Development and First Results of a No-Till Pneumatic Seeder for Maize Precise Sowing in Huang-Huai-Hai Plain of China

Abstract

:1. Introduction

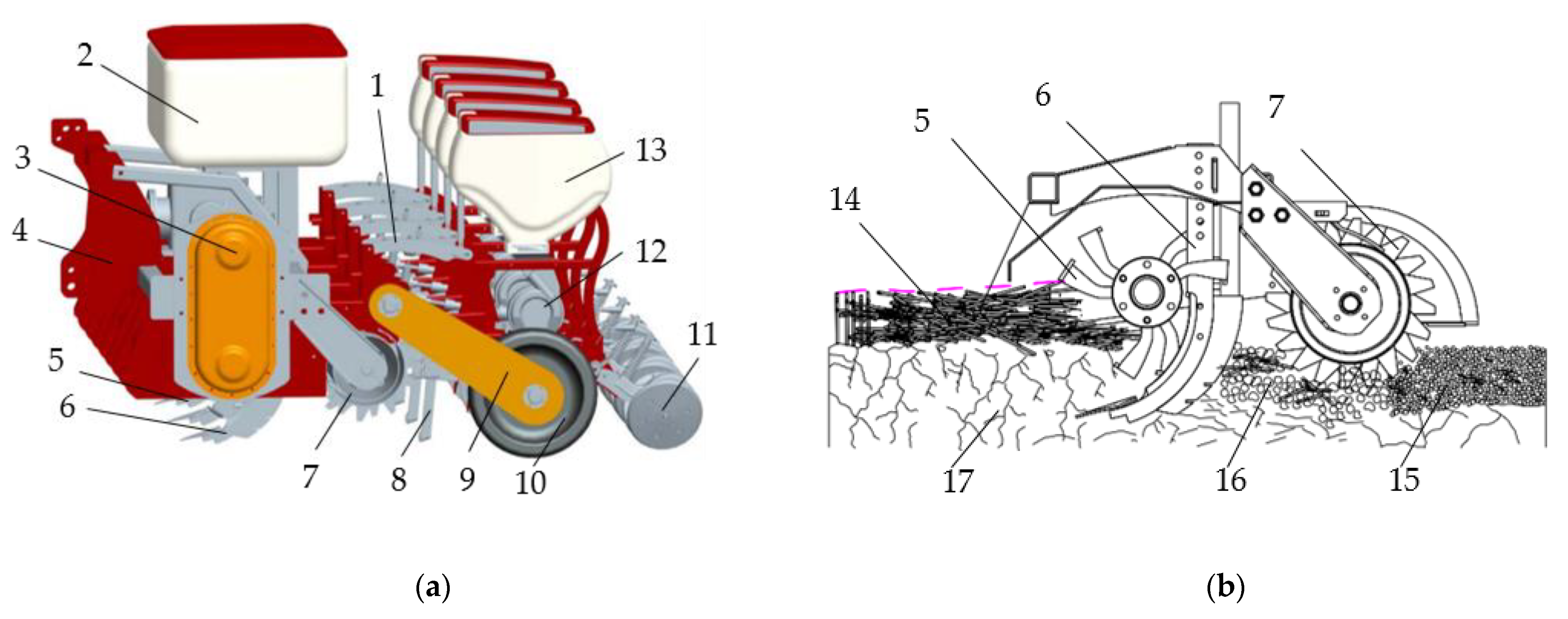

2. Design of the WNPM Seeder

2.1. Machine Structure and Working Principle

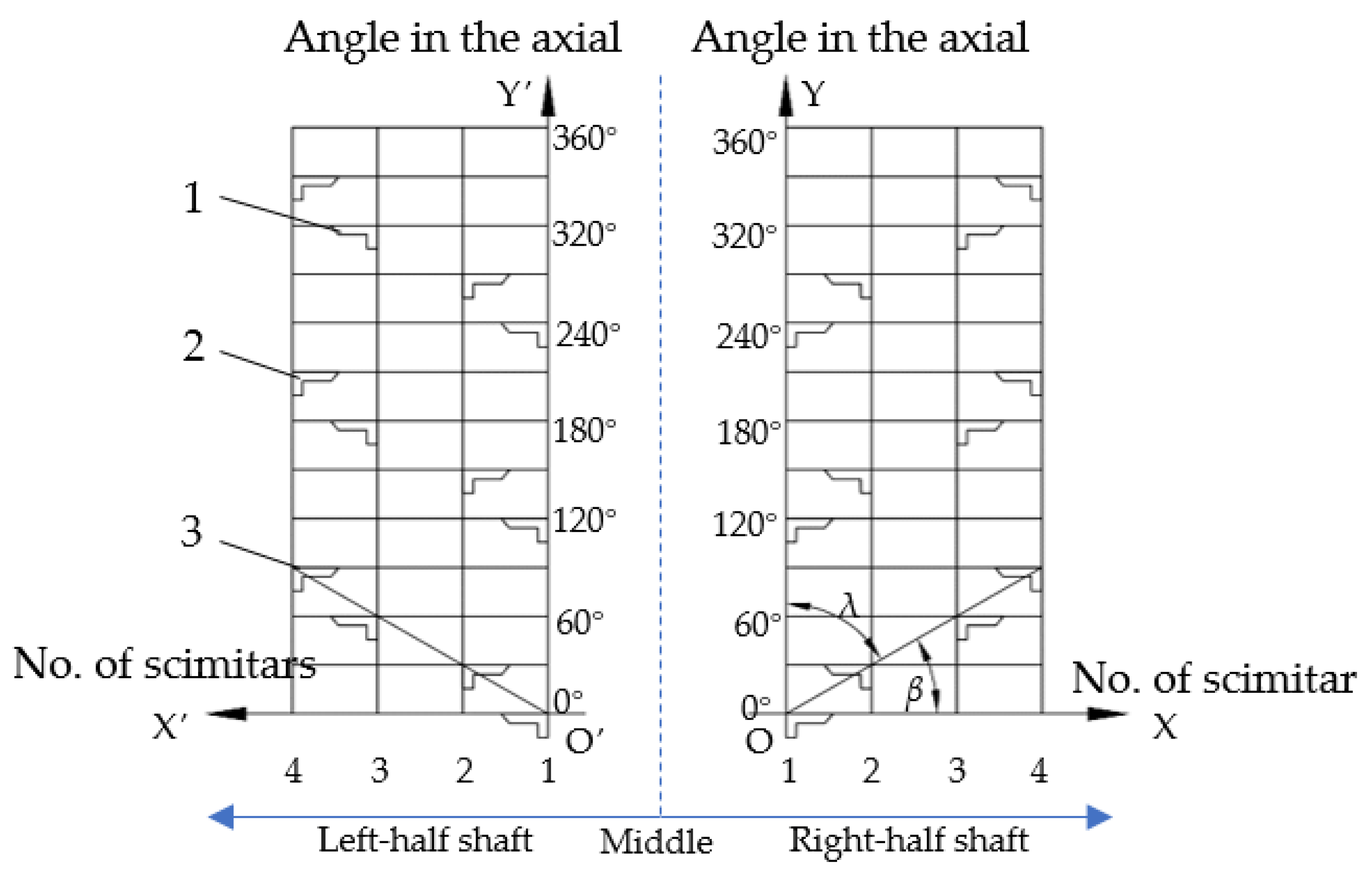

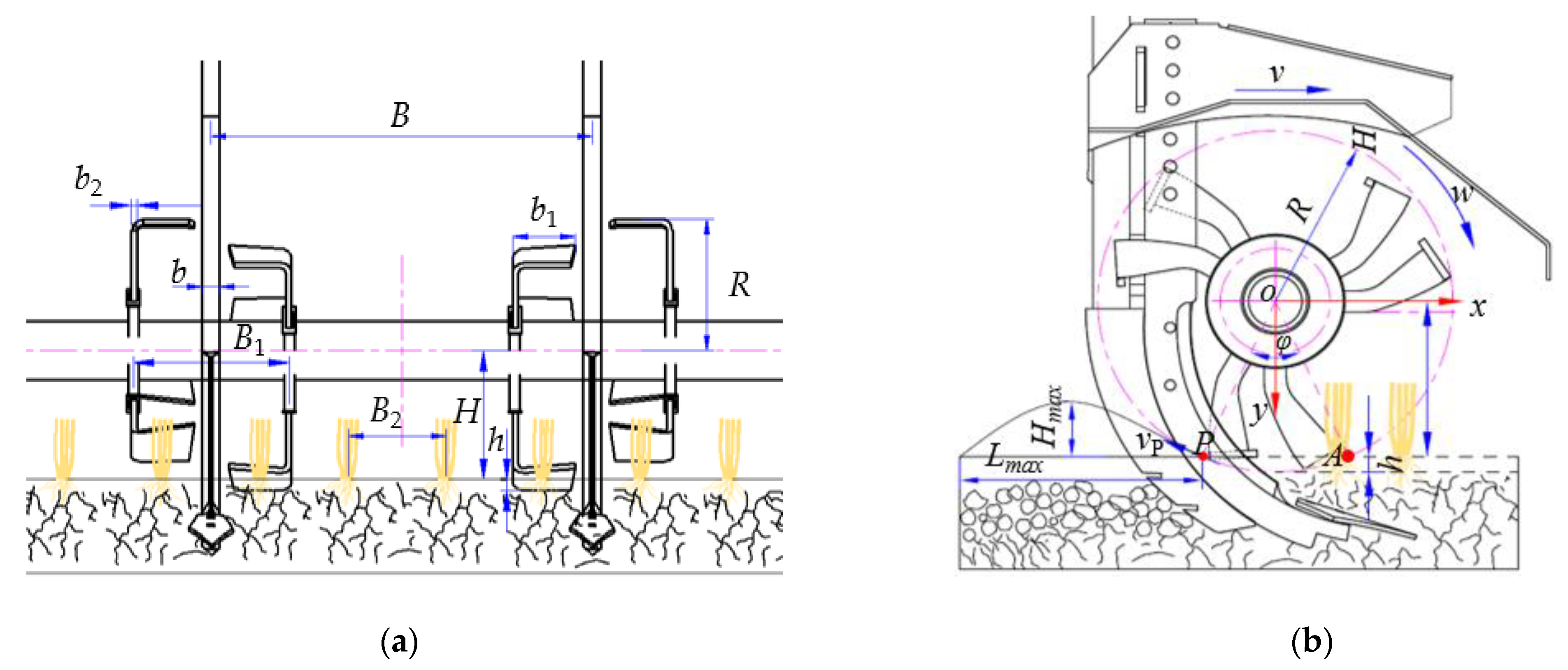

2.2. The Opposite-Placed Anti-Blocking Mechanism

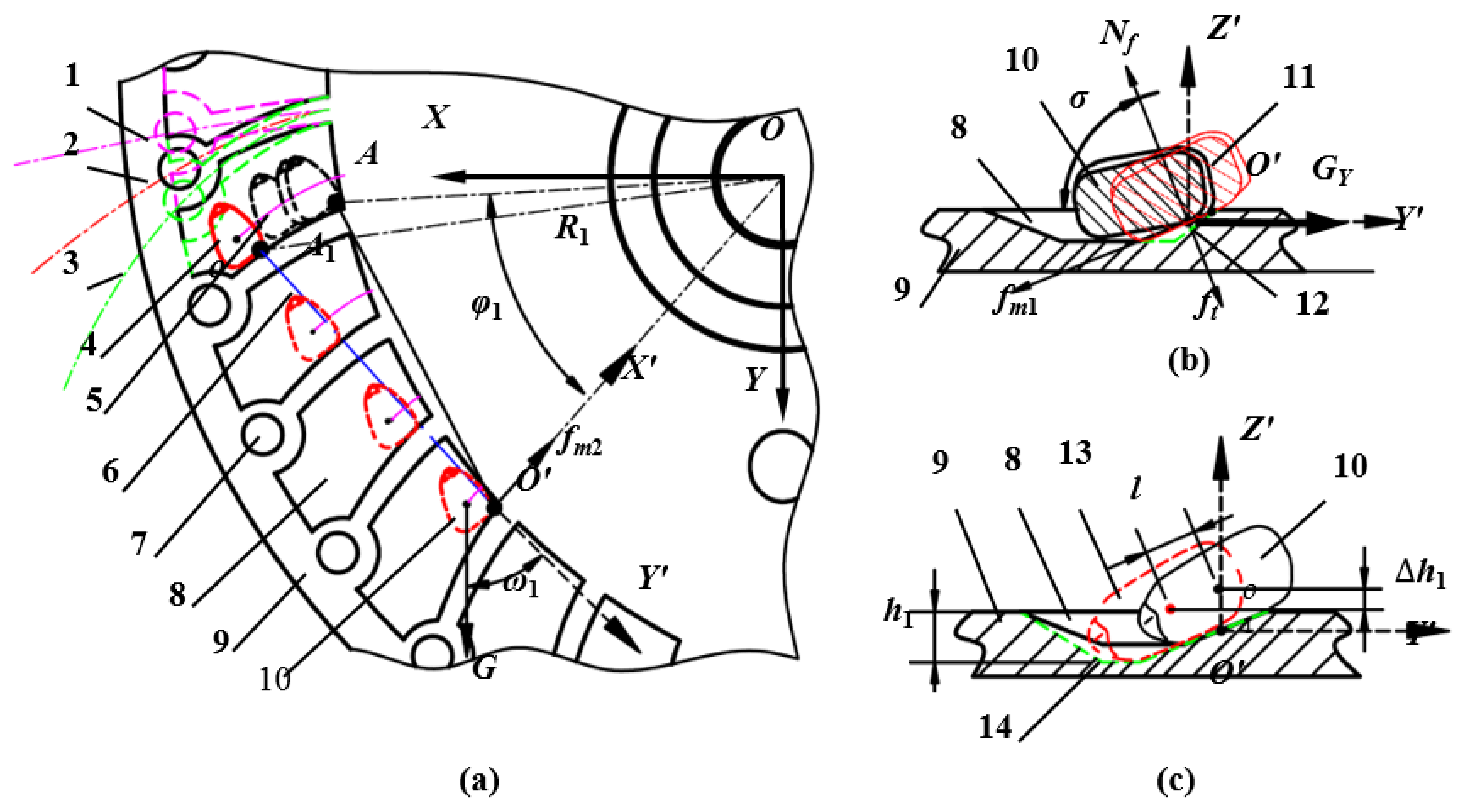

2.3. The Design of Maize Seed Meter

3. Optimization of Multi-Parameter through DEM Simulation by EDEM

3.1. Parameter Selection of the Opposite-Placed Anti-Blocking Mechanism

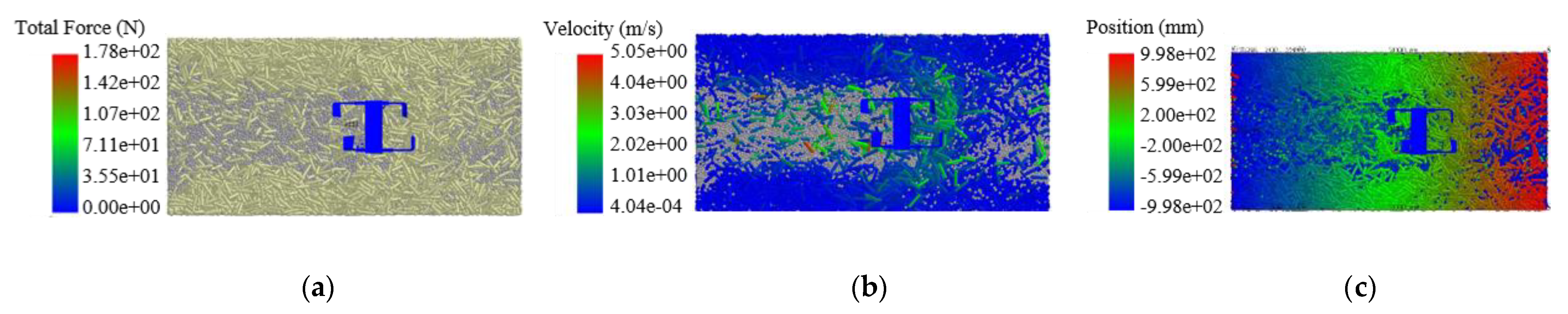

3.1.1. Materials and Methods of the DEM Simulation of the Anti-Blocking Mechanism

3.1.2. Data Analysis

3.1.3. Simulation Results and Discussion of the Opposite-Placed Anti-Blocking Mechanism

3.2. Parameter Selection of the Pneumatic Maize Seed Meter

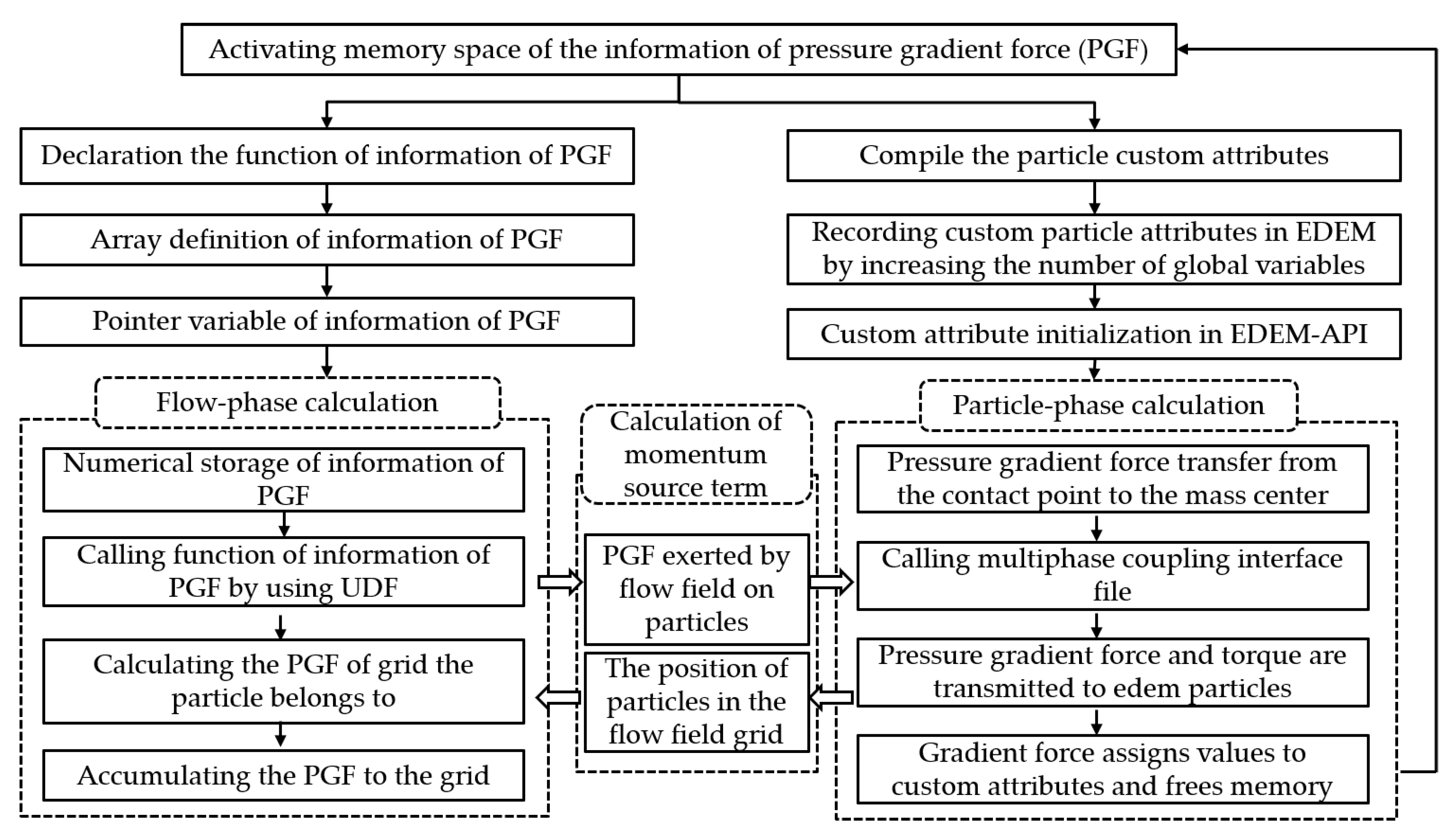

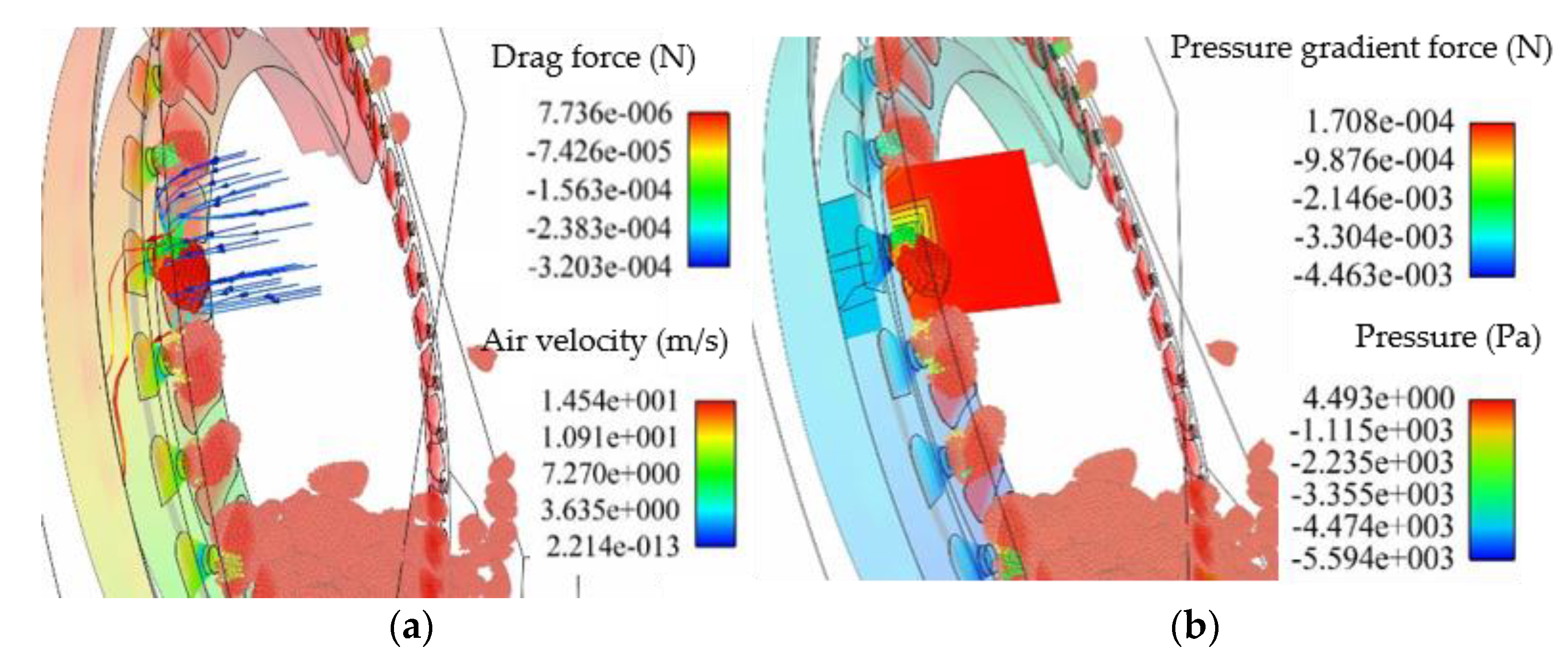

3.2.1. Materials and Methods of the Seed Meter Simulation by DEM-CFD

3.2.2. Simulation Results and Discussion

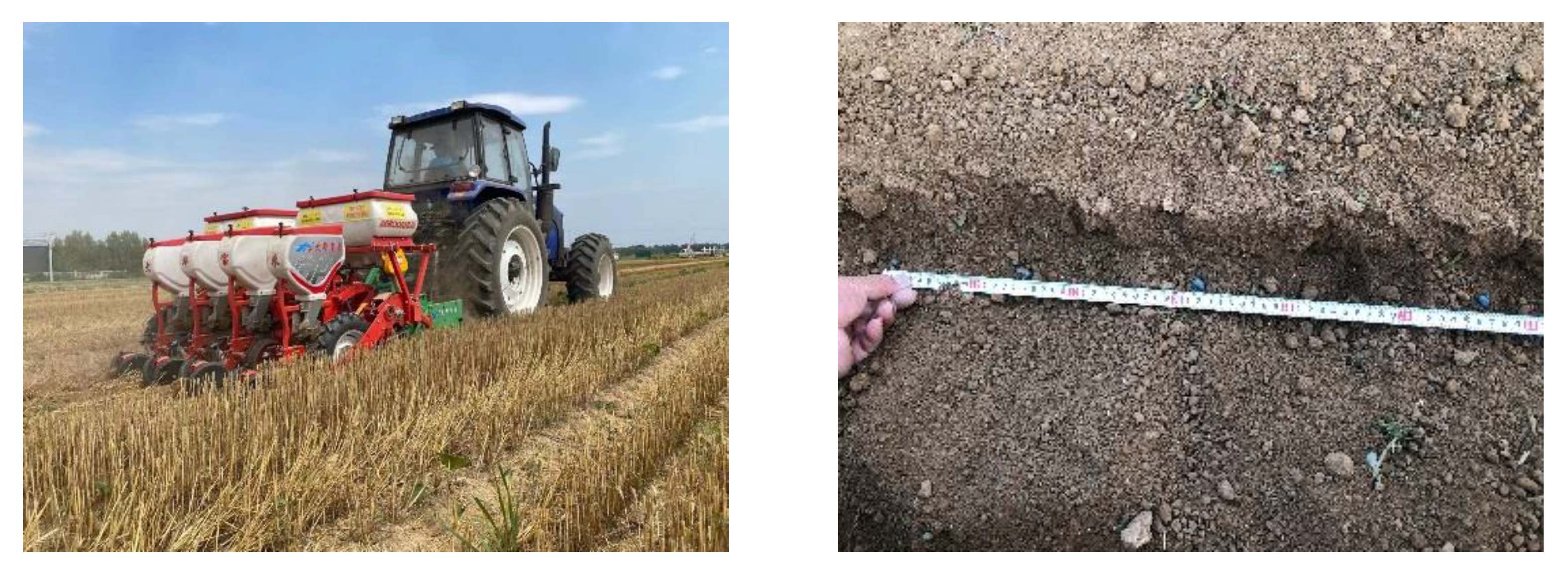

4. Materials and Methods of Field Experiment

4.1. Site Description

4.2. Field Test Contents and Methods

4.2.1. Passing Performance and Soil Disturbance

4.2.2. Straw Cleaning Rate on the Seedbeds’ Belt and the Residue Cover Index

4.2.3. Seed Singulation Performance

4.2.4. Seeding Depth and Plant Population

5. Results and Discussion of the Field Experiment

5.1. Passing Performance and Soil Disturbance

5.2. Straw Cleaning Rate

5.3. Seed Singulation Performance

5.4. Seeding Depth and Plant Population

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xu, F.L.; Guo, B.; Ye, B.; Ye, Q.; Chen, H.; Ju, X.; Guo, J.; Wang, Z. Systematical evaluation of GPMIMERG and TRMM3B42V7 precipitation products in the Huang-Huai-Hai Plain, China. Remote Sens. 2019, 11, 697. [Google Scholar] [CrossRef] [Green Version]

- Wu, D.; Fang, S.; Li, X.; He, D.; Zhu, Y.; Yang, Z.; Xu, J.; Wu, Y. Spatial temporal variation in irrigation water requirement for the winter wheat-summer maize rotation system since the 1980s on the North China Plain. Agric Water Manag. 2019, 214, 78–86. [Google Scholar] [CrossRef]

- NBSC (National Bureau of Statistics, China). The Statistical Bulletin of National Economy and Social Development in China; Peoples Republic of China, National Bureau of Statistics: Beijing, China, 2015. [Google Scholar]

- Zhang, D.; Yang, L.; Sun, S.; Dong, Y.; Zhang, D.; Xu, L.; Lu, J.; Cui, T.; Geng, D.; Li, S.; et al. Chapter I: General situation of maize production in China. In Technology and Equipment of Mechanized Maize Production, 1st ed.; Zhang, S., Ed.; China Agricultural University Press: Beijing, China, 2014. [Google Scholar]

- Qin, S.; Liang, L.; Xiang, L.; Hui, L.; Zhang, L. Dynamic analysis of drought trend in Huang-huai-hai region based on MODIS and TVDI. In IGARSS 2016—2016 IEEE International Geoscience and Remote Sensing Symposium; IEEE: Beijing, China, 2016. [Google Scholar]

- Li, H.W.; Gao, H.W.; Wu, H.D.; Li, W.Y.; Wang, X.Y.; He, J. Effects of 15 years of conservation tillage on soil structure and productivity of wheat cultivation in northern China. Aust. J. Soil Res. 2007, 45, 344–350. [Google Scholar] [CrossRef]

- Li, H.W.; He, J.; Gao, H.W.; Chen, Y.; Zhang, Z.Q. The effect of conservation tillage on crop yield in China. Front. Agric. Sci. Eng. 2015, 2, 179–185. [Google Scholar]

- He, J.; Li, H.; McHugh, A.D.; Wang, Q.; Lu, Z.; Li, W.; Zhang, Y. Permanent raised beds improved crop performance and water use on the North China Plain. J. Soil Water Conserv. 2015, 70, 54–62. [Google Scholar] [CrossRef]

- He, J.; Li, H.W.; Chen, H.T.; Lu, C.Y.; Wang, Q. Research Progress of Conservation Tillage Technology and Machine. Trans. Chin. Soc. Agric. Mach. 2018, 49, 1–19. [Google Scholar]

- Gao, W.S. Development trends and basic principles of conservation tillage. Sci. Agric. Sin. 2007, 40, 2702–2708. [Google Scholar]

- Zhu, G.H.; Li, W.Y.; He, J. Design and experiment on 2BFML-5 no-till planter for permanent raised bed. Trans. Chin. Soc. Agric. Mach. 2008, 2, 51–54. [Google Scholar]

- Li, H.W.; Chen, J.D.; Deng, J.; Zhao, W.D. Study on technology and machines of mechanized conservation tillage for dryland maize. J. China Agric. Univ. 2000, 4, 68–72. [Google Scholar]

- Yao, Z.L.; Gao, H.W.; Wang, X.Y. Design and experiment on 2BMX-5 No-till Wheat-maize Seeder. Trans. Chin. Soc. Agric. Mach. 2008, 39, 64–68. [Google Scholar]

- Chen, H.; Huang, H.; Yang, Y.L.; Li, H.W. Design of Row-followed No-till Wheat and Maize Planter under Controlled Traffic Farming System. Trans. Chin. Soc. Agric. Mach. 2009, 40, 72–76. [Google Scholar]

- Zhang, X.R.; He, J.; Li, H.W.; Wang, Q.J.; Wu, S.S. Design and experiment on No-till Planter in Horizontal Residue-throwing Finger-wheel type for maize. Trans. Chin. Soc. Agric. Mach. 2010, 41, 39–43. [Google Scholar]

- Zhang, J.C.; Yan, X.L.; Xue, S.P.; Zhu, R.X.; Su, G.Y. Design of No-tillage Maize Planter with Straw Smashing and Fertilizing. Trans. Chin. Soc. Agric. Mach. 2012, 43, 51–55. [Google Scholar]

- Yang, Z.D.; Liu, N.N.; Geng, D.Y.; Chai, S.; Ma, M.J.; Du, R.C. Design and Experiment on Type 2BYM-12 Folding and Dynamic Anti-blocking No-till Planter. Trans. Chin. Soc. Agric. Mach. 2013, 44, 46–50. [Google Scholar]

- Li, F.H.; Du, R.C.; Diao, P.S.; Zhang, Y.P.; Cui, Q.; Li, T. Design and Experiment of Helm-shaped No-tillage Precision Fertilization Planter for Corn. Trans. Chin. Soc. Agric. Mach. 2013, 44, 33–38. [Google Scholar]

- Gao, N.N.; Zhang, D.X.; Yang, L.; Liu, J.; Cui, T. Design and experiment of drum-type anti-blocking mechanism of no-till planter for maize. Trans. Chin. Soc. Agric. Eng. 2012, 28, 31–37. [Google Scholar]

- Cao, X.P.; Wang, Q.J.; Li, H.W.; He, J.; Lu, C.Y. Combined Row Cleaners Research with Side Cutter and Stubble Clean Disk of Corn No-till Seeder. Trans. Chin. Soc. Agric. Mach. 2021, 52, 36–44. [Google Scholar]

- Wang, W.W.; Zhu, C.X.; Chen, L.Q.; Li, Z.D.; Huang, X.; Li, J.C. Design and experiment of active straw-removing anti-blocking device for maize no-tillage planter. Trans. Chin. Soc. Agric. Mach. 2017, 33, 10–17. [Google Scholar]

- Yao, W.Y.; Zhao, D.B.; Xu, G.F.; Chen, M.Z.; Miao, H.Q.; Diao, P.S. Design and Experiment of Anti-blocking Device for Strip to row Active Corn No-tillage Seeding. Trans. Chin. Soc. Agric. Mach. 2020, 51, 55–62, 71. [Google Scholar]

- Siemens, M.C.; Wilkins, D.E.; Correa, R.F. Development and evaluation of a residue management wheel for hoe-type no-till drills. Trans. Am. Soc. Agric. Eng. 2004, 47, 397–404. [Google Scholar] [CrossRef]

- Niu, M.M.; Fang, H.M.; FA, C.; Shi, S.; Xue, Y.; Liu, H. Design and Experiment of Separating-guiding Anti-blocking Mechanism for No-tillage Maize Planter. Trans. Chin. Soc. Agric. Mach. 2019, 50, 52–58. [Google Scholar]

- Li, Y.; Yan, B.; Yu, Y.; He, X.; Liu, Q.; Liang, Z.; Yin, X.; Cui, T.; Zhang, D. Global overview of research progress and development of precision maize planters. Int. J. Agric. Biol. Eng. 2016, 9, 9–26. [Google Scholar]

- Hudspeth, E.B.; Wanjura, D.F. A planter for precision depth and placement of cotton seed. Trans. ASAE 1970, 13, 153–155. [Google Scholar] [CrossRef]

- Karayel, D.; Barut, Z.B.; Özmerzi, A. Mathematical modelling of vacuum pressure on a precision seeder. Biosyst. Eng. 2004, 87, 437–444. [Google Scholar] [CrossRef]

- Karayel, D. Performance of a modified precision vacuum seeder for no-till sowing of maize and soybean. Soil Tillage Res. 2009, 104, 121–125. [Google Scholar] [CrossRef]

- John Deere No-Till Air Dill. Available online: https://www.deere.com/en/seeding-equipment/ (accessed on 12 August 2021).

- Vaderstad Tempo. Available online: https://www.vaderstad.com/en/planting/tempo-planter/tempo-r-4–6/ (accessed on 15 August 2021).

- Fallahi, S.; Raoufat, M.H. Row-crop planter attachments in a conservation tillage system: A comparative study. Soil Tillage Res. 2008, 98, 27–34. [Google Scholar] [CrossRef]

- Swan, J.B.; Higgs, R.L.; Bailey, T.B.; Wollenhaupt, N.C.; Paulson, W.H.; Peterson, A.E. Surface residue an in-row treatment effects on long-term no-tillage and continuous corn. Agron. J. 1994, 86, 711–718. [Google Scholar] [CrossRef]

- Nafziger, D.; Carter, P.R.; Graham, E.E. Response of corn to uneven emergence. Crop Sci. 1991, 31, 811–815. [Google Scholar] [CrossRef] [Green Version]

- Ford, J.H.; Hicks, D.R. Corn growth and yield in uneven emerging stands. J. Prod. Agric. 1992, 5, 185–188. [Google Scholar] [CrossRef]

- Mead, J.A.; Chan, K.Y. Effect of deep tillage and seedbed preparation on the growth and yield of wheat on a hard-setting soil. Aust. J. Exp. Agric. 1988, 28, 491–498. [Google Scholar] [CrossRef]

- Yao, Z.; Li, H.; Gao, H.; Wang, X.; HE, J. Crop performance as affected by three opening configurations for no-till seeder in annual double cropping regions of northern China. Soil Res. 2010, 47, 839–847. [Google Scholar] [CrossRef]

- Loon, J.V.; Krupnik, T.J.; López-Gómez, J.A.; Timsina, J.; Govaerts, B.A. Standard methodology for evaluation of mechanical maize seed meters for smallholder farmers comparing devices from latin america, sub-saharan africa, and asia. Agronomy 2020, 10, 1091. [Google Scholar] [CrossRef]

- Timsina, J.; Jat, M.L.; Majumdar, K. Rice-maize systems of South Asia: Current status, future prospects and research priorities for nutrient management. Plant Soil 2010, 335, 65–82. [Google Scholar] [CrossRef]

- Timsina, J.; Buresh, R.J.; Dobermann, A.; Dixon, J. Rice-Maize Systems in Asia: Current Situation and Potential; CIMMYT, IRRI: Los Baños, Phillipines, 2011; p. 235. [Google Scholar]

- Jin, H.; Li, H.; Wang, Q.; Gao, H.; Li, W.; Zhang, X.; Mcgiffen, M. The adoption of conservation tillage in China. Ann. N. Y. Acad. Sci. 2010, 1195, 96–106. [Google Scholar]

- Jin, H.; Zhang, Z.; Li, H.; Wang, Q. Development of small/medium size no-till and minimum-till seeders in Asia: A review. Int. J. Agric. Biol. Eng. 2014, 7, 1–12. [Google Scholar]

- National Standardization Administration Committee of China; General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. GB/T 5669–2017 Rotary Tillage Machinery Knife and Knife Holder; Standards Press of China: Beijing, China, 2017. [Google Scholar]

- Chinese Academy of agricultural mechanization. Design Manual of Agricultural Machinery; China Agricultural Science and Technology Press: Beijing, China, 2007. [Google Scholar]

- Matin, M.A.; Fielke, J.M.; Desbiolles, J.M.A. Furrow parameters in rotary strip-tillage: Effect of blade geometry and rotary speed. Biosyst. Eng. 2014, 118, 7–15. [Google Scholar] [CrossRef]

- Zhang, J.G.; Gao, H.W.; Yang, G. Study on the chopping property of wheat straw. Trans. Chin. Soc. Agric. Eng. 2000, 16, 70–72. [Google Scholar]

- Shi, S.; Zhou, J.L.; Liu, H.; Fang, H.M.; Jian, S.C.; Zhang, R.F. Design and Experiment of Pneumatic Precision Seed-metering Device with Guided Assistant Seed-filling. Trans. Chin. Soc. Agric. Mach. 2019, 50, 61–70. [Google Scholar]

- Cundall, P.; Strack, O. A discrete numerical model for granular assemblies. Geotechnique 1979, 29, 47–65. [Google Scholar] [CrossRef]

- Coetzee, C.J.; Lombard, S.G. The destemming of grapes: Experiments and discrete element modelling. Biosyst. Eng. 2013, 114, 232–248. [Google Scholar] [CrossRef]

- González-Montellano, C.; Ayuga, F.; Ooi, J. Discrete element modelling of grain flow in a planar silo: Influence of simulation parameters. Granul. Matter. 2011, 13, 149–158. [Google Scholar]

- Lenaerts, B.; Aertsen, T.; Tijskens, E.; Ketelaere, B.D.; Ramon, H.; Baerdemaeker, J.D.; Saeys, W. Simulation of grain–straw separation by Discrete Element Modeling with bendable straw particles. Comput. Electron. Agric. 2014, 101, 24–33. [Google Scholar] [CrossRef] [Green Version]

- Van Liedekerke, P.; Tijskens, E.; Dintwa, E.; Rioual, F.; Vangeyte, J.; Ramon, H. DEM simulations of the particle flow on a centrifugal fertilizer spreader. Powder Technol. 2009, 190, 348–360. [Google Scholar] [CrossRef]

- Mak, J.; Chen, Y.; Sadek, M.A. Determining parameters of a discrete element model for soil-tool interaction. Soil Tillage Res. 2012, 118, 117–122. [Google Scholar] [CrossRef]

- Han, D.; Zhang, D.; Jing, H.; Li, Y.; Tao, C.; Ding, Y.; Wang, Z.; Wang, Y.; Zhang, T. Dem-CFD coupling simulation and optimization of an inside-filling air-blowing maize precision seed-metering device. Comput. Electron. Agric. 2018, 150, 426–438. [Google Scholar] [CrossRef]

- Lei, X.; Liao, Y.; Liao, Q. Simulation of seed motion in seed feeding device with DEM-CFD coupling approach for rapeseed and wheat. Comput. Electron. Agric. 2016, 131, 29–39. [Google Scholar] [CrossRef]

- Bravo, E.L.; Tijskens, E.; Suárez, M.H.; Cueto, O.G.; Ramon, H. Prediction model for non-inversion soil tillage implemented on discrete element method. Comput. Electron. Agric. 2014, 106, 120–127. [Google Scholar] [CrossRef]

- Chen, Y.; Munkholm, L.J.; Nyord, T. A discrete element model for soil–sweep interaction in three different soils. Soil Tillage Res. 2013, 126, 34–41. [Google Scholar] [CrossRef]

- Asaf, Z.; Rubinstein, D.; Shmulevich, I. Determination of discrete element model parameters required for soil tillage. Soil Tillage Res. 2007, 92, 227–242. [Google Scholar] [CrossRef]

- Jiang, M.; Liu, C.; Wei, D.; Du, X.; Cai, P.; Song, J. Design and Test of Wide Seedling Strip Wheat Precision Planter. Trans. Chin. Soc. Agric. Mach. 2019, 50, 53–61. [Google Scholar]

- Wang, X.L.; Hu, H.; Wang, Q.J.; Li, H.; Chen, W. Calibration Method of Soil Contact Characteristic Parameters Based on DEM Theory. Trans. Chin. Soc. Agric. Mach. 2017, 48, 78–85. [Google Scholar]

- Fang, H.M. Research on the Straw-Soil-Rotary Blade Interaction Using Discrete Element Method; Nanjing Agricultural University: Nanjing, China, 2016; pp. 33–97. [Google Scholar]

- Fang, H.; Shi, S.; Qiao, L.; Niu, M.; Xu, G.; Jian, S. Numerical and experimental study of working performance of round roller-claw type anti-blocking mechanism. J. Chin. Agric. Mech. 2018, 39, 01–09. [Google Scholar]

- Yang, Q.L.; Li, Z.H.; Li, H.W.; Jin, H.E.; Wang, Q.; Lu, C.Y.; China Agricultural University. Numerical analysis of particle motion in pneumatic centralized fertilizer distribution device based on CFD DEM. Trans. Chin. Soc. Agric. Mach. 2019, 50, 81–89. [Google Scholar]

- Shi, S.; Liu, H.; Wei, G.; Zhou, J.; Jian, S. Optimization and Experiment of Pneumatic Seed Metering Device with Guided Assistant Filling Based on EDEM CFD. Trans. Chin. Soc. Agric. Mach. 2020, 51, 54–66. [Google Scholar]

- Zhang, J.; Li, X.M.; Mou, H.Q. The application of response model methodology in product design improvement. Appl. Stat. Manag. 2004, 23, 43–48. [Google Scholar]

- National Standardization Administration Committee of China; General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. GB/T 20865–2017 No/Less Tillage and Fertilization Seeding; China Standard Press: Beijing, China, 2017. [Google Scholar]

- Ministry of Industry and Information Technology of the People’s Republic of China. GB/T 6973–2005 Test Method for Single Grain (Precision) Planter; China Standards Press: Beijing, China, 2006. [Google Scholar]

- Liu, L.J. Systematic Experiments and Effect Analysis of All Year Conservation Tillage in Two Crops a Year Region; China Agricultural University: Beijing, China, 2004. [Google Scholar]

- Yang, L.; Zhang, R.; Liu, Q.W.; Yin, X.W.; He, X.T.; Cui, T.; Zhang, D.X. Row cleaner and depth control unit improving sowing performance of maize no-till precision planter. Trans. Chin. Soc. Agric. Eng. 2016, 32, 18–23. [Google Scholar]

- Swan, J.B.; Kaspar, T.C.; Erbach, D.C. Seed-row residue management for corn establishment in the northern US Corn Belt. Soil Tillage Res. 1996, 40, 55–72. [Google Scholar] [CrossRef]

- Zhang, J.X.; Liu, C.Y.; Shi, J.L.; Jing, M.; Wang, F. Effects of no tillage with stubble mulch on sowing and seedling of spring wheat in the Hexi Irrigation Area. J. Gansu Agric. Univ. 2006, 4, 31–34. [Google Scholar]

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| Soil density ρ/(kg·m−3) | 1850 | Soil shear modulus G/Mpa | 1 |

| Poisson’s ratio of soil v | 0.35 | Static friction coefficient among soil μs | 0.541 |

| Straw density ρ1/(kg·m−3) | 241 | Shear modulus of straw G1/Mpa | 1 |

| Poisson’s ratio of straw v1 | 0.4 | Static friction coefficient between straws μs1 | 0.3 |

| Iron density ρ2/( kg·m−3) | 7865 | Shear modulus of iron G2/Mpa | 7.9 × 104 |

| Poisson’s ratio of straw iron v2 | 0.3 | Static friction coefficient between soil and iron μs2 | 0.6 |

| Recovery coefficient among soil e | 0.6 | Recovery coefficient among straw e1 | 0.3 |

| Recovery coefficient between soil and iron e2 | 0.6 | Recovery coefficient between straw and iron e3 | 0.3 |

| Rolling friction coefficient among soil μr | 0.31 | Rolling friction coefficient among straw μr1 | 0.02 |

| Rolling friction coefficient between soil and iron μr2 | 0.6 | Rolling friction coefficient between straw and iron μr3 | 0.3 |

| Level | Factors | ||

|---|---|---|---|

| Distance between the Left and Right Machetes B1 (mm) | Rotating Speed of the Cutter Shaft n (r·min−1) | Forward Speed v (km·h−1) | |

| 1 | 200 | 300 | 7 |

| 2 | 260 | 500 | 8 |

| 3 | 320 | 700 | 9 |

| Order Number | Factors | Straw Cleaning Rate/% | Average Displacement of Straw/mm | Anti-Blocking Mechanism Afforded FORCE/N | ||

|---|---|---|---|---|---|---|

| Distance of Machetes | Rotating Speed | Forward Speed | ||||

| 1 | 1 | 1 | 1 | 85.9 a | 602.4 a | 323.9 a |

| 2 | 1 | 2 | 2 | 96.3 b | 698.1 b | 466.1 b |

| 3 | 1 | 3 | 3 | 95.6 bc | 957.3 c | 685.9 c |

| 4 | 2 | 1 | 2 | 84.3 a | 617.1 a | 359.3 a |

| 5 | 2 | 2 | 3 | 94.8 bc | 613.9 a | 501.6 b |

| 6 | 2 | 3 | 1 | 97.5 c | 1123.5 c | 679.5 c |

| 7 | 3 | 1 | 3 | 81.7 a | 617.9 a | 394.9 a |

| 8 | 3 | 2 | 1 | 88.9 ab | 754.1 b | 517.2 b |

| 9 | 3 | 3 | 2 | 90.8 ab | 1055.3 c | 643.9 c |

| Materials | Parameters | |||||

|---|---|---|---|---|---|---|

| Poisson’s Ratio | Shear Modulus/Pa | Density/(g·cm−3) | Collision Recovery Factor (with Particles) | Static Friction Coefficient (with Particles) | Rolling Friction Coefficient (with particles) | |

| Maize | 0.40 | 1.37 × 108 | 2.25 | 0.19 | 0.03 | 0.002 |

| Nilon66 | 0.28 | 3.2 × 109 | 1.14 | 0.73 | 0.44 | 0.087 |

| Acrylic | 0.50 | 1.77 × 108 | 1.18 | 0.71 | 0.46 | 0.093 |

| Order Number | Inclined Angle σ (°) | Depth of the Seed Guide Groove h1 (mm) | Coefficient of Curvature γ | Duration (s) | Removal Resistance (N) | Void Fraction (%) |

|---|---|---|---|---|---|---|

| 1 | 0 | 3 | 0.1 | 1.06 × 10−1 | 8.70 × 10−3 | 61.58 |

| 2 | 0 | 1.6 | 0.5 | 1.19 × 10−1 | 9.90 × 10−3 | 64.46 |

| 3 | 0 | 0.2 | 0.9 | 9.75 × 10−2 | 1.21 × 10−2 | 63.83 |

| 4 | 25 | 3 | 0.5 | 1.08 × 10−1 | 8.90 × 10−3 | 67.37 |

| 5 | 25 | 1.6 | 0.9 | 9.20 × 10−2 | 1.08 × 10−2 | 59.62 |

| 6 | 25 | 0.2 | 0.1 | 1.19 × 10−1 | 1.00 × 10−2 | 64.46 |

| 7 | 50 | 3 | 0.9 | 9.60 × 10−2 | 1.41 × 10−2 | 61.34 |

| 8 | 50 | 1.6 | 0.1 | 1.22 × 10−1 | 1.35 × 10−2 | 64.43 |

| 9 | 50 | 0.2 | 0.5 | 1.08 × 10−1 | 1.43 × 10−2 | 62.03 |

| No. | Blocking Times | Soil Disturbance | Seedbeds’ Width |

|---|---|---|---|

| 1 | 0 | 35.1 | 264.2 |

| 2 | 0 | 38.5 | 265.8 |

| 3 | 0 | 41.2 | 265.4 |

| No. | Residue Weight before Seeding (kg/m2) | Residue Weight after Seeding (kg/m2) | Straw Cleaning Rate (%) | Residue Cover Index (%) |

|---|---|---|---|---|

| 1 | 1.26 | 0.06 | 95.2 | 59.9% |

| 2 | 1.19 | 0.04 | 96.6 | 58.6% |

| 3 | 1.05 | 0.09 | 91.4 | 62.8% |

| No. | Qualified Seed Spacing Index (%) | Repeated Index (%) | Missed Sowing Index (%) | Uniformity Variation Coefficient (%) |

|---|---|---|---|---|

| 1 | 97.4 | 1.1 | 1.5 | 18.6% |

| 2 | 96.7 | 0.5 | 2.8 | 16.9% |

| 3 | 95.9 | 0.8 | 3.6 | 21.7% |

| Mean Depth (mm) | Qualified Index of Sowing Depth (%) | Standard Deviation (mm) | Coefficient of Variation (%) | Plant Population (Plant/m2) |

|---|---|---|---|---|

| 45.6 | 95.1 | 1.2 | 3.2% | 6.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Liu, H.; Zhou, J.; Wei, G.; Shi, S.; Zhang, X.; Zhang, R.; Zhu, H.; He, T. Development and First Results of a No-Till Pneumatic Seeder for Maize Precise Sowing in Huang-Huai-Hai Plain of China. Agriculture 2021, 11, 1023. https://doi.org/10.3390/agriculture11101023

Li H, Liu H, Zhou J, Wei G, Shi S, Zhang X, Zhang R, Zhu H, He T. Development and First Results of a No-Till Pneumatic Seeder for Maize Precise Sowing in Huang-Huai-Hai Plain of China. Agriculture. 2021; 11(10):1023. https://doi.org/10.3390/agriculture11101023

Chicago/Turabian StyleLi, Hui, Hu Liu, Jilei Zhou, Guojian Wei, Song Shi, Xiangcai Zhang, Rongfang Zhang, Huibin Zhu, and Tengfei He. 2021. "Development and First Results of a No-Till Pneumatic Seeder for Maize Precise Sowing in Huang-Huai-Hai Plain of China" Agriculture 11, no. 10: 1023. https://doi.org/10.3390/agriculture11101023

APA StyleLi, H., Liu, H., Zhou, J., Wei, G., Shi, S., Zhang, X., Zhang, R., Zhu, H., & He, T. (2021). Development and First Results of a No-Till Pneumatic Seeder for Maize Precise Sowing in Huang-Huai-Hai Plain of China. Agriculture, 11(10), 1023. https://doi.org/10.3390/agriculture11101023