Rye as an Energy Cover Crop: Management, Forage Quality, and Revenue Opportunities for Feed and Bioenergy

Abstract

:1. Introduction

2. Materials and Methods

2.1. Field Experiment

2.2. Forage Analysis of Fresh Rye

2.3. Forage Quality of Digested Winter Rye and Revenue from Bioenergy and Feed Protein

2.4. GHG Emissions Associated with Integrated Rye Bioenergy System

3. Results and Discussion

3.1. Growing Conditions and Growth Stages

3.2. Forage Quality of Fresh Rye

3.3. Forage Quality of Digested Winter Rye and Revenue from Bioenergy and Feed Protein

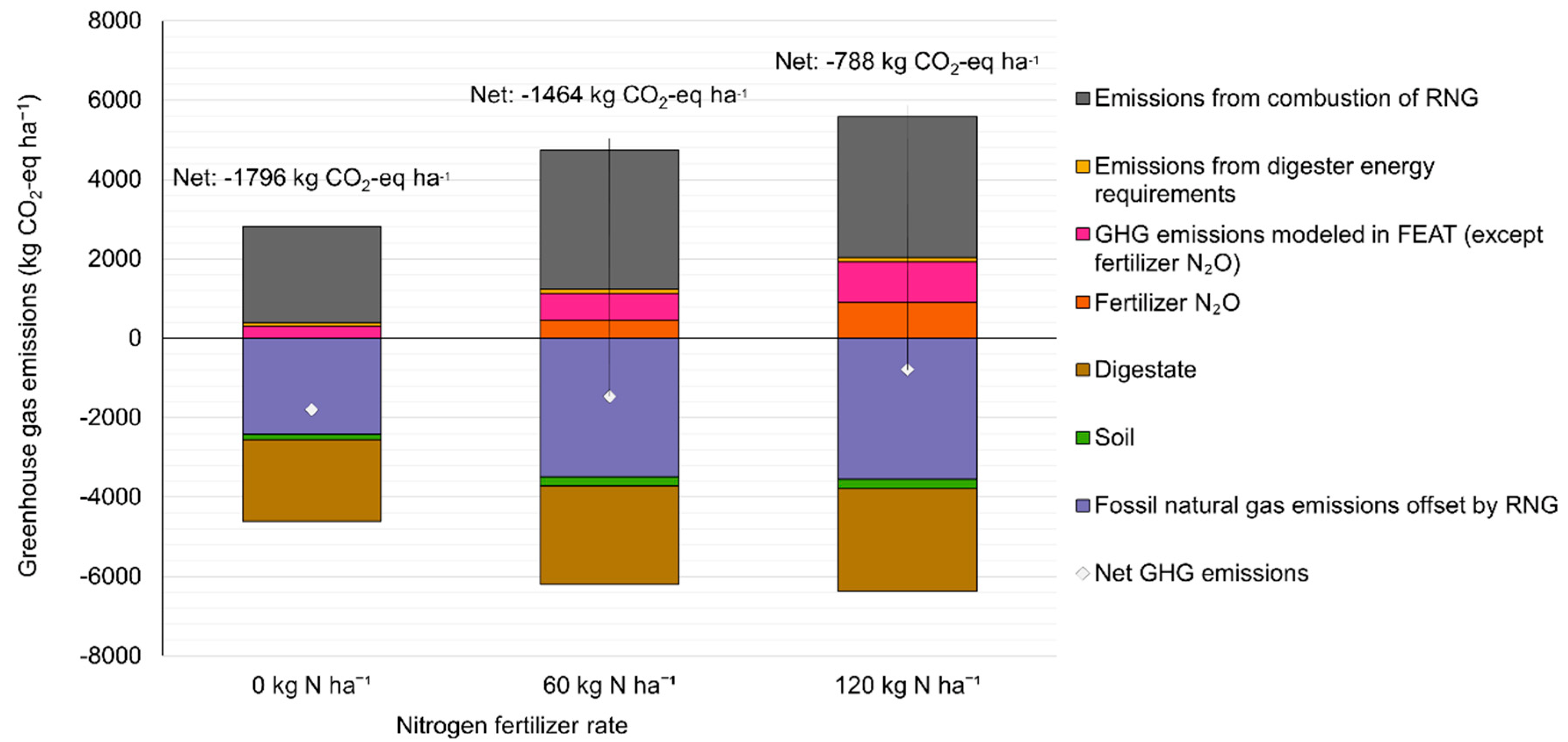

3.4. GHG Mitigation Potential

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rockström, J.; Steffen, W.; Noone, K.; Persson, Å.; Chapin, F.S.; Lambin, E.; Lenton, T.M.; Scheffer, M.; Folke, C.; Schellnhuber, H.J.; et al. Planetary boundaries: Exploring the safe operating space for humanity. Ecol. Soc. 2009, 14, 1–32. [Google Scholar] [CrossRef]

- Rockström, J.; Williams, J.; Daily, G.; Noble, A.; Matthews, N.; Gordon, L.; Wetterstrand, H.; DeClerck, F.; Shah, M.; Steduto, P.; et al. Sustainable intensification of agriculture for human prosperity and global sustainability. Ambio 2017, 46, 4–17. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Baulcombe, D.; Crute, I.; Davies, B.; Dunwell, J.; Gale, M.; Jones, J.; Pretty, J.; Sutherland, W.; Toulmin, C. Reaping the Benefits: Science and the Sustainable Intensification of Global Agriculture; The Royal Society: London, UK, 2009. [Google Scholar]

- Project Drawdown Sustainable Intensification for Smallholders. Available online: https://drawdown.org/solutions/sustainable-intensification-for-smallholders (accessed on 12 September 2021).

- FAO. Sustainable Crop Production Intensification in FAO. Available online: http://www.fao.org/agriculture/crops/thematic-sitemap/theme/spi/scpi-home/framework/sustainable-intensification-in-fao/en/ (accessed on 12 September 2021).

- Launay, C.; Houot, S.; Frédéric, S.; Girault, R.; Levavasseur, F.; Marsac, S.; Constantin, J. Incorporating energy cover crops for biogas production into agricultural systems: Benefits and environmental impacts. A review. Agron. Sustain. Dev. 2022, 42, 1–24. [Google Scholar] [CrossRef]

- Osborne, R. Cereal Rye Cover Crop Can Stretch Your Spring Feed Supply; Michigan State University Extension: East Lansing, MI, USA, 2011. [Google Scholar]

- Shao, X.; Dimarco, K.; Richard, T.L.; Lynd, L.R. Winter rye as a bioenergy feedstock: Impact of crop maturity on composition, biological solubilization and potential revenue. Biotechnol. Biofuels 2015, 8, 1–10. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Heggenstaller, A.H.; Anex, R.P.; Liebman, M.; Sundberg, D.N.; Gibson, L.R. Productivity and nutrient dynamics in bioenergy double-cropping systems. Agron. J. 2008, 100, 1740–1748. [Google Scholar] [CrossRef]

- Krueger, E.S.; Ochsner, T.E.; Baker, J.M.; Porter, P.M.; Reicosky, D.C. Rye-corn silage double-cropping reduces corn yield but improves environmental impacts. Agron. J. 2012, 104, 888–896. [Google Scholar] [CrossRef] [Green Version]

- Ramcharan, A.M.; Richard, T.L. Carbon and nitrogen environmental trade-offs of winter rye cellulosic biomass in the Chesapeake Watershed. Agric. Syst. 2017, 156, 85–94. [Google Scholar] [CrossRef]

- Blanco-Canqui, H.; Sindelar, M.; Wortmann, C.S.; Kreikemeier, G. Aerial interseeded cover crop and corn residue harvest: Soil and crop impacts. Agron. J. 2017, 109, 1344–1351. [Google Scholar] [CrossRef]

- Moore, E.B.; Wiedenhoeft, M.H.; Kaspar, T.C.; Cambardella, C.A. Rye Cover Crop Effects on Soil Quality in No-Till Corn Silage-Soybean Cropping Systems. Soil Sci. Soc. Am. J. 2014, 78, 968–976. [Google Scholar] [CrossRef]

- Malone, R.W.; Obrycki, J.F.; Karlen, D.L.; Ma, L.; Kaspar, T.C.; Jaynes, D.B.; Parkin, T.B.; Lence, S.H.; Feyereisen, G.W.; Fang, Q.X.; et al. Harvesting fertilized rye cover crop: Simulated revenue, net energy, and drainage nitrogen loss. Agric. Environ. Lett. 2018, 3, 170041. [Google Scholar] [CrossRef]

- Liebert, J.A.; DiTommaso, A.; Ryan, M.R. Rolled mixtures of barley and cereal rye for weed suppression in cover crop-based organic no-till planted soybean. Weed Sci. 2017, 65, 426–439. [Google Scholar] [CrossRef]

- Barnes, J.P.; Putnam, A.R. Rye residues contribute weed suppression in no-tillage cropping systems. J. Chem. Ecol. 1983, 9, 1045–1057. [Google Scholar] [CrossRef]

- Willick, I.R.; Tanino, K.K.; Gusta, L.V. The impact of global climate change on the freezing tolerance of winter cereals in Western Canada. J. Agron. Crop Sci. 2021, 207, 88–99. [Google Scholar] [CrossRef]

- Haramoto, E.R. Species, seeding rate, and planting method influence cover crop services prior to soybean. Agron. J. 2019, 111, 1068–1078. [Google Scholar] [CrossRef]

- Fisher, K.A.; Momen, B.; Kratochvil, R.J. Is broadcasting seed an effective winter cover crop planting method? Agron. J. 2011, 103, 472–478. [Google Scholar] [CrossRef]

- USDA. 2017 Census of Agriculture; United States Department of Agriculture National Agricultural Statistics Service: Washington, DC, USA, 2019; Volume 1. [Google Scholar]

- Wicks, N. Cover Crops as Cash Crops: Farmers Angle to Profit off the Practice; Agri-Pulse Communications, Inc.: Washington, DC, USA, 2021. [Google Scholar]

- Feyereisen, G.W.; Camargo, G.G.T.; Baxter, R.E.; Baker, J.M.; Richard, T.L. Cellulosic biofuel potential of a winter rye double crop across the U.S. corn-soybean belt. Agron. J. 2013, 105, 631–642. [Google Scholar] [CrossRef] [Green Version]

- USDA; NASS. National Agricultural Statistics Service. Available online: https://data.nal.usda.gov/dataset/nass-quick-stats (accessed on 12 September 2021).

- 110th Congress. Energy Independence and Security Act of 2007; United States Public Law 110–140; United States Congress: Washington, DC, USA, 2007. Available online: https://www.congress.gov/bill/110th-congress/house-bill/6 (accessed on 12 September 2021).

- Pleima, B. Biogas to RNG Projects: What, Why and How; Biocycle: Emmaus, PA, USA, 2019; Volume 60, p. 38. Available online: https://www.biocycle.net/2019/03/11/biogas-rng-projects/ (accessed on 12 September 2021).

- Valli, L.; Rossi, L.; Fabbri, C.; Sibilla, F.; Gattoni, P.; Dale, B.; Kim, S.; Ong, R.; Bozzetto, S. Greenhouse gas emissions of electricity and biomethane produced using the BiogasdonerightTM system: Four case studies from Italy. Biofuels Bioprod. Biorefining 2017, 11, 847–860. [Google Scholar] [CrossRef]

- VERBIO VERBIO Nevada Biorefinery. Available online: https://www.verbio.us/project/verbio-nevada-biorefinery/ (accessed on 2 February 2022).

- Robertson, G.P.; Hamilton, S.K.; Barham, B.L.; Dale, B.E.; Izaurralde, R.C.; Jackson, R.D.; Landis, D.A.; Swinton, S.M.; Thelen, K.D.; Tiedje, J.M. Cellulosic biofuel contributions to a sustainable energy future: Choices and outcomes. Science 2017, 356, eaal2324. [Google Scholar] [CrossRef] [Green Version]

- Lark, T.J.; Hendricks, N.P.; Smith, A.; Pates, N.; Spawn-Lee, S.A.; Bougie, M.; Booth, E.G.; Kucharik, C.J.; Gibbs, H.K. Environmental Outcomes of the U.S. Renewable Fuel Standard. Proc. Natl. Acad. Sci. USA 2022, 119, e2101084119. [Google Scholar] [CrossRef]

- Field, J.L.; Richard, T.L.; Smithwick, E.A.H.; Cai, H.; Laser, M.S.; LeBauer, D.S.; Long, S.P.; Paustian, K.; Qin, Z.; Sheehan, J.J.; et al. Robust paths to net greenhouse gas mitigation and negative emissions via advanced biofuels. Proc. Natl. Acad. Sci. USA 2020, 117, 201920877. [Google Scholar] [CrossRef] [PubMed]

- Jacobson, M.; Helsel, Z. NEWBio Switchgrass Budget for Biomass Production. Penn State Ext. 2014, 1–4. Available online: https://extension.psu.edu/newbio-switchgrass-budget-for-biomass-production (accessed on 12 September 2021).

- Roley, S.S.; Tank, J.L.; Tyndall, J.C.; Witter, J.D. How cost-effective are cover crops, wetlands, and two-stage ditches for nitrogen removal in the Mississippi River Basin? Water Resour. Econ. 2016, 15, 43–56. [Google Scholar] [CrossRef] [Green Version]

- Balkcom, K.S.; Duzy, L.M.; Arriaga, F.J.; Delaney, D.P.; Watts, D.B. Fertilizer management for a rye cover crop to enhance biomass production. Agron. J. 2018, 110, 1233–1242. [Google Scholar] [CrossRef]

- Blanco-Canqui, H.; Ruis, S.J.; Proctor, C.A.; Creech, C.F.; Drewnoski, M.E.; Redfearn, D.D. Harvesting cover crops for biofuel and livestock production: Another ecosystem service? Agron. J. 2020, 112, 2373–2400. [Google Scholar] [CrossRef]

- Jones, B. Factors for converting percentages of nitrogen in foods and feeds into percentages of proteins. U. S. Dep. Agric. 1941, 183, 22. [Google Scholar]

- Ball, D.; Hoveland, C.; Lacefield, G. Southern Forages; Potash & Phosphate Institute, Foundation for Agronomic Research: Atlanta, GA, USA, 1991. [Google Scholar]

- Malone, R.; O’Brien, P.; Herbstritt, S.; Emmett, B.; Karlen, D.; Kaspar, T.; Kohler, K.; Radke, A.; Lence, S.; Wu, H.; et al. Rye-Soybean Double Crop: Planting Method and N Fertilization Effects in the north central U.S. Renew. Agric. Food Syst. 2022, 37, 445–456. [Google Scholar] [CrossRef]

- Dairy One Forage Lab. Equi-Analytical, Zooquarius Analytical Procedures; Dairy One: Ithaca, NY, USA, 2019; pp. 1–10. Available online: https://dairyone.com/download/forage-forage-lab-analytical-procedures/ (accessed on 12 September 2021).

- Van-Soest, P.J.; Robertson, J.B.; Lewis, B.A. Methods for Dietary Fiber, Neutral Detergent Fiber, and Nonstarch Polysaccharides in Relation to Animal Nutrition. J. Dairy Sci. 1991, 74, 3583–3597. [Google Scholar] [CrossRef]

- Weiss, W.P.; Conrad, H.R.; St. Pierre, N.R. A theoretically-based model for predicting total digestible nutrient values of forages and concentrates. Anim. Feed Sci. Tech 1992, 39, 95–110. [Google Scholar] [CrossRef]

- Weiss, W.P. Theoretical models for estimating available energy concentrations in ruminant feeds. Cons. Des Prod. Anim. Du Que. 1995, 76, 1802–1811. [Google Scholar]

- Hall, M.B.; Hoover, W.H.; Jennings, J.P.; Miller, T.K. Webster Method for partitioning neutral detergent soluble carbohydrates. J. Sci. Food Agric. 1999, 79, 2081. [Google Scholar] [CrossRef]

- Van-Soest, P.J.; Fox, D.G. Discounts for net energy and protein-fifth revision. Proc. Cornell Nutr. Conf. Feed. Manuf. 1992, 54, 40–68. [Google Scholar]

- National Research Council. Nutrient Requirements of Dairy Cattle: Seventh Revised Edition; The National Academies Press: Washington, DC, USA, 2001. [Google Scholar] [CrossRef] [Green Version]

- Klopfenstein, T.J.; Erickson, G.E.; Bremer, V.R. Board invited review: Use of distillers by-products in the beef cattle feeding industry. J. Anim. Sci. 2008, 86, 1223–1231. [Google Scholar] [CrossRef] [PubMed]

- CME Group Henry Hub Natural Gas Futures Quotes. Available online: https://www.cmegroup.com/trading/energy/natural-gas/natural-gas.html (accessed on 12 September 2021).

- U.S. Energy Information Administration Henry Hub Natural Gas Spot Price. Available online: https://www.eia.gov/dnav/ng/hist/rngwhhdm.htm (accessed on 10 July 2021).

- US EPA RIN Trades and Price Information. Available online: https://www.epa.gov/fuels-registration-reporting-and-compliance-help/rin-trades-and-price-information (accessed on 14 July 2021).

- Gilbert, F.; Marcotte, P.; Savard, G. Mixed-logit network pricing. Comput. Optim. Appl. 2013, 57, 105–127. [Google Scholar] [CrossRef]

- Cabrera, V.E.; Armentano, L.; Shaver, R.D. University of Madison-Wisconsin FeedVal v6.0. Available online: https://dairymgt.info/tools/feedval_12_v2/index.php (accessed on 10 September 2021).

- North Dakota State University Combined Feed Value and Protein and Energy Calculator. Available online: https://www.ndsu.edu/agriculture/ag-hub/ag-topics/crop-production/tools/combined-feed-value-and-protein-and-energy-calculator (accessed on 10 September 2021).

- USDA; AMS. National Weekly Feedstuff Wholesale Prices September 2021. United States Department of Agriculture Market News. 2021. Available online: https://www.ams.usda.gov/mnreports/ms_gr852.txt (accessed on 14 September 2021).

- Dairy One Feed Composition Library 2021. Available online: https://dairyone.com/services/forage-laboratory-services/feed-composition-library/ (accessed on 14 September 2021).

- Indigo Ag Enrich your soil, Improve Your Profit. Available online: https://www.indigoag.com/for-growers/indigo-carbon (accessed on 14 September 2021).

- Camargo, G.G.T.; Ryan, M.R.; Richard, T.L. Energy Use and Greenhouse Gas Emissions from Crop Production Using the Farm Energy Analysis Tool. Bioscience 2013, 63, 263–273. [Google Scholar] [CrossRef] [Green Version]

- U.S. EIA Carbon Dioxide Emissions Coefficients. Available online: https://www.eia.gov/environment/emissions/co2_vol_mass.php (accessed on 14 September 2021).

- Olson, R.A.; Frey, K.J. Nutritional Quality of Cereal Grains: Genetic and Agronomic Improvement; American Society of Agronomy: Madison, WI, USA, 1987; p. 0923. ISBN 089118. [Google Scholar]

- Cazzato, E.; Laudadio, V.; Tufarelli, V. Effects of harvest period, nitrogen fertilization and mycorrhizal fungus inoculation on triticale (×Triticosecale Wittmack) forage yield and quality. Renew. Agric. Food Syst. 2012, 27, 278–286. [Google Scholar] [CrossRef]

- Waramit, N.; Moore, K.J.; Fales, S.L. Forage quality of native warm-season grasses in response to nitrogen fertilization and harvest date. Anim. Feed Sci. Technol. 2012, 174, 46–59. [Google Scholar] [CrossRef]

- Richner, J.M.; Kallenbach, R.L.; Roberts, C.A. Dual use switchgrass: Managing switchgrass for biomass production and summer forage. Agron. J. 2014, 106, 1438–1444. [Google Scholar] [CrossRef]

- Kering, M.K.; Guretzky, J.A.; Interrante, S.M.; Butler, T.J.; Biermacher, J.T.; Mosali, J. Harvest timing affects switchgrass production, forage nutritive value, and nutrient removal. Crop Sci. 2013, 53, 1809–1817. [Google Scholar] [CrossRef] [Green Version]

- Guretzky, J.A.; Biermacher, J.T.; Cook, B.J.; Kering, M.K.; Mosali, J. Switchgrass for forage and bioenergy: Harvest and nitrogen rate effects on biomass yields and nutrient composition. Plant Soil 2011, 339, 69–81. [Google Scholar] [CrossRef] [Green Version]

- Obour, A.K.; Harmoney, K.; Holman, J.D. Nitrogen fertilizer application effects on switchgrass herbage mass, nutritive value and nutrient removal. Crop Sci. 2017, 57, 1754–1763. [Google Scholar] [CrossRef]

- Landry, E.; Janovicek, K.; Lee, E.A.; Deen, W. Winter Cereal Cover Crops for Spring Forage in Temperate Climates. Agron. J. 2019, 111, 217–223. [Google Scholar] [CrossRef] [Green Version]

- Binder, J.; Karsten, H.; Beegle, D.; Dell, C. Manure injection and rye double cropping increase nutrient recovery and forage production. Agron. J. 2020, 112, 2968–2977. [Google Scholar] [CrossRef]

- McGill, R.; Tukey, J.W.; Larsen, W.A. Variations of box plots. Am. Stat. 1978, 32, 12–16. [Google Scholar]

- Helsel, Z.R.; Thomas, J.W. Small Grains for Forage. J. Dairy Sci. 1987, 70, 2330–2338. [Google Scholar] [CrossRef]

- Lestingi, A.; Bovera, F.; De Giorgio, D.; Ventrella, D.; Tateo, A. Effects of tillage and nitrogen fertilisation on triticale grain yield, chemical composition and nutritive value. J. Sci. Food Agric. 2010, 90, 2440–2446. [Google Scholar] [CrossRef]

- Dairy One Small Grain Forage, Accumulated Crop Years: 5/1/2004–4/30/2020. Available online: https://dairyone.com/services/forage-laboratory-services/feed-composition-library/interactive-feed-composition-libraries/ (accessed on 10 September 2021).

- Miller, Z.; Bertram, M.; Hoffman, P. Fall forage rye for dairy heifers and dry cows. Univ. Wis. Ext. 2010, 12, 1–2. [Google Scholar]

- Kanter, M.; Sheaffer, C.; Porter, P.; Krueger, E.; Ochsner, T. Growth Stage Influences Forage Yield and Quality of Winter Rye. Forage Grazinglands 2011, 9, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Coblentz, W.K.; Akins, M.S.; Cavadini, J.S.; Jokela, W.E. Net effects of nitrogen fertilization on the nutritive value and digestibility of oat forages. J. Dairy Sci. 2017, 100, 1739–1750. [Google Scholar] [CrossRef] [Green Version]

- Sträuber, H.; Bühligen, F.; Kleinsteuber, S.; Dittrich-Zechendorf, M. Carboxylic acid production from ensiled crops in anaerobic solid-state fermentation—Trace elements as pH controlling agents support microbial chain elongation with lactic acid. Eng. Life Sci. 2018, 18, 447–458. [Google Scholar] [CrossRef] [Green Version]

- Zhao, X.; Liu, J.; Liu, J.; Yang, F.; Zhu, W.; Yuan, X.; Hu, Y.; Cui, Z.; Wang, X. Effect of ensiling and silage additives on biogas production and microbial community dynamics during anaerobic digestion of switchgrass. Bioresour. Technol. 2017, 241, 349–359. [Google Scholar] [CrossRef]

- Field, J.A.; Caldwell, J.S.; Jeyanayagam, S.; Reneau, R.B.; Kroontje, W.; Collins, E.R. Fertilizer recovery from anaerobic digesters. Trans. Am. Soc. Agric. Eng. 1984, 27, 1871–1876. [Google Scholar] [CrossRef]

- Topper, P.; Graves, R.; Richard, T. The fate of nutrients and pathogens during anaerobic digestion of dairy manure. Coll. Agric. Sci. Coop. Ext. 2006. [Google Scholar]

- Goldstein, N. Farm digester progress in Pennsylvania. Biocycle 2013, 54, 26. [Google Scholar]

- Shcherbak, I.; Millar, N.; Robertson, P. Global Metaanalysis of the Nonlinear Response of Soil Nitrous Oxide (N2O) Emissions to Fertilizer Nitrogen. Proc. Natl. Acad. Sci. USA 2014, 111, 9199–9204. [Google Scholar] [CrossRef] [Green Version]

- May, A.J. Cotreatment Enhanced Anaerobic Digestion of Lignocellulosic Biomass; Penn State University: University Park, PA, USA, 2020. [Google Scholar]

- Energy Information Administration How Much Carbon Dioxide Is Produced Per Kilowatthour of U.S. Electricity Generation. Available online: https://www.eia.gov/tools/faqs (accessed on 12 September 2021).

- Börjesson, P.; Berglund, M. Environmental systems analysis of biogas systems-Part II: The environmental impact of replacing various reference systems. Biomass Bioenergy 2007, 31, 326–344. [Google Scholar] [CrossRef]

- Mirsky, S.B.; Ryan, M.R.; Teasdale, J.R.; Curran, W.S.; Reberg-Horton, C.S.; Spargo, J.T.; Wells, M.S.; Keene, C.L.; Moyer, J.W. Overcoming Weed Management Challenges in Cover Crop–Based Organic Rotational No-Till Soybean Production in the Eastern United States. Weed Technol. 2013, 27, 193–203. [Google Scholar] [CrossRef]

- Koehler-Cole, K.; Elmore, R.W.; Blanco-Canqui, H.; Francis, C.A.; Shapiro, C.A.; Proctor, C.A.; Ruis, S.J.; Heeren, D.M.; Irmak, S.; Ferguson, R.B. Cover Crop Productivity and Subsequent Soybean Yield in the Western Corn Belt. Agronomy 2020, 112, 2649–2663. [Google Scholar] [CrossRef]

- Koehler-Cole, K.; Elmore, R.W. Seeding rates and productivity of broadcast interseeded cover crops. Agronomy 2020, 10, 1723. [Google Scholar] [CrossRef]

- Supple, D. Units & Conversions Fact Sheet. Available online: http://web.mit.edu/mit_energy (accessed on 12 September 2021).

- Engle, C.; Anderson, V. Combined Feed Value and Protein and Energy Calculator. Available online: https://www.ag.ndsu.edu/carringtonrec/news/combined-feed-value-and-protein-and-energy-calculator (accessed on 12 September 2021).

- Gessner, H. Feed Value Calculator. Available online: https://extension.sdstate.edu/feed-nutrient-calculator (accessed on 12 September 2021).

- Jones, C. Feed Value Calculator Spreadsheet. Available online: https://extension.psu.edu/feed-value-calculator-spreadsheet (accessed on 12 September 2021).

- Halfman, B.; Akins, M.; Sterry, R. Feedstuff Nutrient Cost Calculator. Available online: https://fyi.extension.wisc.edu/wbic/files/2018/11/UW-feed-cost-tool-10-30-18.xlsx (accessed on 12 September 2021).

| Forage Quality Constituent | 2018 | 2019 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0 kg N ha−1 | 60 kg N ha−1 | 120 kg N ha−1 | p | Planting Method × N Rate | 0 kg N ha−1 | 60 kg N ha−1 | 120 kg N ha−1 | p | Planting Method × N Rate | |

| CP (%) | 9.31 (1.06) a | 11.29 (0.60) b | 11.91 (0.59) c | *** | ** | 8.29 (0.54) a | 10.57 (1.23) b | 12.36 (1.12) c | *** | ns |

| Available P (%) | 8.91 (1.03) a | 10.88 (0.53) b | 11.41 (0.63) c | *** | ** | 7.94 (0.57) a | 10.13 (1.15) b | 11.76 (1.05) c | *** | ns |

| RDP (%) | 78.11 (2.35) b | 76.78 (3.57) ab | 74.94 (3.06) a | ** | ns | 74.89 (2.63) | 74.56 (1.89) | 75.94 (2.24) | ns | ns |

| RUP (%) | 21.89 (2.35) a | 23.22 (3.57) ab | 25.06 (3.06) b | ** | ns | 25.11 (2.63) | 25.44 (1.89) | 24.06 (2.24) | ns | ns |

| ADF (%) | 42.93 (1.52) b | 42.19 (1.03) ab | 41.88 (1.11) a | ** | ns | 43.47 (1.09) a | 45.51 (1.41) b | 45.74 (1.52) b | *** | ns |

| NDF (%) | 65.82 (2.09) b | 64.71 (1.41) b | 63.43 (1.77) a | *** | ns | 68.42 (1.51) | 69.12 (2.21) | 67.83 (1.65) | ns | ns |

| Lignin (%) | 5.70 (0.39) b | 5.57 (0.65) ab | 5.19 (0.49) a | * | ns | 5.21 (0.30) | 5.41 (0.82) | 5.61 (0.51) | ns | ns |

| RFV (%) | 78.56 (4.10) a | 80.67 (2.77) ab | 82.67 (3.63) b | *** | ns | 74.89 (2.78) b | 72.17 (3.71) a | 73.06 (3.00) ab | * | ns |

| TDN (%) | 57.06 (1.51) a | 58.17 (1.15) b | 58.72 (0.96) b | *** | ns | 55.72 (1.13) | 55.06 (1.59) | 55.11 (1.37) | ns | ns |

| NEL (%) | 4.39 (0.26) a | 4.55 (0.15) b | 4.68 (0.16) b | *** | ns | 4.08 (0.19) | 3.98 (0.30) | 4.10 (0.20) | ns | ns |

| NEG (%) | 2.27 (0.22) a | 2.42 (0.15) b | 2.49 (0.12) b | ** | ns | 2.06 (0.16) | 2.00 (0.23) | 2.01 (0.19) | ns | ns |

| NEM (%) | 4.60 (0.24) a | 4.76 (0.17) b | 4.84 (0.13) b | ** | ns | 4.37 (0.17) | 4.31 (0.25) | 4.32 (0.21) | ns | ns |

| Factor | Level | 2018 | 2019 | ||

|---|---|---|---|---|---|

| RNG System (Low Estimate) | RNG System (High Estimate) | RNG System (Low Estimate) | RNG System (High Estimate) | ||

| USD Mg−1 | USD Mg−1 | USD Mg−1 | USD Mg−1 | ||

| N Rate | 0 kg N ha−1 | 306.78 (4.67) | 487.4 (4.67) | 307.93 (3.58) a | 488.55 (3.58) a |

| 60 kg N ha−1 | 306.99 (3.89) | 487.61 (3.89) | 317.91 (4.29) b | 498.53 (4.29) b | |

| 120 kg N ha−1 | 306.94 (4.30) | 487.56 (4.30) | 321.22 (4.71) b | 501.84 (4.71) b | |

| p | ns | ns | *** | *** | |

| Planting Method × N Rate | ns | ns | ns | ns | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Herbstritt, S.; Richard, T.L.; Lence, S.H.; Wu, H.; O’Brien, P.L.; Emmett, B.D.; Kaspar, T.C.; Karlen, D.L.; Kohler, K.; Malone, R.W. Rye as an Energy Cover Crop: Management, Forage Quality, and Revenue Opportunities for Feed and Bioenergy. Agriculture 2022, 12, 1691. https://doi.org/10.3390/agriculture12101691

Herbstritt S, Richard TL, Lence SH, Wu H, O’Brien PL, Emmett BD, Kaspar TC, Karlen DL, Kohler K, Malone RW. Rye as an Energy Cover Crop: Management, Forage Quality, and Revenue Opportunities for Feed and Bioenergy. Agriculture. 2022; 12(10):1691. https://doi.org/10.3390/agriculture12101691

Chicago/Turabian StyleHerbstritt, Steph, Tom L. Richard, Sergio H. Lence, Huaiqing Wu, Peter L. O’Brien, Bryan D. Emmett, Tom C. Kaspar, Douglas L. Karlen, Keith Kohler, and Robert W. Malone. 2022. "Rye as an Energy Cover Crop: Management, Forage Quality, and Revenue Opportunities for Feed and Bioenergy" Agriculture 12, no. 10: 1691. https://doi.org/10.3390/agriculture12101691

APA StyleHerbstritt, S., Richard, T. L., Lence, S. H., Wu, H., O’Brien, P. L., Emmett, B. D., Kaspar, T. C., Karlen, D. L., Kohler, K., & Malone, R. W. (2022). Rye as an Energy Cover Crop: Management, Forage Quality, and Revenue Opportunities for Feed and Bioenergy. Agriculture, 12(10), 1691. https://doi.org/10.3390/agriculture12101691