Simulations and Experiments of the Soil Temperature Distribution after 2.45-GHz Short-Time Term Microwave Treatment

Abstract

:1. Introduction

2. Materials and Methods

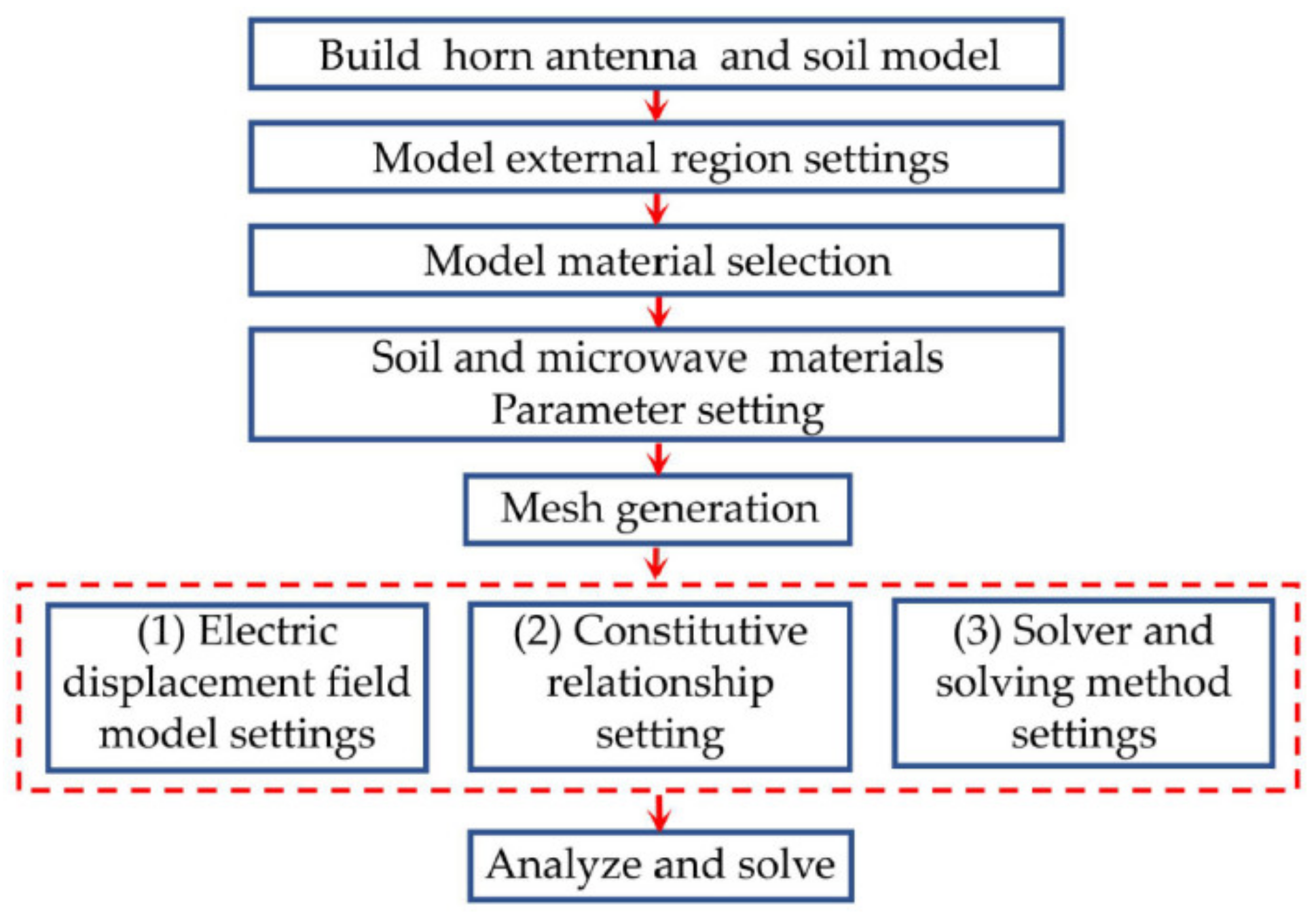

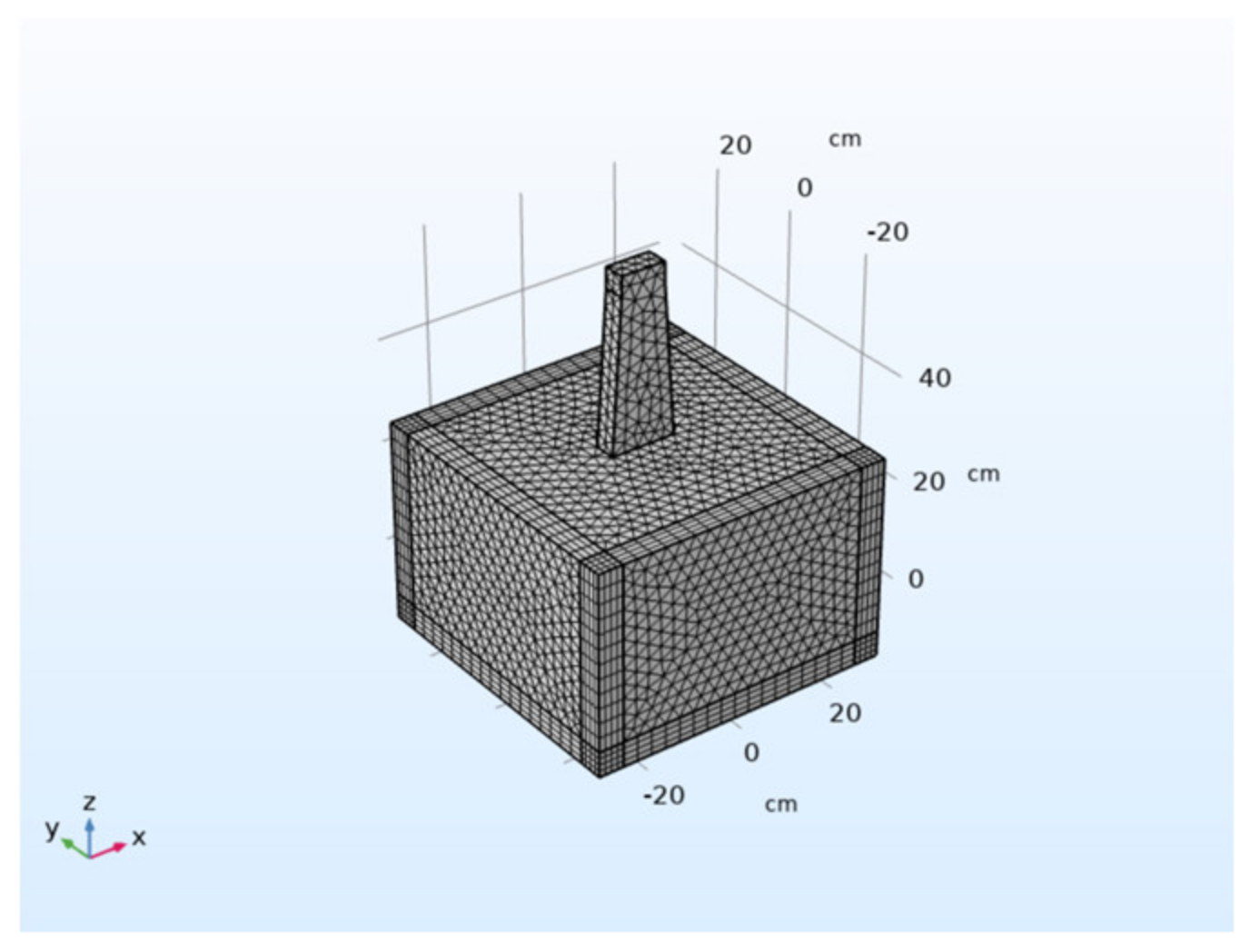

2.1. Electromagnetic Field Simulation with a Soil Model

2.2. Design Microwave Treatment Experiment Bench

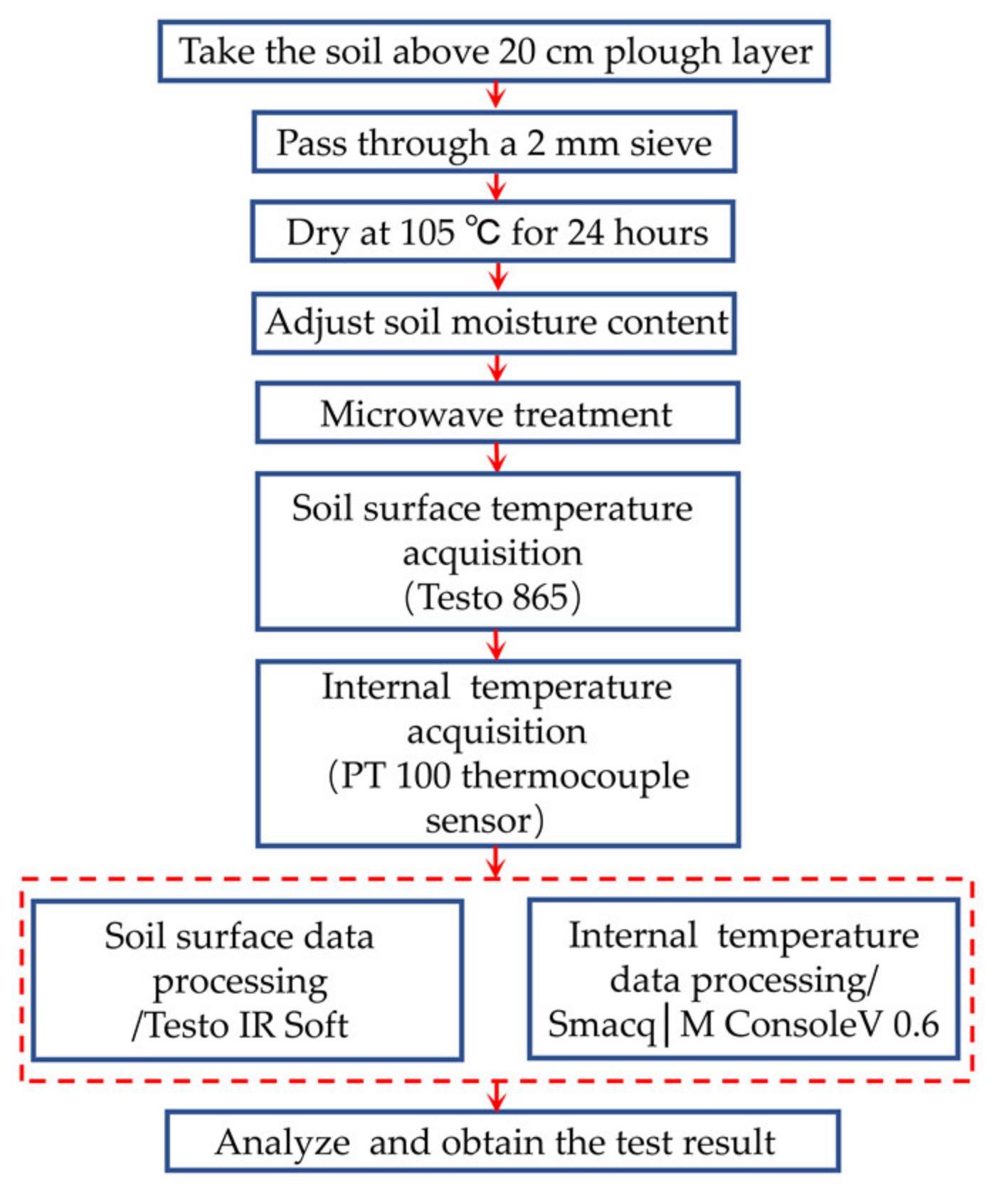

2.3. Experimental Method

3. Results and Discussion

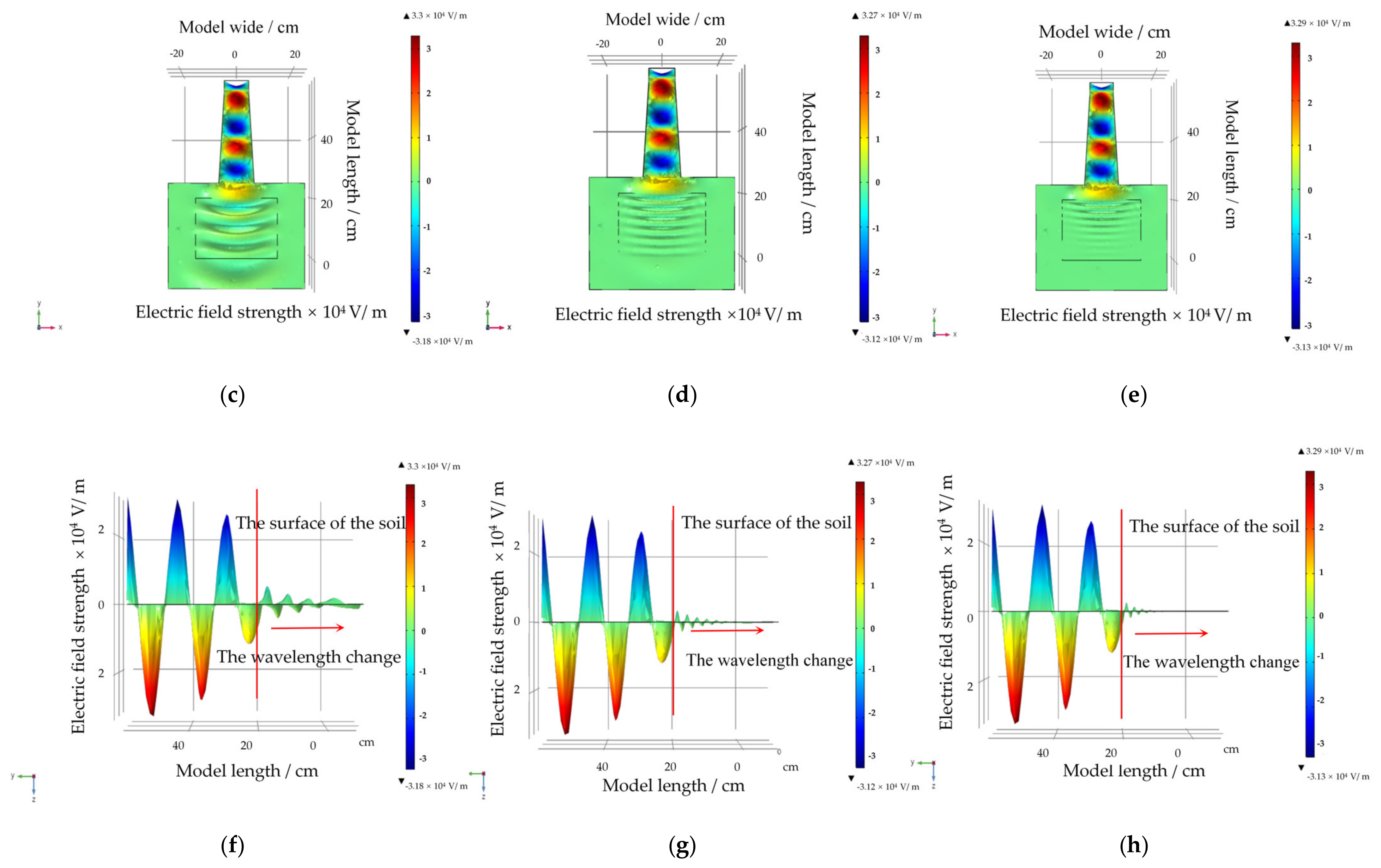

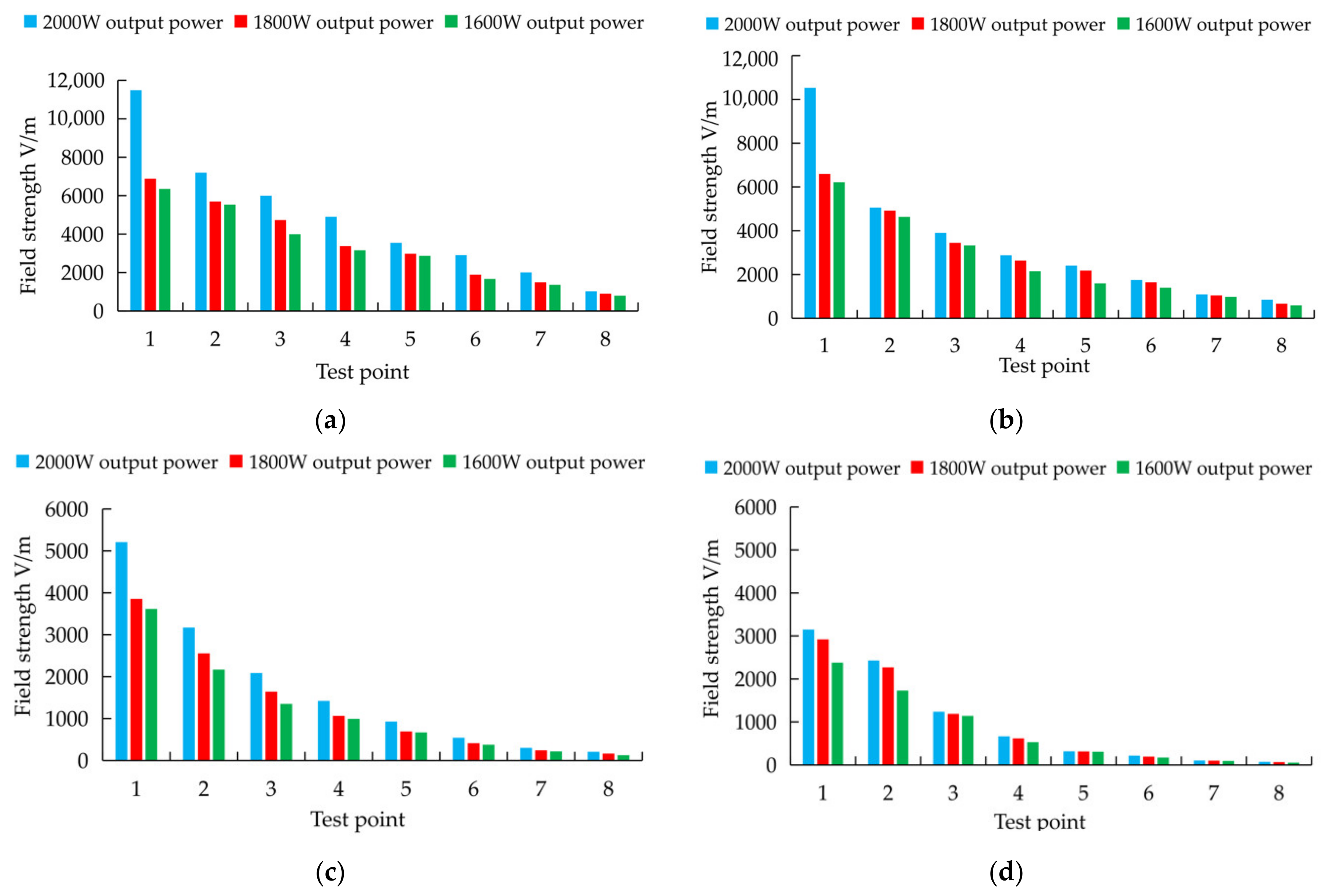

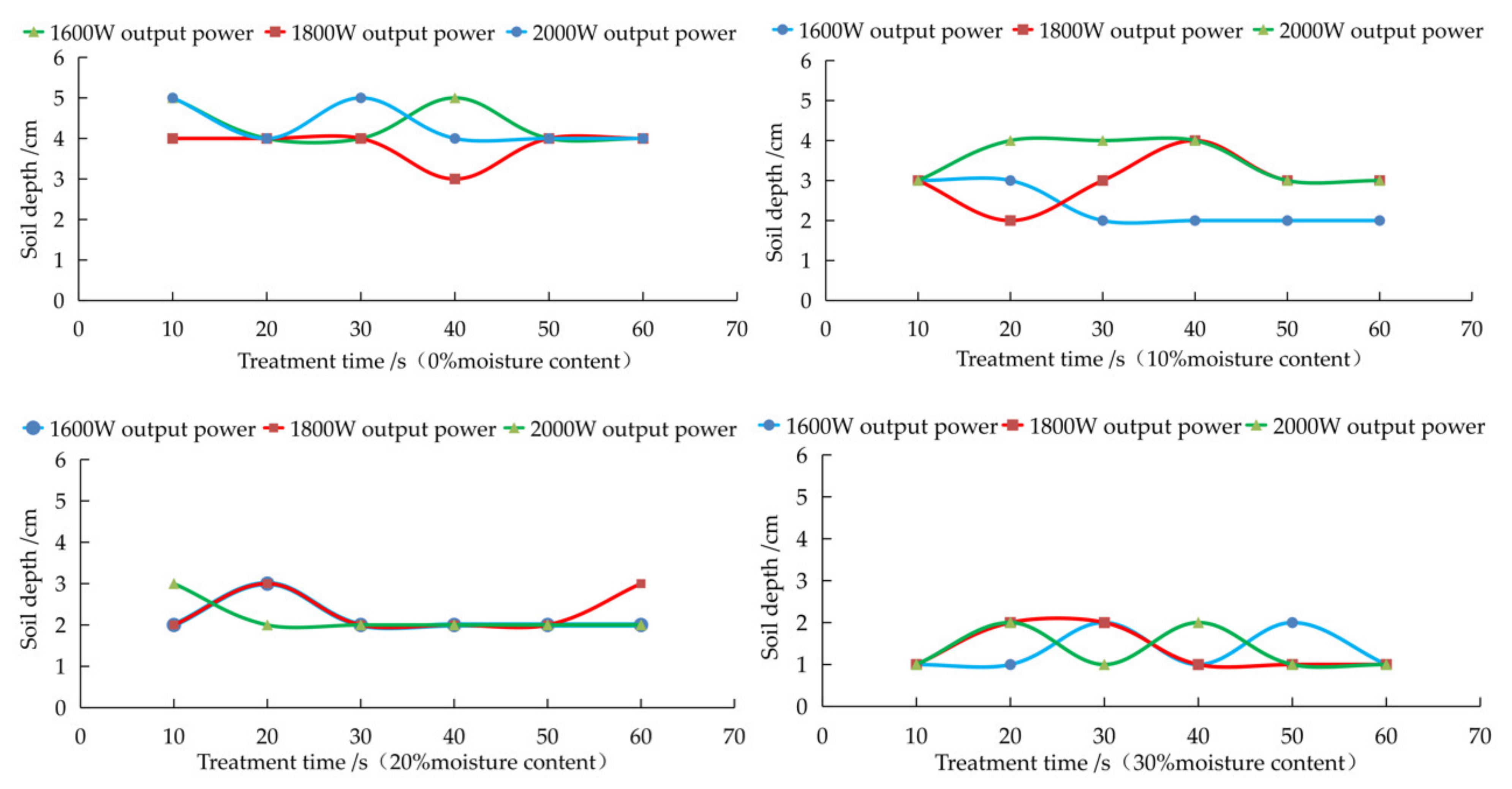

3.1. Simulation Results of Microwave Soil Treatment

3.2. Microwave Soil Treatment Experimental Results

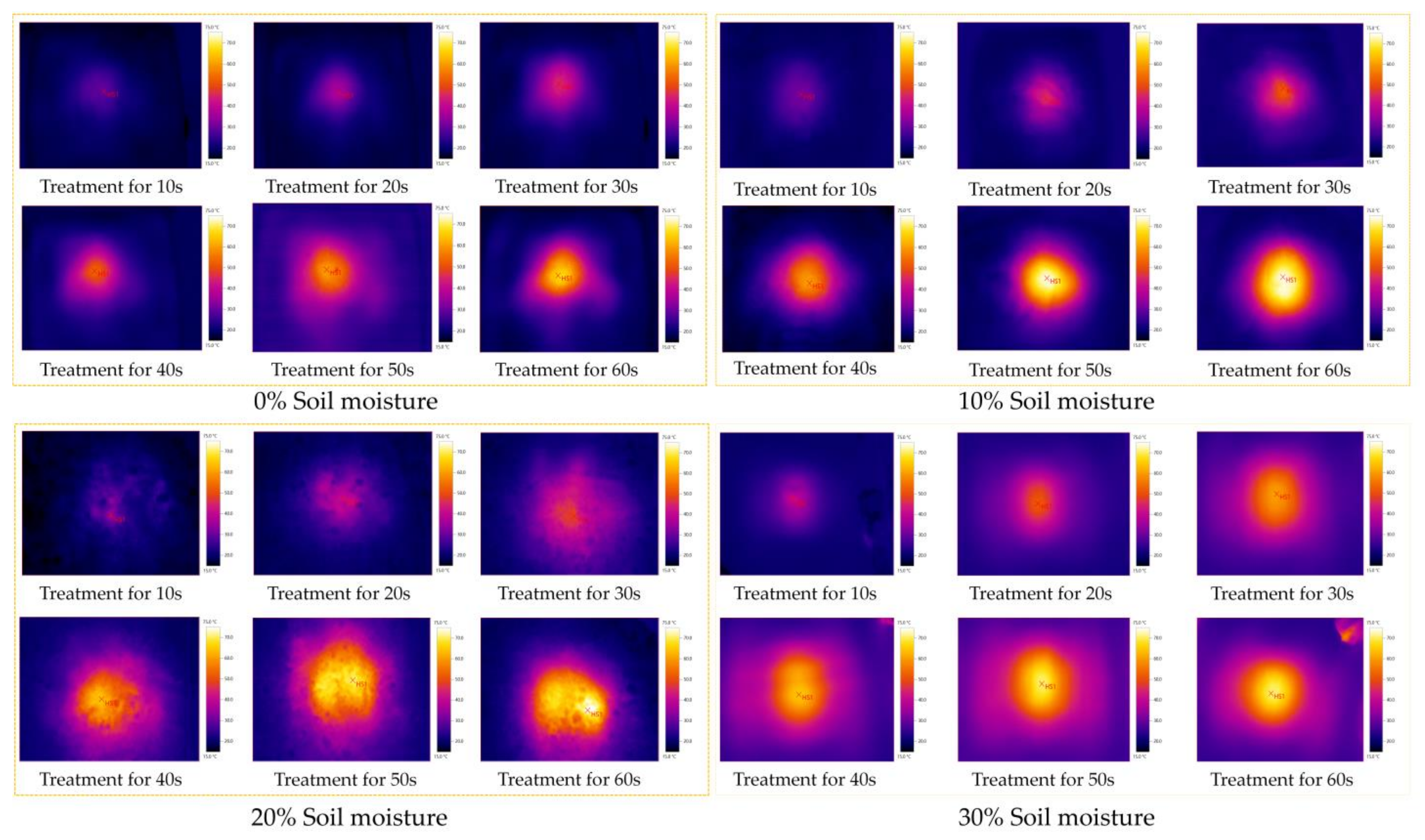

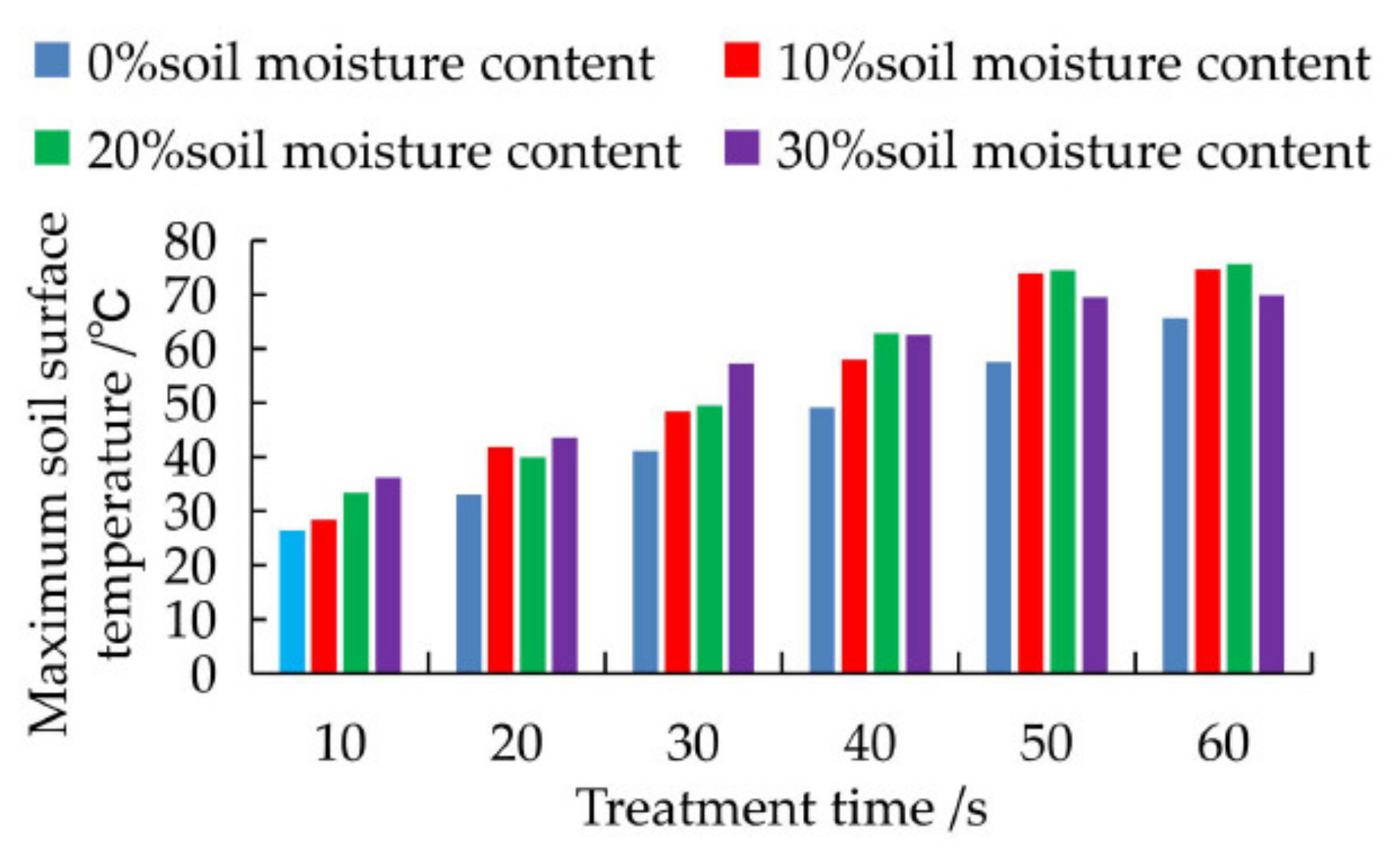

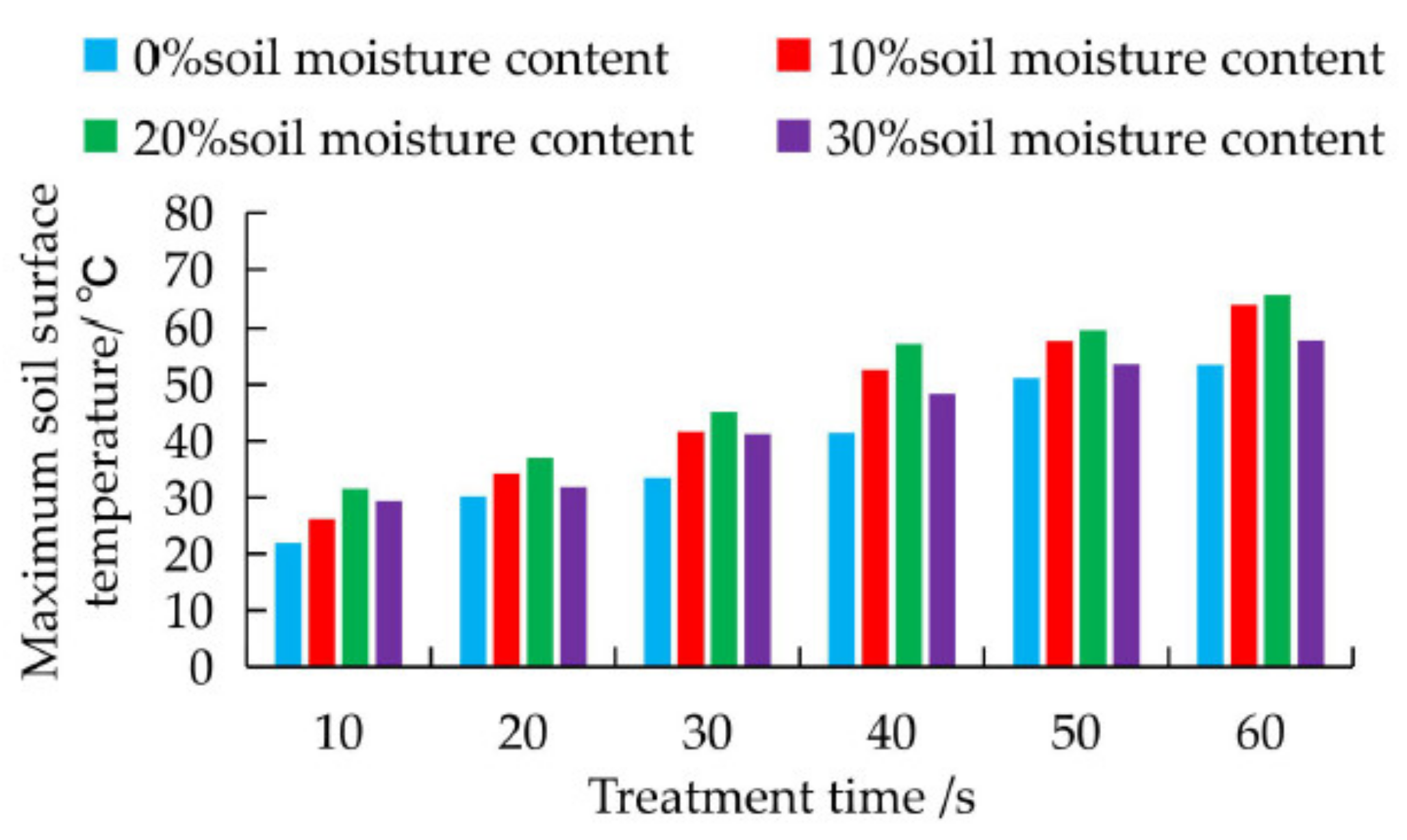

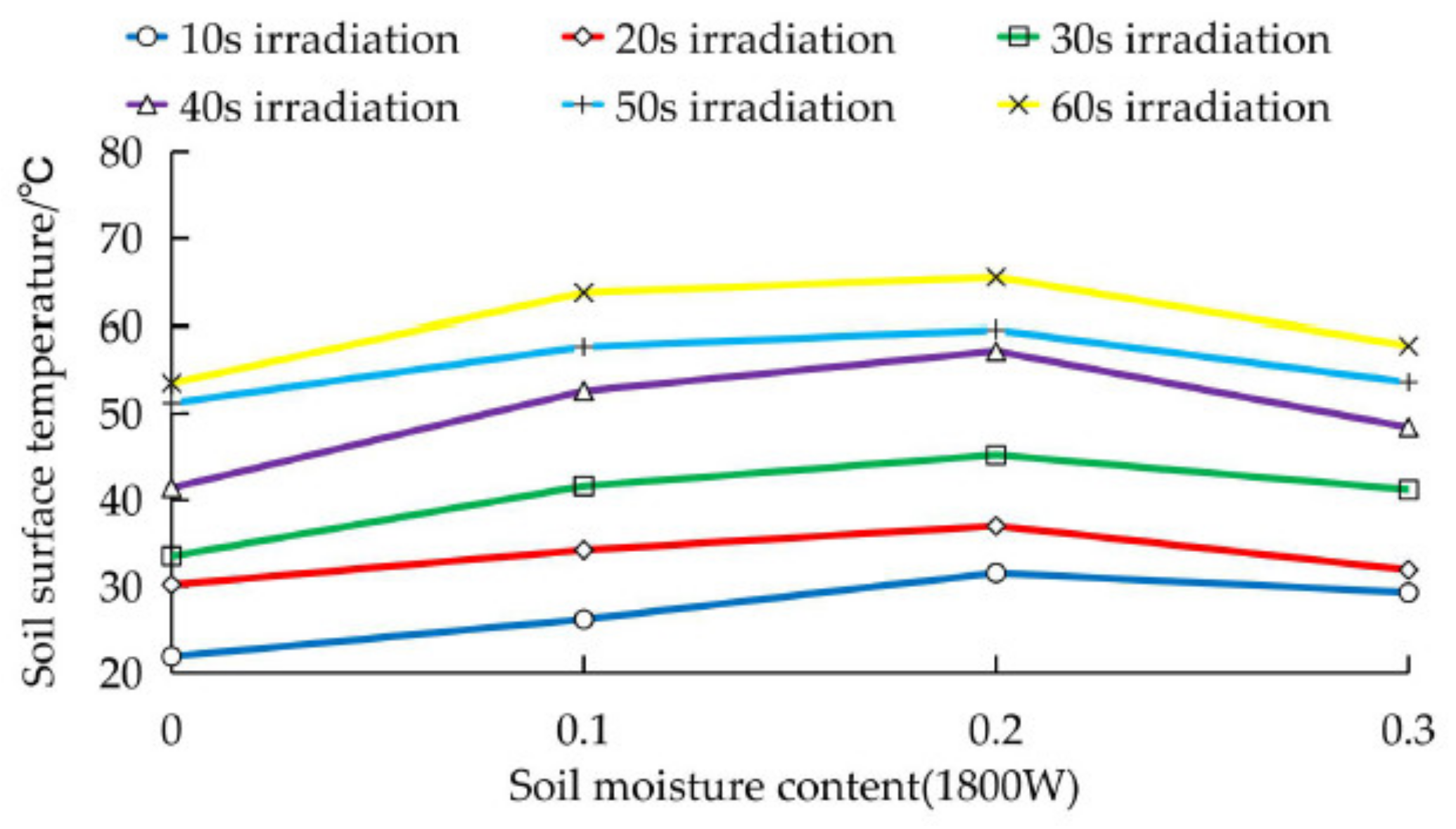

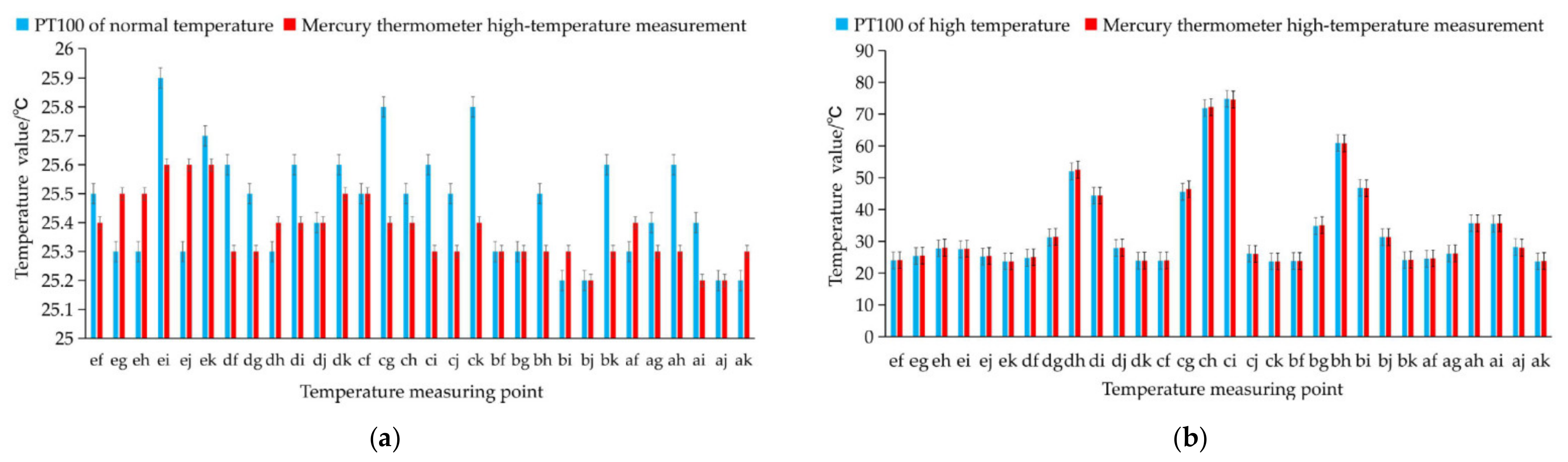

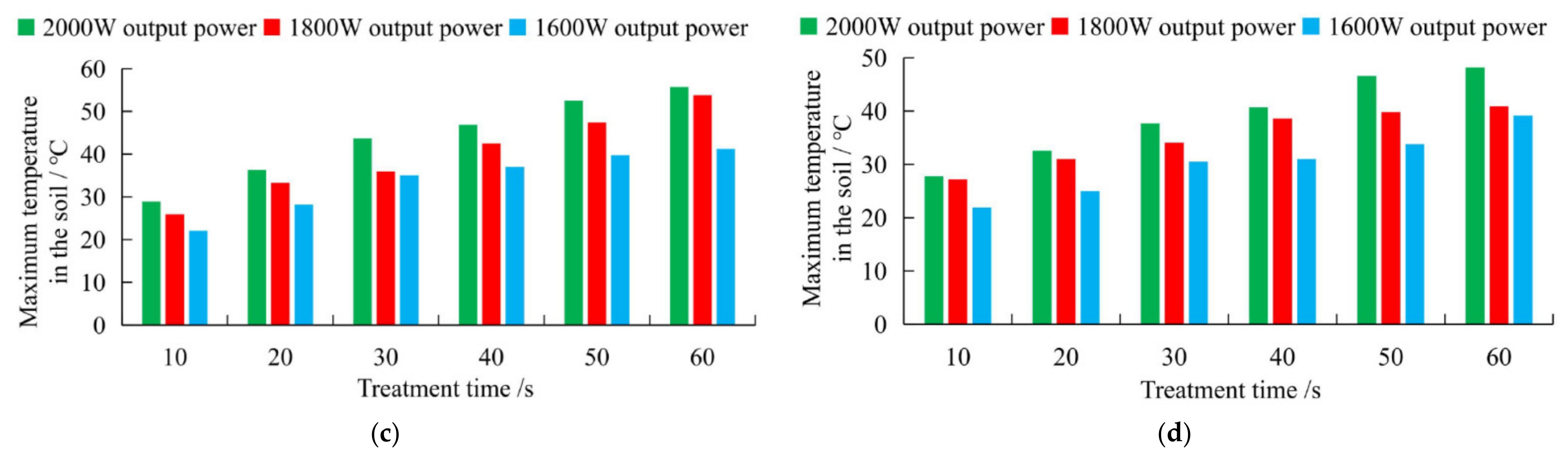

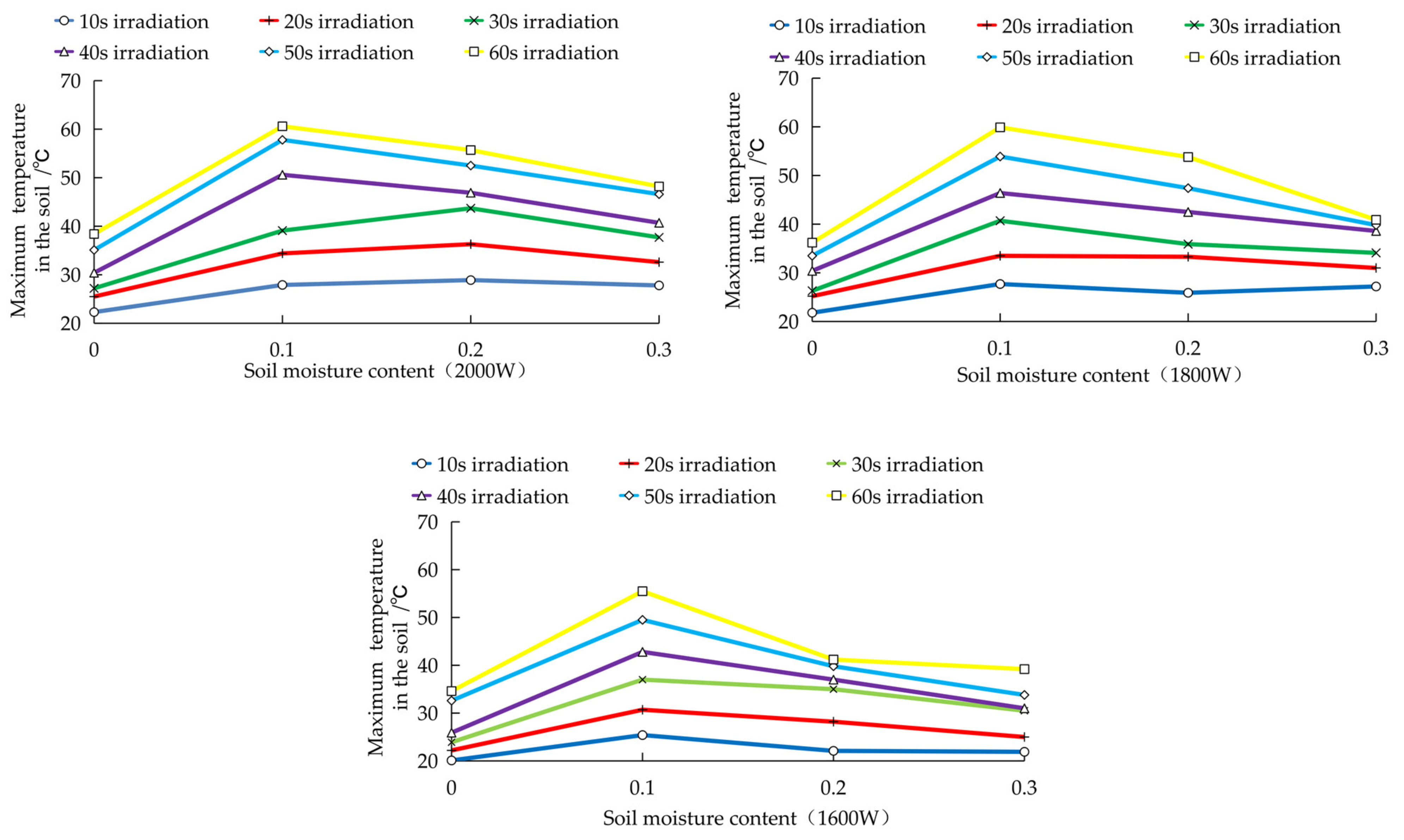

3.2.1. Surface Temperature Experimental Results of Microwave Soil Treatment

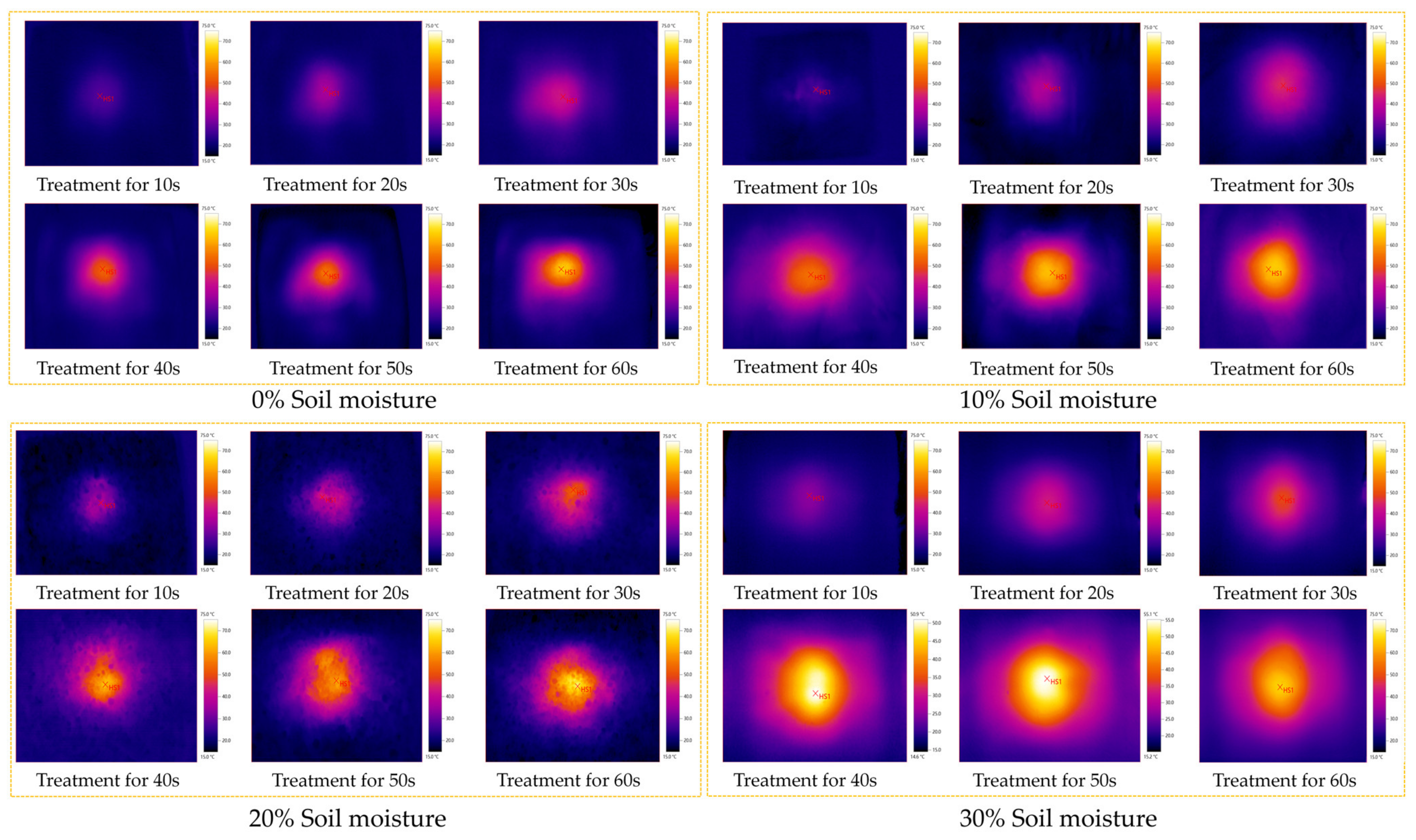

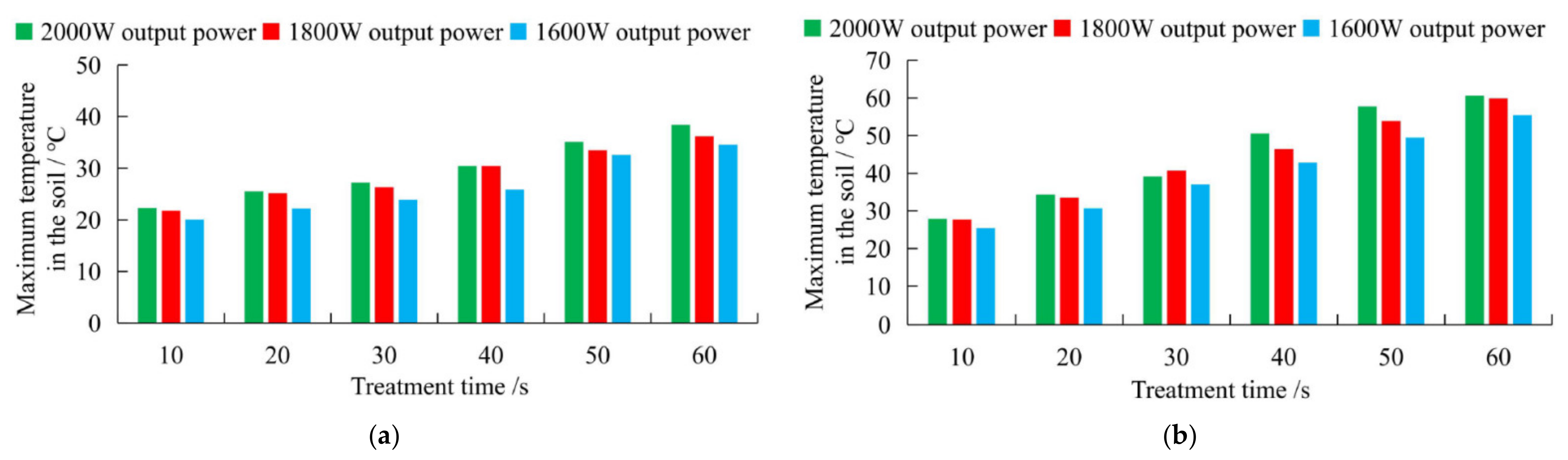

3.2.2. Experimental Results of the Soil Internal Temperature

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lazarova, S.; Coyne, D.; Rodríguez, M.G.; Peteira, B.; Ciancio, A. Functional diversity of soil nematodes in relation to the impact of agriculture—A review. Diversity 2021, 13, 64. [Google Scholar] [CrossRef]

- Veerman, C.; Correia, T.P.; Bastioli, C.; Biro, B.; Bouma, J.; Cienciela, E. Caring for Soil Is Caring for Life—Ensure 75% of Soils Are Healthy by 2030 for Healthy Food, People, Nature and Climate; EU Soil Health and Food Mission Board: Brussels, Belgium, 2020. [Google Scholar]

- Haller, H.E. Microwave Energy Applicator. U.S. Patent 20020090268A1, 11 July 2002. [Google Scholar]

- Vela, G.R.; Wu, J.F.; Smith, D. Effect of 2450 MHz microwave radiation on some soil microorganisms in situ. Soil Sci. 1976, 121, 44–51. [Google Scholar] [CrossRef]

- Wang, X.N.; Cao, A.C.; Yan, D.D.; Qian, W.A.; Huang, B.; Zhu, J.H.; Wang, Q.X.; Yuan, L.I.; Ouyang, C.B.; Guo, M.X. Evaluation of soil flame disinfestation (SFD) for controlling weeds, nematodes and fungi. J. Integr. Agric. 2020, 19, 164–172. [Google Scholar] [CrossRef]

- Mingyou, W.; Hongru, X.; Weidong, S.; Ting, Z.; Run, Z.; Suwei, X. Effects of microwave treatment on root-knot nematode in greenhouse continuous cropping soil. Chin. J. Agric. Mech. 2013, 34, 95–99. [Google Scholar]

- Kissell Charles, W.; Clark William, J. Systems and Methods for in Situ Soil Sterilization, Insect Extermination and Weed Killing. U.S. Patent AU2002330263, 12 December 2003. [Google Scholar]

- Fanti, A.; Spanu, M.; Lodi, M.B.; Desogus, F.; Mazzarella, G. Nonlinear analysis of oil microwave heating: Application to agricultural oils disinfection. IEEE J. Multiscale Multiphysics Comput. Tech. 2017, 2, 105–114. [Google Scholar] [CrossRef]

- O’Brien, M. Microwave: A Fresh Look at Old Technology for Weed Control. Aust. Cottongrower 2017, 38, 26–28. [Google Scholar]

- Wang, M.; Song, W.; Wang, J.; Fei, S.; Chen, H.; Zhou, H. Application of Physical Prevention and Control Technology. Agric. Eng. 2010, 5, 18–20. [Google Scholar]

- Fu, D.; Zhou, T.; Qian, K.J. Study on Microwave Sterilization and Its Mechanism for Biosolids. J. Microw. Sci. 2003, 19, 70–72,82. [Google Scholar]

- Nelson, S.O.; Stetson, L.E. Comparative effectiveness of 39- and 2450-MHz electric fields for control of rice weevils in wheat. J. Econ. Entomol. 1974, 67, 592–595. [Google Scholar] [CrossRef]

- Ferriss, R. Effects of microwave oven treatment on microorganisms in soil. Phytopathology 1984, 74, 121–126. [Google Scholar] [CrossRef]

- Speir, T.W.; Cowling, J.C.; Sparling, G.P.; West, A.W.; Corderoy, D.M. Effects of microwave radiation on the microbial biomass, phosphatase activity and levels of extractable N and P in a low fertility soil under pasture. Soil Biol. Biochem. 1986, 18, 377–382. [Google Scholar] [CrossRef]

- Hendricks, C.W.; Pascoe, N. Soil mcirobial biomass estimates using 2450 MHz microwave irradiation. Plant Soil 1988, 110, 39–47. [Google Scholar] [CrossRef]

- Li, G. Research and Experimental Device Design of Microwave Pest Control in Grain; Dalian University of Technology: Dalian, China, 2011. [Google Scholar]

- Taflove, A. Computational Electrodynamics: The Finite-Difference Time-Domain Method; Artech House: Boston, MA, USA, 1998. [Google Scholar]

- Mironov, V.L.; Bobrov, P.P.; Fomin, S.V.; Karavaiskii, A.Y. Generalized refractive mixing dielectric model of moist soils considering ionic relaxation of soil water. Russ. Phys. J. 2013, 56, 319–324. [Google Scholar] [CrossRef]

- Rahi, G.S.; Rich, J.R. Effect of Moisture on Efficiency of Microwaves to Control Plant-Parasitic Nematodes in Soil. J. Microw. Power Electromagn. Energy 2011, 45, 86–93. [Google Scholar] [CrossRef]

- Rahi, G.S.; Rich, J.R. Potential of Microwaves to Control Plant-Parasitic Nematodes in Soil. J. Microw. Power Electromagn. Energy 2007, 42, 5–12. [Google Scholar] [CrossRef]

- Khan, M.J.; Brodie, G.; Gupta, D. Effect of microwave (2.45 GHz) treatment of soil on yield components of wheat (Triticum aestivum L.). J. Microw. Power Electromagn. Energy 2016, 50, 191–200. [Google Scholar] [CrossRef]

- Rajamannan, A.H.J. Method for killing soil pathogens with micro-wave energy. U.S. Patent US5287818A, 22 February 1994. [Google Scholar]

- Li, X.; Yi, X. Method for the Determination of Soil Water Content GB 7172-87; Beijing Agricultural University: Beijing, China, 1987. [Google Scholar]

- Brodie, G.; Pasma, L.; Bennett, H.; Harris, G.; Woodworth, J. Evaluation of microwave soil pasteurization for controlling germination of perennial ryegrass (Lolium perenne) seeds. Plant Prot. Q. 2007, 22, 150–154. [Google Scholar]

- Cooper, A.P.; Brodie, G. The effect of microwave radiation on keyoil parameters. Plant Prot. Q. 2009, 24, 67–70. [Google Scholar]

- Stratton, A.J. Electromagnetic Theory; Wiley: New Jersey, NJ, USA, 1941. [Google Scholar]

- Fan, R. Research on Raisin Radio Frequency Sterilization Technology; Northwest A&F University: Xianyang, China, 2019. [Google Scholar]

- Li, Y.; Shao, M.; Wang, W.; Wang, Q.; Zhang, J.; Lai, J. Effects of texture on soil thermal properties. Trans. Chin. Soc. Agric. Eng. 2003, 4, 62–65. [Google Scholar]

- Nelson, S.O. A review and assessment of microwave energy for soil treatment to control pests. Trans. ASAE 1996, 39, 281–289. [Google Scholar] [CrossRef]

- Brodie, G.; Hamilton, S.; Woodworth, J. An assessment of microwave oil pasteurization for killing weeds and weeds. Plant. Prot. Q. 2007, 22, 143–149. [Google Scholar]

- Brodie, G.; Ryan, C.; Lancaster, C. Microwave technologies as part of an integrated weed management strategy: A review. Int. J. Agron. 2012, 2012, 636905. [Google Scholar] [CrossRef]

- Wang, S.; Tang, J.; Johnson, J.A.; Mitcham, E.; Hansen, J.D.; Cavalieri, R.P.; Bower, J.; Biasi, B. Process protocols based on radio frequency energy to control field and storage pests in in-shell walnuts. Postharvest Biol. Technol. 2002, 26, 265–273. [Google Scholar] [CrossRef]

- Wahid, F.A.; Wickliffe, J.; Wilson, M.; van Sauers, A.; Bond, N.; Hawkins, W.; Mans, D.; Lichtveld, M. Presence of pesticide residues on produce cultivated in Suriname. Environ. Monit. Assess. 2017, 189, 303. [Google Scholar] [CrossRef]

- Yigit, N.; Velioglu, Y.S. Effects of processing and storage on pesticide residues in foods. Crit. Rev. Food Sci. Nutr. 2020, 60, 3622–3641. [Google Scholar] [CrossRef]

- Liu, Z.; Gao, Y.; Liu, Z.; Duan, A. Effects of rainfall characteristics and mulching patterns on soil moisture in wheat fields. Trans. Chin. Soc. Agric. Eng. 2012, 28, 113–120. [Google Scholar]

- Léonard, J.; Ancelin, O.; Ludwig, B.; Richard, G. Analysis of the dynamics of soil infiltrability of agricultural soils from continuous rainfall-runoff measurements on small plots. J. Hydrol. 2006, 326, 122–134. [Google Scholar] [CrossRef]

| Simulation Parameters | Value (Unit) |

|---|---|

| Soil field length (L1) | 30 (cm) |

| Soil field width (L2) | 30 (cm) |

| Soil field height (H) | 20 (cm) |

| Distance from the horn antenna to the soil (gap) | 5 (cm) |

| Incident frequency (frequency) | 2.45 (GHz) |

| Output power (power) | 2000 (W) |

| PML (perfectly matched layer) thickness (t_pml) | 5 (cm) |

| Relative permeability (μr) | 1 |

| Conductivity | 0 (S/m) |

| Dielectric loss factor (ε′) | 0 |

| Relative permittivity of air | 1 |

| Maximum element size for meshing | C_const/frequency/4 |

| Minimum element size for meshing | 0.1 |

| Maximum cell growth rate for meshing | 1.5 |

| Curvature factor | 0.6 |

| Narrow area resolution | 0.5 |

| Mass Fraction of Water in Soil | Re (eps) | Im (eps) |

|---|---|---|

| 0.021 | 2.99297 | 0 |

| 0.168 | 6.23886 | 0.76203 |

| 0.190 | 9.63988 | 1.10192 |

| 0.248 | 17.14600 | 1.89194 |

| 0.292 | 23.63777 | 3.62815 |

| 0.335 | 26.90753 | 5.08877 |

| Power/W | 2000 | 1800 | 1600 | |

|---|---|---|---|---|

| Treatment Time/s | ||||

| 60 | ||||

| 50 | ||||

| 40 | ||||

| 30 | ||||

| 20 | ||||

| 10 | ||||

| Formula | Temp1 (10~30 s) | Temp1 (40~60 s) | |

|---|---|---|---|

| Moisture Content | |||

| 0% | −2.23 | 6.04 | |

| 10% | 4.56 | 1.16 | |

| 20% | −1.86 | −0.67 | |

| 30% | 3.37 | 7.19 | |

| Formula | Temp2 (10~30 s) | Temp2 (40~60 s) | |

|---|---|---|---|

| Moisture Content | |||

| 0% | −0.8 | −1.06 | |

| 10% | 6.36 | 11.32 | |

| 20% | −0.24 | 5.59 | |

| 30% | 14.21 | 22.47 | |

| Power/W | 2000 | 1800 | 1600 | |

|---|---|---|---|---|

| Treatment Time/s | ||||

| 60 | ||||

| 50 | ||||

| 40 | ||||

| 30 | ||||

| 20 | ||||

| 10 | ||||

| Electric field and temperature values at a microwave output power of 2.0 kW | ||||||||

| Soil moisture/% | Air-soil critical field strength/V/m | Maximum soil surface temperature after microwave treatment/°C | ||||||

| Treatment 10 s | Treatment 20 s | Treatment 30 s | Treatment 40 s | Treatment 50 s | Treatment 60 s | |||

| 0 | 11,490 | 26.5 | 33 | 41.1 | 49.2 | 57.5 | 65.7 | |

| 10 | 10,535 | 28.4 | 41.9 | 48.4 | 58 | 73.9 | 74.7 | |

| 20 | 5208.6 | 33.4 | 40 | 49.5 | 62.9 | 70.5 | 75.6 | |

| 30 | 3149.3 | 36.2 | 43.5 | 57.2 | 62.6 | 69.5 | 69.9 | |

| Soil moisture/% | Field strength at the first wave peak in the soil/V/m | Average depth of the highest temperature inside the soil/cm | Maximum temperature inside the soil after microwave treatment/°C | |||||

| Treatment 10 s | Treatment 20 s | Treatment 30 s | Treatment 40 s | Treatment 50 s | Treatment 60 s | |||

| 0 | 7194.1 | 4.33 | 22.3 | 25.5 | 27.2 | 30.4 | 35.1 | 38.4 |

| 10 | 5059.1 | 3.50 | 27.9 | 34.4 | 39.1 | 50.6 | 57.8 | 60.6 |

| 20 | 3171.2 | 2.16 | 28.9 | 36.3 | 43.7 | 46.9 | 52.5 | 55.7 |

| 30 | 2428.1 | 1.33 | 27.8 | 32.6 | 37.7 | 40.7 | 46.6 | 48.2 |

| Electric field and temperature values at a microwave output power of 1.8 kW | ||||||||

| Soil moisture/% | Air-soil critical field strength/V/m | Maximum soil surface temperature after microwave treatment/°C | ||||||

| Treatment 10 s | Treatment 20 s | Treatment 30 s | Treatment 40 s | Treatment 50 s | Treatment 60 s | |||

| 0 | 8679.3 | 25.5 | 32.4 | 38.5 | 48.9 | 55.6 | 63.7 | |

| 10 | 6597.9 | 26.2 | 34.2 | 41.6 | 52.6 | 61.7 | 63.7 | |

| 20 | 3885.6 | 31.54 | 37 | 45.2 | 57.2 | 59.6 | 70.5 | |

| 30 | 2920.0 | 30.1 | 39 | 45.3 | 50.9 | 55.1 | 64.1 | |

| Soil moisture/% | Field strength at the first wave peak in the soil/V/m | Average depth of the highest temperature inside the soil/cm | Maximum temperature inside the soil after microwave treatment/°C | |||||

| Treatment 10 s | Treatment 20 s | Treatment 30 s | Treatment 40 s | Treatment 50 s | Treatment 60 s | |||

| 0 | 5697.1 | 3.83 | 21.8 | 25.2 | 26.3 | 30.4 | 33.5 | 36.2 |

| 10 | 4922.8 | 3.0 | 27.7 | 33.5 | 40.7 | 46.4 | 53.9 | 59.9 |

| 20 | 2555.6 | 2.33 | 25.9 | 33.3 | 35.9 | 42.5 | 47.4 | 58.8 |

| 30 | 2269.9 | 1.33 | 27.2 | 31.0 | 34.1 | 38.6 | 39.8 | 40.9 |

| Electric field and temperature values at a microwave output power of 1.6 kW | ||||||||

| Soil moisture/% | Air-soil critical field strength/V/m | Maximum soil surface temperature after microwave treatment/°C | ||||||

| Treatment 10 s | Treatment 20 s | Treatment 30 s | Treatment 40 s | Treatment 50 s | Treatment 60 s | |||

| 0 | 6352.2 | 21.9 | 30.2 | 33.5 | 41.4 | 51.2 | 53.5 | |

| 10 | 6219.7 | 26 | 32 | 41 | 42.9 | 52.1 | 57.7 | |

| 20 | 3617.2 | 26.1 | 31.3 | 41.6 | 49.4 | 54.7 | 59.5 | |

| 30 | 2379.5 | 29.3 | 31.9 | 41.2 | 48.4 | 53.6 | 57.8 | |

| Soil moisture/% | Field strength at the first wave peak in the soil/V/m | Average depth of the highest temperature inside the soil/cm | Maximum temperature inside the soil after microwave treatment/°C | |||||

| Treatment 10 s | Treatment 20 s | Treatment 30 s | Treatment 40 s | Treatment 50 s | Treatment 60 s | |||

| 0 | 5533.2 | 4.33 | 20.1 | 22.2 | 23.9 | 25.9 | 32.6 | 34.6 |

| 10 | 4632.5 | 2.33 | 25.4 | 30.7 | 37 | 42.8 | 49.5 | 55.5 |

| 20 | 2169.9 | 2.16 | 22.1 | 28.2 | 35.0 | 37.0 | 39.8 | 41.2 |

| 30 | 1728.7 | 1.33 | 21.9 | 25.0 | 30.5 | 31.0 | 33.8 | 39.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, X.; Zhai, C.; Yang, S.; Ma, H.; Zhao, C. Simulations and Experiments of the Soil Temperature Distribution after 2.45-GHz Short-Time Term Microwave Treatment. Agriculture 2021, 11, 933. https://doi.org/10.3390/agriculture11100933

Sun X, Zhai C, Yang S, Ma H, Zhao C. Simulations and Experiments of the Soil Temperature Distribution after 2.45-GHz Short-Time Term Microwave Treatment. Agriculture. 2021; 11(10):933. https://doi.org/10.3390/agriculture11100933

Chicago/Turabian StyleSun, Xiaohe, Changyuan Zhai, Shuo Yang, Haolin Ma, and Chunjiang Zhao. 2021. "Simulations and Experiments of the Soil Temperature Distribution after 2.45-GHz Short-Time Term Microwave Treatment" Agriculture 11, no. 10: 933. https://doi.org/10.3390/agriculture11100933