Degree Days as a Method to Estimate the Optimal Harvest Date of ‘Conference’ Pears

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Location

2.2. Sampling

2.3. Measurements

2.3.1. Phenological Phases

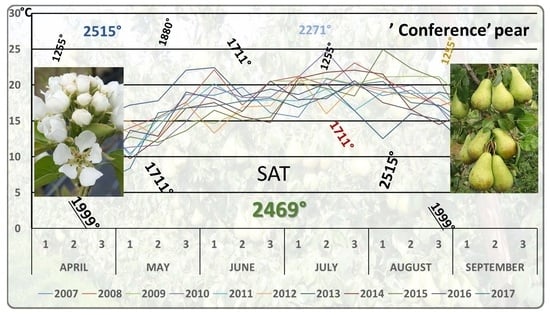

2.3.2. Temperature

2.3.3. Maturity and Ripening at Harvest Were Evaluated According to Well-Known Standard Methods

- −

- Firmness: penetrometer (probe—8 mm in depth, 11 mm in diameter), two opposite sides of the fruit, in N;

- −

- Total soluble solids (TSS): refractometer, in %;

- −

- Starch disintegration: a 10-point scale, where 1 is no conversion and 10 is totally converted;

- −

- Titratable acidity (TA): titration with 1 n NaOH to 8.1 pH, mval/100 mL;

- −

- Ethylene production: around 1 kg of pears was put in a gas-tight box; after an hour, ethylene concentration was measured and converted into 1000 g of fruit.

2.3.4. Storage Conditions and Evaluation of Storability

2.3.5. Evaluation

- (1)

- Fruit mass loss was measured for each stored box. Twenty pears were numbered and weighed with an accuracy of 0.1 g before and after storage. A total of 80 pears from one harvest were examined. Scores were given according to an analysis of variance (ANOVA) between the harvest dates. If there were no significant differences between samples, each sample received the same score, and it was 1. If there were two groups with significant differences, samples could receive a score of 1 or 2, where a higher score was assigned to the sample with significantly lower weight loss. If the analysis showed a significant difference in mass loss between each harvest date, every sample was scored with a different score (1, 2, 3, or 4), and the highest value (4) was assigned to the sample with the lowest mass loss.

- (2)

- The incidence of disorders and diseases was scored separately according to the same rules as those applied to fruit mass loss. After being taken out of cold storage, pears went through a week of shelf life at room temperature. Fruit infected with more than one disease was counted only once because it could no longer qualify as commercial-quality fruit anyway. If the share of non-healthy fruit in a box was higher than 10%, a sample received 1 point independently of the analysis of variance.

- (3)

- Fruit firmness after storage was measured in the same way as before storage and was scored using the mean N value. Readings were taken from 20 fruits with the procedure described in Section 2.3.3. Samples of fruit softer than 40 N could not receive more than 1 point. Samples harder than 40 N could receive up to four points depending on the results of the analysis of variance (ANOVA). If the firmness of fruits was higher than 40 N and ANOVA showed significant differences between the four harvest dates, then each group had a different score, and the lowest score was assigned to the softest group.

- (4)

- TSS and TA were measured according to the rules presented above (Section 2.3.3.). However, a sample of fruit with TSS content less than 11% and TA (understood as the content of citric acid) below 0.185 could not receive more than one point. Other fruit could be scored higher using ANOVA analysis. If the sample had significantly higher TSS and TA than the “minimum sample”, it received one score higher (2) compared to the lowest value. If there were differences between each harvest date, the samples received four different scores.The point scale for the minimum firmness, TSS value, and TA value was developed independently based on the research by Konopacka et al. [27], who examined the relation between texture attributes and consumer preferences.

- (5)

- Sensory tests were carried out twice: on the day after the end of storage and a week later. Fruit was evaluated by 3–5 professional judges according to the overall acceptance on the market using the following scale: 0—no acceptance on the market; 1—poor acceptance; 2—good; and 3—excellent. The average judgement was rounded to 1.0 point.

3. Results and Discussion

4. Conclusions

Supplementary Materials

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- USDA United States Department of Agriculture. Global Agricultural Information Network. Prognosfruit 2020. Available online: https://apps.fas.usda.gov/newgainapi/api/Report/DownloadReportByFileName?fileName=Prognosfruit%202020%20_Berlin_European%20Union_08–18–2020 (accessed on 22 May 2022).

- Łysiak, G.P.; Rutkowski, K.; Walkowiak-Tomczak, D. Effect of Storage Conditions on Storability and Antioxidant Potential of Pears cv. ‘Conference’. Agriculture 2021, 11, 545. [Google Scholar] [CrossRef]

- Kolniak-Ostek, J.; Kłopotowska, D.; Rutkowski, K.P.; Skorupińska, A.; Kruczyńska, D.E. Bioactive Compounds and Health-Promoting Properties of Pear (Pyrus communis L.) Fruits. Molecules 2020, 25, 4444. [Google Scholar] [CrossRef] [PubMed]

- Elgar, H.J.; Watkins, C.B.; Murray, S.H.; Gunson, F.A. Quality of “Buerre Bosc” and “Doyenne du Comice” pears in relation to harvest date and storage period. Postharvest Biol. Technol. 1997, 10, 29–37. [Google Scholar] [CrossRef]

- Saquet, A.A. Storage of pears. Sci. Hortic. 2019, 246, 1009–1016. [Google Scholar] [CrossRef]

- Raese, J.T.; Drake, S.R. Effect of calcium sprays, time of harvest, cold storage and ripeness on fruit quality of ‘Anjou’ pears. J. Plant Nutr. 2000, 23, 843–853. [Google Scholar] [CrossRef]

- Valero, D.; Serrano, M. Postharvest Biology and Technology for Preserving Fruit Quality; CRC Press: Boca Raton, FL, USA, 2010; ISBN 1–4398–0267-X. [Google Scholar]

- Kader, A.A. Postharvest Technology of Horticultural Crops; University of California: Berkeley, CA, USA, 1992. [Google Scholar]

- Tomala, K. Orchard factors affecting fruit storage quality and prediction of harvest date of apples. Acta Hortic. 1999, 489, 373–382. [Google Scholar] [CrossRef]

- Łysiak, G. Measurement of ethylene production as a method for determining the optimum harvest date of ‘Jonagored’ apples. Folia Hortic. 2014, 26, 117–124. [Google Scholar] [CrossRef]

- Skic, A.; Szymańska-Chargot, M.; Kruk, B.; Chylińska, M.; Pieczywek, P.M.; Kurenda, A.; Zdunek, A.; Rutkowski, K.P. Determination of the Optimum Harvest Window for Apples Using the Non-Destructive Biospeckle Method. Sensors 2016, 16, 661. [Google Scholar] [CrossRef]

- Łysiak, G. The determination of harvest index of Šampion apples intended for long storage. Acta Sci. Pol. Hortorum Cultus 2011, 10, 273–282. [Google Scholar]

- Hay, B. A brief history of the thermal properties metrology. Measurement 2020, 155, 107556. [Google Scholar] [CrossRef]

- de Oliveira Aparecido, L.E.; de Souza Rolim, G. Models for simulating the frequency of pests and diseases of Coffea arabica L. Int. J. Biometeorol. 2020, 64, 1063–1084. [Google Scholar] [CrossRef] [PubMed]

- Szyga-Pluta, K. Assessment of Changing Agroclimatic Conditions in Poland Based on Selected Indicators. Atmosphere 2022, 13, 1232. [Google Scholar] [CrossRef]

- Cortázar-Atauri, G.I.; Brisson, N.; Gaudillere, J.P. Performance of several models for predicting budburst date of grapevine (Vitis vinifera L.). Int. J. Biometeorol. 2009, 53, 317–326. [Google Scholar] [CrossRef] [PubMed]

- Mandelli, F.; Berlato, M.A.; Tonietto, J.; Bergamaschi, H. Predicting the date of budbreak of grapevine grown in the Serra Gaucha region. J. Int. Des Sci. Vigne Vin 2003, 37, 229–235. [Google Scholar] [CrossRef]

- Zapata, D.; Salazar, M.; Chaves, B.; Keller, M.; Hoogenboom, G. Estimation of the base temperature and growth phase duration in terms of thermal time for four grapevine cultivars. Int. J. Biometeorol. 2015, 59, 1771–1781. [Google Scholar] [CrossRef]

- Szot, I.; Łysiak, G.P. Effect of the Climatic Conditions in Central Europe on the Growth and Yield of Cornelian Cherry Cultivars. Agriculture 2022, 12, 1295. [Google Scholar] [CrossRef]

- Bieniek, A.; Dragańska, E.; Pranckietis, V. Assesment of climatic conditions for Actinidia arguta cultivation in north-eastern Poland. Zemdirb. Agric. 2016, 103, 311–318. [Google Scholar] [CrossRef]

- Litschmann, T.; Oukropec, I.; Krizan, B. Predicting individual phenological phases in peaches using meteorological data. Hortic. Sci. 2008, 35, 65–71. [Google Scholar] [CrossRef]

- Di Paola, A.; Chiriacò, M.V.; Di Paola, F.; Nieddu, G. A Phenological Model for Olive (Olea europaea L. var europaea) Growing in Italy. Plants 2021, 10, 1115. [Google Scholar] [CrossRef]

- Dinu, D.G.; Ricciardi, V.; Demarco, C.; Zingarofalo, G.; De Lorenzis, G.; Buccolieri, R.; Cola, G.; Rustioni, L. Climate Change Impacts on Plant Phenology: Grapevine (Vitis vinifera) Bud Break in Wintertime in Southern Italy. Foods 2021, 10, 2769. [Google Scholar] [CrossRef]

- Bokhorst, S.; Convey, P.; Casanova-Katny, A.; Aerts, R. Warming impacts potential germination of non-native plants on the Antarctic Peninsula. Commun. Biol. 2021, 25, 403. [Google Scholar] [CrossRef] [PubMed]

- Łysiak, G. The Sum of Active Temperatures as a Method of Determining the Optimum Harvest Date of ‘Šampion’ and ‘Ligol’ Apple Cultivars. Acta Sci. Pol. Hort. Cultus 2012, 11, 3–13. [Google Scholar]

- Yang, S.; Logan, J.; Coffey, D. Mathematical formulae for calculating the base temperature for growing degree days. Agr. Forest Meteorol. 1995, 74, 61–74. [Google Scholar] [CrossRef]

- Konopacka, D.; Rutkowski, K.P.; Kruczyńska, D.E.; Skorupińska, D.; Płocharski, W. Quality Potential of Some New Pear Cultivars–How to Obtain Fruit of The Best Sensory Characteristics? J. Hortic. Res. 2014, 22, 71–84. [Google Scholar] [CrossRef]

- Hatfield, J.L.; Prueger, J.H. Temperature extremes: Effect on plant growth and development. Weather. Clim. Extrem. 2015, 10, 4–10. [Google Scholar] [CrossRef]

- Wawrzynczak, A.; Rutkowski, K.P.; Kruczynska, D.E. Ripening Of ‘Radana’ And ‘Conference’ Pears as Influenced by Cold Storage Duration. Acta Hortic. 2008, 800, 1091–1098. [Google Scholar] [CrossRef]

- Streif, J.; Xuan, H.; Saquet, A.A.; Rabus, C. CA-storage related disorders in ‘Conference’ pears. Acta Hortic. 2001, 553, 635–638. [Google Scholar] [CrossRef]

- Saquet, A. Storability of ‘Conference’ Pear Under Various Controlled Atmospheres. Erwerbs Obstbau 2018, 60, 5. [Google Scholar] [CrossRef]

- Streif, J. Ripening Management and Postharvest Fruit Quality. Acta Hortic. 2010, 858, 121–129. [Google Scholar] [CrossRef]

- Błaszczyk, J.; Gasparski, K. Influence of 1-methylocyclopropene (1-MCP) on the quality and storability of ‘Red Jonaprince’ apples stored in different conditions. Acta Sci. Pol. Hortoru. 2019, 18, 7–15. [Google Scholar] [CrossRef]

- Li, X.; Xu, C.; Korban, S.S.; Chen, K. Regulatory Mechanisms of Textural Changes in Ripening Fruits. Crit. Rev. Plant Sci. 2010, 29, 222–243. [Google Scholar] [CrossRef]

- Zdunek, A.; Cybulska, J.; Konopacka, D.; Rutkowski, K. New contact acoustic emission detector for texture evaluation of apples. J. Food Eng. 2010, 99, 83–91. [Google Scholar] [CrossRef]

- Konopacka, D.; Plocharski, W.J. Effect of storage conditions on the relationship between apple firmness and texture acceptability. Postharvest Biol. Technol. 2004, 32, 205–211. [Google Scholar] [CrossRef]

- Lachapelle, M.; Bourgeois, G.; DeEll, J.R. Effects of Preharvest Weather Conditions on Firmness of ‘McIntosh’ Apples at Harvest Time. Hort. Sci. 2013, 48, 474–480. [Google Scholar] [CrossRef]

- Lipa, T.; Szot, I. Effect of fertilization methods on growth of pear trees, yielding and fruit quality. Mod. Phytomorphol. 2013, 4, 55–58. [Google Scholar]

- Yuri, J.A.; Moggia, C.; Sepulveda, A.; Poblete-Echeverría, C.; Valdés-Gómez, H.; Torres, C.A. Effect of cultivar, rootstock, and growing conditions on fruit maturity and postharvest quality as part of a six-year apple trial in Chile. Sci. Hortic. 2019, 253, 70–79. [Google Scholar] [CrossRef]

- Doerflinger, F.C.; Miller, W.B.; Nock, J.F.; Watkins, C.B. Relationships between starch pattern indices and starch concentrations in four apple cultivars. Postharvest Biol. Technol. 2015, 110, 86–95. [Google Scholar] [CrossRef]

- Menesatti, P.; Zanella, A.; D’Andrea, S.; Costa, C.; Paglia, G.; Pallottino, F. Supervised multivariate analysis of Hyper-spectral NIR images to evaluate the starch index of apples. Food Bioprocess. Technol. 2009, 2, 308–314. [Google Scholar] [CrossRef]

- Neuwald, D.A.; Streif, J.; Kittemann, D. Fruit Starch Degradation Patterns in Apple Cultivars on-Tree and off-Tree at Different Holding Temperatures. Acta Hortic. 2010, 858, 263–266. [Google Scholar] [CrossRef]

- Streif, J. Der optimale Erntetermin beim Apfel. Qualitätsentwicklung und Reife. Gartenbauwissemschaft 1983, 48, 154–159. (In German) [Google Scholar]

- Johnson, D.S.; Luton, M.T. Maturity indices to predict optimum harvest date for the storage of Conference pears in the UK COST 94. The postharvest treatment of fruit and vegetables. In Proceedings of the Meeting of the Working Group on Optimum Harvest Date, Lofthus, Norway, 9–10 June 1996; pp. 133–147. [Google Scholar]

- de Jager, A.; Roelofs, F.P.M.M. Prediction of optimum harvest date of Jonagold. COST 94. The postharvest treatment of fruit and vegetables. In Proceedings of the Meeting of the Working Group on Optimum Harvest Date, Lofthus, Norway, 9–10 June 1996; pp. 22–31. [Google Scholar]

- Meresz, P.; Sass, P.; Lovasz, T. Evaluation of harvest indexes of apples grown in Hungary COST 94. The postharvest treatment of fruit and vegetables. In Proceedings of the Meeting of the Working Group on Optimum Harvest Date, Lofthus, Norway, 9–10 June 1996; pp. 53–60. [Google Scholar]

- Baumann, H. Optimum harvest date of some apple varieties in the ‘Rhineland’ from 1989 to 1992. COST 94. The postharvest treatment of fruit and vegetables. In Proceedings of the Meeting of the Working Group on Optimum Harvest Date, Lofthus, Norway, 9–10 June 1996; pp. 33–38. [Google Scholar]

- Łysiak, G.; Kurlus, R.; Zydlik, Z.; Walkowiak-Tomczak, D. Apple skin colour changes during harvest as an indicator of maturity. Acta Sci. Pol. Hortorum Cultus 2014, 13, 71–83. [Google Scholar]

- Tomala, K.; Guzek, D.; Głąbska, D.; Małachowska, M.; Widłak, Ł.; Krupa, T.; Gutkowska, K. Maintaining the Quality of ‘Red Jonaprince’ Apples during Storage by 1-Methylcyclopropene Preharvest and Postharvest Treatment. Agriculture 2022, 12, 1189. [Google Scholar] [CrossRef]

- Łysiak, G.; Walkowiak-Tomczak, D. Quality of Plum Fruits after Storage Depended of Quality Parameters during Harvest. Ecol. Chem. Eng. A 2010, 17, 1361–1367. [Google Scholar]

- Nečas, T.; Wolf, J.; Kiss, T.; Gottingerová, M.; Ivo, O.; Bieniasz, M. Evaluation of certain pomological and phenological traits of selected asian pear varieties growing in Middle European conditions. Hort. Sci. 2020, 47, 81–92. [Google Scholar] [CrossRef]

- Xanthopoulos, G.T.; Templalexis, C.G.; Aleiferis, N.P.; Lentzou, D.I. The contribution of transpiration and respiration in water loss of perishable agricultural products: The case of pears. Biosyst. Eng. 2017, 158, 76–85. [Google Scholar] [CrossRef]

- Tellinghuisen, J. Van’t Hoff analysis of K° (T): How good… or bad? Biophys. Chem. 2006, 120, 114–120. [Google Scholar] [CrossRef]

| No. of Measurement | Years and Dates | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 2007 | 2008 | 2009 | 2010 | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | |

| Date of full bloom | 21 April | 23 April | 25 April | 21 April | 30 April | 24 April | 17 April | 19 April | 25 April | 29 April | 18 April |

| 1 M | 28 Aug. | - | 15 Aug. | 16 Aug. | 25 Aug. | 24 Aug. | 17 Aug. | 23 Aug. | 29 Aug. | - | - |

| 2 M | 01 Sept. | 15 Aug. | 20 Aug. | 21 Aug. | 30 Aug. | 28 Aug. | 21 Aug. | 27 Aug. | 02 Sept. | 24 Aug. | 01 Sept. |

| 3 M | 05 Sept. | 20 Aug. | 24 Aug. | 25 Aug. | 03 Sept. | 01 Sept. | 26 Aug. | 01 Sept. | 05 Sept. | 27 Aug. | 05 Sept. |

| 4 M | 10 Sept. | 25 Aug. | 28 Aug. | 30 Aug. | 08 Sept. | 06 Sept. | 30 Aug. | 04 Sept. | 09 Sept. | 31 Sept. | 09 Sept. |

| 5 M, 1 S | 15 Sept. | 29 Aug. | 02 Sept. | 03 Sept. | 12 Sept. | 11 Sept. | 04 Sept. | 08 Sept. | 13 Sept. | 07 Sept. | 13 Sept. |

| 6 M, 2 S | 19 Sept. | 03 Sept. | 07 Sept. | 07 Sept. | 17 Sept. | 16 Sept. | 09 Sept. | 12 Sept. | 17 Sept. | 12 Sept. | 18 Sept. |

| 7 M, 3 S | 24 Sept. | 08 Sept. | 12 Sept. | 11 Sept. | 21 Sept. | 20 Sept. | 13 Sept. | 16 Sept. | 21 Sept. | 16 Sept. | 22 Sept. |

| 8 M, 3 S | 29 Sept. | 13 Sept. | 16 Sept. | 16 Sept. | 26 Sept. | 24 Sept. | 18 Sept. | 20 Sept. | 25 Sept. | 20 Sept. | 26 Sept. |

| Date of end of storage of first harvest in days | 22 March 2008 | 16 March 2009 | 07 March 2010 | 02 March 2011 | 15 March 2012 | 20 March 2013 | 12 March 2014 | 21 March 2015 | 10 March 2016 | 21 March 2017 | 17 March 2018 |

| Length of storage in days | 190 | 200 | 185 | 181 | 186 | 190 | 190 | 195 | 185 | 190 | |

| Year | Date | AT | Maturity Indicators | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| F | OHD | No. | Sum of Active Temperatures | Quality Parameters | |||||||||||||

| 0 °C | 1 °C | 2 °C | 3 °C | 5 °C | 10 °C | 15 °C | FR | TSS | SDI | StI | TA | TSS/ TA | |||||

| 2007 | 21 Apr. | 15 Sept. | 147 | 16.6 | 2457 | 2309 | 2161 | 2013 | 1719 | 1002 | 405 | 65.9 | 10.8 | 7.4 | 1.25 | 0.186 | 58.2 |

| 2008 | 23 Apr. | 03 Sept. | 133 | 18.6 | 2495 | 2362 | 2227 | 2093 | 1825 | 1155 | 527 | 65.6 | 11.5 | 7.0 | 1.26 | 0.278 | 41.3 |

| 2009 | 25 Apr. | 07 Sept. | 135 | 18.2 | 2478 | 2343 | 2206 | 2070 | 1798 | 1111 | 502 | 63.2 | 11.4 | 6.6 | 1.71 | 0.182 | 62.5 |

| 2010 | 21 Apr. | 11 Sept. | 143 | 17.1 | 2467 | 2324 | 2179 | 2035 | 1747 | 1046 | 463 | 60.2 | 11.4 | 8.2 | 0.97 | 0.171 | 66.9 |

| 2011 | 30 Apr. | 17 Sept. | 140 | 17.3 | 2427 | 2287 | 2145 | 2004 | 1713 | 1032 | 402 | 70.2 | 11.2 | 8.7 | 1.08 | 0.188 | 59.6 |

| 2012 | 24 Apr. | 16 Sept. | 145 | 17.0 | 2478 | 2333 | 2186 | 2040 | 1748 | 1023 | 391 | 63.4 | 12.2 | 6.2 | 1.72 | 0.180 | 68.1 |

| 2013 | 17 Apr. | 04 Sept. | 140 | 17.5 | 2467 | 2327 | 2185 | 2044 | 1762 | 950 | 435 | 64.2 | 11.5 | 7.0 | 1.22 | 0.314 | 36.7 |

| 2014 | 19 Apr. | 12 Sept. | 146 | 16.6 | 2446 | 2300 | 2152 | 2005 | 1692 | 1078 | 407 | 65.2 | 11.5 | 7.3 | 1.21 | 0.188 | 61.1 |

| 2015 | 25 Apr. | 17 Sept. | 145 | 17.1 | 2480 | 2335 | 2188 | 2042 | 1750 | 1047 | 454 | 64.0 | 12.6 | 8.3 | 0.94 | 0.195 | 65.4 |

| 2016 | 29 Apr. | 16 Sept. | 140 | 17.6 | 2487 | 2347 | 2205 | 2064 | 1782 | 1070 | 436 | 61.0 | 12.1 | 7.2 | 1.09 | 0.153 | 78.9 |

| 2017 | 18 Apr. | 22 Sept. | 157 | 15.7 | 2479 | 2322 | 2163 | 2003 | 1670 | 968 | 342 | 63.8 | 11.5 | 8.3 | 1.02 | 0.186 | 61.8 |

| Mean | 23 Apr. | 13 Sept. | 142.8 | 17.2 | 2469 | 2326 | 2182 | 2037 | 1746 | 1044 | 433 | 64.2 | 11.6 | 7.47 | 1.22 | 0.202 | 60.0 |

| MD | 13 | 19 | 24 | 2.93 | 68 | 75 | 82 | 90 | 155 | 205 | 185 | 12.8 | 1.8 | 2.5 | 0.75 | 0.130 | 42.2 |

| SD | 4.0 | 5.7 | 6.2 | 0.76 | 20 | 22 | 25 | 45 | 46 | 60 | 52 | 3.6 | 0.5 | 0.80 | 0.27 | 0.046 | 11.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Łysiak, G.P. Degree Days as a Method to Estimate the Optimal Harvest Date of ‘Conference’ Pears. Agriculture 2022, 12, 1803. https://doi.org/10.3390/agriculture12111803

Łysiak GP. Degree Days as a Method to Estimate the Optimal Harvest Date of ‘Conference’ Pears. Agriculture. 2022; 12(11):1803. https://doi.org/10.3390/agriculture12111803

Chicago/Turabian StyleŁysiak, Grzegorz P. 2022. "Degree Days as a Method to Estimate the Optimal Harvest Date of ‘Conference’ Pears" Agriculture 12, no. 11: 1803. https://doi.org/10.3390/agriculture12111803

APA StyleŁysiak, G. P. (2022). Degree Days as a Method to Estimate the Optimal Harvest Date of ‘Conference’ Pears. Agriculture, 12(11), 1803. https://doi.org/10.3390/agriculture12111803