- Zhu, S.; Nie, L. Progress in fabrication of one-dimensional catalytic materials by electrospinning technology. J. Ind. Eng. Chem. 2020, 93, 28–56. [Google Scholar] [CrossRef]

- Park, H.-S.; Park, Y.O. Filtration properties of Electrospun ultrafine fiber webs. Korean J. Chem. Eng. 2005, 22, 165–172. [Google Scholar] [CrossRef]

- Sawhney, A.; Condon, B.; Singh, K.; Pang, S.; Li, G.; Hui, D. Modern Applications of Nanotechnology in Textiles. Text. Res. J. 2008, 78, 731–739. [Google Scholar] [CrossRef]

- Sridhar, R.; Lakshminarayanan, R.; Madhaiyan, K.; Barathi, V.A.; Lim, K.H.C.; Ramakrishna, S. Electrosprayed nanoparticles and electrospun nanofibers based on natural materials: Applications in tissue regeneration, drug delivery and pharmaceuticals. Chem. Soc. Rev. 2014, 44, 790–814. [Google Scholar] [CrossRef]

- Santos, D.; Baptista, R.M.F.; Handa, A.; Almeida, B.; Rodrigues, P.V.; Torres, A.R.; Machado, A.; Belsley, M.; Gomes, E.d.M. Bioinspired cyclic dipeptide functionalized nanofibers for thermal sensing and energy harvesting. Materials 2023, 16, 2477. [Google Scholar] [CrossRef]

- Tan, G.Z.; Zhou, Y. Tunable 3D nanofiber architecture of polycaprolactone by divergence electrospinning for potential tissue engineering applications. Nano-Micro Lett. 2018, 10, 1–10. [Google Scholar] [CrossRef]

- Wang, X.; Yang, T.; Jiao, K. Controllable fabrication of Au micro/nanostructures on self-doped polyaniline nanofibers via electrochemical deposition and its application for DNA immobilization. Chin. Sci. Bull. 2010, 55, 4125–4131. [Google Scholar] [CrossRef]

- Shi, S.; Zhi, C.; Zhang, S.; Yang, J.; Si, Y.; Jiang, Y.; Ming, Y.; Lau, K.-T.; Fei, B.; Hu, J. lotus leaf-inspired breathable membrane with structured microbeads and nanofibers. ACS Appl. Mater. Interfaces 2022, 14, 39610–39621. [Google Scholar] [CrossRef] [PubMed]

- Qiu, Y.; Li, G.; Hou, Y.; Pan, Z.; Li, H.; Li, W.; Liu, M.; Ye, F.; Yang, X.; Zhang, Y. Vertically aligned carbon nanotubes on carbon nanofibers: A hierarchical three-dimensional carbon nanostructure for high-energy flexible supercapacitors. Chem. Mater. 2015, 27, 1194–1200. [Google Scholar] [CrossRef]

- An, X.; Xu, G.; Xie, B.; Hu, Y. Structural tailoring of hierarchical fibrous composite membranes to balance mass transfer and heat transfer for state-of-the-art desalination performance in membrane distillation. J. Mater. Chem. A 2019, 7, 2376–2384. [Google Scholar] [CrossRef]

- Liao, Y.; Wang, R.; Fane, A.G. Fabrication of bioinspired composite nanofiber membranes with robust Superhydrophobicity for direct contact membrane distillation. Environ. Sci. Technol. 2014, 48, 6335–6341. [Google Scholar] [CrossRef]

- Li, Z.; Xu, Y.; Fan, L.; Kang, W.; Cheng, B. Fabrication of polyvinylidene fluoride tree-like nanofiber via one-step electrospinning. Mater. Des. 2016, 92, 95–101. [Google Scholar] [CrossRef]

- Han, S.O.; Son, W.K.; Cho, D.; Youk, J.H.; Park, W.H. Preparation of porous ultra-fine fibres via selective thermal degradation of electrospun polyetherimide/poly(3-hydroxybutyrate-co-3-hydroxyvalerate) fibres. Polym. Degrad. Stab. 2004, 86, 257–262. [Google Scholar] [CrossRef]

- Zhuge, Y.; Liu, F. Controlled preparation of polyimide/polysulfone amide (PI/PSA) porous micro-nano fiber membranes by microemulsion electrospinning for excellent thermal insulation. Eur. Polym. J. 2023, 194, 112170. [Google Scholar] [CrossRef]

- Li, S.; Li, L.; Zhong, J.; Ma, R.; Xu, X.; Wu, H.; Yu, Y. Engineering beads-on-string structural electrospun nanofiber Janus membrane with multi-level roughness for membrane distillation. Desalination 2022, 539, 115950. [Google Scholar] [CrossRef]

- Moheman, A.; Alam, M.S.; Mohammad, A. Recent trends in electrospinning of polymer nanofibers and their applications in ultra thin layer chromatography. Adv. Colloid Interface Sci. 2016, 229, 1–24. [Google Scholar] [CrossRef]

- Grosshaus, C.; Bakirci, E.; Berthel, M.; Hrynevich, A.; Kade, J.C.; Hochleitner, G.; Groll, J.; Dalton, P.D. Melt electrospinning of nanofibers from medical-grade Poly(epsilon-caprolactone) with a modified nozzle. Small 2020, 16, e2003471. [Google Scholar] [CrossRef] [PubMed]

- Bazrafshan, Z.; Stylios, G.K. A novel approach to enhance the spinnability of collagen fibers by graft polymerization. Mater. Sci. Eng. C 2018, 94, 108–116. [Google Scholar] [CrossRef] [PubMed]

- Boccaccio, T.; Bottino, A.; Capannelli, G.; Piaggio, P. Characterization of PVDF membranes by vibrational spectroscopy. J. Membr. Sci. 2002, 210, 315–329. [Google Scholar] [CrossRef]

- Yang, J.; Li, S.; Jiang, H.; Su, C.; Shao, Y.; Gao, Y.; Li, J. Preparation of recycled graphite/expanded polystyrene by a facile solvent dissolution method. J. Mater. Sci. 2018, 54, 1197–1204. [Google Scholar] [CrossRef]

- Zheng, L.; Wang, J.; Yu, D.; Zhang, Y.; Wei, Y. Preparation of PVDF-CTFE hydrophobic membrane by non-solvent induced phase inversion: Relation between polymorphism and phase inversion. J. Membr. Sci. 2018, 550, 480–491. [Google Scholar] [CrossRef]

- Nasef, M.; Zubir, N.; Ismail, A.; Khayet, M.; Dahlan, K.; Saidi, H.; Rohani, R.; Ngah, T.; Sulaiman, N. PSSA pore-filled PVDF membranes by simultaneous electron beam irradiation: Preparation and transport characteristics of protons and methanol. J. Membr. Sci. 2006, 268, 96–108. [Google Scholar] [CrossRef]

- Merlet, R.B.; Amirilargani, M.; de Smet, L.C.; Sudhölter, E.J.; Nijmeijer, A.; Winnubst, L. Growing to shrink: Nano-tunable polystyrene brushes inside 5 nm mesopores. J. Membr. Sci. 2019, 572, 632–640. [Google Scholar] [CrossRef]

- Gao, X.; Zhou, J.; Du, R.; Xie, Z.; Deng, S.; Liu, R.; Liu, Z.; Zhang, J. Robust Superhydrophobic Foam: A Graphdiyne-Based Hierarchical Architecture for Oil/Water Separation. Adv. Mater. 2015, 28, 168–173. [Google Scholar] [CrossRef]

- Webster, T.J.; Tran, P. Understanding the wetting properties of nanostructured selenium coatings: The role of nanostructured surface roughness and air-pocket formation. Int. J. Nanomed. 2013, 8, 2001–2009. [Google Scholar] [CrossRef]

- Li, Z.; Cheng, B.; Ju, J.; Kang, W.; Liu, Y. Development of a novel multi-scale structured superhydrophobic nanofiber membrane with enhanced thermal efficiency and high flux for membrane distillation. Desalination 2020, 501, 114834. [Google Scholar] [CrossRef]

- Deng, N.; He, H.; Yan, J.; Zhao, Y.; Ben Ticha, E.; Liu, Y.; Kang, W.; Cheng, B. One-step melt-blowing of multi-scale micro/nano fabric membrane for advanced air-filtration. Polymer 2019, 165, 174–179. [Google Scholar] [CrossRef]

| Solution Concentration (%) | Solution Ratio PS: PVDF-HFP | Voltage (kV) | Reception (cm) |

|---|---|---|---|

| 1:7 | 30 | 18 | |

| 16 | 1:7 | 30 | 18 |

| 18 | 1:7 | 30 | 18 |

| 20 | 1:7 | 30 | 18 |

| 18 | 1:3 | 30 | 18 |

| 18 | 1:5 | 30 | 18 |

| 18 | 1:9 | 30 | 18 |

| 18 | 1:7 | 20 | 18 |

| 18 | 1:7 | 25 | 18 |

| 18 | 1:7 | 35 | 18 |

| 18 | 1:7 | 30 | 12 |

| 18 | 1:7 | 30 | 15 |

| 18 | 1:7 | 30 | 21 |

| Membrane | PS | PH | PS/3PH | PS/5PH | PS/7PH | PS/9PH |

|---|---|---|---|---|---|---|

| Thickness (μm) | 250 ± 20 | 250 ± 20 | 250 ± 20 | 250 ± 20 | 250 ± 20 | 250 ± 20 |

| Mean pore size (μm) | 4.52 ± 0.2 | 2.77 ± 0.10 | 4.54 ± 0.10 | 5.74 ± 0.20 | 4.38 ± 0.10 | 4.64 ± 0.20 |

| Maximum pore size (μm) | 6.32 ± 0.2 | 4.00 ± 0.10 | 5.92 ± 0.10 | 8.12 ± 0.20 | 5.26 ± 0.10 | 5.34 ± 0.20 |

| Porosity (%) | 74.1 ± 3.2 | 81.9 ± 2.1 | 76.4 ± 3.1 | 77.8 ± 3.5 | 78.9 ± 3.5 | 72.8 ± 2.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Zhang, Z.; Zhang, Y.; Huang, Y.; Chen, Y.; Chen, B.; Kang, W.; Ju, J. Fabrication of PS/PVDF-HFP Multi-Level Structured Micro/Nano Fiber Membranes by One-Step Electrospinning. Membranes 2023, 13, 807. https://doi.org/10.3390/membranes13100807

Zhao Y, Zhang Z, Zhang Y, Huang Y, Chen Y, Chen B, Kang W, Ju J. Fabrication of PS/PVDF-HFP Multi-Level Structured Micro/Nano Fiber Membranes by One-Step Electrospinning. Membranes. 2023; 13(10):807. https://doi.org/10.3390/membranes13100807

Chicago/Turabian StyleZhao, Yixia, Zehao Zhang, Yan Zhang, Yuting Huang, Yanfei Chen, Bofei Chen, Weimin Kang, and Jingge Ju. 2023. "Fabrication of PS/PVDF-HFP Multi-Level Structured Micro/Nano Fiber Membranes by One-Step Electrospinning" Membranes 13, no. 10: 807. https://doi.org/10.3390/membranes13100807

APA StyleZhao, Y., Zhang, Z., Zhang, Y., Huang, Y., Chen, Y., Chen, B., Kang, W., & Ju, J. (2023). Fabrication of PS/PVDF-HFP Multi-Level Structured Micro/Nano Fiber Membranes by One-Step Electrospinning. Membranes, 13(10), 807. https://doi.org/10.3390/membranes13100807