Enabling Year-round Cultivation in the Nordics-Agrivoltaics and Adaptive LED Lighting Control of Daily Light Integral

Abstract

:1. Introduction

- sole-source LED lighting for indoor cultivation during the winter months;

- adaptive LED lighting control of DLI to supplement the light changes and extend the greenhouse growing season through spring and autumn;

- an outdoor cultivation phase in the summer months;

- greenhouses or other buildings with integrated PV to produce electricity.

2. Materials and Methods

2.1. Data Sources

- Global irradiance on the horizontal plane (Gh, W·m−2);

- Direct irradiance component on the horizontal plane (Gb, W·m−2);

- Diffuse irradiance component on the horizontal plane (Gd, W·m−2);

- Ambient temperature calculated at 2 m above the ground (Ta, °C).

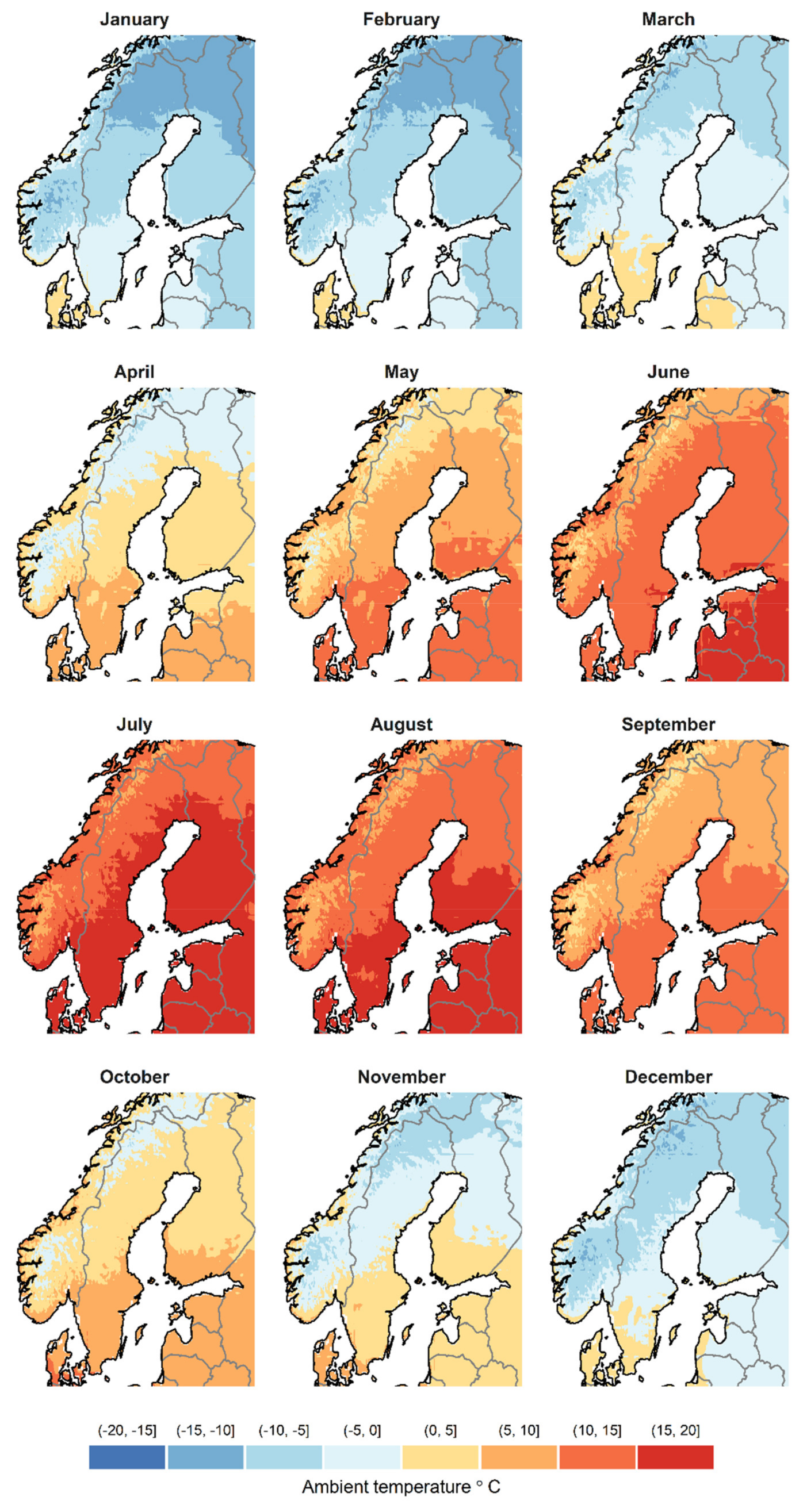

2.2. Ambient Temperature

- April to October in southern latitudes (at 55° N, about 210 days);

- May to September in the central regions (at 63° N, about 180 days);

- June to August in Iceland and the northernmost regions (at 70° N, about 100 days).

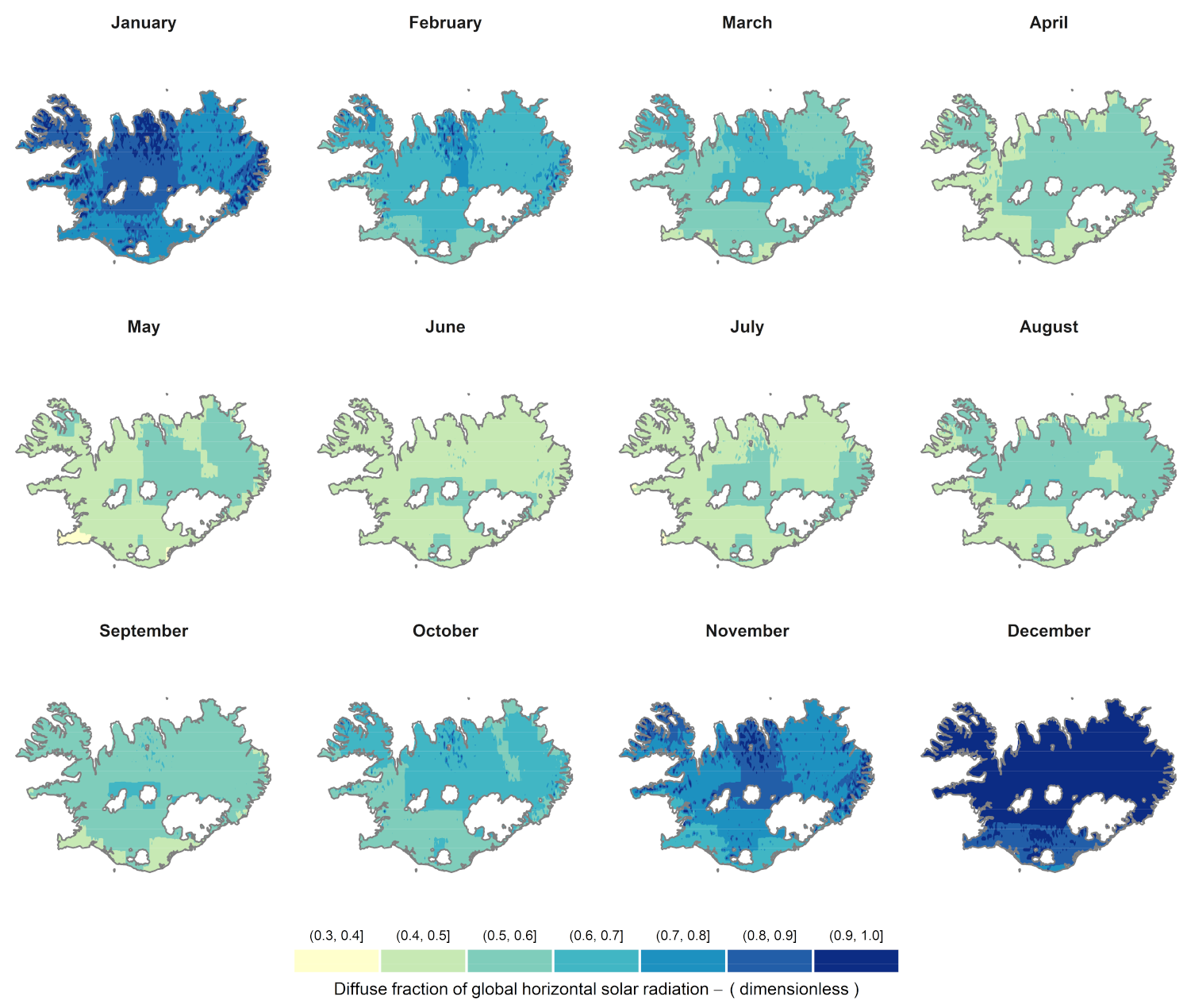

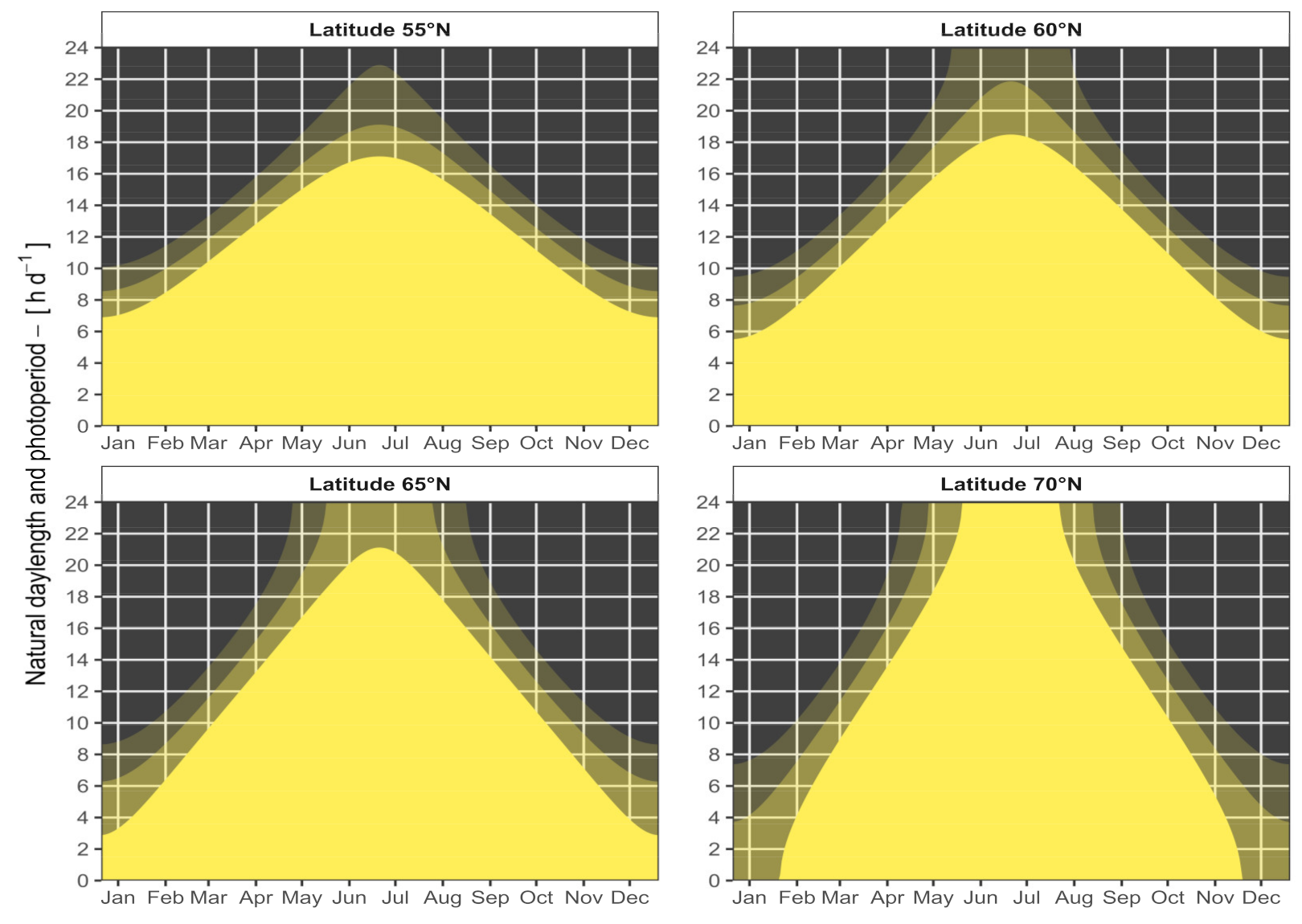

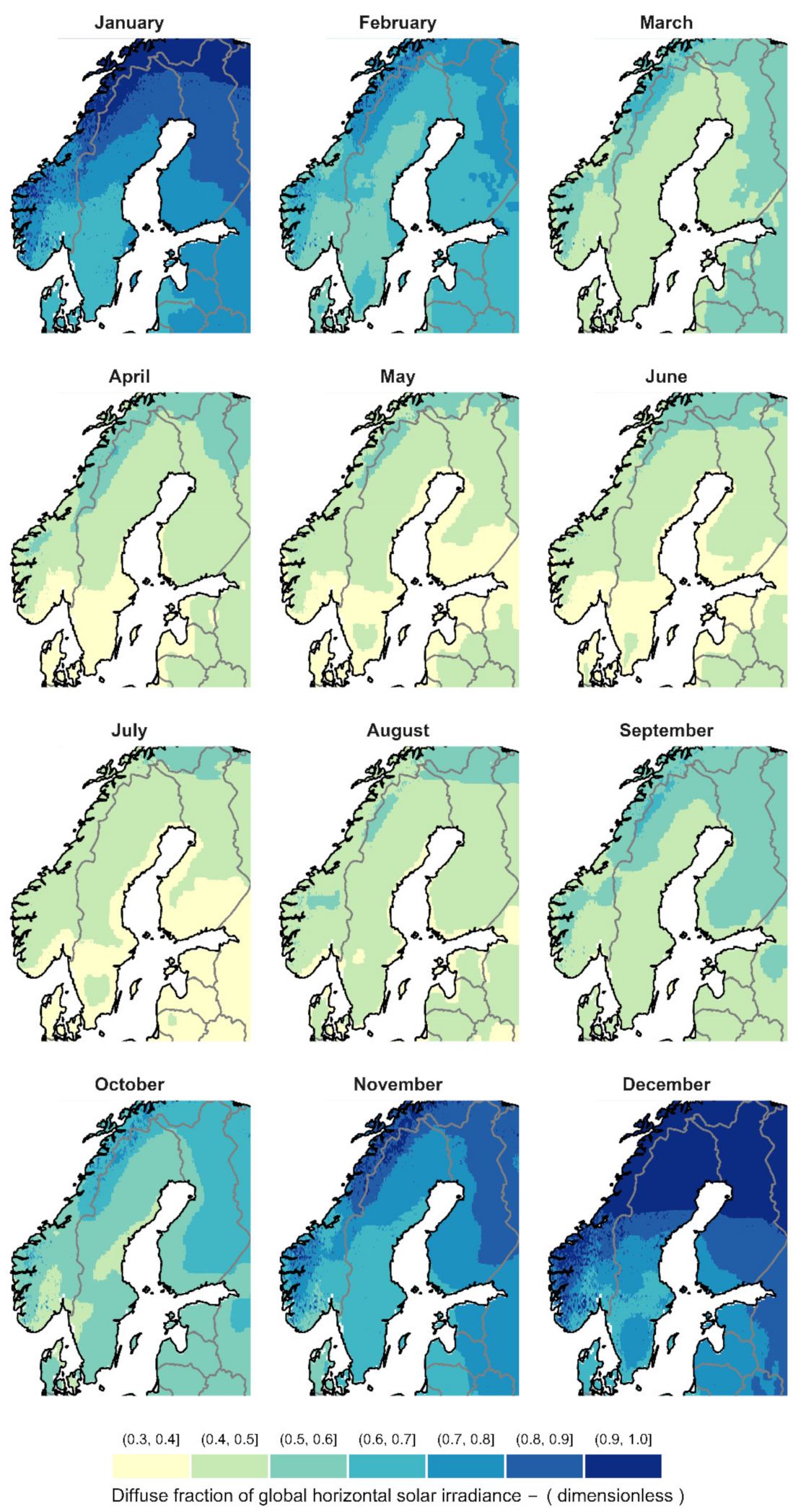

2.3. Outdoor Light Conditions

2.3.1. Natural Daylength and Photoperiod

2.3.2. Estimating PPFD from Global Irradiance

2.4. Indoor Light Conditions

2.4.1. Sole-Source Lighting

2.4.2. Greenhouse Light Transmission

2.4.3. Greenhouse Lighting Control Protocols

2.5. Year-Round Cultivation Concept

- late-May to late-August: transfer outside for outdoor cultivation;

- late-August to October: greenhouse cultivation with supplementary lighting;

- November to January: indoor growth room cultivation with sole-source lighting;

- February to late May: greenhouse cultivation with supplementary lighting.

2.5.1. Outdoor Cultivation

2.5.2. Indoor Cultivation in Growth Room with Sole-Source Lighting

- PPE = 2.0 µmol·J−1, considering a standard LED luminaire;

- PPE = 2.75 µmol·J−1, for a state-of-the-art standard, LED luminaire;

- PPE = 3.5 µmol·J−1, to account for upcoming developments.

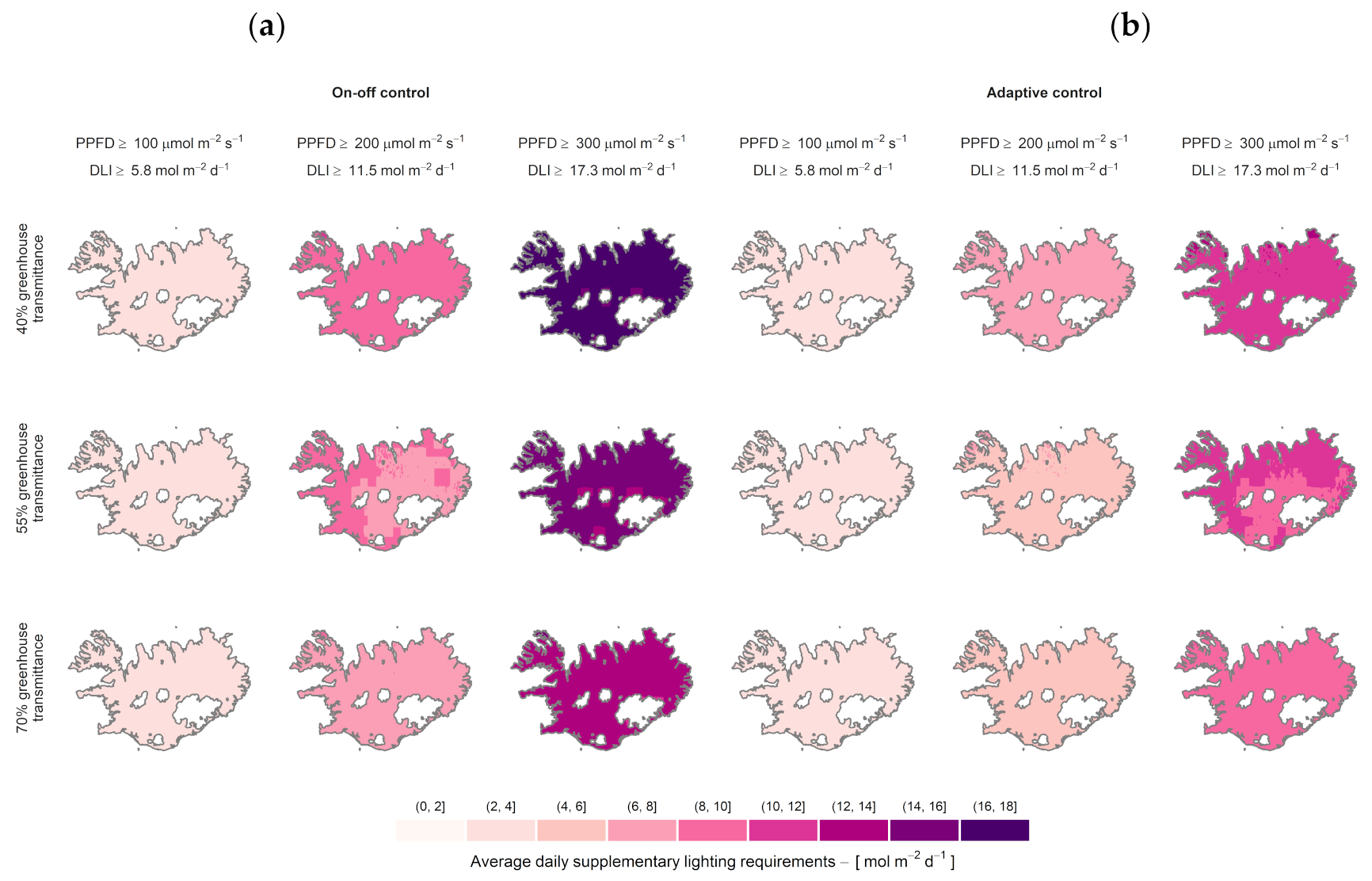

2.5.3. Greenhouse Cultivation with Supplementary Lighting

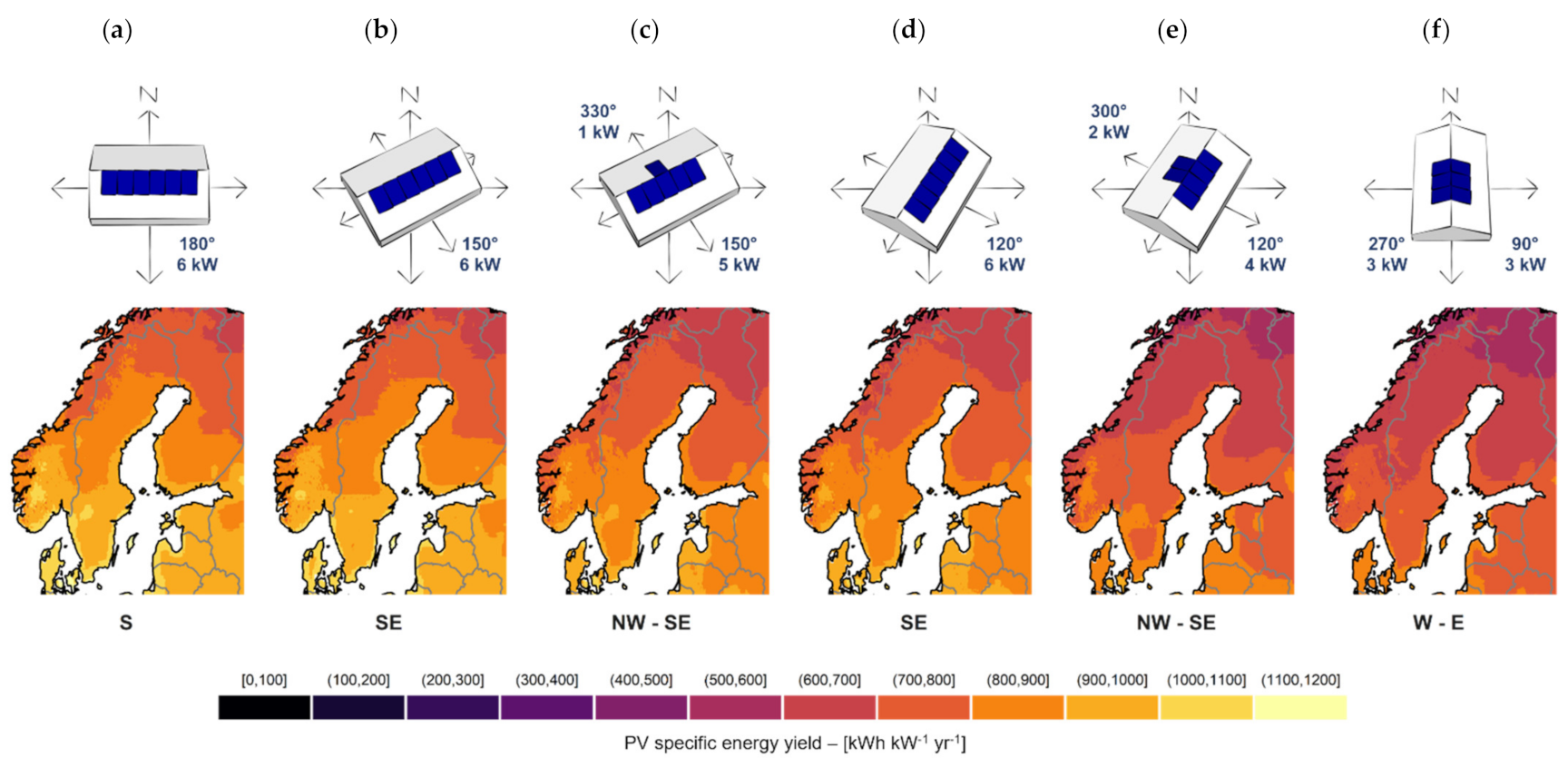

2.6. Photovoltaics on Greenhouses

PV System Parameters

- PPV,STC: 6 kW;

- PV technology: crystalline silicon (c-Si);

- mounting position: fixed and building-integrated;

- horizon: yes;

- estimated system losses: 14% (PVGIS default).

2.7. Data Analysis

3. Results

3.1. Outdoor Ambient Conditions

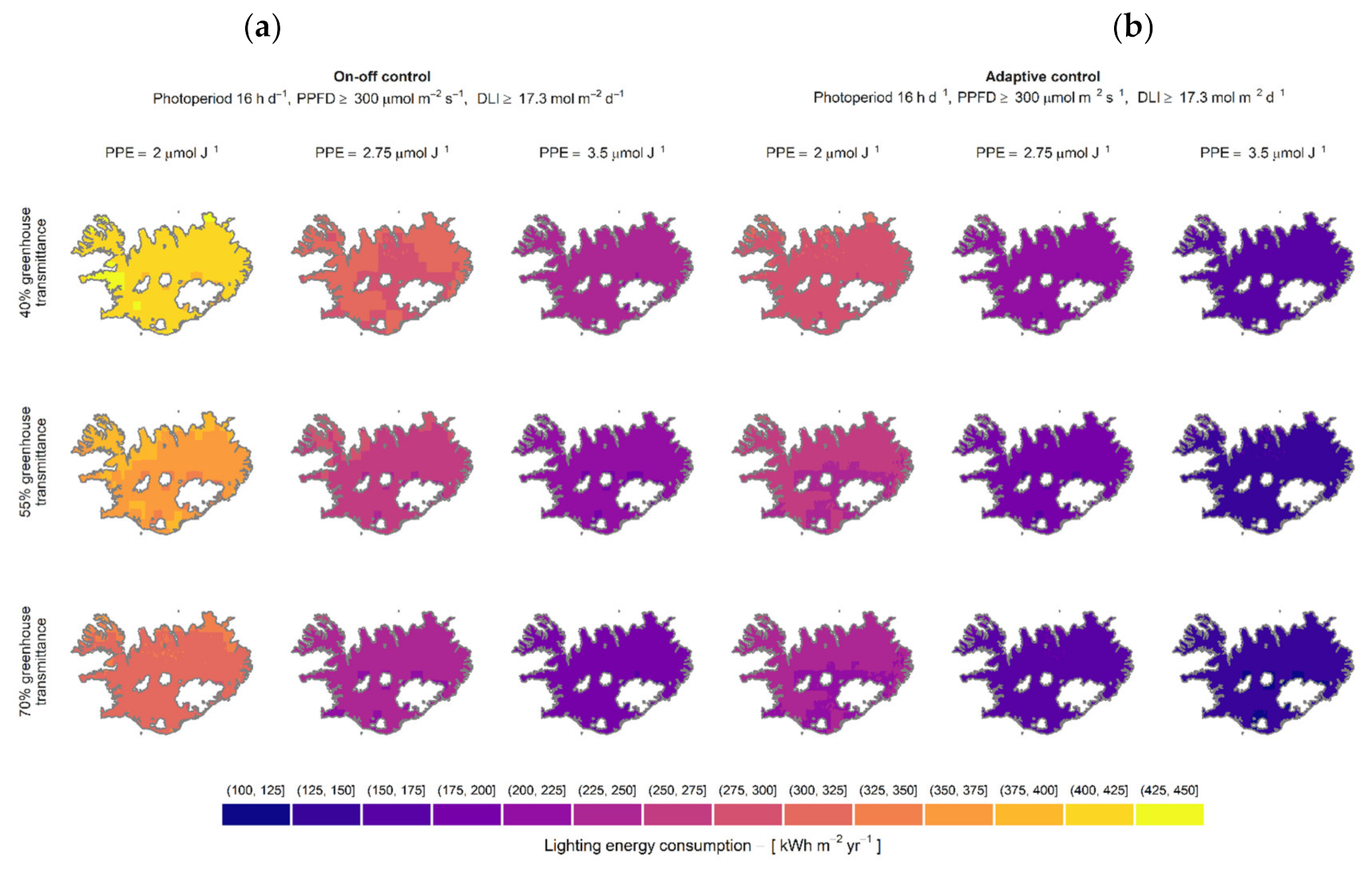

3.2. Sole-Source Lighting Requirements

3.3. Greenhouse Supplementary Lighting Requirements

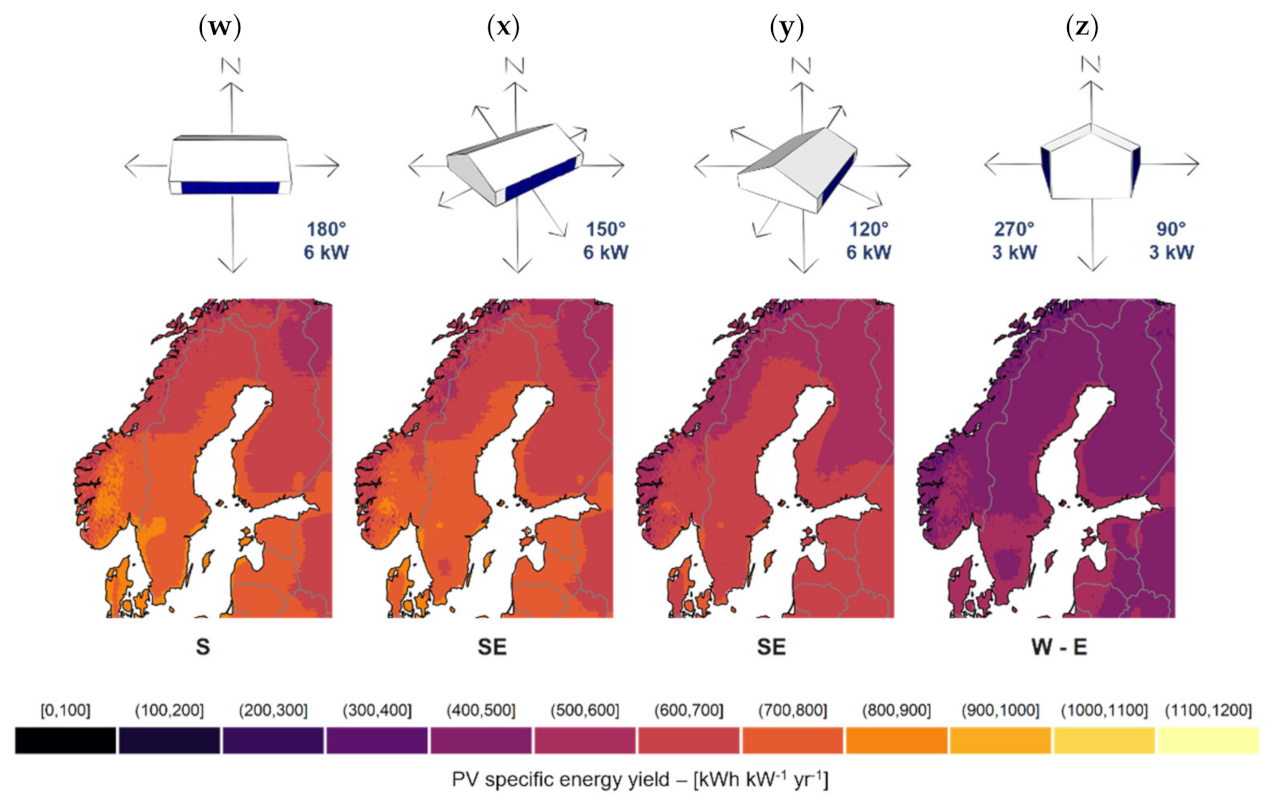

3.4. PV Systems Specific Energy Yield

3.5. Year-Round Concept Implementation for One Location

4. Discussion

5. Conclusions

- Ambient temperature and natural DLI levels are suitable for outdoor cultivation during at least three months in the summer for most of the region.

- Greenhouses can be used to start the cultivation earlier in spring and extend the vegetation period until later in autumn.

- Transmittance levels of natural light inside the greenhouse can significantly influence the supplementary lighting needed for the plants.

- Among the options compared, LED lamps with adaptive lighting control have the highest energy-saving potential. They can benefit from the available sunlight inside the greenhouse, avoiding unnecessary energy waste and supplementing only enough light to reach the DLI target for the cultivated species.

- During the winter months, indoor cultivation in closed growth chambers offers a standardized and controlled environment independent from outdoor conditions.

- Light intensity and duration of the photoperiod together with the efficacy of the lamps determine the amount of electricity needed for lighting in the growth room.

- Greenhouses with integrated PV provide an alternative for using the abundant sunshine in the summer and offsetting some of the electricity used for lighting during the darker months.

- To avoid negative effects on the plants caused by excessive shading from the solar panels, careful planning is required based on the design, location, and orientation of the greenhouse.

- Additional studies that consider the investment and running costs for heating and cooling of the growth rooms and greenhouses with regard to the lighting control protocols and LED lamps are necessary. Only when both electrical and thermal energy requirements are evaluated together can the feasibility of the year-round cultivation concept be truly evaluated.

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Swedish Meteorological and Hydrological Institute (SMHI) Climate Indicators—Length of Vegetation Period. Available online: https://www.smhi.se/en/climate/climate-indicators/climate-indicators-length-of-vegetation-period-1.91482 (accessed on 23 August 2020).

- Albright, L.D.; Langhans, R.W. Controlled Environment Agriculture Scoping Study; Electric Power Research Institute: Ithaca, NY, USA, 1996. [Google Scholar]

- Despommier, D. The Vertical Farm: Feeding the World in the 21st Century; Macmillan: New York, NY, USA, 2010. [Google Scholar]

- Vadiee, A.; Martin, V. Energy Analysis and Thermoeconomic Assessment of the Closed Greenhouse—The Largest Commercial Solar Building. Appl. Energy 2013, 102, 1256–1266. [Google Scholar] [CrossRef]

- Nimmermark, S.; Nielsen, J.M. Klimatisering, Belysning, Bevattning Och Mekanisering I Växthus; Alnarp, Sweden, 2014; p. 30. [Google Scholar]

- Stanghellini, C.; Van’t Ooster, B.; Heuvelink, E. Greenhouses: Why? In Greenhouse Horticulture; Wageningen Academic Publishers: Wageningen, The Netherlands, 2018; pp. 15–25. ISBN 978-90-8686-329-7. [Google Scholar]

- Nelson, J.A.; Bugbee, B. Economic Analysis of Greenhouse Lighting: Light Emitting Diodes vs. High Intensity Discharge Fixtures. PLoS ONE 2014, 9, e99010. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fisher, P.; Both, A.J.; Bugbee, B. Supplemental Lighting—Technology, Costs, and Efficiency. In Light Management in Controlled Environments; Lopez, R., Runkle, E.S., Eds.; CreateSpace Independent Publishing Platform: Willoughby, OH, USA, 2017; pp. 74–81. ISBN 978-1-5442-5449-4. [Google Scholar]

- Landis, T.D.; Tinus, R.W.; McDonald, S.E.; Barnett, J.P. Chapter 3: Light. In Atmospheric Environment—The Container Tree Nursery Manual; Agriculture Handbook 674; USDA Forest Service: Washington, DC, USA, 1992; Volume 3, p. 145. [Google Scholar]

- Nelson, P. Greenhouse Operation and Management, 7th ed.; Pearson: Boston, MA, USA, 2011; ISBN 978-0-13-243936-7. [Google Scholar]

- Runkle, E. Strategies for Supplemental Lighting; Greenhouse Product News: Sparta, MI, USA, 2009; p. 50. [Google Scholar]

- Bugbee, B. Effects of Radiation Quality, Intensity, and Duration on Photosynthesis and Growth; Plants, Soils, and Biometeorology Department Utah State University: Logan, UT, USA, 1994; N96-18128; p. 12. [Google Scholar]

- Aphalo, P.J.; Ballaré, C.L.; Scopel, A.L. Plant-Plant Signalling, the Shade-Avoidance Response and Competition. J. Exp. Bot. 1999, 50, 1629–1634. [Google Scholar] [CrossRef]

- Aphalo, P.J. Light Signals and the Growth and Development of Plants—A Gentle Introduction; Department of Biosciences Plant Biology University of Helsinki: Helsinki, Finland, 2010. [Google Scholar]

- McCree, K.J. The Action Spectrum, Absorptance and Quantum Yield of Photosynthesis in Crop Plants. Agric. Meteorol. 1971, 9, 191–216. [Google Scholar] [CrossRef]

- McCree, K.J. Test of Current Definitions of Photosynthetically Active Radiation against Leaf Photosynthesis Data. Agric. Meteorol. 1972, 10, 443–453. [Google Scholar] [CrossRef]

- Craver, J.K.; Lopez, R.G. Control of Morphology by Manipulating Light Quality and Daily Light Integral Using LEDs. In LED Lighting for Urban Agriculture; Springer: Berlin/Heidelberg, Germany, 2016; pp. 203–217. [Google Scholar]

- Riikonen, J.; Kettunen, N.; Gritsevich, M.; Hakala, T.; Särkkä, L.; Tahvonen, R. Growth and Development of Norway Spruce and Scots Pine Seedlings under Different Light Spectra. Environ. Exp. Bot. 2016, 121, 112–120. [Google Scholar] [CrossRef]

- Bantis, F.; Radoglou, K. Morphology, Development, and Transplant Potential of Prunus avium and Cornus sanguinea Seedlings Growing under Different LED Lights. Turk. J. Biol. 2017, 41, 314–321. [Google Scholar] [CrossRef]

- Hernandez, R.; Kubota, C. Light Quality and Photomorphogenensis. In Light Management in Controlled Environments; Lopez, R., Runkle, E.S., Eds.; CreateSpace Independent Publishing Platform: Willoughby, OH, USA, 2017; pp. 29–37. ISBN 978-1-5442-5449-4. [Google Scholar]

- Stuefer, J.F.; Huber, H. Differential Effects of Light Quantity and Spectral Light Quality on Growth, Morphology and Development of Two Stoloniferous Potentilla Species. Oecologia 1998, 117, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Marcelis, L.F.M.; Broekhuijsen, A.G.M.; Meinen, E.; Nijs, E.; Raaphorst, M.G.M. Quantification of the Growth Response to Light Quantity of Greenhouse Grown Crops. In Proceedings of the V International Symposium on Artificial Lighting in Horticulture 711, Lillehammer, Norway, 21–24 June 2005; pp. 97–104. [Google Scholar]

- Gerovac, J.R.; Craver, J.K.; Boldt, J.K.; Lopez, R.G. Light Intensity and Quality from Sole-Source Light-Emitting Diodes Impact Growth, Morphology, and Nutrient Content of Brassica Microgreens. HortScience 2016, 51, 497–503. [Google Scholar] [CrossRef] [Green Version]

- Poorter, H.; Niinemets, Ü.; Ntagkas, N.; Siebenkäs, A.; Mäenpää, M.; Matsubara, S.; Pons, T. A Meta-Analysis of Plant Responses to Light Intensity for 70 Traits Ranging from Molecules to Whole Plant Performance. New Phytol. 2019, 223, 1073–1105. [Google Scholar] [CrossRef] [Green Version]

- Hernandez Velasco, M.; Mattsson, A. Light Quality and Intensity of Light-Emitting Diodes during Pre-Cultivation of Picea abies (L.) Karst. and Pinus sylvestris L. Seedlings—Impact on Growth Performance, Seedling Quality and Energy Consumption. Scand. J. For. Res. 2019, 34, 159–177. [Google Scholar] [CrossRef] [Green Version]

- Canham, A.E.; Canham, A.F. Plants and Light. Sci. Hortic. 1964, 17, 155–160. [Google Scholar]

- Hutchinson, V.A.; Currey, C.J.; Lopez, R.G. Photosynthetic Daily Light Integral during Root Development Influences Subsequent Growth and Development of Several Herbaceous Annual Bedding Plants. HortScience 2012, 47, 856–860. [Google Scholar] [CrossRef] [Green Version]

- Faust, J.E.; Logan, J. Daily Light Integral: A Research Review and High-Resolution Maps of the United States. HortScience 2018, 53, 1250–1257. [Google Scholar] [CrossRef] [Green Version]

- Spaargaren, J.J. Supplemental Lighting for Greenhouse Crops; Hortilux Schreder: Monster, The Netherlands, 2001. [Google Scholar]

- Korczynski, P.C.; Logan, J.; Faust, J.E. Mapping Monthly Distribution of Daily Light Integrals across the Contiguous United States. HortTechnology 2002, 12, 12–16. [Google Scholar] [CrossRef] [Green Version]

- Faust, J.E. Light. In Ball RedBook: Crop Production; Hamrick, D., Ed.; Ball Publishing: Batavia, IL, USA, 2003; Volume 2, pp. 71–84. ISBN 978-1-883052-35-5. [Google Scholar]

- Torres, A.P.; Lopez, R.G. Measuring Daily Light Integral in a Greenhouse; Purdue University Extension; Purdue Department of Horticulture and Landscape Architecture: West Lafayette, IN, USA, 2010; p. 7. [Google Scholar]

- Morrow, R.C. LED Lighting in Horticulture. HortScience 2008, 43, 1947–1950. [Google Scholar] [CrossRef] [Green Version]

- Mitchell, C.A.; Dzakovich, M.P.; Gomez, C.; Lopez, R.; Burr, J.F.; Hernández, R.; Kubota, C.; Currey, C.J.; Meng, Q.; Runkle, E.S.; et al. Light-Emitting Diodes in Horticulture. In Horticultural Reviews; John Wiley & Sons: Hoboken, NJ, USA, 2015; Volume 43, pp. 1–88. [Google Scholar]

- Bantis, F.; Smirnakou, S.; Ouzounis, T.; Koukounaras, A.; Ntagkas, N.; Radoglou, K. Current Status and Recent Achievements in the Field of Horticulture with the Use of Light-Emitting Diodes (LEDs). Sci. Hortic. 2018, 235, 437–451. [Google Scholar] [CrossRef]

- Bugbee, B. Economics of LED Lighting. In Light Emitting Diodes for Agriculture: Smart Lighting; Dutta Gupta, S., Ed.; Springer: Singapore, 2017; pp. 81–99. ISBN 978-981-10-5807-3. [Google Scholar]

- Massa, G.D.; Kim, H.-H.; Wheeler, R.M.; Mitchell, C.A. Plant Productivity in Response to LED Lighting. HortScience 2008, 43, 1951–1956. [Google Scholar] [CrossRef]

- Craver, J.K.; Boldt, J.K.; Lopez, R.G. Comparison of Supplemental Lighting Provided by High-Pressure Sodium Lamps or Light-Emitting Diodes for the Propagation and Finishing of Bedding Plants in a Commercial Greenhouse. HortScience 2019, 54, 52–59. [Google Scholar] [CrossRef] [Green Version]

- Albright, L.D.; Both, A.-J.; Chiu, A.J. Controlling Greenhouse Light to a Consistent Daily Integral. Trans. ASAE 2000, 43, 421. [Google Scholar] [CrossRef]

- Pinho, P.; Hytönen, T.; Rantanen, M.; Elomaa, P.; Halonen, L. Dynamic Control of Supplemental Lighting Intensity in a Greenhouse Environment. Light Res. Technol. 2013, 45, 295–304. [Google Scholar] [CrossRef]

- Clausen, A.; Maersk-Moeller, H.M.; Soerensen, J.C.; Joergensen, B.N.; Kjaer, K.H.; Ottosen, C.O. Integrating Commercial Greenhouses in the Smart Grid with Demand Response Based Control of Supplemental Lighting; Atlantis Press: Dordrecht, The Netherlands, 2015; pp. 199–213. [Google Scholar]

- van Iersel, M.W.; Gianino, D. An Adaptive Control Approach for Light-Emitting Diode Lights Can Reduce the Energy Costs of Supplemental Lighting in Greenhouses. HortScience 2017, 52, 72–77. [Google Scholar] [CrossRef]

- Ji, Y.; Davis, R.; O’Rourke, C.; Chui, E.W.M. Compatibility Testing of Fluorescent Lamp and Ballast Systems. IEEE Trans. Ind. Appl. 1999, 35, 1271–1276. [Google Scholar] [CrossRef]

- Moe, R.; Grimstad, S.O.; Gislerod, H.R. The Use of Artificial Light in Year Round Production of Greenhouse Crops in Norway. Acta Hortic. 2006, 711, 35–42. [Google Scholar] [CrossRef]

- Panova, G.G.; Chernousov, I.N.; Udalova, O.R.; Alexandrov, A.V.; Karmanov, I.V.; Anikina, L.M.; Sudakov, V.L.; Yakushev, V.P. Scientific Basis for Large Year-Round Yields of High-Quality Crop Products under Artificial Lighting. Russ. Agric. Sci. 2015, 41, 335–339. [Google Scholar] [CrossRef]

- Särkkä, L.E.; Jokinen, K.; Ottosen, C.-O.; Kaukoranta, T. Effects of HPS and LED Lighting on Cucumber Leaf Photosynthesis, Light Quality Penetration and Temperature in the Canopy, Plant Morphology and Yield. Agric. Food Sci. 2017, 26, 102–110. [Google Scholar] [CrossRef] [Green Version]

- Van Delm, T.; Stoffels, K.; Melis, P.; Vervoort, M.; Vanderbruggen, R. Overcoming Climatic Limitations: Cultivation Systems and Winter Production under Assimilation Lighting Resulting in Year-Round Strawberries. Acta Hortic. 2017, 1156, 517–528. [Google Scholar] [CrossRef]

- Despommier, D. The Vertical Farm: Controlled Environment Agriculture Carried out in Tall Buildings Would Create Greater Food Safety and Security for Large Urban Populations. J. Verbraucherschutz. Leb. 2010, 6, 233–236. [Google Scholar] [CrossRef]

- Goto, E. Plant Production in a Closed Plant Factory with Artificial Lighting. In Proceedings of the VII International Symposium on Light in Horticultural Systems 956, Wageningen, The Netherlands, 14–18 October 2012. [Google Scholar]

- Randall, W.C.; Lopez, R.G. Comparison of Bedding Plant Seedlings Grown Under Sole-Source Light-Emitting Diodes (LEDs) and Greenhouse Supplemental Lighting from LEDs and High-Pressure Sodium Lamps. HortScience 2015, 50, 705–713. [Google Scholar] [CrossRef] [Green Version]

- Pattison, P.M.; Tsao, J.Y.; Brainard, G.C.; Bugbee, B. LEDs for Photons, Physiology and Food. Nature 2018, 563, 493–500. [Google Scholar] [CrossRef]

- Stanghellini, C.; Van’t Ooster, B.; Heuvelink, E. Vertical Farms. In Greenhouse Horticulture; Wageningen Academic Publishers: Wageningen, The Netherlands, 2018; pp. 279–285. ISBN 978-90-8686-329-7. [Google Scholar]

- Kozai, T.; Niu, G. Role of the Plant Factory with Artificial Lighting (PFAL) in Urban Areas. In Plant Factory, 2nd ed.; Kozai, T., Niu, G., Takagaki, M., Eds.; Academic Press: Cambridge, MA, USA, 2020; pp. 7–34. ISBN 978-0-12-816691-8. [Google Scholar]

- Kusuma, P.; Pattison, P.M.; Bugbee, B. From Physics to Fixtures to Food: Current and Potential LED Efficacy. Hortic. Res. 2020, 7, 56. [Google Scholar] [CrossRef] [Green Version]

- Graamans, L.; Baeza, E.; van den Dobbelsteen, A.; Tsafaras, I.; Stanghellini, C. Plant Factories versus Greenhouses: Comparison of Resource Use Efficiency. Agric. Syst. 2018, 160, 31–43. [Google Scholar] [CrossRef]

- Dinesh, H.; Pearce, J.M. The Potential of Agrivoltaic Systems. Renew. Sustain. Energy Rev. 2016, 54, 299–308. [Google Scholar] [CrossRef] [Green Version]

- Trommsdorff, M.; Kang, J.; Reise, C.; Schindele, S.; Bopp, G.; Ehmann, A.; Weselek, A.; Högy, P.; Obergfell, T. Combining Food and Energy Production: Design of an Agrivoltaic System Applied in Arable and Vegetable Farming in Germany. Renew. Sustain. Energy Rev. 2021, 140, 110694. [Google Scholar] [CrossRef]

- Campana, P.E.; Stridh, B.; Amaducci, S.; Colauzzi, M. Optimization of Vertically Mounted Agrivoltaic Systems. arXiv 2021, arXiv:2104.02124. [Google Scholar]

- Toledo, C.; Scognamiglio, A. Agrivoltaic Systems Design and Assessment: A Critical Review, and a Descriptive Model towards a Sustainable Landscape Vision (Three-Dimensional Agrivoltaic Patterns). Sustainability 2021, 13, 6871. [Google Scholar] [CrossRef]

- Yano, A.; Furue, A.; Kadowaki, M.; Tanaka, T.; Hiraki, E.; Miyamoto, M.; Ishizu, F.; Noda, S. Electrical Energy Generated by Photovoltaic Modules Mounted inside the Roof of a North–South Oriented Greenhouse. Biosyst. Eng. 2009, 103, 228–238. [Google Scholar] [CrossRef]

- Sonneveld, P.J.; Swinkels, G.L.A.M.; Campen, J.; van Tuijl, B.A.J.; Janssen, H.J.J.; Bot, G.P.A. Performance Results of a Solar Greenhouse Combining Electrical and Thermal Energy Production. Biosyst. Eng 2010, 106, 48–57. [Google Scholar] [CrossRef]

- Poncet, C.; Muller, M.M.; Brun, R.; Fatnassi, H. Photovoltaic Greenhouses, Non-Sense or a Real Opportunity for the Greenhouse Systems? Acta Hortic. 2012, 927, 75–79. [Google Scholar] [CrossRef]

- Yano, A.; Cossu, M. Energy Sustainable Greenhouse Crop Cultivation Using Photovoltaic Technologies. Renew. Sustain. Energy Rev. 2019, 109, 116–137. [Google Scholar] [CrossRef]

- Fatnassi, H.; Poncet, C.; Bazzano, M.M.; Brun, R.; Bertin, N. A Numerical Simulation of the Photovoltaic Greenhouse Microclimate. Sol. Energy 2015, 120, 575–584. [Google Scholar] [CrossRef]

- Cossu, M.; Cossu, A.; Deligios, P.A.; Ledda, L.; Li, Z.; Fatnassi, H.; Poncet, C.; Yano, A. Assessment and Comparison of the Solar Radiation Distribution inside the Main Commercial Photovoltaic Greenhouse Types in Europe. Renew. Sustain. Energy Rev. 2018, 94, 822–834. [Google Scholar] [CrossRef]

- López-Díaz, G.; Carreño-Ortega, A.; Fatnassi, H.; Poncet, C.; Díaz-Pérez, M. The Effect of Different Levels of Shading in a Photovoltaic Greenhouse with a North–South Orientation. Appl. Sci. 2020, 10, 882. [Google Scholar] [CrossRef] [Green Version]

- Barbera, E.; Sforza, E.; Vecchiato, L.; Bertucco, A. Energy and Economic Analysis of Microalgae Cultivation in a Photovoltaic-Assisted Greenhouse: Scenedesmus Obliquus as a Case Study. Energy 2017, 140, 116–124. [Google Scholar] [CrossRef]

- Bambara, J.; Athienitis, A.K. Energy and Economic Analysis for the Design of Greenhouses with Semi-Transparent Photovoltaic Cladding. Renew. Energy 2019, 131, 1274–1287. [Google Scholar] [CrossRef]

- Ureña-Sánchez, R.; Callejón-Ferre, Á.J.; Pérez-Alonso, J.; Carreño-Ortega, Á. Greenhouse Tomato Production with Electricity Generation by Roof-Mounted Flexible Solar Panels. Sci. Agric. 2012, 69, 233–239. [Google Scholar] [CrossRef]

- Cossu, M.; Yano, A.; Solinas, S.; Deligios, P.A.; Tiloca, M.T.; Cossu, A.; Ledda, L. Agricultural Sustainability Estimation of the European Photovoltaic Greenhouses. Eur. J. Agron. 2020, 118, 126074. [Google Scholar] [CrossRef]

- Huld, T.; Müller, R.; Gambardella, A. A New Solar Radiation Database for Estimating PV Performance in Europe and Africa. Sol. Energy 2012, 86, 1803–1815. [Google Scholar] [CrossRef]

- PVGIS© European Communities JRC Photovoltaic Geographical Information System (PVGIS 5.1). Available online: https://ec.europa.eu/jrc/en/pvgis (accessed on 10 September 2021).

- Hersbach, H.; Bell, B.; Berrisford, P.; Biavati, G.; Horányi, A.; Muñoz Sabater, J.; Nicolas, J.; Peubey, C.; Radu, R.; Rozum, I. ERA5 Hourly Data on Single Levels from 1979 to Present. In Copernicus Climate Change Service (C3S) Climate Data Store (CDS); European Union: Luxembourg, 2018; Volume 10. [Google Scholar] [CrossRef]

- Hersbach, H.; Bell, B.; Berrisford, P.; Hirahara, S.; Horányi, A.; Muñoz-Sabater, J.; Nicolas, J.; Peubey, C.; Radu, R.; Schepers, D.; et al. The ERA5 Global Reanalysis. Q. J. R. Meteorol. Soc. 2020, 146, 1999–2049. [Google Scholar] [CrossRef]

- Suri, M.; Huld, T.; Dunlop, E.; Albuisson, M.; Wald, L. Online Data and Tools for Estimation of Solar Electricity in Africa: The PVGIS Approach. In Proceedings of the International Conference; WIP-Renewable Energies, Dresden, Germany, 4 October 2006; pp. 2623–2626. [Google Scholar]

- Baskerville, G.L.; Emin, P. Rapid Estimation of Heat Accumulation from Maximum and Minimum Temperatures. Ecology 1969, 50, 514–517. [Google Scholar] [CrossRef]

- McMaster, G.S.; Wilhelm, W.W. Growing Degree-Days: One Equation, Two Interpretations. Agric. For. Meteorol. 1997, 87, 291–300. [Google Scholar] [CrossRef] [Green Version]

- Miller, P.; Lanier, W.; Brandt, S. Using Growing Degree Days to Predict Plant Stages. AgExtension Commun. Coord. Commun. Serv. Mont. State Univ.-Bozeman Bozeman MO 2001, 59717, 994–2721. [Google Scholar]

- Bigras, F.J.; Ryyppö, A.; Lindström, A.; Stattin, E. Cold Acclimation and Deacclimation of Shoots and Roots of Conifer Seedlings. In Conifer Cold Hardiness; Bigras, F.J., Colombo, S.J., Eds.; Tree Physiology; Springer: Dordrecht, The Netherlands, 2001; pp. 57–88. ISBN 978-94-015-9650-3. [Google Scholar]

- Xu, Y. Seven Dimensions of Light in Regulating Plant Growth. In Proceedings of the VIII International Symposium on Light in Horticulture 1134, East Lansing, MI, USA, 22–26 May 2016; pp. 445–452. [Google Scholar]

- Serrano-Bueno, G.; Romero-Campero, F.J.; Lucas-Reina, E.; Romero, J.M.; Valverde, F. Evolution of Photoperiod Sensing in Plants and Algae. Curr. Opin. Plant Biol. 2017, 37, 10–17. [Google Scholar] [CrossRef]

- Clapham, D.H.; Dormling, I.; Ekberg, L.; Eriksson, G.; Qamaruddin, M.; Vince-Prue, D. Latitudinal Cline of Requirement for Far-Red Light for the Photoperiodic Control of Budset and Extension Growth in Picea abies (Norway Spruce). Physiol. Plant. 1998, 102, 71–78. [Google Scholar] [CrossRef]

- Chiang, C.; Aas, O.T.; Jetmundsen, M.R.; Lee, Y.; Torre, S.; Fløistad, I.S.; Olsen, J.E. Day Extension with Far-Red Light Enhances Growth of Subalpine Fir (Abies lasiocarpa (Hooker) Nuttall) Seedlings. Forests 2018, 9, 175. [Google Scholar] [CrossRef] [Green Version]

- Riikonen, J.; Lappi, J. Responses of Norway Spruce Seedlings to Different Night Interruption Treatments in Autumn. Can. J. Res. 2016, 46, 478–484. [Google Scholar] [CrossRef]

- Riikonen, J. Efficiency of Night Interruption Treatments with Red and Far-Red Light-Emitting Diodes (LEDs) in Preventing Bud Set in Norway Spruce Seedlings. Can. J. For. Res. 2018, 48, 1001–1006. [Google Scholar] [CrossRef]

- Mattsson, A. Regeneration Practices in Scandinavia: State-of-the-Art and New Trends. Thin Green Line 2005, 25–30. [Google Scholar]

- Fløistad, I.S.; Granhus, A. Timing and Duration of Short-Day Treatment Influence Morphology and Second Bud Flush in Picea Abies Seedlings. Silva Fenn. 2013, 47, 1–10. [Google Scholar] [CrossRef]

- Mattsson, A. Reforestation Challenges in Scandinavia. Reforesta 2016, 1, 67–85. [Google Scholar] [CrossRef] [Green Version]

- Wallin, E.; Gräns, D.; Jacobs, D.F.; Lindström, A.; Verhoef, N. Short-Day Photoperiods Affect Expression of Genes Related to Dormancy and Freezing Tolerance in Norway Spruce Seedlings. Ann. For. Sci. 2017, 74, 59. [Google Scholar] [CrossRef] [Green Version]

- Riikonen, J.; Luoranen, J. Use of Short-Day Treatment in the Production of Norway Spruce Mini-Plug Seedlings under Plant Factory Conditions. Scand. J. For. Res. 2018, 33, 625–632. [Google Scholar] [CrossRef]

- Riikonen, J.; Luoranen, J. An Assessment of Storability of Norway Spruce Container Seedlings in Freezer Storage as Affected by Short-Day Treatment. Forests 2020, 11, 692. [Google Scholar] [CrossRef]

- Bennie, J.; Davies, T.W.; Cruse, D.; Gaston, K.J. Ecological Effects of Artificial Light at Night on Wild Plants. J. Ecol. 2016, 104, 611–620. [Google Scholar] [CrossRef] [Green Version]

- Bowditch, N. 2019 American Practical Navigator Bowditch Vol 1 & 2 Combined Edition; Paradise Cay Publications: Blue Lake, CA, USA, 2020; ISBN 978-1-951116-05-7. [Google Scholar]

- Duffie, J.; Beckman, W. Solar Engineering of Thermal Processes, 3nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2006; ISBN 978-0-471-69867-8. [Google Scholar]

- Herbert Glarner Length of Day and Twilight. Available online: http://www.gandraxa.com/length_of_day.xml (accessed on 31 August 2021).

- Zhen, S.; Bugbee, B. Substituting Far-Red for Traditionally Defined Photosynthetic Photons Results in Equal Canopy Quantum Yield for CO2 Fixation and Increased Photon Capture During Long-Term Studies: Implications for Re-Defining PAR. Front. Plant Sci. 2020, 11, 1433. [Google Scholar] [CrossRef] [PubMed]

- Zhen, S.; van Iersel, M.; Bugbee, B. Why Far-Red Photons Should Be Included in the Definition of Photosynthetic Photons and the Measurement of Horticultural Fixture Efficacy. Front. Plant Sci. 2021, 12, 1158. [Google Scholar] [CrossRef]

- Britton, C.M.; Dodd, J.D. Relationships of Photosynthetically Active Radiation and Shortwave Irradiance. Agric. Meteorol. 1976, 17, 1–7. [Google Scholar] [CrossRef]

- Thimijan, R.W.; Heins, R.D. Photometric, Radiometric, and Quantum Light Units of Measure: A Review of Procedures for Interconversion. HortScience 1983, 18, 818–822. [Google Scholar]

- Rodskjer, N. Spectral Daily Insolation at Uppsala, Sweden. Arch. Meteorol. Geophys. Bioclimatol. Ser. B 1983, 33, 89–98. [Google Scholar] [CrossRef]

- Howell, T.A.; Meek, D.W.; Hatfield, J.L. Relationship of Photosynthetically Active Radiation to Shortwave Radiation in the San Joaquin Valley. Agric. Meteorol. 1983, 28, 157–175. [Google Scholar] [CrossRef]

- Papaioannou, G.; Papanikolaou, N.; Retalis, D. Relationships of Photosynthetically Active Radiation and Shortwave Irradiance. Theor. Appl. Climatol. 1993, 48, 23–27. [Google Scholar] [CrossRef]

- Alados, I.; Foyo-Moreno, I.; Alados-Arboledas, L. Photosynthetically Active Radiation: Measurements and Modelling. Agric. For. Meteorol. 1996, 78, 121–131. [Google Scholar] [CrossRef]

- Jacovides, C.P.; Timbios, F.; Asimakopoulos, D.N.; Steven, M.D. Urban Aerosol and Clear Skies Spectra for Global and Diffuse Photosynthetically Active Radiation. Agric. For. Meteorol. 1997, 87, 91–104. [Google Scholar] [CrossRef]

- Hassika, P.; Berbigier, P. Annual Cycle of Photosynthetically Active Radiation in Maritime Pine Forest. Agric. For. Meteorol. 1998, 90, 157–171. [Google Scholar] [CrossRef]

- Akitsu, T.; Kume, A.; Hirose, Y.; Ijima, O.; Nasahara, K.N. On the Stability of Radiometric Ratios of Photosynthetically Active Radiation to Global Solar Radiation in Tsukuba, Japan. Agric. For. Meteorol. 2015, 209–210, 59–68. [Google Scholar] [CrossRef]

- Blonquist, J.M.; Bugbee, B. Solar, Net, and Photosynthetic Radiation. In Agroclimatology; John Wiley & Sons: Hoboken, NJ, USA, 2018; pp. 1–49. ISBN 978-0-89118-358-7. [Google Scholar]

- Jacovides, C.P.; Steven, M.D.; Asimakopoulos, D.N. Spectral Solar Irradiance and Some Optical Properties For Various Polluted Atmospheres. Sol. Energy 2000, 69, 215–227. [Google Scholar] [CrossRef]

- Escobedo, J.F.; Gomes, E.N.; Oliveira, A.P.; Soares, J. Modeling Hourly and Daily Fractions of UV, PAR and NIR to Global Solar Radiation under Various Sky Conditions at Botucatu, Brazil. Appl. Energy 2009, 86, 299–309. [Google Scholar] [CrossRef]

- Von Zabeltitz, C. Light Transmittance of Greenhouses. In Integrated Greenhouse Systems for Mild Climates: Climate Conditions, Design, Construction, Maintenance, Climate Control; Von Zabeltitz, C., Ed.; Springer: Berlin, Heidelberg, 2011; pp. 137–143. ISBN 978-3-642-14582-7. [Google Scholar]

- Both, A.J.; Faust, J.E. Light Transmission: The Impact of Glazing Material and Greenhouse Design. In Light Management in Controlled Environments; Lopez, R., Runkle, E.S., Eds.; CreateSpace Independent Publishing Platform: Willoughby, OH, USA, 2017; pp. 74–81. ISBN 978-1-5442-5449-4. [Google Scholar]

- Stanghellini, C.; Van’t Ooster, B.; Heuvelink, E. Radiation, Greenhouse Cover and Temperature. In Greenhouse Horticulture; Wageningen Academic Publishers: Wageningen, The Netherlands, 2018; pp. 15–25. ISBN 978-90-8686-329-7. [Google Scholar]

- Kozai, T.; Goudriaan, J.; Kimura, T. Light Transmission and Photosynthesis in Greenhouses; Pudoc: Wageningen, The Netherlands, 1978; ISBN 90-220-0646-8. [Google Scholar]

- Roberts, W.J. Glazing Materials, Structural Design, and Other Factors Affecting Light Transmission in Greenhouses. In GreenHouse Glazing and Solar Radiation Transmission Workshop; Rutgers University: New Brunswick, NJ, USA, 1998; Volume 8. [Google Scholar]

- Von Elsner, B.; Briassoulis, D.; Waaijenberg, D.; Mistriotis, A.; von Zabeltitz, C.; Gratraud, J.; Russo, G.; Suay-Cortes, R. Review of Structural and Functional Characteristics of Greenhouses in European Union Countries: Part I, Design Requirements. J. Agric. Eng. Res. 2000, 75, 1–16. [Google Scholar] [CrossRef] [Green Version]

- Mattsson, A. Odlingsmiljö: En analys av 80-talets Växthus för Produktion av Skogsplantor; Institutionen För Skogsproduktion; Sveriges Lantbruksuniversitet: Garpenberg, Sweden, 1982; Volume 7, ISBN 91-576-1214-5. [Google Scholar]

- Tantau, H.-J.; Hinken, J.; von Elsner, B.; Max, J.; Ulbrich, A.; Schurr, U.; Hofmann, T.; Reisinger, G. Solar Transmittance of Greenhouse Covering Materials. Acta Hortic. 2012, 956, 441–448. [Google Scholar] [CrossRef]

- Hemming, S.; Mohammadkhani, V.; Dueck, T. Diffuse Greenhouse Covering Materials-Material Technology, Measurements and Evaluation of Optical Properties. In Proceedings of the International Workshop on Greenhouse Environmental Control and Crop Production in Semi-Arid Regions 797, Tucson, AZ, USA, 20–24 October 2008; pp. 469–475. [Google Scholar]

- Bergstrand, K.-J.; Mortensen, L.M.; Suthaparan, A.; Gislerød, H.R. Acclimatisation of Greenhouse Crops to Differing Light Quality. Sci. Hortic. 2016, 204, 1–7. [Google Scholar] [CrossRef]

- Navidad, H.; Fløistad, I.S.; Olsen, J.E.; Torre, S. Subalpine Fir (Abies Laciocarpa) and Norway Spruce (Picea Abies) Seedlings Show Different Growth Responses to Blue Light. Agronomy 2020, 10, 712. [Google Scholar] [CrossRef]

- IEC 60904-1:2020. Photovoltaic Devices—Part 1: Measurement of Photovoltaic Current-Voltage Characteristics; International Electrotechnical Commission: Geneva, Switzerland, 2020; Volume 67. [Google Scholar]

- Kurtz, S.; Repins, I.; Metzger, W.K.; Verlinden, P.J.; Huang, S.; Bowden, S.; Tappan, I.; Emery, K.; Kazmerski, L.L.; Levi, D. Historical Analysis of Champion Photovoltaic Module Efficiencies. IEEE J. Photovolt. 2018, 8, 363–372. [Google Scholar] [CrossRef]

- Deutsche Gesellschaft für Sonnenenergie (Ed.) Planning and Installing Photovoltaic Systems: A Guide for Installers, Architects and Engineers; Routledge: Oxfordshire, UK, 2013. [Google Scholar]

- Von Elsner, B.; Briassoulis, D.; Waaijenberg, D.; Mistriotis, A.; von Zabeltitz, C.; Gratraud, J.; Russo, G.; Suay-Cortes, R. Review of Structural and Functional Characteristics of Greenhouses in European Union Countries, Part II: Typical Designs. J. Agric. Eng. Res. 2000, 75, 111–126. [Google Scholar] [CrossRef] [Green Version]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2021. [Google Scholar]

- Wickham, H. Tidy Data. J. Stat. Softw. 2014, 59, 1–23. [Google Scholar] [CrossRef] [Green Version]

- Wickham, H.; Averick, M.; Bryan, J.; Chang, W.; McGowan, L.D.; François, R.; Grolemund, G.; Hayes, A.; Henry, L.; Hester, J.; et al. Welcome to the Tidyverse. J. Open Source Softw. 2019, 4, 1686. [Google Scholar] [CrossRef]

- Wickham, H. Ggplot2: Elegant Graphics for Data Analysis; Springer: New York, NY, USA, 2009; ISBN 978-0-387-98140-6. [Google Scholar]

- Wickham, H.; Chang, W.; Henry, L.; Pedersen, T.L.; Takahashi, K.; Wilke, C.; Woo, K.; Yutani, H.; Dunnington, D. RStudio Ggplot2: Create Elegant Data Visualisations Using the Grammar of Graphics; CRAN.R Project 2021. Available online: https://ggplot2.tidyverse.org (accessed on 29 August 2021).

- Pebesma, E. Simple Features for R: Standardized Support for Spatial Vector Data. R J. 2018, 10, 439–446. [Google Scholar] [CrossRef] [Green Version]

- Pebesma, E.; Bivand, R.; Racine, E.; Sumner, M.; Cook, I.; Keitt, T.; Lovelace, R.; Wickham, H.; Ooms, J.; Müller, K.; et al. Sf: Simple Features for R; CRAN.R Project, 2021. Available online: https://CRAN.R-project.org/package=sf (accessed on 29 August 2021).

- Natural Earth—Free Vector and Raster Map Data. Available online: https://www.naturalearthdata.com/ (accessed on 29 August 2021).

- South, A. Rnaturalearth: World Map Data from Natural Earth; CRAN.R Project 2017. Available online: https://CRAN.R-project.org/package=rnaturalearth (accessed on 29 August 2021).

- Smirnakou, S.; Ouzounis, T.; Radoglou, K. Effects of Continuous Spectrum LEDs Used in Indoor Cultivation of Two Coniferous Species Pinus sylvestris L. and Abies Borisii-Regis Mattf. Scand. J. Res. 2017, 32, 115–122. [Google Scholar] [CrossRef]

- Soriano, T.; Suárez-Rey, E.M.; Morales, M.I.; Romero, M.; Hernández, J.; Montero, J.I.; Antón, A.; Castilla, N. Solar Radiation Transmission in Mediterranean Plastic Greenhouses. Acta Hortic. 2009, 807, 73–78. [Google Scholar] [CrossRef]

- Critten, D.L. Greenhouse Light Transmission: The Shading Effect of Infinite Parallel Cylinders under Diffuse Light. J. Agric. Eng. Res. 1983, 28, 569–572. [Google Scholar] [CrossRef]

- Kittas, C.; Baille, A.; Giaglaras, P. Influence of Covering Material and Shading on the Spectral Distribution of Light in Greenhouses. J. Agric. Eng. Res. 1999, 73, 341–351. [Google Scholar] [CrossRef]

- Hemming, S.; Dueck, T.A.; Marissen, N.; Jongschaap, R.E.E.; Kempkes, F.L.K.; van de Braak, N.J. Diffuus Licht: Het Effect van Lichtverstrooiende Kasdekmaterialen op Kasklimaat, Lichtdoordringing en Gewasgroei; Rapport/Wageningen UR, Agrotechnology & Food Innovations; Agrotechnology & Food Innovations: Wageningen, The Netherlands, 2005; ISBN 978-90-6754-978-3. [Google Scholar]

- Kotilainen, T.; Robson, T.M.; Hernández, R. Light Quality Characterization under Climate Screens and Shade Nets for Controlled-Environment Agriculture. PLoS ONE 2018, 13, e0199628. [Google Scholar] [CrossRef] [PubMed]

- Cossu, M.; Ledda, L.; Urracci, G.; Sirigu, A.; Cossu, A.; Murgia, L.; Pazzona, A.; Yano, A. An Algorithm for the Calculation of the Light Distribution in Photovoltaic Greenhouses. Sol. Energy 2017, 141, 38–48. [Google Scholar] [CrossRef]

- Bakker, J.C.; Bot, G.P.A.; Challa, H.; van de Braak, N.J. Greenhouse Climate Control: An Integrated Approach; Wageningen Academic Publishers: Wageningen, The Netherlands, 1995; ISBN 978-90-74134-17-0. [Google Scholar]

- Graamans, L.; van den Dobbelsteen, A.; Meinen, E.; Stanghellini, C. Plant Factories; Crop Transpiration and Energy Balance. Agric. Syst. 2017, 153, 138–147. [Google Scholar] [CrossRef]

- Wallace, C.; Both, A.J. Evaluating Operating Characteristics of Light Sources for Horticultural Applications. Acta Hortic. 2016, 435–444. [Google Scholar] [CrossRef]

- Radetsky, L.C. LED and HID Horticultural Luminaire Testing Report; Lighting Research Center, Rensselaer Polytechnic Institute: Troy, NY, USA, 2018. [Google Scholar]

- Stober, K.; Lee, K.; Yamada, M.; Pattison, M. Energy Savings Potential of SSL in Horticultural Applications; EERE Publication and Product Library: Washington, DC, USA, 2017. [Google Scholar]

- Harbick, K.; Albright, L.D. Comparison of Energy Consumption: Greenhouses and Plant Factories. Acta Hortic. 2016, 1134, 285–292. [Google Scholar] [CrossRef] [Green Version]

- Molin, E.; Martin, M. Assessing the Energy and Environmental Performance of Vertical Hydroponic Farming; IVL Swedish Environmental Research Institute: Stockholm, Sweden, 2018; p. 36. [Google Scholar]

- Liaros, S.; Botsis, K.; Xydis, G. Technoeconomic Evaluation of Urban Plant Factories: The Case of Basil (Ocimum basilicum). Sci. Total Environ. 2016, 554–555, 218–227. [Google Scholar] [CrossRef] [PubMed]

| Lighting Control | PPFDthreshold | DLIthreshold 1 | τh, PAR | PPE |

|---|---|---|---|---|

| On-off control | 100 µmol·m−2·s−1 | 5.8 mol·m−2·d−1 | 40% | 2.0 µmol·J−1 |

| Adaptive control | 200 µmol·m−2·s−1 | 11.5 mol·m−2·d−1 | 55% | 2.75 µmol·J−1 |

| 300 µmol·m−2·s−1 | 17.3 mol·m−2·d−1 | 70% | 3.5 µmol·J−1 |

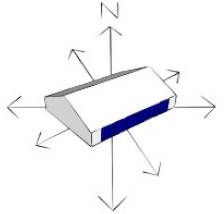

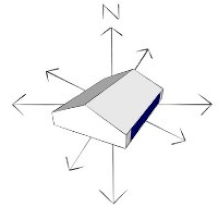

| Roof-mounted systems |  |  |  |  | ||||

| slope: 25° | ||||||||

| orientation | N―S | NW―SE | NW―SE | W―E | ||||

| azimuth | 0° | 180° | 330° | 150° | 300° | 120° | 270° | 90° |

| PPV,STC | 6 kW | 6 kW | 6 kW | 3 kW | 3 kW | |||

| PPV,STC 1 | 1 kW | 5 kW | 2 kWp | 4 kW | ||||

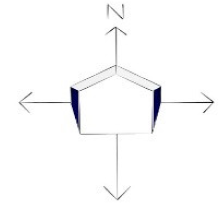

| Wall-mounted systems |  |  |  |  | ||||

| slope: 90° | ||||||||

| orientation | N―S | NW―SE | NW―SE | W―E | ||||

| azimuth | 0° | 180° | 330° | 150° | 300° | 120° | 270° | 90° |

| PPV,STC | 6 kW | 6 kW | 6 kW | 3 kW | 3 kW | |||

| Monthly Average Values | Jan | Feb | Mar | Apr | May | Jun | Jul | Aug | Oct | Nov | Dec |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Ambient temperature-Ta (°C) | −4.8 | −4.4 | −0.9 | 4.7 | 10.0 | 14.1 | 16.7 | 15.1 | 11.3 | 5.5 | 1.4 |

| Daily global horizontal irradiation—Hh (kWh·m−2·d−1) | 0.3 | 0.9 | 2.3 | 3.9 | 4.8 | 5.3 | 4.8 | 3.7 | 2.4 | 1.1 | 0.4 |

| Daily Light Integral-DLIsun (mol·m−2·d−1) | 2.2 | 6.6 | 17.1 | 28.3 | 34.8 | 38.8 | 35.2 | 26.9 | 17.5 | 8.1 | 2.5 |

| Diffuse to global horizontal irradiance ratio (Gd/Gh) | 67% | 59% | 44% | 41% | 41% | 40% | 41% | 43% | 46% | 51% | 64% |

| Indoor cultivation with sole-source LED lighting 1 |  |  | |||||||||

| Greenhouse cultivation with supp. LED lighting |  |  | |||||||||

| Outdoor cultivation with natural light |  | ||||||||||

| Greenhouse parameters | On−off lighting control protocol | ||||||||

| Minimum PAR level (PPFDthreshold) | 100 µmol·m−2·s−1 | 200 µmol·m−2·s−1 | 300 µmol·m−2·s−1 | ||||||

| Transmittance (τh, PAR) | 40% | 55% | 70% | 40% | 55% | 70% | 40% | 55% | 70% |

| Daily supplementary lighting requirements (DLIlamps, mol·m−2·d−1) | 2.9 | 2.5 | 2.3 | 8.4 | 7.3 | 6.3 | 15.6 | 12.9 | 12.0 |

| Lamps’ photosynthetic photon efficacy (PPE) | Yearly 1 lighting energy consumption (Eel, lamps, kWh·m−2·yr−1) | ||||||||

| PPE = 2 µmol·J−1 | 73 | 63 | 58 | 210 | 183 | 159 | 393 | 325 | 302 |

| PPE = 2.75 µmol·J−1 | 53 | 46 | 43 | 153 | 133 | 116 | 286 | 236 | 219 |

| PPE = 3.5 µmol·J−1 | 42 | 36 | 33 | 120 | 104 | 91 | 225 | 185 | 172 |

| Greenhouse parameters | Adaptive lighting control protocol | ||||||||

| Minimum PAR light level (PPFDthreshold) | 100 µmol·m−2·s−1 | 200 µmol·m−2·s−1 | 300 µmol·m−2·s−1 | ||||||

| Transmittance (τh, PAR) | 40% | 55% | 70% | 40% | 55% | 70% | 40% | 55% | 70% |

| Daily supplementary lighting requirements (DLIlamps, mol·m−2·d−1) | 2.2 | 2.0 | 1.8 | 5.8 | 5.0 | 4.5 | 10.5 | 9.0 | 8.1 |

| Lamps’ photosynthetic photon efficacy (PPE) | Yearly 1 lighting energy consumption (Eel, lamps, kWh·m−2·yr−1) | ||||||||

| PPE = 2 µmol·J−1 | 54 | 49 | 46 | 146 | 126 | 114 | 264 | 227 | 204 |

| PPE = 2.75 µmol·J−1 | 39 | 36 | 34 | 106 | 91 | 83 | 192 | 165 | 148 |

| PPE = 3.5 µmol·J−1 | 31 | 28 | 27 | 83 | 72 | 65 | 151 | 130 | 116 |

| Roof-Mounted (25°) | Wall-Mounted (90°) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Greenhouse Integrated PV Systems | a | b | c | d | e | f | w | x | y | z |

| Yearly PV specific energy yield (Erel,PV, kWh·kW−1·yr−1) | 904 | 888 | 823 | 825 | 743 | 708 | 745 | 732 | 648 | 484 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hernandez Velasco, M. Enabling Year-round Cultivation in the Nordics-Agrivoltaics and Adaptive LED Lighting Control of Daily Light Integral. Agriculture 2021, 11, 1255. https://doi.org/10.3390/agriculture11121255

Hernandez Velasco M. Enabling Year-round Cultivation in the Nordics-Agrivoltaics and Adaptive LED Lighting Control of Daily Light Integral. Agriculture. 2021; 11(12):1255. https://doi.org/10.3390/agriculture11121255

Chicago/Turabian StyleHernandez Velasco, Marco. 2021. "Enabling Year-round Cultivation in the Nordics-Agrivoltaics and Adaptive LED Lighting Control of Daily Light Integral" Agriculture 11, no. 12: 1255. https://doi.org/10.3390/agriculture11121255

APA StyleHernandez Velasco, M. (2021). Enabling Year-round Cultivation in the Nordics-Agrivoltaics and Adaptive LED Lighting Control of Daily Light Integral. Agriculture, 11(12), 1255. https://doi.org/10.3390/agriculture11121255