Effects of Nitrogen Application Rate on Protein Components and Yield of Low-Gluten Rice

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Site Information

2.2. Experiment Design

2.3. Measurements and Methods

2.3.1. Yield and Yield Components

2.3.2. Photosynthetic Characteristics and Enzyme Activity Measurements

2.3.3. Total Protein and Protein Components in the Rice Grain

2.3.4. Rice Quality Indicators

2.4. Data Analysis

3. Results

3.1. Effect of Nitrogen on Yield and Yield Components

3.2. Effect of Nitrogen Rate on Dry Matter (DM) Accumulation

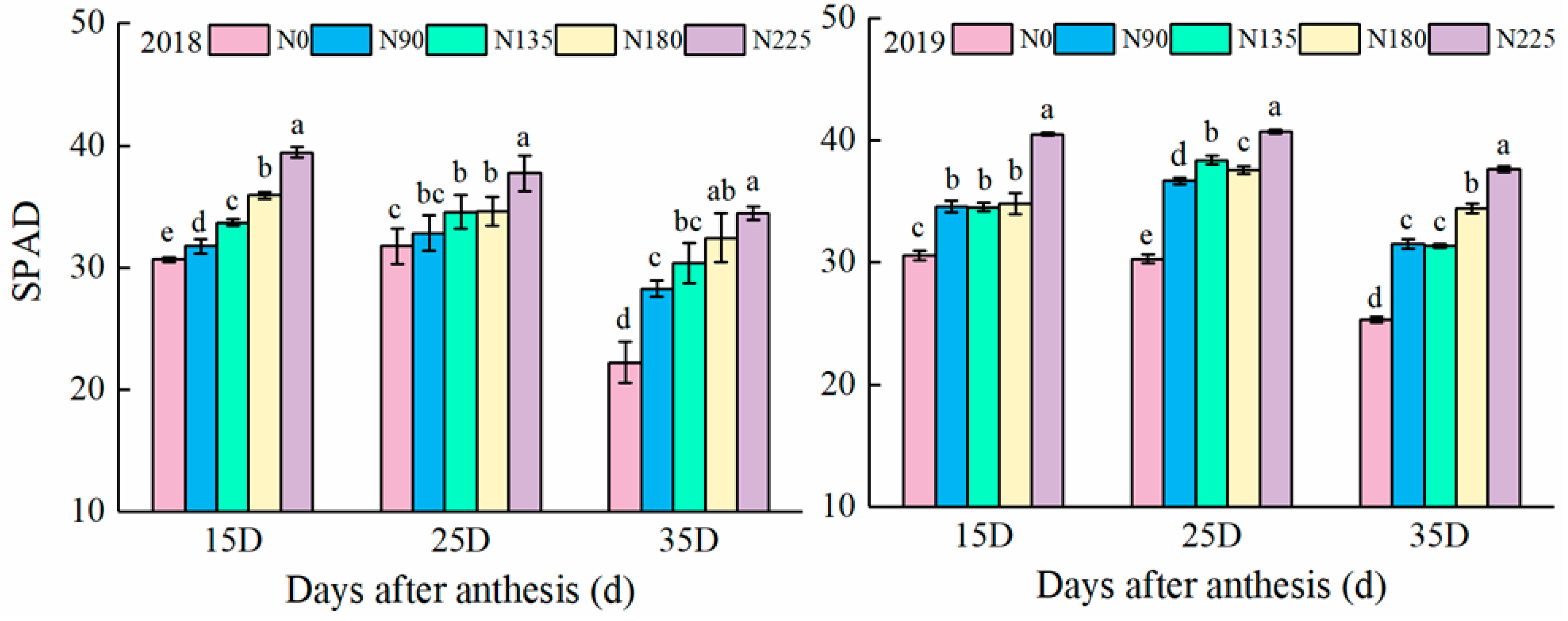

3.3. Effect of Nitrogen Application Rate on Leaf SPAD

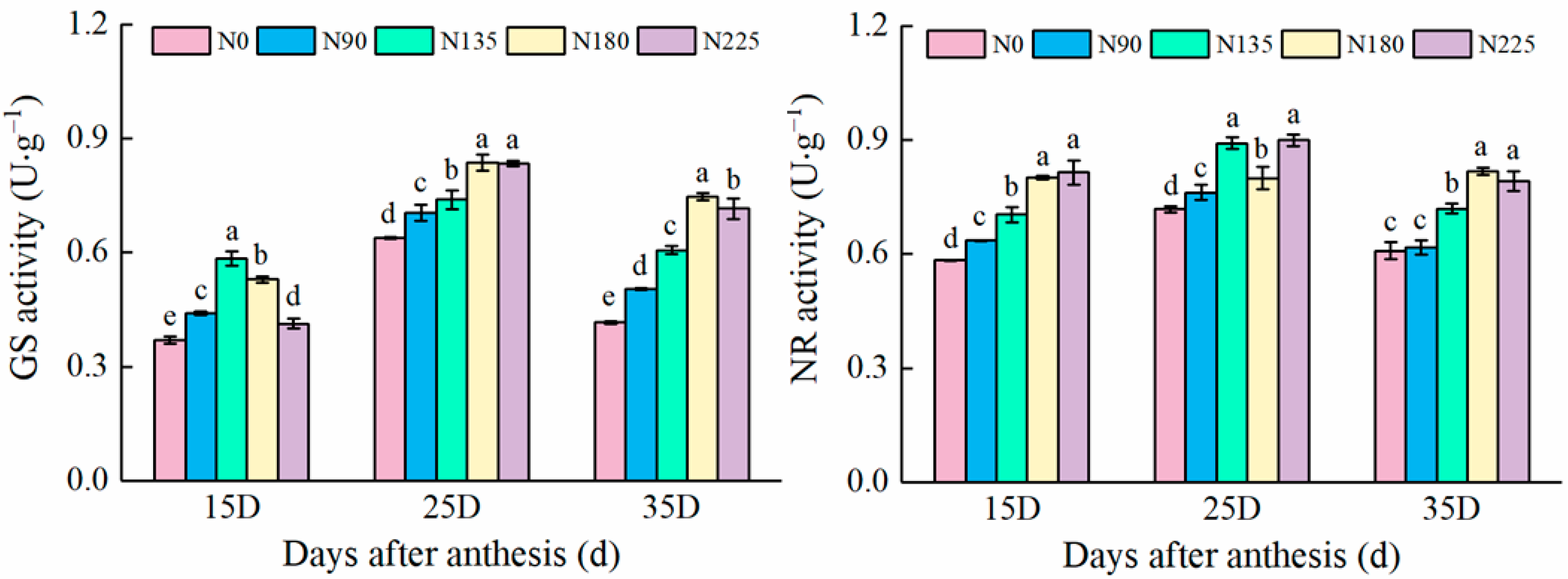

3.4. Effects of Nitrogen Application on Enzyme Activity

3.5. Effect of Nitrogen Rate on Rice Physical and Chemical Properties

3.6. Effect of Nitrogen Rate on Rice Processing Quality

3.7. Effect of Nitrogen Rate on Protein Content

3.8. Effect of Nitrogen Rate on the Proportion of Each Component Protein to Total Protein at Maturity

4. Discussion

4.1. The Effect of Nitrogen Fertilizer on the Physical and Chemical Properties and the Processing Quality of Low-Gluten Rice

4.2. Effect of Nitrogen Fertilizer on Rice Grain Protein and Its Components

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mizuma, T.; Sachiko, I.; Kiyokawa, Y.; Wakai, Y.; Yamamoto, Y.; Tsutsui, N.; Matsushita, K.; Maeda, H.; Iida, S.; Nemoto, H. Characteristics of Low-Glutelin Rice for Sake Brewing—Studies on Rice for Sake Brewing. J. Biosci. Bioeng. 2002, 80, 512–520. [Google Scholar] [CrossRef]

- Furukawa, S.; Itou, M.; Masumura, T.; Tanaka, K.; Kiyokawa, Y.; Wakai, Y. Ultrastructure of low-glutelin rice endosperm. Plant Biotechnol. 2007, 24, 227–229. [Google Scholar] [CrossRef]

- Zhou, C.; Huang, Y.; Jia, B.; Wang, Y.; Wang, Y.; Xu, Q.; Li, R.; Wang, S.; Dou, F. Effects of Cultivar, Nitrogen Rate, and Planting Density on Rice-Grain Quality. Agronomy 2018, 8, 246. [Google Scholar] [CrossRef] [Green Version]

- Mochizuki, T.; Hara, S. Usefulness of the low protein rice on the diet therapy in patients with chronic renal failure. Nihon Jinzo Gakkai Shi 2000, 42, 24–29. [Google Scholar]

- Martinez, M.F.; Arelovich, H.M.; Wehrhahne, L.N. Grain yield, nutrient content and lipid profile of oat genotypes grown in a semiarid environment. Field Crop. Res. 2010, 116, 92–100. [Google Scholar] [CrossRef]

- Chen, P.; Shen, Z.; Ming, L.; Li, Y.; Dan, W.; Lou, G.; Peng, B.; Wu, B.; Li, Y.; Zhao, D.; et al. Genetic Basis of Variation in Rice Seed Storage Protein (Albumin, Globulin, Prolamin, and Glutelin) Content Revealed by Genome-Wide Association Analysis. Front. Plant Sci. 2018, 9, 612. [Google Scholar] [CrossRef] [Green Version]

- Yang, M.; Lu, K.; Zhao, F.-J.; Xie, W.; Ramakrishna, P.; Wang, G.; Du, Q.; Liang, L.; Sun, C.; Zhao, H.; et al. Genome-Wide Association Studies Reveal the Genetic Basis of Ionomic Variation in Rice. Plant Cell 2018, 30, 2720–2740. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jin, Z.X.; Qiu, T.Q.; Sun, Y.L.; Zhao, J.M.; Jin, X.Y. Effect of nitrogen fertilizer on chalkiness ratio and cooking and eating quality properties of rice grain. Plant Nutr. Fert. Sci. 2001, 7, 31–35, (In Chinese with English abstract). [Google Scholar]

- Jin, T.; Xiyang, Q.Y.; Chengxin, J.; Lijun, L.; Hao, Z. Grain quality and its response to nitrogen fertilizer in mid-season indica rice varieties planted in different decades from 1950s to 2010s. Acta Agron. Sin. 2016, 42, 1352–1362, (In Chinese with English abstract). [Google Scholar]

- Han, Z.Y.; Guan, X.Y.; Zhao, Q.; Wu, C.Y.; Huang, F.D.; Pan, G.; Cheng, F.M. Individual and combined effects of air temperature at filling stage and nitrogen application on storage protein accumulation and its different components in rice grains. Acta Agron. Sin. 2020, 46, 1087–1098. [Google Scholar] [CrossRef]

- Zhang, H.; Wu, G.; Huo, Z.; Xu, K.; Gao, H.; Wei, H.; Wan, L.; Huang, Y. Precise postponing nitrogen application and its mechanism in rice. Acta Agron. Sin. 2011, 37, 1837–1851, (In Chinese with English abstract). [Google Scholar] [CrossRef]

- Hu, Y.J.; Zhu, D.W.; Xing, Z.P.; Gong, J.Z.; Zhang, H.Z.; Dai, Q.G.; Huo, Z.Y.; Ke, X.; Wei, H.U.; Guo, B.W. Modifying nitrogen fertilization ratio in increase the yield and nitrogen uptake of super japonica rice. Plant Nutr. Fert. Sci. 2015, 21, 12–22, (In Chinese with English). [Google Scholar]

- Zhu, D.-W.; Zhang, H.-C.; Guo, B.-W.; Xu, K.; Dai, Q.-G.; Wei, H.-Y.; Gao, H.; Hu, Y.-J.; Cui, P.-Y.; Huo, Z.-Y. Effects of nitrogen level on yield and quality of japonica soft super rice. J. Integr. Agric. 2017, 16, 1018–1027. [Google Scholar] [CrossRef]

- Godfrey, D.; Hawkesford, M.J.; Powers, S.J.; Millar, S.; Shewry, P.R. Effects of Crop Nutrition on Wheat Grain Composition and End Use Quality. J. Agric. Food Chem. 2010, 58, 3012–3021. [Google Scholar] [CrossRef]

- Lea, P.J.; Blackwell, R.D.; Chen, F.L. Enzymes of primary metabolism. In Methods in Plant Biochemistry; Harborne, J.B., Ed.; Academic Press: New York, NY, USA, 1990; Volume 3, pp. 260–273. ISBN 0124610137. [Google Scholar]

- Hesheng, L. Experimental Principles and Techniques of Plant Physiology and Biochemistry; Higher Education Press: Beijing, China, 2000; pp. 125–127. [Google Scholar]

- Gilani, G.S.; Xiao, C.W.; Cockell, K.A. Impact of Antinutritional Factors in Food Proteins on the Digestibility of Protein and the Bioavailability of Amino Acids and on Protein Quality. Br. J. Nutr. 2012, 108, S315–S332. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.T. A Guide to Modern Plant Physiology Experiments; Science Press: Beijing, China, 1999; ISBN 7-03-008099-8. [Google Scholar]

- Yan, Y.; Zhang, L.X.; Wan, C.Z.; Shuju, W. Correlation between RVA spectral characteristic value and physical and chemical index of rice starch and taste value. Plant Physiol. J. 2016, 52, 1884–1890. [Google Scholar] [CrossRef]

- Wei, H.Y.; Chen, Z.F.; Xing, Z.P.; Zhou, L.L.; Liu, Q.Y.; Zhang, Z.Z.; Jiang, Y.; Hu, Y.J. Effects of slow or controlled release fertilizer types and fertilization modes on yield and quality of rice. J. Integr. Agric. 2018, 17, 2222–2234. [Google Scholar] [CrossRef]

- Zhu, D.; Zhang, H.; Guo, B.; Xu, K.; Dai, Q.; Wei, C.; Zhou, G.; Huo, Z. Effects of nitrogen level on structure and physicochemical properties of rice starch. Food Hydrocoll. 2017, 63, 525–532. [Google Scholar] [CrossRef]

- Tang, S.; Zhang, H.; Liu, W.; Dou, Z.; Zhou, Q.; Chen, W.; Wang, S.; Ding, Y. Nitrogen fertilizer at heading stage effectively compensates for the deterioration of rice quality by affecting the starch-related properties under elevated temperatures. Food Chem. 2019, 277, 455–462. [Google Scholar] [CrossRef] [PubMed]

- Baghdadi, A.; Halim, R.A.; Ghasemzadeh, A.; Ramlan, M.F.; Sakimin, S.Z. Impact of organic and inorganic fertilizers on the yield and quality of silage corn intercropped with soybean. PeerJ 2018, 6, e5280. [Google Scholar] [CrossRef] [Green Version]

- Khan, A.; Tan, D.K.Y.; Afridi, M.Z.; Luo, H.; Tung, S.A.; Ajab, M.; Fahad, S. Nitrogen fertility and abiotic stresses management in cotton crop: A review. Environ. Sci. Pollut. Res. 2017, 24, 14551–14566. [Google Scholar] [CrossRef] [PubMed]

- Clerici, M.T.P.S.; Sampaio, U.M.; Schmiele, M. Identification and Analysis of Starch. Starches Food Appl. 2019, 23–69. [Google Scholar] [CrossRef]

- Zhang, X.M.; Shi, C.H.; Fu, T.G. Correlation analysis between starch characteristics and taste quality in japonica rice. Chin. J. Rice Sci. 2002, 16, 157–161, (In Chinese with English abstract). [Google Scholar]

- Ji, H.J.; Zhao, B.H.; Chen, G. Response of grain yield and quality of Yangjing 805 to wheat straw returning and nitrogen management. J. Yangzhou Univ. Agric. Life Sci. 2016, 37, 60–64, (In Chinese with English abstract). [Google Scholar]

- Wang, Y.W.; Li, H.X.; Tian, G.; Sun, M.R.; Shi, Q.X.; Guo, E.H. Relationship between cooked millet palatability and both visual quality and RVA profile character of starch. Shanxi Agric. Sci. 2008, 36, 34–39, (In Chinese with English abstract). [Google Scholar]

- Lan, Y.; Huang, P.; Jiang, G.U. Effect of nitrogen application and planting density on grain yield and quality of japonica rice cultivar D46 in the planting area of Chengdu plain. J. Zhejiang Univ. 2016, 42, 63–73, (In Chinese with English abstract). [Google Scholar]

- Wu, H.K.; Liu, S.J.; Jiang, L. Relationship between protein composition and total protein content and starch RVA profile properties in rice. Chin. J. Rice Sci. 2009, 23, 421–426, (In Chinese with English abstract). [Google Scholar]

- Blumenthal, J.M.; Baltensperger, D.D.; Cassman, K.G.; Mason, S.C.; Pavlista, A.D. Importance and Effect of Nitrogen on Crop Quality and Health. In Nitrogen in the Environment; Elsevier BV: Amsterdam, The Netherlands, 2008; Volume 3, pp. 51–70. [Google Scholar]

- Li, G.H.; Chen, Y.L.; Ding, Y.F.; Geng, C.M.; Quan, L.I.; Liu, Z.H.; Wang, S.H.; She, T.A. Charactering protein fraction concentrations as influenced by nitrogen application in low-glutelin rice cultivars. J. Integr. Agric. 2016, 15, 537–544, (In Chinese with English abstract). [Google Scholar] [CrossRef] [Green Version]

- Wei, H.-Y.; Wang, Y.-J.; Meng, T.-Y.; Ge, M.-J.; Zhang, H.-C.; Dai, Q.-G.; Huo, Z.-Y.; Xu, K. Response of yield, quality and nitrogen use efficiency to nitrogen fertilizer from mechanical transplanting super japonica rice. J. Appl. Ecol. 2014, 25, 488–496. [Google Scholar]

- Otto, R.; Mulvaney, R.L.; Khan, S.A.; Trivelin, P.C.O. Quantifying soil nitrogen mineralization to improve fertilizer nitrogen management of sugarcane. Biol. Fertil. Soils 2013, 49, 893–904. [Google Scholar] [CrossRef]

- Yang, J.; Luo, Q.X.; Qian, C.R. Effects of nitrogen on the content of protein components and cooking and eating quality of rice. J. Northeast Agric. Univ. 2006, 37, 145–150, (In Chinese with English abstract). [Google Scholar]

- Chi, Z.Z.; Zhao, G.C.; Zheng, J.G. Effect of nitrogen application amount on protein components in grain of different varieties wheat. Southwest China J. Agric. Sci. 2010, 23, 427–431, (In Chinese with English abstract). [Google Scholar]

- Wang, S. Effect of Nitrogen Application and Transplanting Density on Protein Content and Rice Quality in Cold Japonica Rice. Harbin: Northeast Agricultural University. 2015. Available online: http://en.cnki.com.cn/Article_en/cjfdtotalhljn201907010 (accessed on 5 December 2020).

- Geng, C.M. Effect of Nitrogen and Seeding Date on the yield and Quality of Low Glutelin Rice. Nanjing: Nanjing Agriculture University. 2011. (In Chinese with English abstract). Available online: https://b41aa555638a4e353337c5fc6691e9b1&site=xueshu_se (accessed on 5 December 2020).

- Zhang, X.; Shi, L.L.; Liu, X.Y. Effect of Different Fertilizer Treatments on Rice Yield, Grain Quality and Protein Fraction Content. Chin. Agric. Sci. Bull. 2010, 26, 104–108. [Google Scholar]

- Xu, D.Y.; Fang, Z.W.; Gao, Y. Effects of N fertilizer on protein content, composition and amino acid content of rice grains. In China Youth Agricultural Science Academic Annual Report; China Agriculture Press Pub: Beijing, China, 2004; (In Chinese with English abstract). [Google Scholar]

- Zhao, N.C.; Zhang, X.M.; Ye, H.S. Effects of different cultivation methods and nitrogen application on grain phytic acid contents and nutritional quality for japonica rice. Acta Agric. Zhejiangensis 2009, 21, 259–263, (In Chinese with English abstract). [Google Scholar]

| ANOVA | Albumin | Globulin | Gliadin | Glutenin | SPAD | GS | NR | DM | GY |

|---|---|---|---|---|---|---|---|---|---|

| Year | 177.49 ** | 25.55 ** | 0.82 ns | 237.82 ** | 43.50 ** | 2.87 ns | 1.98 ns | 525.54 ** | 49.86 ** |

| Year × N | 1.49 ns | 0.46 ns | 2.09 ns | 8.68 * | 23.33 ** | 2.17 ns | 0.97 ns | 14.41 * | 23.57 * |

| Year | Treatment | PN | SPN | SSR | 1000-GW | GY |

|---|---|---|---|---|---|---|

| (×104·hm−2) | (panicle−1) | (%) | (g) | (kg·hm−2) | ||

| 2018 | N0 | 218.39 d | 57.04 e | 88.61 c | 26.14 c | 288.64 e |

| N90 | 278.22 c | 67.48 d | 90.65 bc | 26.84 c | 456.93 d | |

| N135 | 298.66 c | 70.60 c | 91.14 b | 27.06 b | 520.12 c | |

| N180 | 315.55 b | 82.39 a | 92.25 a | 27.82 b | 667.31 a | |

| N225 | 326.28 a | 76.03 b | 91.10 b | 28.67 a | 648.11 b | |

| 2019 | N0 | 256.12 d | 66.51 d | 92.64 c | 27.52 b | 434.29 d |

| N90 | 281.01 bc | 78.68 c | 92.69 c | 27.97 a b | 573.21 c | |

| N135 | 282.81 b | 81.34 b | 92.61 c | 27.38 c | 583.29 b | |

| N180 | 304.15 a | 85.15 a | 94.57 b | 28.04 a | 686.75 a | |

| N225 | 308.82 a | 85.02 a | 94.56 b | 27.43 c | 681.01 ab |

| Year | Treatment | PKV | HPV | BDV | FV | SBV |

|---|---|---|---|---|---|---|

| (cp) | (cp) | (cp) | (cp) | (cp) | ||

| 2018 | N0 | 2357.45 a | 1330.37 a | 1026.62 a | 2665.79 a | 308.03 d |

| N90 | 2239.51 b | 1299.67 b | 939.33 b | 2661.35 a | 422.28 c | |

| N135 | 1726.91 e | 1091.75 c | 634.08 d | 2346.37 d | 620.39 a | |

| N180 | 2115.16 c | 1182.25 c | 933.66 b | 2452.04 c | 337.37 d | |

| N225 | 2014.33 d | 1219.67 b | 794.74 c | 2511.33 b | 497.33 b | |

| 2019 | N0 | 2916.29 a | 1754.58 a | 1175.27 a | 2934.67 a | 319.91 d |

| N90 | 2670.16 b | 1617.83 b | 1163.06 a | 2711.04 b | 433.56 c | |

| N135 | 2346.25 d | 1482.63 c | 993.33 b c | 2532.91 d | 631.81 a | |

| N180 | 2526.21 c | 1604.63 b | 1056.58 b | 2633.37 b c | 348.96 d | |

| N225 | 2475.12 cd | 1613.16 b | 729.71 d | 2706.22 b | 508.63 b |

| Year | Treatment | BRR | MRR | HRR | CR | LWR |

|---|---|---|---|---|---|---|

| (%) | (%) | (%) | (%) | |||

| 2018 | N0 | 80.87 b | 71.47 b | 62.52 d | 25.37 a | 1.71 a |

| N90 | 81.8 ab | 71.62 b | 63.84 c | 24.07 b | 1.75 a | |

| N135 | 82.93 ab | 73.12 ab | 65.46 ab | 24.23 b | 1.82 a | |

| N180 | 83.13 ab | 73.61 ab | 66.41 ab | 23.53 bc | 1.76 a | |

| N225 | 84.01 a | 74.67 a | 67.62 a | 21.23 c | 1.74 a | |

| 2019 | N0 | 77.33 b | 65.96 c | 65.21 c | 18.96 a | 1.79 a |

| N90 | 79.21 ab | 68.41 b | 66.53 b | 12.83 c | 1.77 a | |

| N135 | 80.16 ab | 69.71 ab | 68.15 ab | 16.46 b | 1.72 a | |

| N180 | 80.85 ab | 70.17 ab | 69.19 a | 11.56 d | 1.75 a | |

| N225 | 81.31 a | 71.71 a | 70.31 a | 8.13 e | 1.71 a |

| Year | Treatment | Total Protein | Albumin | Globulin | Gliadin | Glutenin | Other Protein |

|---|---|---|---|---|---|---|---|

| mg·g−1 | (%) | (%) | (%) | (%) | (%) | ||

| 2018 | N0 | 61.883 e | 14.559 a | 18.029 a | 13.369 b | 45.424 b | 8.619 b |

| N90 | 64.180 d | 14.797 a | 17.524 b | 13.875 b | 47.226 a | 6.578 c | |

| N135 | 75.480 c | 13.795 a | 15.987 c | 13.143 b | 42.896 e | 14.180 a | |

| N180 | 76.367 b | 14.585 a | 17.298 b | 15.331 a | 44.715 c | 8.072 b | |

| N225 | 80.327 a | 14.035 a | 17.292 b | 15.889 a | 43.820 d | 8.964 b | |

| 2019 | N0 | 61.620 e | 19.018 b | 17.047 b | 14.327 c | 43.851 a | 5.757 b |

| N90 | 64.067 d | 18.994 b | 17.031 b | 15.342 b | 43.420 a | 5.213 b | |

| N135 | 67.730 c | 19.005 b | 16.737 b | 16.261 a | 41.279 b | 6.717 a | |

| N180 | 74.620 b | 18.838 b | 16.344 b | 15.319 b | 43.381 a | 6.117 a | |

| N225 | 81.007 a | 22.029 a | 18.421 a | 15.508 b | 43.070 a | 0.972 c |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lan, Y.; Sui, X.; Wang, J.; Duan, Q.; Wu, C.; Ding, C.; Li, T. Effects of Nitrogen Application Rate on Protein Components and Yield of Low-Gluten Rice. Agriculture 2021, 11, 302. https://doi.org/10.3390/agriculture11040302

Lan Y, Sui X, Wang J, Duan Q, Wu C, Ding C, Li T. Effects of Nitrogen Application Rate on Protein Components and Yield of Low-Gluten Rice. Agriculture. 2021; 11(4):302. https://doi.org/10.3390/agriculture11040302

Chicago/Turabian StyleLan, Yan, Xiaodong Sui, Jin Wang, Qiang Duan, Chaoyue Wu, Chunbang Ding, and Tian Li. 2021. "Effects of Nitrogen Application Rate on Protein Components and Yield of Low-Gluten Rice" Agriculture 11, no. 4: 302. https://doi.org/10.3390/agriculture11040302