Analysis and Design of Operating Parameters of Floor-Standing Jujube Pickup Device Based on Discrete Element Method

Abstract

:1. Introduction

2. Materials and Methods

2.1. Pickup Device Operation Object

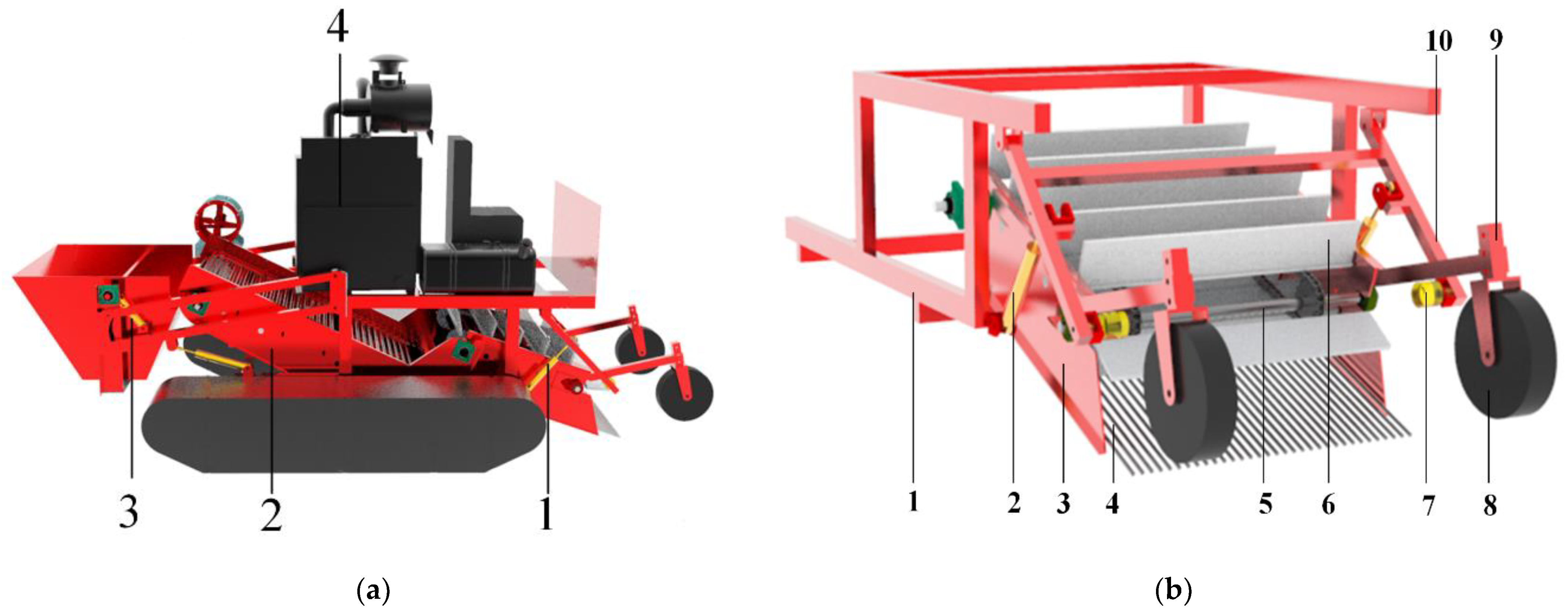

2.2. Structure and Working Principle

Working Principles of the Pickup Device

2.3. Design of Key Components

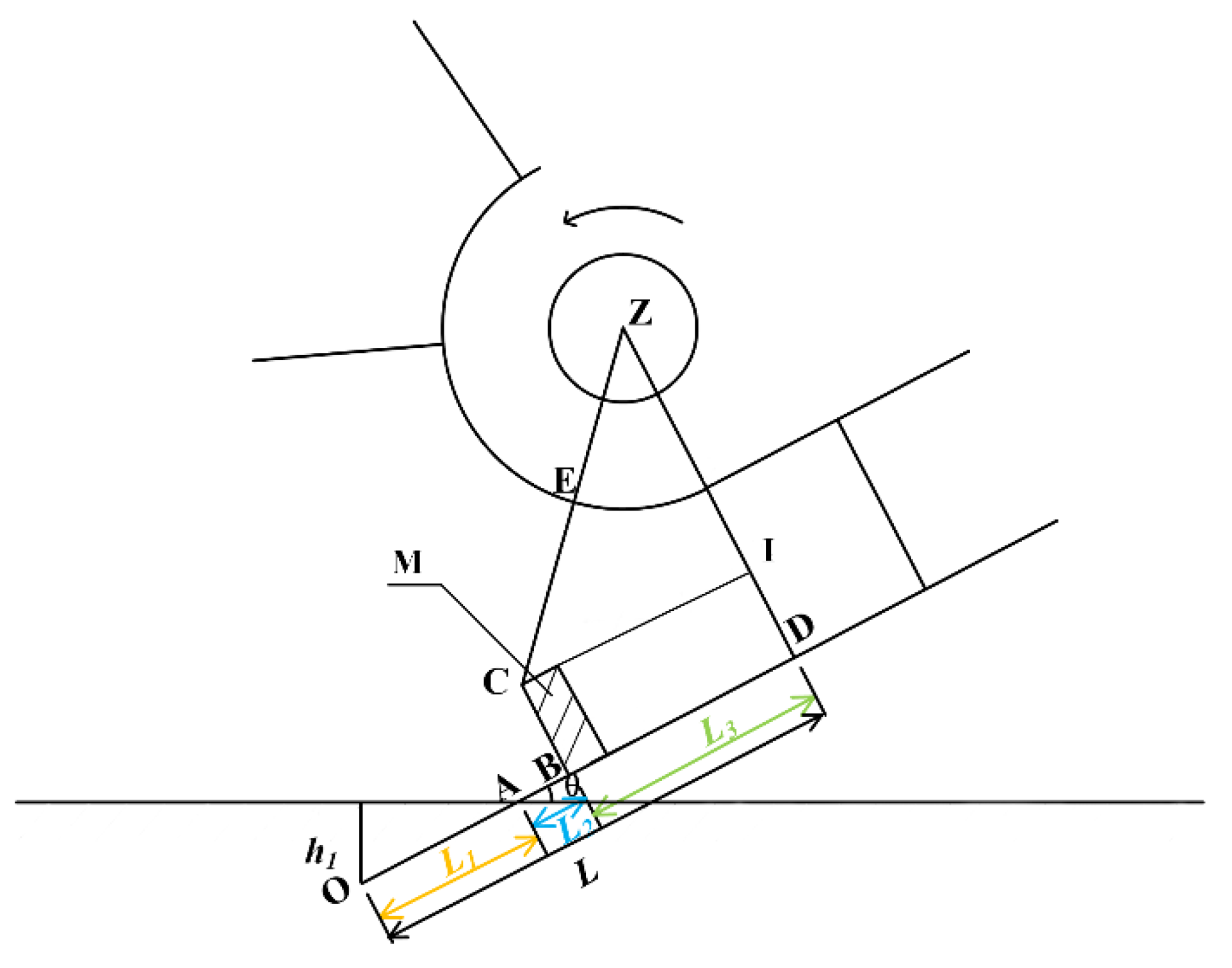

2.3.1. Working Principles of the Pickup Device

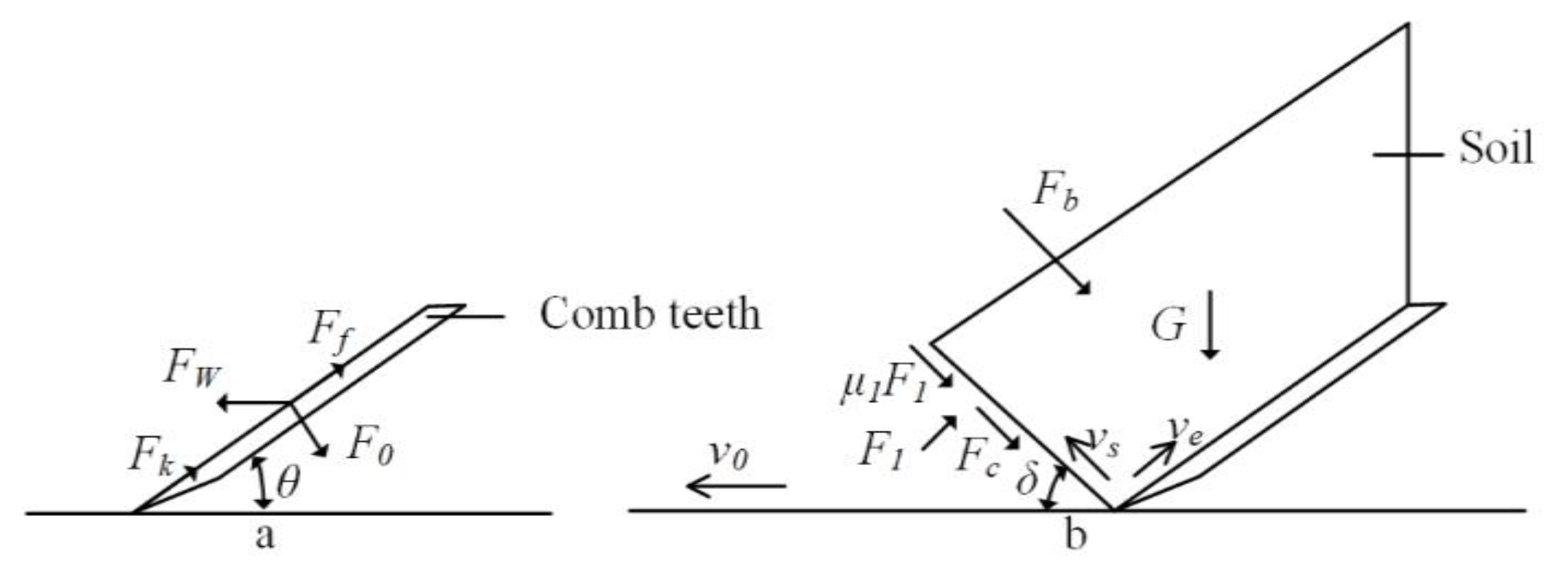

2.3.2. Analysis of Factors Affecting Strip Brush Picking of Jujubes and Design of Related Structural Parameters

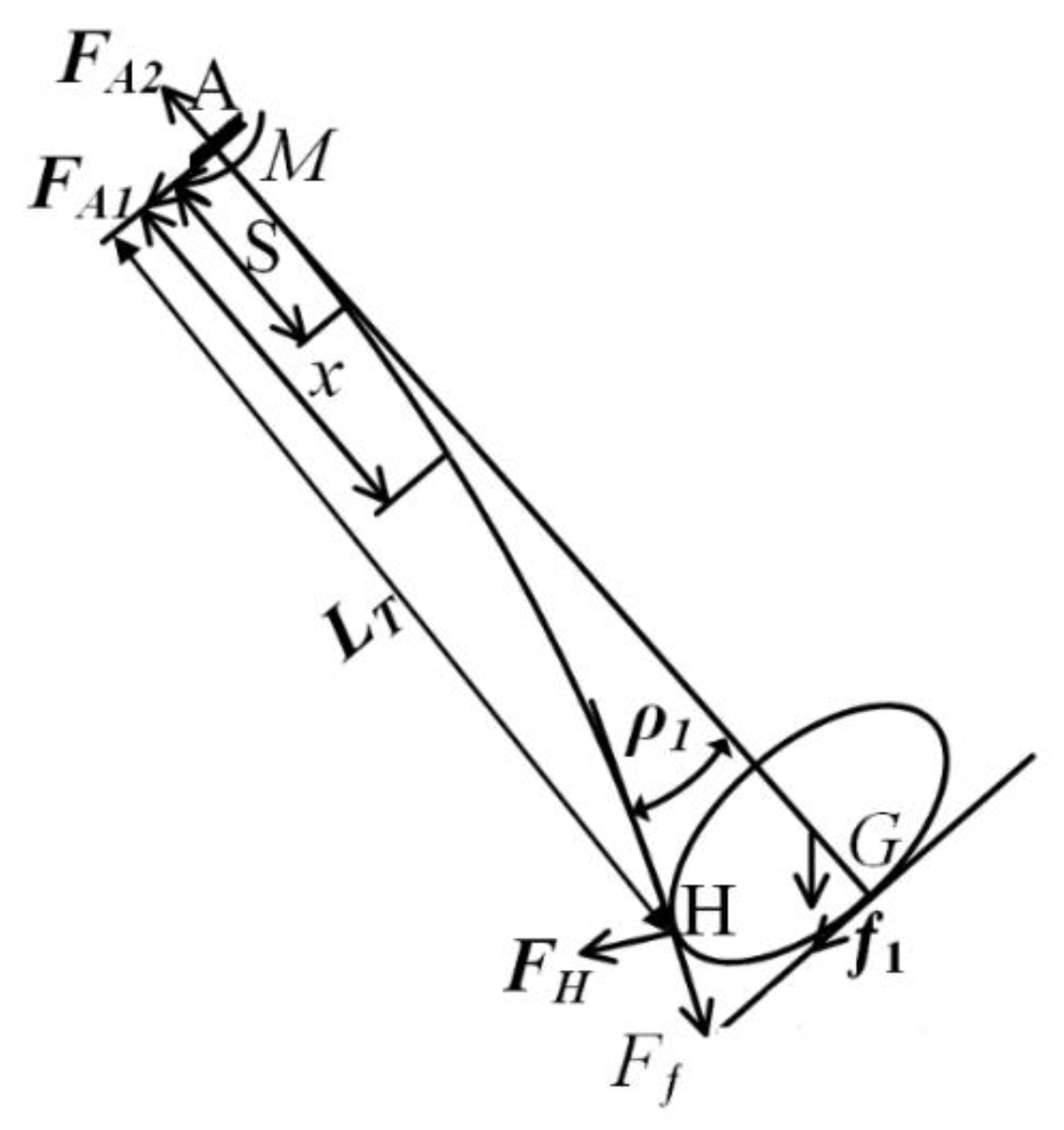

2.3.3. CT Structure Design and Force Analysis of the CT in the Soil

2.3.4. CT Structure Parameter Design

2.3.5. Force Analysis of CT in Working Conditions in Jujube Orchard Soil

2.4. Analysis of Pickup Device Operation Parameters Based on DEM

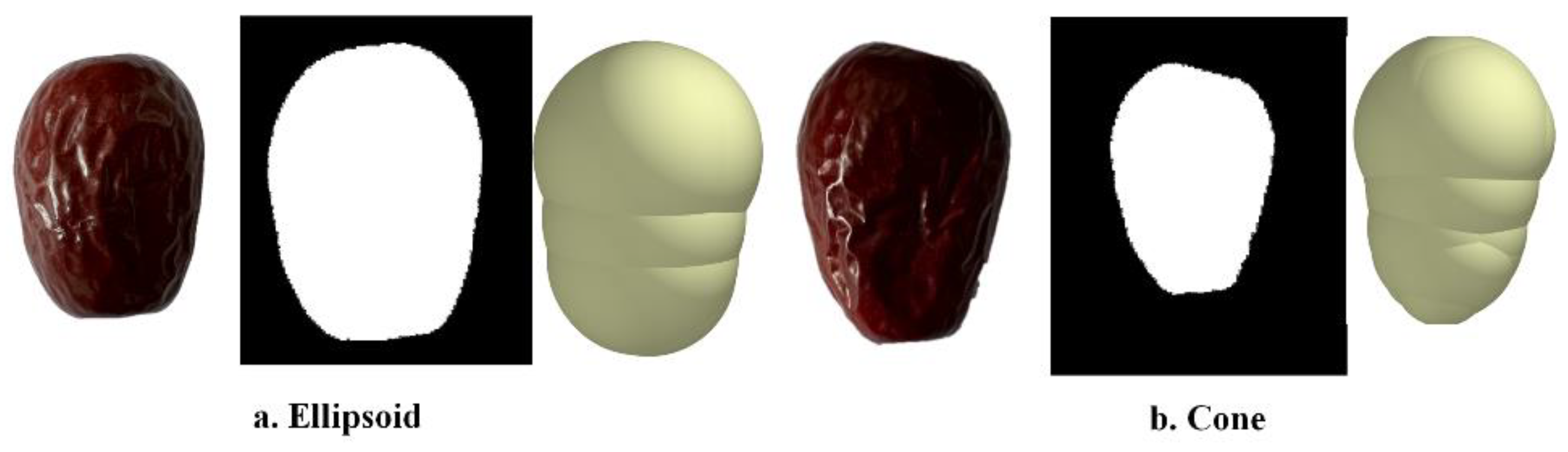

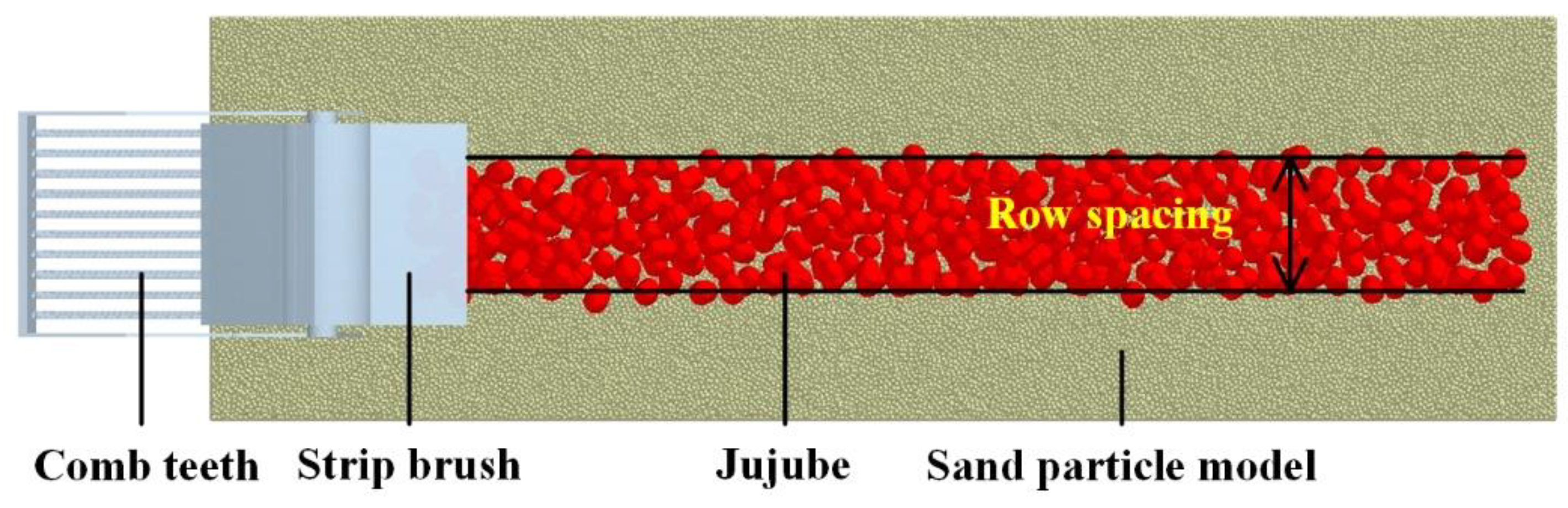

Simulation Model Establishment and Parameter Determination

3. Results and Discussion

3.1. Analysis of Pickup Device Operation Parameters Based on DEM

3.1.1. Simulation Model Establishment and Parameter Determination

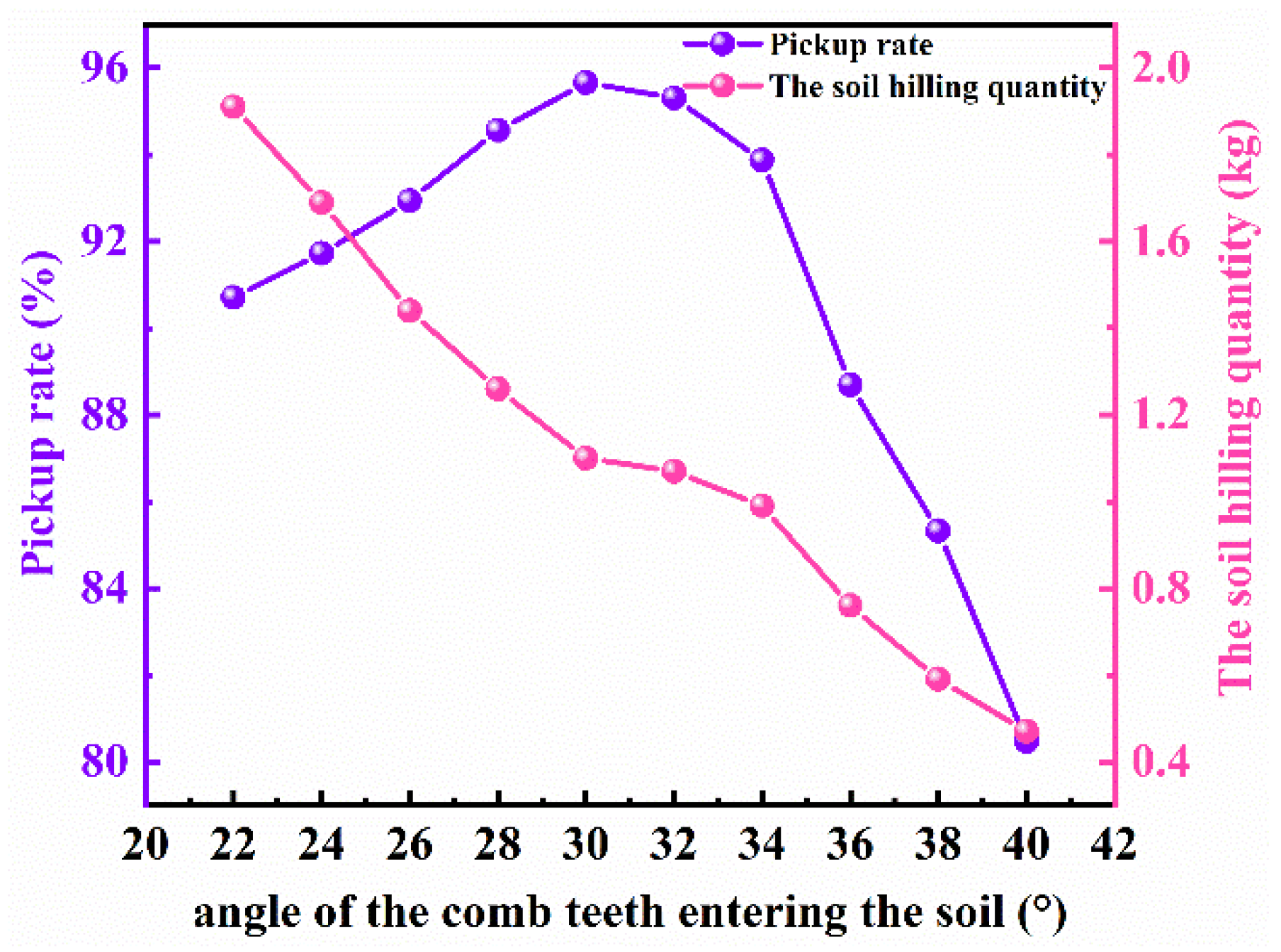

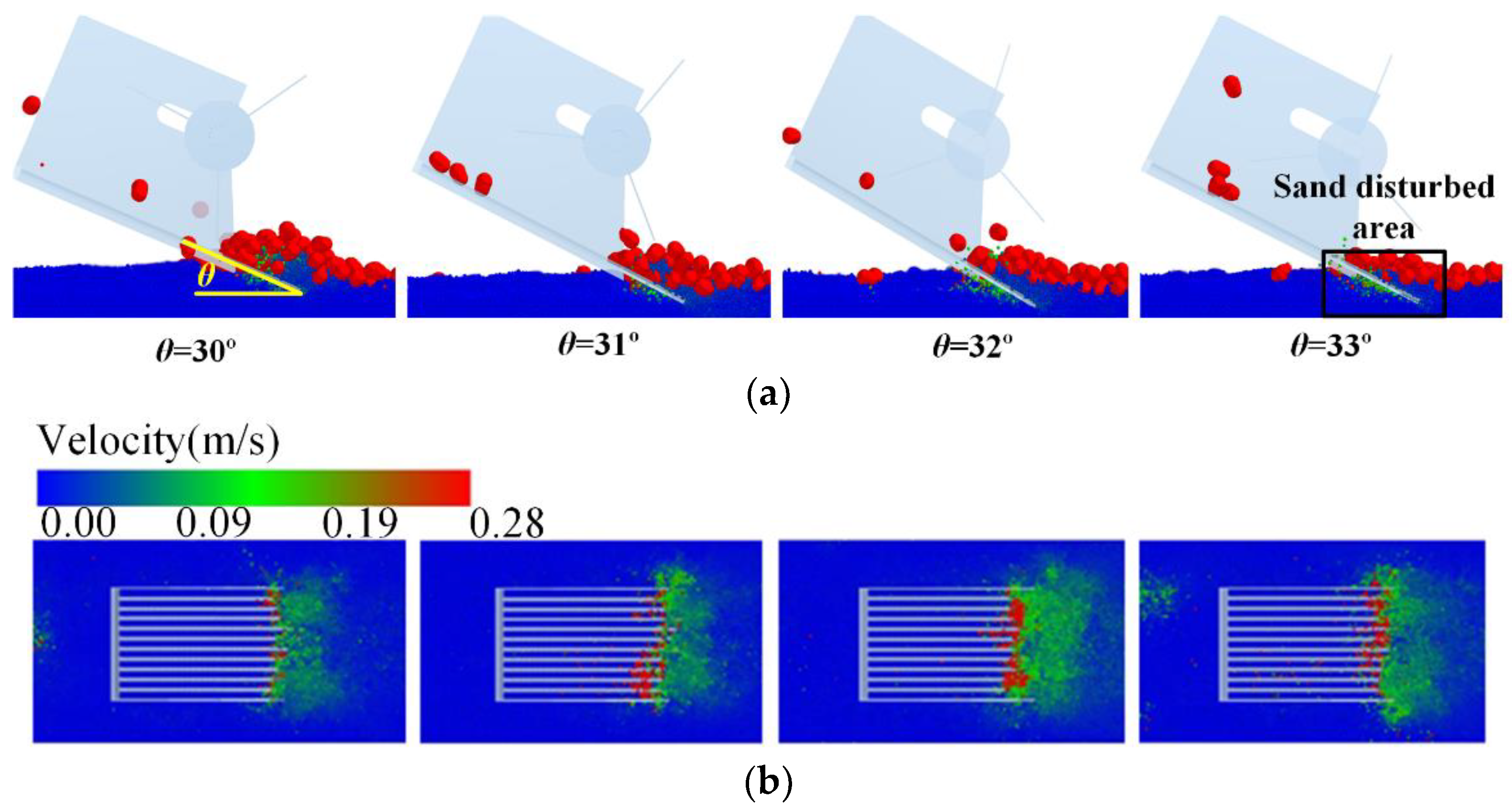

3.1.2. Simulation Test of ACT

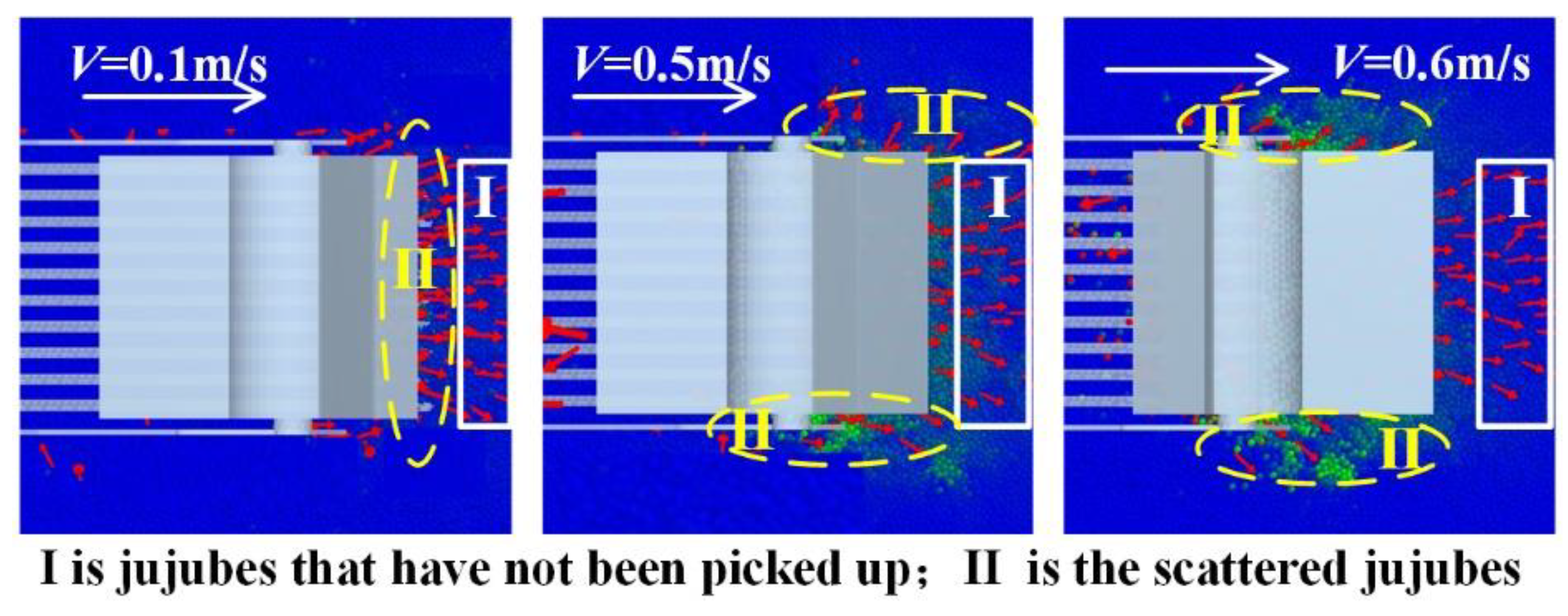

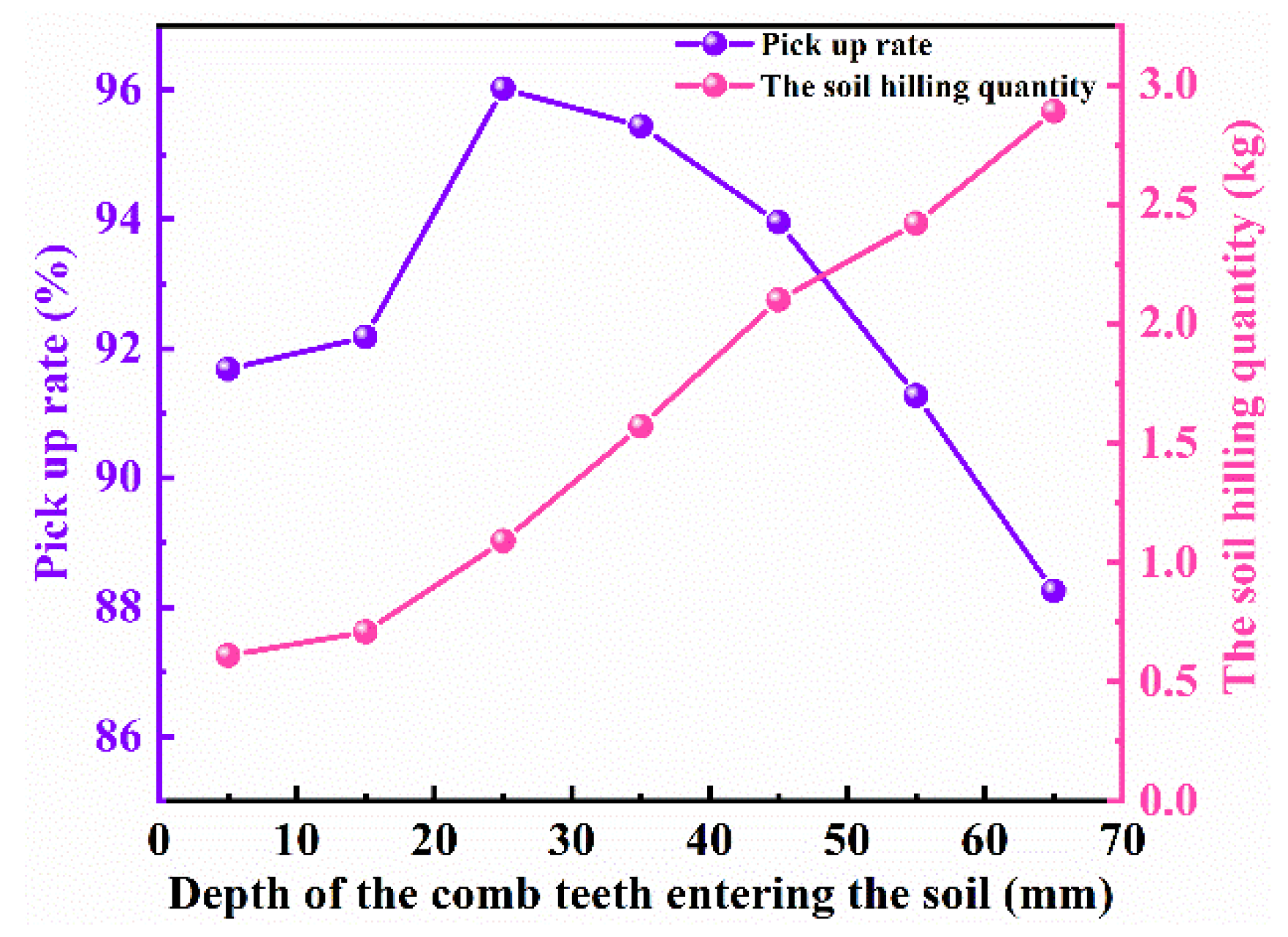

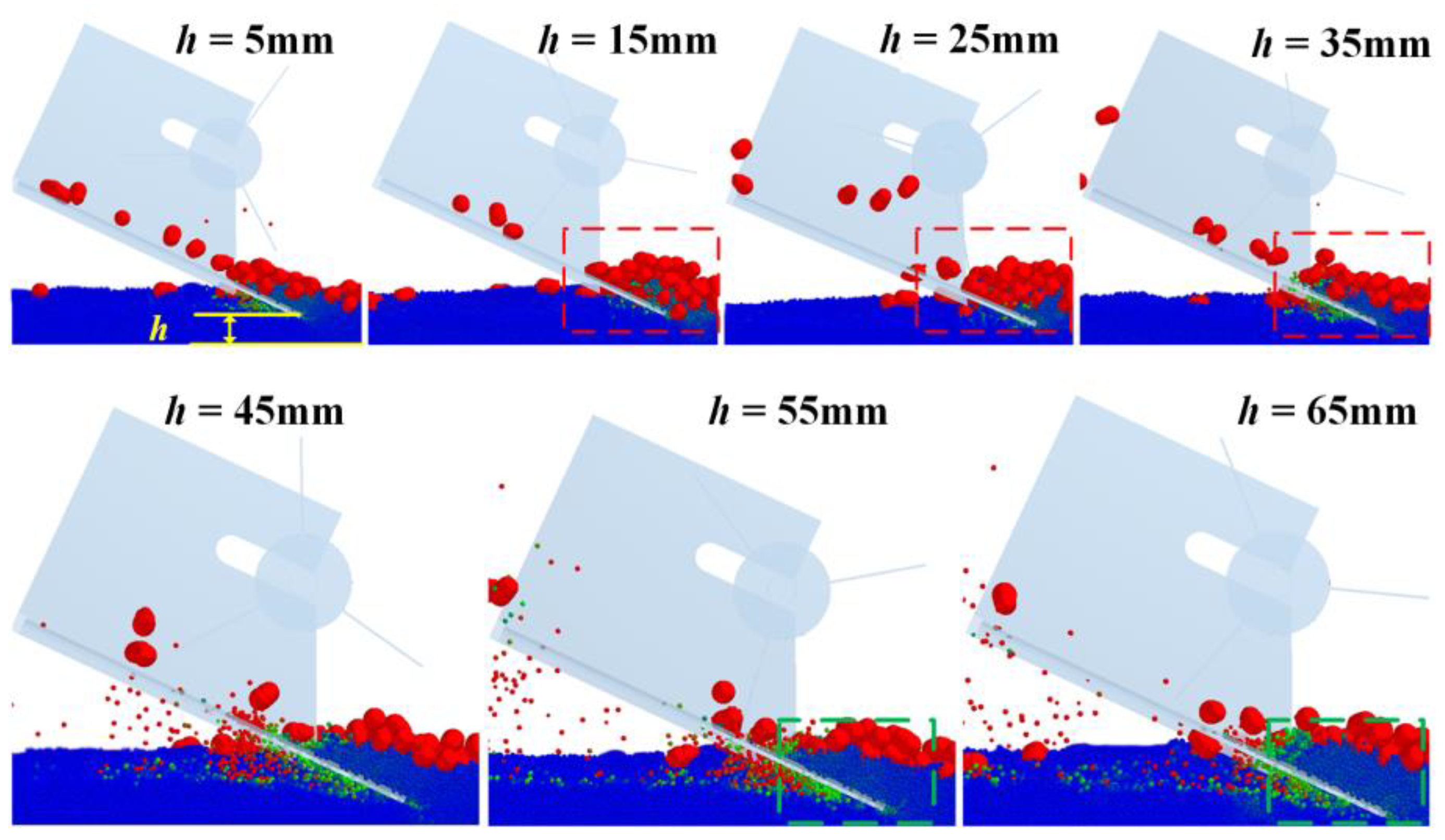

3.1.3. Analysis of a Single-Factor Simulation Test of CWS and DCS

3.2. Field Test Materials

3.3. Field Test Methods

3.4. Analysis of Field Test Results

3.5. Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Fu, W.; Cui, J.; Zhang, H.; Kan, Z.; Wang, L.; Li, J. The research and development of mechanization harvesting technology for forest fruit. Agric. Mech. Res 2016, 38, 264–268. [Google Scholar]

- Fu, W.; He, R.; Qu, J.; Sun, Y.; Wang, L.; Kan, Z. Design of self-propelled dwarf and close planting jujube harvester. Agric. Mech. Res. 2018, 36, 106–109. [Google Scholar]

- Fu, W.; Zhang, Z.; Liu, Y.; Pan, J.; Cui, J.; Ding, K.; Zhang, H. Simulation experiment in lab on force transfer effect of jujube under vibration excitation. Trans. Chin. Soc. Agric. Eng. 2017, 33, 65–72. [Google Scholar]

- Zhang, Z.Y. Optimization Design and Experiment of Jujube Exciter Based on Dynamics Similarity Theory; Shihezi University: Xinjiang, China, 2019. [Google Scholar]

- Shi, G.; Li, J.; Kan, Z.; Ding, L.; Ding, H.; Zhou, L.; Wang, L. Design and Parameters Optimization of a Provoke-Suction Type Harvester for Ground Jujube Fruit. Agriculture 2022, 12, 409. [Google Scholar] [CrossRef]

- Dong, Y.; Li, B.; Liu, Y.; Wang, T.; Wang, S.; Liu, X. Present Research Situation and Development Suggestion for Red Jujube Harvest Mechinery in Xinjiang. Xinjiang Agric. Mech. 2022, 04, 25–29. [Google Scholar]

- Yao, S.; Shi, G.; Wang, B.; Peng, H.; Meng, H.; Kan, Z. Calibration of the simulation parameters of jujubes in dwarfing and closer cultivation in Xinjiang during harvest period. Int. J. Agric. Biol. Eng. 2022, 15, 256–264. [Google Scholar] [CrossRef]

- Lu, G.; Third, J.R.; Müller, C.R. Discrete element models for non-spherical particle systems: From theoretical developments to applications. Chem. Eng. Sci. 2015, 127, 425–465. [Google Scholar] [CrossRef]

- Sinnott, M.D.; Cleary, P.W. The effect of particle shape on mixing in a high shear mixer. Comput. Part. Mech. 2016, 3, 477–504. [Google Scholar] [CrossRef]

- Dai, F.; Guo, W.; Song, X.; Shi, R.; Zhao, W.; Zhang, F. Design and test of crosswise belt type whole plastic-film ridging-mulching corn seeder on double ridges. Int. J. Agric. Biol. Eng. 2019, 12, 88–96. [Google Scholar] [CrossRef]

- He, H.; Wang, Z.; Guo, L.; Zheng, X.; Zhang, J.; Li, W.; Fan, B. Distribution characteristics of residual film over a cotton field under long-term film mulching and drip irrigation in an oasis agroecosystem. Soil Tillage Res. 2018, 180, 194–203. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, J.; Wang, X.; Zhao, Y.; Xue, S.; Su, Z. Parameters Optimization and Test of an arc-shaped nail-tooth roller type recovery machine for sowing layer residual film. Agriculture 2022, 12, 660. [Google Scholar] [CrossRef]

- Zhao, S.; Gao, L.; Yuan, Y.; Hou, L.; Zhang, X.; Yang, Y. Maize straw motion law in subsoiling operation using discrete element method. Trans. Chin. Soc. Agric. Eng. 2021, 37, 53–62. [Google Scholar]

- Hou, J.; Chen, Y.; Li, Y.; Li, T.; Li, G.; Guo, H. Design and experiment of shovel-screen combined green onion digging, shaking, and soil tillage device. Trans. Chin. Soc. Agric. Eng. 2021, 37, 29–39. [Google Scholar]

- Zhao, S.; Liu, H.; Hou, L.; Zhang, X.; Yuan, Y.; Yang, Y. Development of deep fertilizing no-tillage segmented maize sowing opener using discrete element method. Trans. Chin. Soc. Agric. Eng. 2021, 37, 1–10. [Google Scholar]

- Rao, H.; Wang, Y.; Li, Q.; Wang, B.; Yang, J.; Liu, M. Design and experiment of camellia fruit layered harvesting device. Trans. Chin. Soc. Agric. Mach. 2021, 52, 203–212. [Google Scholar]

- Wang, C.; Ding, L.; Dou, F.; Kan, Z.; Li, F.; Li, J. Design and experiment of comb type picking device of ground jujube. Shihezi Univ. Nat. Sci. 2021, 39, 409–414. [Google Scholar]

- Zhang, Z.; Wang, H.; Li, Y.; Yang, X.; Ibrahim, I.; Zhang, Z. Design and experiment of multi-stage separation buffer potato harvester. Trans. Chin. Soc. Agric. Mach. 2021, 52, 96–109. [Google Scholar]

- Shi, G.; Li, J.; Ding, L.; Zhang, Z.; Ding, H.; Li, N.; Kan, Z. Calibration and Tests for the Discrete Element Simulation Parameters of Fallen Jujube Fruit. Agriculture 2022, 12, 38. [Google Scholar] [CrossRef]

- Zhou, L.; Li, J.; Ding, L.; Ding, H.; Shi, G.; Li, D. Design and evaluation of a mechanical floor-standing jujube picker. Agriculture 2022, 12, 1203. [Google Scholar] [CrossRef]

- Gill, W.R.; VandenBerg, G.E. Soil Dynamics in Tillage and Traction; China Agricultural Machinery Press: Beijing, China, 1983; pp. 143–149. [Google Scholar]

- Liu, L.; Ma, C.; Liu, Z. EDEM-based parameter optimization and experiment of full-layer fertilization shovel for strip subsoiling. Trans. Chin. Soc. Agric. Mach. 2021, 52, 74–83. [Google Scholar]

- Zhao, J.; Zhang, J. Design and implementation of land flatness evaluation system based on laser sensor. Agric. Mech. Res. 2012, 34, 83–85. [Google Scholar]

- Zhang, R.; Han, D.; Ji, Q.; He, Y.; Li, J. Calibration methods of sandy soil parameters in simulation of discrete element method. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2017, 48, 49–56. [Google Scholar]

- Fang, H.M. Research on the Straw-Soil-Rotary Blade Interaction Using Discrete Element Method; Nanjing Agricultural University: Nanjing, China, 2016. [Google Scholar]

- Ding, Q.; Ren, J.; Belal, E.A.; Zhao, J.; Ge, S.; Li, Y. DEM analysis of subsoiling process in wet clayey paddy soil. Trans. Chin. Soc. Agric. Mach. 2017, 48, 38–48. [Google Scholar]

- Song, Z.; Li, H.; Yan, Y.; Tian, F.; Li, Y.; Li, F. Calibration method of contact characteristic parameters of soil in mulberry field based on unequal-diameter particles DEM theory. Trans. Chin. Soc. Agric. Mach. 2022, 53, 21–33. [Google Scholar]

- Wu, M.; Cong, J.; Yan, Q.; Zhu, T.; Peng, X.; Wang, Y. Calibration and experiments for discrete element simulation parameters of peanut seed particles. Trans. Chin. Soc. Agric. Eng. 2020, 36, 30–38. [Google Scholar]

- Tong, J.; Jiang, X.; Wang, Y.; Ma, Y.; Li, W.; Sun, Y. Tillage force and disturbance characteristics of different geometric-shaped subsoilers via DEM. Adv. Manuf. 2020, 8, 392–404. [Google Scholar] [CrossRef]

- Hang, C.; Huang, Y.; Zhu, R. Analysis of the movement behaviour of soil between subsoilers based on the discrete element method. J. Terramech. 2017, 74, 35–43. [Google Scholar] [CrossRef]

- Huo, X.C. The Experimental Research on Discrete Element Analysis Parameters of the Agaricus Bisporus Seeds and the Seed Metering Device Optimization; Chinese Academy of Agricultural Sciences: Beijing, China, 2019. [Google Scholar]

- Li, L.; Chen, J.; Ma, C.; Meng, H.; Qi, J.; Li, Y.; Zhang, P. Study on soil throwing performance and ditch depth stability of ditching device in sandy orchards in southern Xinjiang. Appl. Sci. 2022, 24, 12058. [Google Scholar] [CrossRef]

- Wang, C.X. Experimental Study and Parameter Optimization of Comb-Brush Roller Type Picking Device of Ground Jujube; Shihezi University: Xinjiang, China, 2021. [Google Scholar]

- Shi, G.; Li, J.; Ding, L.; Kan, Z. Design and Experiment of Inertia Pneumatic Type Cleaner System of Jujube Fruit. Trans. Chin. Soc. Agric. Mach. 2022, 53, 167–176. [Google Scholar]

| Parameters | Value |

|---|---|

| Poisson’s ratio of sandy soil | 0.3 [19,32,33] |

| Sandy soil shear modulus/Pa | 1.15 × 107 [19,32,33] |

| Density of sandy soil/kg·m−3 | 1379.07 [19,32,33] |

| Poisson’s ratio of steel | 0.3 [19,33] |

| Steel shear modulus/Pa | 7.0 × 107 [19,33] |

| Steel density/kg·mm−3 | 7850 [19,33] |

| Jujube Poisson’s ratio | 0.248 [19,33] |

| Jujube Density/kg·m−3 | 807.87 [19,33] |

| Shear modulus of jujubes/Pa | 6 × 104 [19,33] |

| Sandy soil-sandy soil Recovery Factor | 0.229 * |

| Sandy soil-sandy soil static friction coefficient | 0.609 * |

| Sandy soil-sandy soil rolling friction coefficient | 0.217 * |

| Sandy soil-steel recovery factor | 0.398 * |

| Sandy soil-steel static friction coefficient | 0.321 * |

| Sandy soil-steel rolling friction coefficient | 0.126 * |

| Jun jujube recovery factor | 0.35 [19] |

| Jun jujube-steel static friction coefficient | 0.309 [19] |

| Jun jujube-steel rolling friction coefficient | 0.035 [19] |

| Jun jujube-Jun jujube recovery factor | 0.25 [19] |

| Jun jujube-Jun jujube static friction coefficient | 0.48 [19] |

| Jun jujube-Jun jujube rolling friction coefficient | 0.04 [19] |

| Sandy soil-Jun jujube recovery factor | 0.33 [33] |

| Sandy soil-Jun jujube static friction coefficient | 0.79 [33] |

| Sandy soil-Jun jujube rolling friction coefficient | 0.16 [33] |

| Test Sequence | CWS/ (m/s) | DCS/mm | Simulation Test Pickup Rate/% | Filed Test-Pickup Rate/% | Relative Error/% |

|---|---|---|---|---|---|

| 1 | 0.2 | 5 | 84.17 | 91.23 | 7.73 |

| 2 | 0.2 | 25 | 94.31 | 93.49 | 0.08 |

| 3 | 0.2 | 45 | 94.97 | 94.52 | 0.47 |

| 4 | 0.3 | 5 | 87.53 | 92.66 | 5.53 |

| 5 | 0.3 | 25 | 96.61 | 95.03 | 1.6 |

| 6 | 0.3 | 45 | 94.34 | 93.69 | 0.69 |

| 7 | 0.4 | 5 | 85.77 | 90.27 | 4.98 |

| 8 | 0.4 | 25 | 94.29 | 94.72 | 0.45 |

| 9 | 0.4 | 45 | 92.82 | 91.78 | 1.13 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, L.; Li, J.; Ding, L.; Ding, H.; Liang, J. Analysis and Design of Operating Parameters of Floor-Standing Jujube Pickup Device Based on Discrete Element Method. Agriculture 2022, 12, 1904. https://doi.org/10.3390/agriculture12111904

Zhou L, Li J, Ding L, Ding H, Liang J. Analysis and Design of Operating Parameters of Floor-Standing Jujube Pickup Device Based on Discrete Element Method. Agriculture. 2022; 12(11):1904. https://doi.org/10.3390/agriculture12111904

Chicago/Turabian StyleZhou, Lun, Jingbin Li, Longpeng Ding, Huizhe Ding, and Junpeng Liang. 2022. "Analysis and Design of Operating Parameters of Floor-Standing Jujube Pickup Device Based on Discrete Element Method" Agriculture 12, no. 11: 1904. https://doi.org/10.3390/agriculture12111904

APA StyleZhou, L., Li, J., Ding, L., Ding, H., & Liang, J. (2022). Analysis and Design of Operating Parameters of Floor-Standing Jujube Pickup Device Based on Discrete Element Method. Agriculture, 12(11), 1904. https://doi.org/10.3390/agriculture12111904