1. Introduction

Teff (

Eragrostis tef) is an important crop for smallholder farmers in Ethiopia because it contributes to both their food security and income [

1]. In Ethiopia, more than three million hectares of land are cultivated with teff annually [

2]. However, teff production there is constrained by lodging, drought, reduced soil fertility, and the need for continuous cropping [

3]. These problems are worsened by traditional crop cultivation practices such as plant residue removal; frequent tillage and soil compaction; and a lack of knowledge and access to inputs such as improved seed, fertilizers, and irrigation technologies [

4]. Usually, teff is cultivated using local cultivars and a high seeding rate (>25 kg ha

−1); plowing is usually performed with oxen, and broadcast sowing, harvesting, and threshing are usually performed by hand [

5]. Although smallholder farmers have their own reasons for using this approach, these practices are considered to be the inherent cause of low crop productivity and the degradation of natural resources [

4]. Thus, cost-effective crop management practices for increasing teff productivity are needed.

Traditionally, farmers will plow their teff fields four to eight times, depending on the area, to create a fine seedbed for better seed establishment and to minimize weed and pest infestations [

6]. However, excess tilling wastes money, and disturbing the soil increases erosion and organic matter loss [

7]. To address these concerns, and potentially reverse the negative impacts of conventional tillage approaches, the concept of reduced tillage, which encompasses minimizing the amount of tillage, using mixed cropping or crop rotation, incorporating crop residues, and using pre-emergent herbicides to control weeds, was developed [

8]. Reduced tillage approaches have been shown to improve crop productivity, improve soil quality, and reduce soil erosion in major cereals such as maize [

9], sorghum [

10], and wheat [

11]. However, because reduced tillage results in large weed populations, which can compete with the crop for nutrients and reduce the crop biomass that will be later used as feed for livestock or as an energy source for cooking, this approach requires application of pesticides that are potentially harmful to the environment [

11]. Another drawback of reduced tillage is that it needs to be practiced for a long period of time before the desired changes in soil quality and crop yield are seen [

12]; this is problematic because farmers generally prefer to use technologies that offer an immediate economic benefit. Despite these drawbacks, the implementation of reduced tillage activities in Ethiopia has been reported to reduce soil erosion and improve yield in maize [

13], sorghum [

14], and teff [

15].

Another characteristic of traditional teff farming in Ethiopia is the use of broadcast sowing (hand-scattering at a high seeding rate) as a means of controlling weeds, producing high-quality straw for livestock, and reducing labor costs [

16]. However, broadcast sowing results in uneven seed distribution and low tillering capacity, and allows weeds to compete with the crop for applied nutrients. Row sowing is an alternative to broadcast sowing, and although the effects of row sowing are highly dependent on soil type, the tillering capacity of the cultivar used, timing and amounts of nutrients applied, and seeding density and spacing between rows, this approach has been shown in teff to improve growth and yield, and to use less seed than broadcast sowing [

16,

17]. In addition, unlike in broadcast sowing, in row sowing nutrients can be placed near the root zone [

18]. It has been suggested that the improvements in teff productivity brought about by row sowing are the result of efficient resource utilization, increased tillering, reduced lodging, and the facilitation of farm activities [

19]. In teff, row sowing has also been shown to be more economical than broadcast sowing and seedling transplantation [

16]. Despite these many advantages, the current adoption of row sowing in teff cultivation is very low due to the high labor costs associated with row-making, sowing, and weeding, and because this approach results in poor-quality (tough) straw for livestock.

A unique practice in teff production is the process of compacting the soil by human or animal (cattle, donkey, or horses) trampling immediately before sowing [

15]. The purpose is to increase the contact area between the seed and the soil, reduce the risk of the seed being displaced by rain water, and seal the soil surface to reduce the loss of moisture through evaporation [

20]. However, compaction is a costly practice because it requires a large number of people or animals to thoroughly compact large planting areas. Compacting the soil is also known to aggravate soil loss via runoff by reducing rainwater infiltration [

21]. Recently, [

4] have reported that trampling has little or no impact on economic yield in teff.

In addition, crop cultivation by the smallholder farmers in Ethiopia is largely contributing to land degradation through less efficient crop management systems such as intensive tillage operations, soil compaction, and the application of less input than removed from the soil [

22]. Farmers also keep animals as a source draft power for tillage and soil compaction in Ethiopia that caused overgrazing leading to land degradation and reduced crop productivity [

23]. Keeping animals for the sake of a specific farm activity (e.g., tillage, soil compaction and threshing) without any additional economic benefits will expose farmers to unnecessary costs for feed, shelter and healthcare [

24]. Conservation agriculture that minimizes soil disturbance and restores soil degradation such as reduced tillage and avoiding soil compaction together with crop residue retention, crop rotation and intercropping practices improves crop productivity and farmer’s income with no or less impact on the environment [

25].

Although reduced tillage, row sowing, and avoiding soil compaction have been demonstrated to have agronomic, economic, and environmental advantages over traditional teff production practices, little is known about their impacts when applied in combination. However, previous findings do suggest that combining these practices may be a cost-effective means of improving teff productivity. Here, we examined whether the application of these three farming practices, individually and in combination, could improve the agronomic (plant population, plant height, panicle length, loading, and yield) and economic performance of teff cultivation in the northwestern highlands of Ethiopia.

2. Materials and Methods

2.1. Study Area

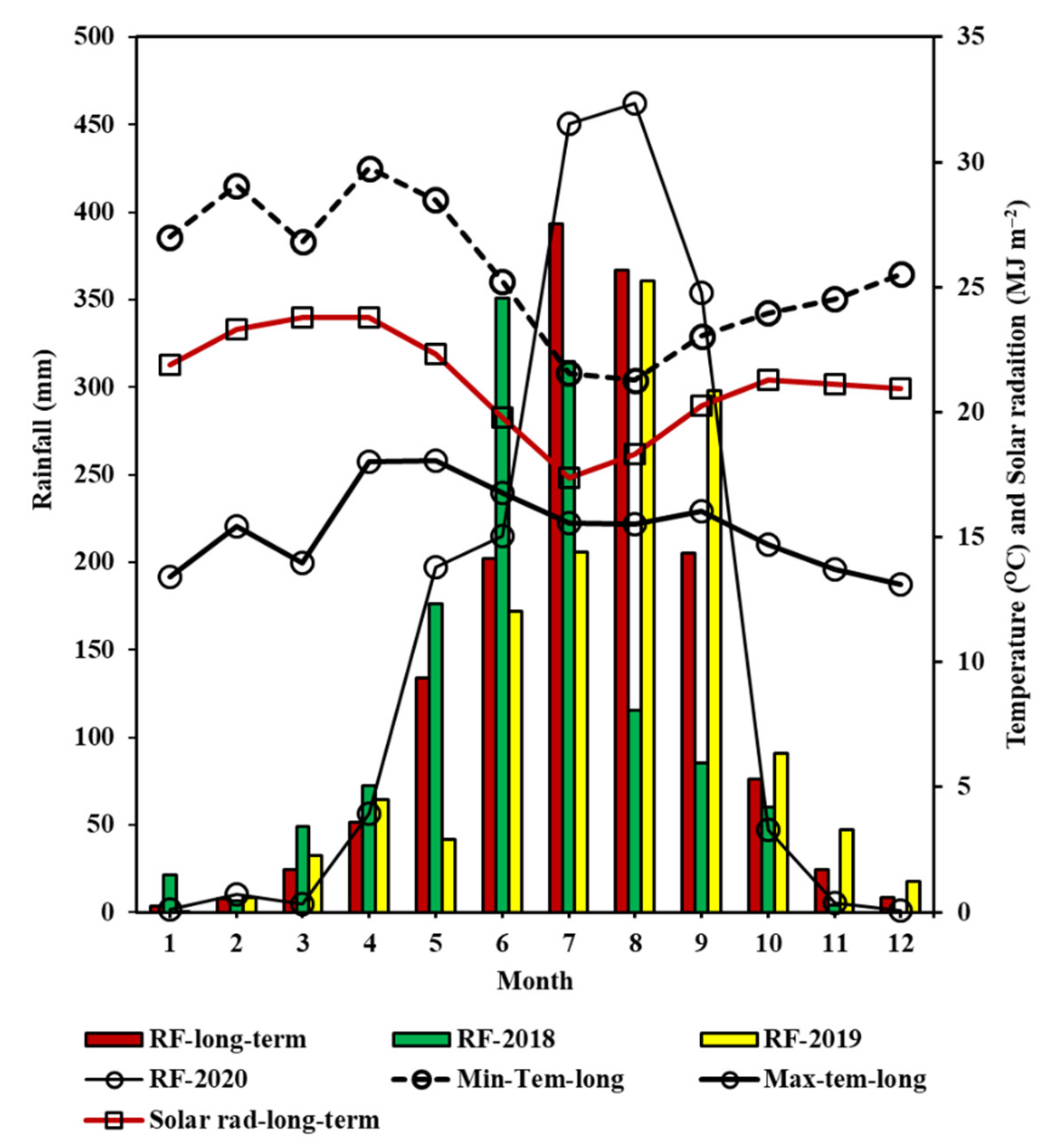

The study was performed in the Aba Gerima watershed (11°38′40.65″ N, 37°29′30.02″ E), which was selected as an area representative of the midland agro-ecological zone in the northwestern Ethiopia [

4]. Based on long-term observations (

Figure 1), the study area receives an average annual rainfall ranging from 900 to 2000 mm and an average monthly maximum temperature of 26 °C and minimum temperature of 15 °C. The main rainy season (growing season) falls from June to September. The soils in the study area are predominantly luvisols and leptosols; soil parameters measured for soil samples collected at the study site are shown in

Table 1.

2.2. Experimental Setup

Experimental plots were established to evaluate two tillage practices (conventional tillage, CT; reduced tillage, RT), two seeding practices (broadcast planting, BP; row planting, RP), and two soil compaction practices (with compaction, WC; with no compaction, NC) as follows:

Tillage: In accordance with current practice in the study area, CT plots were plowed four times: once in April, two times in June, and once in July. RT plots were plowed once at planting in July. In all plots, plowing was performed manually using a hand-hoe.

Planting: In accordance with current practice in the study area, BP was performed by manually scattering seed at a rate of 25 kg ha−1. In RP plots, teff was planted in rows at a spacing of 25 cm and a seeding rate of 10 kg ha−1.

Soil compaction: In accordance with current practice in the study area, soil compaction was performed immediately before planting by using human labor. No trampling was conducted in the plots without soil compaction.

Treatments were arranged following a split–split plot design with four replications. Tillage was assigned to the main plots, planting to the sub plots, and soil compaction to the sub- sub plots. The gross plot size was 5 m × 3 m; the net plot size was 4 m × 2 m; spacing between blocks was 0.6 m. Planting was performed on 25 July 2018, 29 July 2019, and 7 August 2020. The teff variety “Quncho” was used. To help determine the amount of fertilizer to be applied, composite topsoil samples of the studied plots were analyzed for selected parameters (

Table 1, see also

Section 2.3). Nitrogen (N) and phosphorous (P) were applied at rates of 64 kg N ha

−1 and 46 kg P ha

−1, respectively. All P and half of the N was applied at planting; the remaining N was applied at 30 days after planting. Weeding was performed two times, at 30 and 45 days after sowing. Harvesting was performed on 5 November 2018, 27 November 2019, and 2 December 2020.

2.3. Data Collection and Analysis

To evaluate the soil properties of the experimental plots, a composite topsoil (0–20 cm) sample from the experimental plots was collected before the start of the experiment (in 2018) and analyzed for total nitrogen, total organic carbon, bulk density, pH, available P, exchangeable K, and electrical conductivity (

Table 1). Total nitrogen was determined by using the Kjeldahl method [

26]. Total organic carbon was determined as described by Nelson and Sommers [

27]. Available P was determined by using the Olsen extraction method [

28]. pH and electrical conductivity were determined based on the potentiometer principle [

29]; using a soil: water (1:25) solution, pH was determined using a pH meter and electrical conductivity was measured with a conductivity meter.

During the experiment in 2019 and 2020, soil moisture was monitored every 30 min by using a moisture sensor (Decagon EC-5, METER Group, Inc., Pullman, WA, USA) and data logger (EM 50) installed in each plot at a depth of 40 cm.

During the experiment in 2018, 2019, and 2020, plant height was measured every 15 days by randomly sampling 5 teff plants in each plot. Panicle length was measured immediately before harvesting by randomly sampling 5 teff plants from each plot. The plant population was counted within a 0.25-m2 quadrat placed at two randomly selected points in each plot; counting was conducted twice during the growing period—at the early growth stage (20 days after sowing) and at harvest. The weed population was also counted within a 0.25-m2 quadrat placed at two randomly selected points in each plot immediately before the first and second weeding. Lodging was visually estimated as a percentage of teff stands in each plot inclined below 45° during physiological maturity. Leaf area index was quantified with an LAI-2200C Plant Canopy Analyzer following standard procedures. Grain and straw yields were quantified using samples collected within a 1-m2 quadrat at two spots from each plot during physiological maturity. The samples were sun-dried for at least 4 days and manually threshed; husks were manually separated from the grain by using sieves. Grain and straw yields were quantified by using a LABMAN analytical balance.

Labor costs of tillage, sowing, trampling, and the cost of seed were recorded to estimate the variable costs associated with the experimental practices. Non-variable costs such as the costs of fertilizers, harvesting, and threshing were assumed to be constant across treatments. A cost–benefit analysis was performed by using input costs (labor and seed), selling prices of teff grain, and straw yields documented by nearby cooperatives. All costs and benefits (in USD) were calculated as average values across the three monitoring seasons (2018, 2019, and 2020) and are expressed on a per hectare basis. Total variable cost was determined as the sum of the costs of seed and labor for the different tillage, planting, and soil compaction methods. Gross benefit was calculated as the sum of income obtained from grain and straw yield sales. Net benefit was calculated by subtracting the total variable cost from the gross benefit.

R statistical software version 3.3.2 [

30] was used to analyze the data. The Shapiro–Wilk test [

31] was used to check the normality of the data. The least significant difference test [

32] was used to detect differences between treatments. The statistical significance of each difference in the agronomic and economic parameters among treatments was tested at the 1% and 5% probability levels.