Industrial Processing Affects Product Yield and Quality of Diced Tomato

Abstract

:1. Introduction

2. Materials and Methods

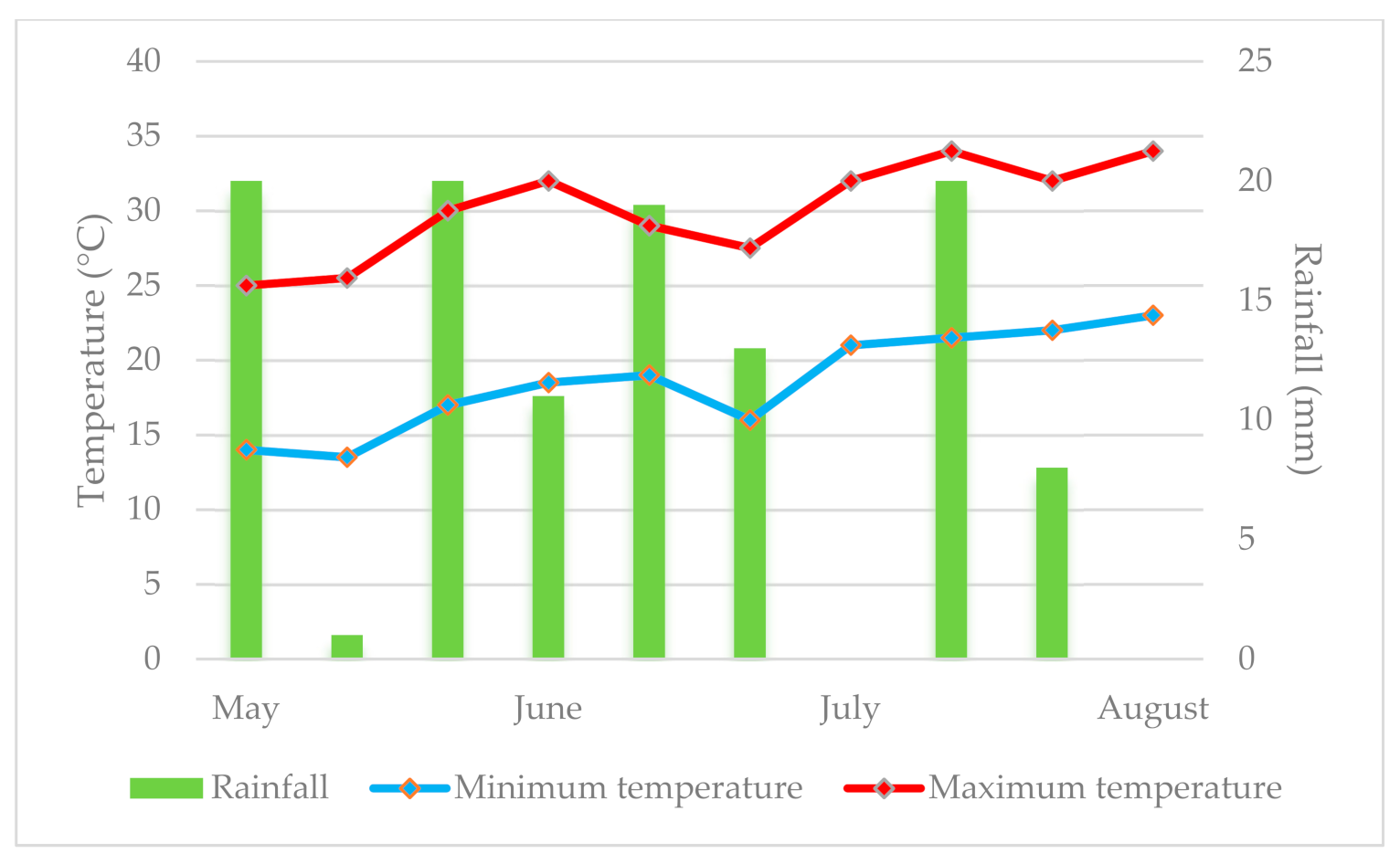

2.1. Experimental Protocol and Growth Conditions

2.2. Yield and Processing Efficiency Determinations

2.3. Quality Attributes and Antioxidants Determinations

2.4. Sensorial Determinations

2.5. Statistical Processing

3. Results and Discussion

3.1. Yield and Processing Efficiency

3.2. Quality Attributes and Antioxidants

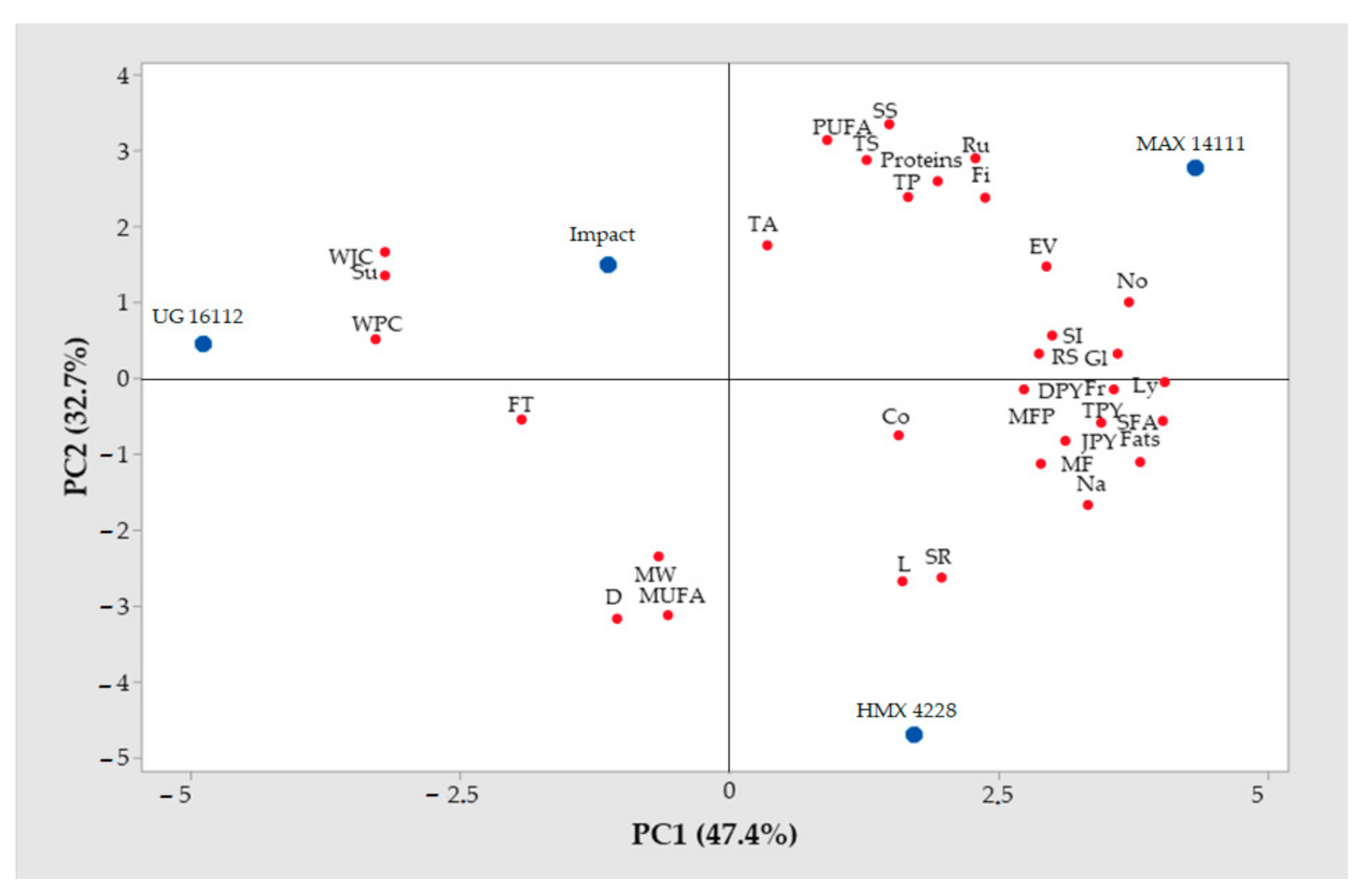

3.3. Principal Component Analysis (PCA)

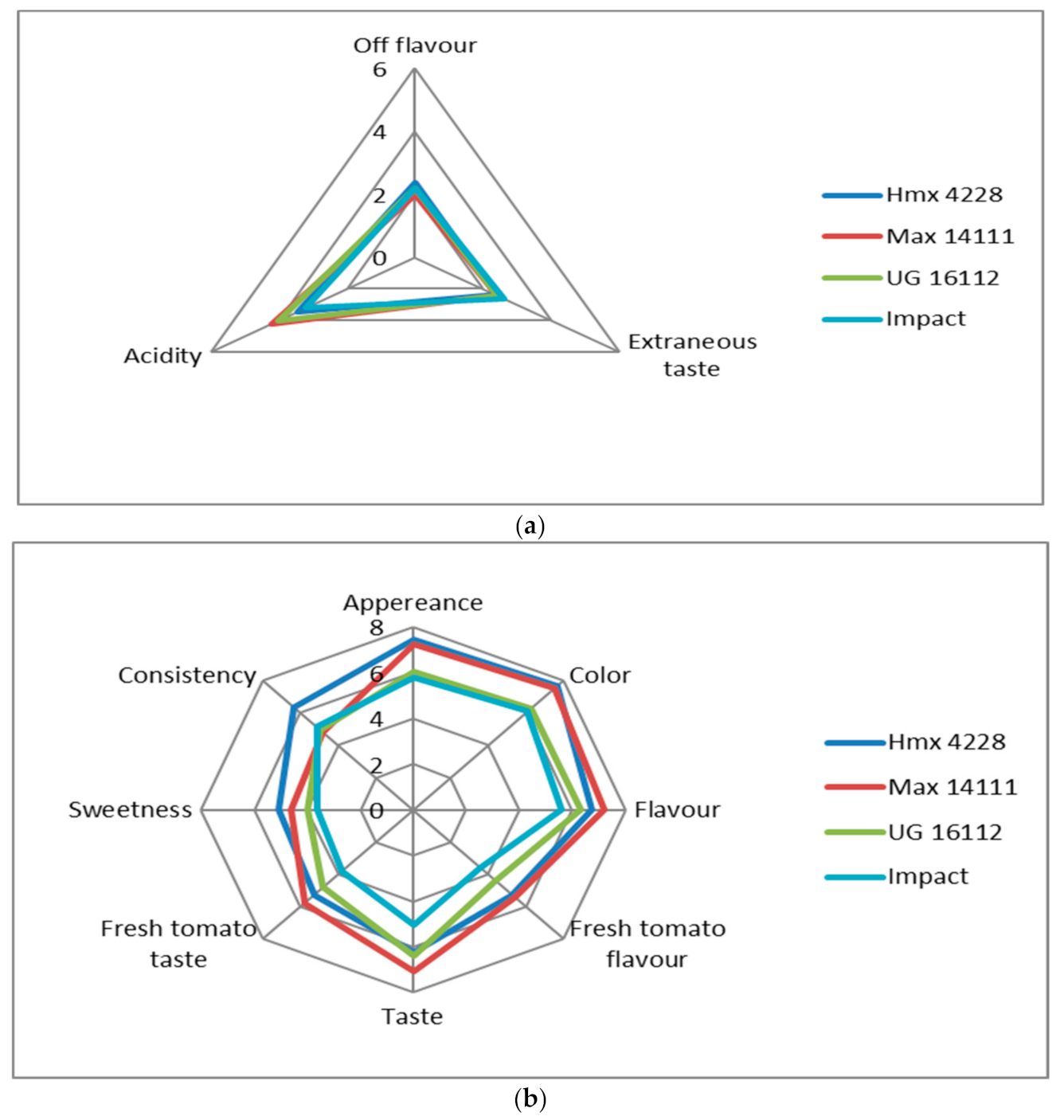

3.4. Sensorial Features

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Trewavas, A. Urban myths of organic farming. Nature 2001, 410, 409–410. [Google Scholar] [CrossRef]

- FaoStat—Food and Agriculture Organization. Available online: http://www.fao.org/faostat/en/#data/QC (accessed on 7 August 2020).

- Frusciante, L.; Carli, P.; Ercolano, M.R.; Pernice, R.; Di Matteo, A.; Fogliano, V.; Pellegrino, N. Antioxidant nutritional quality of tomato. Mol. Nutr. Food. Res. 2007, 51, 609–617. [Google Scholar] [CrossRef] [PubMed]

- García-Díaz, Y.D.; Aquino-Bolaños, E.N.; Chávez-Servia, J.L.; Vera-Guzmán, A.M.; Carrillo-Rodríguez, J.C. Bioactive compounds and antioxidant activity in the common bean are influenced by cropping season and genotype. Chil. J. Agric. Res. 2018, 78, 255–265. [Google Scholar] [CrossRef] [Green Version]

- De Sio, F.; Rapacciuolo, M.; De Giorgi, A.; Sandei, L.; Giuliano, B.; Sekara, A.; Tallarita, A.; Morano, G.; Cuciniello, A.; Cozzolino, E.; et al. Yield and quality performances of organic tomato as affected by genotype and industrial processing in southern Italy. Italus Hortus 2020, 27, 85–99. [Google Scholar] [CrossRef]

- Panthee, D.R.; Labate, J.A.; McGrath, M.T.; Breksa, A.P.; Robertson, L.D. Genotype and environmental interaction for fruit quality traits in vintage tomato varieties. Euphytica 2013, 193, 169–182. [Google Scholar] [CrossRef]

- Doganlar, S.; Tanksley, S.D.; Mutschler, M.A. Identification and molecular mapping of loci controlling fruit ripening time in tomato. Theor. Appl. Genet. 2000, 100, 249–255. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, Z.; Zhu, H.; Zhang, Y.; Gao, W.; Wang, X.; Zou, Q. Phenotypic diversity and genome-wide association mapping of earliness-related traits in cultivated tomato (Solanum Lycopersicum L.). Sci. Hortic. 2020, 264, 109194. [Google Scholar] [CrossRef]

- Page, D.; Vilas Boas, A.; Giovinazzo, R.; Bertin, N.; Fanciullino, A.L.; Biau, N.; Bureau, S. Selecting tomato for their ability to react and conserve their quality during the process. Acta Hortic. 2018, 1233, 163–168. [Google Scholar] [CrossRef]

- Zhang, L.; Barrett, D.M.; McCarthy, M.J. Characterization of the red layer and pericarp of processing tomato using magnetic resonance imaging. J. Food Sci. 2013, 78, 50–55. [Google Scholar] [CrossRef] [PubMed]

- Pavlović, N.V.; Mladenović, J.D.; Pavlović, R.M.; Moravčević, Đ.Ž.; Zdravković, J.M. The impact of different thermal processing of tomato to its antioxidant activity, vitamin E, dry matter and sugar content. Food Feed Res. 2017, 44, 123–132. [Google Scholar] [CrossRef] [Green Version]

- Vidyarthi, S.K.; El-Mashad, H.M.; Khir, R.; Zhang, R.; McHugh, T.H.; Pan, Z. Tomato peeling performance under pilot scale catalytic infrared heating. J. Food Eng. 2019, 246, 224–231. [Google Scholar] [CrossRef]

- Carli, P.; Barone, A.; Fogliano, V.; Frusciante, L.; Ercolano, M.R. Dissection of genetic and environmental factors involved in tomato organoleptic quality. BMC Plant Biol. 2011, 11, 58. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kamiloglu, S.; Boyacioglu, D.; Capanoglu, E. The effect of food processing on bioavailability of tomato antioxidants. J. Berry Res. 2013, 3, 65–77. [Google Scholar] [CrossRef] [Green Version]

- George, B.; Kaur, C.; Khurdiya, D.S.; Kapoor, H.C. Antioxidants in tomato (Lycopersium esculentum) as a function of genotype. Food Chem. 2004, 84, 45–51. [Google Scholar] [CrossRef]

- Di Mascio, P.; Kaiser, S.; Sies, H. Lycopene as the most efficient biological carotenoid singlet oxygen quencher. Arch. Biochem. 1989, 274, 532–538. [Google Scholar] [CrossRef]

- Conn, P.F.; Schalch, W.; Truscott, T.G. The singlet oxygen and carotenoid interaction. J. Photochem. Photobiol. B 1991, 11, 41–47. [Google Scholar] [CrossRef]

- Rao, A.V.; Agrawal, S. Role of lycopene as antioxidant carotenoid in the prevention of chronic diseases; a review. Nutr. Res. 1999, 19, 305–323. [Google Scholar] [CrossRef]

- Giovannucci, E. Tomatoes, tomato-based products, lycopene and cancer: Review of epidemiologic literature. J. Natl. Cancer Inst. 1999, 91, 317–331. [Google Scholar] [CrossRef] [PubMed]

- Allen, R.G.; Pereira, L.S.; Raes, D.; Smith, M. Crop Evapotranspiration: Guidelines for Computing Crop Requirements. In FAO Irrigation and Drainage Paper; No. 56; FAO: Rome, Italy, 1998. [Google Scholar]

- Caruso, G.; Villari, G.; Borrelli, C.; Russo, G. Effects of crop method and harvest seasons on yield and quality of green asparagus under tunnel in southern Italy. Adv. Hortic. Sci. 2012, 26, 51–58. [Google Scholar]

- Golubkina, N.A.; Nadezhkin, S.M.; Agafonov, A.F.; Kosheleva, O.V.; Molchanova, A.V.; Russo, G.; Cuciniello, A.; Caruso, G. Seed oil content, fatty acids composition and antioxidant properties as affected by genotype in Allium cepa L. and perennial onion species. Adv. Hortic. Sci. 2015, 29, 199–206. [Google Scholar]

- Conti, S.; Villari, G.; Amico, E.; Caruso, G. Effects of production system and transplanting time on yield, quality and antioxidant content of organic winter squash (Cucurbita moschata Duch.). Sci. Hortic. 2015, 183, 136–143. [Google Scholar] [CrossRef]

- De Sio, F.; Servillo, L.; Loiudice, R.; Laratta, B.; Castando, D. A chromatographic procedure for the determination of carotenoids and chlorophylls in vegetable products. Acta Aliment. 2001, 30, 395. [Google Scholar] [CrossRef]

- Golubkina, N.A.; Kosheleva, O.V.; Krivenkof, L.V.; Dobrutskaya, H.G.; Nadezhkin, S.; Caruso, G. Intersexual differences in plant growth, yield, mineral composition and antioxidants of spinach (Spinacia oleracea L.) as affected by selenium form. Sci. Hortic. 2017, 225, 350–358. [Google Scholar] [CrossRef]

- Jones, R.A.; Scott, S.J. Improvement of tomato flavor by genetically increasing sugar and acid contents. Euphytica 1983, 32, 845–855. [Google Scholar] [CrossRef]

- Clark, M.S.; Horwath, W.R.; Shennan, C.; Scow, K.M.; Lantni, W.T.; Ferris, H. Nitrogen, weeds and water as yield-limiting factors in conventional, low-input, and organic tomato systems. Agric. Ecosyst. Environ. 1999, 73, 257–270. [Google Scholar] [CrossRef]

- Clark, S.; Klonsky, K.; Livingston, P.; Temple, S. Crop-yield and economic comparisons of organic, low-input, and conventional farming systems in California’s Sacramento Valley. Am. J. Aternative Agric. 1999, 14, 109–121. [Google Scholar] [CrossRef]

- Garcia, E.; Watnik, M.R.; Barrett, D.M. Can we predict peeling performance of processing tomatoes? J. Food Process. Preserv. 2006, 30, 46–55. [Google Scholar] [CrossRef] [Green Version]

- Mohr, W.P. Tomato anatomy: Solids: Consistency relationships. Influence of fruit anatomy and solids composition of tomatoes on product consistency. Can. Inst. Food Sci. Technol. J. 1990, 23, 193–197. [Google Scholar] [CrossRef]

- Winsor, G.W.; Davies, J.N.; Massey, D.M. Composition of tomato fruit. III. Juices from whole fruit and locules at different stages of ripeness. J. Sci. Food Agric. 1962, 13, 108–115. [Google Scholar] [CrossRef]

- Winsor, G.W.; Davies, J.N.; Massey, D.M. Composition of tomato fruit. IV. Changes in some constituents of the fruit walls during ripening. J. Sci. Food Agric. 1962, 13, 141–145. [Google Scholar] [CrossRef]

- Davies, J.N. Changes in the non-volatile organic acids of tomato fruit during ripening. J. Sci. Food Agric. 1966, 17, 396–400. [Google Scholar] [CrossRef] [PubMed]

- Stevens, M.A. Citrate and malate concentrations in tomato fruits: Genetic control and maturational effects. J. Am. Soc. Hortic. Sci. 1972, 97, 655–685. [Google Scholar]

- Hallmann, E. The influence of organic and conventional cultivation systems on the nutritional value and content of bioactive compounds in selected tomato types. J. Sci. Food Agric. 2012, 92, 2840–2848. [Google Scholar] [CrossRef]

- Hobson, G.E.; Adams, P.; Dixon, T.J. Assessing the colour of tomato fruit during ripening. J. Sci. Food Agric. 1983, 34, 286–292. [Google Scholar] [CrossRef]

- Gormley, R.; Egan, S. Firmness and colour of the fruit of some tomato cultivars from various sources during storage. J. Sci. Food Agric. 1978, 29, 534–538. [Google Scholar] [CrossRef]

- De bruyn, J.W.; Garretsen, F.; Oistra, L.K. Variation in taste and chemical composition of the tomato (Lycopersicon esculentum Mill.). Euphytica 1971, 20, 214–227. [Google Scholar] [CrossRef]

- Stevens, M.A.; Kader, A.A.; Albright, M. Potential for increasing tomato flavor via increased sugar and acid content. J. Am. Soc. Hortic. Sci. 1979, 104, 40–42. [Google Scholar]

- Kazeniac, S.J.; Hall, R.M. Flavor chemistry of tomato volatiles. J. Food Sci. 1970, 35, 519–530. [Google Scholar] [CrossRef]

- Kader, A.A.; Stevens, M.A.; Albright-Holton, M.; Morris, L.L.; Algazi, M. Effect of fruit ripeness when picked on flavor and composition in fresh market tomatoes. J. Am. Soc. Hortic. Sci. 1977, 102, 724–731. [Google Scholar]

- Paulson, K.N.; Stevens, M.A. Relationships among titratable acidity, pH and buffer composition of tomato fruit. J. Food Sci. 1974, 39, 354–357. [Google Scholar] [CrossRef]

- Anthon, G.E.; Le Strange, M.; Barrett, D.M. Changes in pH, acids, sugars and other quality parameters during extended vine holding of ripe processing tomatoes. J. Sci. Food Agric. 2011, 91, 1175–1181. [Google Scholar] [CrossRef]

- Fuke, S.; Shimizu, T. Sensory and preference aspects of umami. Trends Food Sci. Technol. 1993, 4, 246–261. [Google Scholar] [CrossRef]

- Suarez, M.H.; Rodriguez, E.R.; Romero, C.D. Analysis of organic acid content in cultivars of tomatoes harvested in Tenerife. Eur. Food Res. Technol. 2008, 226, 423–435. [Google Scholar] [CrossRef]

- Zhao, J.; Xu, Y.; Ding, Q.; Huang, X.; Zhang, Y.; Zou, Z.; Zhang, J. Association mapping of main tomato fruit sugars and organic acids. Front. Plant Sci. 2016, 7, 1286. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.; Chin, C.K.; Ho, C.T.; Hwang, C.F.; Polashock, J.J.; Martin, C.E. Changes of fatty acids and fatty acid-derived flavor compounds by expressing the yeast Δ-9 desaturase gene in tomato. J. Agric. Food Chem. 1996, 44, 3399–3402. [Google Scholar] [CrossRef]

- Tomas-Barberan, F.; Espin, J. Phenolic compounds and related enzymes as determinants of quality in fruits and vegetables. J. Sci. Food Agric. 2001, 81, 853–876. [Google Scholar] [CrossRef]

- Capanoglu, E.; Beekwilder, J.; Boyacioglu, D.; Hall, R.; de Vos, R. Changes in antioxidant and metabolite profiles during production of tomato paste. J. Agric. Food Chem. 2008, 56, 964–973. [Google Scholar] [CrossRef] [PubMed]

- Vallverdú-Queralt, A.; Medina-Remón, A.; Andres-Lacueva, C.; Lamuela-Raventos, R.M. Changes in phenolic profile and antioxidant activity during production of diced tomatoes. Food Chem. 2011, 126, 1700–1707. [Google Scholar] [CrossRef]

- Abushita, A.A.; Daood, H.G.; Biacs, P.A. Change in carotenoids and antioxidant vitamins in tomato as a function of varietal and technological factors. J. Agric. Food Chem. 2000, 48, 2075–2081. [Google Scholar] [CrossRef]

- Dewanto, V.; Wu, X.; Adom, K.K.; Liu, R.H. Thermal processing enhances the nutritional value of tomatoes by increasing total antioxidant activity. J. Agric. Food Chem. 2002, 50, 3010–3014. [Google Scholar] [CrossRef]

- Gould, W.A. Tomato Production, Processing and Technology; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Kaur, C.; Walia, S.; Nagal, S.; Walia, S.; Singh, J.; Singh, B.B.; Jaggi, S. Functional quality and antioxidant composition of selected tomato (Solanum lycopersicon L.) cultivars grown in Northern India. LWT-Food Sci. Technol. 2013, 50, 139–145. [Google Scholar] [CrossRef]

- Yamamoto, T.; Yoshimura, M.; Yamaguchi, F.; Kouchi, T.; Tsuji, R.; Saito, M.; Kikuchi, M. Anti-allergic activity of naringenin chalcone from a tomato skin extract. Biosci. Biotechnol. Biochem. 2004, 68, 1706–1711. [Google Scholar] [CrossRef] [Green Version]

- De Sio, F.; Rapacciuolo, M.; De Giorgi, A.; Trifirò, A.; Giuliano, B.; Vitobello, L.; Cuciniello, A.; Caruso, G. Yield, quality and antioxidants of peeled tomato as affected by genotype and industrial processing in southern Italy. Adv. Hortic. Sci. 2018, 32, 379–387. [Google Scholar]

- De Sio, F.; Rapacciuolo, M.; De Giorgi, A.; Trifirò, A.; Giuliano, B.; Morano, G.; Cuciniello, A.; Caruso, G. Yield, quality, antioxidant, and sensorial properties of diced tomato as affected by genotype and industrial processing in Southern Italy. Acta Aliment. 2019, 48, 132–141. [Google Scholar] [CrossRef]

- Gupta, R.; Kopec, R.E.; Schwartz, S.J.; Balasubramaniam, V.M. Combined pressure–Temperature effects on carotenoid retention and bioaccessibility in tomato juice. J. Agric. Food Chem. 2011, 59, 7808–7817. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Knockaert, G.; Pulissery, S.K.; Colle, I.; Van Buggenhout, S.; Hendrickx, M.; Van Loey, A. Lycopene degradation, isomerization and in vitro bioaccessibility in high pressure homogenized tomato puree containing oil: Effect of additional thermal and highpressure processing. Food Chem. 2012, 135, 1290–1297. [Google Scholar] [CrossRef] [PubMed]

- Anese, M.; Mirolo, G.; Beraldo, P.; Lippe, G. Effect of ultrasound treatments of tomato pulp on microstructure and lycopene in vitro bioaccessibility. Food Chem. 2013, 136, 458–463. [Google Scholar] [CrossRef]

- Sanchez-Moreno, C.; Plaza, L.; Ancos, B.; Cano, M.P. Nutritional characterisation of commercial traditional pasteurised tomato juices: Carotenoids, vitamin C and radical-scavenging capacity. Food Chem. 2006, 98, 749–756. [Google Scholar] [CrossRef]

- George, S.; Tourniaire, F.; Gautier, H.; Goupy, P.; Rock, E.; Caris-Veyrat, C. Changes in the contents of carotenoids, phenolic compounds and vitamin C during technical processing and lyophilisation of red and yellow tomatoes. Food Chem. 2011, 124, 1603–1611. [Google Scholar] [CrossRef]

- Graziani, G.; Pernice, R.; Lanzuise, S.; Vitaglione, P.; Anese, M.; Fogliano, V. Effect of peeling and heating on carotenoid content and antioxidant activity of tomato and tomato-virgin olive oil systems. Eur. Food Res. Technol. 2003, 216, 116–121. [Google Scholar] [CrossRef]

- Sharma, S.K.; Le Maguer, M. Lycopene in tomatoes and tomato pulp fractions. Ital. J. Food Sci. 1996, 8, 107–113. [Google Scholar]

- Thane, C.; Reddy, S. Processing of fruit and vegetables: Effect on carotenoids. Nutr. Food Sci. 1997, 2, 58–65. [Google Scholar] [CrossRef]

| Marketable Fruits | ||||||||

|---|---|---|---|---|---|---|---|---|

| Hybrid | Yield t·ha−1 | Yield %/Total | Number Per Plant | Mean Weight g | Diameter cm | Length cm | Shape Index | Flesh Thickness mm |

| HMX 4228 | 73.0 ± 1.67 a | 92.4 ± 1.25 a | 25.3 ± 0.62 b | 72.1 ± 1.42 a | 4.8 ± 1.10 a | 5.8 ± 1.17 a | 1.21 ± 0.04 | 7.53 ± 0.26 |

| MAX 14111 | 71.9 ± 1.87 a | 89.9 ± 1.67 a | 28.3 ± 0.82 a | 63.5 ± 1.37 b | 4.4 ± 1.10 b | 5.5 ± 1.10 ab | 1.25 ± 0.05 | 7.50 ± 0.21 |

| UG 16112 | 62.3 ± 1.35 b | 81.0 ± 1.47 b | 22.7 ± 0.85 c | 68.9 ± 1.77 a | 4.6 ± 1.17 ab | 5.5 ± 1.17 ab | 1.18 ± 0.05 | 7.70 ± 0.25 |

| Impact | 62.5 ± 1.78 b | 92.2 ± 1.41 a | 25.3 ± 0.72 b | 61.7 ± 1.18 b | 4.5 ± 1.10 ab | 5.4 ± 1.10 b | 1.16 ± 0.05 | 7.37 ± 0.26 |

| n.s. | n.s. | |||||||

| Processing Yield | Waste Fruits along Peeling Chain | Waste Fruits along Juice Chain | |||

|---|---|---|---|---|---|

| Hybrid | Product | Diced | Juice | % | % |

| HMX 4228 | 79.3 ± 1.95 a | 60.3 ± 1.57 a | 96.4 ± 2.97 a | 39.7 ± 1.51 b | 3.7 ± 0.17 d |

| MAX 14111 | 78.5 ± 1.28 a | 60.0 ± 1.65 a | 93.5 ± 4.36 a | 40.2 ± 1.81 b | 6.5 ± 0.26 c |

| UG 16112 | 67.6 ± 1.47 b | 51.3 ± 1.32 b | 81.2 ± 4.31 b | 48.8 ± 1.71 a | 18.8 ± 1.37 a |

| Impact | 77.0 ± 1.87 a | 59.7 ± 1.85 a | 90.1 ± 4.15 a | 40.2 ± 1.35 b | 9.9 ± 0.72 b |

| Treatment | Total Solids g·100 g−1 f.w. | Soluble Solids °Brix | Reducing Sugars g·100 g−1 f.w. | Sugar Ratio % | Color a/b | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Industrial processing | ||||||||||

| Raw | 6.11 ± 0.28 | b | 5.37 ± 0.25 | b | 2.73 ± 0.16 | b | 44.7 ± 2.30 | 2.55 ± 0.12 | a | |

| Diced | 7.53 ± 0.34 | a | 6.54 ± 0.30 | a | 3.38 ± 0.18 | a | 44.9 ± 2.34 | 1.88 ± 0.10 | b | |

| n.s. | ||||||||||

| Hybrid | ||||||||||

| HMX 4228 | 6.51 ± 0.79 | b | 5.71 ± 0.67 | b | 3.10 ± 0.38 | ab | 47.7 ± 1.53 | a | 2.26 ± 0.40 | a |

| MAX 14111 | 7.15 ± 0.84 | a | 6.21 ± 0.72 | a | 3.21 ± 0.40 | a | 45.0 ± 1.41 | b | 2.19 ± 0.38 | ab |

| UG 16112 | 6.79 ± 0.82 | ab | 5.90 ± 0.64 | ab | 3.00 ± 0.38 | b | 44.0 ± 1.43 | bc | 2.11 ± 0.38 | b |

| Impact | 6.83 ± 0.76 | ab | 6.00 ± 0.67 | ab | 2.92 ± 0.36 | b | 42.8 ± 1.32 | c | 2.31 ± 0.36 | a |

| Hybrid | Titratable Acidity g Anhydrous Citric Acid·100 g−1 f.w. | Proteins g·100 g−1 f.w. | Fats g·100 g−1 f.w. | Fiber g·100 g−1 f.w. | Energetic Value Kcal·100 g−1 f.w. |

|---|---|---|---|---|---|

| HMX 4228 | 0.41 ± 0.017 b | 2.02 ± 0.13 | 0.24 ± 0.04 | 0.86 ± 0.03 b | 26.5 ± 0.62 b |

| MAX 14111 | 0.51 ± 0.020 a | 2.13 ± 0.14 | 0.24 ± 0.05 | 1.12 ± 0.08 a | 28.5 ± 0.75 a |

| UG 16112 | 0.49 ± 0.017 a | 2.03 ± 0.15 | 0.21 ± 0.03 | 0.87 ± 0.09 b | 26.4 ± 0.92 b |

| Impact | 0.40 ± 0.020 b | 2.12 ± 0.14 | 0.22 ± 0.04 | 1.05 ± 0.10 a | 26.1 ± 0.87 b |

| n.s. | n.s. |

| Sugars | Fatty Acids | |||||

|---|---|---|---|---|---|---|

| Hybrid | Glucose g·100 g−1 f.w. | Fructose g·100 g−1 f.w. | Sucrose mg·100 g−1 f.w. | Saturated g·100 g−1 f.w. | Monounsaturated g·100 g−1 f.w. | Polyunsaturated g·100 g−1 f.w. |

| HMX 4228 | 1.53 ± 0.10 | 1.81 ± 0.07 a | n.d. | 0.07 ± 0.010 a | 0.07 ± 0.010 a | 0.09 ± 0.005 b |

| MAX 14111 | 1.58 ± 0.12 | 1.92 ± 0.07 a | n.d. | 0.07 ± 0.005 a | 0.05 ± 0.010 b | 0.11 ± 0.005 a |

| UG 16112 | 1.48 ± 0.17 | 1.60 ± 0.08 b | 210 ± 20 a | 0.05 ± 0.010 b | 0.06 ± 0.005 ab | 0.10 ± 0.010 ab |

| Impact | 1.46 ± 0.11 | 1.52 ± 0.05 b | 230 ± 20 a | 0.06 ± 0.005 ab | 0.05 ± 0.010 b | 0.10 ± 0.005 ab |

| n.s. |

| Treatment | Total Polyphenols mg eq. Gallic Acid 100 g−1 f.w. | Rutin mg·kg−1 f.w. | Naringenin mg·kg−1 f.w. | Lycopene mg·kg−1 f.w. |

|---|---|---|---|---|

| Industrial Processing | ||||

| Raw | 35.7 ± 1.5 b | 18.7 ± 2.4 b | n.d. | 158.9 ± 12.8 |

| Diced | 41.0 ± 2.1 a | 49.9 ± 5.8 a | 11.9 | 155.2 ± 15.0 |

| n.s. | ||||

| Hybrid | ||||

| HMX 4228 | 37.0 ± 2.4 b | 30.6 ± 15.4 c | 6.3 ± 6.9 a | 158.8 ± 15.5 |

| MAX 14111 | 40.3 ± 3.7 a | 39.6 ± 20.0 a | 6.1 ± 6.7 ab | 160.4 ± 16.1 |

| UG 16112 | 38.3 ± 3.7 ab | 31.6 ± 16.0 c | 5.6 ± 6.1 b | 153.7 ± 11.4 |

| Impact | 37.7 ± 2.8 ab | 35.5 ± 17.5 b | 5.9 ± 6.5 ab | 155.3 ± 14.3 |

| n.s. |

| Sensorial Variables | Cultivar | Cultivar | Δ | F crit |

|---|---|---|---|---|

| Appearance | Impact | HMX 4228 | 1.65 | 1.07 |

| Impact | Max 14111 | 1.45 | 1.10 | |

| HMX 4228 | UG 16112 | 1.4 | 1.10 | |

| Max 14111 | UG 16112 | 1.2 | 1.10 | |

| Color | Impact | HMX 4228 | 1.6 | 0.97 |

| Impact | Max 14111 | 1.5 | 0.99 | |

| HMX 4228 | UG 16112 | 1.4 | 1.00 | |

| Max 14111 | UG 16112 | 1.3 | 1.00 | |

| Flavor | Impact | Max 14111 | 1.6 | 1.27 |

| Fresh tomato Flavor | Impact | HMX 4228 | 1.7 | 1.22 |

| Impact | Max 14111 | 1.8 | 1.25 | |

| Taste | Impact | Max 14111 | 2.0 | 1.34 |

| Impact | UG 16112 | 1.3 | 1.27 | |

| Fresh Tomato Taste | Impact | HMX 4228 | 1.5 | 1.21 |

| Impact | Max 14111 | 2.0 | 1.24 | |

| Sweetness | Impact | HMX 4228 | 1.5 | 1.24 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Sio, F.; Rapacciuolo, M.; De Giorgi, A.; Sandei, L.; Giuliano, B.; Tallarita, A.; Golubkina, N.; Sekara, A.; Stoleru, V.; Cuciniello, A.; et al. Industrial Processing Affects Product Yield and Quality of Diced Tomato. Agriculture 2021, 11, 230. https://doi.org/10.3390/agriculture11030230

De Sio F, Rapacciuolo M, De Giorgi A, Sandei L, Giuliano B, Tallarita A, Golubkina N, Sekara A, Stoleru V, Cuciniello A, et al. Industrial Processing Affects Product Yield and Quality of Diced Tomato. Agriculture. 2021; 11(3):230. https://doi.org/10.3390/agriculture11030230

Chicago/Turabian StyleDe Sio, Francesco, Mariateresa Rapacciuolo, Alessandro De Giorgi, Luca Sandei, Bonaventura Giuliano, Alessio Tallarita, Nadezhda Golubkina, Agnieszka Sekara, Vasile Stoleru, Antonio Cuciniello, and et al. 2021. "Industrial Processing Affects Product Yield and Quality of Diced Tomato" Agriculture 11, no. 3: 230. https://doi.org/10.3390/agriculture11030230

APA StyleDe Sio, F., Rapacciuolo, M., De Giorgi, A., Sandei, L., Giuliano, B., Tallarita, A., Golubkina, N., Sekara, A., Stoleru, V., Cuciniello, A., Morano, G., & Caruso, G. (2021). Industrial Processing Affects Product Yield and Quality of Diced Tomato. Agriculture, 11(3), 230. https://doi.org/10.3390/agriculture11030230