Abstract

The production of ‘Premium’ olive oil depends in large part on the quality of the fruit. Small producers see themselves confronted with vast investments and logistic snags when they intend to optimize the harvesting. Today, manual harvesting devices promise less damaged fruit when compared to the traditional methods with nets while the use of a cooling room on the farm is suggested as a solution when the harvesting needs to be stretched out over several days. The use of a manual inverted umbrella during the harvest, together with a storage of up to 14 days at 5 °C, was studied for three cultivars (‘Arbequina’, ‘Picual’, and ‘Verdial’). Ten parameters of the produced oil were examined in two consecutive years together with an extended sensory analysis in the first year. The results underline the importance of the used harvesting and conservation method on the quality of the extracted oil, although the effect size of each factor varied in time and according to the cultivar. The results indicate that small producers with financial and logistic restrictions can obtain a high-quality product following the actions shown in this work, being able to compete in terms of quality in the market, either by combining both methods or by choosing the one that guarantees the best results given the cultivar and the specific storage time they need to consider.

1. Introduction

The olive production in Spain is one of the main sources of income for more than 250 villages only in Andalusia (south of Spain) [1]. Of the 170,000 exploitations, 60% are smaller than 5 ha and 80% less than 10 ha. Moreover, more than 50% of the Agricultural Work Units are done in a strictly family context, in particular as non-salary-compensated work. These structural factors have a direct impact on the used harvesting methods as they limit the financial possibilities of the small producers. Many of them define agriculture as their prime activity but are not inclined to make big investments in machinery [2]. There are several methods available for harvesting olives trees that target the tree in different ways [3]. The impossibility to amortize sophisticated but expensive machinery on the one hand, or to contract specialized services on the other, explains why many small farmers continue to harvest their olives traditionally, beating the olive tree with sticks with nets put on the ground around it.

These traditional methods imply that once the fruit is detached, the nets are dragged to the next tree, where they are spread out again until their weight is too heavy to be lugged any further. At that time the fruit is collected in containers or a truckload. Dragging the fruit on the nets over the ground damages the fruit inevitably, and also the harvesters can step on the fallen fruit while beating the branches. The relation between the quality of the fruit and the extracted oil has been the object of many studies and has proven to be primordial to obtain an excellent end-product [4,5,6]. However, when one decides to maximize the yield of the production, the quality of the fruit becomes less important compared to the applied extraction techniques. During the last decade, a growing number of Spanish mills started to produce so-called EVOO Premiums, instead of the common one-sided attention on maximizing the quantity. This shift gained more ground with the growing importance of international olive oil contests, manned with expert tasters who set the stage for levels of organoleptic excellence beyond the official limits, although without generally accepted standards [7]. This fact entails the need to rigorously assess the quality of the product throughout the production chain, especially at the reception point of the mill [8,9].

The need to produce good quality oils is emphasized when olive production is approached from a small producer’s point of view, not only for them but also for the member of the local cooperative who will be reimbursed not only on the yield but also on the quality of the fruit. These producers do not only face the challenge to optimize their harvesting but also confront an additional problem if they do not extract the oil themselves. On one hand, the necessity to bring in at least several tons of olives to process them as a single batch implies several days of harvesting when working on a family scale. While it is common knowledge that the olives are ideally processed as soon as possible, the conservation of the picked fruits thus becomes a core problem for these small producers. On the other hand, not all harvesting systems can be taken over by small farmers, but fortunately, there are several affordable devices designed for this purpose. One promising method for this purpose is the Manual Inverted Umbrella (MIU) which consists of a foldable umbrella that is mounted on a movable structure to collect the fallen fruit harvested using manual aids methods such as branch shakers or shaker rakes. The use of such an MIU turned out to be competitive when compared with the traditional method, while the quality of the picked fruit was significantly better [10].

To maintain the fruit at its best, conservation at 5 °C has been extensively studied and proven for more than 25 years [11,12,13]. These studies were mainly focused on prolonging the use of the extraction lines and thus envisioned conservation up to one month or more [14]. The benefits of adequate conservation at a shorter time have not been yet studied, especially when the aim is to produce premium quality virgin olive oil and not just avoiding a significant deterioration of its initial quality [15]. Nevertheless, it might offer a solution for the individual farmer who seeks to keep his harvested olives for a limited time on the farm before their transport to the mill. It makes it possible to plan the harvesting according to the available workforce, to anticipate bad weather, and to organize in advance a convenient transport and time slot in the mill.

Knowing that both methods (harvesting and conservation) contribute in a significant way to a better result does not answer the question of which one has a major impact on the quality parameters of the produced olive oil, especially when the storage time is taken into account as a complementary factor. This work aims to study the effect of MIU harvesting and cold storage on the quality of olive oils. This study becomes vital when the economic resources of the farmer are viewed as a limiting factor in the decision process.

2. Materials and Methods

2.1. Harvesting Method and Conservation Facilities

The experiment took place in the olive groove of ‘Del Cetino’, situated in Bollullos par del Condado (Huelva) with the varieties ‘Arbequina’, ‘Picual’, and ‘Verdial’, planted between 2005 and 2007 at distances of 6 × 7 m and irrigated on a deficient regimen at 50% of the estimated crop evapotranspiration. The trials took place between the end of September and the beginning of November for two consecutive years (2017–2018).

Two branch shakers (Stihl SP471) were used to detach the fruit. Two types of harvesting were performed: one using the MIU system (R1), as a control group, and another using a traditional one, collecting the fruit detached on nets on the ground (R2), both storing the caught fruit in the same perforated boxes. The MIU was the same used and described by [10]. Then, the boxes were stored in a pile in a cooling room as described in [10]. The temperature was set at 5 °C (±1 °C). The boxes of the control group were stored outside under a protected roof at ambient temperature (15.4 (min) and 29.3 °C (max) measured in 2017, and 14.2 (min) and 24.7 °C (max) measured in 2018). Hence, two types of conservation were performed: one using the cooling room (C1) and another storing the boxes outside at ambient temperature (C2). The maturity index resulted in values between 1.5 and 2.5 (Jaen Index) in all fruit samples, indicating that the majority of the olives were still green at harvest.

2.2. Experimental Material

To assess the effects of the harvesting, conservation method, and conservation time on the fruit and the produced oil, an equal amount of fruit from the ‘Arbequina’, ‘Picual’, and ‘Verdial’ cultivars were taken at the same moments and under the same conditions as those intended for industrial extraction. To evaluate each factor, triplicates of olive samples of both harvesting methods were kept during the distinct periods, each one in 6 ventilated boxes of 20 kg, which were previously distributed in the cooling room at 5 °C and outside at ambient temperature. All the fruit was homogenized before distribution in the boxes. The two harvesting methods (R1 and R2), two types of conservation (C1 and C2), and four distinct conservation periods, at the day of harvesting (T0), after 4 days (T4), 8 days (T8), and 14 days (T14), gave rise to 18 different combinations of factors for each variety and each year. Samples of the fruit of each combination were evaluated on the following parameters: incidence of decay, weight losses, skin color and firmness, respiration rate, and ethylene production, reported in [16]. The conditions during the transport were not taken into account as a separated factor in the experiment.

The oil extraction was carried out in the laboratory using an ‘Abencor’ system, which is different from the method used in Spanish oil mills but has been recognized for decades as a valid technique for the purpose of comparing the different samples. Individual samples of 1500 g were taken at random from the olives harvested with the different methods and were crushed in the hammer mill (grid 5.5 mm) and the resulting paste was distributed in two subsamples of 700 g, which were weighed in two stainless steel casserole pots. Then, the paste was malaxated in the thermoblender for 30 min at 30 °C. Afterward, the malaxated paste of each pot was centrifuged for 1 min at 1372 g relative centrifugal force. The resulting solid phase of the paste was discarded and the liquid obtained was placed in a graduated 500 mL test tube for separating the aqueous phase of the lipid phase. The Virgin Olive Oil (VOO) extracted from both subsamples was taken from the lipid phases using a Pasteur pipette equipped with a pacifier, filtered with filter paper, and placed in a dark glass bottle of 250 mL, which was filled with nitrogen and kept at −20 °C until further examination. Every experiment was done in threefold.

2.3. Physico-Chemical Analysis

Free fatty acidity (FFA), peroxide value, and absorbency at 232 and 270 nm were determined according to the official analytical methods as described in EEC guidelines (EEC, 1991).

The oxidative stability was evaluated using the Rancimat method. The stability was expressed as the oxidation induction time (h) measured with the Rancimat apparatus (Metrohm AG, Herison, Switzerland) at a temperature of 120 °C and an airflow rate of 20 L/h. The obtained results were multiplied by factor 4.17 to facilitate comparison with other studies with values obtained at 100 °C [17].

The chlorophyll and carotenoid pigment profile was obtained by measuring the spectrophotometric absorbency in the ultraviolet at 470 nm for the carotenoids and 670 nm for the chlorophyll fraction, respectively [18].

The bitterness index used to estimate the presence of the attribute ‘bitterness’, was calculated according to [19]. The total polyphenols were estimated by the sum of the calculated amount of polyphenols obtained by measuring the spectrophotometric absorbency at 280 and 335 nm. The described method was considered to be more accurate than Folin–Ciocalteau, as it measured phenols purified from oils at their precise wavelengths. For the phenolic compounds that absorb at 280 nm, being the majority of them except flavones and ferulic acid (phenols A), p-hydroxyphenylacetic acid was used. The calibration curve (y = 0.0585 × −0.007) was constructed using concentrations of 0.020, 0.030, 0.040, and 0.050 mg/kg of olive oil. The presence of flavones and ferulic acid that absorb at 335 nm (Phenols B), was estimated using ortho-coumaric acid. The calibration curve (y = 0.0218x + 0.001) was constructed using concentrations of 0.002, 0.003, 0.004, and 0.005 mg/kg of oil. To estimate the content of the phenolic compounds, the starting concentration with which the absorbency value was obtained was taken into account, adapting it to the same measure as used with the standard. In this case, the absorbency obtained was considered per kg of oil per ml of solvent. This implies dividing the absorbency obtained by the concentration of the sample, expressed in kg, and the 25 mL in which the absorbency of the phenols extracted from this sample was finally measured. To estimate the total content of phenolic compounds, the values of A and B were added, obtaining the value in mg/kg of sample oil: Total Phenols (mg/kg) = Phenols A (mg/kg) + Phenols B (mg/kg) (Equations (1) and (2)).

The content of α-tocopherols was determined through high-performance liquid chromatography (HPLC) using the IUPAC method [20]).

2.4. Sensory Analysis

A sensory evaluation of the oils was performed to reveal significant differences between the treatments in the first year. The analytical panel was formed by 8 members of the sensorial analytical panel of the Instituto de la Grasa (CSIC) in Sevilla (accreditation UNE-EN-ISO/IEC 17025). They applied the method as described in the EC regulation 640/2008. The procedure permits the classification of the EOVs according to the presence of negative attributes (muddy, musty, winey, frostbitten, rancid, and others) as well as a measurement of the intensity of positive attributes (fruity, bitter, pungent). The panel members were also asked to classify the presented samples in order of preference to examine whether there were significant differences noticeable between the different treatments at each storage day. To reduce the number of unnecessary tastings the selection started with the samples of day 0 and day 14. If no significant difference between them was detected, no further analysis was performed on the oils extracted from the same cultivar on days 4 and 8.

2.5. Evaluation of Premium Quality

To evaluate whether olive oil, extracted from fruit harvested with an MIU and cool stored for several days, attained a quality level that could be regarded as ‘premium’, samples were sent to the New York International Olive Oil Competition in 2017, 2018, and 2019. The NYIOOC is recognized as one of the major competitions worldwide with tasting panels composed of highly respected professional tasters [7]. Samples of ‘Picual’, ‘Arbequina’, and ‘Verdial’ were taken from the production of the Del Cetino farm where an MIU as described in the study was used for harvesting and the olives were stored at 5 °C for up to 5 days before their transport to the mill. As the production was very limited, only one extraction was performed for each variety. The extractions took place at the pilot plant of the Instituto de la Grasa (Sevilla).

2.6. Statistical Data Analysis

Statistical data analysis of the physicochemical parameters was performed using PASW Statistics 18.0 (SPSS). For each cultivar, one-way ANOVA determined the effect of the storage time, considering independently each combination of the other factors (harvesting and conservation method), as well the effect of these four combinations for each separately. Similarly, for each period, the effect of harvesting was studied independently for each conservation method and vice versa. The effect of the storage time and the treatments, defined as the four possible combinations of, on the one hand, R1, R2, and on the other C1, C2, was tested with two-way ANOVA. Finally, the effect of three factors (storage time, harvesting method, and conservation method) was studied by three-way ANOVA. If a significant effect of one of the factors was detected in a parameter, the Tukey test was applied to discriminate mean values (p < 0.05) in each variable.

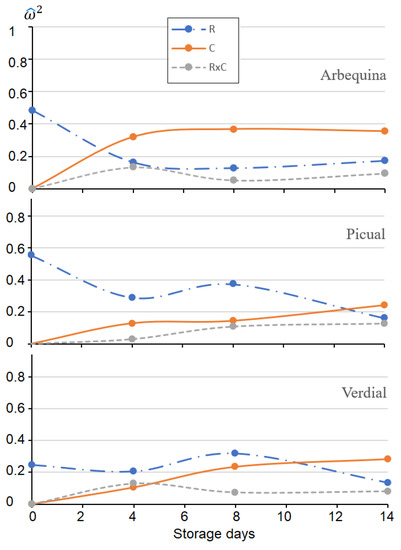

For each time, the effect size of the different factors and their interaction was determined by calculating the value. The effect size is a descriptive statistic indicating the proportion of variability in the observed data that is accounted for by the treatments [21]. The obtained value, multiplied by 100, thus represents the variance in the population as explained by each factor. The effect size can be estimated in various ways, but the calculation of the Omega-Square () was preferred because this estimation resulted in less bias when dealing with small samples as compared to Eta and Partial Eta-Squared [21,22]. The calculation was performed using the data from the SPSS analysis using Equation (3).

where:

- SSEffect= the sum of squares of each effect (R, C, or R × C);

- dfEffect =the degrees of freedom of each effect (R, C, or R × C);

- MSError= the mean square error;

- SSTotal = sum of squares total.

Negative values were set to zero. Omega-squared measures become positive when the observed F value exceeds 1.0. Only in these cases, the effect accounts for variance in the population. To estimate the tendency of the overall effect of the methods on the produced olive oil over time, the average of the values for all the parameters and both years for each ST were calculated. The selection of these parameters was not predetermined because to date there is no theoretical model that integrates the various parameters and their weights.

The Friedman test was used to detect differences in treatments in the sensory evaluation [23]. This non-parametric statistical test involves ranking each taster’s judgement together, then considering the values of the ranks by columns. The null hypothesis expects that there are no differences between the treatments. When the calculated probability is significant (p < 0.05) it can be concluded that at least 2 of the treatments are significantly different from each other.

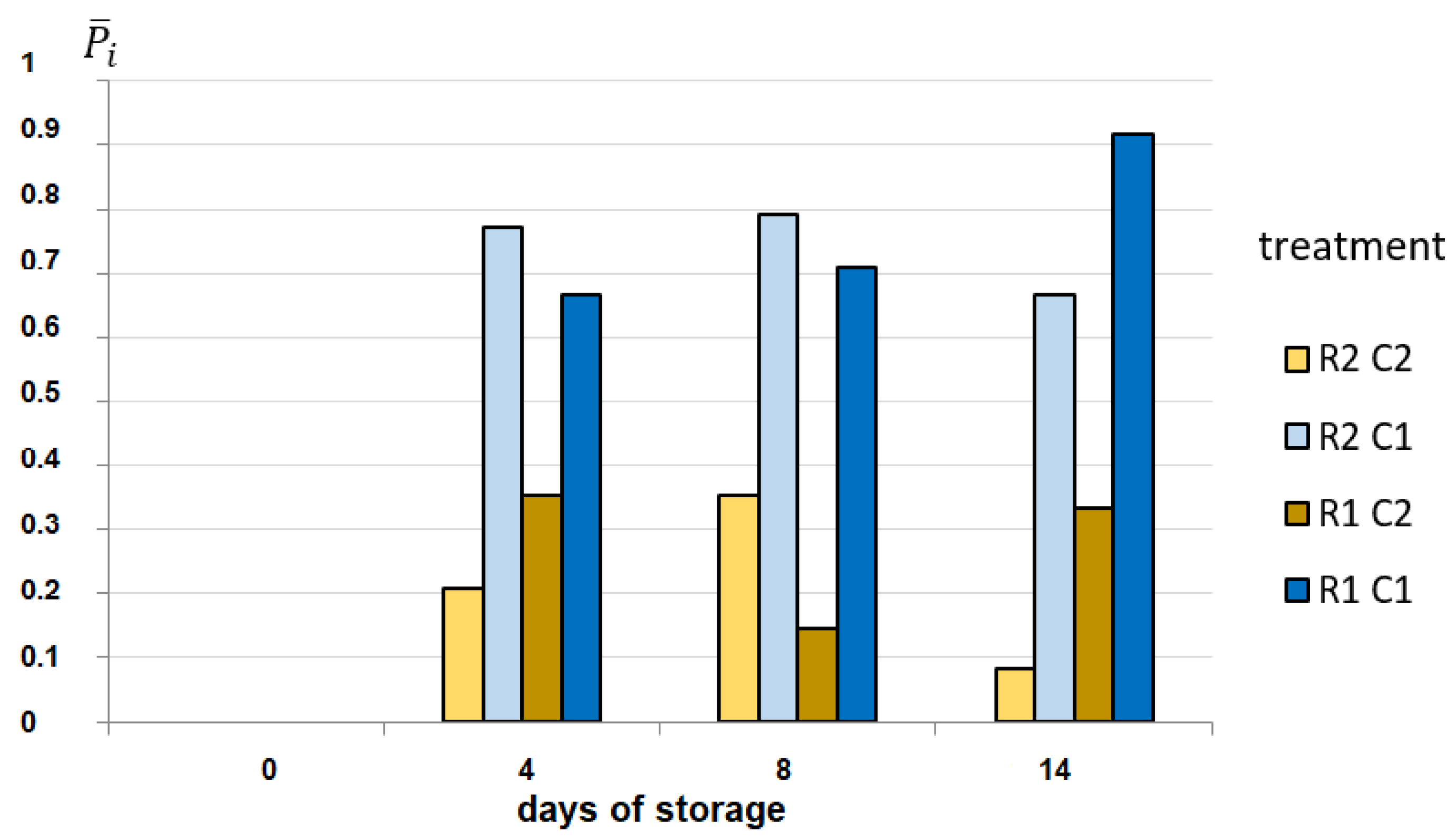

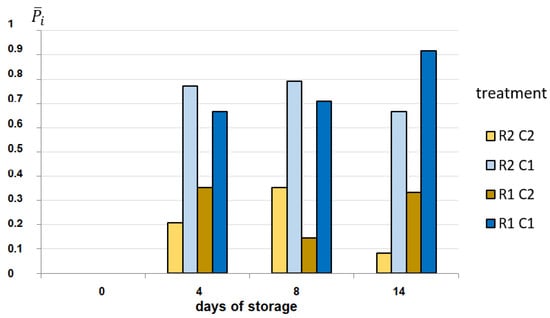

Once a significant difference was identified within a tasting cluster, the preference of the panel for the treatments was further deciphered through a new statistic: the Panel Preference (), which permits a qualitative positioning of the judgments of a panel, composed of n members who individually rank t different treatments. The procedure consists of two steps. In the first one, the value of each is calculated as a ratio with, as the numerator, the sum of the rank given to treatment i by each member, subtracted by the minimum sum of ranks of a treatment, which equals n, to afford comparison of -values from panels with a different size (Equation (4)). The denominator is formed by the corrected maximum sum of ranks, being the product of t and (n − 1). In a second step, the panel preference ratio of the specific treatment () values of the different treatments, each with a value between 0 and 1, are ranked in descending order, with the highest-ranked treatment having the highest ratio and the lowest-ranked one the lowest.

where:

- Rij = ranking given by panel member j on treatment I;

- n = number of members in the tasting panel;

- t = total number of treatments to be compared in conjunction.

3. Results

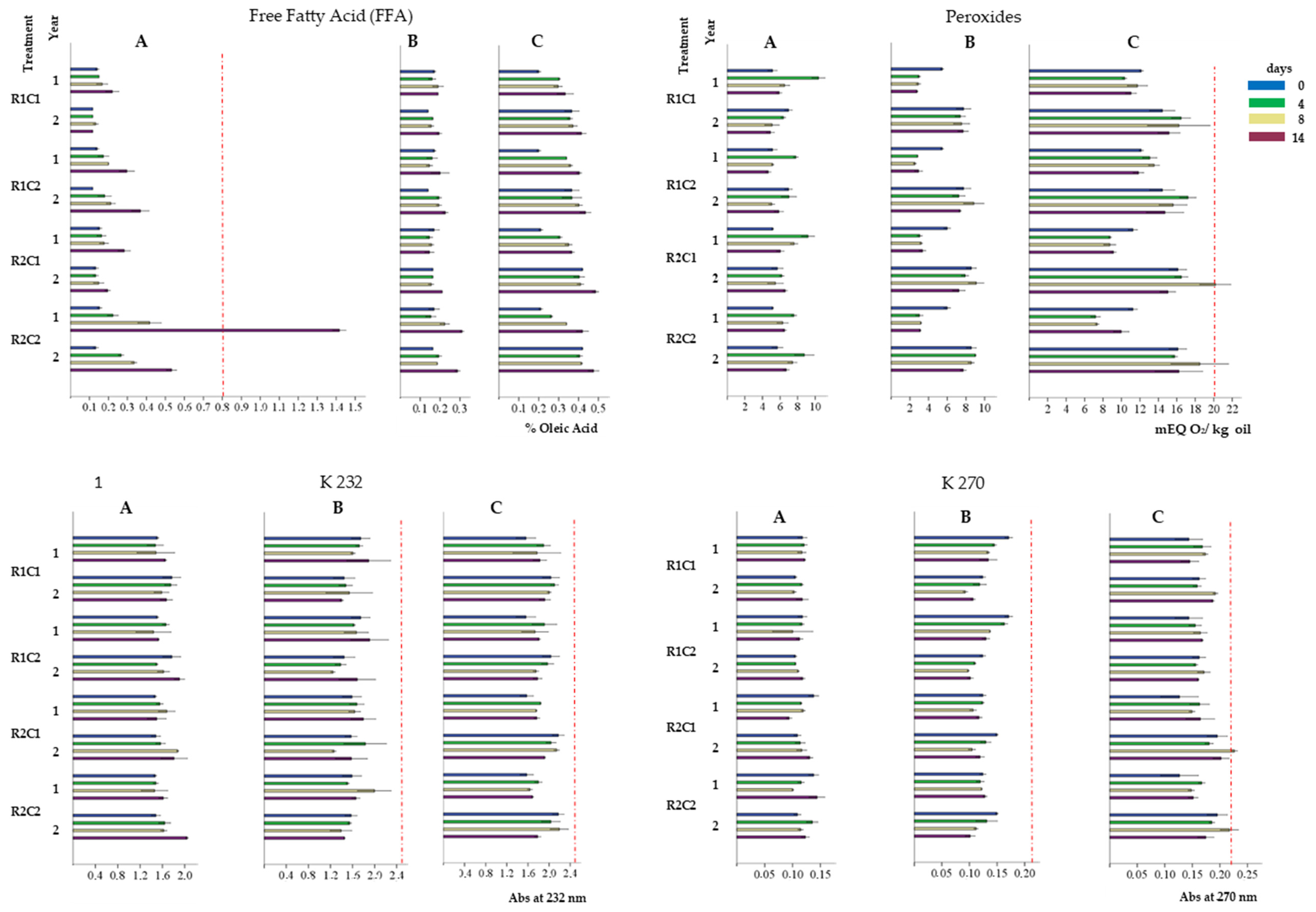

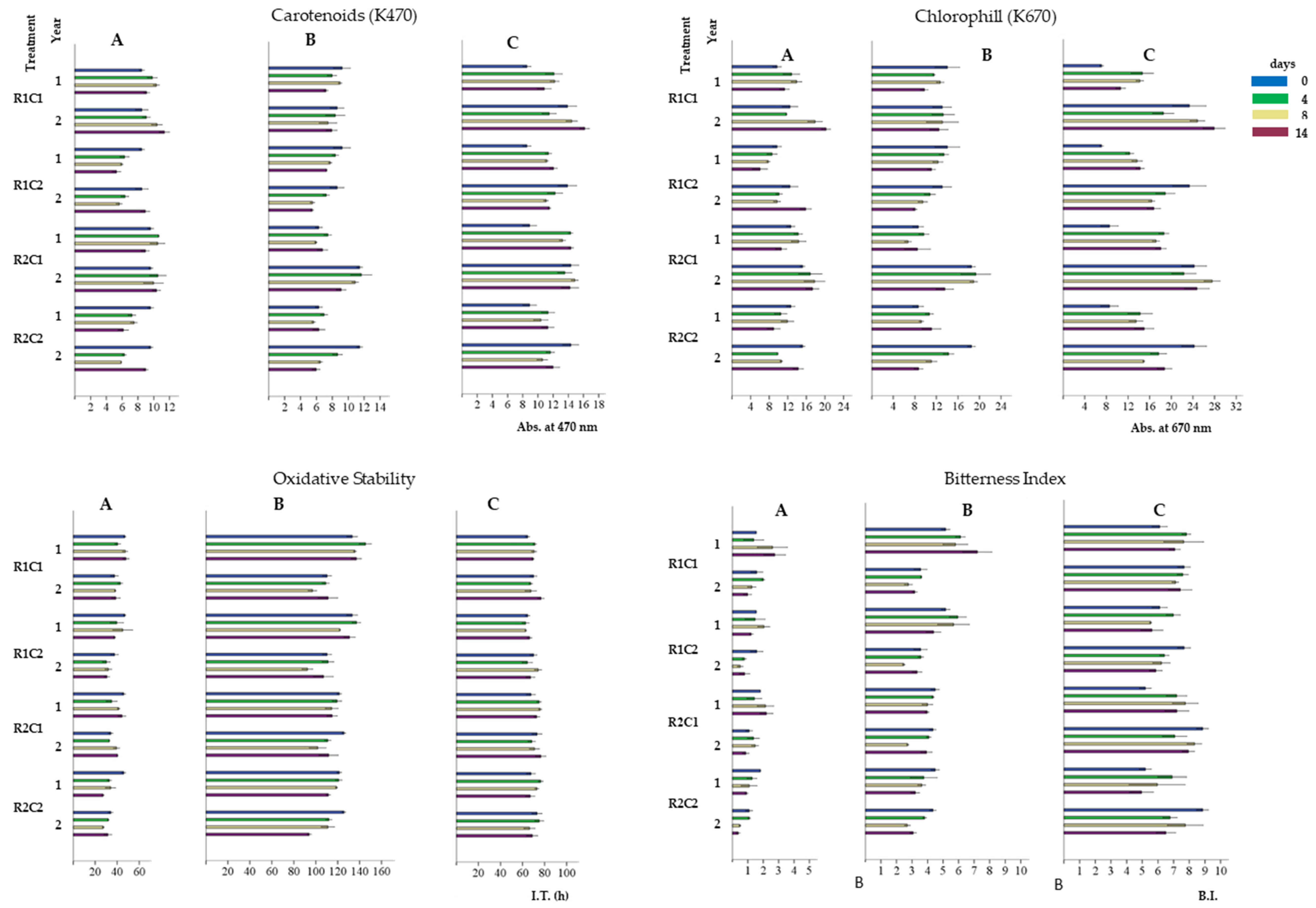

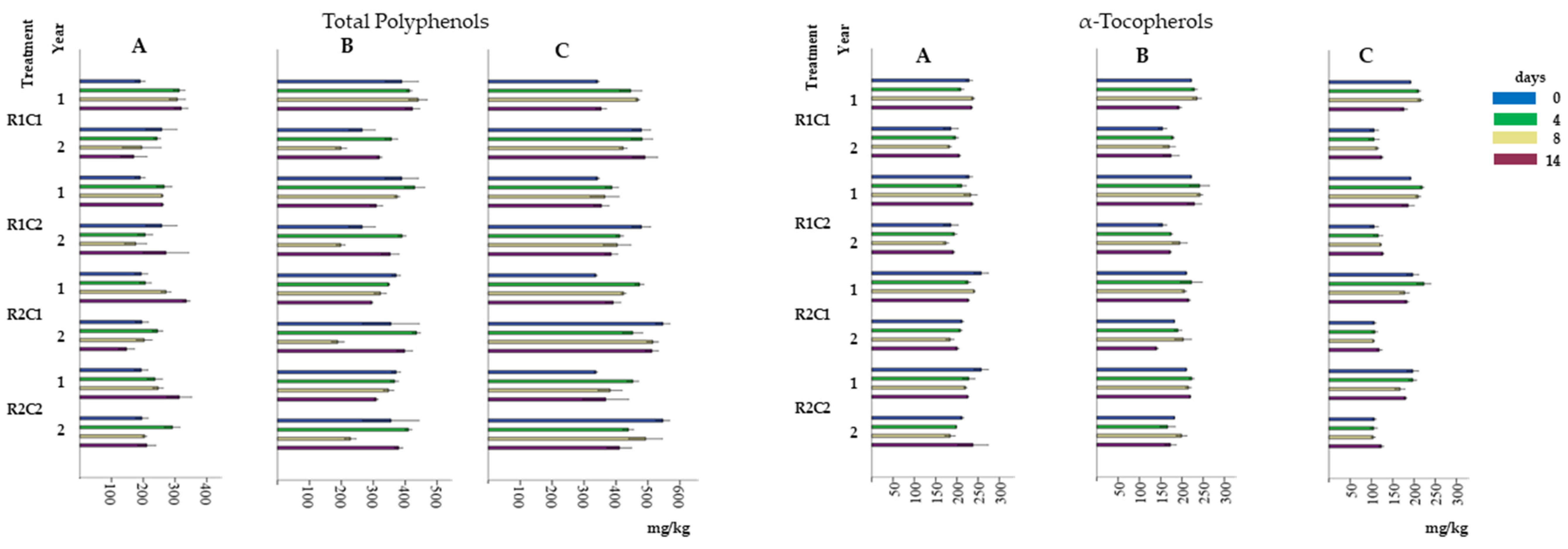

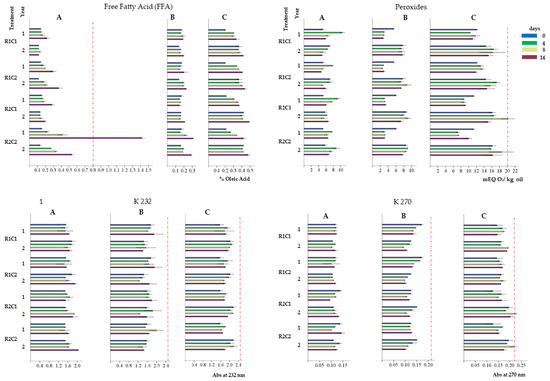

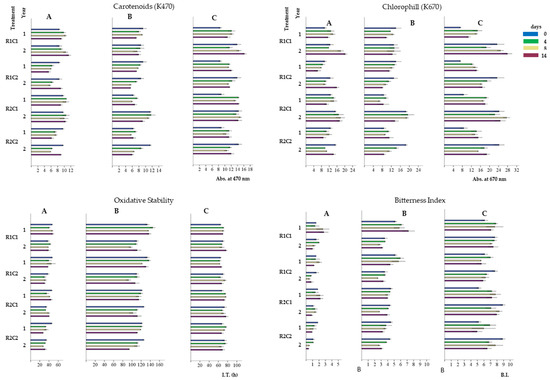

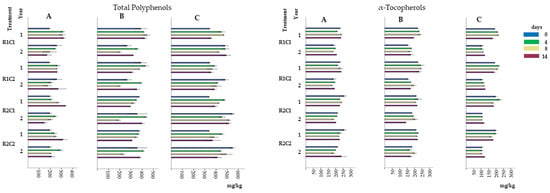

Figure 1, Figure 2 and Figure 3 show the values measured of the different parameters studied, extracted from the olive oil of each variety for each harvesting and conservation method. Table 1 shows the omega-square paramter as a measure of the effect of the factor harvesting, conservation, and the interaction between both for each storage time. The most relevant results are set out below.

Figure 1.

Free fatty acid (% oleic acid), peroxides (mEq O2/ kg oil), and absorbency at 232 and 270 nm, noted in the ‘Arbequina’ (A), ‘Picual’ (B), and ‘Verdial’ (C) olive oils extracted from fruit, picked with a Manual Inverted Umbrella (R1) and in a traditional way (R2) and stored for different days at 5 °C (C1) and ambient temperature (C2) during two consecutive years. Each bar is the mean ± SD of 3 replicates. Dotted lines indicate EVOO min. values (EEC).

Figure 2.

Carotenoids (K460), chlorophylls (K670), oxidative stability (h), and bitterness index, noted in the ‘Arbequina’ (A), ‘Picual’ (B), and ‘Verdial’ (C) olive oils extracted from fruit, picked with a Manual Inverted Umbrella (R1) and in a traditional way (R2) and stored for different days at 5 °C (C1) and ambient temperature (C2) during two consecutive years (year 1 and 2). Each bar is the mean ± SD of 3 replicates.

Figure 3.

Total polyphenols (mg/kg) and α-tocopherols (mg/kg), noted in the ‘Arbequina’ (A), ‘Picual’ (B), and ‘Verdial’ (C) olive oils extracted from fruit, picked with a Manual Inverted Umbrella (R1) and in a traditional way (R2) and stored for different days at 5 °C (C1) and ambient temperature (C2) during two consecutive years (year 1 and 2). Each bar is the mean ± SD of 3 replicates.

Table 1.

Values of as a measure of the effect of the factor harvesting (R), conservation (C), and the interaction between both (R × C), for each of the 4 storage times during year 1 and 2. Negative values are set to 0.00.

3.1. Free Fatty Acidity

In all of the three varieties, the storage time was shown to be highly significant in year 1 and 2, although the ‘Arbequina’ variety turned out to be much more vulnerable when compared to ‘Picual’ and ‘Verdial’, since in both years ‘Arbequina’ showed a highly significant effect of the factors R and S (Figure 1, Supplementary Materials Table S1). After 4 days there was a clear difference between the oils extracted from fruits harvested with nets and stored at room temperature (R2C2) and the other three possible combinations. In year 1, the FAA of these samples even exceeded the limit of 0.80% of oleic acid, and as a consequence could not be classified as ‘extra’. In year 2, the effect of the cooling was more prominent when compared with year 1 and led to a clear differentiation between the oils on day 14, with the lowest values for treatment R1C1: 0.12 ± 0.00, and the highest for R2C2: 0.53 ± 0.03. The values of the presented for both years a similar profile over 14 days. On the day of the harvest, day 0, the method of harvesting turned out to explain the variance slightly above 30% (Table 1). From day 4 on, the effect of the conservation method was always greater than the harvesting method. However, in year 1, the interaction between both methods gained importance from day 4 on, indicating that the effects of the storage method depended in large part on the intactness of the fruit. In year 2, the role of this interaction was downplayed with an obvious effect of C from day 4, and explaining more than 80% of the variance on day 14.

The ‘Picual’ variety showed more resistance toward an increase in the FFA, with similar tendencies on day 14, although without exceeding the official limits. In both years, the R2C2 treatment presented the highest values at day 14. In year 1, no significant effect of the harvesting method was detected (Supplementary Materials Table S1). Measurement of the effect revealed two different profiles (Table 1). In year 1, a steep increase in the importance of the interaction between both methods became visible from day 4. The same happened for the effect of the conservation method from day 8 on. Both balanced each other in importance at day 14, explaining almost 80% of the variance. In year 2, 76% of the variance was explained by the storage method on day 4 which implies a downplaying of the role of the harvesting method. On day 14, the effect of the latter, as well as its interaction with the storage method, gained importance in explaining the obtained results.

Over the 2 years, the ‘Verdial’ variety presented a confusing image. While the storage time and the treatment were significant in both years, the conservation method was shown to be highly significant in year 1, but not the harvesting method, while in the following year it was exactly the inverse (Figure 1, Supplementary Materials Table S1). This profile was reflected in the calculated effect, which showed in year 1 an increasing importance of the conservation method from day 4 up to almost 60% on day 14. In year 2, this effect was absent while the importance of the harvesting method fluctuated between 30 and 60% (Table 1).

3.2. Peroxides

The degree of initial oxidation of the three studied cultivars was similar in the two years but showed a clear difference between ‘Arbequina’ and ‘Picual’ on one side, and ‘Verdial’ on the other (Figure 1). While oils of the former presented values that were always far below the official maximum of 20 mEq O2/kg oil, the extracted oils of the latter came close to that threshold in the second year and even surpassed it the first year at day 14 when harvested with nets (R2). The storage time and the harvesting method stood out as significant factors in all of the six different cases, while the conservation method and the interaction between the R and C-factors were only significant in three cases, namely both years in ‘Arbequina’ and the first year in ‘Verdial’ (Supplementary Materials Table S2).

The magnitude of the effect of the different methods showed a similar profile (Table 1). In all the cases, the harvesting method stood out as the most influential factor on day 14. In ‘Arbequina’ an increase from day 4 was present in both years. The effect of the harvesting method was at the maximum during the first 4 days, in which it explained the variance for more than 60% (year 1) and more than 40% (year 2). From then on it descended below 5% on day 14. An effect of the interaction was also involved, although not in the same matter in both years. In year 1, it became visible from day 8 where it attained more than 30% on day 14, while in year 2, the effect was at its maximum of 16% on day 8. For the ‘Picual’ variety the effect of the conservation method was negligible over the whole period while the effect of the harvesting method differed in both years. The profile for ‘Verdial’ was consistent, although the effect of the harvesting method fluctuated between 60 and 80% during year 1 and between 15 and 30% in year 2.

3.3. K 232 and K 270

The calculated values of the absorbency at 232 nm were only affected by the different factors in one case out of six, namely in year 2 of the ‘Verdial’ cultivar. ‘Arbequina’ and ‘Picual’ did not show a significant difference in the harvesting and conservation methods in either of the studied years (Figure 1). The storage time was shown to be significant in ‘Verdial’ and year 2 in ‘Arbequina’ (Figure 1, Supplementary Materials Table S3). Concerning the absorbency at 270 nm the storage time was the only significant factor in all of the six cases. The three cultivars were comparable regarding the significance of the harvesting and storage method. All showed a significant effect in the second year for the factor R, while C was not a significant factor in the ‘Arbequina’ and ‘Picual’ cases, and only during year 2 in the ‘Verdial’ variety, in which the official threshold of 0.22 was surpassed (Figure 1, Supplementary Materials Table S4).

In year 2, the magnitude of the effect of the harvesting method was substantial in all the three varieties. In ‘Arbequina’, it was responsible for 35% (day 8), in ‘Picual’ for 62% (day 8), and in ‘Verdial’ for 82 (day 4) and 72% (day 8) of the variance. A notable effect of the conservation method in the ‘Verdial’ variety increased from day 8 (8%) and attained 55% on day 14, at the cost of the importance of the harvesting method, which was reduced to 21% at that time (Table 1).

3.4. Oxidative Stability

The induction time, expressed in hours, varied consistently in the three studied cultivars over both years (Figure 2). The highest values were measured in ‘Picual’, within an overall range between 90 and 145 h; ‘Verdial’ showed values between 60 and 80 h, and ‘Arbequina’ between 27 and 47 h. In ‘Arbequina’, there was a clear difference in the distinct treatments and a significant effect of harvesting and storage methods. In both years there was a significant effect of the interaction between the conservation method and the storage time; however, only in year 1, an interaction effect between the harvesting method and the storage time was observable. In ‘Picual’, the harvesting method turned out to be a highly significant factor, and this was found in both years, while this was not the case for the conservation method, except when studied in interaction with the ST. The ‘Verdial’ cultivar showed a confusing profile when comparing both years. In year 1, the storage time, harvesting method, and conservation method were very significant; however, in year 2 neither one of these factors showed a significant effect (Figure 2, Supplementary Materials Table S5).

The impact of the different factors was consistent in the three varieties, characterized by a superior impact of the harvesting method for up to 4 days, followed by a decrease from then on. In the course of the 14 days, the strength of the used conservation method increased; however, its maximum and velocity varied along with the cultivars: in ‘Arbequina’ it attained almost 80% on day 14, in ‘Verdial’ 40%, and ‘Picual’ 20%. The results over the 2 years also indicated that the importance of the interaction varies between them. ‘Arbequina’ showed an importance of 20% at day 4 in year 2. In year 1 of ‘Picual’, 20% was explained by the interaction on day 8 and increased up to 40% on day 14, while in year 2, the highest impact was on day 8 with 12%. In the case of ‘Verdial’, an increase of up to 20% in both years was present on day 4. However, in year 1, the impact from then on diminished, while in year 2, levels over 20% were present for up to 8 days (Table 1).

3.5. Photosynthetic Pigments

The amount of carotenoids and chlorophylls were similar over the two years (Figure 2). In both cases, the three cultivars showed a significant effect on both the storage time and the treatment (Figure 2, Supplementary Materials Tables S6 and S7). The three varieties diverted slightly on the effect of the used harvesting and storage methods over the two years. Overall, a significant effect of these factors was present for both photosynthetic pigments over the two years. In year 2, deviant results were obtained in ‘Arbequina’ and ‘Verdial’ regarding the effect of the harvesting method on the level of carotenoids. In that same year, the ‘Verdial’ cultivar did not demonstrate an effect of the harvesting method on the amount of chlorophylls. Finally, the storage method was significant in all cases except in one case, namely in year 1, with regard to the carotenoids in the ‘Picual’ cultivar.

The measures of effect on both pigments were comparable, although they varied between the cultivar (Table 1). In ‘Arbequina’, both years demonstrated the impressive importance of the storage method, attaining from day 4 up to day 14 values situated around 80% of the explained variance. In ‘Picual’, the importance of the conservation method was only visible in year 2, with a linear growth from day 0 (0%) to day 14 (80%). In year 1, the used harvesting method explained the variance with values above 50% from day 0, only to descend to 28% on day 14. The ‘Verdial’ cultivar, was shown to be highly sensitive to the storage method. This was the clearest in year 2, where a steep increase was noticeable from day 4 to day 8, explaining more than 90% of the variance, up to day 14 with approximately 70%. In year 1, a linear increase started from day 0 to day 8, after which it descended beneath 10%. This decline from day 8 went together with a remarkable increase in the importance of the interaction of the factors conservation and harvesting, explaining at day 14 more than 40% of the variance.

3.6. Bitterness Index

The three cultivars presented distinct trends over the 14 days for the Bitterness Index (Figure 2). In ‘Arbequina’, the storage time and the kind of treatment induced significant effects in both years, but the factor harvesting did not. The factor conservation, as well as its interaction with the storage time, came to the fore as very significant in both years. The ‘Picual’ oils did not show a significant effect due to the storage time in year 1; however, the effect of the interactions of this factor with the factors harvesting and conservation, respectively, turned out to be very significant. Separately, the used harvesting and conservation methods exerted significant effects on this parameter. In both years, the bitterness index of ‘Verdial’ oils experienced significant effects due to the storage and treatment factor. In year 2, the effects of the used harvesting and conservation methods were significant, while in year 1 only the factor conservation was (Figure 2, Supplementary Materials Table S8).

The magnitude of the effects also varied according to the cultivars. While in ‘Arbequina’ the effect of the harvesting method disappeared after day 4, the storage method gained in importance from that moment on, in year 1, attaining its maximum at day 14 of 71%, and in year 2, even 83% at day 8 (Table 1). ‘Picual’ maintained in year 1 a high explanatory power for the factor ‘harvesting’ with a value that fluctuated between 50 and 80%. In year 2, a value around 60% was observable up to day 4, after which it sharply descended towards a negligible value. The factor ‘conservation’ on the other hand, presented only a slight increase in day 14 of up to 30% in year 1, while in year 2, the values did not exceed 10%. The ‘Verdial’ cultivar expressed a steady increase in factor conservation method in year 1, attaining a maximum above 60% on day 14. In year 2, the same maximum was reached, although interrupted with a slight decline at day 8. The difference between the two years was reflected in reverse when comparing the values of factor harvesting, characterized in year 1 by the disappearance of the effect on day 4 and rebound at day 8 in year 2 (Table 1).

3.7. Total Polyphenols

The way the amount of polyphenols was influenced by the harvesting method and storage method varied markedly between the two years for the ‘Arbequina’ cultivar (Figure 3, Supplementary Materials Table S9). While in year 1 there was a clear effect of all the factors studied, in year 2 no effect due to the factor was detected. The ‘Picual’ and the ‘Verdial’ variety showed consistent effects due to storage time and the kind of treatment in both years but diverged in the effect of the factors harvesting and conservation. In ‘Picual’ oils, the used harvesting method induced significant effects on polyphenol content in both years, while the conservation method only exerted a significant effect during year 1. In year 2, the used harvesting and conservation methods induced significant effects on the polyphenol content of ‘Verdial’ oil; however, the effect of the factor harvesting was absent in year 1.

The three varieties expressed the strength of the various factors in different ways (Table 1). In year 1, the profile of the ‘Arbequina’ cultivar was marked by a steep increase in the importance of the used conservation method from day 8, attaining a maximum of 40% up to day 14. Meanwhile, the impact of the used harvesting method decreased rapidly from day 4 to 20% on day 8. In ‘Picual’, harvesting came to the fore as the main factor, responsible for explaining between 60 and 80% of the variance during the 14 days, while the impact of the conservation method was 7%, far less important in year 1. In year 2, the strength of the used harvesting method stayed below 60% (day 4) and even disappeared from day 8 on. The ‘Verdial’ variety also presented a confusing result. In year 1, the magnitude of strength of the factor ‘conservation’ was characterized by an increase of almost 60% at day 8 and followed by a subsequent decrease, while at year 2, the effect at that moment was absent whilst the impact was reduced to less than 40% and brought forward to day 4. The factor ‘harvesting’, with no significant effect in year 1, presented in year 2 a steep increase on day 8 (60%), only to descend rapidly to a negligible level on day 14.

3.8. α-Tocopherols

During the two assay years, the storage time and the used harvesting method induced a significant effect on the amount of α-tocopherols in the oils of the three varieties, as well as the interaction of these factors (Figure 3, Supplementary Materials Table S10). In contrast, the effect of the used conservation method was absent in both years for the ‘Arbequina’ and ‘Verdial’ oils. In the ‘Picual’ cultivar the effect of this factor was only significant in year 1, while in the second year there was detected a significant effect due to the interaction of this factor and the storage time.

The magnitude of the strength of the factor ‘harvesting’ varied clearly between the two years and among the distinct varieties (Table 1). In ‘Arbequina’ there was a clear difference at day 0 (both years 60%), followed by a descent to 0% at day 8 and a renewed increase up to almost 80% in year 1 but only 14% in year 2. In ‘Picual’, the same high values for day 0 were present, although the profile was different when compared with ‘Arbequina’. On day 4 the effect faded away, only to rise to 75% on day 8, after which it once again descended towards a negligible value on day 14. During both years, the ‘Verdial’ variety showed no effect of the factor ‘harvesting’ at day 0 but expressed from day 4 a profile that was comparable with ‘Picual’ at year 1, with a steady increase in day 8 (60–80%), after which descent set in towards values below 10%.

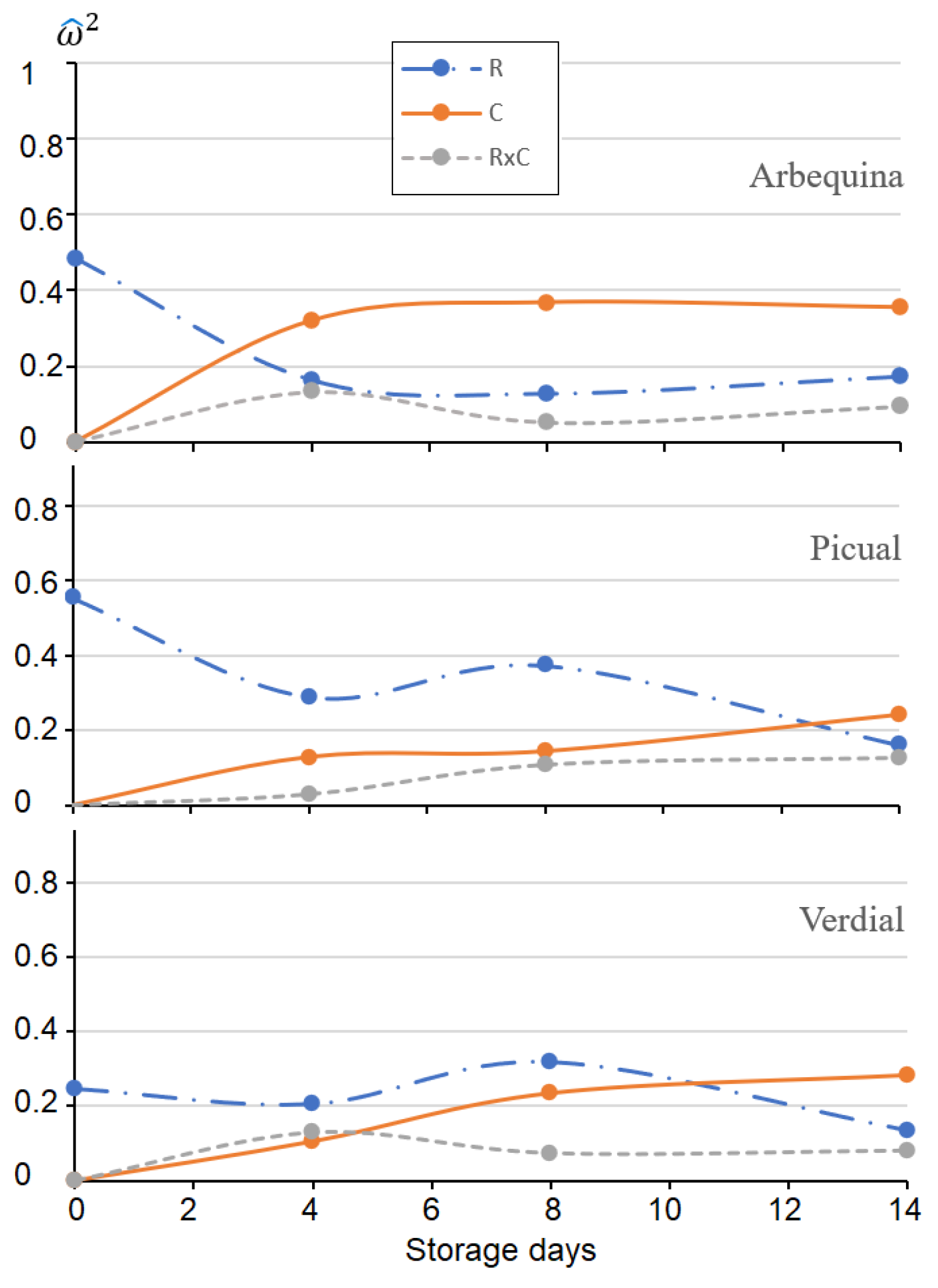

3.9. Overall Effect of the Factors

The means of the obtained values for both years and all parameters were used to express the tendency of the magnitude of strength that characterized the different factors along the storage time of the olives (Figure 4). In ‘Arbequina’ the profile of the three factors under study, namely the harvesting and conservation methods, and the interaction between both, was characterized by a rapid decrease in the initial importance of the factor ‘harvesting’ towards day 4 (60%), after which its explanatory share settled around 15% for the rest of the studied period. On day 4, the factor ‘conservation’ became responsible for more than 30% and further increased to almost 40% on day 14. The interaction of both factors was situated at 15% on day 4, after which it slightly fell to around 10%. The descending importance of the used harvesting method and the increasing importance of the used conservation methods became equal around day 3, after which the factor ‘conservation’ started to exert a major effect on the final result. In ‘Picual’, the harvesting method was the most important factor in explaining the variance. Despite a moderate decrease from day 1 (55%) to day 4, the values on this day and day 8 were situated around 30%. From then on, the value descended further to less than 15%. The factor ‘conservation’ on the contrary did not attain a level above 15% until day 14, where it surpassed the impact of the factor ‘harvesting’ and attained about 25%. The effect of the interaction came only into play on day 8 with values slightly above 10%. The ‘Verdial’ cultivar presented a similar profile as ‘Picual’ concerning the used harvesting method, although with lesser importance at day 0 (25%) and overall lower values when compared to the latter. The same could be observed for the factor ‘conservation’, although its effect gained more importance from day 8 (25%) up to day 14 (30%). The steeper inclination of both curves advanced the crossing point to an earlier moment in time. When in ‘Picual’ this took place around day 13, it occurred in ‘Verdial’ around day 10. In a similar way as in ‘Arbequina’, the interaction factor exerted its influence at its maximum (15%) around day 4, after which it decreased to values below 10%.

Figure 4.

Magnitude of strength of the factors harvesting and conservation and their interaction for three different varieties (‘Arbequina’, ‘Picual’, and ‘Verdial’), based on the mean of the calculated omega-squared () values of 10 parameters (FFA, peroxides, K232, K270, oxidative stability, photosynthetic pigments, bitterness index, total polyphenols, and α-tocopherols) over 14 days.

3.10. Sensory Analysis

The research design foresaw that, if no significant differences were found between the samples of D0 and D14 or between those of D14, the samples of D4 and D8 would not be tasted. It turned out that only in the ‘Arbequina’ variety was the panel able to significantly distinguish differences between the treatments after 14 days of storage. Therefore, only D4 and D8 oils of this variety were further examined. The official limit that disallows the use of the quality label of ‘Extra Virgin’ was only exceeded once: in the R2C2 treatment of the ‘Arbequina’ sample on day 14, the ‘extra’ category was lost due to a median of the ‘Mold’ defect above 0, namely 1.2.

The evolution of the positive attributes disclosed a clear difference between the ‘Arbequina’ cultivar on the one hand and the ‘Picual’ and ‘Verdial’ varieties on the other (Table 2). The bitterness and pungency levels of the ‘Arbequina’ oils were significantly affected by the storage time and the conservation method, while no significant effect was found due to the interaction between the factors ‘harvesting’ and ‘conservation’. The fruity attribute was not affected by the storage time, nor by the type of treatment. The ‘Picual’ variety presented no effect of the studied factors on the different attributes. In the ‘Verdial’ cultivar, the attributes ‘fruitiness’ and ‘bitterness’ were only significantly influenced by the type of harvesting, showing that the oils from olives collected with the MIU presented values significantly higher, while the storage time decreased the intensity of the attribute ‘pungency’.

Table 2.

Intensity of three positive attributes (Fruitiness, Bitterness, and Pungency) as noted by a sensory analysis panel in the ‘Arbequina’, ‘Picual’, and ‘Verdial’ olive oils extracted from fruit, picked with a Manual Inverted Umbrella (R1) and in a traditional way (R2) and stored for 0, 4, 8, and 14 days at 5 °C (C1) and at ambient temperature (C2). The panel was formed by 8 approved tasters.

According to the official regulations, most of the samples analyzed did not receive the minimum number of negative evaluations necessary to lower their quality. Nevertheless, these negative evaluations can be considered to detail the applied treatments that were shown to be different, as was the case with the ‘Arbequina’ variety. This was achieved by calculating the median of the scores given by each of the tasters to the most negative attribute of a sample of a specific treatment. It is obvious that this calculation differs profoundly from the official one and that no normative maximum value can be given. However, it does permit us to compare the different treatments (Table 3). Calculating the median of the maximum grouped defects of each sample revealed that the deterioration became first visible in the treatments that were kept at room temperature. On day 14, fruit harvested with the traditional method (R2) and cold-stored (C1) presented the onset of deterioration. The oils from fruit picked with the MIU (R1) and kept at 5 °C (C1) did not show a median above 0 during the time under investigation (Table 3).

Table 3.

Number of defects and the median of their intensity as reported by the sensory panel, in the oil extracted from the ‘Arbequina’ cultivar, harvested with a Manual Inverted Umbrella (R1) or in a traditional way (R2) and stored for 0, 4, 8, and 14 days at 5 °C (C1) or at ambient temperature (C2). The panel was formed by 8 approved tasters.

For each cultivar and each storage time, the tasters ranked the oils in order of preference. The two from day 0 and the four from day 14 were evaluated together. The Friedman’s test detected significant differences, with a χ² = 11.07 (p = 0.05), between the six presented samples in the three cultivars, with χ²R values of 13.43 for the ‘Arbequina’ c.v., 14.34 for the ‘Picual’ c.v., and 11.35 for the ‘Verdial’ c.v. However, when the ranking was restricted to the four samples on day 14, no significant difference could be detected by the panel between the treatments of the ‘Picual’ and ‘Verdial’ varieties. As a consequence, no further sensory analysis was performed on the samples of day 4 and day 8 of these varieties. The oil samples of the ‘Arbequina’ cultivar not only showed a significant difference between the treatments on day 14 (χ²R = 12.45**), but also on day 4 and day 8, with a χ²R value of 12.64* and 13.07*, respectively.

The Panel Preference (), obtained raking results for the ‘Arbequina’ oil samples from storage at days 4, 8, and 14 (Figure 5). The calculation and the subsequent ranking of the obtained values revealed a clear preference for the cold-stored olives from day 4 up to day 14. The impact of the harvesting method did not come to the fore as a major factor. On day 0, the tasters almost split in giving preference over one of the two methods (three preferred R1 against five in favor of R2), while only on day 14 a consistent pattern was observed in giving preference to a treatment that included the R1.

Figure 5.

The Panel Preference () for the oil extracted from the ‘Arbequina’ cultivar, recollected with a Manual Inverted Umbrella (R1) or in a traditional way (R2) and stored for 4, 8, and 14 days at 5 °C (C1) or at ambient temperature (C2). The panel was formed by 8 approved tasters. Data at day 0 are not shown as the Friedman test cannot be performed on two treatments.

3.11. Evaluation of Premium Quality

The premium quality of the ‘Picual’ variety was recognized in the NYIOOC in all of the three years, with gold medals in 2017 and 2019, and a silver medal in 2018. The ‘Arbequina’ monovarietal EVOO obtained a gold medal only in 2019. The ‘Verdial’ monovarietal EVOO did not acquire a medal in 2018.

4. Discussion

The positive correlation of the conservation temperature with the level of FFA as well as the combined effect of a mechanized harvest and the conservation method was confirmed in the three varieties, as well as the fact that the effect of these factors varied between the cultivars tested. These results are in line with earlier research that underlined the close relationship between the level of the FFA and the time and temperature of conservation [24,25,26].

The necessary time to attain levels above 0.80%, the ‘Picual’ c.v., kept at 5 °C, was reported to surmount to 23 [25] and 30 days [27], while the ‘Arbequina’ c.v., recollected mechanically and kept at 3 °C, was beyond that limit after 10 days [26]. Only in the first year did ‘Arbequina’, harvested traditionally, attain this limit, after being kept at an ambient temperature for more than 8 days. The difference between the two years can be explained by the difference in decay incidence, which attained a level of 45% in year 1 and 35% in year 2 for this variety and treatment [16].

While [26] pointed to the profound impact of the mechanical harvesting method on the quality of the oil extracted from the ‘Arbequina’ c.v., even independently of the temperature of conservation, [25] did not observe such an effect on ‘Picual’, but neither discarded an effect on other varieties, such as ‘Barnea’ and ‘Koroneiki’. [6] observed for ‘Arbequina’ significant differences in FFA after 1 week of storage between the gentle manual harvest and the hand-held combs, hand-held machine, and straddle machine. The authors further underlined that the traditional harvesting method with nets and hand-held combs is comparable with mechanized harvesting when compared to gentle hand picking. Harvesting with an MIU falls in between the first two mentioned categories and the obtained results confirmed for the ‘Arbequina’ variety. The results obtained for the ‘Picual’ and ‘Verdial’ varieties are comparable with those [6] for ‘Frantoio’, where no significant differences were present between the harvesting methods after one week of storage. The obtained results with the ‘Arbequina’, ‘Picual’, and ‘Verdial’ varieties do underline the importance of the variety as a crucial factor in the optimization of the harvesting and conservation, as reported earlier by [6,25,26].

The observed degree of oxidation (peroxides, K232, and K270) demonstrated no consistent tendencies for the factors ‘harvesting’ and ‘conservation’ over the studied years. It was only in year 2 that a significant effect was observed for the peroxides and the K270 in all of the three varieties, while only in the ‘Arbequina’ and ‘Verdial’ cultivars concerning the K232. [26] mention values of peroxides, K232, and K270 that were significantly higher when ‘Arbequina’ was recollected mechanically and relate this to the internal ruptures as a consequence of the received blows during the harvesting and the consequential higher decay incidence. The results in year 2 support this hypothesis, indicating a slight difference between the oils from ‘Arbequina’ and ‘Verdial’ olives compared to the ‘Picual’ oils.

The photosynthetic pigments (K470 and K670) evolved consistently in the three varieties. However, the calculated strength of the present factors underlines the increasing importance of the factor ‘conservation’ in explaining the observed differences, especially for the ‘Arbequina’ and ‘Verdial’ oils. A similar descent was obtained by Yousfi et al. (2008) concerning the level of carotenoids in the ‘Picual’ and ‘Verdial’ c.v.s, although not in the ‘Arbequina’ variety. The obtained results in both years do contradict this earlier finding and underline the impact of the storing temperature for this variety concerning the photosynthetic pigments.

The results of the bitterness index followed the expected evolution characterized by a significant influence of the temperature and the duration time [11,15,27]. The effect of the harvesting method was present in both years, although more pronounced in the second one, and especially for the ‘Picual’ and ‘Verdial’ varieties. The ‘Arbequina’ evolved differently, given the more pronounced effect of the storing conditions.

It is known that oxidative stability varies significantly between varieties, while to a lesser extent, a local factor is present [17,28]. The obtained data on the day of harvest did not deviate from the published induction times for the studied cultivars and did confirm a strong genetic effect [28,29]. It was also reported that the values within each cultivar were reduced during conservation, while this process was slowed when cooled [24,30]. The results support the hypothesis that the reduction in the oxidation time is not only related to the progress of ripening but also to the aggressiveness of the harvesting method, especially when harvesting the ‘Arbequina’ variety [26].

The polyphenols concentration of EVOO varies greatly depending on the olive cultivar, agronomic practices, degree of fruit ripening, conditions of processing, and fruit and oil storage [28,31,32]. The obtained results are in line with earlier published research for the total amount of polyphenols. The levels for the different varieties fall within the known margins of each variety and do confirm the difference between them, with the lowest levels for ‘Arbequina’, and slightly higher values for ‘Verdial’ when compared with ‘Picual’. The importance of the genetic factor was present as well as the impact of the harvesting and conservation method for the majority of studied varieties and years [24,33,34]. However, the mentioned complex interactions may play a role in explaining why the results did not fully follow the same evolution concerning the factor conservation as reported by [15,24]. Instead of an overall decrease in the polyphenols during the storage, an inverse process was observed in ‘Arbequina’ in the first year and no significant effect was observed in the second.

The obtained values of the α-tocopherols are consistent with those published by [35]. The presence and the evolution of the α-tocopherols were genetically related while significant differences were observable between the two studied years. Annual biochemical changes and differences in annual rainfall and temperature are known to be responsible for the different conditions of each year that accelerate or delay ripening by increasing or decreasing the content of vitamins such as tocopherols [35,36]. [26] documented that their level is influenced by the harvest method and the storage temperature and time. However, their hypothesis that mechanized harvesting and conservation at 18 °C favor the degradation of these compounds was not confirmed, as the ‘Arbequina’ cultivar showed an inverse relationship in both years. The other two cultivars did conform to the hypothesis, especially ‘Verdial’, where the effect of the harvesting was the most prominent.

While various parameters indicated the importance of the genetic factor when evaluating the effect of the harvesting and conservation method on the various parameters, it is only when the magnitude of the strength of these factors are taken together and compared that their full impact comes to the fore. The obtained results point to the critical interrelation that exists between the two factors and their interaction, and demonstrate the differences between the three cultivars as the storage time increases. The vulnerability of the ‘Arbequina’ towards deterioration as compared to the ‘Picual’, and to a lesser degree to the ‘Verdial’, is obvious when taking the crossing point of the two curves (harvesting and conservation strength) as a point of reference. The curious rebounding of the harvesting strength in the ‘Picual’ and ‘Verdial’ cultivars at day 8 may indicate that the effects of produced damage, due to a more detrimental harvesting method, can be constrained during the first week due to the cooling of the fruit. However, this initial compensating effect loses power over the following week.

The results of the tasting panel did follow the results based on the physicochemical analysis. The outcome of the ‘Arbequina’ oil judging allowed specifying in detail how the effects of the different treatments were reflected in the quality levels of the samples at each storage time. The fine-tuning of the negative attributes revealed a striking parallel with the measured levels of free fatty acids and peroxide, while the presence of positive attributes was mirrored in the raking scores and the panel preference. The different strength profiles were closely related to the results of the tasting panel, especially in the case of the ‘Arbequina’ cultivar, where the increase in the storage factor from day 4 matched with a clear panel preference for cool-stored oils.

The results obtained at the NYIOOC confirm that the used harvesting and conservation method do make it possible to obtain olive oils that match the highest standards of the consumer market. However, the results of this contest also illustrated the differences between the varieties. While the ‘Picual’ obtained every year a silver or a gold medal, the ‘Arbequina’ acquired only in one year a gold one. The ‘Verdial’, which participated in just one year, was not qualified. As the extraction was performed under ideal conditions in all of the three years, it can be concluded that the ‘Picual’ did not suffer from the used harvesting and storage methods. The higher vulnerability of the ‘Verdial’ and especially ‘Arbequina’, already demonstrated in the physicochemical analysis and tasting panel, was reflected in the verdict of the panel members. However, this did not impede that the latter obtained in one year a very good result.

5. Conclusions

The study underlines the importance of both harvesting method and conservation in the quality of the oils extracted before their processing and confirms the presence of a genetic predisposition of the different varieties studied.

The use of the MIU and the consequent storage of the picked olives at 5 °C did affect the majority of the parameters in a significant way when compared with traditional harvesting and storage at ambient temperature, especially in a more sensible variety such as ‘Arbequina’ as compared with ‘Picual’ or ‘Verdial’. The calculation of the magnitude of strengths and the calculated panel preference made it possible to discern the explanatory weight of each of the factors, to understand the differences between the varieties with regard to the factors, and to emphasize the need to consider the days of storage when evaluating their importance. This information is crucial to decide which solution fits the farmer best given the specific constraints he has to deal with. When the storage time falls within the range of a few days, the quality of the fruit is best guaranteed by an optimized harvesting method. In the case of an expected longer storage, high day temperatures, or when one is dealing with very sensitive varieties, cold storage becomes unavoidable when a high-quality end-product is the main objective.

The results of the tasting panel and the qualitative appreciation at the international competition do confirm that small producers can obtain premium olive oils when applying the described harvesting and storage method. However, specific chemical analysis is necessary to reveal in more detail to what extent the volatile characteristics of the produced oils are influenced by the studied factors.

The novelty and strength of the study lies not only in showing the effects of the different factors studied over time, but also in showing the possibilities for smallholders to optimize their production through accessible and cost-effective modifications. In many cases, small producers’ commitment to quality will be the only viable solution for their economic profitability in a market where large producers impose market prices.

Supplementary Materials

The following are available online at https://www.mdpi.com/article/10.3390/agriculture11050417/s1, Table S1: Free Fatty Acid (% oleic acid) noted in the ‘Arbequina’, ‘Picual’, and ‘Verdial’ olive oils extracted from fruit, picked with a Manual Inverted Umbrella (R1) and in a traditional way (R2) and stored during 0, 4, 8, and 14 days at 5 °C (C1) and ambient temperature (C2)a. Table S2: Peroxide Value (mEq O2/ kg oil) noted in the ‘Arbequina’, ‘Picual’, and ‘Verdial’ olive oils extracted from fruit, picked with a Manual Inverted Umbrella (R1) and in a traditional way (R2) and stored during 0, 4, 8, and 14 days at 5 °C (C1) and ambient temperature (C2)a. Table S3: Absorbency at 232 nm (K232) noted in the ‘Arbequina’, ‘Picual’, and ‘Verdial’ olive oils extracted from fruit. picked with a Manual Inverted Umbrella (R1) and in a traditional way (R2) and stored during 0, 4, 8, and 14 days at 5 °C (C1) and ambient temperature (C2)a. Table S4: Absorbance at 270 nm (K270) noted in the ‘Arbequina’. ‘Picual’ and ‘Verdial’ olive oils extracted from fruit, picked with a Manual Inverted Umbrella (R1) and in a traditional way (R2) and stored during 0, 4, 8, and 14 days at 5 °C (C1) and ambient temperature (C2)a. Table S5: Induction time (h) noted in the ‘Arbequina’. ‘Picual’ and ‘Verdial’ olive oils extracted from fruit, picked with a Manual Inverted Umbrella (R1) and in a traditional way (R2) and stored during 0, 4, 8, and 14 days at 5 °C (C1) and ambient temperature (C2)a. Table S6: Absorbance at 470 nm (Carotenoids) noted in the ‘Arbequina’. ‘Picual’ and ‘Verdial’ olive oils extracted from fruit picked with a Manual Inverted Umbrella (R1) and in a traditional way (R2) and stored during 0, 4, 8, and 14 days at 5 °C (C1) and ambient temperature (C2)a. Table S7: Absorbency at 670 nm (Chlorophyll) noted in the ‘Arbequina’. ‘Picual’ and ‘Verdial’ olive oils extracted from fruit, picked with a Manual Inverted Umbrella (R1) and in a traditional way (R2) and stored during 0, 4, 8, and 14 days at 5 °C (C1) and ambient temperature (C2)a. Table S8: Bitterness Index noted in the ‘Arbequina’. ‘Picual’ and ‘Verdial’ olive oils extracted from fruit, picked with a Manual Inverted Umbrella (R1) and in a traditional way (R2) and stored during 0, 4, 8, and 14 days at 5 °C (C1) and ambient temperature (C2)a. Table S9: Total Polyphenols (mg/kg) noted in the ‘Arbequina’, ‘Picual’, and ‘Verdial’ olive oils extracted from fruit, picked with a Manual Inverted Umbrella (R1) and in a traditional way (R2) and stored during 0, 4, 8, and 14 days at 5 °C (C1) and ambient temperature (C2)a. Table S10: α-Tocopherols (mg/kg) noted in the ‘Arbequina’, ‘Picual’, and ‘Verdial’ olive oils extracted from fruit, picked with a Manual Inverted Umbrella (R1) and in a traditional way (R2) and stored during 0, 4, 8, and 14 days at 5 °C (C1) and ambient temperature (C2)a.

Author Contributions

Conceptualization, E.P. and J.M.G.; Methodology, E.P., J.M.G., and M.C.F.; Formal Analysis, E.P. and R.R.S.-G.; Resources, J.M.G. and M.C.F.; Writing, E.P., J.M.G., M.C.F., and R.R.S.-G. All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded by the Spanish Ministry of Science and Innovation (research project AGL2015-71585-R).

Acknowledgments

We thank the Del Cetino Olive Farm and its personnel for their collaboration and Carmen Martínez for her technical assistance.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Comunidad Autónoma de Andalucía. Ley 5/2011, de 6 de Octubre, del Olivar de Andalucía; Comunidad Autónoma de Andalucía: Andalucía, España, 2011.

- Colombo, S.; Perujo-Villanueva, M. Inefficiency due to parcel fragmentation in olive orchards. Acta Hortic. 2018, 16, 159–164. [Google Scholar] [CrossRef]

- Sola-Guirado, R.R.; Castro-García, S.; Blanco-Roldán, G.L.; Jiménez-Jiménez, F.; Castillo-Ruiz, F.J.; Gil-Ribes, J.A. Traditional olive tree response to oil olive harvesting technologies. Biosyst. Eng. 2014, 118, 186–193. [Google Scholar] [CrossRef]

- García, J.M.; Yousfi, K. The postharvest of mill olives. Grasas Aceites 2006, 57, 16–24. [Google Scholar] [CrossRef]

- Rallo, L.; Díez, C.M.; Morales-Sillero, A.; Miho, H.; Priego-Capote, F.; Rallo, P. Quality of olives: A focus on agricultural preharvest factors. Sci. Hortic. 2018, 233, 491–509. [Google Scholar] [CrossRef]

- Famiani, F.; Farinelli, D.; Urbani, S.; Al Hariri, R.; Paoletti, A.; Rosati, A.; Esposto, S.; Selvaggini, R.; Taticchi, A.; Servili, M. Harvesting system and fruit storage affect basic quality parameters and phenolic and volatile compounds of oils from intensive and super-intensive olive orchards. Sci. Hortic. 2020, 263, 109045. [Google Scholar] [CrossRef]

- Rébufa, C.; Pinatel, C.; Artaud, J.; Girard, F. A comparative study of the main international extra virgin olive oil competitions: Their impact on producers and consumers. Trends Food Sci. Technol. 2021, 107, 445–454. [Google Scholar] [CrossRef]

- Puerto, D.A.; Moreno, Ó.C.; Gila, D.M.M.; Ortega, J.G.; García, J.G. Online system for the identification and classification of olive fruits for the olive oil production process. J. Food Meas. Charact. 2019, 13, 716–727. [Google Scholar] [CrossRef]

- Soto, J.N.; Martínez, S.S.; Gila, D.M.; Ortega, J.G.; García, J.G. Fast and Reliable Determination of Virgin Olive Oil Quality by Fruit Inspection Using Computer Vision. Sensors 2018, 18, 3826. [Google Scholar] [CrossRef] [PubMed]

- Plasquy, E.; Sola-Guiraldo, R.R.; Florido, C.; García, J.M.; Blanco-Roldán, G. Evaluation of a manual olive fruit harvester for small producers. Res. Agric. Eng. 2019, 65, 105–111. [Google Scholar] [CrossRef]

- Garcia, J.; Gutierrez, F.; Castellano, J.; Perdiguero, S.; Morilla, A.; Albi, M. Storage of olives destined for oil extraction. Acta Hortic. 1994, 368, 673–681. [Google Scholar] [CrossRef]

- Canet, M.; García, J.M. Repercusión de la frigoconservacion de la aceituna de molino en el proceso de producción de aceite de oliva virgen. Grasas Aceites 1999, 50, 181–184. [Google Scholar] [CrossRef]

- Pereira, J.A.; Casal, S.; Bento, A.; Oliveira, M.B.P.P. Influence of Olive Storage Period on Oil Quality of Three Portuguese Cultivars ofOlea europea, Cobrançosa, Madural, and Verdeal Transmontana. J. Agric. Food Chem. 2002, 50, 6335–6340. [Google Scholar] [CrossRef] [PubMed]

- García, J.M.; Gutiérrez, F.; Barrera, M.J.; Albi, M.A. Storage of Mill Olives on an Industrial Scale. J. Agric. Food Chem. 1996, 44, 590–593. [Google Scholar] [CrossRef]

- Kalua, C.M.; Bedgood, D.R.; Bishop, A.G.; Prenzler, P.D. Changes in Virgin Olive Oil Quality during Low-Temperature Fruit Storage. J. Agric. Food Chem. 2008, 56, 2415–2422. [Google Scholar] [CrossRef]

- Plasquy, E.; Blanco-Roldán, G.; Florido, M.C.; García, J.M. Effects of an integrated harvest system for small producers on the quality of the recollected olive fruit. Grasas Aceites 2021, 72, e436. [Google Scholar]

- Mateos, R.; Uceda, M.; Aguilera, M.P.; Escuderos, M.E.; Maza, G.B. Relationship of Rancimat method values at varying temperatures for virgin olive oils. Eur. Food Res. Technol. 2005, 223, 246–252. [Google Scholar] [CrossRef]

- Minguez-Mosquera, M.I.; Rejano-Navarro, L.; Gandul-Rojas, B.; Sanchezgomez, A.H.; Garrido-Fernandez, J. Color-pigment correlation in virgin olive oil. J. Am. Oil Chem. Soc. 1991, 68, 332–336. [Google Scholar] [CrossRef]

- Gutierrez, F.; Perdiguero, S.; Garcia, J.M.; Castellano, J.M. Quality of oils from olives stored under controlled atmosphere. J. Am. Oil Chem. Soc. 1992, 69, 1215–1218. [Google Scholar] [CrossRef]

- IUPAC. Standard Methods for the Analysis of Oils, Fats, and Derivates, 7th ed.; Pergamon Press: Oxford, UK, 1992. [Google Scholar]

- Percy, D.F.; Maxwell, S.E.; Delaney, H.D. Designing Experiments and Analyzing Data. J. R. Stat. Soc. 1991, 40, 353. [Google Scholar] [CrossRef]

- Yigit, S.; Mendes, M. Which Effect Size Measure is Appropriate for One-way and Two-way Anova Models? A Monte Carlo Simulation Study. Revstat Stat. J. 2018, 16, 295–313. [Google Scholar]

- Lindley, D.V.; Sprent, P.; Smeeton, N.C. Applied Nonparametric Statistical Methods. Math. Gaz. 2002, 86, 187. [Google Scholar] [CrossRef]

- Clodoveo, M.; Delcuratolo, D.; Gomes, T.; Colelli, G. Effect of different temperatures and storage atmospheres on Coratina olive oil quality. Food Chem. 2006, 102, 571–576. [Google Scholar] [CrossRef]

- Dag, A.; Boim, S.; Sobotin, Y.; Zipori, I. Effect of Mechanically Harvested Olive Storage Temperature and Duration on Oil Quality. HortTechnology 2012, 22, 528–533. [Google Scholar] [CrossRef]

- Yousfi, K.; Weiland, C.M.; García, J.M. Effect of Harvesting System and Fruit Cold Storage on Virgin Olive Oil Chemical Composition and Quality of Superintensive Cultivated ‘Arbequina’ Olives. J. Agric. Food Chem. 2012, 60, 4743–4750. [Google Scholar] [CrossRef]

- Yousfi, K.; Cayuela, J.A.; García, J.M. Reduction of Virgin Olive Oil Bitterness by Fruit Cold Storage. J. Agric. Food Chem. 2008, 56, 10085–10091. [Google Scholar] [CrossRef]

- Serrano, A.; De la Rosa, R.; Sánchez-Ortiz, A.; Cano, J.; Pérez, A.G.; Sanz, C.; Arias-Calderón, R.; Velasco, L.; León, L. Chemical components influencing oxidative stability and sensorial properties of extra virgin olive oil and effect of genotype and location on their expression. LWT 2021, 136, 110257. [Google Scholar] [CrossRef]

- Tous, J.; Uceda, M.; Romero, A.; Beltrán, G.; Días, I.; Jiménez, A. Composición del Aceite. In Variabilidad y Selección. In Variedades de Olivo en España; Rallo, L., Barranco, D., Caballero, J.M., del Río, C., Martín, A., Tous, J., Trujillo, I., Eds.; Mundi-Prensa: Madrid, Spain, 2005; pp. 357–372. [Google Scholar]

- Kiritsakis, A.; Nanos, G.D.; Polymenopulos, Z.; Thomai, T.; Sfakiotakis, E.M. Effect of fruit storage conditions on olive oil quality. J. Am. Oil Chem. Soc. 1998, 75, 721–724. [Google Scholar] [CrossRef]

- Beltrán, G.; Ruano, M.T.; Jiménez, A.; Uceda, M.; Aguilera, M.P. Evaluation of virgin olive oil bitterness by total phenol content analysis. Eur. J. Lipid Sci. Technol. 2007, 109, 193–197. [Google Scholar] [CrossRef]

- Borges, T.H.; Serna, A.; López, L.C.; Lara, L.; Nieto, R.; Seiquer, I. Composition and Antioxidant Properties of Spanish Extra Virgin Olive Oil Regarding Cultivar, Harvest Year and Crop Stage. Antioxidants 2019, 8, 217. [Google Scholar] [CrossRef]

- Nabil, B.Y.; Ouni, Y.; Nizar, D.; Bechir, B.; Chedly, A.; Mokhtar, Z. Effect of olive storage period at two different temperatures on oil quality of two Tunisian cultivars of Olea europea, Chemlali and Chétoui. Afr. J. Biotechnol. 2012, 11, 888–895. [Google Scholar]

- Morales-Sillero, A.; Pérez, A.G.; Casanova, L.; García, J.M. Cold storage of ‘Manzanilla de Sevilla’ and ‘Manzanilla Cacereña’ mill olives from super-high density orchards. Food Chem. 2017, 237, 1216–1225. [Google Scholar] [CrossRef] [PubMed]

- Beltrán, G.; Jiménez, A.; Del Rio, C.; Sánchez, S.; Martínez, L.; Uceda, M.; Aguilera, M.P. Variability of vitamin E in virgin olive oil by agronomical and genetic factors. J. Food Compos. Anal. 2010, 23, 633–639. [Google Scholar] [CrossRef]

- Velasco, L.; De La Rosa, R.; Leon, L. Advanced olive selections with enhanced quality for minor constituents. Grasas Aceites 2015, 66, e100. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).