A Study on Tencel/LMPET–TPU/Triclosan Laminated Membranes: Excellent Water Resistance and Antimicrobial Ability

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

2.2. Preparation of Tencel/LMPET-TPU/Triclosan Laminated Membranes

2.3. Measurements and Characterizations

3. Results and Discussion

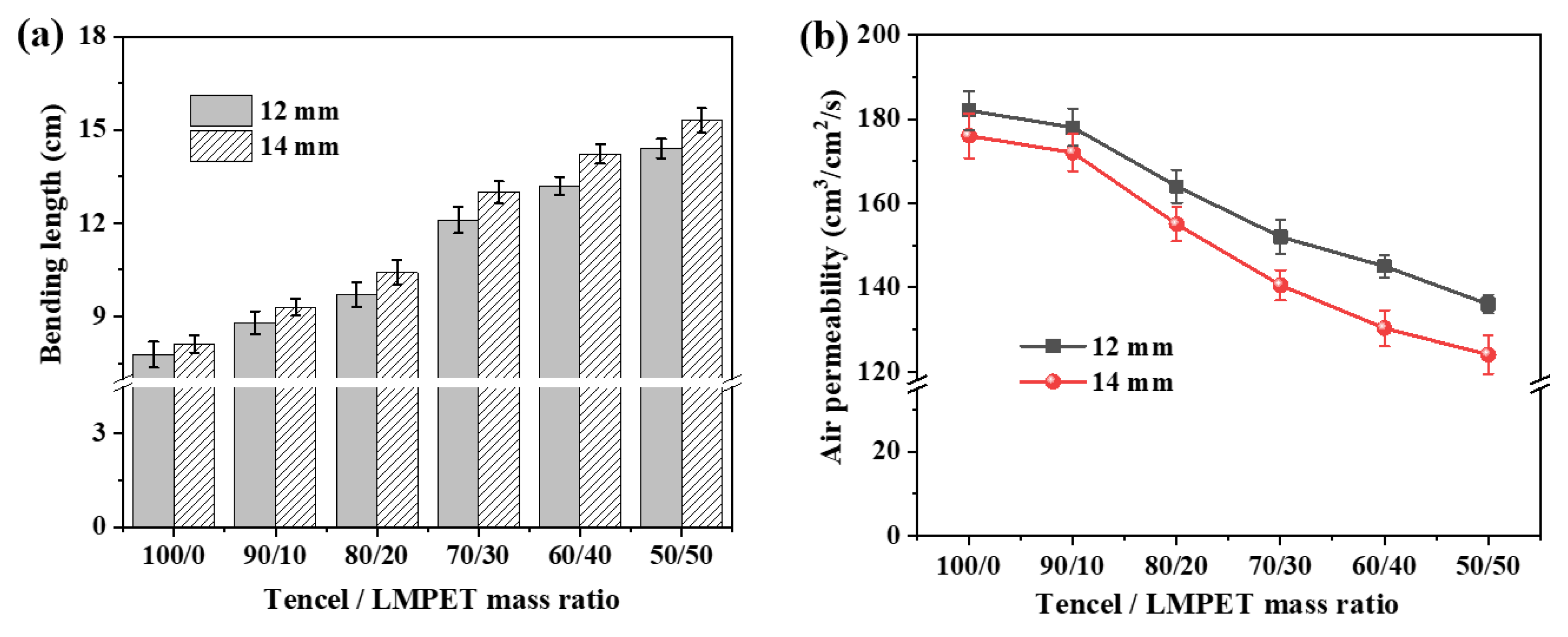

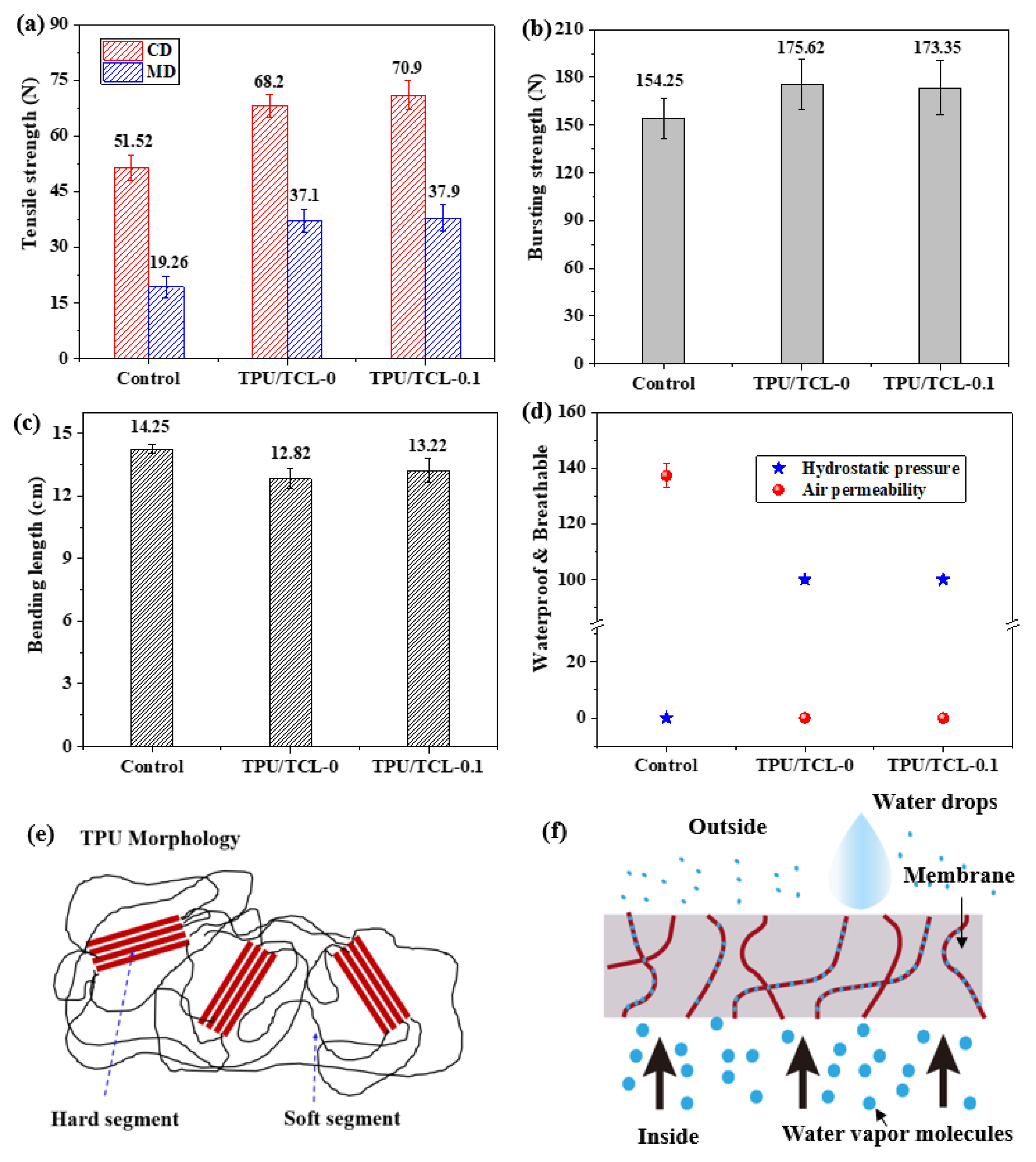

3.1. Mechanical, Breathable Properties, and Flexibility of Tencel/LMPET Nonwoven Fabrics

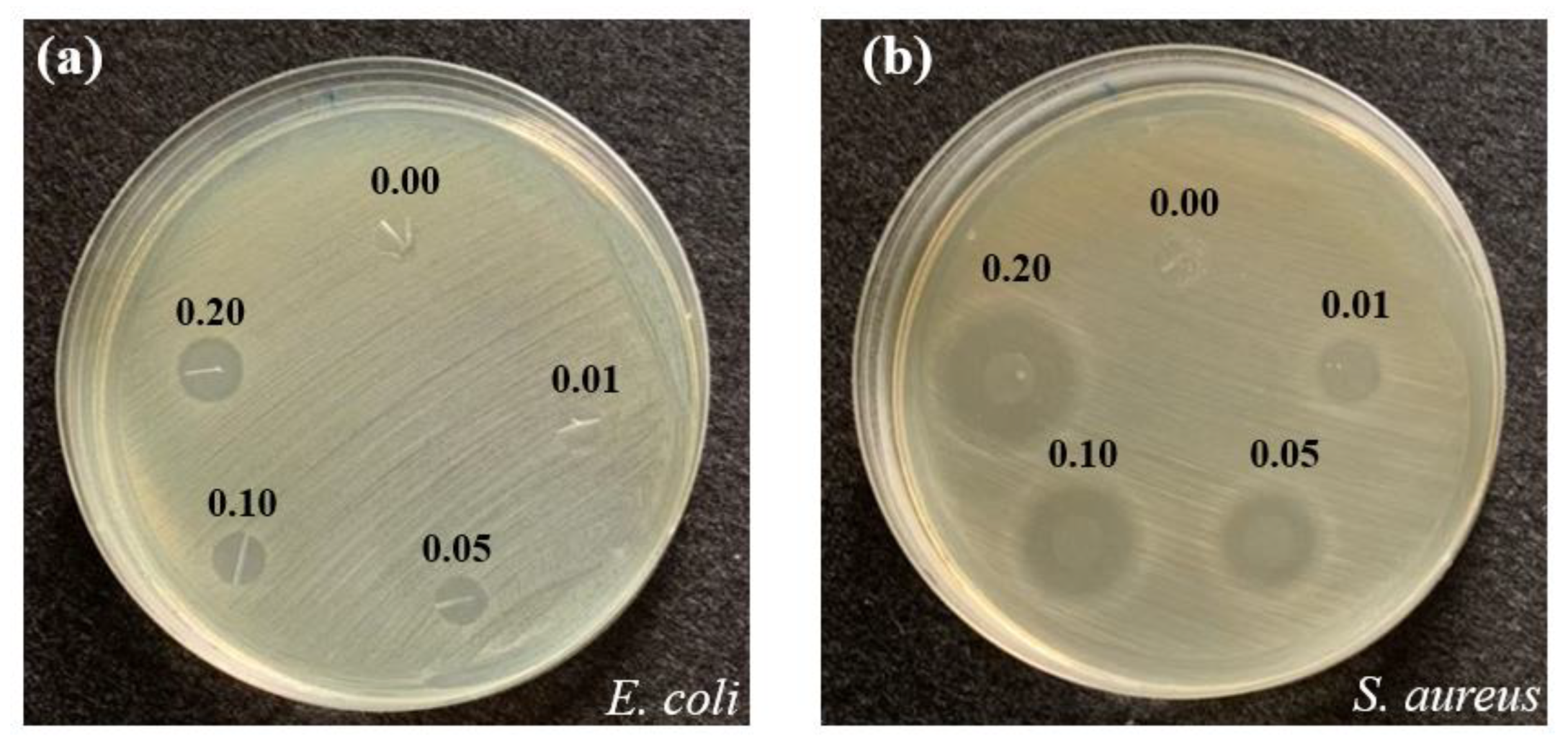

3.2. Antimicrobial Activity Evaluation of the TPU/Triclosan (TCL) Membrane

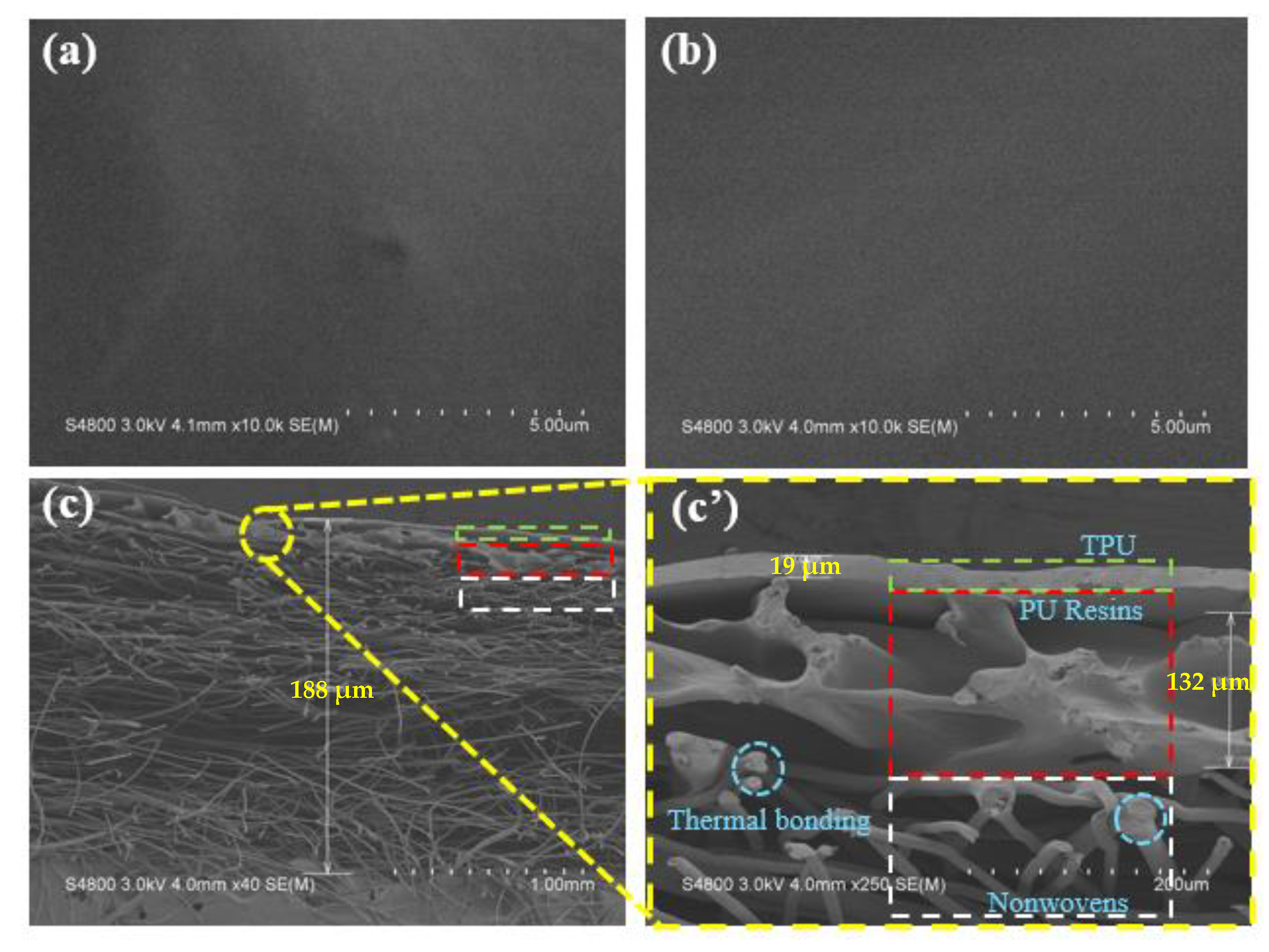

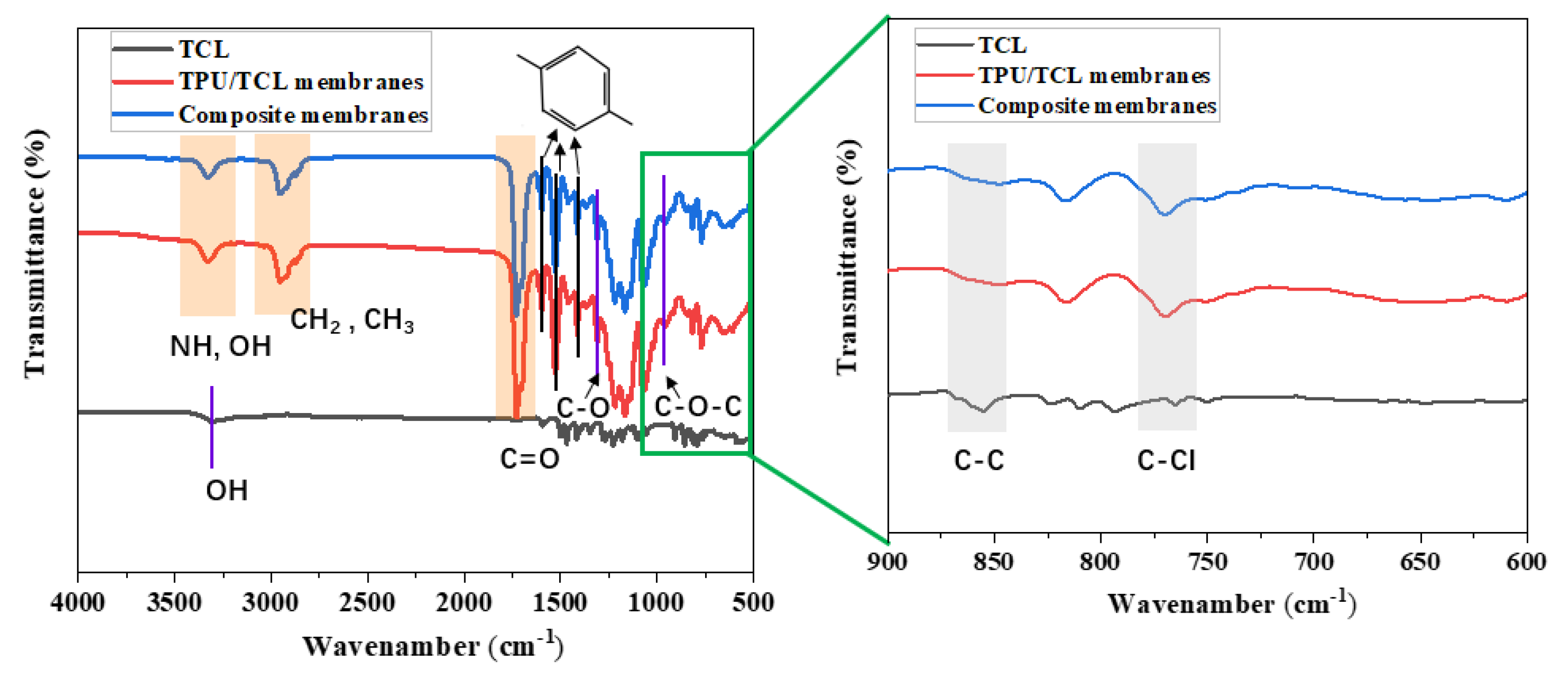

3.3. Morphology and FTIR of the Lamination Composite Membranes

3.4. Water Resistance and Machanical Properties of the Lamination Composite Membranes

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tang, X.; Zhang, X.; Zhang, H.; Zhuang, X.; Yan, X. Facile dip-coating process towards multifunctional nonwovens: Robust noise reduction, abrasion resistance and antistatic electricity. Text. Res. J. 2017, 88, 2568–2578. [Google Scholar] [CrossRef]

- Yoon, B.; Lee, S. Designing waterproof breathable materials based on electrospun nanofibers and assessing the performance characteristics. Fibers Polym. 2011, 12, 57–64. [Google Scholar] [CrossRef]

- Hong, K.A.; Yoo, H.S.; Kim, E. Effect of waterborne polyurethane coating on the durability and breathable waterproofing of electrospun nanofiber web-laminated fabrics. Text. Res. J. 2014, 85, 160–170. [Google Scholar] [CrossRef]

- Knížek, R.; Karhánková, D.; Bajzík, V.; Jirsák, O. Lamination of Nanofibre Layers for Clothing Applications. Fibres Text. East. Eur. 2019, 27, 16–22. [Google Scholar] [CrossRef]

- Zeng, Z.-H.; Wu, N.; Wei, J.-J.; Yang, Y.-F.; Wu, T.-T.; Li, B.; Hauser, S.B.; Yang, W.-D.; Liu, J.-R.; Zhao, S.-Y. Porous and ultra-flexible crosslinked MXene/polyimide composites for multifunctional electromagnetic interference shielding. Nano-Micro Lett. 2022, 14, 59. [Google Scholar] [CrossRef]

- Karaszewska, A.; Kamińska, I.; Kiwała, M.; Gadzinowski, M.; Gosecki, M.; Slomkowski, S. Preparation and properties of textile materials modified with triclosan-loaded polylactide microparticles. Polym. Adv. Technol. 2017, 28, 1185–1193. [Google Scholar] [CrossRef]

- Valle, L.J.D. Biodegradable polyesters reinforced with triclosan loaded polylactide micro/nanofibers: Properties, release and biocompatibility. Express Polym. Lett. 2012, 6, 266–282. [Google Scholar] [CrossRef]

- Zeng, Z.; Wu, T.; Han, D.; Ren, Q.; Siqueira, G.; Nystrom, G. Ultralight, flexible, and biomimetic nanocellulose/silver nanowire aerogels for electromagnetic interference shielding. ACS Nano 2020, 14, 2927–2938. [Google Scholar] [CrossRef]

- Kaffashi, B.; Davoodi, S.; Oliaei, E. Poly(epsilon-caprolactone)/triclosan loaded polylactic acid nanoparticles composite: A long-term antibacterial bionanocomposite with sustained release. Int. J. Pharm. 2016, 508, 10–21. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, X.; Liu, L.; Yu, J.; Ding, B. Human Skin-Like, Robust Waterproof, and Highly Breathable Fibrous Membranes with Short Perfluorobutyl Chains for Eco-Friendly Protective Textiles. ACS Appl. Mater. Interfaces 2018, 10, 30887–30894. [Google Scholar] [CrossRef]

- Dong, Y.; Thomas, N.L.; Lu, X. Electrospun dual-layer mats with covalently bonded ZnO nanoparticles for moisture wicking and antibacterial textiles. Mater. Des. 2017, 134, 54–63. [Google Scholar] [CrossRef] [Green Version]

- Moustafa, H.; Darwish, N.A.; Youssef, A.M. Rational formulations of sustainable polyurethane/chitin/rosin composites reinforced with ZnO-doped-SiO2 nanoparticles for green packaging applications. Food Chem. 2022, 371, 131193. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, T.-T.; Shiu, B.-C.; Sun, F.; Ren, H.-T.; Zhang, X.; Lou, C.-W.; Lin, J.-H. Eco-friendly versatile protective polyurethane/triclosan coated polylactic acid nonwovens for medical covers application. J. Clean. Prod. 2021, 282, 124455. [Google Scholar] [CrossRef]

- Shiu, B.-C.; Jhang, J.-C.; Li, T.-T.; Peng, H.-K.; Wu, L.-W.; Lou, C.-W.; Lin, J.-H. Using antibacterial fibers and metallic wires to make woven fabrics used as smart diapers. J. Ind. Text. 2022, 51, 9017S–9030S. [Google Scholar] [CrossRef]

- Lee, J.-C.; Park, D.-H.; Choi, J.R.; Kim, K.-Y. Tensile Properties and Poisson’s Ratio of Thermocompression-bonded PET Nonwoven Fabrics Prepared by Needle-punching. Fibers Polym. 2019, 20, 1969–1974. [Google Scholar] [CrossRef]

- Russell, A.D. Whither triclosan? J. Antimicrob. Chemother. 2004, 53, 693–695. [Google Scholar] [CrossRef] [Green Version]

- Suller, M.T.E.; Russell, A.D. Triclosan and antibiotic resistance in Staphylococcus aureus. J. Antimicrob. Chemother. 2000, 46, 11–18. [Google Scholar] [CrossRef] [Green Version]

- McMahon, T. Revised 5-Chloro-2-(2,4-dichlorophenoxy)phenol (Triclosan): Toxicology Chapter for the Reregistration Eligibility Decision (RED) Document. Case No 2340. Pcode: 054901. DP Barcode 373536. 14 May 2008. Available online: https://archive.epa.gov/pesticides/reregistration/web/pdf/2340red.pdf (accessed on 24 June 2023).

- Senczuk, W. Toksykologia Wspólczesna [Modern Toxicology]; Medical Publishing House PZWL: Warsaw, Poland, 2005. (In Polish) [Google Scholar]

- Cieślak, M.; Solarz, K.; Kamińska, I. Effect of bioactive modified nonwoven systems on the development of house dust mites Dermatophagoides farinae (Acari: Pyroglyphidae) in laboratory assay. Text. Res. J. 2014, 85, 469–478. [Google Scholar] [CrossRef]

- Zain, N.B.M.; Akindoyo, J.O.; Beg, M.D.H. Synthetic Antimicrobial Agent and Antimicrobial Fabrics: Progress and Challenges. IIUM Eng. J. 2018, 19, 10–29. [Google Scholar] [CrossRef] [Green Version]

- Fiori, M.A.; Paula, M.M.S.; da Silva, L.; Santos, M.F.; Angioletto, E.; Riella, H.G.; Quadri, M.G.N. Extrusion Effects with Bactericidal Additives in Polymer Wood Composites. Int. Polym. Process. 2009, 24, 414–420. [Google Scholar] [CrossRef]

- Comim, L.M.; Gazolla, P.S.; Santiago, T.V.F.; Duarte, G.W.; Angioletto, E.; Pich, C.T.; Piletti, R.; Fiori, J.; Riella, H.G.; Fiori, M.A. Effect of the Extrusion Process on the Bactericidal Performance of Biocidal Polypropylene Catheters. Polym. Plast. Technol. Eng. 2012, 51, 283–289. [Google Scholar] [CrossRef]

- Pandimurugan, R.; Thambidurai, S. UV protection and antibacterial properties of seaweed capped ZnO nanoparticles coated cotton fabrics. Int. J. Biol. Macromol. 2017, 105, 788–795. [Google Scholar] [CrossRef]

- Yu, Z.-C.; Zhang, J.-F.; Lou, C.-W.; He, H.-L.; Chen, A.-P.; Lin, J.-H. Moisture Comfort and Antibacterial Properties of Elastic Warp-Knitted Fabrics. Autex Res. J. 2015, 15, 60–66. [Google Scholar] [CrossRef] [Green Version]

- Yousefi, N.; Gudarzi, M.M.; Zheng, Q.; Lin, X.; Shen, X.; Jia, J.; Sharif, F.; Kim, J.-K. Highly aligned, ultralarge-size reduced graphene oxide/polyurethane nanocomposites: Mechanical properties and moisture permeability. Compos. Part A Appl. Sci. Manuf. 2013, 49, 42–50. [Google Scholar] [CrossRef]

- Zhang, L.; Li, Y.; Yu, J.; Ding, B. Fluorinated polyurethane macroporous membranes with waterproof, breathable and mechanical performance improved by lithium chloride. RSC Adv. 2015, 5, 79807–79814. [Google Scholar] [CrossRef]

- Zeng, Z.; Mavrona, E.; Kummer, N.; Nystrm, G. Terahertz Birefringent Biomimetic Aerogels Based on Cellulose Nanofibers and Conductive Nanomaterials. ACS Nano 2021, 15, 1381. [Google Scholar] [CrossRef] [PubMed]

- Moiz, A.; Padhye, R.; Wang, X. Coating of TPU-PDMS-TMS on Polycotton Fabrics for Versatile Protection. Polymers 2017, 9, 660. [Google Scholar] [CrossRef] [Green Version]

- Moiz, A.; Vijayan, A.; Padhye, R.; Wang, X. Chemical and water protective surface on cotton fabric by pad-knife-pad coating of WPU-PDMS-TMS. Cellulose 2016, 23, 3377–3388. [Google Scholar] [CrossRef]

- Yu, Z.; Liu, J.; He, H.; Ma, S.; Yao, J. Flame-retardant PNIPAAm/sodium alginate/polyvinyl alcohol hydrogels used for fire-fighting application: Preparation and characteristic evaluations. Carbohydr. Polym. 2021, 255, 117485. [Google Scholar] [CrossRef]

- Bulut, Y.; Sariişik, M.; Sülar, V. Effects of process parameters on mechanical properties of coated fabrics. Int. J. Cloth. Sci. Technol. 2011, 23, 205–221. [Google Scholar] [CrossRef]

- Prapruddivongs, C.; Sombatsompop, N. Roles and evidence of wood flour as an antibacterial promoter for triclosan-filled poly(lactic acid). Compos. Part B Eng. 2012, 43, 2730–2737. [Google Scholar] [CrossRef]

- Wook, A.H.; Hee, P.C.; Eun, C.S. Waterproof and breathable properties of nanoweb applied clothing. Text. Res. J. 2011, 81, 1438–1447. [Google Scholar]

- Sheng, J.; Zhang, M.; Xu, Y.; Yu, J.; Ding, B. Tailoring Water-Resistant and Breathable Performance of Polyacrylonitrile Nanofibrous Membranes Modified by Polydimethylsiloxane. ACS Appl. Mater. Interfaces 2016, 8, 27218–27226. [Google Scholar] [CrossRef]

- Sheng, J.; Li, Y.; Wang, X.; Si, Y.; Yu, J.; Ding, B. Thermal inter-fiber adhesion of the polyacrylonitrile/fluorinated polyurethane nanofibrous membranes with enhanced waterproof-breathable performance. Sep. Purif. Technol. 2016, 158, 53–61. [Google Scholar] [CrossRef]

- Li, Y.; Zhu, Z.; Yu, J.; Ding, B. Carbon Nanotubes Enhanced Fluorinated Polyurethane Macroporous Membranes for Waterproof and Breathable Application. ACS Appl. Mater. Interfaces 2015, 7, 13538–13546. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Li, T.-T.; Lou, C.-W.; Lin, J.-H. Facile method for tent fabrics with eco-friendly/durable properties using waterborne polyurethane/lignin: Preparation and evaluation. J. Ind. Text. 2022, 51, 4149S–4166S. [Google Scholar] [CrossRef]

- Zhang, M.; Sheng, J.; Yin, X.; Yu, J.; Ding, B. Polyvinyl Butyral Modified Polyvinylidene Fluoride Breathable-Waterproof Nanofibrous Membranes with Enhanced Mechanical Performance. Macromol. Mater. Eng. 2017, 302. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Li, Y.; Tian, H.; Sheng, J.; Yu, J.; Ding, B. Waterproof and breathable membranes of waterborne fluorinated polyurethane modified electrospun polyacrylonitrile fibers. RSC Adv. 2014, 4, 61068–61076. [Google Scholar] [CrossRef]

- Gu, J.; Gu, H.; Zhang, Q.; Zhao, Y.; Li, N.; Xiong, J. Sandwich-structured composite fibrous membranes with tunable porous structure for waterproof, breathable, and oil-water separation applications. J. Colloid. Interface Sci. 2018, 514, 386–395. [Google Scholar] [CrossRef]

- Erdem, R.; Rajendran, S. Influence of silver loaded antibacterial agent on knitted and nonwoven fabrics and some fabric properties. J. Eng. Fibers Fabr. 2016, 11. [Google Scholar] [CrossRef]

- Rahli, O.; Tadrist, L.; Miscevic, M.; Santini, R. Fluid Flow Through Randomly Packed Monodisperse Fibers: The Kozeny-Carman Parameter Analysis. J. Fluids Eng. 1997, 119, 188–192. [Google Scholar] [CrossRef]

- Rogina-Car, B.; Rogina, J.; Bajsić, E.G.; Budimir, A. Propolis—Eco-friendly natural antibacterial finish for nonwoven fabrics for medical application. J. Ind. Text. 2018, 49, 1100–1119. [Google Scholar] [CrossRef]

| Test Name | Test Criterion | Instrument | Sample Size, cm |

|---|---|---|---|

| Hydrostatic pressure | AATCC 127 | YG812, Nantong Hongda Experiment Instruments Co., Ltd., Nantong, China | circular with a diameter of 100 |

| Bursting Strength | ASTM F2054-07 | Instron 5565, Instron, Boston, MA, USA | 15 × 15 |

| Tensile strength | ASTM D5035-11 | Instron 5565, Instron, Boston, MA, USA | 180 × 2.54 |

| Windproof performance | ISO 9273:1995 | TEXTEST FX3300, Aidengwei Automation Instruments, Shanghai, China | 25 × 25 |

| Flexibility | GB/T18318.1-2009 | DRK207BDRK, DRK Experiment Instruments Co., Ltd., Shandong, China | 2.5 × 25 |

| Antimicrobial properties | AATCC 90-2011 | Solid agar Petri plate, Hengfeng Medical Instruments Co., Ltd., Huangshi, China | circular with a diameter of 1 |

| Substrate | Modifacation Materils | Treatment Method | Hydrostatic Pressure, kPa | Antimicrobial Activity | Ref. | |

|---|---|---|---|---|---|---|

| E. coli | S. aureus | |||||

| Tencel/LMPET@PU | PU/TCL | Lamination | 100 | ○ | ○ | This work |

| Polyester@PU | PU | Lamination | 78 | × | × | [2] |

| Taslan@PU | PU | Lamination | 84 | × | × | [3] |

| Cotton@PU | PU | Lamination | 52 | × | × | [4] |

| PAN@PVDF/ZnO | PVDF/ZnO | Electrospun | — | ○ | × | [11] |

| Nylon@PU | PU | Lamination | 32 | × | × | [34] |

| Nylon@WPU | WPU | Coating | 15 | × | × | [38] |

| PVDF/PVB | PVB | Electrospinning | 58 | × | × | [39] |

| PAN/WFPU | WFPU | Electrospinning | 83 | × | × | [40] |

| PVDF/PU/PVDF | PVDF | Electrospinning | 38 | × | × | [41] |

| PET/VIS/cotton@AgCl | AgCl | Spraying | — | ○ | ○ | [42] |

| Tencel/cotton@propoils | propoils | Dip coating | — | ○ | ○ | [44] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Lin, J.-H.; Cheng, D.-H.; Li, X.; Wang, H.-Y.; Lu, Y.-H.; Lou, C.-W. A Study on Tencel/LMPET–TPU/Triclosan Laminated Membranes: Excellent Water Resistance and Antimicrobial Ability. Membranes 2023, 13, 703. https://doi.org/10.3390/membranes13080703

Zhang Y, Lin J-H, Cheng D-H, Li X, Wang H-Y, Lu Y-H, Lou C-W. A Study on Tencel/LMPET–TPU/Triclosan Laminated Membranes: Excellent Water Resistance and Antimicrobial Ability. Membranes. 2023; 13(8):703. https://doi.org/10.3390/membranes13080703

Chicago/Turabian StyleZhang, Yue, Jia-Horng Lin, De-Hong Cheng, Xing Li, Hong-Yang Wang, Yan-Hua Lu, and Ching-Wen Lou. 2023. "A Study on Tencel/LMPET–TPU/Triclosan Laminated Membranes: Excellent Water Resistance and Antimicrobial Ability" Membranes 13, no. 8: 703. https://doi.org/10.3390/membranes13080703

APA StyleZhang, Y., Lin, J.-H., Cheng, D.-H., Li, X., Wang, H.-Y., Lu, Y.-H., & Lou, C.-W. (2023). A Study on Tencel/LMPET–TPU/Triclosan Laminated Membranes: Excellent Water Resistance and Antimicrobial Ability. Membranes, 13(8), 703. https://doi.org/10.3390/membranes13080703