Cellulose Membranes: Synthesis and Applications for Water and Gas Separation and Purification

Abstract

:1. Membranes: Requirements, Types, Classification, and Separation Mechanisms

1.1. Requirements of Membranes

1.2. Types and Classification

1.3. Molecules and Particle Separation Mechanisms

1.4. Factors Affecting Permeation (Permeance and Selectivity)

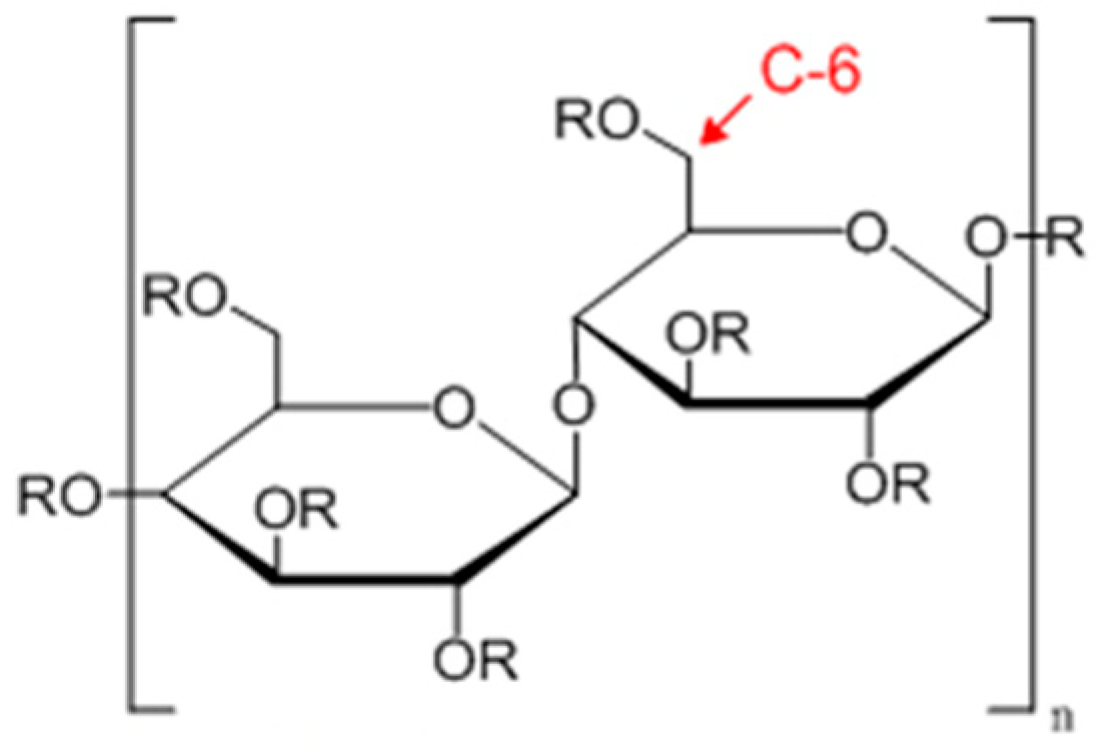

2. Cellulose Membranes

2.1. Cellulose Forms

2.2. Cellulosic Membrane Classification

- ❖

- Cellulose membranes made from the solution of cellulose and cellulose derivatives

- ✓

- Regenerated cellulose membranes

- ✓

- Cellulose derivative membranes

- ○

- Cellulose acetate membranes

- ○

- Cellulose nitrate membranes

- ○

- Ethyl cellulose membranes

- ○

- Composite membranes

- ❖

- Cellulose membranes made from cellulose particles

- ✓

- Cellulose fiber filters

- ✓

- Electrospun cellulose nanofiber membranes

- ✓

- Nanocellulose membranes

- ○

- Cellulose nanofibril membranes

- ○

- Cellulose nanocrystal membranes

- ✓

- Composite membranes

- ○

- Cellulose particle-reinforced polymer membranes

- ○

- Polymer fiber-reinforced cellulose membranes

2.3. Potential of Cellulose as a Material for Membranes

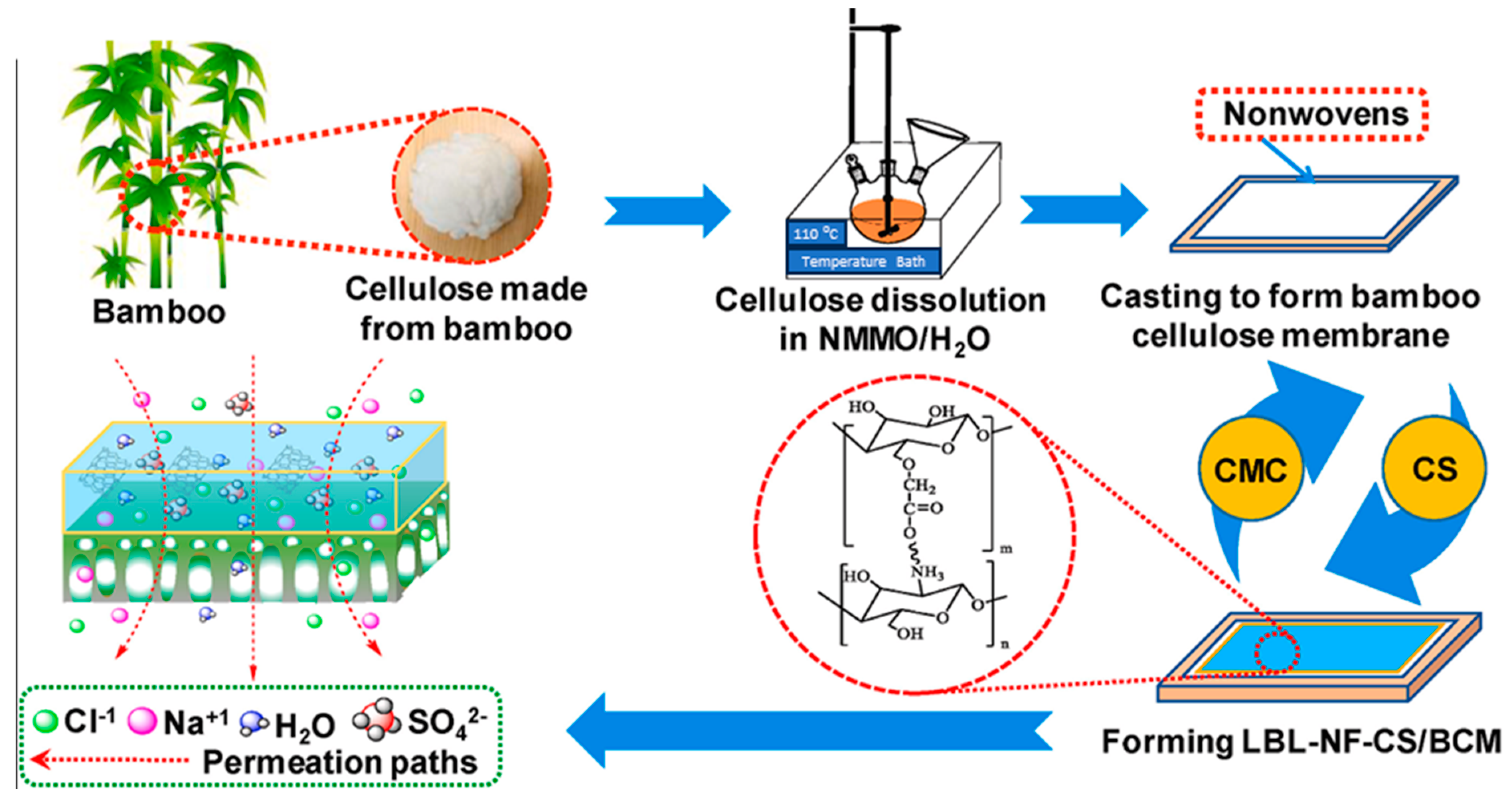

3. Preparation and Structure of Cellulosic Membranes through Dissolution

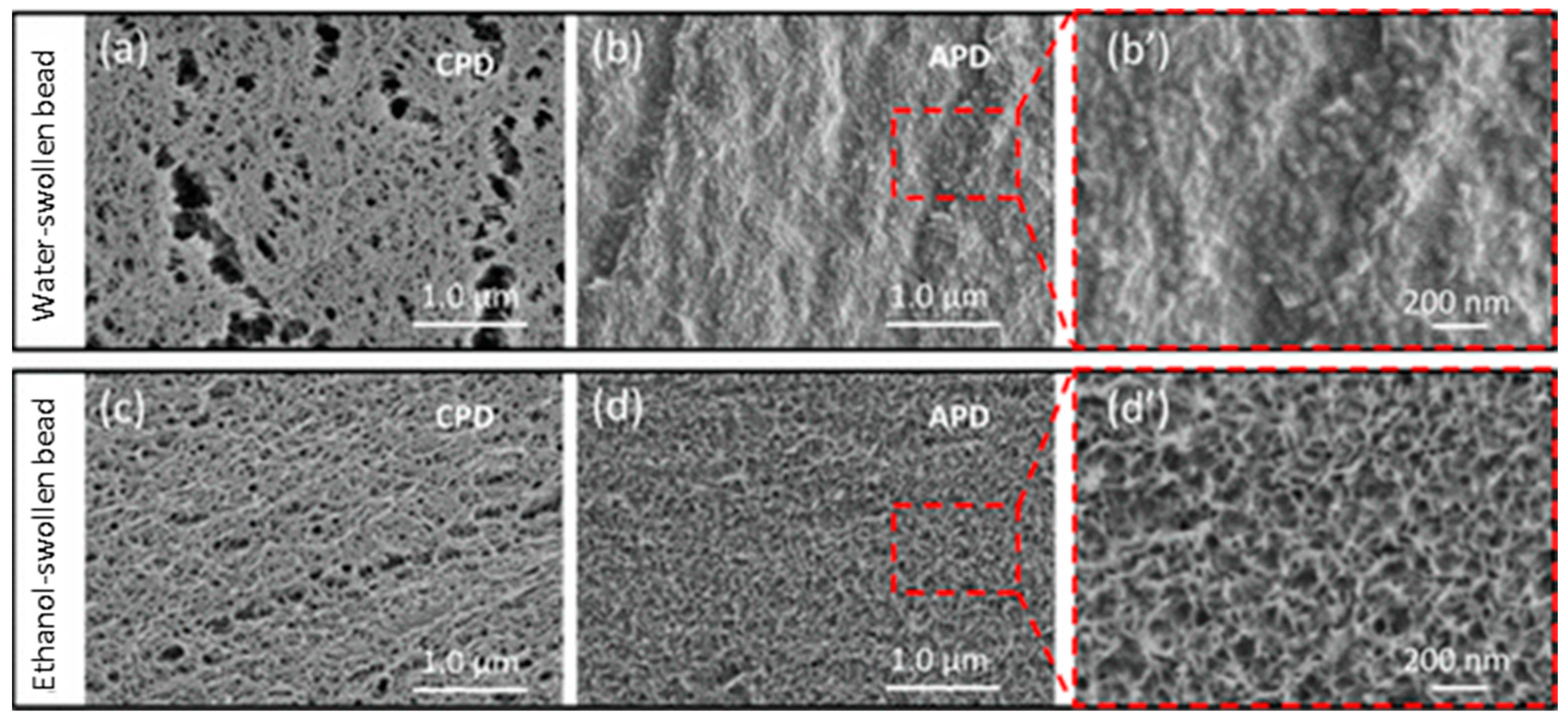

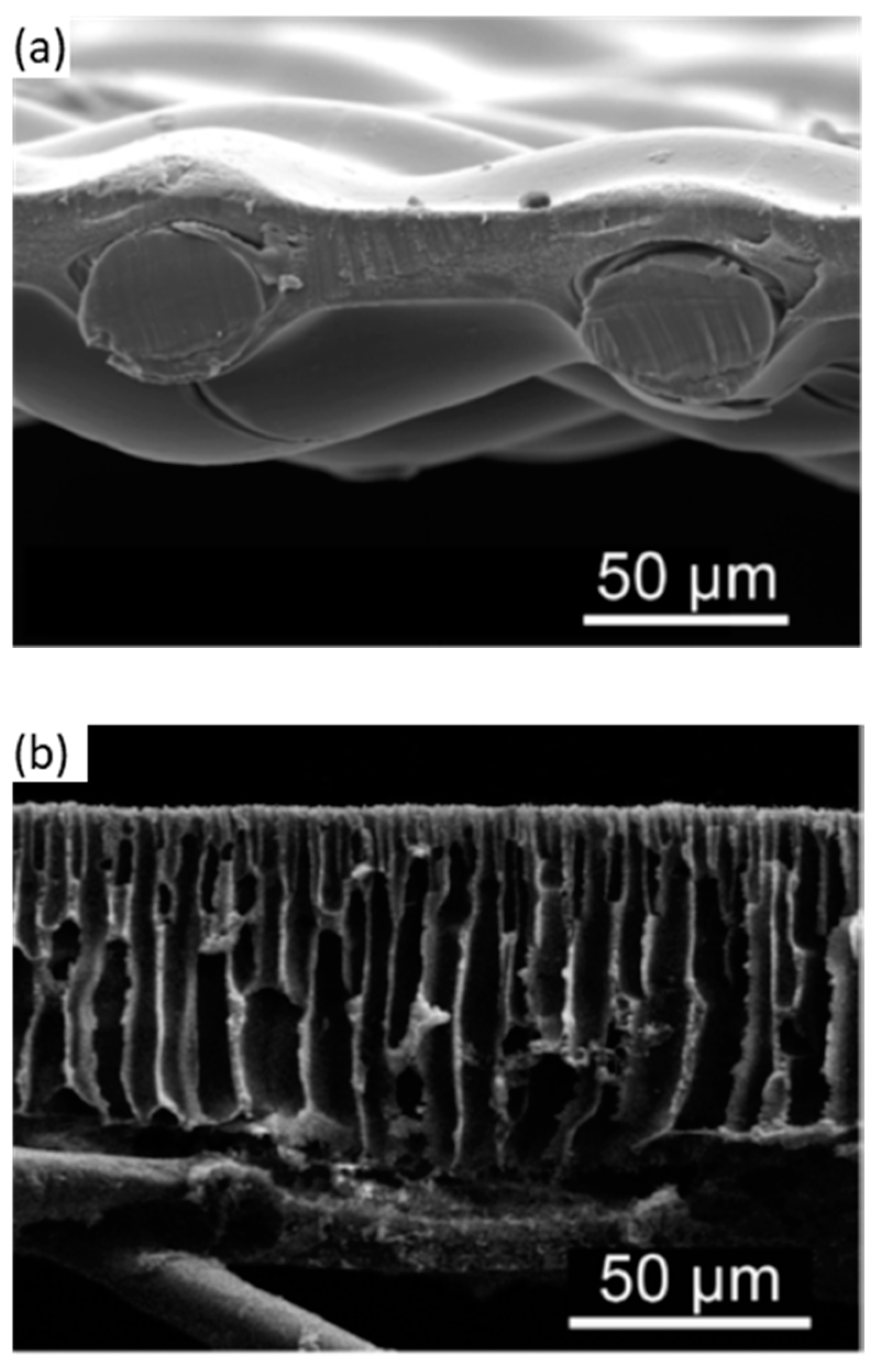

3.1. Phase Inversion

3.2. Structure of Phase Inversion Membranes

3.3. Factors Affecting Structure and Properties of Phase Inversion Membranes

3.4. Regenerated Cellulose Membranes

3.5. Cellulose Acetate Membranes

3.6. Other Cellulose Derivative Membranes

3.7. Composite Cellulosic Membranes

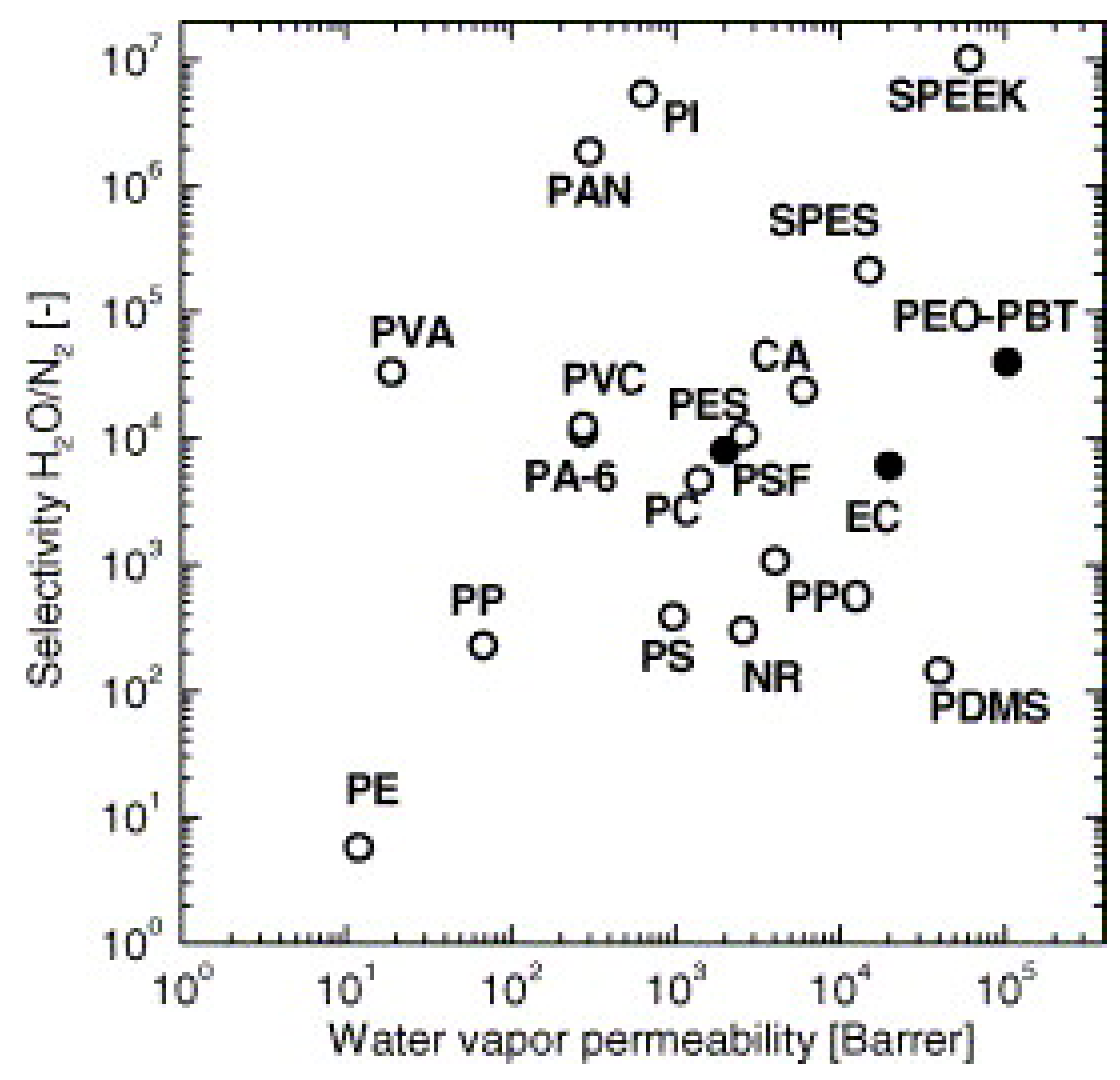

3.8. Water Vapor Separation Applications

3.9. Carbon Dioxide Capture Applications

| Cellulosic Material | Permeability (Barrer) | Selectivity Coefficient | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| H2O | CO2 | H2 | O2 | N2 | H2O/N2 | CO2/N2 | H2/N2 | O2/N2 | ||

| Regenerated cellulose | 0%RH | 0.005 | 0.006 | 0.002 | 0.003 | 1.5 | 2.0 | 0.7 | ||

| 43%RH | 0.013 | 0.016 | 0.007 | 0.007 | 1.9 | 2.4 | 1.1 | |||

| 76%RH | 0.072 | 0.033 | 0.009 | 0.007 | 9.6 | 4.4 | 1.2 | |||

| 100%RH | 25,198 | 0.256 | 0.080 | 0.012 | 0.018 | 1,369,565 | 13.9 | 4.3 | 0.6 | |

| Dry * | 127.7 | 9.14 | 6.28 | 2.58 | 49.5 | 3.5 | 2.4 | |||

| Wet * | 1957.4 | 134.7 | 93.42 | 37.13 | 52.7 | 3.6 | 2.5 | |||

| Cellulose acetate ** | 7333 | 23.07 | 3.506 | 0.780 | 0.280 | 26,191 | 82.4 | 12.5 | 2.8 | |

| Cellulose nitrate | 6293 | 2.120 | 2.000 | 1.947 | 0.116 | 54,253 | 18.3 | 17.2 | 16.8 | |

| Ethylcellulose | 8933 | 113.1 | 87.06 | 14.67 | 4.426 | 2018 | 25.5 | 19.7 | 3.3 | |

| Polydimethylsiloxane | 43,000 | 4651.6 | 939.9 | 926.6 | 470.6 | 91.4 | 9.9 | 2.0 | 2.0 | |

4. Nonwoven Membranes from Cellulose Particles

4.1. Types of Cellulose Particles

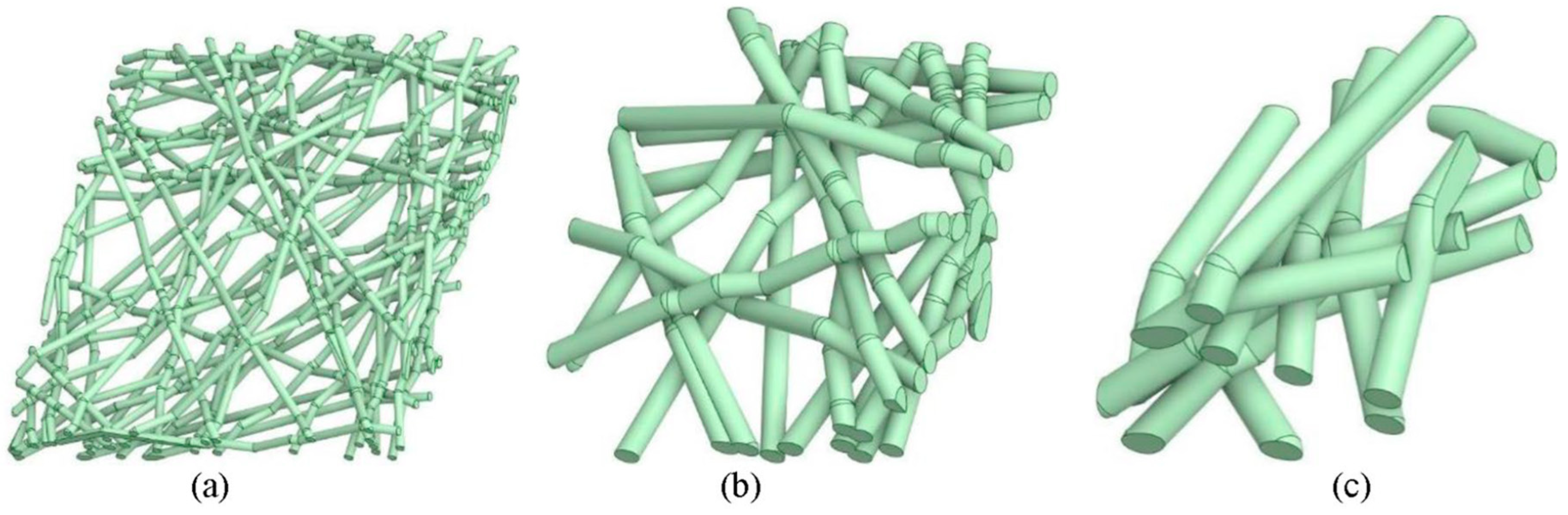

4.2. Impact of Particle Morphology on Pore Size and Porosity of Membrane Materials

4.3. Structure of Membrane Materials Made from Cellulose Particles

4.4. Processing–Structure Relationship of Cellulose Particle-Based Materials

4.5. Cellulose Particle-Based Membrane Structure Design

4.6. CNF Membranes

4.7. CNC Membranes

4.8. Bacterial Nanocellulose (BNC) Membranes

4.9. Antifouling

4.10. Factors Affecting Mechanical Strength

5. Summary and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Tanskyi, O. Zeolite Membrane Water Vapor Separation for Building Air-Conditioning and Ventilation Systems. Ph.D. Thesis, Texas A & M University, College Station, TX, USA, 2015. [Google Scholar]

- Werber, J.R.; Osuji, C.O.; Elimelech, M. Materials for Next-Generation Desalination and Water Purification Membranes. Nat. Rev. Mater. 2016, 1, 16018. [Google Scholar] [CrossRef]

- Le, N.L.; Nunes, S.P. Materials and Membrane Technologies for Water and Energy Sustainability. Sustain. Mater. Technol. 2016, 7, 1–28. [Google Scholar] [CrossRef]

- Lee, A.; Elam, J.W.; Darling, S.B. Membrane Materials for Water Purification: Design, Development, and Application. Environ. Sci. Water Res. Technol. 2016, 2, 17–42. [Google Scholar] [CrossRef]

- Tan, H.-F.; Ooi, B.S.; Leo, C.P. Future Perspectives of Nanocellulose-Based Membrane for Water Treatment. J. Water Process Eng. 2020, 37, 101502. [Google Scholar] [CrossRef]

- Bowen, W.R.; Cassey, B.; Jones, P.; Oatley, D.L. Modelling the Performance of Membrane Nanofiltration—Application to an Industrially Relevant Separation. J. Membr. Sci. 2004, 242, 211–220. [Google Scholar] [CrossRef]

- Galiano, F.; Briceño, K.; Marino, T.; Molino, A.; Christensen, K.V.; Figoli, A. Advances in Biopolymer-Based Membrane Preparation and Applications. J. Membr. Sci. 2018, 564, 562–586. [Google Scholar] [CrossRef]

- Mansoori, S.; Davarnejad, R.; Matsuura, T.; Ismail, A.F. Membranes Based on Non-Synthetic (Natural) Polymers for Wastewater Treatment. Polym. Test. 2020, 84, 106381. [Google Scholar] [CrossRef]

- Schell, W.; Wensley, C.; Chen, M.; Venugopal, K.; Miller, B.; Stuart, J. Recent Advances in Cellulosic Membranes for Gas Separation and Pervaporation. Gas Sep. Purif. 1989, 3, 162–169. [Google Scholar] [CrossRef]

- Hung, D.C.; Nguyen, N.C. Membrane Processes and Their Potential Applications for Fresh Water Provision in Vietnam. Vietnam J. Chem. 2017, 55, 533. [Google Scholar]

- Yang, Z.; Zhou, Y.; Feng, Z.; Rui, X.; Zhang, T.; Zhang, Z. A Review on Reverse Osmosis and Nanofiltration Membranes for Water Purification. Polymers 2019, 11, 1252. [Google Scholar] [CrossRef]

- Yu, Y.; Chen, H.; Liu, Y.; Craig, V.S.; Lai, Z. Selective Separation of Oil and Water with Mesh Membranes by Capillarity. Adv. Colloid Interface Sci. 2016, 235, 46–55. [Google Scholar] [CrossRef] [PubMed]

- Ding, M.; Kantzas, A. Capillary Number Correlations for Gas-Liquid Systems. J. Can. Pet. Technol. 2007, 46. [Google Scholar] [CrossRef]

- Siddiqui, M.A.Q.; Salvemini, F.; Ramandi, H.L.; Fitzgerald, P.; Roshan, H. Configurational Diffusion Transport of Water and Oil in Dual Continuum Shales. Sci. Rep. 2021, 11, 2152. [Google Scholar] [CrossRef] [PubMed]

- Bernardo, P.; Drioli, E.; Golemme, G. Membrane Gas Separation: A Review/State of the Art. Ind. Eng. Chem. Res. 2009, 48, 4638–4663. [Google Scholar] [CrossRef]

- Shieh, J.; Chung, T.S. Gas Permeability, Diffusivity, and Solubility of Poly (4-vinylpyridine) Film. J. Polym. Sci. Part B Polym. Phys. 1999, 37, 2851–2861. [Google Scholar] [CrossRef]

- Wikipedia Kinetic Diameter. Available online: https://en.wikipedia.org/wiki/Kinetic_diameter (accessed on 21 May 2024).

- Wikipedia Critical Point (Thermodynamics). Available online: https://en.wikipedia.org/wiki/Critical_point_(thermodynamics) (accessed on 21 May 2024).

- Li, H.; Zhang, X.; Chu, H.; Qi, G.; Ding, H.; Gao, X.; Meng, J. Molecular Simulation on Permeation Behavior of CH4/CO2/H2S Mixture Gas in PVDF at Service Conditions. Polymers 2022, 14, 545. [Google Scholar] [CrossRef]

- Houde, A.; Stern, S. Solubility and Diffusivity of Light Gases in Ethyl Cellulose at Elevated Pressures Effects of Ethoxy Content. J. Membr. Sci. 1997, 127, 171–183. [Google Scholar] [CrossRef]

- Gul, B.Y.; Pekgenc, E.; Vatanpour, V.; Koyuncu, I. A Review of Cellulose-Based Derivatives Polymers in Fabrication of Gas Separation Membranes: Recent Developments and Challenges. Carbohydr. Polym. 2023, 321, 121296. [Google Scholar]

- Visanko, M.; Liimatainen, H.; Sirviö, J.A.; Hormi, O. A Cross-Linked 2,3-Dicarboxylic Acid Cellulose Nanofibril Network: A Nanoporous Thin-Film Layer with Tailored Pore Size for Composite Membranes. Sep. Purif. Technol. 2015, 154, 44–50. [Google Scholar] [CrossRef]

- Norizan, M.N.; Shazleen, S.S.; Alias, A.H.; Sabaruddin, F.A.; Asyraf, M.R.M.; Zainudin, E.S.; Abdullah, N.; Samsudin, M.S.; Kamarudin, S.H.; Norrrahim, M.N.F. Nanocellulose-Based Nanocomposites for Sustainable Applications: A Review. Nanomaterials 2022, 12, 3483. [Google Scholar] [CrossRef]

- Abdelhamid, H.N.; Mathew, A.P. Cellulose-Based Materials for Water Remediation: Adsorption, Catalysis, and Antifouling. Front. Chem. Eng. 2021, 3, 790314. [Google Scholar] [CrossRef]

- Li, S.; Gao, Y.; Bai, H.; Zhang, L.; Qu, P.; Bai, L. Preparation and Characteristics of Polysulfone Dialysis Composite Membranes Modified with Nanocrystalline Cellulose. BioResources 2011, 6, 1670–1680. [Google Scholar] [CrossRef]

- Li, S.; Wang, D.; Xiao, H.; Zhang, H.; Cao, S.; Chen, L.; Ni, Y.; Huang, L. Ultra-Low Pressure Cellulose-Based Nanofiltration Membrane Fabricated on Layer-by-Layer Assembly for Efficient Sodium Chloride Removal. Carbohydr. Polym. 2021, 255, 117352. [Google Scholar] [CrossRef] [PubMed]

- Shaari, N.Z.K.; Abd Rahman, N.; Sulaiman, N.A.; Tajuddin, R.M. Thin Film Composite Membranes: Mechanical and Antifouling Properties. In Proceedings of the International Symposium on Civil and Environmental Engineering 2016 (ISCEE 2016), Melaka, Malaysia, 5–6 December 2016; EDP Sciences: Les Ulis, France, 2017; Volume 103, p. 06005. [Google Scholar]

- Ladewig, B.; Al-Shaeli, M.N.Z.; Ladewig, B.; Al-Shaeli, M.N.Z. Fundamentals of Membrane Processes. In Fundamentals of Membrane Bioreactors: Materials, Systems and Membrane Fouling; Springer: Berlin/Heidelberg, Germany, 2017; pp. 13–37. [Google Scholar]

- Tree, D.R.; Delaney, K.T.; Ceniceros, H.D.; Iwama, T.; Fredrickson, G.H. A Multi-Fluid Model for Microstructure Formation in Polymer Membranes. Soft Matter 2017, 13, 3013–3030. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Song, H.; Ren, L.; Talukder, M.E.; Chen, S.; Shao, J. Study on the Preparation of Cellulose Acetate Separation Membrane and New Adjusting Method of Pore Size. Membranes 2021, 12, 9. [Google Scholar] [CrossRef] [PubMed]

- Rozelle, L.; Cadotte, J.; Corneliussen, R.; Erickson, E.; Cobian, K.; Kopp, C., Jr. Phase Inversion Membranes. In Encyclopedia of Separation Science; Academic Press: Cambridge, MA, USA, 2000; pp. 3331–3346. [Google Scholar]

- Smolders, C.; Reuvers, A.; Boom, R.; Wienk, I. Microstructures in Phase-Inversion Membranes. Part 1. Formation of Macrovoids. J. Membr. Sci. 1992, 73, 259–275. [Google Scholar] [CrossRef]

- Ju, Z.; Yu, Y.; Feng, S.; Lei, T.; Zheng, M.; Ding, L.; Yu, M. Theoretical Mechanism on the Cellulose Regeneration from a Cellulose/EmimOAc Mixture in Anti-Solvents. Materials 2022, 15, 1158. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Lu, A.; Zhang, L. Recent Advances in Regenerated Cellulose Materials. Prog. Polym. Sci. 2016, 53, 169–206. [Google Scholar] [CrossRef]

- Li, H.; Kruteva, M.; Mystek, K.; Dulle, M.; Ji, W.; Pettersson, T.; Wågberg, L. Macro-and Microstructural Evolution during Drying of Regenerated Cellulose Beads. ACS Nano 2020, 14, 6774–6784. [Google Scholar] [CrossRef]

- Tekin, F.S.; Çulfaz-Emecen, P.Z. Controlling Cellulose Membrane Performance via Solvent Choice during Precursor Membrane Formation. ACS Appl. Polym. Mater. 2023, 5, 2185–2194. [Google Scholar] [CrossRef]

- Alsvik, I.L.; Hägg, M.-B. Pressure Retarded Osmosis and Forward Osmosis Membranes: Materials and Methods. Polymers 2013, 5, 303–327. [Google Scholar] [CrossRef]

- Song, Z.; Chen, R.; Luo, S.; Yu, W.; Yuan, J.; Lin, F.; Wang, M.; Cao, X.; Liao, Y.; Huang, B. Regenerated Cellulose Membranes for Efficient Separation of Organic Mixtures. Sep. Purif. Technol. 2024, 328, 125118. [Google Scholar] [CrossRef]

- Makarov, I.S.; Golova, L.K.; Bondarenko, G.N.; Anokhina, T.S.; Dmitrieva, E.S.; Levin, I.S.; Makhatova, V.E.; Galimova, N.Z.; Shambilova, G.K. Structure, Morphology, and Permeability of Cellulose Films. Membranes 2022, 12, 297. [Google Scholar] [CrossRef] [PubMed]

- Yushkin, A.; Anokhina, T.; Volkov, A. Application of Cellophane Films as Nanofiltration Membranes. Pet. Chem. 2015, 55, 746–752. [Google Scholar] [CrossRef]

- Mao, Z.; Cao, Y.; Jie, X.; Kang, G.; Zhou, M.; Yuan, Q. Dehydration of Isopropanol–Water Mixtures Using a Novel Cellulose Membrane Prepared from Cellulose/N-Methylmorpholine-N-Oxide/H2O Solution. Sep. Purif. Technol. 2010, 72, 28–33. [Google Scholar] [CrossRef]

- Acharya, S.; Liyanage, S.; Parajuli, P.; Rumi, S.S.; Shamshina, J.L.; Abidi, N. Utilization of Cellulose to Its Full Potential: A Review on Cellulose Dissolution, Regeneration, and Applications. Polymers 2021, 13, 4344. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Lin, X.; White, K.L.; Lin, S.; Wu, H.; Cao, S.; Huang, L.; Chen, L. Effect of the Degree of Substitution on the Hydrophobicity of Acetylated Cellulose for Production of Liquid Marbles. Cellulose 2016, 23, 811–821. [Google Scholar] [CrossRef]

- Araújo, D.; Castro, M.C.R.; Figueiredo, A.; Vilarinho, M.; Machado, A. Green Synthesis of Cellulose Acetate from Corncob: Physicochemical Properties and Assessment of Environmental Impacts. J. Clean. Prod. 2020, 260, 120865. [Google Scholar] [CrossRef]

- Peng, B.; Yao, Z.; Wang, X.; Crombeen, M.; Sweeney, D.G.; Tam, K.C. Cellulose-Based Materials in Wastewater Treatment of Petroleum Industry. Green Energy Environ. 2020, 5, 37–49. [Google Scholar] [CrossRef]

- Shenvi, S.S.; Isloor, A.M.; Ismail, A.F. A Review on RO Membrane Technology: Developments and Challenges. Desalination 2015, 368, 10–26. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, D.; Zhang, S.; Hu, L.; Jin, J. Interfacial Design of Mixed Matrix Membranes for Improved Gas Separation Performance. Adv. Mater. 2016, 28, 3399–3405. [Google Scholar] [CrossRef] [PubMed]

- Li, F.; Fei, P.; Cheng, B.; Meng, J.; Liao, L. Synthesis, Characterization and Excellent Antibacterial Property of Cellulose Acetate Reverse Osmosis Membrane via a Two-Step Reaction. Carbohydr. Polym. 2019, 216, 312–321. [Google Scholar] [CrossRef] [PubMed]

- Zou, F.; Yao, F.; Liu, L.; Cai, M. Recyclable Heterogeneous Palladium-Catalyzed Carbon–Carbon Coupling Polycondensations toward Highly Purified Conjugated Polymers. J. Polym. Res. 2019, 27, 1. [Google Scholar] [CrossRef]

- De Guzman, M.R.; Andra, C.K.A.; Ang, M.B.M.Y.; Dizon, G.V.C.; Caparanga, A.R.; Huang, S.-H.; Lee, K.-R. Increased Performance and Antifouling of Mixed-Matrix Membranes of Cellulose Acetate with Hydrophilic Nanoparticles of Polydopamine-Sulfobetaine Methacrylate for Oil-Water Separation. J. Membr. Sci. 2021, 620, 118881. [Google Scholar] [CrossRef]

- Kanagaraj, P.; Nagendran, A.; Rana, D.; Matsuura, T. Separation of Macromolecular Proteins and Removal of Humic Acid by Cellulose Acetate Modified UF Membranes. Int. J. Biol. Macromol. 2016, 89, 81–88. [Google Scholar] [CrossRef] [PubMed]

- Kumar, M.; Isloor, A.M.; Todeti, S.R.; Ibrahim, G.P.S.; Inamuddin; Ismail, A.F.; Asiri, A.M. Improved Separation of Dyes and Proteins Using Membranes Made of Polyphenylsulfone/Cellulose Acetate or Acetate Phthalate. Environ. Chem. Lett. 2020, 18, 881–887. [Google Scholar] [CrossRef]

- Kumar, M.; RaoT, S.; Isloor, A.M.; Ibrahim, G.P.S.; Inamuddin; Ismail, N.; Ismail, A.F.; Asiri, A.M. Use of Cellulose Acetate/Polyphenylsulfone Derivatives to Fabricate Ultrafiltration Hollow Fiber Membranes for the Removal of Arsenic from Drinking Water. Int. J. Biol. Macromol. 2019, 129, 715–727. [Google Scholar] [CrossRef]

- Lu, W.; Duan, C.; Zhang, Y.; Gao, K.; Dai, L.; Shen, M.; Wang, W.; Wang, J.; Ni, Y. Cellulose-Based Electrospun Nanofiber Membrane with Core-Sheath Structure and Robust Photocatalytic Activity for Simultaneous and Efficient Oil Emulsions Separation, Dye Degradation and Cr(VI) Reduction. Carbohydr. Polym. 2021, 258, 117676. [Google Scholar] [CrossRef]

- Herron, J. Asymmetric Forward Osmosis Membranes. U.S. Patent 7,445,712, 4 November 2008. [Google Scholar]

- Yip, N.Y.; Tiraferri, A.; Phillip, W.A.; Schiffman, J.D.; Elimelech, M. High Performance Thin-Film Composite Forward Osmosis Membrane. Environ. Sci. Technol. 2010, 44, 3812–3818. [Google Scholar] [CrossRef]

- Alsvik, I.L.; Hägg, M.-B. Preparation of Thin Film Composite Membranes with Polyamide Film on Hydrophilic Supports. J. Membr. Sci. 2013, 428, 225–231. [Google Scholar] [CrossRef]

- Islam, M.D.; Uddin, F.J.; Rashid, T.U.; Shahruzzaman, M. Cellulose Acetate-Based Membrane for Wastewater Treatment—A State-of-the-Art Review. Mater. Adv. 2023, 4, 4054–4102. [Google Scholar] [CrossRef]

- Vos, K.D.; Burris, F.O., Jr.; Riley, R.L. Kinetic Study of the Hydrolysis of Cellulose Acetate in the pH Range of 2–10. J. Appl. Polym. Sci. 1966, 10, 825–832. [Google Scholar] [CrossRef]

- Taha, A.A.; Wu, Y.; Wang, H.; Li, F. Preparation and Application of Functionalized Cellulose Acetate/Silica Composite Nanofibrous Membrane via Electrospinning for Cr(VI) Ion Removal from Aqueous Solution. J. Environ. Manag. 2012, 112, 10–16. [Google Scholar] [CrossRef] [PubMed]

- Emam, H.E.; El-Shahat, M.; Abdelhameed, R.M. Observable Removal of Pharmaceutical Residues by Highly Porous Photoactive Cellulose acetate@MIL-MOF Film. J. Hazard. Mater. 2021, 414, 125509. [Google Scholar] [CrossRef] [PubMed]

- Vatanpour, V.; Pasaoglu, M.E.; Barzegar, H.; Teber, O.O.; Kaya, R.; Bastug, M.; Khataee, A.; Koyuncu, I. Cellulose Acetate in Fabrication of Polymeric Membranes: A Review. Chemosphere 2022, 295, 133914. [Google Scholar] [CrossRef] [PubMed]

- Sun, H.; Liu, S.; Ge, B.; Xing, L.; Chen, H. Cellulose Nitrate Membrane Formation via Phase Separation Induced by Penetration of Nonsolvent from Vapor Phase. J. Membr. Sci. 2007, 295, 2–10. [Google Scholar] [CrossRef]

- Li, X.-G.; Kresse, I.; Xu, Z.-K.; Springer, J. Effect of Temperature and Pressure on Gas Transport in Ethyl Cellulose Membrane. Polymer 2001, 42, 6801–6810. [Google Scholar] [CrossRef]

- Li, L.; Baig, M.I.; de Vos, W.M.; Lindhoud, S. Preparation of Sodium Carboxymethyl Cellulose–Chitosan Complex Membranes through Sustainable Aqueous Phase Separation. ACS Appl. Polym. Mater. 2023, 5, 1810–1818. [Google Scholar] [CrossRef]

- Chen, G.Q.; Kanehashi, S.; Doherty, C.M.; Hill, A.J.; Kentish, S.E. Water Vapor Permeation through Cellulose Acetate Membranes and Its Impact upon Membrane Separation Performance for Natural Gas Purification. J. Membr. Sci. 2015, 487, 249–255. [Google Scholar] [CrossRef]

- Wang, J.; Gardner, D.J.; Stark, N.M.; Bousfield, D.W.; Tajvidi, M.; Cai, Z. Moisture and Oxygen Barrier Properties of Cellulose Nanomaterial-Based Films. ACS Sustain. Chem. Eng. 2017, 6, 49–70. [Google Scholar] [CrossRef]

- Alikhani, N.; Bousfield, D.W.; Wang, J.; Li, L.; Tajvidi, M. Numerical Simulation of the Water Vapor Separation of a Moisture-Selective Hollow-Fiber Membrane for the Application in Wood Drying Processes. Membranes 2021, 11, 593. [Google Scholar] [CrossRef] [PubMed]

- Alikhani, N.; Li, L.; Wang, J.; Dewar, D.; Tajvidi, M. Exploration of Membrane-Based Dehumidification System to Improve the Energy Efficiency of Kiln Drying Processes: Part I Factors That Affect Moisture Removal Efficiency. Wood Fiber Sci. 2020, 52, 313–325. [Google Scholar] [CrossRef]

- Metz, S.J.; Van de Ven, W.; Potreck, J.; Mulder, M.; Wessling, M. Transport of Water Vapor and Inert Gas Mixtures through Highly Selective and Highly Permeable Polymer Membranes. J. Membr. Sci. 2005, 251, 29–41. [Google Scholar] [CrossRef]

- Wu, J.; Yuan, Q. Gas Permeability of a Novel Cellulose Membrane. J. Membr. Sci. 2002, 204, 185–194. [Google Scholar] [CrossRef]

- Pauly, S. Permeability and Diffusion Data. In The Wiley Database of Polymer Properties; Wiley Online Library: New York, NY, USA, 2003; pp. 543–568. [Google Scholar]

- Kaushik, M.; Fraschini, C.; Chauve, G.; Putaux, J.-L.; Moores, A. Transmission Electron Microscopy for the Characterization of Cellulose Nanocrystals. In The Transmission Electron Microscope-Theory and Applications; IntechOpen: London, UK, 2015; pp. 130–163. [Google Scholar]

- Patten, A.M.; Vassão, D.G.; Wolcott, M.P.; Davin, L.B.; Lewis, N.G. 3.27—Trees: A Remarkable Biochemical Bounty. In Comprehensive Natural Products II; Liu, H.-W., Mander, L., Eds.; Elsevier: Oxford, UK, 2010; pp. 1173–1296. ISBN 978-0-08-045382-8. [Google Scholar]

- Wu, J.; Ding, Q.; Yang, W.; Wang, L.; Wang, H. Influence of Submicron Fibrillated Cellulose Fibers from Cotton on Hydration and Microstructure of Portland Cement Paste. Molecules 2021, 26, 5831. [Google Scholar] [CrossRef] [PubMed]

- Tayeb, A.H.; Tajvidi, M.; Bousfield, D. Paper Based Oil Barrier Packaging Using Lignin-Containing Cellulose Nanofibrils. Molecules 2020, 25, 1344. [Google Scholar] [CrossRef]

- Kunaver, M.; Anžlovar, A.; Žagar, E. The Fast and Effective Isolation of Nanocellulose from Selected Cellulosic Feedstocks. Carbohydr. Polym. 2016, 148, 251–258. [Google Scholar] [CrossRef]

- Beckman, I.P.; Berry, G.; Cho, H.; Riveros, G. Alternative High-Performance Fibers for Nonwoven HEPA Filter Media. Aerosol Sci. Eng. 2023, 7, 36–58. [Google Scholar] [CrossRef]

- Henriksson, M.; Berglund, L.A.; Isaksson, P.; Lindstrom, T.; Nishino, T. Cellulose Nanopaper Structures of High Toughness. Biomacromolecules 2008, 9, 1579–1585. [Google Scholar] [CrossRef]

- Matilainen, K.; Hämäläinen, T.; Savolainen, A.; Sipiläinen-Malm, T.; Peltonen, J.; Erho, T.; Smolander, M. Performance and Penetration of Laccase and ABTS Inks on Various Printing Substrates. Colloids Surf. B Biointerfaces 2012, 90, 119–128. [Google Scholar] [CrossRef]

- Aslannejad, H.; Hassanizadeh, S.; Raoof, A.; de Winter, D.; Tomozeiu, N.; Van Genuchten, M.T. Characterizing the Hydraulic Properties of Paper Coating Layer Using FIB-SEM Tomography and 3D Pore-Scale Modeling. Chem. Eng. Sci. 2017, 160, 275–280. [Google Scholar] [CrossRef]

- Rioux, R.W. The Rate of Fluid Absorption in Porous Media. Master’s Thesis, University of Maine, Orono, ME, USA, 2003. [Google Scholar]

- Motamedian, H.R.; Halilovic, A.E.; Kulachenko, A. Mechanisms of Strength and Stiffness Improvement of Paper after PFI Refining with a Focus on the Effect of Fines. Cellulose 2019, 26, 4099–4124. [Google Scholar] [CrossRef]

- Toivonen, M.S.; Onelli, O.D.; Jacucci, G.; Lovikka, V.; Rojas, O.J.; Ikkala, O.; Vignolini, S. Anomalous-Diffusion-Assisted Brightness in White Cellulose Nanofibril Membranes. Adv. Mater. 2018, 30, 1704050. [Google Scholar] [CrossRef] [PubMed]

- Rosu, C.; Maximean, D.M.; Kundu, S.; Almeida, P.L.; Danila, O. Perspectives on the Electrically Induced Properties of Electrospun Cellulose/Liquid Crystal Devices. J. Electrost. 2011, 69, 623–630. [Google Scholar] [CrossRef]

- Kim, C.-W.; Kim, D.-S.; Kang, S.-Y.; Marquez, M.; Joo, Y.L. Structural Studies of Electrospun Cellulose Nanofibers. Polymer 2006, 47, 5097–5107. [Google Scholar] [CrossRef]

- Ma, H.; Burger, C.; Hsiao, B.S.; Chu, B. Ultrafine Polysaccharide Nanofibrous Membranes for Water Purification. Biomacromolecules 2011, 12, 970–976. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.G.; Deng, C.; Soyekwo, F.; Liu, Q.L.; Zhu, A.M. Sub-10 Nm Wide Cellulose Nanofibers for Ultrathin Nanoporous Membranes with High Organic Permeation. Adv. Funct. Mater. 2016, 26, 792–800. [Google Scholar] [CrossRef]

- Mautner, A.; Lee, K.-Y.; Tammelin, T.; Mathew, A.P.; Nedoma, A.J.; Li, K.; Bismarck, A. Cellulose Nanopapers as Tight Aqueous Ultra-Filtration Membranes. React. Funct. Polym. 2015, 86, 209–214. [Google Scholar] [CrossRef]

- Nuruddin, M.; Chowdhury, R.A.; Lopez-Perez, N.; Montes, F.J.; Youngblood, J.P.; Howarter, J.A. Influence of Free Volume Determined by Positron Annihilation Lifetime Spectroscopy (PALS) on Gas Permeability of Cellulose Nanocrystal Films. ACS Appl. Mater. Interfaces 2020, 12, 24380–24389. [Google Scholar] [CrossRef]

- Wohlert, M.; Benselfelt, T.; Wågberg, L.; Furó, I.; Berglund, L.A.; Wohlert, J. Cellulose and the Role of Hydrogen Bonds: Not in Charge of Everything. Cellulose 2022, 29, 1–23. [Google Scholar] [CrossRef]

- Sharma, P.R.; Sharma, S.K.; Lindström, T.; Hsiao, B.S. Nanocellulose-enabled Membranes for Water Purification: Perspectives. Adv. Sustain. Syst. 2020, 4, 1900114. [Google Scholar] [CrossRef]

- Sehaqui, H.; Michen, B.; Marty, E.; Schaufelberger, L.; Zimmermann, T. Functional Cellulose Nanofiber Filters with Enhanced Flux for the Removal of Humic Acid by Adsorption. ACS Sustain. Chem. Eng. 2016, 4, 4582–4590. [Google Scholar] [CrossRef]

- Lalia, B.S.; Guillen, E.; Arafat, H.A.; Hashaikeh, R. Nanocrystalline Cellulose Reinforced PVDF-HFP Membranes for Membrane Distillation Application. Desalination 2014, 332, 134–141. [Google Scholar] [CrossRef]

- Ma, H.; Burger, C.; Hsiao, B.S.; Chu, B. Ultra-Fine Cellulose Nanofibers: New Nano-Scale Materials for Water Purification. J. Mater. Chem. 2011, 21, 7507–7510. [Google Scholar] [CrossRef]

- Soyekwo, F.; Zhang, Q.; Gao, R.; Qu, Y.; Lin, C.; Huang, X.; Zhu, A.; Liu, Q. Cellulose Nanofiber Intermediary to Fabricate Highly-Permeable Ultrathin Nanofiltration Membranes for Fast Water Purification. J. Membr. Sci. 2017, 524, 174–185. [Google Scholar] [CrossRef]

- Liu, P.; Zhu, C.; Mathew, A.P. Mechanically Robust High Flux Graphene Oxide-Nanocellulose Membranes for Dye Removal from Water. J. Hazard. Mater. 2019, 371, 484–493. [Google Scholar] [CrossRef] [PubMed]

- Ma, H.; Burger, C.; Hsiao, B.S.; Chu, B. Nanofibrous Microfiltration Membrane Based on Cellulose Nanowhiskers. Biomacromolecules 2012, 13, 180–186. [Google Scholar] [CrossRef] [PubMed]

- Ma, H.; Burger, C.; Hsiao, B.S.; Chu, B. Highly Permeable Polymer Membranes Containing Directed Channels for Water Purification. ACS Macro Lett. 2012, 1, 723–726. [Google Scholar] [CrossRef] [PubMed]

- Karim, Z.; Mathew, A.P.; Grahn, M.; Mouzon, J.; Oksman, K. Nanoporous Membranes with Cellulose Nanocrystals as Functional Entity in Chitosan: Removal of Dyes from Water. Carbohydr. Polym. 2014, 112, 668–676. [Google Scholar] [CrossRef]

- Ku, B.-J.; Kim, D.H.; Yasin, A.S.; Mnoyan, A.; Kim, M.-J.; Kim, Y.J.; Ra, H.; Lee, K. Solar-Driven Desalination Using Salt-Rejecting Plasmonic Cellulose Nanofiber Membrane. J. Colloid Interface Sci. 2023, 634, 543–552. [Google Scholar] [CrossRef]

- Yin, Z.; Li, M.; Chen, Z.; Chen, X.; Liu, K.; Zhou, D.; Xue, M.; Ou, J.; Xie, Y.; Lei, S.; et al. A Superhydrophobic Pulp/Cellulose Nanofiber (CNF) Membrane via Coating ZnO Suspensions for Multifunctional Applications. Ind. Crops Prod. 2022, 187, 115526. [Google Scholar] [CrossRef]

- Ma, H.; Yoon, K.; Rong, L.; Mao, Y.; Mo, Z.; Fang, D.; Hollander, Z.; Gaiteri, J.; Hsiao, B.S.; Chu, B. High-Flux Thin-Film Nanofibrous Composite Ultrafiltration Membranes Containing Cellulose Barrier Layer. J. Mater. Chem. 2010, 20, 4692–4704. [Google Scholar] [CrossRef]

- Bettotti, P.; Scarpa, M. Nanocellulose and Its Interface: On the Road to the Design of Emerging Materials. Adv. Mater. Interfaces 2022, 9, 2101593. [Google Scholar] [CrossRef]

- Uetani, K.; Izakura, S.; Kasuga, T.; Koga, H.; Nogi, M. Self-Alignment Sequence of Colloidal Cellulose Nanofibers Induced by Evaporation from Aqueous Suspensions. Colloids Interfaces 2018, 2, 71. [Google Scholar] [CrossRef]

- Ma, H.; Burger, C.; Hsiao, B.S.; Chu, B. Fabrication and Characterization of Cellulose Nanofiber Based Thin-Film Nanofibrous Composite Membranes. J. Membr. Sci. 2014, 454, 272–282. [Google Scholar] [CrossRef]

- Liu, S.; Low, Z.-X.; Xie, Z.; Wang, H. TEMPO-Oxidized Cellulose Nanofibers: A Renewable Nanomaterial for Environmental and Energy Applications. Adv. Mater. Technol. 2021, 6, 2001180. [Google Scholar] [CrossRef]

- Norrrahim, M.N.F.; Mohd Kasim, N.A.; Knight, V.F.; Ong, K.K.; Mohd Noor, S.A.; Abdul Halim, N.; Ahmad Shah, N.A.; Jamal, S.H.; Janudin, N.; Misenan, M.S.M.; et al. Emerging Developments Regarding Nanocellulose-Based Membrane Filtration Material against Microbes. Polymers 2021, 13, 3249. [Google Scholar] [CrossRef] [PubMed]

- Sharma, P.R.; Sharma, S.K.; Hsiao, B.S. Chapter 5—Nanocellulose in Membrane Technology for Water Purification. In Separation Science and Technology; Ahuja, S., Ed.; Academic Press: Cambridge, MA, USA, 2022; Volume 15, pp. 69–85. ISBN 1877-1718. [Google Scholar]

- Zhu, C.; Liu, P.; Mathew, A.P. Self-Assembled TEMPO Cellulose Nanofibers: Graphene Oxide-Based Biohybrids for Water Purification. ACS Appl. Mater. Interfaces 2017, 9, 21048–21058. [Google Scholar] [CrossRef]

- Rabiee, N.; Sharma, R.; Foorginezhad, S.; Jouyandeh, M.; Asadnia, M.; Rabiee, M.; Akhavan, O.; Lima, E.C.; Formela, K.; Ashrafizadeh, M.; et al. Green and Sustainable Membranes: A Review. Environ. Res. 2023, 231, 116133. [Google Scholar] [CrossRef]

- Visanko, M.; Liimatainen, H.; Sirviö, J.A.; Haapala, A.; Sliz, R.; Niinimäki, J.; Hormi, O. Porous Thin Film Barrier Layers from 2,3-Dicarboxylic Acid Cellulose Nanofibrils for Membrane Structures. Carbohydr. Polym. 2014, 102, 584–589. [Google Scholar] [CrossRef]

- Ma, H.; Hsiao, B.S.; Chu, B. Thin-Film Nanofibrous Composite Membranes Containing Cellulose or Chitin Barrier Layers Fabricated by Ionic Liquids. Polymer 2011, 52, 2594–2599. [Google Scholar] [CrossRef]

- Yin, Z.; Cheng, Y.; Deng, Y.; Li, Z.; Liu, K.; Li, M.; Chen, X.; Xue, M.; Ou, J.; Lei, S.; et al. Functional and Versatile Colorful Superhydrophobic Nanocellulose-Based Membrane with High Durability, High-Efficiency Oil/Water Separation and Oil Spill Cleanup. Surf. Coat. Technol. 2022, 445, 128714. [Google Scholar] [CrossRef]

- Bai, H.; Wang, X.; Zhou, Y.; Zhang, L. Preparation and Characterization of Poly(Vinylidene Fluoride) Composite Membranes Blended with Nano-Crystalline Cellulose. Prog. Nat. Sci. Mater. Int. 2012, 22, 250–257. [Google Scholar] [CrossRef]

- Norfarhana, A.S.; Ilyas, R.A.; Ngadi, N. A Review of Nanocellulose Adsorptive Membrane as Multifunctional Wastewater Treatment. Carbohydr. Polym. 2022, 291, 119563. [Google Scholar] [CrossRef] [PubMed]

- Bai, L.; Liu, Y.; Bossa, N.; Ding, A.; Ren, N.; Li, G.; Liang, H.; Wiesner, M.R. Incorporation of Cellulose Nanocrystals (CNCs) into the Polyamide Layer of Thin-Film Composite (TFC) Nanofiltration Membranes for Enhanced Separation Performance and Antifouling Properties. Environ. Sci. Technol. 2018, 52, 11178–11187. [Google Scholar] [CrossRef] [PubMed]

- Shojaeiarani, J.; Bajwa, D.S.; Chanda, S. Cellulose Nanocrystal Based Composites: A Review. Compos. Part C Open Access 2021, 5, 100164. [Google Scholar] [CrossRef]

- Bai, L.; Ding, A.; Li, G.; Liang, H. Application of Cellulose Nanocrystals in Water Treatment Membranes: A Review. Chemosphere 2022, 308, 136426. [Google Scholar] [CrossRef] [PubMed]

- Bai, L.; Wu, H.; Ding, J.; Ding, A.; Zhang, X.; Ren, N.; Li, G.; Liang, H. Cellulose Nanocrystal-Blended Polyethersulfone Membranes for Enhanced Removal of Natural Organic Matter and Alleviation of Membrane Fouling. Chem. Eng. J. 2020, 382, 122919. [Google Scholar] [CrossRef]

- Solhi, L.; Guccini, V.; Heise, K.; Solala, I.; Niinivaara, E.; Xu, W.; Mihhels, K.; Kröger, M.; Meng, Z.; Wohlert, J.; et al. Understanding Nanocellulose–Water Interactions: Turning a Detriment into an Asset. Chem. Rev. 2023, 123, 1925–2015. [Google Scholar] [CrossRef]

- Wu, Z.; Ji, X.; He, Q.; Gu, H.; Zhang, W.; Deng, Z. Nanocelluloses Fine-Tuned Polyvinylidene Fluoride (PVDF) Membrane for Enhanced Separation and Antifouling. Carbohydr. Polym. 2024, 323, 121383. [Google Scholar] [CrossRef]

- Karim, Z.; Mathew, A.P.; Kokol, V.; Wei, J.; Grahn, M. High-Flux Affinity Membranes Based on Cellulose Nanocomposites for Removal of Heavy Metal Ions from Industrial Effluents. RSC Adv. 2016, 6, 20644–20653. [Google Scholar] [CrossRef]

- Lv, J.; Zhang, G.; Zhang, H.; Zhao, C.; Yang, F. Improvement of Antifouling Performances for Modified PVDF Ultrafiltration Membrane with Hydrophilic Cellulose Nanocrystal. Appl. Surf. Sci. 2018, 440, 1091–1100. [Google Scholar] [CrossRef]

- Zheng, S.; Yang, S.; Ouyang, Z.; Zhang, Y. Robust and Highly Hydrophilic Ultrafiltration Membrane with Multi-Branched Cellulose Nanocrystals for Permeability-Selectivity Anti-Trade-off Property. Appl. Surf. Sci. 2023, 614, 156157. [Google Scholar] [CrossRef]

- Asempour, F.; Emadzadeh, D.; Matsuura, T.; Kruczek, B. Synthesis and Characterization of Novel Cellulose Nanocrystals-Based Thin Film Nanocomposite Membranes for Reverse Osmosis Applications. Desalination 2018, 439, 179–187. [Google Scholar] [CrossRef]

- Wang, D.; Mhatre, S.; Chen, J.; Shi, X.; Yang, H.; Cheng, W.; Yue, Y.; Han, G.; Rojas, O.J. Composites Based on Electrospun Fibers Modified with Cellulose Nanocrystals and SiO2 for Selective Oil/Water Separation. Carbohydr. Polym. 2023, 299, 120119. [Google Scholar] [CrossRef] [PubMed]

- Gao, M.; Li, J.; Bao, Z.; Hu, M.; Nian, R.; Feng, D.; An, D.; Li, X.; Xian, M.; Zhang, H. A Natural in Situ Fabrication Method of Functional Bacterial Cellulose Using a Microorganism. Nat. Commun. 2019, 10, 437. [Google Scholar] [CrossRef]

- Saud, A.; Saleem, H.; Zaidi, S.J. Progress and Prospects of Nanocellulose-Based Membranes for Desalination and Water Treatment. Membranes 2022, 12, 462. [Google Scholar] [CrossRef] [PubMed]

- Ullah, H.; Wahid, F.; Santos, H.A.; Khan, T. Advances in Biomedical and Pharmaceutical Applications of Functional Bacterial Cellulose-Based Nanocomposites. Carbohydr. Polym. 2016, 150, 330–352. [Google Scholar] [CrossRef] [PubMed]

- Wijeyaratne, W.D.N. Potential Differences of Plant Nanocellulose and Bacterial Nanocellulose in Water Purification. In Nanocellulose and Its Composites for Water Treatment Applications; CRC Press: Boca Raton, FL, USA, 2021; pp. 91–105. [Google Scholar]

- Tahir, D.; Karim, M.R.A.; Hu, H.; Naseem, S.; Rehan, M.; Ahmad, M.; Zhang, M. Sources, Chemical Functionalization, and Commercial Applications of Nanocellulose and Nanocellulose-Based Composites: A Review. Polymers 2022, 14, 4468. [Google Scholar] [CrossRef]

- Xu, T.; Jiang, Q.; Ghim, D.; Liu, K.-K.; Sun, H.; Derami, H.G.; Wang, Z.; Tadepalli, S.; Jun, Y.-S.; Zhang, Q.; et al. Catalytically Active Bacterial Nanocellulose-Based Ultrafiltration Membrane. Small 2018, 14, 1704006. [Google Scholar] [CrossRef]

- Yang, L.; Chen, C.; Hu, Y.; Wei, F.; Cui, J.; Zhao, Y.; Xu, X.; Chen, X.; Sun, D. Three-Dimensional Bacterial Cellulose/Polydopamine/TiO2 Nanocomposite Membrane with Enhanced Adsorption and Photocatalytic Degradation for Dyes under Ultraviolet-Visible Irradiation. J. Colloid Interface Sci. 2020, 562, 21–28. [Google Scholar] [CrossRef] [PubMed]

- Ferreira-Neto, E.P.; Ullah, S.; da Silva, T.C.A.; Domeneguetti, R.R.; Perissinotto, A.P.; de Vicente, F.S.; Rodrigues-Filho, U.P.; Ribeiro, S.J.L. Bacterial Nanocellulose/MoS2 Hybrid Aerogels as Bifunctional Adsorbent/Photocatalyst Membranes for in-Flow Water Decontamination. ACS Appl. Mater. Interfaces 2020, 12, 41627–41643. [Google Scholar] [CrossRef] [PubMed]

- Gholami Derami, H.; Jiang, Q.; Ghim, D.; Cao, S.; Chandar, Y.J.; Morrissey, J.J.; Jun, Y.-S.; Singamaneni, S. A Robust and Scalable Polydopamine/Bacterial Nanocellulose Hybrid Membrane for Efficient Wastewater Treatment. ACS Appl. Nano Mater. 2019, 2, 1092–1101. [Google Scholar] [CrossRef]

- Jiang, Q.; Ghim, D.; Cao, S.; Tadepalli, S.; Liu, K.-K.; Kwon, H.; Luan, J.; Min, Y.; Jun, Y.-S.; Singamaneni, S. Photothermally Active Reduced Graphene Oxide/Bacterial Nanocellulose Composites as Biofouling-Resistant Ultrafiltration Membranes. Environ. Sci. Technol. 2019, 53, 412–421. [Google Scholar] [CrossRef] [PubMed]

- Das, R.; Lindström, T.; Sharma, P.R.; Chi, K.; Hsiao, B.S. Nanocellulose for Sustainable Water Purification. Chem. Rev. 2022, 122, 8936–9031. [Google Scholar] [CrossRef] [PubMed]

- Liang, Y.; Ma, H.; Taha, A.A.; Hsiao, B.S. High-Flux Anti-Fouling Nanofibrous Composite Ultrafiltration Membranes Containing Negatively Charged Water Channels. J. Membr. Sci. 2020, 612, 118382. [Google Scholar] [CrossRef]

- Hadi, P.; Yang, M.; Ma, H.; Huang, X.; Walker, H.; Hsiao, B.S. Biofouling-Resistant Nanocellulose Layer in Hierarchical Polymeric Membranes: Synthesis, Characterization and Performance. J. Membr. Sci. 2019, 579, 162–171. [Google Scholar] [CrossRef]

- Aguilar-Sanchez, A.; Jalvo, B.; Mautner, A.; Rissanen, V.; Kontturi, K.S.; Abdelhamid, H.N.; Tammelin, T.; Mathew, A.P. Charged Ultrafiltration Membranes Based on TEMPO-Oxidized Cellulose Nanofibrils/Poly(Vinyl Alcohol) Antifouling Coating. RSC Adv. 2021, 11, 6859–6868. [Google Scholar] [CrossRef]

- Benítez, A.J.; Walther, A. Cellulose Nanofibril Nanopapers and Bioinspired Nanocomposites: A Review to Understand the Mechanical Property Space. J. Mater. Chem. A 2017, 5, 16003–16024. [Google Scholar] [CrossRef]

- Lindström, T. Aspects on Nanofibrillated Cellulose (NFC) Processing, Rheology and NFC-Film Properties. Curr. Opin. Colloid Interface Sci. 2017, 29, 68–75. [Google Scholar] [CrossRef]

- Sharma, P.R.; Sharma, S.K.; Lindström, T.; Hsiao, B.S. Water Purification: Nanocellulose-Enabled Membranes for Water Purification: Perspectives (Adv. Sustainable Syst. 5/2020). Adv. Sustain. Syst. 2020, 4, 2070009. [Google Scholar] [CrossRef]

- Yang, W.; Bian, H.; Jiao, L.; Wu, W.; Deng, Y.; Dai, H. High Wet-Strength, Thermally Stable and Transparent TEMPO-Oxidized Cellulose Nanofibril Film via Cross-Linking with Poly-Amide Epichlorohydrin Resin. RSC Adv. 2017, 7, 31567–31573. [Google Scholar] [CrossRef]

- Mautner, A.; Lucenius, J.; Österberg, M.; Bismarck, A. Multi-Layer Nanopaper Based Composites. Cellulose 2017, 24, 1759–1773. [Google Scholar] [CrossRef]

- Toivonen, M.S.; Kurki-Suonio, S.; Schacher, F.H.; Hietala, S.; Rojas, O.J.; Ikkala, O. Water-Resistant, Transparent Hybrid Nanopaper by Physical Cross-Linking with Chitosan. Biomacromolecules 2015, 16, 1062–1071. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Shi, L.; Feng, X. Use of Chitosan to Reinforce Transparent Conductive Cellulose Nanopaper. J. Mater. Chem. C 2018, 6, 242–248. [Google Scholar] [CrossRef]

- Pahimanolis, N.; Salminen, A.; Penttilä, P.A.; Korhonen, J.T.; Johansson, L.-S.; Ruokolainen, J.; Serimaa, R.; Seppälä, J. Nanofibrillated Cellulose/Carboxymethyl Cellulose Composite with Improved Wet Strength. Cellulose 2013, 20, 1459–1468. [Google Scholar] [CrossRef]

- Visanko, M.; Liimatainen, H.; Sirvio, J.A.; Heiskanen, J.P.; Niinimäki, J.; Hormi, O. Amphiphilic Cellulose Nanocrystals from Acid-Free Oxidative Treatment: Physicochemical Characteristics and Use as an Oil–Water Stabilizer. Biomacromolecules 2014, 15, 2769–2775. [Google Scholar] [CrossRef] [PubMed]

- Fernandes Diniz, J.; Gil, M.; Castro, J. Hornification—Its Origin and Interpretation in Wood Pulps. Wood Sci. Technol. 2004, 37, 489–494. [Google Scholar] [CrossRef]

- Idström, A.; Brelid, H.; Nydén, M.; Nordstierna, L. CP/MAS 13C NMR Study of Pulp Hornification Using Nanocrystalline Cellulose as a Model System. Carbohydr. Polym. 2013, 92, 881–884. [Google Scholar] [CrossRef]

- Österberg, M.; Vartiainen, J.; Lucenius, J.; Hippi, U.; Seppälä, J.; Serimaa, R.; Laine, J. A Fast Method to Produce Strong NFC Films as a Platform for Barrier and Functional Materials. ACS Appl. Mater. Interfaces 2013, 5, 4640–4647. [Google Scholar] [CrossRef]

- Smyth, M.; Fournier, C.; Driemeier, C.; Picart, C.; Foster, E.J.; Bras, J. Tunable Structural and Mechanical Properties of Cellulose Nanofiber Substrates in Aqueous Conditions for Stem Cell Culture. Biomacromolecules 2017, 18, 2034–2044. [Google Scholar] [CrossRef] [PubMed]

- Blanc, P.D. Fake Silk: The Lethal History of Viscose Rayon; Yale University Press: New Haven, CT, USA, 2016; ISBN 0-300-20466-3. [Google Scholar]

- Sayyed, A.J.; Deshmukh, N.A.; Pinjari, D.V. A Critical Review of Manufacturing Processes Used in Regenerated Cellulosic Fibres: Viscose, Cellulose Acetate, Cuprammonium, LiCl/DMAc, Ionic Liquids, and NMMO Based Lyocell. Cellulose 2019, 26, 2913–2940. [Google Scholar] [CrossRef]

- Rieland, J.M.; Love, B.J. Ionic Liquids: A Milestone on the Pathway to Greener Recycling of Cellulose from Biomass. Resour. Conserv. Recycl. 2020, 155, 104678. [Google Scholar] [CrossRef]

| Size Range | Terminology |

|---|---|

| Nanoscale 1–100 nm | nanoparticles, nanomaterial, electrospun nanofibers, nanofibrils, nanocrystals, nanoporous, nanopores, nanofiltration (1–2 nm), ultrafiltration (2–100 nm) |

| Microscale 100 nm–10 µm | microfibrils, microcrystals, microfibers, electrospun microfibers, fibrils, crystallites, microporous, micropores |

| Macroscale >10 µm | fibers, electrospun fibers, crystals, microporous, macropores |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Abbas, S.C.; Li, L.; Walker, C.C.; Ni, Y.; Cai, Z. Cellulose Membranes: Synthesis and Applications for Water and Gas Separation and Purification. Membranes 2024, 14, 148. https://doi.org/10.3390/membranes14070148

Wang J, Abbas SC, Li L, Walker CC, Ni Y, Cai Z. Cellulose Membranes: Synthesis and Applications for Water and Gas Separation and Purification. Membranes. 2024; 14(7):148. https://doi.org/10.3390/membranes14070148

Chicago/Turabian StyleWang, Jinwu, Syed Comail Abbas, Ling Li, Colleen C. Walker, Yonghao Ni, and Zhiyong Cai. 2024. "Cellulose Membranes: Synthesis and Applications for Water and Gas Separation and Purification" Membranes 14, no. 7: 148. https://doi.org/10.3390/membranes14070148

APA StyleWang, J., Abbas, S. C., Li, L., Walker, C. C., Ni, Y., & Cai, Z. (2024). Cellulose Membranes: Synthesis and Applications for Water and Gas Separation and Purification. Membranes, 14(7), 148. https://doi.org/10.3390/membranes14070148