Research on Dynamic Load Characteristics of Advanced Variable Speed Drive System for Agricultural Machinery during Engagement

Abstract

:1. Introduction

2. Materials and Methods

2.1. Reference Data Analysis Method Based on PLS

2.2. Test Bench for Dynamic Load Characteristic Measurement

2.3. Dynamic Load Characteristics Test and Data Acquisition

2.4. Establish and Compare Multiple Dynamic Load Characteristic Models Based on I-SA

2.5. The Establishment Method of Tractor Dynamic Load MAP under Three Working Conditions

3. Results and Discussion

3.1. Data Analysis of References Based on PLS

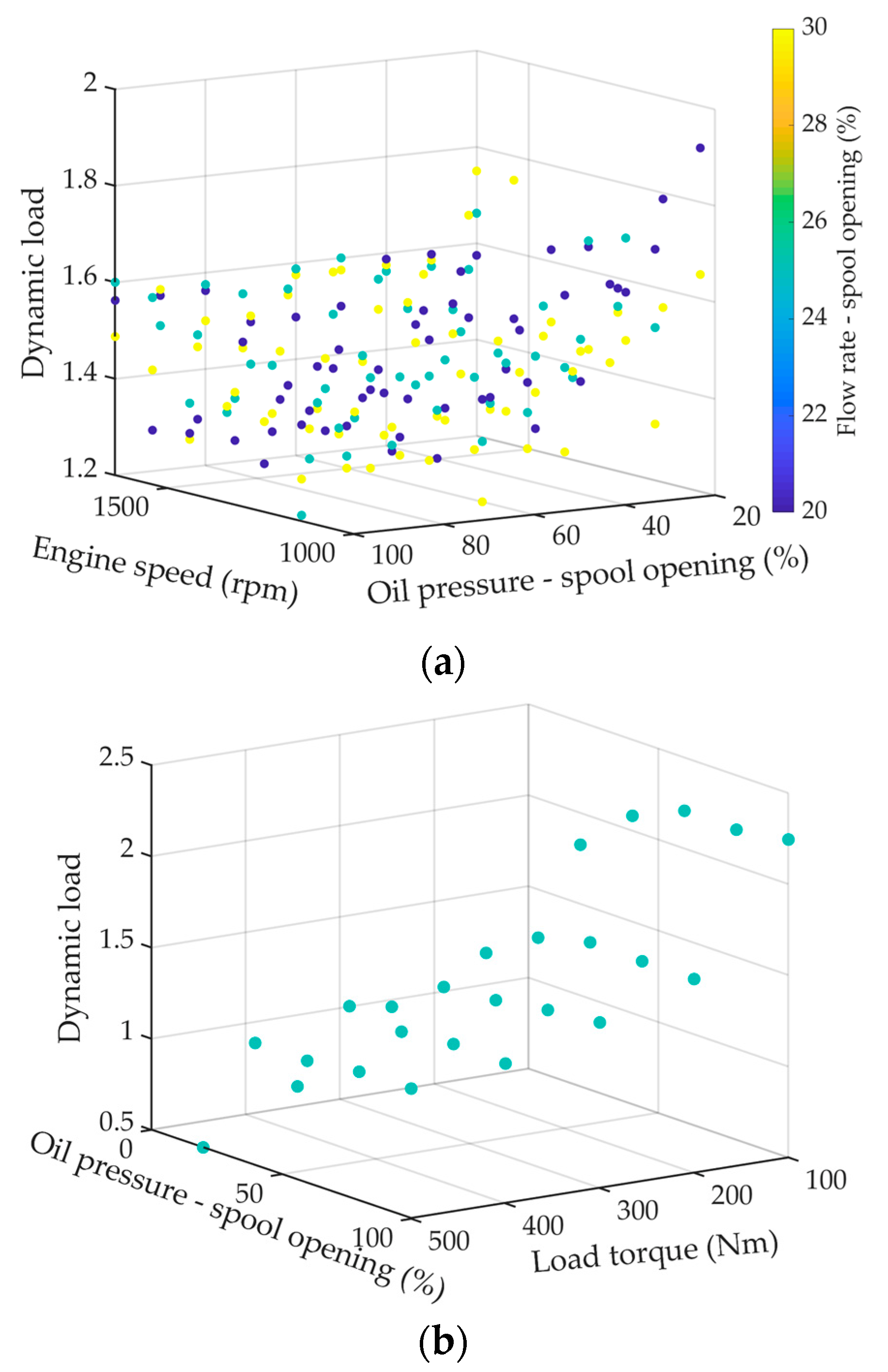

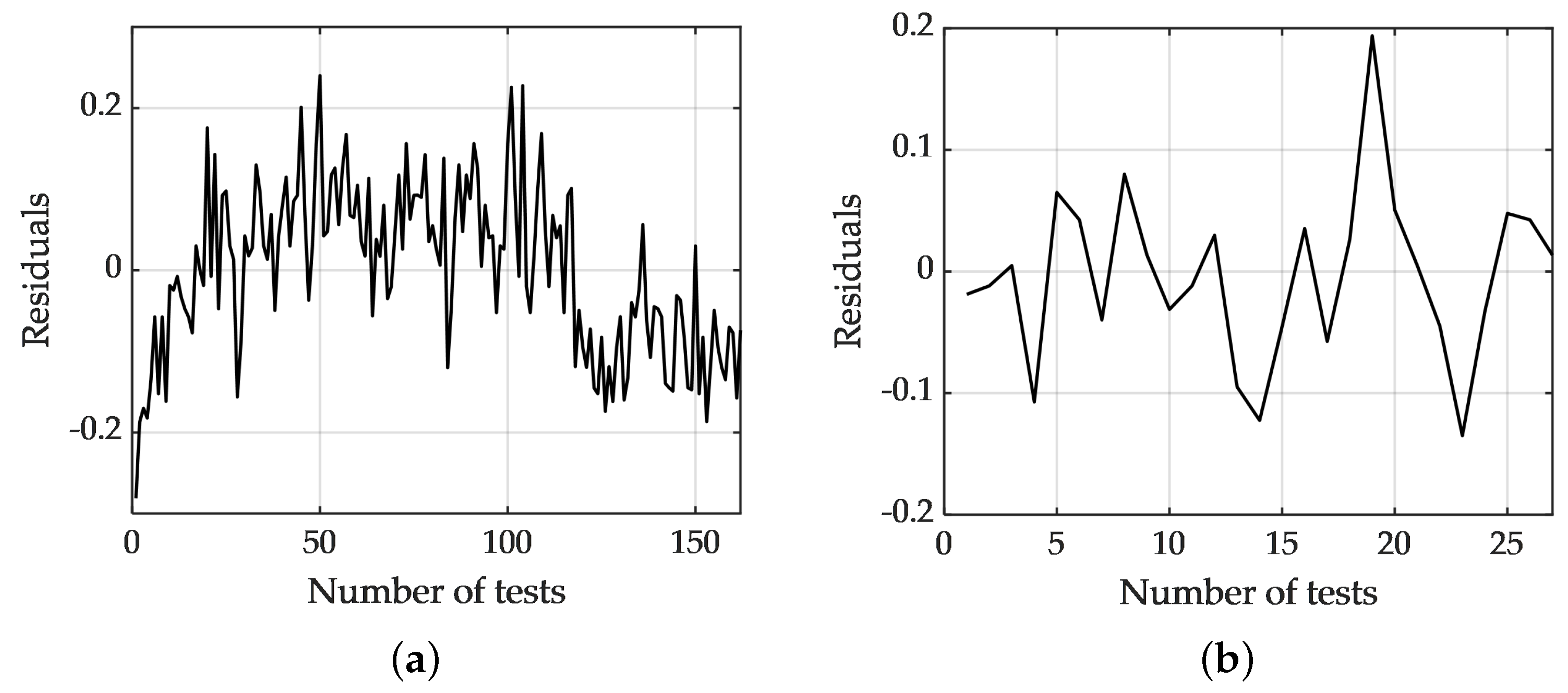

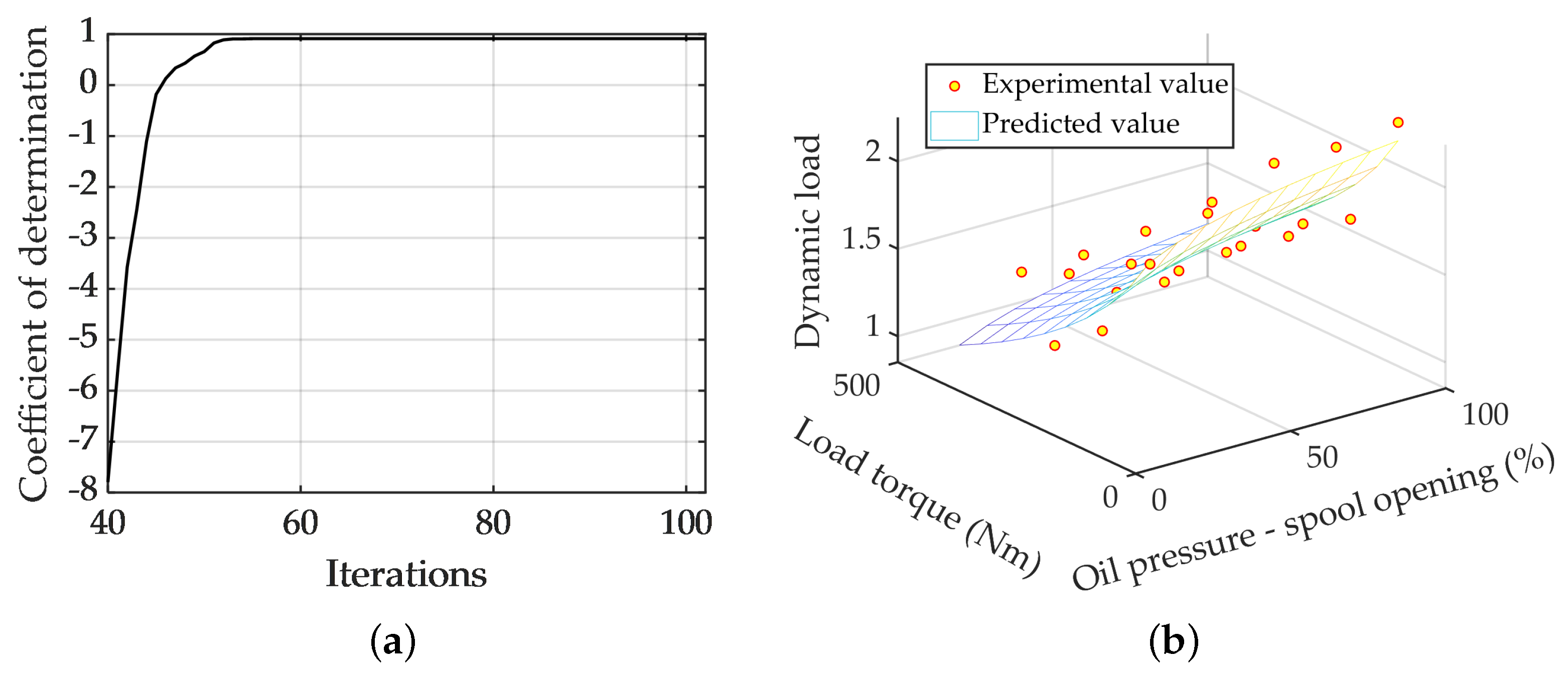

3.2. Establishment and Analysis of Dynamic Load Model under Low Load

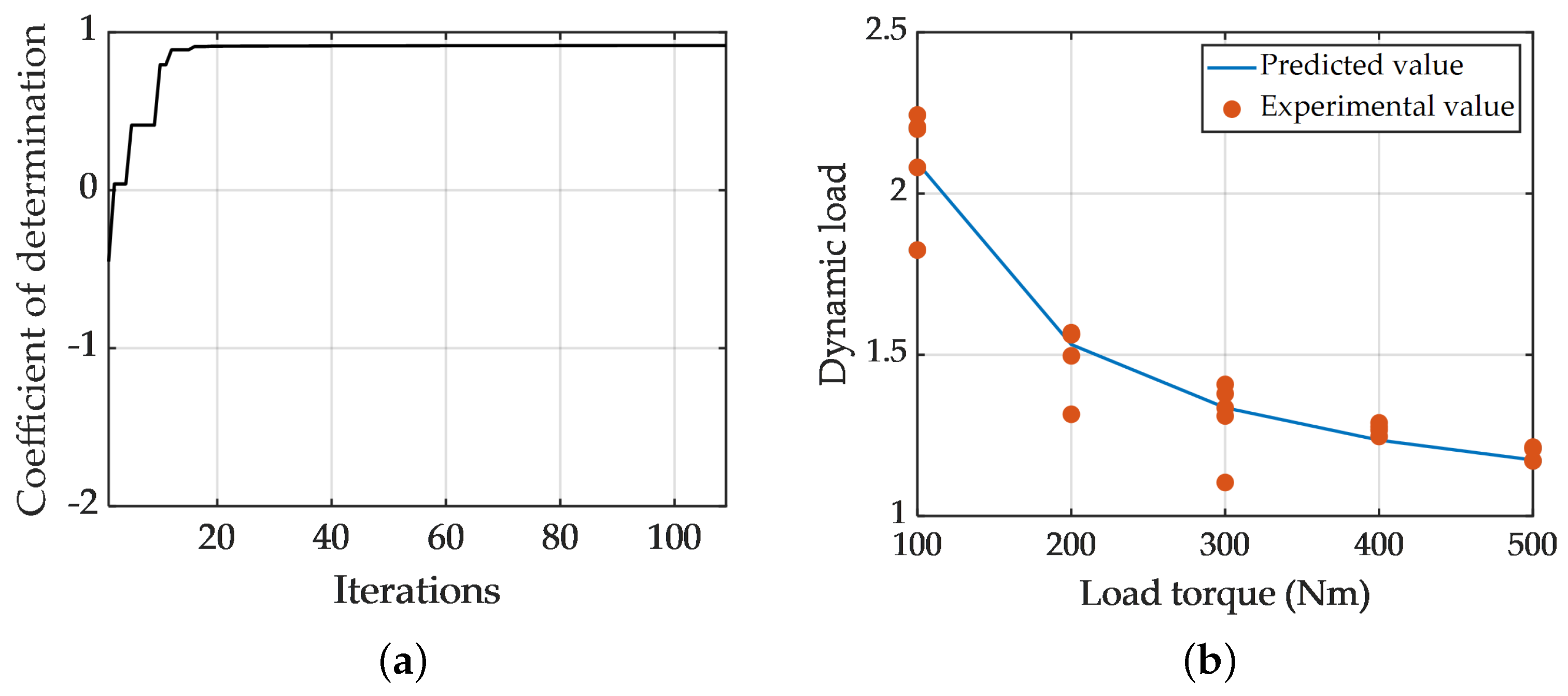

3.3. Establishment and Analysis of Dynamic Load Model under Medium and High Load

3.4. Acquisition and Analysis of Dynamic Load Characteristics MAP of Tractor under Three Working Conditions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cheng, Z.; Lu, Z.; Qian, J. A new non-geometric transmission parameter optimization design method for HMCVT based on improved GA and maximum transmission efficiency. Comput. Electron. Agric. 2019, 167, 105034. [Google Scholar] [CrossRef]

- Wang, J.Y.; Xia, C.G.; Fan, X.; Cai, J.Y. Research on transmission characteristics of hydromechanical continuously variable transmission of tractor. Math. Probl. Eng. 2020, 2020, 6978329. [Google Scholar] [CrossRef]

- Jenane, C.; Bashford, L.L. Tractive performance of a mechanical front-wheel assist tractor as related to forward speeds. J. Agric. Eng. Res. 2000, 77, 221–226. [Google Scholar] [CrossRef]

- Lu, L.Q.; Zhou, Y.Q.; Li, H.; Wang, Y.; Yin, Y.F.; Zhao, J. Electro-hydraulic shift quality of power shift transmission of heavy duty tractor. Trans. Chin. Soc. Agric. Mach. 2020, 51, 550–556, 602. [Google Scholar]

- Xi, Z.Q.; Zhou, Z.L.; Zhang, M.Z.; Cao, Q.M. Shift characteristics and control strategy of powershift transmission on tractor. Trans. Chin. Soc. Agric. Mach. 2016, 47, 350–357. [Google Scholar]

- Wan, L.R.; Dai, H.Z.; Zeng, Q.L.; Sun, Z.Y.; Tian, M.Q. Characteristic analysis and co-validation of hydro-mechanical continuously variable transmission based on the wheel loader. Appl. Sci. 2020, 10, 5900. [Google Scholar] [CrossRef]

- Zhu, Z.; Gao, X.; Cao, L.L.; Cai, Y.M.; Pan, D.Y. Research on the shift strategy of HMCVT based on the physical parameters and shift time. Appl. Math. Model. 2016, 40, 6889–6907. [Google Scholar] [CrossRef]

- Li, T.H.; Xie, B.; Li, Z.; Li, J.K. Design and optimization of a dual-input coupling powertrain system: A case study for electric tractors. Appl. Sci. 2020, 10, 1608. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.N.; Xie, B.; Du, Y.F.; Mao, E.R. Powertrain parameter matching and optimal design of dual-motor driven electric tractor. Int. J. Agric. Biol. Eng. 2019, 12, 33–41. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Qian, Y.; Lu, Z.; Zhou, S.; Xiao, M.; Bartos, P.; Xiong, Y.; Jin, G.; Zhang, W. Dynamic characteristic analysis and clutch engagement test of HMCVT in the high-power tractor. Complexity 2021, 2021, 8891127. [Google Scholar] [CrossRef]

- Han, H.W.; Han, J.S.; Chung, W.J.; Kim, J.T.; Park, Y.J. Prediction of synchronization time for tractor power-shift transmission using multi-body dynamic simulation. Trans. ASABE 2021, 64, 1483–1498. [Google Scholar] [CrossRef]

- Raikwar, S.; Tewari, V.K.; Mukhopadhyay, S.; Verma, C.R.B.; Rao, M.S. Simulation of components of a power shuttle transmission system for an agricultural tractor. Comput. Electron. Agric. 2015, 114, 114–124. [Google Scholar] [CrossRef]

- Li, B.G.; Sun, D.Y.; Hu, M.H.; Liu, J.L. Automatic starting control of tractor with a novel power-shift transmission. Mech. Mach. Theory 2019, 131, 75–91. [Google Scholar] [CrossRef]

- Tan, L.D.; Zong, X.J.; Chang, Z.Y.; Wang, Y.B.; Chen, D.H. Design and test of biomimetic wear resistant for wet clutch friction plate for heavy tractor. Trans. Chin. Soc. Agric. Eng. 2018, 34, 54–59. [Google Scholar]

- Song, Y.; Liu, F.P.; Wang, G.M.; Han, M.M.; Huang, D.M.; Song, G.M. Design of hydraulic test bench for big-power wet clutch shifting tractor. J. Chin. Agric. Mech. 2019, 40, 78–84. [Google Scholar]

- Qian, Y.; Cheng, Z.; Lu, Z.X. Bench testing and modeling analysis of optimum shifting point of HMCVT. Complexity 2021, 2021, 6629561. [Google Scholar] [CrossRef]

- Lu, K.; Lu, Z.X.; Cheng, Z.; Zheng, S.Q. Study on influence rules of clutch parameters on HMCVT shift performance. Mech. Sci. Technol. Aerosp. Eng. 2019, 38, 1695–1701. [Google Scholar]

- Wang, G.M.; Zhang, X.H.; Zhu, S.H.; Zhang, H.J.; Tai, J.J.; Nguyen, V. Shift performance of tractor hydraulic power-split continuously variable transmission. Trans. Chin. Soc. Agric. Mach. 2015, 46, 7–15. [Google Scholar]

- Qian, Y.; Cheng, Z.; Lu, Z.X. Study on stepwise regression optimization of shift quality of heavy-duty tractor HMCVT based on five factors. J. Nanjing Agric. Univ. 2020, 43, 564–573. [Google Scholar]

- Xu, L.Y.; Liu, H.L.; Zhou, Z.L.; Wang, X.B. Evaluation indexes of shifting quality for dual clutch transmission for tractor. Trans. Chin. Soc. Agric. Eng. 2015, 31, 48–53. [Google Scholar]

- Ni, X.D.; Zhu, S.H.; Zhang, H.J.; Chang, Y.L.; Ouyang, D.Y.; Wang, G.M. Experiment of shift quality factors for hydro-mechanical CVT. Trans. Chin. Soc. Agric. Mach. 2013, 44, 29–34. [Google Scholar]

- Wang, G.M. Study on Characteristics, Control and Fault Diagnosis of Tractor Hydro-Mechanical CVT; Nanjing Agricultural University: Nanjing, China, 2014. [Google Scholar]

- Wang, G.M.; Zhu, S.H.; Shi, L.X.; Tao, H.L.; Nguyen, V. Experimental optimization on shift control of hydraulic mechanical continuously variable transmission for tractor. Trans. Chin. Soc. Agric. Eng. 2013, 29, 51–59. [Google Scholar]

- Yu, L.; Ma, B.; Chen, M.; Xue, J.Q.; Zhao, P.Y. Variation mechanism of the friction torque in a Cu-based wet clutch affected by operating parameters. Tribol. Int. 2020, 147, 106169. [Google Scholar] [CrossRef]

- Park, J.; Choi, S.; Oh, J.; Eo, J. Adaptive torque tracking control during slip engagement of a dry clutch in vehicle powertrain. Mech. Mach. Theory 2019, 134, 249–266. [Google Scholar] [CrossRef]

- Xia, L. Analysis of partial least squares modeling and multi-collinearity ability. Agro Food Ind. Hi-Tech 2017, 28, 885–889. [Google Scholar]

- Xu, Q.S.; Liang, Y.Z.; Shen, H.L. Generalized PLS regression. J. Chemom. 2001, 15, 135–148. [Google Scholar] [CrossRef]

- Cheng, Z.; Lu, Z.X. Research on load disturbance based variable speed PID control and a novel denoising method based effect evaluation of HST for agricultural machinery. Agriculture 2021, 11, 960. [Google Scholar] [CrossRef]

- Cheng, Z.; Lu, Z.X. Research on the PID control of the ESP system of tractor based on improved AFSA and improved SA. Comput. Electron. Agric. 2018, 148, 142–147. [Google Scholar] [CrossRef]

- Cheng, Z.; Lu, Z.X.; Dai, F. Research on HMCVT efficiency model based on the improved SA algorithm. Math. Probl. Eng. 2019, 2019, 2856908. [Google Scholar] [CrossRef]

| Factors | Oil Pressure (Opening of Valve Core/%) | Rotational Speed of Engine (rpm) | Flow Rate (Opening of Valve Core/%) | Load (Nm) |

|---|---|---|---|---|

| Test 1 | 9 levels (20–100%) | 7 levels (1040–1640 rpm) | 3 levels (50–100%) | - |

| Test 2 | 5 levels (20–100%) | - | - | 5 levels (100–500 Nm) |

| Mass of the Whole Vehicle/kg | Radius of Driving Wheel/m | Coefficient of Air Resistance | Frontal Area/m2 | Maximum Trailer Mass/kg | Coefficient of Rolling Resistance | Speed Ratio of Variable Speed System | Soil Specific Resistance/kPa | Width of a Single Plough/cm |

|---|---|---|---|---|---|---|---|---|

| 1635 | 0.64 | 0.9 | 3.135 | 3000 | 0.05 | 9 | 50 | 25 |

| Model | a0 | a1 | a2 | a3 | a4 | a5 | R2 | MAPE (%) |

|---|---|---|---|---|---|---|---|---|

| 1 | −1.368 | 1.419 | 0.0000132 | −0.0195 | 0.00144 | - | 0.9122 | 6.2806 |

| 2 | 2.299 | 0.00809 | −0.00655 | −0.0000231 | −0.00000892 | 0.00000827 | 0.9545 | 4.1938 |

| 3 | 0.906 | 84.497 | −0.926 | - | - | - | 0.9164 | 4.5929 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, Z.; Lu, Z. Research on Dynamic Load Characteristics of Advanced Variable Speed Drive System for Agricultural Machinery during Engagement. Agriculture 2022, 12, 161. https://doi.org/10.3390/agriculture12020161

Cheng Z, Lu Z. Research on Dynamic Load Characteristics of Advanced Variable Speed Drive System for Agricultural Machinery during Engagement. Agriculture. 2022; 12(2):161. https://doi.org/10.3390/agriculture12020161

Chicago/Turabian StyleCheng, Zhun, and Zhixiong Lu. 2022. "Research on Dynamic Load Characteristics of Advanced Variable Speed Drive System for Agricultural Machinery during Engagement" Agriculture 12, no. 2: 161. https://doi.org/10.3390/agriculture12020161

APA StyleCheng, Z., & Lu, Z. (2022). Research on Dynamic Load Characteristics of Advanced Variable Speed Drive System for Agricultural Machinery during Engagement. Agriculture, 12(2), 161. https://doi.org/10.3390/agriculture12020161