WG-3D: A Low-Cost Platform for High-Throughput Acquisition of 3D Information on Wheat Grain

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Materials

2.2. Experimental Device

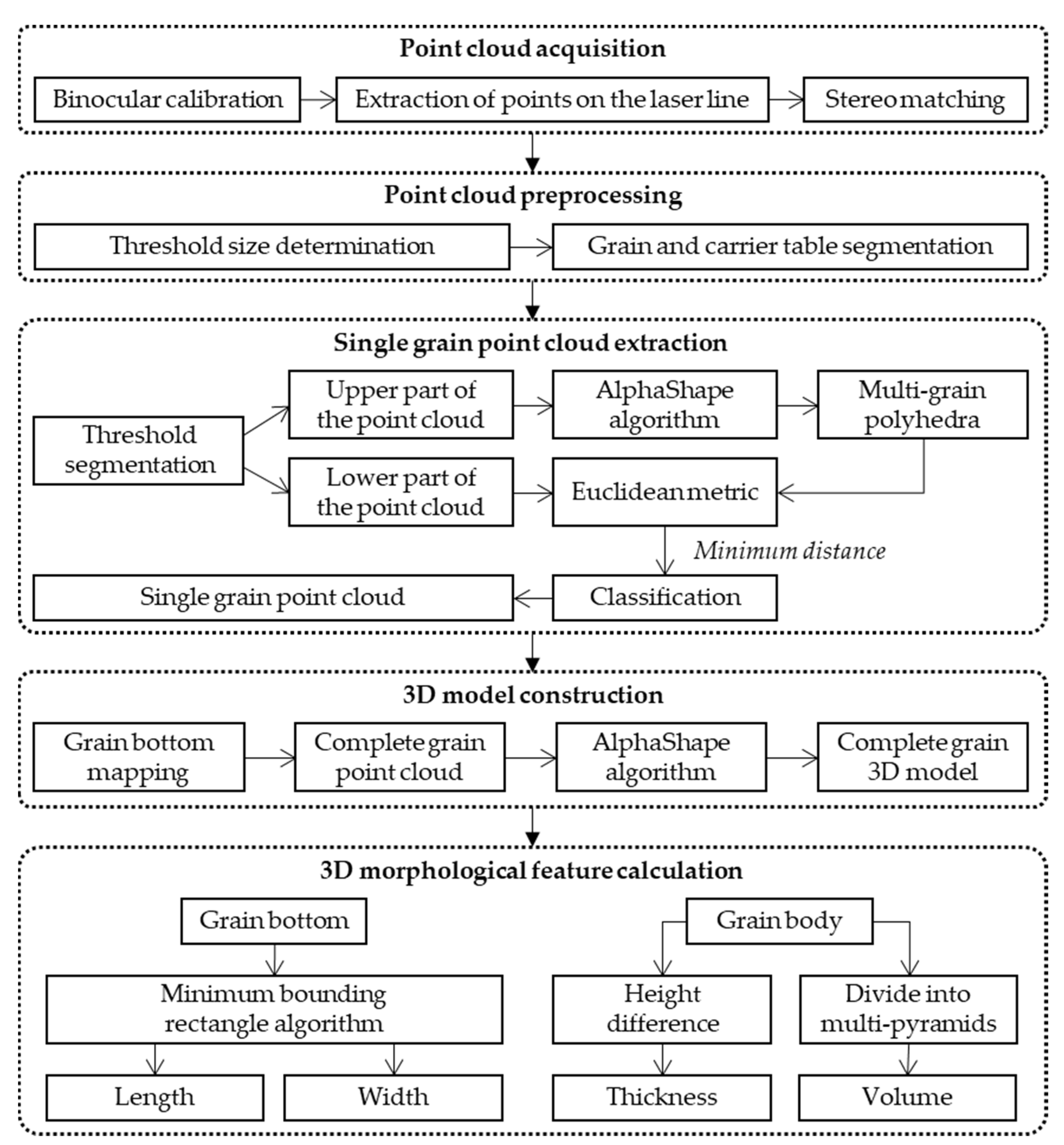

2.3. Grain Point Cloud Processing Pipeline

2.3.1. Point Cloud Acquisition

- Binocular calibration. This uses the known correspondence between the world coordinate system (calibration plate) and the image coordinate system (after processing the image of the calibration plate) to calculate the parameter information of the binocular camera in the current position relationship. Before binocular calibration, it is also necessary to perform single camera calibration for each camera to determine its distortion coefficient, camera internal reference matrix, and other parameters.

- Extraction of points of interest (feature extraction). In this process, the binocular camera extracts all data points on the laser line. Two pictures taken with the left and right cameras from different angles are used to describe the laser line. Then, a suitable pre-processing algorithm is added to extract and segment the laser lines from the two images.

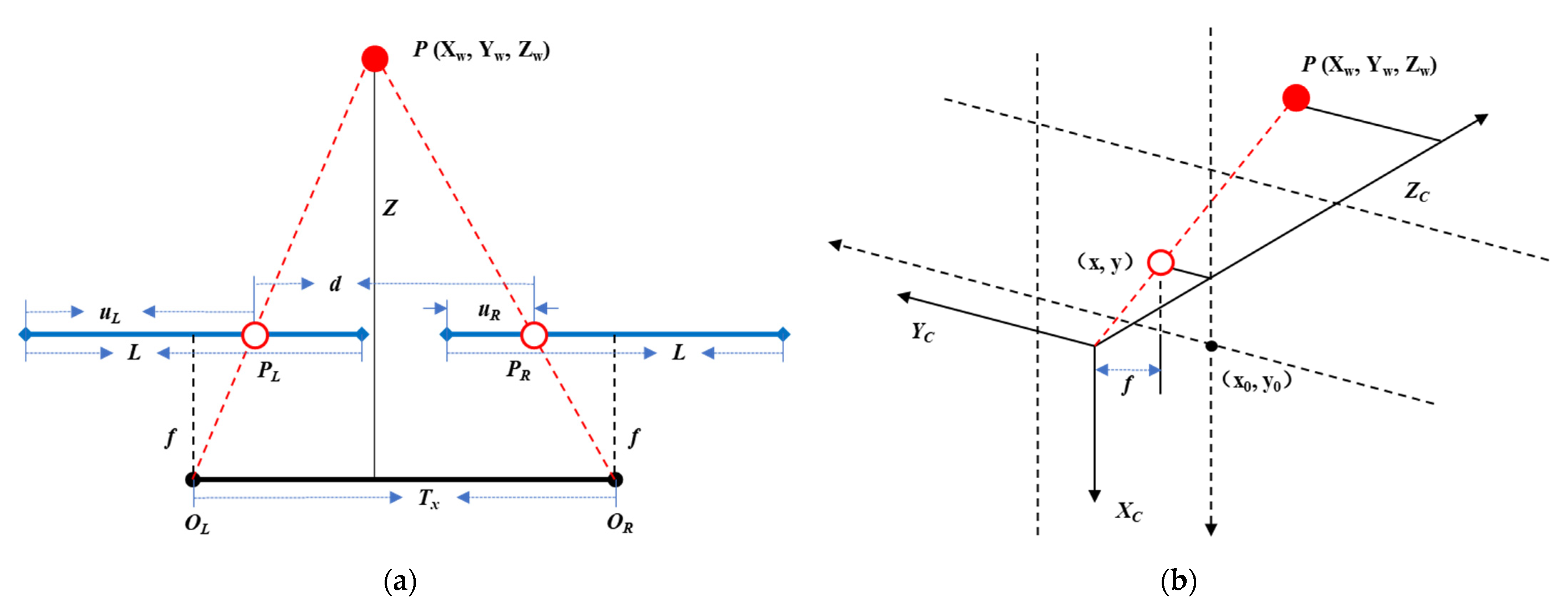

- Accurate digital description (stereo matching). In this stage, the “stereo matching” algorithm is used, which calculates the base matrix based on the coordinate points of the feature points in the left and right images and corresponds the coordinate points of the same name in the left and right images one by one. The calculation is performed using the parallax principle (Figure 4).

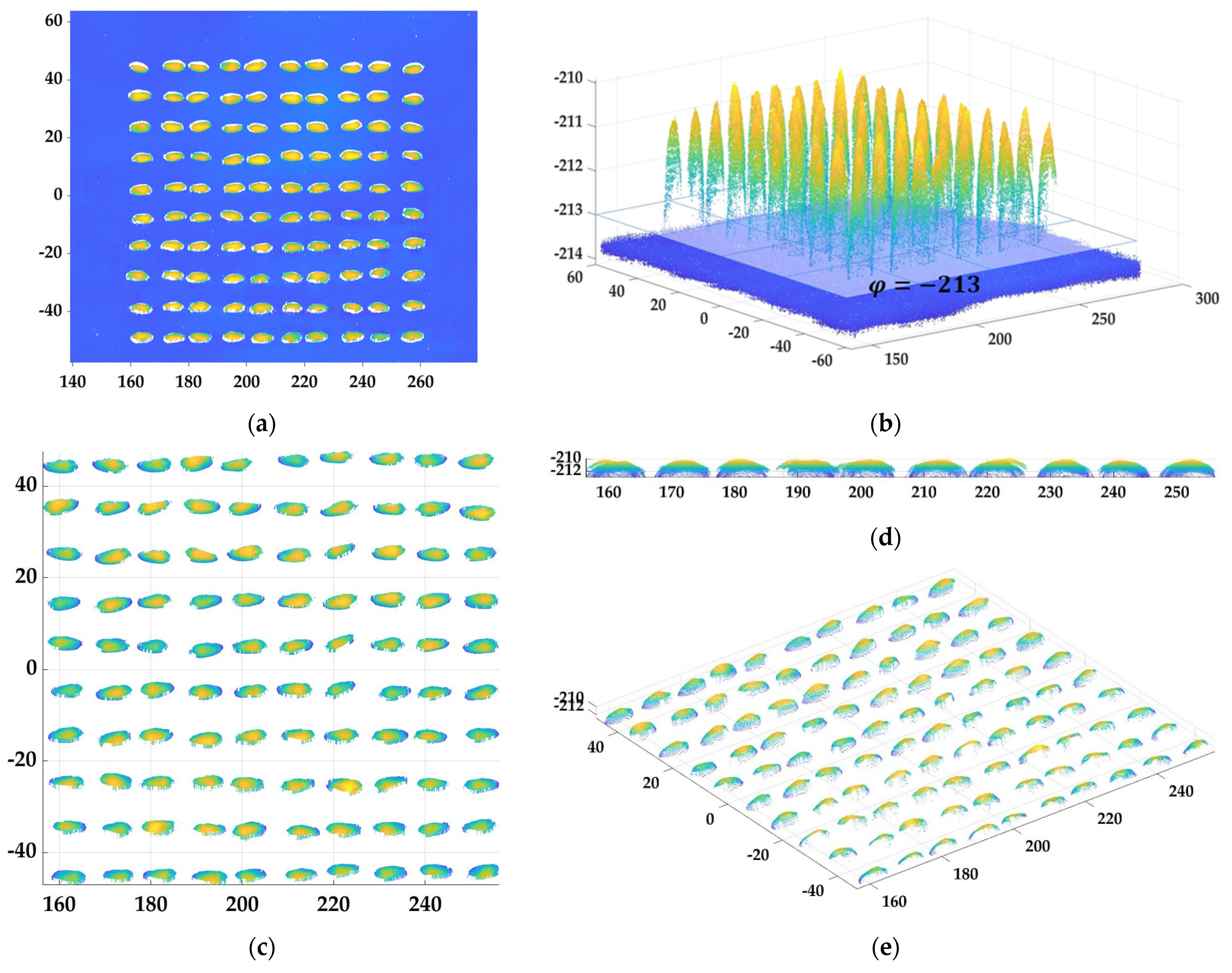

2.3.2. Point Cloud Preprocessing

2.3.3. Single-Grain Point-Cloud Extraction

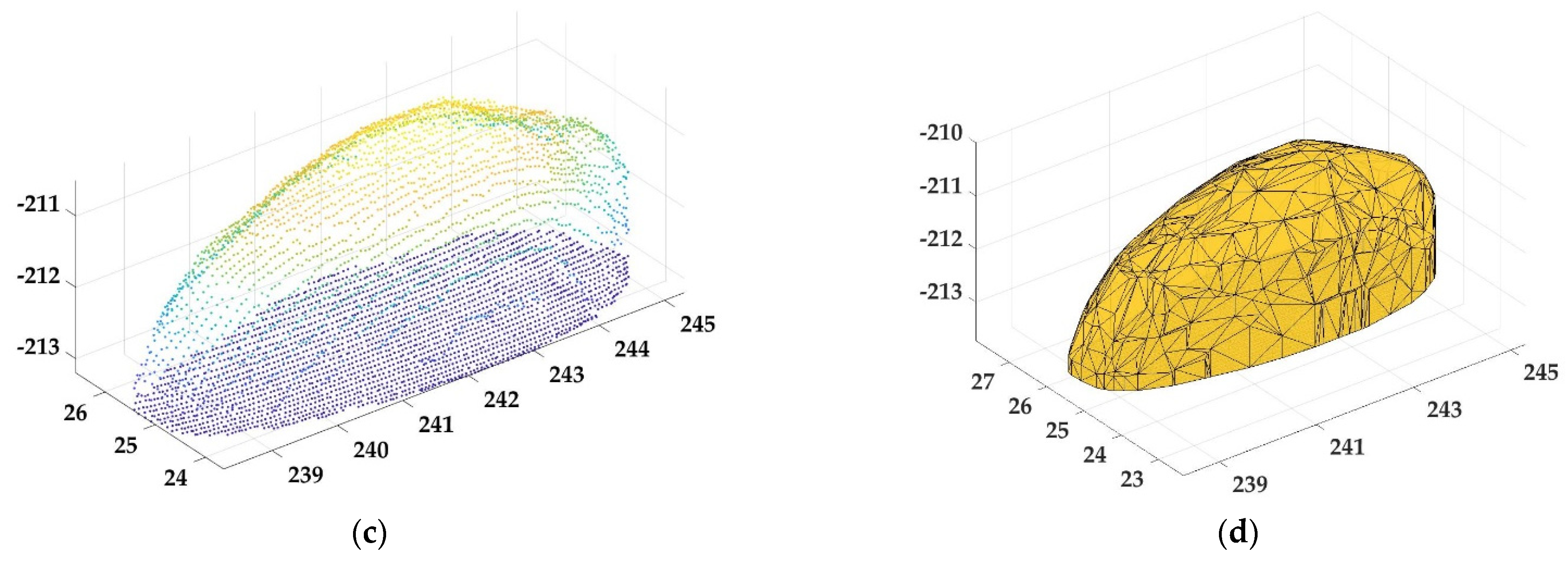

2.3.4. 3D Model Construction

2.3.5. 3D Morphological Feature Calculation

2.4. Manual Measurement Indicators

2.5. Evaluation Indicators

2.6. Data Processing and Analysis Software

3. Results

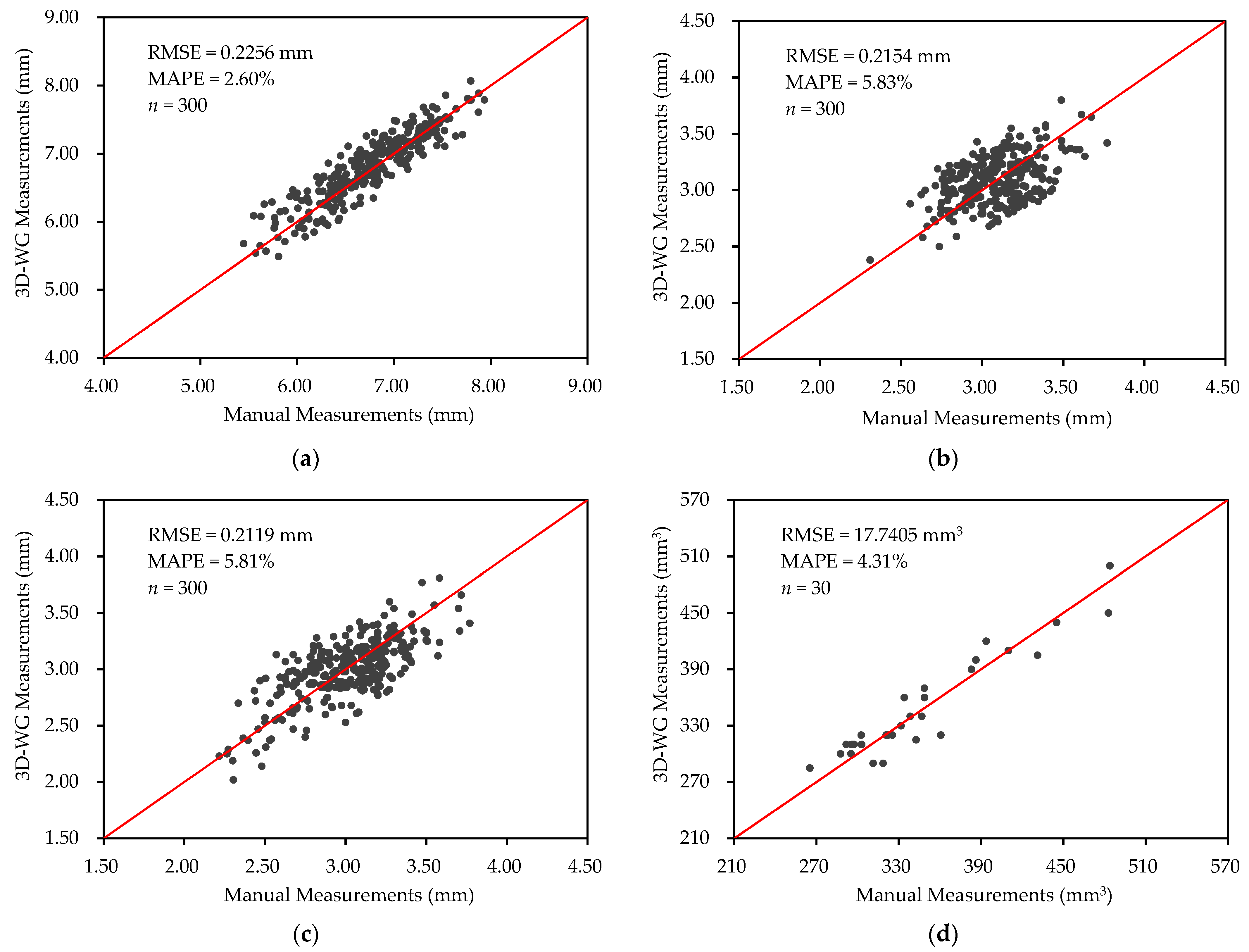

3.1. Measurement Accuracy

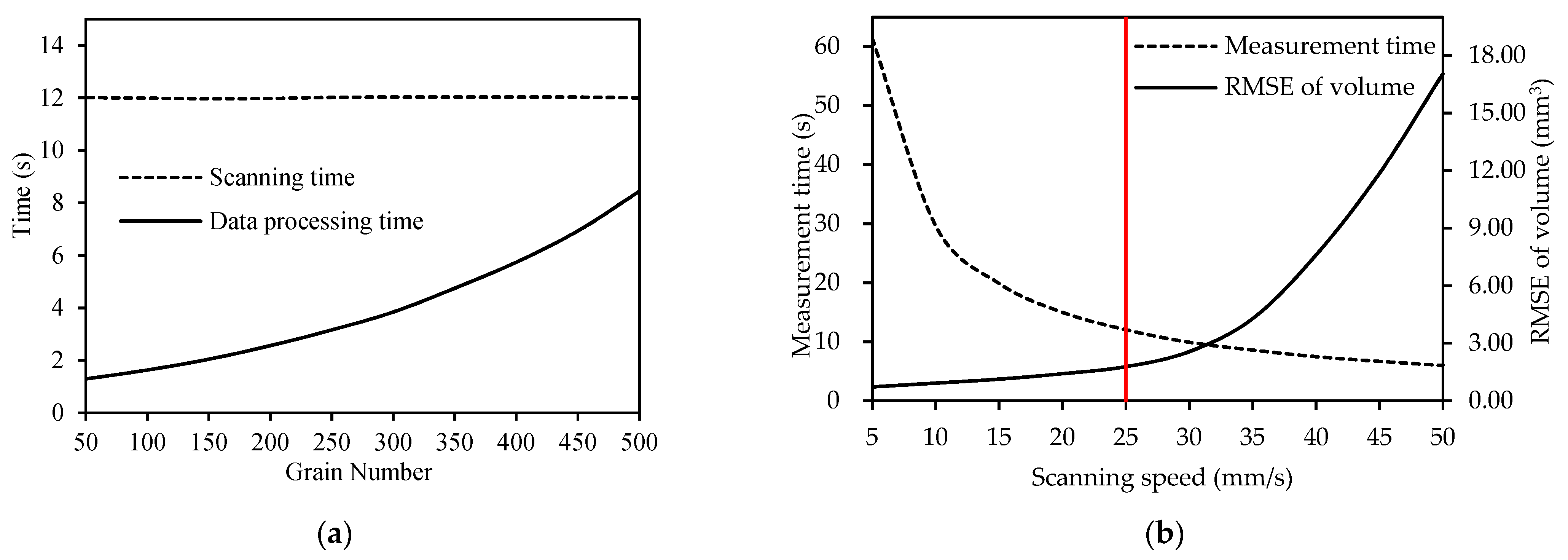

3.2. Measurement Efficiency

4. Discussion

4.1. Comparison of Related Studies

4.2. 3D Morphological Cluster Analysis

4.3. Advantages and Disadvantages

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dixon, L.E.; Pasquariello, M.; Badgami, R.; Levin, K.A.; Poschet, G.; Ng, P.Q.; Orford, S.; Chayut, N.; Adamski, N.M.; Brinton, J.; et al. MicroRNA-resistant alleles of HOMEOBOX DOMAIN-2 modify inflorescence branching and increase grain protein content of wheat. Sci. Adv. 2022, 8, eabn5907. [Google Scholar] [PubMed]

- Okamoto, Y.; Kajimura, T.; Ikeda, T.M.; Takumi, S. Evidence from principal component analysis for improvement of grain shape-and spikelet morphology-related traits after hexaploid wheat speciation. Genes Genet. Syst. 2012, 87, 299–310. [Google Scholar] [PubMed] [Green Version]

- Liu, X.; Mou, C.; Zhou, C.; Cheng, Z.; Jiang, L.; Wan, J. Research progress on cloning and regulation mechanism of rice grain shape genes. Chin. J. Rice Sci. 2018, 32, 1–11. [Google Scholar]

- Botwright, T.L.; Condon, A.G.; Rebetzke, G.J.; Richards, R.A. Field evaluation of early vigour for genetic improvement of grain yield in wheat. Aust. J. Agric. Res. 2002, 53, 1137–1145. [Google Scholar]

- Chastain, T.G.; Ward, K.J.; Wysocki, D.J. Stand establishment response of soft white winter wheat to seedbed residue and seed size. Crop Sci. 1995, 35, 213–218. [Google Scholar] [CrossRef]

- Kumar, A.; Mantovani, E.E.; Seetan, R.; Soltani, A.; Echeverry-Solarte, M.; Jain, S.; Simsek, S.; Doehlert, D.; Alamri, M.S.; Elias, E.M.; et al. Dissection of genetic factors underlying wheat kernel shape and size in an elite x nonadapted cross using a high density SNP linkage map. Plant. Genome 2016, 9, 1–22. [Google Scholar]

- Breseghello, F.; Sorrells, M.E. QTL analysis of kernel size and shape in two hexaploid wheat mapping populations. Field. Crop Res. 2007, 101, 172–179. [Google Scholar]

- Ramya, P.; Chaubal, A.; Kulkarni, K.; Gupta, L.; Kadoo, N.; Dhaliwal, H.S.; Chhuneja, P.; Lagu, M.; Gupt, V. QTL mapping of 1000-kernel weight, kernel length, and kernel width in bread wheat (Triticum aestivum L.). J. Appl. Genet. 2010, 51, 421–429. [Google Scholar]

- Williams, K.; Munkvold, J.; Sorrells, M. Comparison of digital image analysis using elliptic Fourier descriptors and major dimensions to phenotype seed shape in hexaploid wheat (Triticum aestivum L.). Euphytica 2013, 190, 99–116. [Google Scholar]

- Su, Z.; Jin, S.; Lu, Y.; Zhang, G.; Chao, S.; Bai, G. Single nucleotide polymorphism tightly linked to a major QTL on chromosome 7A for both kernel length and kernel weight in wheat. Mol. Breed. 2016, 36, 15. [Google Scholar]

- Campbell, K.G.; Bergman, C.J.; Gualberto, D.G.; Anderson, J.A.; Giroux, M.J.; Hareland, G.; Gary Fulcher, R.; Sorrells, M.E.; Finney, P.L. Quantitative trait loci associated with kernel traits in a soft× hard wheat cross. Crop Sci. 1999, 39, 1184–1195. [Google Scholar] [CrossRef]

- Gegas, V.C.; Nazari, A.; Griffiths, S.; Simmonds, J.; Fish, L.; Orford, S.; Sayers, L.; Doonan, J.H.; Snape, J.W. A genetic framework for grain size and shape variation in wheat. Plant Cell 2010, 22, 1046–1056. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Abdipour, M.; Ebrahimi, M.; Izadi-Darbandi, A.; Mastrangelo, A.M.; Najafian, G.; Arshad, Y.; Mirniyam, G. Association between grain size and shape and quality traits, and path analysis of thousand grain weight in Iranian bread wheat landraces from different geographic regions. Not. Bot. Horti Agrobot. 2016, 44, 228–236. [Google Scholar] [CrossRef] [Green Version]

- Cheng, R.; Kong, Z.; Zhang, L.; Xie, Q.; Jia, H.; Yu, D.; Huang, Y.; Ma, Z. Mapping QTLs controlling kernel dimensions in a wheat inter-varietal RIL mapping population. Theor. Appl. Genet. 2017, 130, 1405–1414. [Google Scholar] [CrossRef]

- Kaur, H.; Singh, B. Classification and grading rice using multi-class SVM. Int. J. Sci. Res. Publ. 2013, 3, 1–5. [Google Scholar]

- Wu, W.; Yang, T.; Li, R.; Chen, C.; Liu, T.; Zhou, K.; Sun, C.; Li, C.; Zhu, X.; Guo, W. Detection and enumeration of wheat grains based on a deep learning method under various scenarios and scales. J. Integr. Agric. 2020, 19, 1998–2008. [Google Scholar] [CrossRef]

- Mahajan, S.; Das, A.; Sardana, H.K. Image acquisition techniques for assessment of legume quality. Trends Food. Sci. Technol. 2015, 42, 116–133. [Google Scholar] [CrossRef]

- Guindo, D.; Davrieux, F.; Teme, N.; Vaksmann, M.; Doumbia, M.; Fliedel, G.; Bastianelli, D.; Verdeil, J.L.; Mestres, C.; Kouressy, M.; et al. Pericarp thickness of sorghum whole grain is accurately predicted by NIRS and can affect the prediction of other grain quality parameters. J. Cereal Sci. 2016, 69, 218–227. [Google Scholar] [CrossRef]

- Lu, L.; Deng, S.; Zhu, Z.; Tian, S. Classification of rice by combining electronic tongue and nose. Food Anal. Method 2015, 8, 1893–1902. [Google Scholar] [CrossRef]

- Ferreira, D.S.; Pallone, J.A.L.; Poppi, R.J. Direct analysis of the main chemical constituents in Chenopodium quinoa grain using Fourier transform near-infrared spectroscopy. Food Control 2015, 48, 91–95. [Google Scholar] [CrossRef]

- Guelpa, A.; du Plessis, A.; Kidd, M.; Manley, M. Non-destructive estimation of maize (Zea mays L.) kernel hardness by means of an X-ray micro-computed tomography (μCT) density calibration. Food Bioprocess Technol. 2015, 8, 1419–1429. [Google Scholar] [CrossRef]

- Ravikanth, L.; Singh, C.B.; Jayas, D.S.; White, N.D. Classification of contaminants from wheat using near-infrared hyperspectral imaging. Biosyst. Eng. 2015, 135, 73–86. [Google Scholar] [CrossRef]

- Pearson, T. High-speed sorting of grains by color and surface texture. Appl. Eng. Agric. 2010, 26, 499–505. [Google Scholar] [CrossRef]

- Golpour, I.; Chayjan, R.A. Identification and classification of bulk paddy, brown, and white rice cultivars with colour features extraction using image analysis and neural network. Czech J. Food Sci. 2014, 32, 280–287. [Google Scholar] [CrossRef] [Green Version]

- Anami, B.S.; Naveen, N.M.; Hanamaratti, N.G. Behavior of HSI color co-occurrence features in variety recognition from bulk paddy grain image samples. Int. J. Signal Process. Image Process. Pattern Recognit. 2015, 8, 19–30. [Google Scholar] [CrossRef]

- Dubosclard, P.; Larnier, S.; Konik, H.; Herbulot, A.; Devy, M. Automated visual grading of grain kernels by machine vision. In Proceedings of the Twelfth International Conference on Quality Control by Artificial Vision 2015, Le Creusot, France, 3–5 June 2015; SPIE: Bellingham, WA, USA, 2015; Volume 9534, pp. 112–119. [Google Scholar]

- Li, H.; Qian, Y.; Cao, P.; Yin, W.; Dai, F.; Hu, F.; Yan, Z. Calculation method of surface shape feature of rice seed based on point cloud. Comput. Electron. Agric. 2017, 142, 416–423. [Google Scholar] [CrossRef]

- Rungyaem, K.; Sukvichai, K.; Phatrapornnant, T.; Kaewpunya, A.; Hasegawa, S. Comparison of 3D Rice Organs Point Cloud Classification Techniques. In Proceedings of the 2021 25th International Computer Science and Engineering Conference (ICSEC), Chiang Rai, Thailand, 18–20 November 2021; pp. 196–199. [Google Scholar]

- Gong, L.; Du, X.; Zhu, K.; Lin, K.; Lou, Q.; Yuan, Z.; Huang, G.; Liu, C. Panicle-3D: Efficient Phenotyping Tool for Precise Semantic Segmentation of Rice Panicle Point Cloud. Plant Phenomics 2021, 2021, 9838929. [Google Scholar] [CrossRef]

- Sun, Y.; Luo, Y.; Chai, X.; Zhang, P.; Zhang, Q.; Xu, L.; Wei, L. Double-Threshold Segmentation of Panicle and Clustering Adaptive Density Estimation for Mature Rice Plants Based on 3D Point Cloud. Electronics 2021, 10, 872. [Google Scholar] [CrossRef]

- Rattanasuwan, P.; Kumazawa, I.; Kasetkasem, T. Non-destructive measurement of rice leaf dimension in 3D point cloud. IOP Conf. Ser. Earth Environ. Sci. 2021, 633, 012013. [Google Scholar] [CrossRef]

- Sun, C.; Berman, M.; Coward, D.; Osborne, B. Thickness measurement and crease detection of wheat grains using stereo vision. Pattern Recogn. Lett. 2007, 28, 1501–1508. [Google Scholar] [CrossRef]

- Gardiner, J.D.; Behnsen, J.; Brassey, C.A. Alpha shapes: Determining 3D shape complexity across morphologically diverse structures. BMC Evol. Biol. 2018, 18, 184. [Google Scholar] [CrossRef] [PubMed]

- Zhong, X.; Chen, W.; Liu, T.; Hao, X.; Li, Z.; Sun, C. Three-dimensional information measurement of wheat grain based on image technology. Guangdong Agric. Sci. 2016, 43, 150–155. [Google Scholar]

- Qin, Z.; Zhang, Z.; Hua, X.; Yang, W.; Liang, X.; Zhai, R.; Huang, C. Cereal grain 3D point cloud analysis method for shape extraction and filled/unfilled grain identification based on structured light imaging. Sci. Rep. 2022, 12, 3145. [Google Scholar] [CrossRef]

- Zhang, X.; Li, M.; Liu, D.; Jiang, W.; Zhang, Y.; Gao, D. Analysis of quality traits and breeding inspiration in Yangmai series wheat varieties. Sci. Agric. Sin. 2020, 53, 1309–1321. [Google Scholar]

| Variety | Abbreviation | Variety | Abbreviation |

|---|---|---|---|

| Yangmai No.1 | Y 1# | Yangmai No.17 | Y 17# |

| Yangmai No.2 | Y 2# | Yangmai No.18 | Y 18# |

| Yangmai No.3 | Y 3# | Yangmai No.19 | Y 19# |

| Yangmai No.4 | Y 4# | Yangmai No.20 | Y 20# |

| Yangmai No.5 | Y 5# | Yangmai No.21 | Y 21# |

| Yangmai No.6 | Y 6# | Yangmai No.22 | Y 22# |

| Yangmai No.10 | Y 10# | Yangmai No.23 | Y 23# |

| Yangmai No.11 | Y 11# | Yangmai No.24 | Y 24# |

| Yangmai No.12 | Y 12# | Yangmai No.25 | Y 25# |

| Yangmai No.13 | Y 13# | Yangmai No.26 | Y 26# |

| Yangmai No.14 | Y 14# | Yangmai No.27 | Y 27# |

| Yangmai No.15 | Y 15# | Yangmai No.28 | Y 28# |

| Yangmai No.16 | Y 16# | Yangmai 158 | Y 158 |

| Indicators | Zhenmai No.9 | Yangmai No.23 | Ningmai No.13 | |||

|---|---|---|---|---|---|---|

| RMSE (mm) | MAPE (%) | RMSE (mm) | MAPE (%) | RMSE (mm3) | MAPE (%) | |

| Length (n = 100) | 0.2000 | 2.24 | 0.2369 | 2.61 | 0.2400 | 2.96 |

| Width (n = 100) | 0.2235 | 6.10 | 0.2095 | 5.53 | 0.2133 | 5.86 |

| Thickness (n = 100) | 0.2054 | 5.32 | 0.2164 | 6.10 | 0.2137 | 5.99 |

| Volume (n = 10) | 18.1267 | 3.56 | 21.8453 | 5.66 | 13.2494 | 3.72 |

| Varieties | Length (n = 40) | Width (n = 40) | Thickness (n = 40) | Volume (n = 40) | ||||

|---|---|---|---|---|---|---|---|---|

| RMSE (mm) | MAPE (%) | RMSE (mm) | MAPE (%) | RMSE (mm) | MAPE (%) | RMSE (mm3) | MAPE (%) | |

| Y 1# | 0.2157 | 3.04 | 0.2070 | 6.08 | 0.2195 | 5.99 | 1.9167 | 5.77 |

| Y 2# | 0.2195 | 3.07 | 0.1748 | 4.95 | 0.1928 | 4.69 | 1.7286 | 4.56 |

| Y 3# | 0.2021 | 2.85 | 0.2024 | 5.86 | 0.1846 | 4.86 | 1.7815 | 4.64 |

| Y 4# | 0.2540 | 3.25 | 0.1864 | 5.05 | 0.1981 | 4.88 | 1.9893 | 4.42 |

| Y 5# | 0.2109 | 2.67 | 0.1920 | 5.24 | 0.2103 | 5.05 | 2.2179 | 5.60 |

| Y 6# | 0.2223 | 2.99 | 0.1759 | 4.65 | 0.2070 | 5.36 | 1.8763 | 4.56 |

| Y 10# | 0.2251 | 2.89 | 0.2076 | 6.02 | 0.2196 | 5.90 | 2.1199 | 5.18 |

| Y 11# | 0.2099 | 2.65 | 0.2047 | 5.73 | 0.1794 | 4.60 | 2.0713 | 4.89 |

| Y 12# | 0.2064 | 2.77 | 0.1919 | 5.65 | 0.1898 | 4.99 | 1.9241 | 5.05 |

| Y 13# | 0.2264 | 3.36 | 0.2223 | 6.40 | 0.2103 | 5.31 | 1.8587 | 4.53 |

| Y 14# | 0.2205 | 2.90 | 0.2114 | 5.49 | 0.1958 | 4.75 | 1.8364 | 4.05 |

| Y 15# | 0.1990 | 2.70 | 0.1975 | 4.96 | 0.1992 | 4.80 | 1.8151 | 4.00 |

| Y 16# | 0.2248 | 2.93 | 0.2212 | 6.54 | 0.2019 | 5.24 | 1.7937 | 4.40 |

| Y 17# | 0.2267 | 2.96 | 0.1910 | 4.81 | 0.2077 | 5.17 | 1.8920 | 4.53 |

| Y 18# | 0.2212 | 2.87 | 0.1927 | 5.30 | 0.2088 | 5.23 | 1.9557 | 4.60 |

| Y 19# | 0.2005 | 2.87 | 0.2116 | 5.89 | 0.2128 | 5.51 | 1.8025 | 4.06 |

| Y 20# | 0.2451 | 3.32 | 0.1748 | 4.80 | 0.2045 | 5.36 | 1.7236 | 3.98 |

| Y 21# | 0.2101 | 2.56 | 0.1709 | 4.60 | 0.2023 | 5.05 | 1.8269 | 4.04 |

| Y 22# | 0.2392 | 3.59 | 0.2086 | 5.66 | 0.1955 | 5.06 | 2.1455 | 5.53 |

| Y 23# | 0.1944 | 2.47 | 0.1992 | 5.74 | 0.1998 | 5.30 | 1.6590 | 4.16 |

| Y 24# | 0.2204 | 3.08 | 0.1949 | 5.22 | 0.2092 | 5.04 | 1.9749 | 4.69 |

| Y 25# | 0.1878 | 2.34 | 0.1974 | 5.06 | 0.1951 | 4.68 | 1.8148 | 4.08 |

| Y 26# | 0.2379 | 3.15 | 0.1897 | 4.82 | 0.2289 | 6.01 | 1.9700 | 4.43 |

| Y 27# | 0.1950 | 2.67 | 0.2005 | 5.39 | 0.2011 | 4.93 | 1.9104 | 4.56 |

| Y 28# | 0.2246 | 3.01 | 0.1989 | 5.40 | 0.2009 | 4.92 | 1.6983 | 4.10 |

| Y 158 | 0.2315 | 3.11 | 0.2059 | 5.85 | 0.1957 | 5.10 | 2.0877 | 5.40 |

| Average | 0.2181 | 2.93 | 0.1974 | 5.43 | 0.2027 | 5.15 | 1.8997 | 4.61 |

| Methods | Device | Length (mm) | Width (mm) | Thickness (mm) | Volume (mm3) | Efficiency | Additional |

|---|---|---|---|---|---|---|---|

| Reference [32] | Binocular camera | -- | -- | 0.1635 | -- | high | Single indicator |

| Reference [34] | Single camera | 0.0988 | 0.0841 | 0.0917 | -- | high | Unstable accuracy |

| Reference [27] | Binocular camera | 0.0300 | 0.0428 | 0.0362 | 0.3789 | low | One grain one time |

| Reference [35] | Binocular camera | 0.1840 | 0.0700 | 0.0420 | -- | low | Multi-angle acquisition |

| WG-3D-25 | Binocular camera | 0.2256 | 0.2154 | 0.2119 | 1.7740 | high | Scanning speed at 25 mm/s |

| WG-3D-5 | Binocular camera | 0.1018 | 0.0938 | 0.0916 | 0.6457 | middle | Scanning speed at 5 mm/s |

| Varieties | Length (mm) | Width (mm) | Thickness (mm) | Volume (mm3) |

|---|---|---|---|---|

| Y 1# | 5.96 | 2.98 | 3.21 | 29.92 |

| Y 2# | 6.04 | 3.13 | 3.41 | 34.12 |

| Y 3# | 6.15 | 3.11 | 3.34 | 34.06 |

| Y 4# | 6.84 | 3.22 | 3.56 | 39.93 |

| Y 5# | 6.34 | 3.08 | 3.57 | 37.00 |

| Y 6# | 6.27 | 3.20 | 3.46 | 34.81 |

| Y 10# | 6.71 | 3.12 | 3.38 | 36.92 |

| Y 11# | 6.74 | 3.16 | 3.36 | 38.49 |

| Y 12# | 6.39 | 2.96 | 3.33 | 33.23 |

| Y 13# | 5.90 | 3.15 | 3.44 | 37.00 |

| Y 14# | 6.46 | 3.44 | 3.55 | 38.99 |

| Y 15# | 6.31 | 3.44 | 3.75 | 39.88 |

| Y 16# | 6.83 | 3.08 | 3.31 | 34.51 |

| Y 17# | 6.48 | 3.37 | 3.49 | 37.84 |

| Y 18# | 6.72 | 3.09 | 3.51 | 37.20 |

| Y 19# | 6.04 | 3.17 | 3.47 | 38.39 |

| Y 20# | 6.28 | 3.11 | 3.46 | 36.21 |

| Y 21# | 6.97 | 3.15 | 3.55 | 40.53 |

| Y 22# | 5.97 | 3.20 | 3.36 | 34.50 |

| Y 23# | 6.49 | 3.15 | 3.20 | 33.63 |

| Y 24# | 6.27 | 3.27 | 3.62 | 36.93 |

| Y 25# | 6.44 | 3.37 | 3.64 | 38.45 |

| Y 26# | 6.63 | 3.32 | 3.46 | 37.69 |

| Y 27# | 6.27 | 3.18 | 3.58 | 37.43 |

| Y 28# | 6.32 | 3.17 | 3.60 | 36.44 |

| Y 158 | 6.30 | 3.12 | 3.29 | 34.05 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, W.; Zhao, Y.; Wang, H.; Yang, T.; Hu, Y.; Zhong, X.; Liu, T.; Sun, C.; Sun, T.; Liu, S. WG-3D: A Low-Cost Platform for High-Throughput Acquisition of 3D Information on Wheat Grain. Agriculture 2022, 12, 1861. https://doi.org/10.3390/agriculture12111861

Wu W, Zhao Y, Wang H, Yang T, Hu Y, Zhong X, Liu T, Sun C, Sun T, Liu S. WG-3D: A Low-Cost Platform for High-Throughput Acquisition of 3D Information on Wheat Grain. Agriculture. 2022; 12(11):1861. https://doi.org/10.3390/agriculture12111861

Chicago/Turabian StyleWu, Wei, Yuanyuan Zhao, Hui Wang, Tianle Yang, Yanan Hu, Xiaochun Zhong, Tao Liu, Chengming Sun, Tan Sun, and Shengping Liu. 2022. "WG-3D: A Low-Cost Platform for High-Throughput Acquisition of 3D Information on Wheat Grain" Agriculture 12, no. 11: 1861. https://doi.org/10.3390/agriculture12111861

APA StyleWu, W., Zhao, Y., Wang, H., Yang, T., Hu, Y., Zhong, X., Liu, T., Sun, C., Sun, T., & Liu, S. (2022). WG-3D: A Low-Cost Platform for High-Throughput Acquisition of 3D Information on Wheat Grain. Agriculture, 12(11), 1861. https://doi.org/10.3390/agriculture12111861