Development of an Air-Recirculated Ventilation System for a Piglet House, Part 2: Determination of the Optimal Module Combination Using the Numerical Model

Abstract

:1. Introduction

2. Materials and Methods

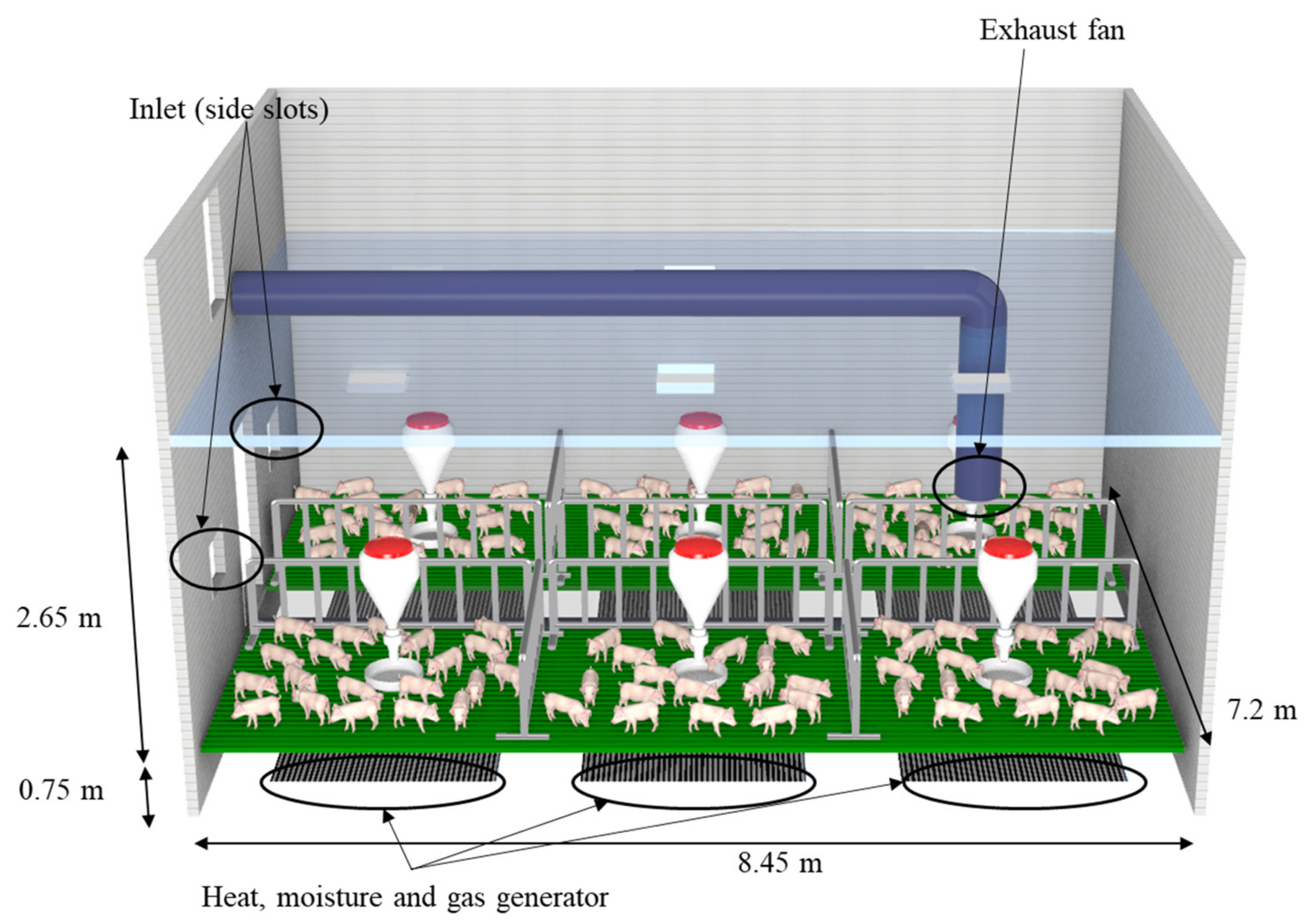

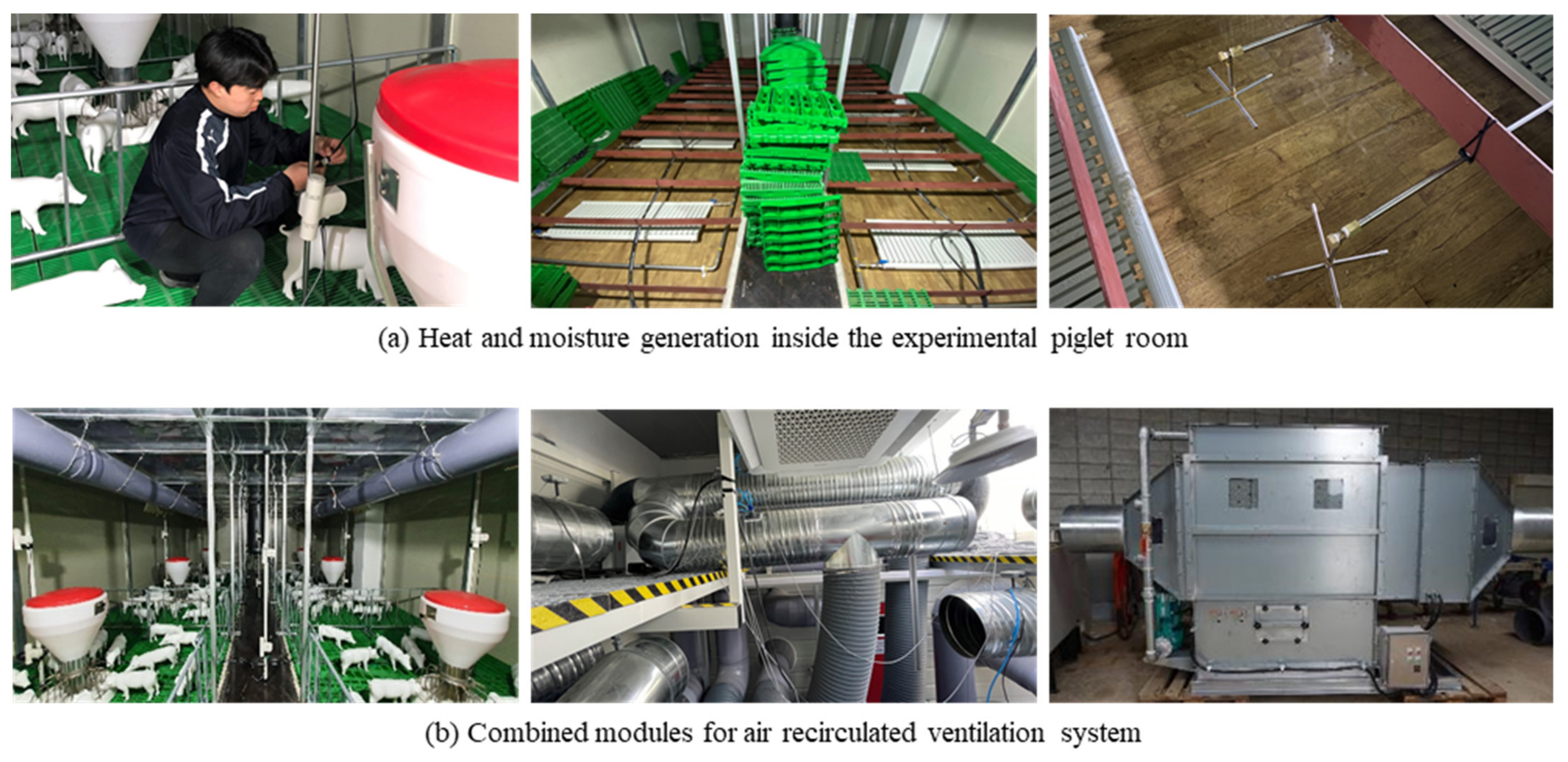

2.1. Target Facility

2.2. Balance Equations of Environment inside the Experimental Piglet Room

2.3. Design Equation of the ARVS

2.4. Numerical Design Condition of the ARVS

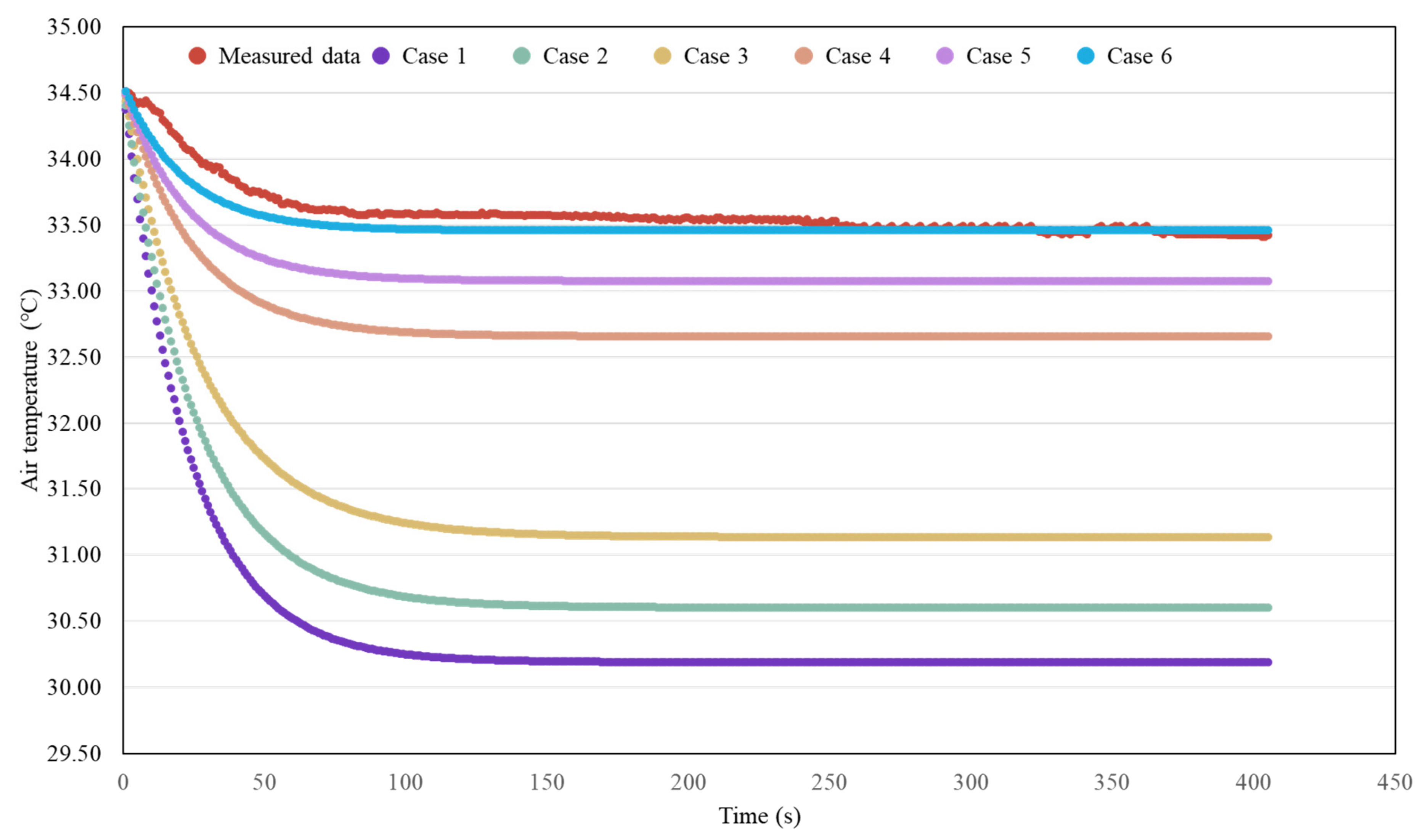

2.5. Validation of the Numerical Model of the ARVS

2.6. Case Studies with the Numerical Model of the ARVS

3. Results and Discussions

3.1. Design and Validation of the Numerical Model of the ARVS

3.2. The Results of the Gas Concentration According to the Ventilation Rate and Outdoor Air Mixing Ratio

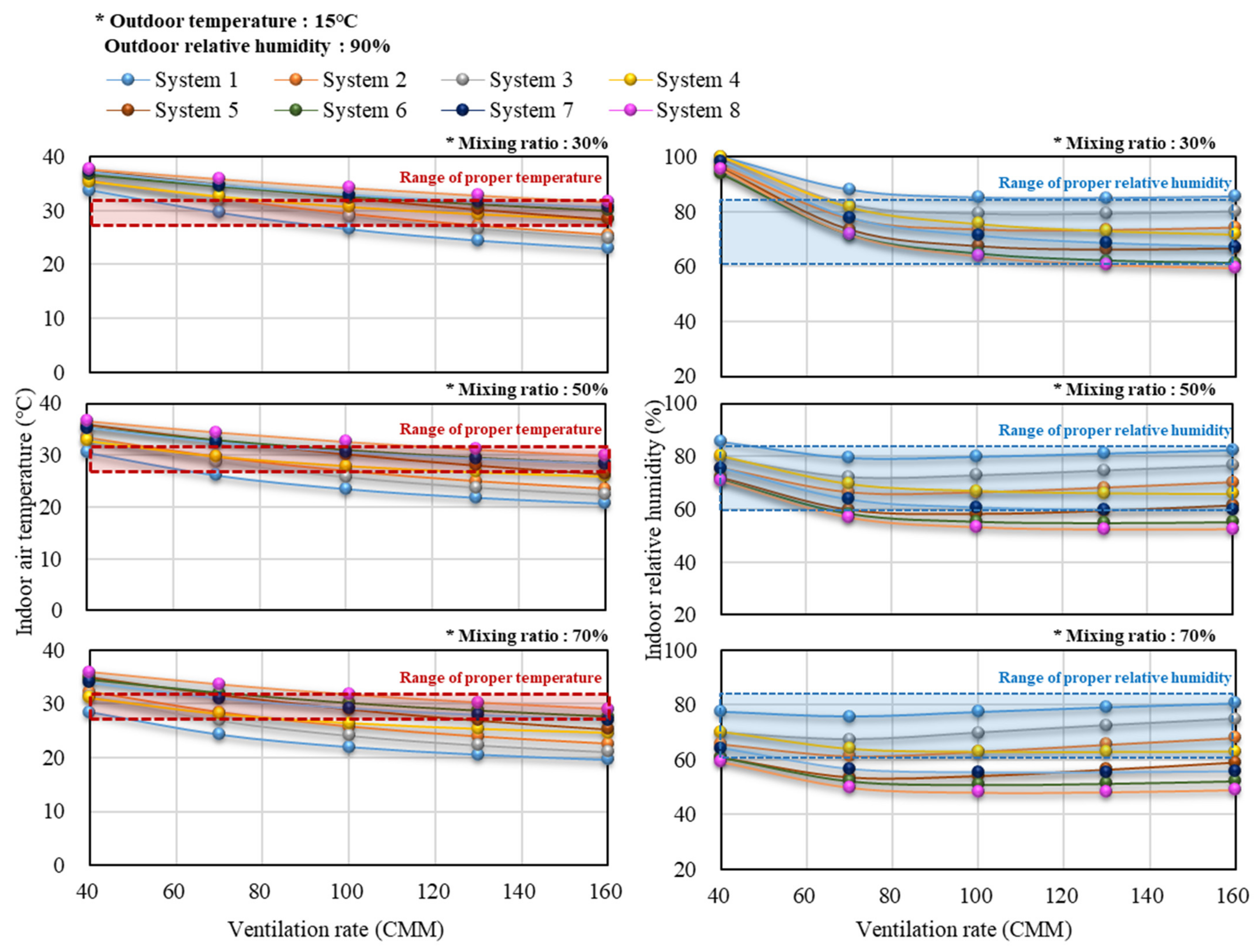

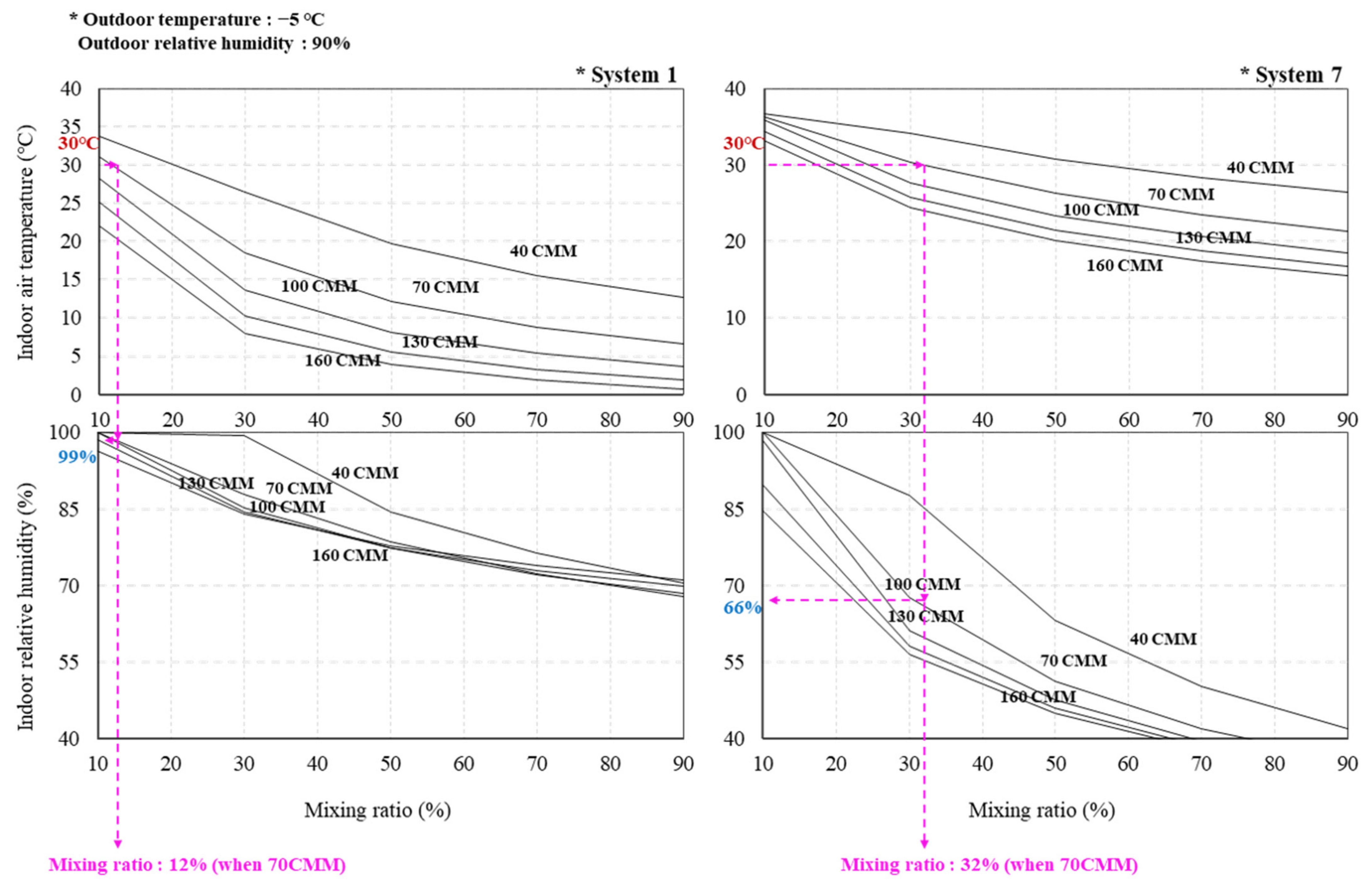

3.3. Air Temperature and Relative Humidity Results in the Experimental Piglet Room with the ARVS Applied

3.4. Example of Optimal Operation for ARVS

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ministry of Agriculture Food and Rural Affairs. 2020. Available online: www.mafra.go.kr (accessed on 8 July 2020).

- Bai, X.; Plastow, G.S. Breeding for disease resilience: Opportunities to manage polymicrobial challenge and improve commercial performance in the pig industry. CABI Agric. Biosci. 2022, 3, 6. [Google Scholar] [CrossRef] [PubMed]

- Yeo, U.-H.; Decano-Valentin, C.; Ha, T.; Lee, I.-B.; Kim, R.-W.; Lee, S.-Y.; Kim, J.-G. Impact analysis of environmental conditions on odour dispersion emitted from pig house with complex terrain using CFD. Agronomy 2020, 10, 1828. [Google Scholar] [CrossRef]

- Kim, J.G.; Lee, I.B.; Lee, S.Y.; Park, S.J.; Jeong, D.Y.; Choi, Y.B.; Decano-Valentin, C.; Yeo, U.H. Development of an Air-Recirculated Ventilation System for a Piglet House, Part 1: Analysis of Representative Problems through Field Experiment and Aerodynamic Analysis Using CFD Simulation for Evaluating Applicability of System. Agriculture 2022, 12, 1139. [Google Scholar] [CrossRef]

- Pexas, G.; Mackenzie, S.G.; Wallace, M.; Kyriazakis, I. Cost-effectiveness of environmental impact abatement measures in a European pig production system. Agric. Syst. 2020, 182, 102843. [Google Scholar] [CrossRef]

- McMichael, A.J.; Powles, J.W.; Butler, C.D.; Uauy, R. Food, livestock production, energy, climate change, and health. Lancet 2007, 370, 1253–1263. [Google Scholar] [CrossRef]

- Racewicz, P.; Ludwiczak, A.; Skrzypczak, E.; Składanowska-Baryza, J.; Biesiada, H.; Nowak, T.; Nowaczewski, S.; Zaborowicz, M.; Stanisz, M.; Ślósarz, P. Welfare health and productivity in commercial pig herds. Animals 2021, 11, 1176. [Google Scholar] [CrossRef] [PubMed]

- Besant, R.W.; Simonson, C.J. Air-to-air energy recovery. ASHRAE J. 2000, 42, 31–43. [Google Scholar]

- Burton, D.J. Air recirculation: A case study. Occup. Health Saf. 2004, 73, 28–30. [Google Scholar]

- Ekinci, K.; Keener, H.; Akbolat, D. Effects of feedstock, airflow rate, and recirculation ratio on performance of composting systems with air recirculation. Bioresour. Technol. 2006, 97, 922–932. [Google Scholar] [CrossRef] [PubMed]

- Hall, A.; Saindon, J.; Nel, L.; Hardcastle, S. Feasibility of controlled recirculation of exhaust air to reduce heating costs at Ruttan Mine, Manitoba. In Proceedings of the CIM BULLETIN, Edmonton, AB, Canada, 4–6 June 1987; p. 89. [Google Scholar]

- Park, S.; Seo, J. Analysis of Air-side economizers in terms of cooling-energy performance in a data center considering Exhaust air recirculation. Energies 2018, 11, 444. [Google Scholar] [CrossRef]

- Ziegler, T.; Jubaer, H.; Schütz, M. Increasing the Energy Efficiency of Batch-Type Drying with Partial Air Recirculation. Chem. Ing. Tech. 2016, 88, 208–214. [Google Scholar] [CrossRef]

- American National Standards Institute (ANSI). 2007. Available online: websotre.ansi.org (accessed on 8 July 2020).

- Donham, K.J. Association of environmental air contaminants with disease and productivity in swine. Am. J. Vet. Res. 1991, 52, 1723–1730. [Google Scholar] [PubMed]

- Alvarado, A.C.; Predicala, B.Z. Control of Gas and Odor Levels in Swine Facilities Using Filters with Zinc Oxide Nanoparticles. Trans. ASABE 2017, 60, 943–956. [Google Scholar] [CrossRef]

- Anthony, T.R.; Altmaier, R.; Jones, S.; Gassman, R.; Park, J.H.; Peters, T.M. Use of recirculating ventilation with dust filtration to improve wintertime air quality in a swine farrowing room. J. Occup. Environ. Hyg. 2015, 12, 635–646. [Google Scholar] [CrossRef] [PubMed]

- Anthony, T.R.; Altmaier, R.; Park, J.H.; Peters, T.M. Modeled effectiveness of ventilation with contaminant control devices on indoor air quality in a swine farrowing facility. J. Occup. Environ. Hyg. 2014, 11, 434–449. [Google Scholar] [CrossRef]

- Anthony, T.R.; Yang, A.Y.; Peters, T.M. Assessment of interventions to improve air quality in a livestock building. J. Agric. Saf. Health 2017, 23, 247–263. [Google Scholar] [CrossRef]

- Park, J.H.; Peters, T.M.; Altmaier, R.; Jones, S.M.; Gassman, R.; Anthony, T.R. Simulation of air quality and operating cost to ventilate swine farrowing facilities in the midwest US during winter. Trans. ASABE 2017, 60, 465–477. [Google Scholar]

- Lau, A.; Vizcarra, A.; Lo, K.; Luymes, J. Recirculation of filtered air in pig barns. Can. Agric. Eng. 1996, 38, 297–304. [Google Scholar]

- Wenke, C.; Pospiech, J.; Reutter, T.; Altmann, B.; Truyen, U.; Speck, S. Impact of different supply air and recirculating air filtration systems on stable climate, animal health, and performance of fattening pigs in a commercial pig farm. PLoS ONE 2018, 13, e0194641. [Google Scholar] [CrossRef]

- Peters, T.M.; Sawvel, R.A.; Park, J.H.; Anthony, T.R. Evaluation of a shaker dust collector for use in a recirculating ventilation system. J. Occup. Environ. Hyg. 2015, 12, D201–D210. [Google Scholar] [CrossRef]

- Mostafa, E.; Hoelscher, R.; Diekmann, B.; Ghaly, A.; Buescher, W. Evaluation of two indoor air pollution abatement techniques in forced-ventilation fattening pig barns. Atmos. Pollut. Res. 2017, 8, 428–438. [Google Scholar] [CrossRef]

- Ministry of Agriculture Food and Rural Affairs. 2006. Available online: www.mafra.go.kr (accessed on 8 July 2020).

- CIGR. Heat and Moisture Production at Animal and House Levels; International Commission of Agricultural and Biosystems Engineerin: Liège, Belgium, 2002; pp. 37–40. [Google Scholar]

- ASHRAE. American Society of Heating and Air-Conditioning Engineers; ASHRAE: New York, NY, USA, 2017. [Google Scholar]

- Hayes, M.D.; Brown-Brandl, T.M.; Stinn, J.P.; Li, H.; Xin, H.; Nienaber, J.A.; Shepherd, T.A. House-level moisture production of modern swine by age, temperature and source. In Proceedings of Transactions of the ASABE (American Society of Agricultural and Biological Engineers), Kansas City, MO, USA, 21–24 July 2013; ASABE: Joseph, MI, USA, 2013; p. 1. [Google Scholar]

- National Institute of Environmental Research. 2013. Available online: www.nier.go.kr (accessed on 8 July 2020).

- Van Ouwerkerk, E.; Pedersen, S. Application of the carbon dioxide mass balance method to evaluate ventilation rates in livestock buildings. In Proceedings of the XII CIGR World Congress on Agricultural Engineering, Milan, Italy, 29 August–1 September 1994; pp. 516–529. [Google Scholar]

- Nam, S. Agricultural Facility Engineering; Korea Academy Publishing Association: Seoul, Korea, 2018. [Google Scholar]

- Zhao, Y.; Aarnink, A.; De Jong, M.; Ogink, N.; Koerkamp, P.G. Effectiveness of multi-stage scrubbers in reducing emissions of air pollutants from pig houses. Trans. ASABE 2011, 54, 285–293. [Google Scholar] [CrossRef]

- Hundy, G. Refrigeration, Air Conditioning and Heat Pumps; Butterworth-Heinemann: Oxford, UK, 2016. [Google Scholar]

- Midwest Plan Service. Swine Housing and Equipment Handbook; Midwest Plan Service: Ames, IA, USA, 1983. [Google Scholar]

| Contents | Value |

|---|---|

| Heads of piglets | 174 |

| Weight of each piglet (kg) | 15 |

| Daily feed energy | 3.44 |

| Total heat (kcal·h−1·head−1) (in 34.5 °C) | 79 |

| Sensible heat (kcal·h−1·head−1) (in 34.5 °C) | 25 |

| Latent heat (kcal·h−1·head−1) (in 34.5 °C) | 54 |

| Case 1 | Case 2 | Case 3 | Case 4 | Case 5 | Case 6 | |

|---|---|---|---|---|---|---|

| Infiltration rate (%) | 10 | 5 | 1 | 10 | 5 | 1 |

| Ventilation rate (CMM) | 100 | 80 | ||||

| Descriptive Statistics | Acronyms | Equations |

|---|---|---|

| Mean Bias Errors | MBE (%) | |

| Root Mean Square Error | RMSE |

| Schematic Diagram of the ARVS | |

| System 1 | Basic module |

| System 2 | Basic module + (1) |

| System 3 | Basic module + (2) |

| System 4 | Basic module + (3) |

| System 5 | Basic module + (1), (2) |

| System 6 | Basic module + (1), (3) |

| System 7 | Basic module + (2), (3) |

| System 8 | Basic module + (1), (2), (3) |

| Environmental condition | |

| Outdoor air temperature (°C) | −0, 0, 5, 10, 15, 20, 25, 30, 35 |

| Outdoor air relative humidity (%) | 50, 60, 70, 80, 90, 100 |

| Ventilation rate (CMM) | 40, 70, 100, 130, 160 |

| Mixing ratio of outdoor air (%) | 10, 30, 50, 70, 90 |

| Total cases | |

| 10,800 | |

| Case 1 | Case 2 | Case 3 | Case 4 | Case 5 | Case 6 | |

|---|---|---|---|---|---|---|

| MBE (%) | 9.38 | 6.59 | 8.15 | 2.45 | 1.29 | 0.23 |

| RMSE | 3.19 | 2.78 | 2.25 | 0.83 | 0.44 | 0.11 |

| External Air Temperature (°C) | External Relative Humidity (%) | Ventilation Rate (CMM) | Mixing Ratio of External Air (%) | Air Condition Inside the Piglet Room | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Temp (°C) | RH (%) | Temp (°C) | RH (%) | Temp (°C) | RH (%) | Temp (°C) | RH (%) | ||||

| System 1 | System 2 | System 3 | System 4 | ||||||||

| 35 | 90 | 160 | 10 | 38.7 | 100 | 39.1 | 100 | 39.2 | 100 | 39.2 | 100 |

| 160 | 30 | 37.3 | 98 | 37.8 | 95 | 37.7 | 96 | 38.0 | 95 | ||

| 160 | 50 | 36.5 | 94 | 37.2 | 91 | 36.8 | 93 | 37.4 | 91 | ||

| 160 | 70 | 36.3 | 92 | 37.0 | 89 | 36.4 | 91 | 37.1 | 88 | ||

| 160 | 90 | 36.2 | 90 | 37.0 | 87 | 36.3 | 90 | 37.0 | 87 | ||

| 15 | 90 | 100 | 10 | 34.5 | 100 | 36.0 | 100 | 36.5 | 100 | 36.6 | 100 |

| 100 | 30 | 26.6 | 85 | 29.4 | 73 | 28.9 | 79 | 30.7 | 76 | ||

| 100 | 50 | 23.5 | 80 | 27.0 | 66 | 25.8 | 73 | 28.0 | 67 | ||

| 100 | 70 | 22.0 | 77 | 25.8 | 63 | 24.1 | 70 | 26.4 | 63 | ||

| 100 | 90 | 21.0 | 76 | 25.0 | 61 | 23.1 | 68 | 25.3 | 61 | ||

| −5 | 90 | 70 | 10 | 31.0 | 100 | 33.4 | 100 | 34.2 | 100 | 34.2 | 100 |

| 70 | 30 | 18.5 | 88 | 23.2 | 68 | 24.1 | 77 | 25.5 | 75 | ||

| 70 | 50 | 12.2 | 79 | 18.2 | 57 | 18.1 | 65 | 20.0 | 62 | ||

| 70 | 70 | 8.8 | 72 | 15.5 | 52 | 14.4 | 58 | 16.6 | 54 | ||

| 70 | 90 | 6.7 | 68 | 13.8 | 48 | 12.0 | 54 | 14.1 | 49 | ||

| System 5 | System 6 | System 7 | System 8 | ||||||||

| 35 | 90 | 160 | 10 | 39.5 | 100 | 39.4 | 100 | 39.6 | 100 | 39.6 | 100 |

| 160 | 30 | 38.3 | 94 | 38.4 | 93 | 38.4 | 94 | 38.7 | 92 | ||

| 160 | 50 | 37.6 | 89 | 38.0 | 88 | 37.7 | 90 | 38.2 | 87 | ||

| 160 | 70 | 37.4 | 87 | 37.8 | 85 | 37.4 | 87 | 37.9 | 85 | ||

| 160 | 90 | 37.2 | 86 | 37.8 | 83 | 37.2 | 86 | 37.8 | 83 | ||

| 15 | 90 | 100 | 10 | 37.7 | 100 | 37.2 | 100 | 37.9 | 100 | 38.1 | 100 |

| 100 | 30 | 32.3 | 67 | 32.8 | 65 | 33.0 | 71 | 34.2 | 64 | ||

| 100 | 50 | 30.2 | 58 | 31.0 | 55 | 30.6 | 61 | 32.6 | 53 | ||

| 100 | 70 | 29.0 | 54 | 30.1 | 51 | 29.2 | 56 | 31.7 | 48 | ||

| 100 | 90 | 28.3 | 52 | 29.6 | 48 | 28.2 | 52 | 31.1 | 45 | ||

| −5 | 90 | 70 | 10 | 36.0 | 100 | 35.3 | 100 | 36.3 | 100 | 36.6 | 100 |

| 70 | 30 | 29.5 | 60 | 28.8 | 57 | 30.3 | 68 | 32.1 | 57 | ||

| 70 | 50 | 25.6 | 46 | 25.4 | 43 | 26.3 | 51 | 29.3 | 41 | ||

| 70 | 70 | 23.1 | 39 | 23.3 | 37 | 23.5 | 42 | 27.4 | 33 | ||

| 70 | 90 | 21.4 | 35 | 22.0 | 33 | 21.4 | 36 | 26.1 | 29 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.-g.; Lee, I.-b.; Lee, S.-y.; Jeong, D.-y.; Choi, Y.-b.; Cho, J.-h.; Kim, R.-w.; Aarnink, A. Development of an Air-Recirculated Ventilation System for a Piglet House, Part 2: Determination of the Optimal Module Combination Using the Numerical Model. Agriculture 2022, 12, 1533. https://doi.org/10.3390/agriculture12101533

Kim J-g, Lee I-b, Lee S-y, Jeong D-y, Choi Y-b, Cho J-h, Kim R-w, Aarnink A. Development of an Air-Recirculated Ventilation System for a Piglet House, Part 2: Determination of the Optimal Module Combination Using the Numerical Model. Agriculture. 2022; 12(10):1533. https://doi.org/10.3390/agriculture12101533

Chicago/Turabian StyleKim, Jun-gyu, In-bok Lee, Sang-yeon Lee, Deuk-young Jeong, Young-bae Choi, Jeong-hwa Cho, Rack-woo Kim, and Andre Aarnink. 2022. "Development of an Air-Recirculated Ventilation System for a Piglet House, Part 2: Determination of the Optimal Module Combination Using the Numerical Model" Agriculture 12, no. 10: 1533. https://doi.org/10.3390/agriculture12101533

APA StyleKim, J.-g., Lee, I.-b., Lee, S.-y., Jeong, D.-y., Choi, Y.-b., Cho, J.-h., Kim, R.-w., & Aarnink, A. (2022). Development of an Air-Recirculated Ventilation System for a Piglet House, Part 2: Determination of the Optimal Module Combination Using the Numerical Model. Agriculture, 12(10), 1533. https://doi.org/10.3390/agriculture12101533