Vibration Characteristics of Corn Combine Harvester with the Time-Varying Mass System under Non-Stationary Random Vibration

Abstract

:1. Introduction

2. Time–Frequency Analysis

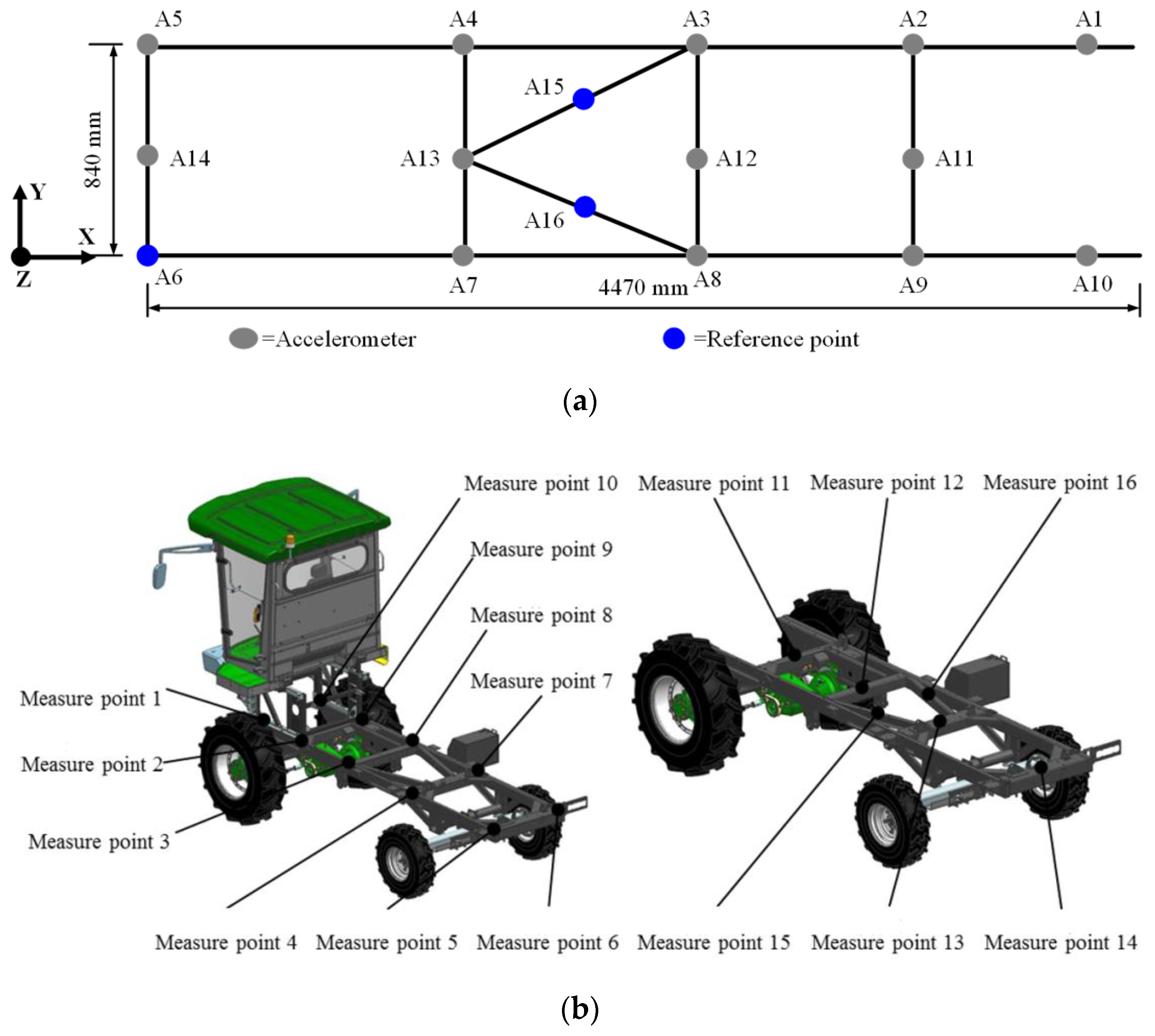

3. Operational Modal Test of Corn Harvester Frame

4. Time and Frequency Domain Characteristics of Harvester’s Vibration Signals

4.1. Time Domain Characteristics of Vibration Signals

4.2. Frequency Domain Characteristics of Non-Stationary Random Vibration Signals

4.2.1. Vibration Frequency Distribution Characteristics of FFT

4.2.2. Vibration Frequency Distribution Characteristics of STFT

4.2.3. Vibration Frequency Distribution Characteristics of CWT

4.2.4. Comparison of Vibration Frequency Distribution Characteristics

5. Correlation ofVibration Frequencies and Modal Frequencies

5.1. Comparison of Primary Frequencies and Modal Frequencies under Harvesting Conditions

5.2. Correlation of Primary Frequencies and Modal Frequencies under Harvesting Condition

6. Conclusions

- (1)

- It was found that the random vibration characteristics of the corn harvester are approximately stationary in running conditions (non-time-varying mass system). The vibration signals in the harvesting operation conform to non-stationary random vibration characteristics (time-varying mass system).

- (2)

- The vibration frequencies of the corn harvester calculated by FFT were relatively dense, and most measurement points had more than 35 frequency peaks in the frequency spectrum. The vibration frequencies obtained by STFT and CWT methods were relatively sparse, with fewer than 30 frequency peaks at the most measurement point.

- (3)

- Under harvesting (time-varying mass) conditions, the increased mass had a negligible effect on vibration frequencies, and the nonlinear relationship between vibration frequencies and mass was not apparent.

- (4)

- Under the non-stationary random characteristics condition, the average correlation degree of the main vibration frequencies obtained by the FFT, STFT, and CWT methods and the modal frequencies were 0.98, 0.99, and 0.98, respectively. The primary frequencies of the STFT method were more likely to correspond with operating modal frequencies. The STFT method was more suitable for analyzing the harvester’s signal.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, X.; Zhao, S.; Song, H.; Xu, L. Research on seat vibration of combine harvester based on operational transmission path analysis. J. Henan Univ. Sci. Technol. 2022, 43, 24–30. [Google Scholar]

- Yao, Y.; Song, Z.; Du, Y.; Zhao, X.; Mao, E.; Liu, F. Analysis of vibration characteristics and its major influenced factors of header for corn combine harvesting machine. Trans. Chin. Soc. Agric. Eng. 2017, 33, 40–49. [Google Scholar]

- Gao, Z.; Xu, L.; Li, Y.; Wang, Y.; Sun, P. Vibration measure and analysis of crawler-type rice and wheat combine harvester in field harvesting condition. Trans. Chin. Soc. Agric. Eng. 2017, 33, 48–55. [Google Scholar]

- Cui, T.; Fan, C.; Zhang, D.; Yang, L.; Li, Y.; Zhao, H. Research progress of maize mechanized harvesting technology. Trans. Chin. Soc. Agric. Mach. 2019, 50, 1–13. [Google Scholar]

- Chen, S.; Zhou, Y.; Tang, Z.; Lu, S. Modal vibration response of rice combine harvester frame under multi-source excitation. Biosyst. Eng. 2020, 194, 177–195. [Google Scholar] [CrossRef]

- Zhu, S.; Xu, G.; Yuan, J.; Ma, J.; Yi, L.; Li, K. Influence of implement’s mass on vibration characteristics of tractor-implement system. Trans. Chin. Soc. Agric. Eng. 2014, 30, 30–37. [Google Scholar]

- Zheng, E.; Zhong, X.; Zhu, R.; Xue, J.; Cui, S.; Gao, H.; Lin, X. Investigation into the vibration characteristics of agricultural wheeled tractor-implement system with hydro-pneumatic suspension on the front axle. Biosyst. Eng. 2019, 186, 14–33. [Google Scholar] [CrossRef]

- Tang, Z.; Zhang, B.; Wang, M.; Zhang, H. Damping behaviour of a prestressed composite beam designed for the thresher of a combine harvester. Biosyst. Eng. 2021, 204, 130–146. [Google Scholar] [CrossRef]

- Akash, B.; Sachin, K.; Anuj Kumar, S.; Ishbir, S. Comparative Study of different Seat Cushion Materials to improve the Comfort of Tractor Seat. J. Inst. Eng. Ser. A 2022, 103, 387–396. [Google Scholar]

- Jannifar, A.; Zubir, M.N.M.; Kazi, S.N. An innovative approach for conducting experimental modal analysis (EMA) in running harmonic for structural modal identification. Measurement 2020, 159, 107795. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, D.; Kong, D.; Huang, B.; Zhang, Z.; He, Y. The anti-fatigue lightweight design of heavy tractor frame based on a modified decision method. Struct. Multidiscip. Optim. 2022, 65, 280. [Google Scholar] [CrossRef]

- Phromjan, J.; Suvanjumrat, C. Vibration effect of two different tires on baggage towing tractors. J. Mech. Sci. Technol. 2018, 32, 1539–1548. [Google Scholar] [CrossRef]

- Ribeiro, D.; Braganca, C.; Costa, C.; Jorge, P.; Silva, R.; Arede, A.; Calcada, R. Calibration of the numerical model of a freight railway vehicle based on experimental modal parameters. Structures 2022, 38, 108–122. [Google Scholar] [CrossRef]

- Watanabe, M.; Sakai, K. Impact dynamics model for a nonlinear bouncing tractor during inclined passage. Biosyst. Eng. 2019, 182, 84–94. [Google Scholar] [CrossRef]

- Watanabe, M.; Sakai, K. Novel power hop model for an agricultural tractor with coupling bouncing, stick-slip, and free-play Dynamics. Biosyst. Eng. 2021, 204, 156–169. [Google Scholar] [CrossRef]

- Shao, X.; Zheng, B.; Luo, Z.; Song, Z. Establishment and Validation of a Structural Dynamics Model with Power Take-Off Driveline for Agricultural Tractors. Agriculture 2022, 12, 1297. [Google Scholar] [CrossRef]

- Li, Y.; Sun, P.; Pang, J.; Xu, L. Finite element mode analysis and experiment of combine harvester chassis. Trans. Chin. Soc. Agric. Eng. 2013, 29, 38–46. [Google Scholar]

- Chen, K.; Lu, X.; Jin, S.; Li, L.; He, X.; Wang, T.; Mi, G.; Shi, Y.; Li, W. Design of and Experiments with an Automatic Cuttage Device for an Arch Shed Pillar with Force Feedback. Agriculture 2022, 12, 875. [Google Scholar] [CrossRef]

- Zhan, G.; Ma, L.; Zong, W.; Liu, W.; Deng, D.; Lian, G. Study on the Vibration Characteristics of Rape Plants Based on High-Speed Photography and Image Recognition. Agriculture 2022, 12, 727. [Google Scholar] [CrossRef]

- Wu, D.; Zhao, E.; Fang, D.; Jiang, S.; Wu, C.; Wang, W.; Wang, R. Determination of Vibration Picking Parameters of Camellia oleifera Fruit Based on Acceleration and Strain Response of Branches. Agriculture 2022, 12, 1222. [Google Scholar] [CrossRef]

- Zhao, J.; Tsuchikawa, S.; Ma, T.; Hu, G.; Chen, Y.; Wang, Z.; Chen, Q.; Gao, Z.; Chen, J. Modal Analysis and Experiment of a Lycium barbarum L. Shrub for Efficient Vibration Harvesting of Fruit. Agriculture 2021, 11, 519. [Google Scholar] [CrossRef]

- Li, Y.; Pang, J.; Xu, L.; Tang, Z.; Zhou, Y. Manufacturing defect location of cleaning screen of grain combine harvester based on vibration excitation tracing. Trans. Chin. Soc. Agric. Eng. 2019, 35, 10–17. [Google Scholar]

- Pang, J.; Li, Y.; Ji, J.; Xu, L. Vibration excitation identification and control of the cutter of a combine harvester using triaxial accelerometers and partial coherence sorting. Biosyst. Eng. 2019, 185, 25–34. [Google Scholar] [CrossRef]

- Geng, L.; Li, K.; Pang, J.; Jin, X.; Ji, J. Test and analysis of vibration characteristics of transplanting machine based on time frequency and power spectral density. Trans. Chin. Soc. Agric. Eng. 2021, 37, 23–30. [Google Scholar]

- Zhou, S.D.; Ma, Y.C.; Kang, J.; Ma, Z.S.; Yu, L. Output-only modal parameter estimator of linear time-varying structural system based on vector TAR model and least squares support vector machine. Mech. Syst. Signal Process. 2018, 98, 722–755. [Google Scholar] [CrossRef]

- Reynders, E. System identification methods for (operational) modal analysis: Review and comparison. Arch. Comput. Methods Eng. 2012, 19, 51–124. [Google Scholar] [CrossRef]

- Ma, Z.; Ding, Q.; Liu, L.; Zhou, S. Research progress on time-domain modal parameter estimation methods for linear time-varying structure. J. Mech. Eng. 2018, 54, 137–159. [Google Scholar] [CrossRef]

- Ebrahimi, R.; Esfahanian, M.; Ziaei-Rad, S. Vibration modeling and modification of cutting platform in a harvest combine by means of operational modal analysis(OMA). Measurement 2013, 46, 3959–3967. [Google Scholar] [CrossRef]

- Yao, Y.; Zhao, X.; Du, Y.; Song, Z.; Yin, Y.; Mao, E.; Liu, F. Operating modal analysis and test of harvester induced by mass-varying process. Trans. Chin. Soc. Agric. Eng. 2018, 34, 83–94. [Google Scholar]

- Reynders, E.P. Uncertainty quantification in data-driven stochastic subspace identification. Mech. Syst. Signal Process. 2021, 151, 107338. [Google Scholar] [CrossRef]

- Ren, Z.; Liu, Z. Vibration and frequency domain characteristics of high speed EMU. J. Jilin Mech. Eng. 2013, 49, 1–7. [Google Scholar] [CrossRef]

- Zha, H.; Ren, Z.; Xu, N. Impact characteristics of axle box bearing due to wheel flat scars. J. Traffic Transp. Eng. 2020, 20, 165–173. [Google Scholar]

- Adam, S.A.; Abdul, N.; Rezali, K.; Ng, Y.G. The effect of posture and vibration magnitude on the vertical vibration transmissibility of tractor suspension system. Int. J. Ind. Ergon. 2020, 80, 10314. [Google Scholar] [CrossRef]

- Hartmann, T.; Morita, S.; Tanner, G.; Chappel, D.J. High-frequency structure- and air-borne sound transmission for a tractor model using Dynamical Energy Analysis. Wave Motion 2019, 87, 132–150. [Google Scholar] [CrossRef] [Green Version]

- Ji, J.; Xu, L.; Pang, J.; Geng, L.; Wang, X. Analysis of minimum amplitude points and optimization of connection position for header of micro grain combine. Trans. Chin. Soc. Agric. Eng. 2017, 33, 28–33. [Google Scholar]

- Wahab, M.; Gritti, F.; O’Haver, T. Discrete Fourier transform techniques for noise reduction and digital enhancement of analytical signals. Trends Anal. Chem. 2021, 143, 116354. [Google Scholar] [CrossRef]

- Stankovic, L.; Alieva, T.; Bastiaans, M. Time-frequency signal analysis base on the windowed fractional Fourier transform. Signal Process. 2003, 83, 2459–2468. [Google Scholar] [CrossRef]

- Yochum, M.; Renaud, C.; Jacquir, S. Automatic detection of P.QRS and patterns in 12 leads ECK signal base on CWT. Biomed. Signal Process. 2016, 25, 25–46. [Google Scholar] [CrossRef]

- Gao, L.; Li, X.; Yao, Y.; Wang, Y.; Yang, X.; Zhao, X.; Geng, D.; Li, Y.; Liu, L. AModal Frequency Estimation Method of Non-Stationary Signal under Mass Time-Varying Condition Based on EMD Algorithm. Appl. Sci. 2022, 12, 8187. [Google Scholar] [CrossRef]

- Zhang, X.L.; Wang, S.L.; Gao, L.; Sun, Y.C.; Zhao, X.Y.; Yao, Y.C. Vibration test and analysis of silage corn harvesting machine based on smooth random signal. J. Chin. Agric. Mech. 2021, 42, 23–29. [Google Scholar]

- Wang, H.Y.; Qiu, T.S. Unified classification methods for determinate non-stationary signals and random non-stationary signals. J. Commun. 2015, 36, 5–14. [Google Scholar]

| Orders | Enhanced Frequency Domain Decomposition (EFDD) | |

|---|---|---|

| Modal Frequency (Hz) | Damp Ratio (%) | |

| 1 | 21.868 | 1.111 |

| 2 | 29.300 | 0.410 |

| 3 | 39.151 | 0.568 |

| 4 | 45.409 | 0.804 |

| 5 | 54.627 | 0.516 |

| 6 | 59.241 | 0.996 |

| 7 | 64.934 | 0.881 |

| 8 | 77.970 | 0.446 |

| 9 | 79.786 | 0.574 |

| 10 | 84.618 | 0.880 |

| 11 | 97.723 | 0.609 |

| 12 | 109.371 | 0.632 |

| 13 | 117.189 | 0.458 |

| 14 | 122.542 | 0.493 |

| 15 | 136.669 | 0.460 |

| 16 | 141.625 | 0.441 |

| 17 | 150.614 | 0.471 |

| 18 | 156.156 | 0.447 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, Y.; Li, X.; Yang, Z.; Li, L.; Geng, D.; Huang, P.; Li, Y.; Song, Z. Vibration Characteristics of Corn Combine Harvester with the Time-Varying Mass System under Non-Stationary Random Vibration. Agriculture 2022, 12, 1963. https://doi.org/10.3390/agriculture12111963

Yao Y, Li X, Yang Z, Li L, Geng D, Huang P, Li Y, Song Z. Vibration Characteristics of Corn Combine Harvester with the Time-Varying Mass System under Non-Stationary Random Vibration. Agriculture. 2022; 12(11):1963. https://doi.org/10.3390/agriculture12111963

Chicago/Turabian StyleYao, Yanchun, Xiaoke Li, Zihan Yang, Liang Li, Duanyang Geng, Peng Huang, Yongsheng Li, and Zhenghe Song. 2022. "Vibration Characteristics of Corn Combine Harvester with the Time-Varying Mass System under Non-Stationary Random Vibration" Agriculture 12, no. 11: 1963. https://doi.org/10.3390/agriculture12111963