Simultaneous Wastewater Treatment and Resources Recovery by Forward Osmosis Coupled with Microbial Fuel Cell: A Review

Abstract

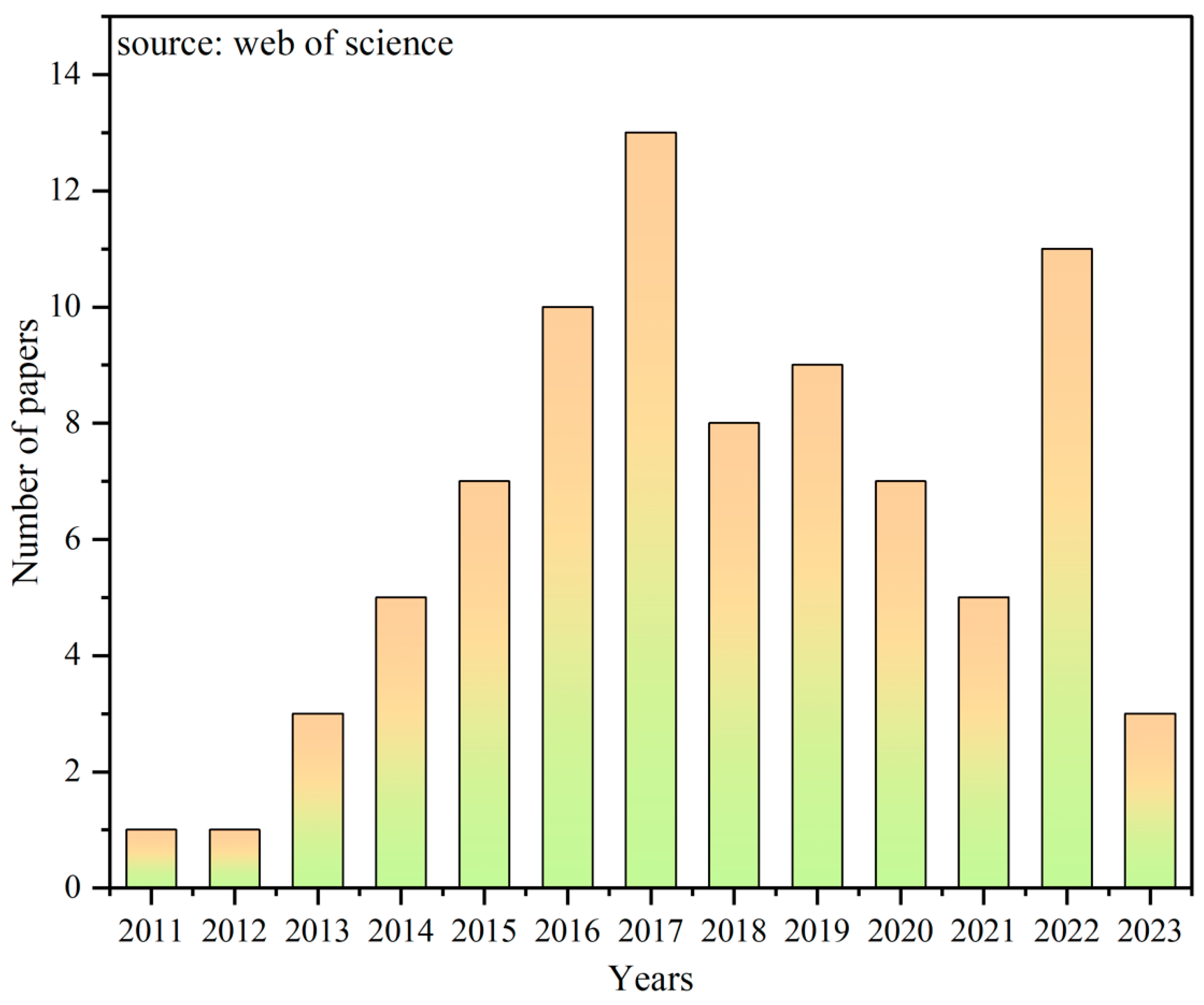

1. Introduction

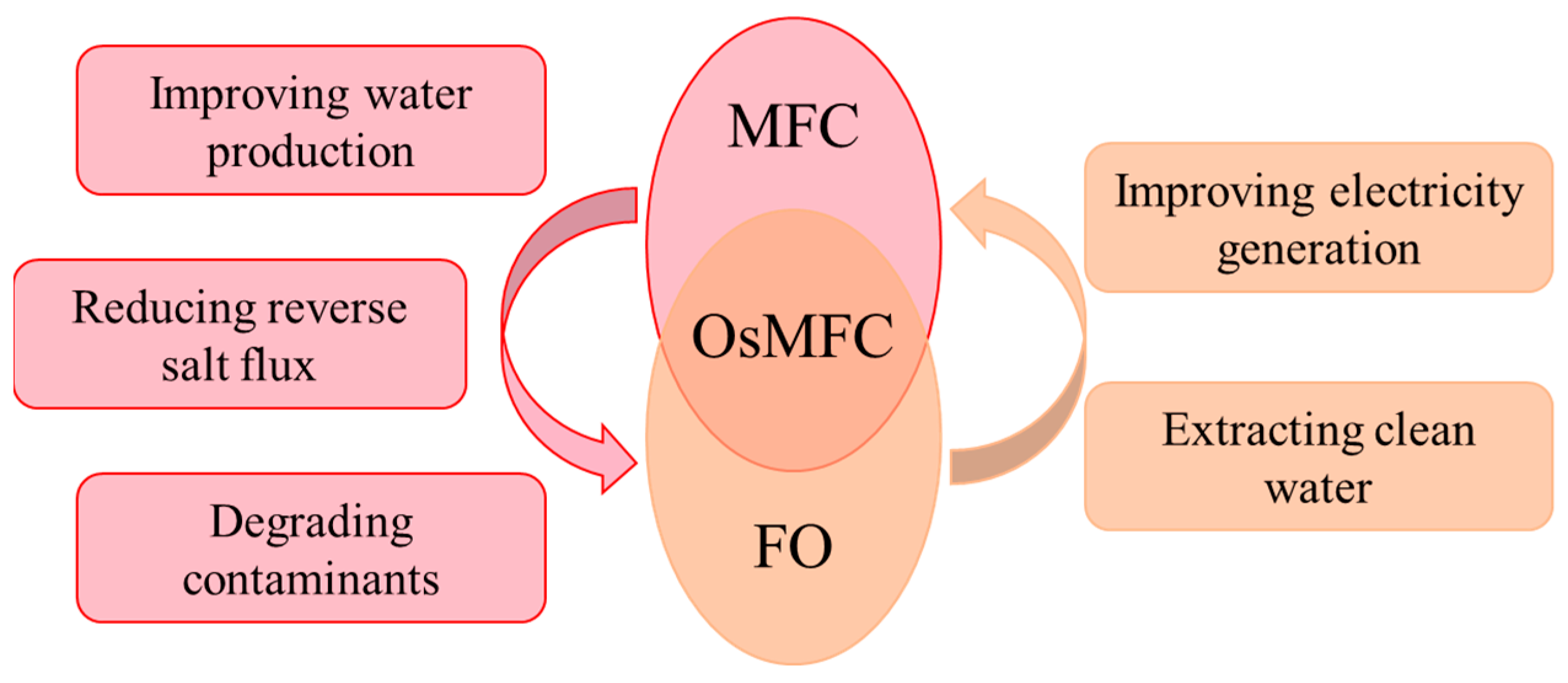

2. Cooperation Mechanisms

2.1. MFC Enhanced FO Performance

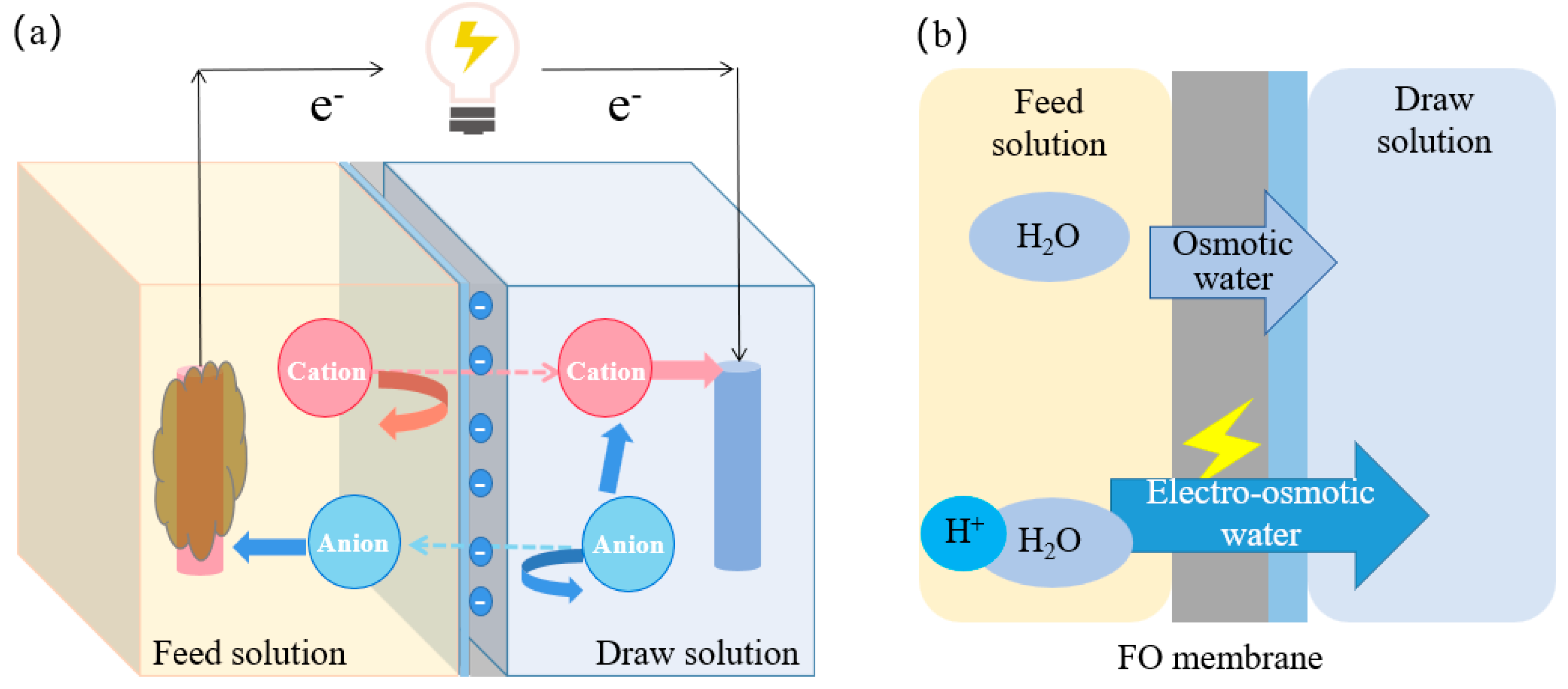

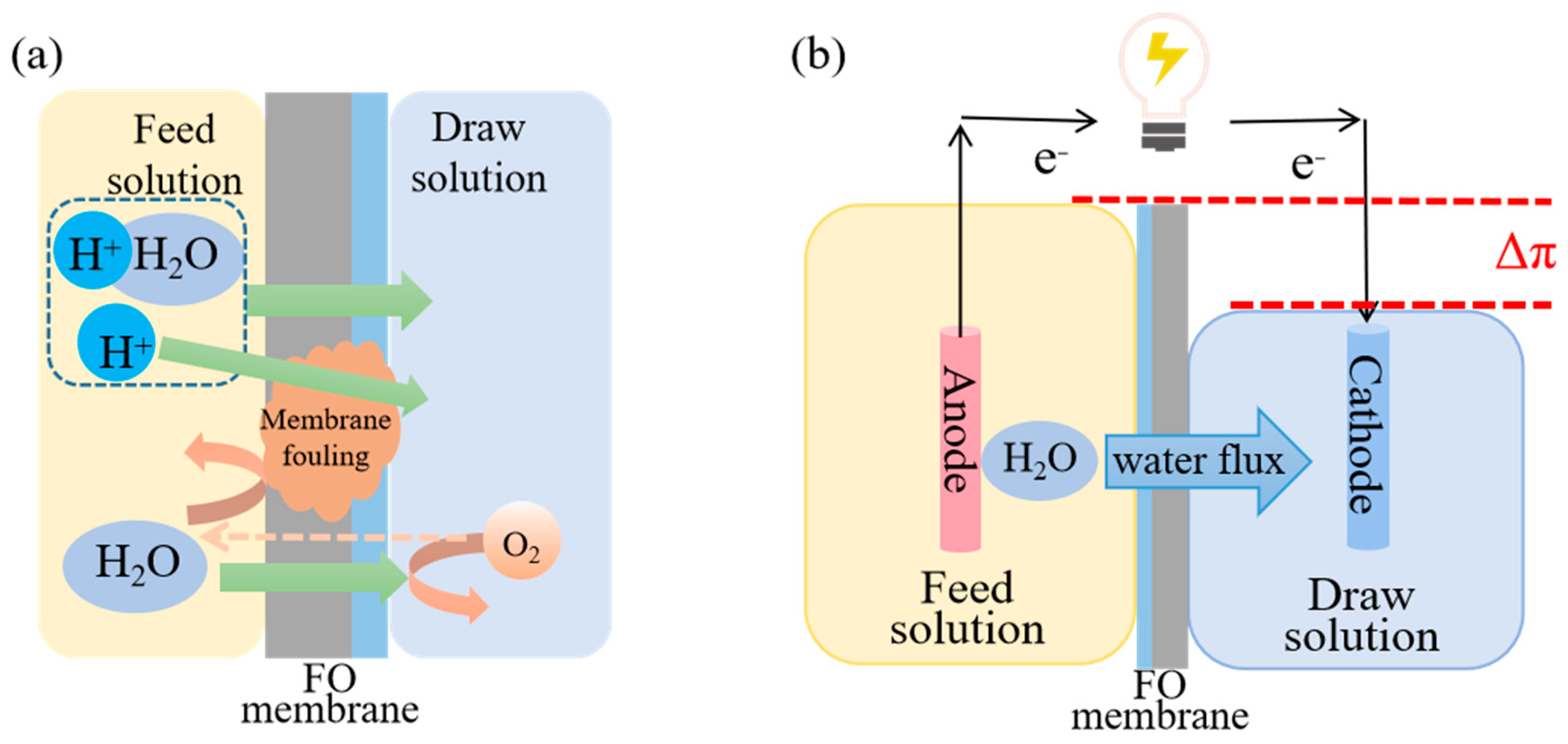

2.1.1. Improving Water Flux

2.1.2. Reducing Reverse Salt Flux

2.1.3. Degrading Contaminants

2.2. FO Improved MFC Performance

2.2.1. Improving Electricity Generation

2.2.2. Extracting Clean Water

3. Resources Recovery

3.1. Nutrient Recovery

3.2. Energy Recovery

3.3. Water Recovery

4. Operational Factors of OsMFCs

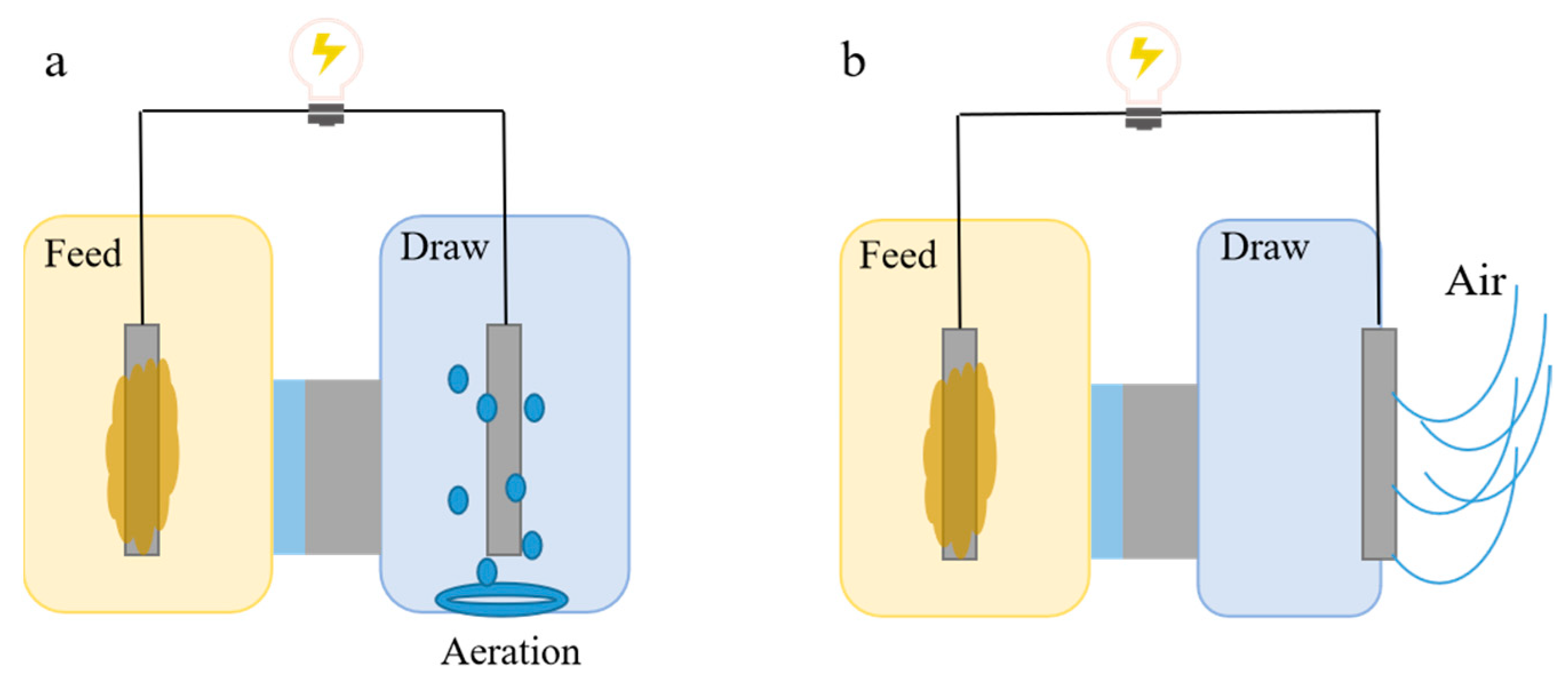

4.1. Configurations of OsMFCs

4.2. The FO Membrane

4.2.1. Types of Membrane

4.2.2. Membrane Orientations

4.2.3. Membrane Modification

4.3. The Draw Solution

4.3.1. Types of Draw Solution

4.3.2. Concentration of the Draw Solution

4.4. The Feed Solution

4.5. Other Factors

5. Perspectives and Challenges

5.1. Potential Applications

5.2. Membrane Fouling

5.3. System Expansion

5.4. Reverse Solute Flux

5.5. Full Life-Cycle Assessment

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Hou, H.; Duan, L.; Zhou, B.; Tian, Y.; Wei, J.; Qian, F. The performance and degradation mechanism of sulfamethazine from wastewater using IFAS-MBR. Chin. Chem. Lett. 2020, 31, 543–546. [Google Scholar] [CrossRef]

- Yang, E.; Chae, K.-J.; Choi, M.-J.; He, Z.; Kim, I.S. Critical review of bioelectrochemical systems integrated with membrane-based technologies for desalination, energy self-sufficiency, and high-efficiency water and wastewater treatment. Desalination 2019, 452, 40–67. [Google Scholar] [CrossRef]

- Omar, A.; Nashed, A.; Li, Q.; Leslie, G.; Taylor, R.A. Pathways for integrated concentrated solar power—Desalination: A critical review. Renew. Sustain. Energy Rev. 2020, 119, 109609. [Google Scholar] [CrossRef]

- Yuan, H.; He, Z. Integrating membrane filtration into bioelectrochemical systems as next generation energy-efficient wastewater treatment technologies for water reclamation: A review. Bioresour. Technol. 2015, 195, 202–209. [Google Scholar] [CrossRef]

- Qin, M.; He, Z. Resource recovery by osmotic bioelectrochemical systems towards sustainable wastewater treatment. Environ. Sci. Water Res. Technol. 2017, 3, 583–592. [Google Scholar] [CrossRef]

- Gao, Q.; Duan, L.; Liu, J.; Zhang, H.; Zhao, Y. Evaluation and optimization of reverse osmosis pretreatment technology using the modified intermediate blocking model. J. Clean. Prod. 2023, 417, 138029. [Google Scholar] [CrossRef]

- Damergi, E.; Madi, H.; Sharma, S.; Boukis, N.; Marechal, F.; Van Herle, J.; Ludwig, C. A combined hydrothermal gasification—Solid oxide fuel cell system for sustainable production of algal biomass and energy. Algal Res. 2019, 41, 101552. [Google Scholar] [CrossRef]

- Zoppi, G.; Pipitone, G.; Pirone, R.; Bensaid, S. Aqueous phase reforming process for the valorization of wastewater streams: Application to different industrial scenarios. Catal. Today 2021, 387, 224–236. [Google Scholar] [CrossRef]

- Guan, Q.; Li, Y.; Zhong, Y.; Liu, W.; Zhang, J.; Yu, X.; Ou, R.; Zeng, G. A review of struvite crystallization for nutrient source recovery from wastewater. J. Environ. Manag. 2023, 344, 118383. [Google Scholar] [CrossRef]

- Zhu, L.; Ding, C.; Zhu, T.; Wang, Y. A review on the forward osmosis applications and fouling control strategies for wastewater treatment. Front. Chem. Sci. Eng. 2021, 16, 661–680. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, Y. Integrated forward osmosis-adsorption process for strontium-containing water treatment: Pre-concentration and solidification. J. Hazard. Mater. 2021, 414, 125518. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Wang, J.; Vecitis, C.D. Fouling reduction and recovery during forward osmosis of wastewater using an electroactive CNT composite membrane. J. Membr. Sci. 2021, 620, 118803. [Google Scholar] [CrossRef]

- Wu, X.; Tanner, J.; Ng, D.; Acharya, D.; Xie, Z. Sewage concentration via a graphene oxide modified thin-film nanocomposite forward osmosis membrane: Enhanced performance and mitigated fouling. Chem. Eng. J. 2021, 420, 127718. [Google Scholar] [CrossRef]

- Deng, S.; Wang, C.; Ngo, H.H.; Guo, W.; You, N.; Tang, H.; Yu, H.; Tang, L.; Han, J. Comparative review on microbial electrochemical technologies for resource recovery from wastewater towards circular economy and carbon neutrality. Bioresour. Technol. 2023, 376, 128906. [Google Scholar] [CrossRef]

- Gupta, S.; Patro, A.; Mittal, Y.; Dwivedi, S.; Saket, P.; Panja, R.; Saeed, T.; Martínez, F.; Yadav, A.K. The race between classical microbial fuel cells, sediment-microbial fuel cells, plant-microbial fuel cells, and constructed wetlands-microbial fuel cells: Applications and technology readiness level. Sci. Total Environ. 2023, 879, 162757. [Google Scholar] [CrossRef]

- Huang, X.; Duan, C.; Duan, W.; Sun, F.; Cui, H.; Zhang, S.; Chen, X. Role of electrode materials on performance and microbial characteristics in the constructed wetland coupled microbial fuel cell (CW-MFC): A review. J. Clean. Prod. 2021, 301, 126951. [Google Scholar] [CrossRef]

- Kim, T.; An, J.; Jang, J.K.; Chang, I.S. Determination of optimum electrical connection mode for multi-electrode-embedded microbial fuel cells coupled with anaerobic digester for enhancement of swine wastewater treatment efficiency and energy recovery. Bioresour. Technol. 2020, 297, 122464. [Google Scholar] [CrossRef]

- Logan, B.E.; Rossi, R.; Ragab, A.A.; Saikaly, P.E. Electroactive microorganisms in bioelectrochemical systems. Nat. Rev. Microbiol. 2019, 17, 307–319. [Google Scholar] [CrossRef]

- Yang, X.L.; Wang, Q.; Li, T.; Xu, H.; Song, H.L. Antibiotic removal and antibiotic resistance genes fate by regulating bioelectrochemical characteristics in microbial fuel cells. Bioresour. Technol. 2022, 348, 126752. [Google Scholar] [CrossRef]

- Ye, Y.; Ngo, H.H.; Guo, W.; Chang, S.W.; Nguyen, D.D.; Liu, Y.; Ni, B.-j.; Zhang, X. Microbial fuel cell for nutrient recovery and electricity generation from municipal wastewater under different ammonium concentrations. Bioresour. Technol. 2019, 292, 121992. [Google Scholar] [CrossRef]

- Song, X.; Jo, C.; Han, L.; Zhou, M. Recent advance in microbial fuel cell reactor configuration and coupling technologies for removal of antibiotic pollutants. Curr. Opin. Electrochem. 2022, 31, 100833. [Google Scholar] [CrossRef]

- Pan, M.; Su, Y.; Zhu, X.; Pan, G.; Zhang, Y.; Angelidaki, I. Bioelectrochemically assisted sustainable conversion of industrial organic wastewater and clean production of microalgal protein. Resour. Conserv. Recycl. 2021, 168, 105441. [Google Scholar] [CrossRef]

- Mutnuri, S.; Sharma, P. Nutrient recovery and microbial diversity in human urine fed microbial fuel cell. Water Sci. Technol. 2019, 79, 718–730. [Google Scholar] [CrossRef]

- Patwardhan, S.B.; Savla, N.; Pandit, S.; Gupta, P.K.; Mathuriya, A.S.; Lahiri, D.; Jadhav, D.A.; Rai, A.K.; KanuPriya; Ray, R.R.; et al. Microbial Fuel Cell United with Other Existing Technologies for Enhanced Power Generation and Efficient Wastewater Treatment. Appl. Sci. 2021, 11, 10777. [Google Scholar] [CrossRef]

- Lu, Y.; Bian, X.; Wang, H.; Wang, X.; Ren, Y.; Li, X. Simultaneously recovering electricity and water from wastewater by osmotic microbial fuel cells: Performance and membrane fouling. Front. Environ. Sci. Eng. 2018, 12, 5. [Google Scholar] [CrossRef]

- Bhagat, M.S.; Mungray, A.K.; Mungray, A.A. Recent advances in osmotic microbial fuel cell technology: A review. J. Indian Chem. Soc. 2022, 99, 100552. [Google Scholar] [CrossRef]

- Iskander, S.M.; Brazil, B.; Novak, J.T.; He, Z. Resource recovery from landfill leachate using bioelectrochemical systems: Opportunities, challenges, and perspectives. Bioresour. Technol. 2016, 201, 347–354. [Google Scholar] [CrossRef]

- Ge, Z.; Ping, Q.; Xiao, L.; He, Z. Reducing effluent discharge and recovering bioenergy in an osmotic microbial fuel cell treating domestic wastewater. Desalination 2013, 312, 52–59. [Google Scholar] [CrossRef]

- Lu, Y.; Qin, M.; Yuan, H.; Abu-Reesh, I.; He, Z. When Bioelectrochemical Systems Meet Forward Osmosis: Accomplishing Wastewater Treatment and Reuse through Synergy. Water 2014, 7, 38–50. [Google Scholar] [CrossRef]

- Zhang, F.; Brastad, K.S.; He, Z. Integrating forward osmosis into microbial fuel cells for wastewater treatment, water extraction and bioelectricity generation. Environ. Sci. Technol. 2011, 45, 6690–6696. [Google Scholar] [CrossRef]

- Jiang, N.; Huang, L.; Huang, M.; Cai, T.; Song, J.; Zheng, S.; Guo, J.; Kong, Z.; Chen, L. Electricity generation and pollutants removal of landfill leachate by osmotic microbial fuel cells with different forward osmosis membranes. Sustain. Environ. Res. 2021, 31, 22. [Google Scholar] [CrossRef]

- Sevda, S.; Abu-Reesh, I.M. Improved petroleum refinery wastewater treatment and seawater desalination performance by combining osmotic microbial fuel cell and up-flow microbial desalination cell. Environ. Technol. 2017, 40, 888–895. [Google Scholar] [CrossRef] [PubMed]

- Moody, C.D.; Kessler, J.O. Forward osmosis extractors. Desalination 1976, 18, 283–295. [Google Scholar] [CrossRef]

- Tian, E.; Liu, Y.; Yin, F.J.; Lu, S.; Zheng, L.; Wang, X.Z.; Wang, Z.P.; Liu, H. Facilitating proton transport by endowing forward osmosis membrane with proton conductive sites in osmotic microbial fuel cell. Chem. Eng. J. 2023, 451, 138767. [Google Scholar] [CrossRef]

- Gajda, I.; Greenman, J.; Melhuish, C.; Santoro, C.; Li, B.; Cristiani, P.; Ieropoulos, I. Electro-osmotic-based catholyte production by Microbial Fuel Cells for carbon capture. Water Res. 2015, 86, 108–115. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Song, Y.H.; Duan, L. Study on the Effect of Water Flux in Osmotic Microbial Fuel Cells on Membrane Water Content and Resistance. Water 2022, 14, 13. [Google Scholar] [CrossRef]

- Akther, N.; Sodiq, A.; Giwa, A.; Daer, S.; Arafat, H.A.; Hasan, S.W. Recent advancements in forward osmosis desalination: A review. Chem. Eng. J. 2015, 102, 4412–4439. [Google Scholar] [CrossRef]

- Klaysom, C.; Cath, T.Y.; Depuydt, T.; Vankelecom, I.F. Forward and pressure retarded osmosis: Potential solutions for global challenges in energy and water supply. Chem. Soc. Rev. 2013, 42, 6959–6989. [Google Scholar] [CrossRef]

- Qin, M.; Abu-Reesh, I.M.; He, Z. Effects of current generation and electrolyte pH on reverse salt flux across thin film composite membrane in osmotic microbial fuel cells. Water Res. 2016, 105, 583–590. [Google Scholar] [CrossRef]

- Gajda, I.; Greenman, J.; Melhuish, C.; Ieropoulos, I. Simultaneous electricity generation and microbially-assisted electrosynthesis in ceramic MFCs. Bioelectrochemistry 2015, 104, 58–64. [Google Scholar] [CrossRef]

- Wu, S.M.; Qian, G.R.; He, Z. Examination of inorganic-based draw solutes and mitigation of their reverse solute flux in osmotic microbial fuel cells. J. Chem. Technol. Biotechnol. 2019, 94, 2107–2114. [Google Scholar] [CrossRef]

- Kim, B.; Gwak, G.; Hong, S. Review on methodology for determining forward osmosis (FO) membrane characteristics: Water permeability (A), solute permeability (B), and structural parameter (S). Desalination 2017, 422, 5–16. [Google Scholar] [CrossRef]

- Xu, W.X.; Ge, Q.C. Synthetic polymer materials for forward osmosis (FO) membranes and FO applications: A review. Rev. Chem. Eng. 2018, 35, 191–209. [Google Scholar] [CrossRef]

- Al-Marnun, A.; Baawain, M.S.; Dhar, B.R.; Kim, I.S. Improved recovery of bioenergy and osmotic water in an osmotic microbial fuel cell using micro-diffuser assisted marine aerobic biofilm on cathode. Biochem. Eng. J. 2017, 128, 235–242. [Google Scholar] [CrossRef]

- Werner, C.M.; Logan, B.E.; Saikaly, P.E.; Amy, G.L. Wastewater treatment, energy recovery and desalination using a forward osmosis membrane in an air-cathode microbial osmotic fuel cell. J. Membr. Sci. 2013, 428, 116–122. [Google Scholar] [CrossRef]

- Cao, T.N.D.; Chen, S.S.; Chang, H.M.; Ray, S.S.; Hai, F.I.; Bui, T.X.; Mukhtar, H. Simultaneous hexavalent chromium removal, water reclamation and electricity generation in osmotic bio-electrochemical system. Sep. Purif. Technol. 2021, 263, 118155. [Google Scholar] [CrossRef]

- Cheng, D.; Ngo, H.H.; Guo, W.; Lee, D.; Duc Long, N.; Zhang, J.; Liang, S.; Varjani, S.; Wang, J. Performance of microbial fuel cell for treating swine wastewater containing sulfonamide antibiotics. Bioresour. Technol. 2020, 311, 123588. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhu, N.; Guo, W.; Wang, Y.; Huang, X.; Wu, P.; Dang, Z.; Zhang, X.; Xian, J. Simultaneous electricity production and antibiotics removal by microbial fuel cells. J. Environ. Manag. 2018, 217, 565–572. [Google Scholar] [CrossRef]

- Yang, E.; Chae, K.-J.; Kim, I.S. Comparison of different semipermeable membranes for power generation and water flux in osmotic microbial fuel cells. J. Chem. Technol. Biotechnol. 2016, 91, 2305–2312. [Google Scholar] [CrossRef]

- Zhu, X.-Z.; Zhang, F.; Li, W.-W.; Liu, H.-Q.; Wang, Y.-K.; Huang, M.-S. Forward osmosis membrane favors an improved proton flux and electricity generation in microbial fuel cells. Desalination 2015, 372, 26–31. [Google Scholar] [CrossRef]

- Xue, W.; He, Y.; Yumunthama, S.; Udomkittayachai, N.; Hu, Y.; Tabucanon, A.S.; Zhang, X.; Kurniawan, T.A. Membrane cleaning and performance insight of osmotic microbial fuel cell. Chemosphere 2021, 285, 131549. [Google Scholar] [CrossRef] [PubMed]

- Choi, M.-J.; Chae, K.-J.; Ajayi, F.F.; Kim, K.-Y.; Yu, H.-W.; Kim, C.-w.; Kim, I.S. Effects of biofouling on ion transport through cation exchange membranes and microbial fuel cell performance. Bioresour. Technol. 2011, 102, 298–303. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Sheng, G.-P.; Luo, H.-W.; Li, W.-W.; Wang, L.-F.; Yu, H.-Q. Fouling of proton exchange membrane (PEM) deteriorates the performance of microbial fuel cell. Water Res. 2012, 46, 1817–1824. [Google Scholar] [CrossRef]

- Zhu, X.-Z.; Zhang, F.; Li, W.-W.; Li, J.; Li, L.-L.; Yu, H.-Q.; Huang, M.-S.; Huang, T.-Y. Insights into enhanced current generation of an osmotic microbial fuel cell under membrane fouling condition. J. Membr. Sci. 2016, 504, 40–46. [Google Scholar] [CrossRef]

- Zhao, Y.; Duan, L.; Liu, X.; Song, Y. Influence of Membrane Fouling and Reverse Salt Flux on Membrane Impedance of Forward Osmosis Microbial Fuel Cell. Membranes 2022, 12, 1165. [Google Scholar] [CrossRef]

- Kelly, P.T.; He, Z. Nutrients removal and recovery in bioelectrochemical systems: A review. Bioresour. Technol. 2014, 153, 351–360. [Google Scholar] [CrossRef]

- Zang, G.-L.; Sheng, G.-P.; Li, W.-W.; Tong, Z.-H.; Zeng, R.J.; Shi, C.; Yu, H.-Q. Nutrient removal and energy production in a urine treatment process using magnesium ammonium phosphate precipitation and a microbial fuel cell technique. Phys. Chem. Chem. Phys. 2012, 14, 1978–1984. [Google Scholar] [CrossRef]

- Ansari, A.J.; Hai, F.I.; Price, W.E.; Drewes, J.E.; Nghiem, L.D. Forward osmosis as a platform for resource recovery from municipal wastewater-A critical assessment of the literature. J. Membr. Sci. 2017, 529, 195–206. [Google Scholar] [CrossRef]

- Kuntke, P.; Sleutels, T.H.J.A.; Rodríguez Arredondo, M.; Georg, S.; Barbosa, S.G.; ter Heijne, A.; Hamelers, H.V.M.; Buisman, C.J.N. (Bio)electrochemical ammonia recovery: Progress and perspectives. Appl. Microbiol. Biotechnol. 2018, 102, 3865–3878. [Google Scholar] [CrossRef]

- Qin, M.; Hynes, E.A.; Abu-Reesh, I.M.; He, Z. Ammonium removal from synthetic wastewater promoted by current generation and water flux in an osmotic microbial fuel cell. J. Clean. Prod. 2017, 149, 856–862. [Google Scholar] [CrossRef]

- Gangadharan, P.; Vadekeetil, A.; Sibi, R.; Sheelam, A. Concentrating nutrients and recovering water and energy from source separated urine using osmotic microbial fuel cell. Chemosphere 2021, 285, 131548. [Google Scholar] [CrossRef] [PubMed]

- Yang, E.; Chae, K.-J.; Alayande, A.B.; Kim, K.-Y.; Kim, I.S. Concurrent performance improvement and biofouling mitigation in osmotic microbial fuel cells using a silver nanoparticle-polydopamine coated forward osmosis membrane. J. Membr. Sci. 2016, 513, 217–225. [Google Scholar] [CrossRef]

- Ismail, Z.Z.; Ibrahim, M.A. Desalination of oilfield produced water associated with treatment of domestic wastewater and bioelectricity generation in microbial osmotic fuel cell. J. Membr. Sci. 2015, 490, 247–255. [Google Scholar] [CrossRef]

- Ge, Z.; He, Z. Effects of draw solutions and membrane conditions on electricity generation and water flux in osmotic microbial fuel cells. Bioresour. Technol. 2012, 109, 70–76. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Q.; Liu, J.; Song, X.; Qiu, Y.; Xue, J.; Shao, Y.; Feng, Y. Energy efficient bioelectro-concentration and recovery system of nutrients from human urine by integrating forward osmosis. Resour. Conserv. Recycl. 2022, 181, 106253. [Google Scholar] [CrossRef]

- Wu, S.; Zou, S.; Yang, Y.; Qian, G.; He, Z. Enhancing the performance of an osmotic microbial fuel cell through self-buffering with reverse-fluxed sodium bicarbonate. Chem. Eng. J. 2018, 349, 241–248. [Google Scholar] [CrossRef]

- Yang, E.; Kim, K.-Y.; Chae, K.-J.; Lee, M.-Y.; Kim, I.S. Evaluation of energy and water recovery in forward osmosis–bioelectrochemical hybrid system with cellulose triacetate and polyamide asymmetric membrane in different orientations. Desalination Water Treat. 2015, 57, 7406–7413. [Google Scholar] [CrossRef]

- Pardeshi, P.M.; Mungray, A.A. Performance of photopolymerized active layer forward osmosis membrane in the osmotic microbial fuel cell. Environ. Technol. Innov. 2021, 23, 101669. [Google Scholar] [CrossRef]

- Bhagat, M.S.; Mungray, A.K.; Mungray, A.A. Performance of pilot-scale constructed wetland osmotic microbial fuel cell under different gravel conditions. Environ. Sci. Pollut. Res. Int. 2022, 29, 66757–66767. [Google Scholar] [CrossRef]

- Pardeshi, P.; Mungray, A. High Flux Layer by Layer Polyelectrolyte FO Membrane: Toward Enhanced Performance for Osmotic Microbial Fuel Cell. Int. J. Polym. Mater. Polym. Biomater. 2014, 63, 595–601. [Google Scholar] [CrossRef]

- Yang, Y.; Qin, M.; Yang, X.; He, Z. Sustainable operation of osmotic microbial fuel cells through effective reproduction of polyelectrolyte draw solutes facilitated by cathodic pH increase. J. Clean. Prod. 2017, 168, 1143–1149. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, S.; He, Z. Production of electricity and water in an osmotic microbial fuel cell by using EDTA-Na2 as a recoverable draw solute. Sci. Total Environ. 2019, 677, 382–389. [Google Scholar] [CrossRef] [PubMed]

- Duan, L.; Tian, Z.; Song, Y.; Jiang, W.; Tian, Y.; Li, S. Influence of solids retention time on membrane fouling: Characterization of extracellular polymeric substances and soluble microbial products. Biofouling 2015, 31, 181–191. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.; Jia, J.; Miao, H.; Ruan, W.; Wang, X. Performance Improvement and Biofouling Mitigation in Osmotic Microbial Fuel Cells via In Situ Formation of Silver Nanoparticles on Forward Osmosis Membrane. Membranes 2020, 10, 122. [Google Scholar] [CrossRef] [PubMed]

- Xu, S.S.; Lin, P.F.; An, X.C.; Hu, Y.X.; Wang, Z.B.; Zhong, L.K.; Niu, Q.S. High Performance Forward Osmosis Membranes Used for Treating High Salinity Oil-bearing Wastewater. Ind. Eng. Chem. Res. 2017, 56, 12385–12394. [Google Scholar] [CrossRef]

- Yip, N.Y.; Tiraferri, A.; Phillip, W.A.; Schiffman, J.D.; Elimelech, M. High performance thin-film composite forward osmosis membrane. Environ. Sci. Technol. 2010, 44, 3812–3818. [Google Scholar] [CrossRef] [PubMed]

- Cath, T.; Childress, A.; Elimelech, M. Forward osmosis: Principles, applications, and recent developments. J. Membr. Sci. 2006, 281, 70–87. [Google Scholar] [CrossRef]

- Ortega-Bravo, J.C.; Ruiz-Filippi, G.; Donoso-Bravo, A.; Reyes-Caniupán, I.E.; Jeison, D. Forward osmosis: Evaluation thin-film-composite membrane for municipal sewage concentration. Chem. Eng. J. 2016, 306, 531–537. [Google Scholar] [CrossRef]

- Li, J.Y.; Ni, Z.Y.; Zhou, Z.Y.; Hu, Y.X.; Xu, X.H.; Cheng, L.H. Membrane fouling of forward osmosis in dewatering of soluble algal products: Comparison of TFC and CTA membranes. J. Membr. Sci. 2018, 552, 213–221. [Google Scholar] [CrossRef]

- Oymaci, P.; Nijmeijer, K.; Borneman, Z. Development of Polydopamine Forward Osmosis Membranes with Low Reverse Salt Flux. Membranes 2020, 10, 94. [Google Scholar] [CrossRef]

- Wei, J.; Qiu, C.Q.; Tang, C.Y.; Wang, R.; Fane, A.G. Synthesis and characterization of flat-sheet thin film composite forward osmosis membranes. J. Membr. Sci. 2011, 372, 292–302. [Google Scholar] [CrossRef]

- Zhang, B.; He, Z. Improving water desalination by hydraulically coupling an osmotic microbial fuel cell with a microbial desalination cell. J. Membr. Sci. 2013, 441, 18–24. [Google Scholar] [CrossRef]

- Hancock, N.T.; Cath, T.Y. Solute coupled diffusion in osmotically driven membrane processes. Environ. Sci. Technol. 2009, 43, 6769–6775. [Google Scholar] [CrossRef]

- Achilli, A.; Cath, T.Y.; Childress, A.E. Selection of inorganic-based draw solutions for forward osmosis applications. J. Membr. Sci. 2010, 364, 233–241. [Google Scholar] [CrossRef]

- Vital, B.; Bartacek, J.; Ortega-Bravo, J.C.; Jeison, D. Treatment of acid mine drainage by forward osmosis: Heavy metal rejection and reverse flux of draw solution constituents. Chem. Eng. J. 2017, 332, 85–91. [Google Scholar] [CrossRef]

- Wang, N.Y.; Feng, Y.J.; Li, Y.F.; Zhang, L.J.; Liu, J.; Li, N.; He, W.H. Effects of ammonia on electrochemical active biofilm in microbial electrolysis cells for synthetic swine wastewater treatment. Water Res. 2022, 219, 118570. [Google Scholar] [CrossRef]

- Chen, J.L.; Lv, Y.; Wang, Y.; Ren, Y.P.; Li, X.F.; Wang, X.H. Endogenous inorganic carbon buffers accumulation and self-buffering capacity enhancement of air-cathode microbial fuel cells through anolyte recycling. Sci. Total Environ. 2019, 676, 11–17. [Google Scholar] [CrossRef]

- Guo, Y.L.; Chen, Z.; Zhang, S.H. Methane-fueled microbial fuel cells with the formate-acclimating electroactive culture. Sci. Total Environ. 2020, 754, 142186. [Google Scholar] [CrossRef]

- Song, H.L.; Zhang, S.; Long, X.; Yang, X.L.; Li, H.; Xiang, W.L. Optimization of Bioelectricity Generation in Constructed Wetland-Coupled Microbial Fuel Cell Systems. Water 2017, 9, 185. [Google Scholar] [CrossRef]

- Fan, Y.Z.; Hu, H.Q.; Liu, H. Sustainable power generation in microbial fuel cells using bicarbonate buffer and proton transfer mechanisms. Environ. Sci. Technol. 2008, 41, 8154–8158. [Google Scholar] [CrossRef]

- Naga Samrat, M.V.V.; Kesava Rao, K.; Ruggeri, B.; Tommasi, T. Denitrification of water in a microbial fuel cell (MFC) using seawater bacteria. J. Clean. Prod. 2017, 178, 449–456. [Google Scholar] [CrossRef]

- Ansari, A.J.; Hai, F.I.; Guo, W.; Ngo, H.H.; Price, W.E.; Nghiem, L.D. Selection of forward osmosis draw solutes for subsequent integration with anaerobic treatment to facilitate resource recovery from wastewater. Bioresour. Technol. 2015, 191, 30–36. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.M.; She, Q.H.; Yan, X.L.; Tang, C.Y. Effect of reverse solute diffusion on scaling in forward osmosis: A new control strategy by tailoring draw solution chemistry. Desalination 2017, 401, 230–237. [Google Scholar] [CrossRef]

- He, Y.; Xue, W.; Xiao, K.; Zhang, C.; Zhang, X.; Hu, Y. Prediction and optimization of the performance in an osmotic microbial fuel cell for water purification and bioelectricity production using a developed process model. J. Clean. Prod. 2022, 372, 133747. [Google Scholar] [CrossRef]

- Tan, F.X.; Zhang, L.H.; Liu, W.F.; Zhu, Y.M. Osmotic Pressure Compensated Solute Ectoine Improves Salt Tolerance of Microbial Cells in Microbial Fuel Cells. Fuel Cells 2019, 19, 616–622. [Google Scholar] [CrossRef]

- Duan, L.; Tian, Y.; Liu, X.; Song, Y.; Yang, L.; Zhang, J. Comparison between moving bed-membrane bioreactor and conventional membrane bioreactor systems. Part II: Bacterial community. Environ. Earth Sci. 2015, 73, 4891–4902. [Google Scholar] [CrossRef]

- Verma, M.; Singh, V.; Mishra, V. Moving towards the enhancement of extracellular electron transfer in electrogens. World J. Microbiol. Biotechnol. 2023, 39, 130. [Google Scholar] [CrossRef]

- Nastro, R.A.; Salvian, A.; Kuppam, C.; Pasquale, V.; Pietrelli, A.; Rossa, C.A. Inorganic Carbon Assimilation and Electrosynthesis of Platform Chemicals in Bioelectrochemical Systems (BESs) Inoculated with Clostridium saccharoperbutylacetonicum N1-H4. Microorganisms 2023, 11, 735. [Google Scholar] [CrossRef]

- Cao, T.N.-D.; Chang, C.-C.; Mukhtar, H.; Sun, Q.; Li, Y.; Yu, C.-P. Employment of osmotic pump as a novel feeding system to operate the laminar-flow microfluidic microbial fuel cell. Environ. Res. 2022, 215, 114347. [Google Scholar] [CrossRef]

- Akman, D.; Cirik, K.; Ozdemir, S.; Ozkaya, B.; Cinar, O. Bioelectricity generation in continuously-fed microbial fuel cell: Effects of anode electrode material and hydraulic retention time. Bioresour. Technol. 2013, 149, 459–464. [Google Scholar] [CrossRef]

- Kim, K.-Y.; Yang, W.; Evans, P.J.; Logan, B.E. Continuous treatment of high strength wastewaters using air-cathode microbial fuel cells. Bioresour. Technol. 2016, 221, 96–101. [Google Scholar] [CrossRef] [PubMed]

- Xue, W.; Chanamarn, W.; Tabucanon, A.S.; Cruz, S.G.; Hu, Y. Treatment of agro-food industrial waste streams using osmotic microbial fuel cells: Performance and potential improvement measures. Environ. Technol. Innov. 2022, 27, 102773. [Google Scholar] [CrossRef]

- Fazli, N.; Mutamim, N.S.A.; Jafri, N.M.A.; Ramli, N.A.M. Microbial Fuel Cell (MFC) in treating spent caustic wastewater: Varies in Hydraulic Retention Time (HRT) and Mixed Liquor Suspended Solid (MLSS). J. Environ. Chem. Eng. 2018, 6, 4339–4346. [Google Scholar] [CrossRef]

- Rahimnejad, M.; Ghoreyshi, A.A.; Najafpour, G.; Jafary, T. Power generation from organic substrate in batch and continuous flow microbial fuel cell operations. Appl. Energy 2011, 88, 3999–4004. [Google Scholar] [CrossRef]

- Li, X.; Zhu, N.; Wang, Y.; Li, P.; Wu, P.; Wu, J. Animal carcass wastewater treatment and bioelectricity generation in up-flow tubular microbial fuel cells: Effects of HRT and non-precious metallic catalyst. Bioresour. Technol. 2013, 128, 454–460. [Google Scholar] [CrossRef] [PubMed]

- Bhagat, M.S.; Mungray, A.K.; Mungray, A.A. Comparative investigation of solenoid magnetic field direction on the performance of osmotic microbial fuel cell. Mater. Today Chem. 2022, 24, 100778. [Google Scholar] [CrossRef]

- Sun, M.; Qin, M.; Wang, C.; Weng, G.; Huo, M.; Taylor, A.D.; Qu, J.; Elimelech, M. Electrochemical-Osmotic Process for Simultaneous Recovery of Electric Energy, Water, and Metals from Wastewater. Environ. Sci. Technol. 2020, 54, 8430–8442. [Google Scholar] [CrossRef] [PubMed]

- Xue, W.; Li, F.; Zhou, Q. Degradation mechanisms of sulfamethoxazole and its induction of bacterial community changes and antibiotic resistance genes in a microbial fuel cell. Bioresour. Technol. 2019, 289, 121632. [Google Scholar] [CrossRef]

- Wu, D.; Sun, F.; Chua, F.J.D.; Zhou, Y. Enhanced power generation in microbial fuel cell by an agonist of electroactive biofilm—Sulfamethoxazole. Chem. Eng. J. 2020, 384, 123238. [Google Scholar] [CrossRef]

- Zhou, Z.; Wu, Y.; Xu, Y.; Wang, Z.; Fu, H.; Zheng, Y. Carbamazepine degradation and genome sequencing of a novel exoelectrogen isolated from microbial fuel cells. Sci. Total Environ. 2022, 838, 156161. [Google Scholar] [CrossRef]

- Hartl, M.; Garcia-Galan, M.J.; Matamoros, V.; Fernandez-Gatell, M.; Rousseau, D.P.L.; Du Laing, G.; Garfi, M.; Puigagut, J. Constructed wetlands operated as bioelectrochemical systems for the removal of organic micropollutants. Chemosphere 2021, 271, 129593. [Google Scholar] [CrossRef] [PubMed]

- Lutchmiah, K.; Verliefde, A.R.D.; Roest, K.; Rietveld, L.C.; Cornelissen, E.R. Forward osmosis for application in wastewater treatment: A review. Water Res. 2014, 58, 179–197. [Google Scholar] [CrossRef]

- Lee, S.; Boo, C.; Elimelech, M.; Hong, S. Comparison of fouling behavior in forward osmosis (FO) and reverse osmosis (RO). J. Membr. Sci. 2010, 365, 34–39. [Google Scholar] [CrossRef]

- Noori, M.T.; Ghangrekar, M.M.; Mukherjee, C.K.; Min, B. Biofouling effects on the performance of microbial fuel cells and recent advances in biotechnological and chemical strategies for mitigation. Biotechnol. Adv. 2019, 37, 107420. [Google Scholar] [CrossRef] [PubMed]

- Jadhav, D.A.; Pandit, S.; Sonawane, J.M.; Gupta, P.K.; Prasad, R.; Chendake, A.D. Effect of membrane biofouling on the performance of microbial electrochemical cells and mitigation strategies. Bioresour. Technol. Rep. 2021, 15, 100822. [Google Scholar] [CrossRef]

- Lay, W.C.L.; Chong, T.H.; Tang, C.Y.Y.; Fane, A.G.; Zhang, J.S.; Liu, Y. Fouling propensity of forward osmosis: Investigation of the slower flux decline phenomenon. Water Sci. Technol. 2010, 61, 927–936. [Google Scholar] [CrossRef] [PubMed]

- Qiu, G.L.; Ting, Y.P. Osmotic membrane bioreactor for wastewater treatment and the effect of salt accumulation on system performance and microbial community dynamics. Bioresour. Technol. 2013, 150, 287–297. [Google Scholar] [CrossRef] [PubMed]

- Zou, S.; Qin, M.; He, Z. Tackle reverse solute flux in forward osmosis towards sustainable water recovery: Reduction and perspectives. Water Res. 2019, 149, 362–374. [Google Scholar] [CrossRef]

- Li, S.; Duan, L.; Zhang, H.; Li, M.; Zhao, Y.; Xing, F. Inhibition Strategies of Reverse Solute Flux in Osmotic Microbial Fuel Cells: Take Forward Osmosis as Reference. ACS EST Water 2023, 3, 2835–2848. [Google Scholar] [CrossRef]

- Ferby, M.; Zou, S.; He, Z. Effects of draw solutes on an integrated forward osmosis-Microbial fuel cell system treating a synthetic wastewater. Water Environ. Res. A Res. Publ. Water Environ. Fed. 2022, 94, e10802. [Google Scholar] [CrossRef]

- Zhao, P.; Gao, B.; Yue, Q.; Kong, J.; Shon, H.K.; Liu, P.; Gao, Y. Explore the forward osmosis performance using hydrolyzed polyacrylamide as draw solute for dye wastewater reclamation in the long-term process. Chem. Eng. J. 2015, 273, 316–324. [Google Scholar] [CrossRef]

- Zhang, J.; Yuan, H.; Deng, Y.; Abu-Reesh, I.M.; He, Z.; Yuan, C. Life cycle assessment of osmotic microbial fuel cells for simultaneous wastewater treatment and resource recovery. Int. J. Life Cycle Assess. 2019, 24, 1962–1975. [Google Scholar] [CrossRef]

| System | Feed Solution | Draw Solution | Maximum Power Density | Current Density or Current | Reference |

|---|---|---|---|---|---|

| OsMFC | synthetic livestock wastewater- | NaCl, 35 g/L | - | 2.6 ± 0.1 Am−2 | [60] |

| OsMFC | fresh urine | NaCl, 0.25 M | 0.12187 Wm−3 | - | [61] |

| OsMFC | artificial wastewater | NaCl, 35 g/L | 61.5 ± 0.9 mWm−2 | - | [62] |

| OsMFC | actual domestic wastewater | real oilfield produced water | 48.52 mWm−2 | 136.3 mAm−2 | [63] |

| OsMFC | synthetic wastewater | NaCl, 1 M | - | 2.1 mA | [64] |

| potassium phosphate buffer | - | 2.5 mA | |||

| CaCl2, 1 M | - | 2.2 mA | |||

| Glucose, 1 M | - | 0 mA | |||

| OsMFC | landfill leachate | NaCl, 1 M | 0.44 W m−2 | - | [31] |

| OsMFC | synthetic fresh human urine | MgCl2, 0.5 M | - | 27.3 Am−3 | [65] |

| OsMFC | synthetic municipal wastewater | NaHCO3, 0.75 M | - | 18.0 Am−3 | [66] |

| OsMFC | synthetic wastewater | NaCl, 35 g/L | - | 374.7 mA m−2 | [67] |

| OsMFC | synthetic wastewater | NaCl, 35 g/L | 7.08 Wm−3 | 5.4 Am−3 | [34] |

| OsMFC | synthetic wastewater | NaCl, 1 M | 12.57 Wm−3 | - | [50] |

| OsMFC | synthetic wastewater | NaCl, 35 g/L | 237.23 mWm−2 | - | [68] |

| CW-OsMFC | synthetic wastewater | NaCl, 2 M | 59.53 mWm−2 | 360.36 mA m−2 | [69] |

| OsMFC | synthetic wastewater | NaCl, 2 M | 4.5 Wm−3 | - | [28] |

| OsMFC | synthetic wastewater | NaCl, 0.5 M | 2.62 Wm−3 | - | [25] |

| OsMFC | synthetic wastewater | NaCl, 2 M | 27.38 Wm−3 | 139.52 Am−3 | [70] |

| OsMFC | synthetic municipal wastewater | PAA-Na, 32 wt% | - | 159.0 Am−3 | [71] |

| System | Membrane Type | Feed Solution | Draw Solution | Water Flux (LMH) | Reference |

|---|---|---|---|---|---|

| OsMFC | TFC | synthetic livestock wastewater | NaCl, 35 g/L | 1.3 | [60] |

| OsMFC | CTA | fresh urine | NaCl, 2 M | 14.27 | [61] |

| OsMFC | CTA | artificial wastewater | NaCl, 35 g/L | 2.33 | [62] |

| OsMFC | CTA | actual domestic wastewater | real oilfield produced water | 4.17 | [63] |

| OsMFC | CTA | synthetic wastewater | NaCl, 1 M | 1.82 | [64] |

| PPB, 1 M | 2.42 | ||||

| OsMFC | CTA-ES | landfill leachate | NaCl, 1 M | 0.98 | [31] |

| CTA-NW | 0.56 | ||||

| TFC-ES | 0.79 | ||||

| OsBCRS | TFC | synthetic fresh human urine | MgCl2, 0.5 M | 18.4 | [65] |

| OsMFC | TFC | synthetic municipal wastewater | NaHCO3, 0.75 M | 3.5 | [66] |

| OsMFC | CTA-NW | synthetic wastewater | NaCl, 35 g/L | 0.57 | [67] |

| OsMFC | modified TFC | synthetic wastewater | NaCl, 35 g/L | 12.29 | [34] |

| OsMFC | TFC | synthetic wastewater | NaCl, 1 M | 6.0 | [50] |

| OsMFC | polyelectrolyte membrane | synthetic wastewater | NaCl, 2 M | 18.43 | [70] |

| OsMFC | photopolymerized active layer FO membrane | synthetic wastewater | NaCl, 35 g/L | 0.95 ± 0.71 | [68] |

| OsMFC | TFC | synthetic wastewater | NaCl, 2 M | 6.66 | [69] |

| OsMFC | CTA | synthetic municipal wastewater | EDTA-Na2, 0.25 M | 1.82 | [72] |

| OsMFC | TFC | synthetic wastewater | NaCl, 0.5 M | 3.57 | [25] |

| OsMFC | TFC | synthetic municipal wastewater | PAA-Na, 32 wt% | 12.7 | [71] |

| OsMFC | modified TFC | synthetic domestic wastewater | NaCl, 0.5 M | 8.5 | [74] |

| Membrane | Application | Feed Solution | Draw Solution | Mode | Mode | Water Flux | RSF | Reference |

|---|---|---|---|---|---|---|---|---|

| CAT-ES | OsMFC | Landfill leachate | NaCl | AL-DS | + | + | [31] | |

| AL-FS | + | |||||||

| TFC-ES | AL-DS | + | + | |||||

| AL-FS | + | |||||||

| CTA-NW | AL-DS | + | + | |||||

| AL-FS | + | |||||||

| CTA-NW | FO-BES | Synthetic wastewater | NaCl | AL-DS | + | + | [67] | |

| AL-FS | ||||||||

| Polyelectrolyte FO Membrane | OsMFC | Synthetic wastewater | NaCl | AL-DS | + | + | [70] | |

| AL-FS | ||||||||

| DI water | AL-DS | + | + | |||||

| AL-FS | ||||||||

| FO Membrane | OsMFC | Synthetic wastewater | NaCl | AL-DS | [82] | |||

| AL-FS | + |

| Membrane | Draw Solution | Current Density (A·m−3) | Water Flux (LMH) | RSF (gMH) | sRSF | Recovery Efficiency (%) | Reference |

|---|---|---|---|---|---|---|---|

| (mg·L−1) | |||||||

| CEM-FO | 2000 PAA-Na (32 wt%) | 159.0 ± 6.0 | 12.7 ± 0.2 | ~0.05 | ~0.9 | >99 | [71] |

| PBS (8 wt%) | 167.0 ± 6.0 | ~3.0 | 9.12 ± 0.10 | ~3000 | - | ||

| CTA-HTI-FO | EDTA-Na2 (0.2 M) | 22.5 | 1.57 ± 0.5 | 0.38 | 250 | >90 | [72] |

| NaCl (0.185 M) | 23.6 | 1.22 | 0.55 | 450 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Duan, L.; Li, S.; Gao, Q.; Li, M.; Xing, F.; Zhao, Y. Simultaneous Wastewater Treatment and Resources Recovery by Forward Osmosis Coupled with Microbial Fuel Cell: A Review. Membranes 2024, 14, 29. https://doi.org/10.3390/membranes14020029

Zhang H, Duan L, Li S, Gao Q, Li M, Xing F, Zhao Y. Simultaneous Wastewater Treatment and Resources Recovery by Forward Osmosis Coupled with Microbial Fuel Cell: A Review. Membranes. 2024; 14(2):29. https://doi.org/10.3390/membranes14020029

Chicago/Turabian StyleZhang, Hengliang, Liang Duan, Shilong Li, Qiusheng Gao, Mingyue Li, Fei Xing, and Yang Zhao. 2024. "Simultaneous Wastewater Treatment and Resources Recovery by Forward Osmosis Coupled with Microbial Fuel Cell: A Review" Membranes 14, no. 2: 29. https://doi.org/10.3390/membranes14020029

APA StyleZhang, H., Duan, L., Li, S., Gao, Q., Li, M., Xing, F., & Zhao, Y. (2024). Simultaneous Wastewater Treatment and Resources Recovery by Forward Osmosis Coupled with Microbial Fuel Cell: A Review. Membranes, 14(2), 29. https://doi.org/10.3390/membranes14020029