Device and Method Suitable for Matching and Adjusting Reel Speed and Forward Speed of Multi-Crop Harvesting

Abstract

:1. Introduction

2. Materials and Methods

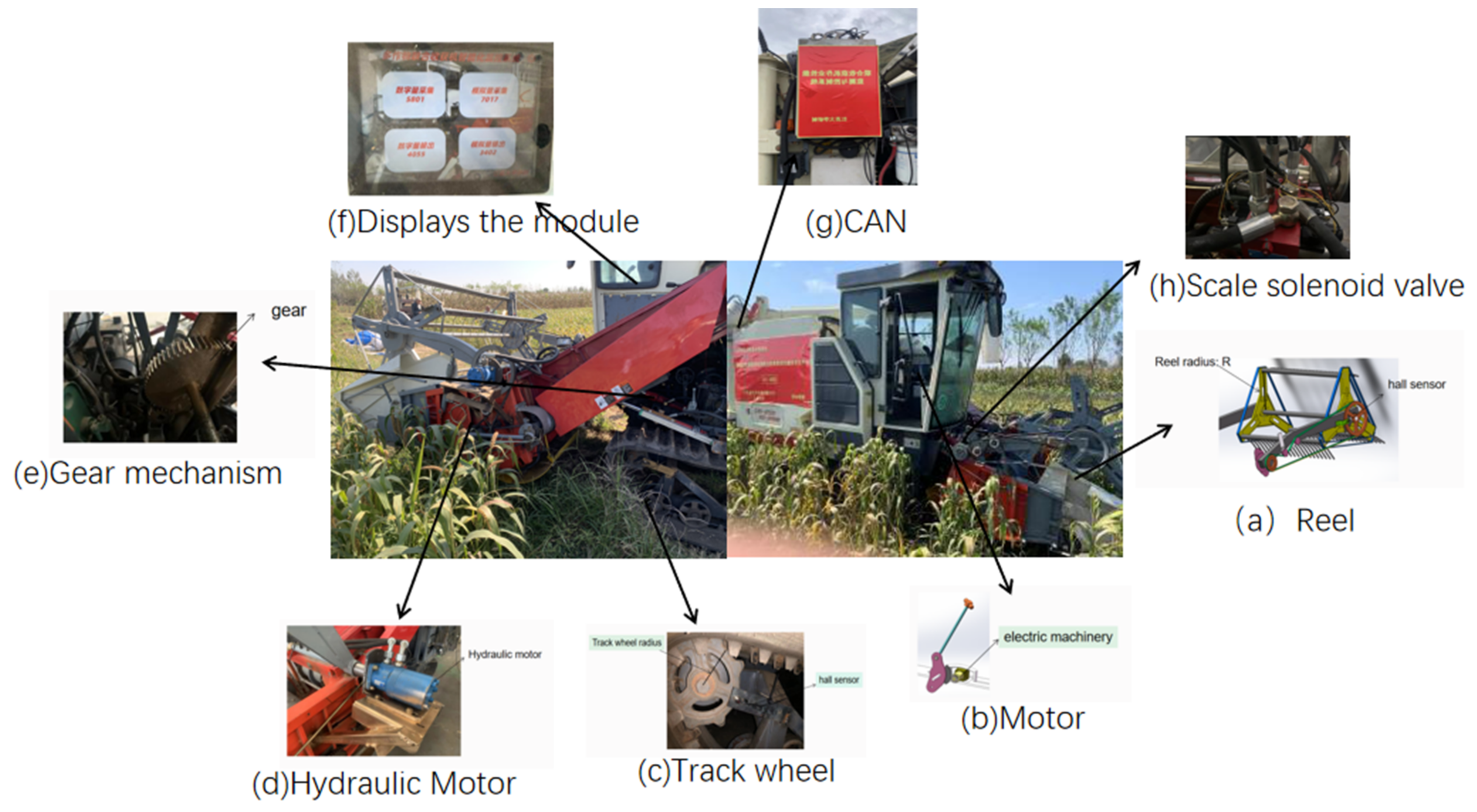

2.1. Mechanism Design of Matching Adjusting Device between the Rotation Speed and the Forward Speed of the Pulling Reel

2.1.1. Driving-Machine Modification

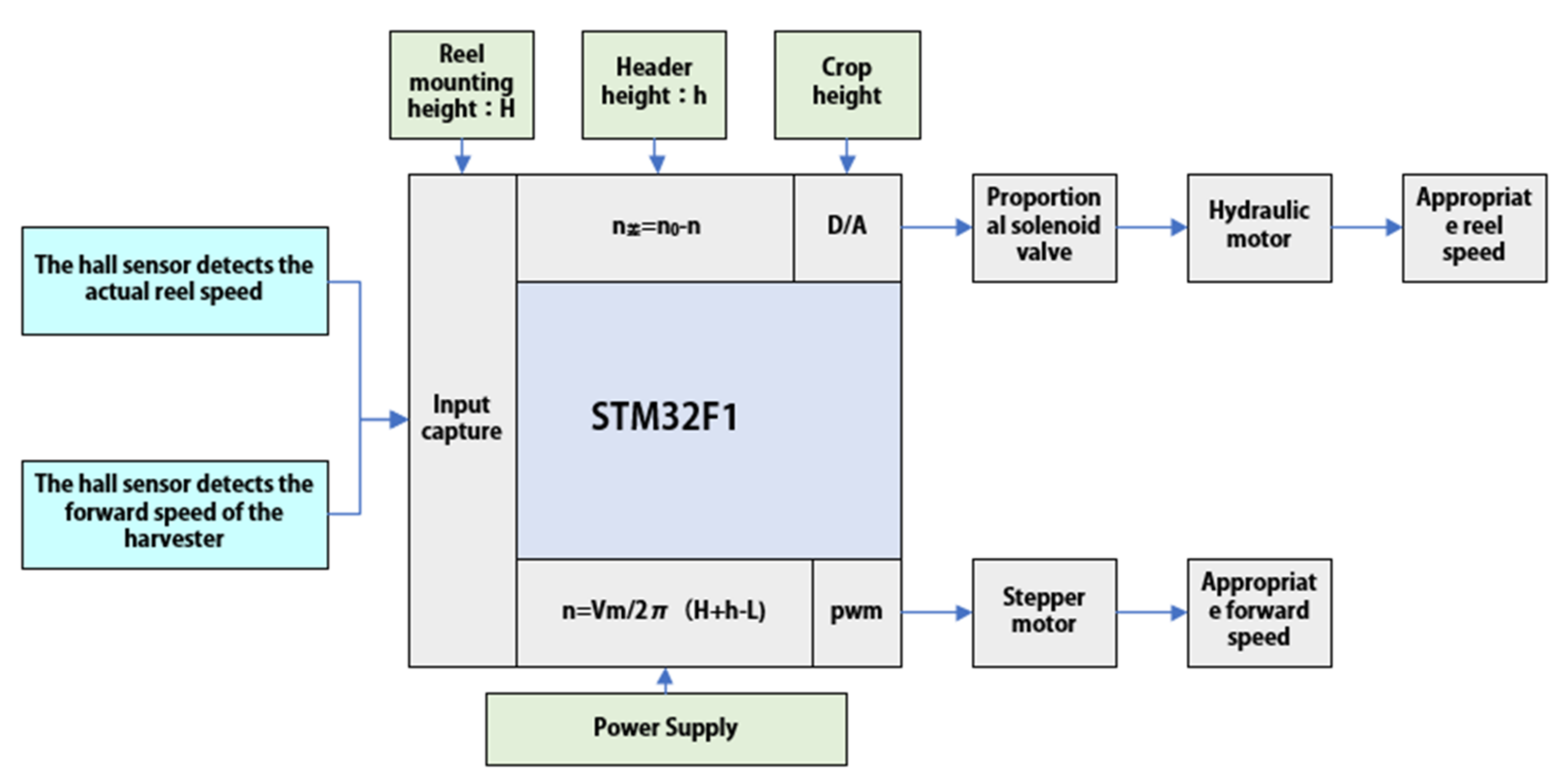

2.1.2. Data Collection, Calculation, and Output Control Section

2.1.3. Signal Acquisition

2.1.4. Actuator Drive

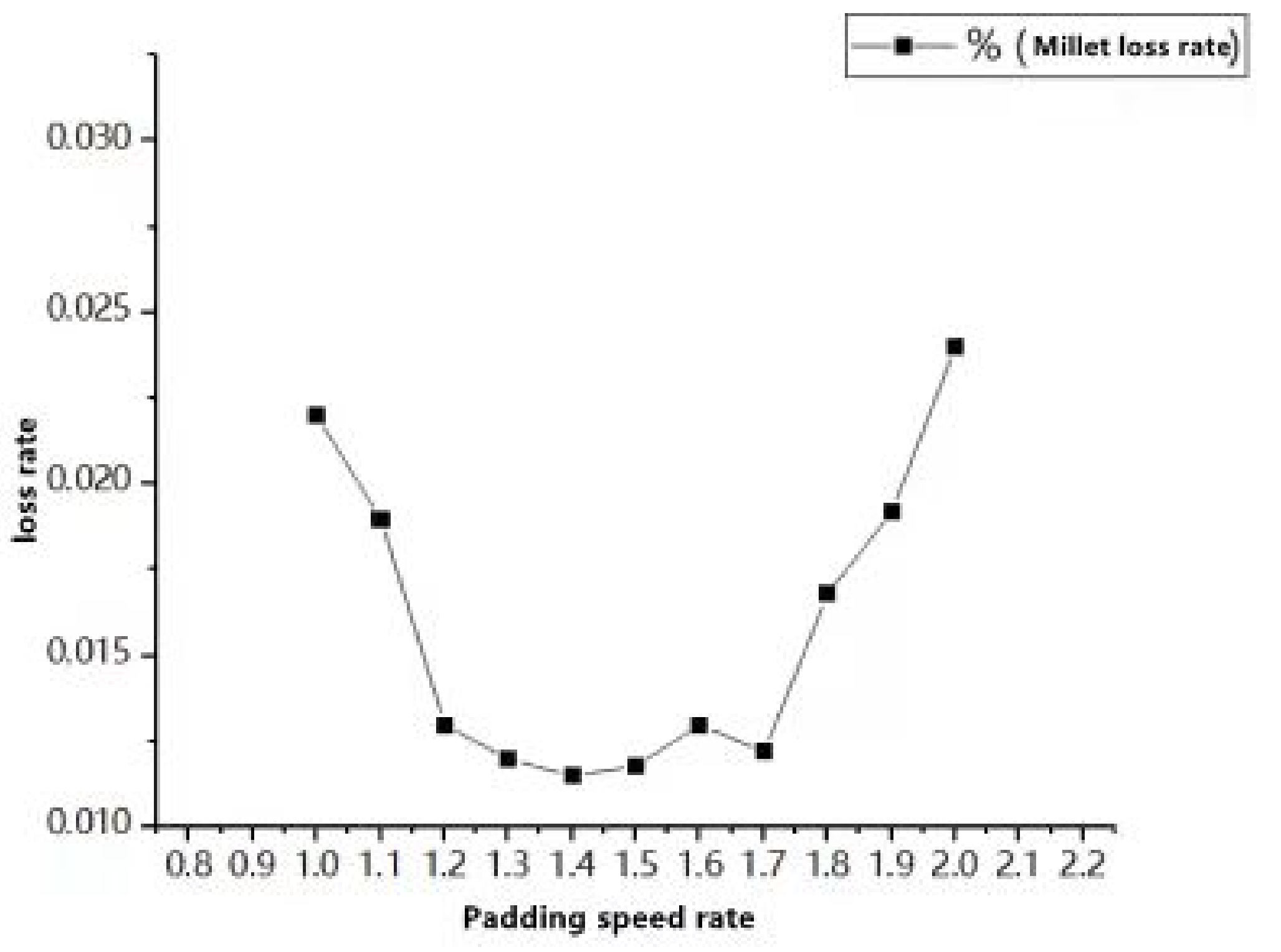

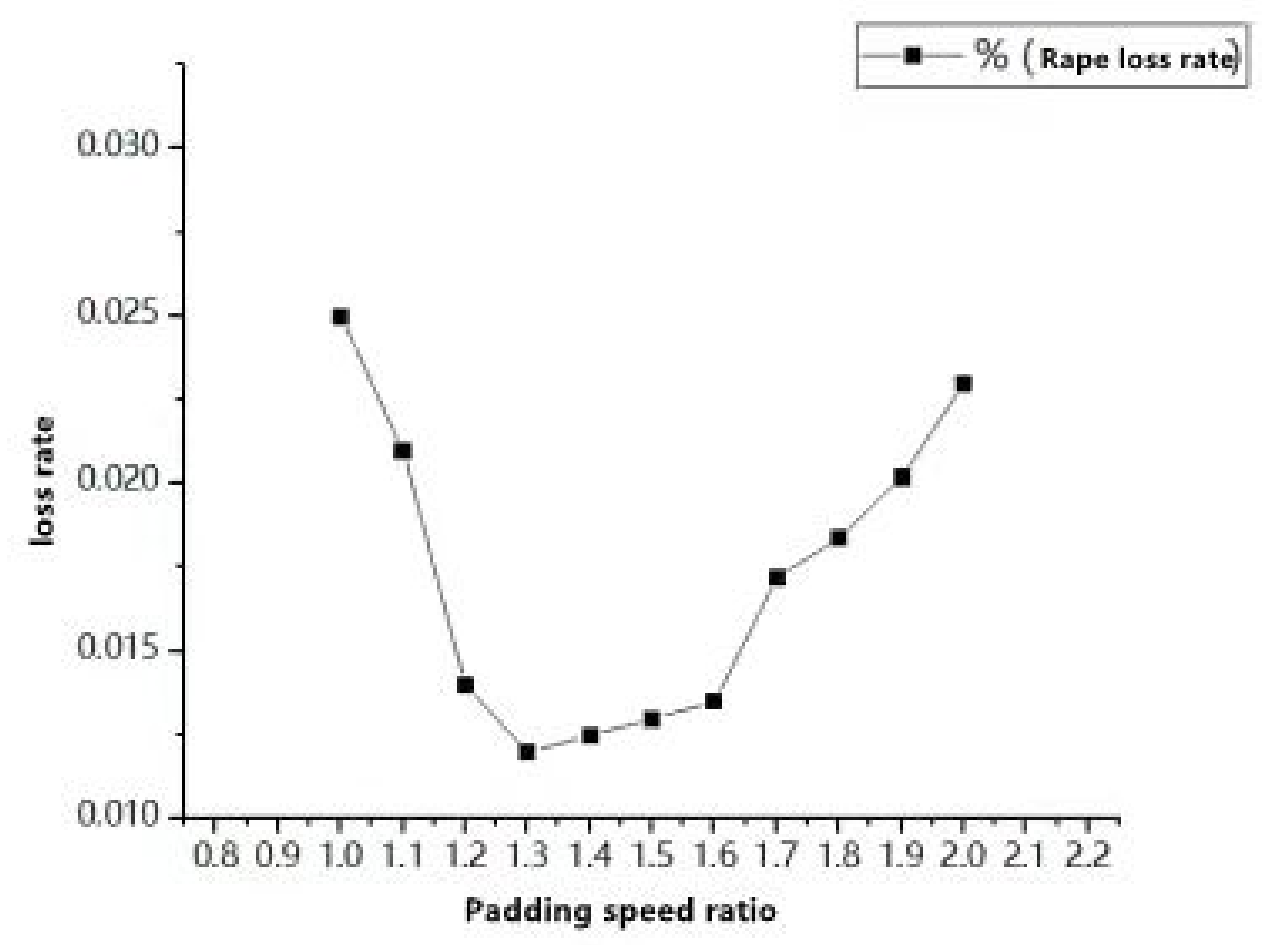

2.2. Selection of a Suitable Speed Ratio Range for Different Crops

- —lost rate of header, %;

- ,—total mass loss of grains in the 10 m test area, kg;

- —total grain weight at grain outlet, kg; for the convenience of calculation, the cleaning loss and entrainment loss are ignored.

- —here take 3;

- —length of measure area, here take 10 m;

- —width of sample slot, here take 20 cm;

- —the quality of the grain received by the I—slot, kg;

- Vb—forward speed of harvester, m/s;

- Vm—line speed of the pulling reel, m/s.

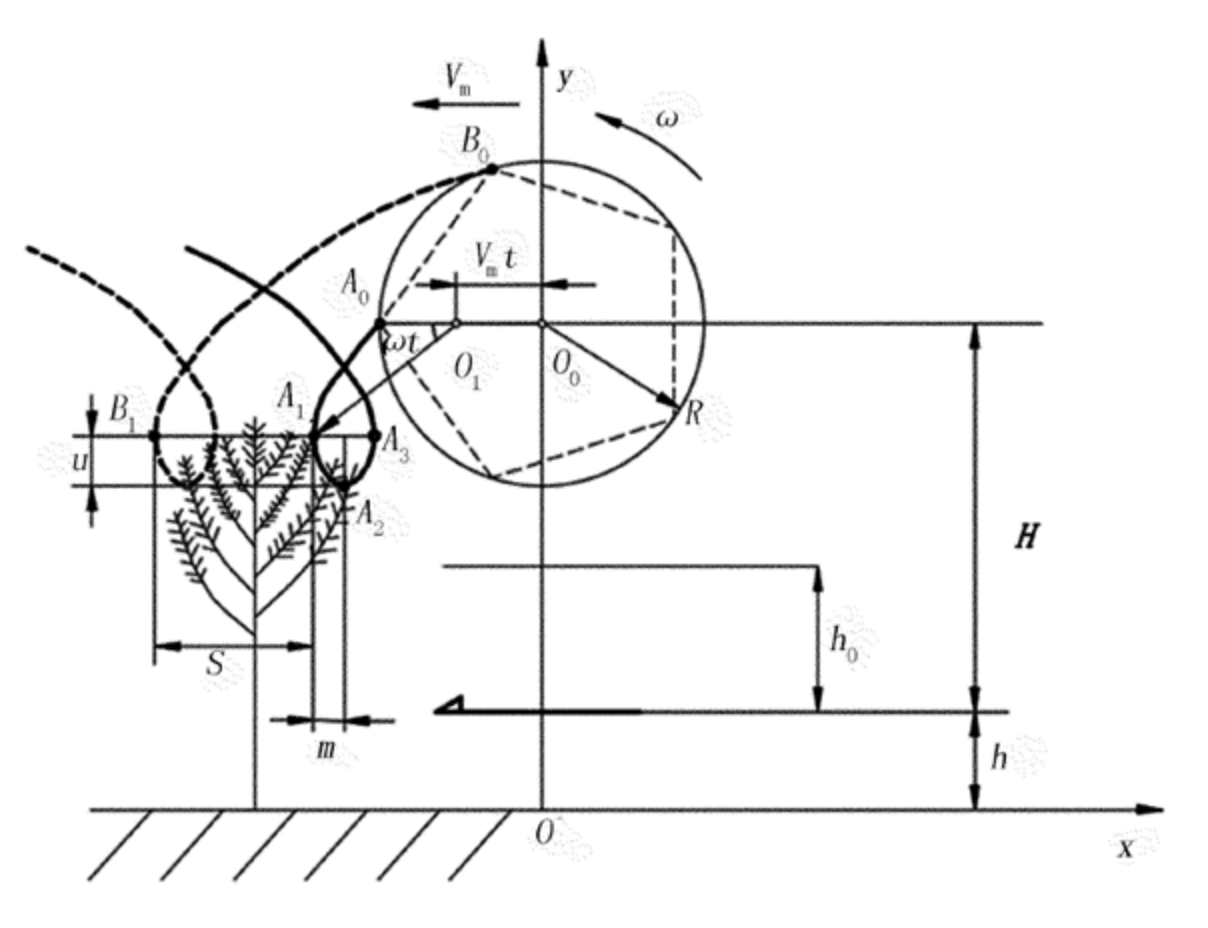

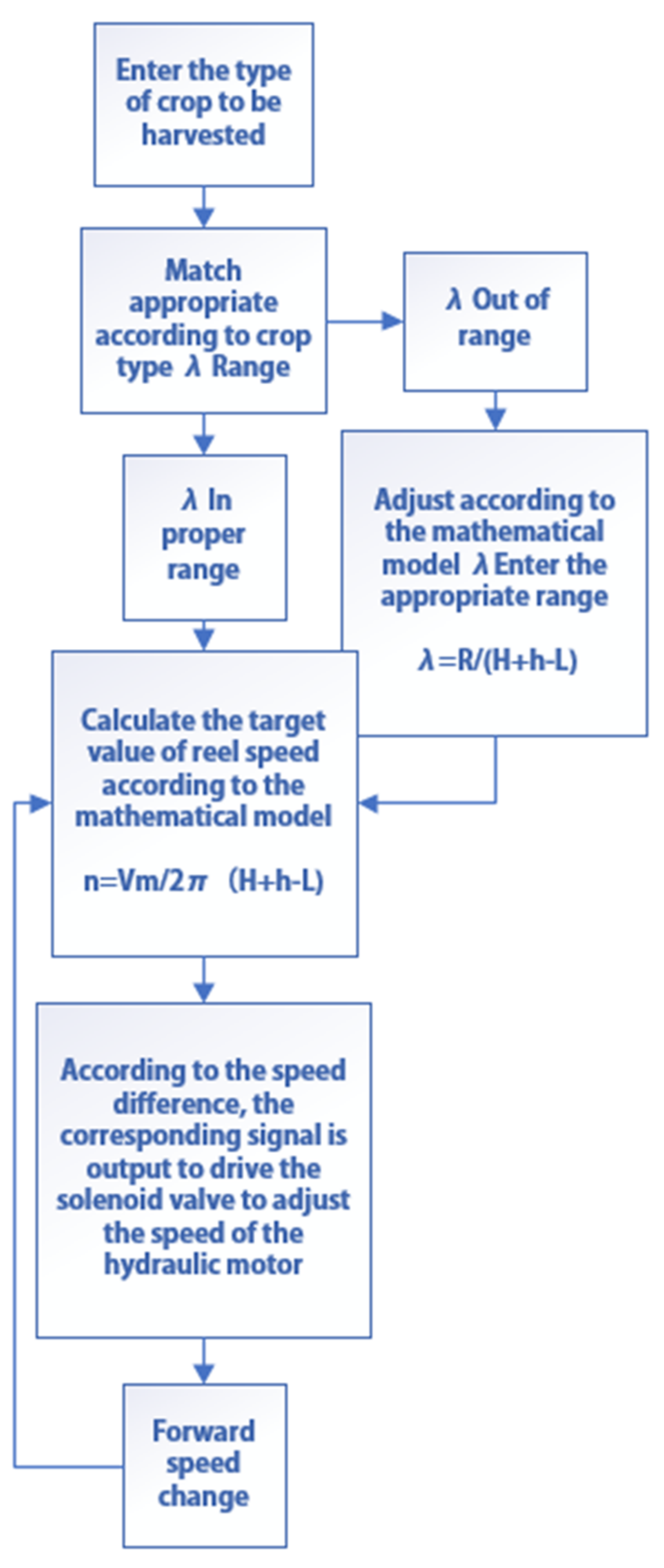

2.3. Matching Adjustment and Control Process of the Rotary Speed of the Pulling Reel and the Forward Speed of the Harvester

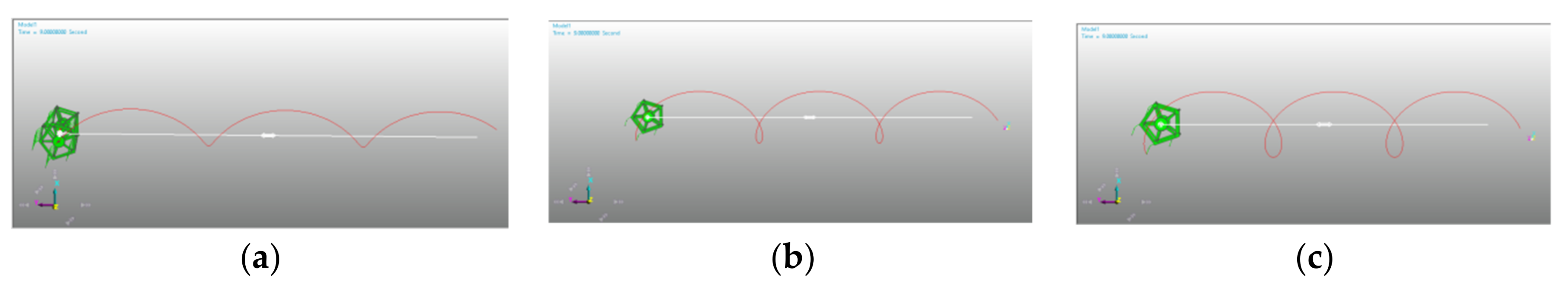

2.3.1. The Mathematical Model of Matching the Weeding Speed Ratio λ and the Rotational Speed of the Reel with the Forward Speed

- —pulling reel radius;

- —angular velocity during the movement of crop harvesting by turning the reel;

- —combined harvester machine forward speed;

- —the time the reel runs in the horizontal direction;

- —the installation height of the pulling reel at combined harvester;

- —crop height at harvest;

- —height of crop wait to be harvested.

2.3.2. Matching of the Rotation Speed and the Forward Speed of the Pulling Reel

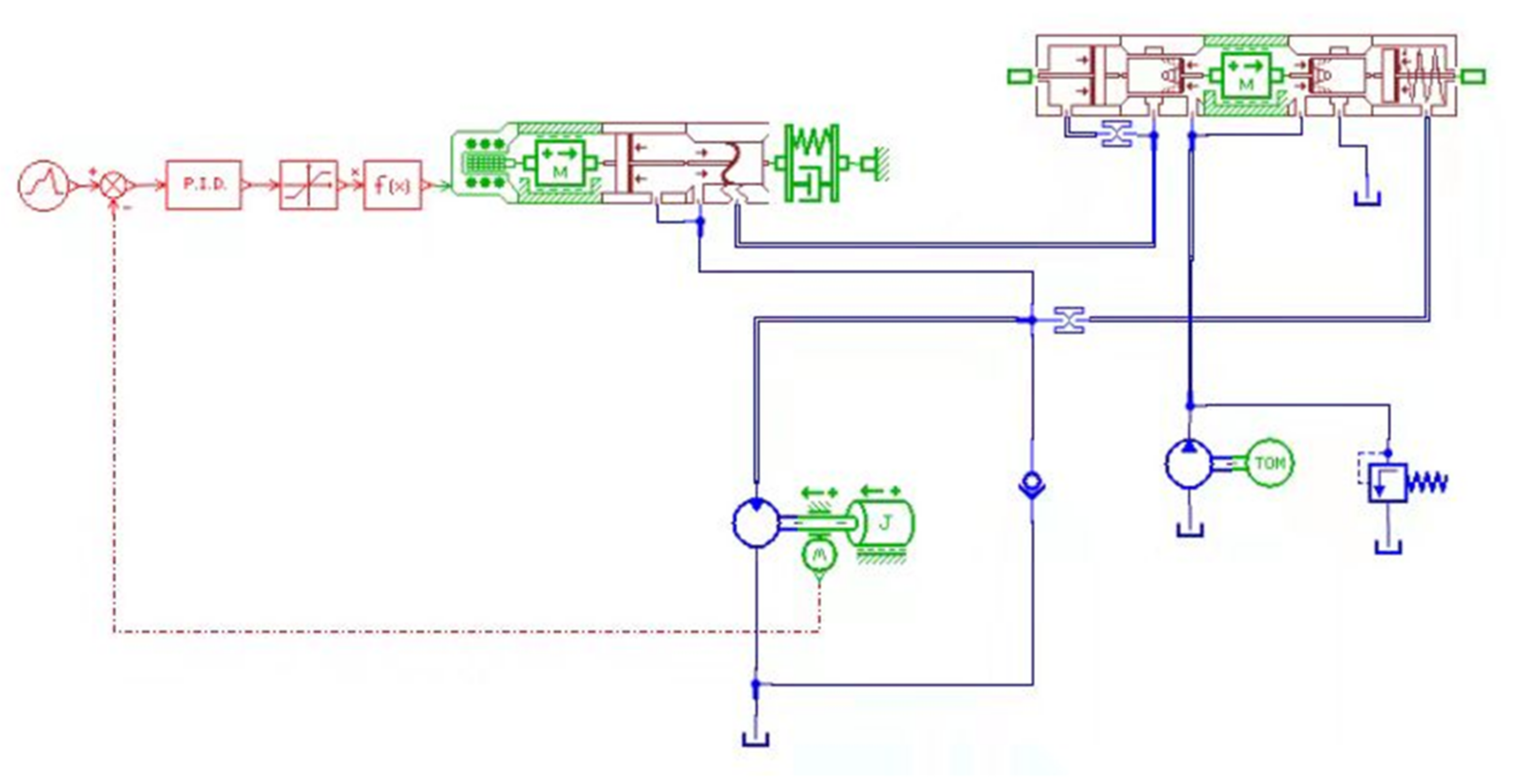

2.3.3. Solenoid Valve Drives the Hydraulic Motor to Adjust the Speed of the Hydraulic Motor

- (1)

- Linearized flow equation for electro-hydraulic ratio:

- (2)

- Flow continuity equation of hydraulic motor:

- (3)

- Torque-balance equation on the motor shaft.

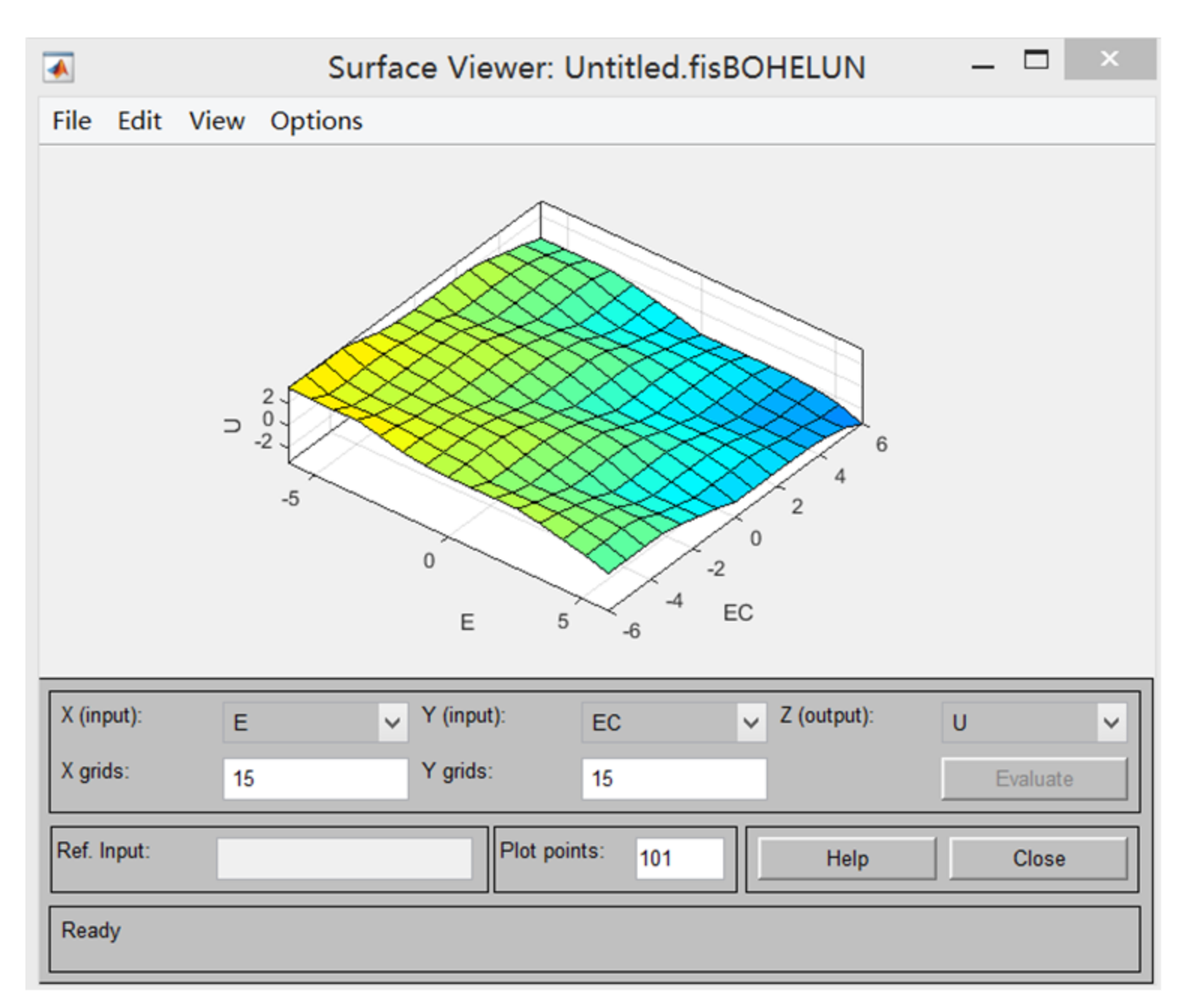

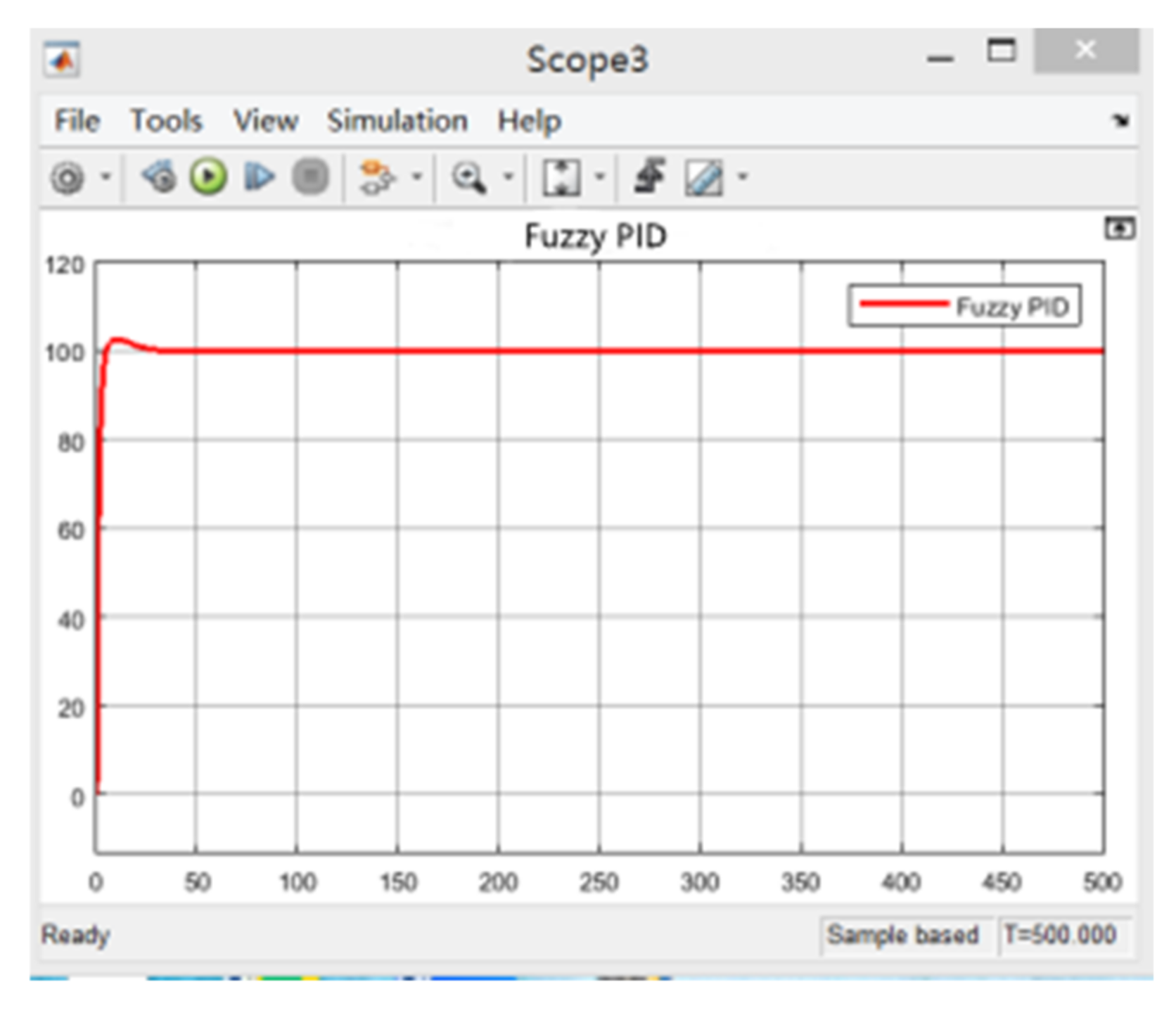

2.3.4. Fuzzy PID Control of the Rotary Speed of the Pulling Reel

3. Result and Discussion

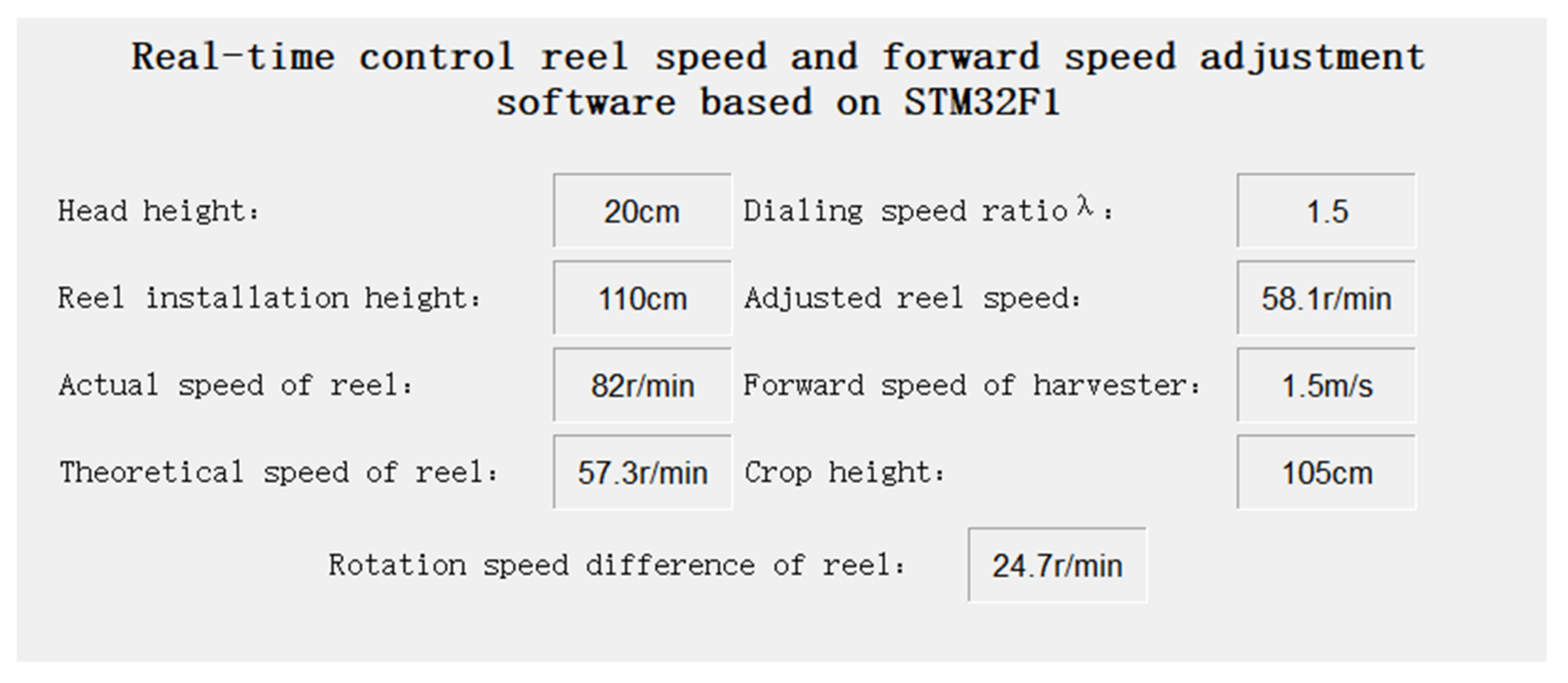

3.1. Test and Results of the Matching Adjustment of the Rotary Speed of the Pulling Reel

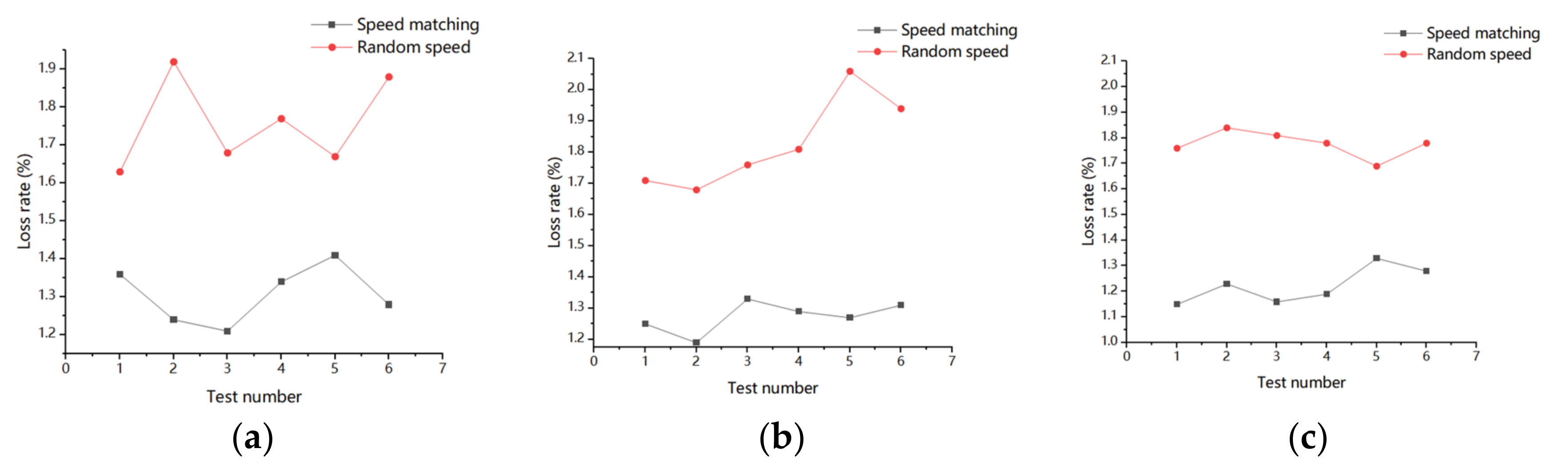

3.2. Comparison Test of Rotary Loss under Speed-Matching and Random Speeds

4. Conclusions

- In this study, the matching-adjustment method of the rotational speed and the forward speed of the rotary wheel was proposed, and in the matching-adjustment process, the range of the rotational-speed ratio suitable for harvesting different crops was satisfied, so as to reduce the loss of the harvest.

- When harvesting different crops, harvest crops under different ratios λ and measure the loss rate of different crops under different ratios λ. The test results show that in the rice-harvest test, the loss-rate fluctuation between 1.4–1.8 was the least. So, in general, when the ratio of rice to grain is between 1.4 and 1.8, it can have a better harvest effect and a lower loss. A ratio of 1.6 was the best. The range of the ratio of rice to grain was between 1.2 and 1.7, and 1.4 was the best. The range of the ratio of rice to grain was between 1.2 and 1.6, and 1.3 was the best. Additionally, the chart illustrates the speed ratio that was designed between close to 1 and 2 regardless of what kind of crop-harvest effect is not ideal; so, the optimization of the speed-ratio value range was designed to influence the effect of the larger harvest. The subsequent wheel speed was designed with the harvest-machine speed-matching to regulate the groundwork. A follow-up can test crops such as sorghum, and a wheat-harvest experiment exploring its optimum ratio range value can be designed.

- According to the Shandong rice-harvest test, we can know that the wheel speed was designed and that the error of the matching-speed-regulating value does not exceed 2%. For meeting the design requirements, one can better achieve a wheel speed, and the speed-matching was designed in the control system to join the selection of the speed ratio, which was designed. To further optimize the match to not only meet the wheel speed but also to guarantee the harvest in the process, speed-matching was designed. The rate of loss was reduced, and the quality of the harvest was improved.

- By comparing the loss rate of harvested crops under speed-matching and that under random speed-matching, it was found that the loss rate of harvested rice and rape was between 1.21% and 1.41% and 1.19% and 1.33%, respectively. The loss rate of harvested millet ranged from 1.15% to 1.33%, and the loss rate of any crop under the matching of rotation speed was lower than that under the random rotation speed. The experiment proved that the matching of the rotation speed and the forward speed could effectively reduce the loss rate.

- The device and method designed in this study are suitable for harvesting multiple crops, including rice, rape, and millet. In the follow-up work, we will continue to increase the harvest experiment of wheat, sorghum, and other crops to achieve multiple crop harvests.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Moses, F.O.; Thomas, O.M.; Jun, S. Kinematics of the tined combine harvester reel. Agric. Eng. Int. CIGR J. 2012, 14, 53–60. [Google Scholar]

- Wu, W.; Wu, C. Research status of Rape Combine Harvester cutting table. Jiangsu Agric. Sci. 2018, 46, 5–11. [Google Scholar]

- Wu, W.; Wu, C. Optimization of cutting table parameters for Rape Combine Harvester. J. Zhejiang Univ. 2018, 44, 481–489. [Google Scholar]

- Xu, H.; Peng, Z. Optimization design of main parameters of reel of new type Rape Harvester. Agric. Equip. Technol. 2007, 33, 58–59. [Google Scholar]

- Oduori, M.F.; Mbuya, T.O.; Sakai, J.; Inoue, E. Shattered rice grain loss attributable to the combine harvester reel: Model formulation and fitting to field data. Agric. Eng. Int. CIGR J. 2008, 10, 1–25. [Google Scholar]

- Oduori, M.F.; Mbuya, T.O.; Sakai, J.; Inoue, E. Shattered Grain Loss Attributable to the Combine Harvester Reel. 2006. Available online: http://erepository.uonbi.ac.ke:8080/xmlui/handle/123456789/15876 (accessed on 20 December 2021).

- Fadlelseed, F.E.A.E. Effect of Combine Harvester forward and reel Speeds the Harvesting Losses of Pearl Millet. Ph.D. Thesis, University of Khartoum, Khartoum, Sudan, 2015. [Google Scholar]

- Tan, L.N.; Pham, T.C. Optimal Tracking Control for PMSM with Partially Unknown Dynamics, Saturation Voltages, Torque, and Voltage Disturbances. IEEE Trans. Ind. Electron. 2021, 69, 3481–3491. [Google Scholar]

- Hobson, R.N.; Bruce, D.M. Seed loss when cutting a standing crop of oilseed rape with two types of combine harvester header. Biosyst. Eng. 2002, 81, 281–286. [Google Scholar] [CrossRef]

- Qing, Y.R.; Li, Y.M.; Xu, L.Z.; Ma, Z. Screen oilseed rape (Brassica napus L.) suitable for lowloss mechanized harvesting. Agriculture 2021, 11, 504. [Google Scholar] [CrossRef]

- Gao, X. Parameter Identification and Fuzzy PID Control Strategy Research of Electro-Hydraulic Proportional Valve Loading System; Chang’an University: Xi’an, China, 2014; (In Chinese with English abstract). [Google Scholar]

- Xu, B.; Su, Q.; Zhang, J.H.; Lu, Z.Y. Analysis for drive circuit and improved current controller for proportional amplifier. J. Zhejiang Univ. Eng. Sci. 2017, 51, 80–806, (in Chinese with English abstract). [Google Scholar]

- Kang, Y. Research and application of electro sydraulic proportional control system based on PWM technology. Colliery Mech. Electr. Technol. 2017, 2, 28–32, (In Chinese with English abstract). [Google Scholar]

- Man, K. PLC Programming Step by Step, Mitsubishi GX Works 2; China Electric Power Press: Beijing, China, 2013. [Google Scholar]

- Zhang, C. Brushless DC Electric Motor; China Machine Press: Beijing, China, 1996. [Google Scholar]

- Wang, J.; Wang, Z.; Jia, J. Research on the track motion of the reel of the low stalk cutting table of Feed Harvester. J. Agric. Mach. 2011, 42, 152–155. [Google Scholar]

- Li, M.L. Study on the method for determining the loss rate of cutting table in Rape Combine Harvester. Chinas Agric. Mech. 2012, 1, 4. [Google Scholar]

- Chen, J.; Wang, S.; Li, Y. Design and test of electric control device for cutting table parameters of rice-wheat combine. Agric. Eng. 2018, 34, 19–26. [Google Scholar]

- Chen, L.; Hong, J. Fuzzy PID controller design for electro hydraulic servo systems. Theor. Algorithms 2021, 11, 9. [Google Scholar]

- Zelenov, M.S.; Chernyshev, A.V. Research of the proportional valve effectivearea dependence on the control signal and the differential pressure. AIP Conf. Proc. 2021, 2318, 130012. [Google Scholar]

- Erzan Topçu, E.L.İ.F.; Bali, E. Modeling and analysis of an electro-pneumatic brake valve with on-off type solenoid driven by PWM technique. J. Fac. Eng. Archit. Gazi Univ. 2021, 36, 1418–1430. [Google Scholar]

- Li, W.; Liu, J.; Chai, B. Research and simulation of fuzzy-PID control system for energy-saving hydraulic pump. Control Eng. 2017, 24, 1347–1351. [Google Scholar]

- Liu, J.; Liu, Z.; Chen, J.; Wang, L. Research of vibration control on nonlinear rotor system with fuzzy-PID. J. Syst. Simul. 2017, 29, 200–205. [Google Scholar]

- Aftab, A.; Luan, X.C. A fuzzy-PID series feedback self-tuned adaptive control of reactor power using nonlinear multipoint kinetic model under reference tracking and disturbance rejection. Ann. Nucl. Energy 2021, 166, 108696. [Google Scholar] [CrossRef]

- Liu, J. Advanced PID Control and Its Matlab Simulation; Publishing House of Electronics Industry: Beijing, China, January 2003. [Google Scholar]

- Xiong, Z.; Liu, Z.; Wang, H.; Huo, J. Design of RBF Neural Network Incremental PID Automatic Steering Control System. Agric. Mech. Res. 2021, 43, 27–32. [Google Scholar]

- Zhao, Z.; Xu, Y.; Huang, K.; Li, X. Research on Fuzzy PID Governor Control of Diesel Generator under Pulse Load. Electr. Technol. 2021, 22, 1–6. [Google Scholar]

- Zhang, Y.; Du, Y.; Zhao, Y.; Xu, Z. The loss rate of rapeseed was higher than that of mechanical harvest. J. Qual. Superv. Agric. Mach. 2015, 9, 23–26. (In Chinese) [Google Scholar]

- Qu, X.; Huang, D.; Cao, F.; Wu, L.P. Did farm machinery reduce rice harvest losses? Acta Agric. Sin. 2019, 24, 165–172. (In Chinese) [Google Scholar]

| Test Number | Weeding Speed Ratio | Total Loss Mass (kg) | Total Harvest Mass (kg) | Loss Ratio (%) |

|---|---|---|---|---|

| 1 | 1 | 0.588 | 19.6 | 3.0 |

| 2 | 1.1 | 0.486 | 18.7 | 2.6 |

| 3 | 1.2 | 0.504 | 20.1 | 2.51 |

| 4 | 1.3 | 0.361 | 19.0 | 1.9 |

| 5 | 1.4 | 0.215 | 17.9 | 1.2 |

| 6 | 1.5 | 0.241 | 19.3 | 1.25 |

| 7 | 1.6 | 0.238 | 20.5 | 1.16 |

| 8 | 1.7 | 0.214 | 18.5 | 1.30 |

| 9 | 1.8 | 0.226 | 18.7 | 1.21 |

| 10 | 1.9 | 0.388 | 19.4 | 2.0 |

| 11 | 2.0 | 0.545 | 20.2 | 2.70 |

| Test Number | Weeding Speed Ratio | Total Loss Mass (kg) | Total Harvest Mass (kg) | Loss Ratio % |

|---|---|---|---|---|

| 1 | 1 | 0.275 | 12.5 | 2.2 |

| 2 | 1.1 | 0.226 | 11.9 | 1.9 |

| 3 | 1.2 | 0.159 | 12.2 | 1.30 |

| 4 | 1.3 | 0.142 | 11.8 | 1.20 |

| 5 | 1.4 | 0.151 | 13.1 | 1.15 |

| 6 | 1.5 | 0.149 | 12.6 | 1.18 |

| 7 | 1.6 | 0.101 | 11.2 | 0.90 |

| 8 | 1.7 | 0.154 | 12.6 | 1.22 |

| 9 | 1.8 | 0.215 | 12.8 | 1.68 |

| 10 | 1.9 | 0.250 | 13.0 | 1.92 |

| 11 | 2.0 | 0.295 | 12.3 | 2.40 |

| Test Number | Weeding Speed Ratio | Total Loss Mass (kg) | Total Harvest Mass (kg) | Loss Ratio (%) |

|---|---|---|---|---|

| 1 | 1 | 0.265 | 10.6 | 2.5 |

| 2 | 1.1 | 0.218 | 10.4 | 2.10 |

| 3 | 1.2 | 0.139 | 9.9 | 1.40 |

| 4 | 1.3 | 0.122 | 10.2 | 1.20 |

| 5 | 1.4 | 0.131 | 10.5 | 1.25 |

| 6 | 1.5 | 0.134 | 10.3 | 1.30 |

| 7 | 1.6 | 0.130 | 9.6 | 1.35 |

| 8 | 1.7 | 0.174 | 10.1 | 1.72 |

| 9 | 1.8 | 0.190 | 10.3 | 1.84 |

| 10 | 1.9 | 0.210 | 10.4 | 2.02 |

| 11 | 2.0 | 0.246 | 10.7 | 2.30 |

| kq | 8.66 × 10−4 | Wh | 9.5 | Displacement ml/r | 500 |

| 10 × 10−6 | 6.58 | Flow rate ml/r | 58 | ||

| 3.2 × 10−12 | 0.55 | Rotational speed r/min | 128 | ||

| 1.5 × 2 × 3.14 × Dm | 464 | Pressure mp | 9 | ||

| 5.76 | Torque N.m | 464 |

| EC | E | ||||

|---|---|---|---|---|---|

| NB | NS | ZR | PS | PB | |

| NB | PB | PB | PS | PS | ZR |

| NS | PB | PS | PS | ZR | ZR |

| ZR | PS | PS | ZR | ZR | NS |

| PS | PS | ZR | ZR | NS | NS |

| PB | ZR | ZR | NS | NS | NB |

| Test Number | Forward Speed Vm (m/s) | nTheory(r) (min) | nActual (r) (min) | Error (%) |

|---|---|---|---|---|

| 1 | 1.0 | 47.5 | 48.0 | 1.04 |

| 2 | 1.2 | 58.2 | 57.3 | 1.57 |

| 3 | 1.4 | 65.7 | 66.8 | 1.65 |

| 4 | 1.6 | 77.0 | 76.4 | 0.78 |

| 5 | 1.8 | 88.6 | 90.0 | 0.44 |

| 6 | 2.0 | 96.6 | 95.5 | 1.01 |

| (Speed Match) Test Number | Loss Ratio (%) | (Random Speed) Test Number | Loss Ratio (%) |

|---|---|---|---|

| 1 | 1.36 | 1 | 1.63 |

| 2 | 1.24 | 2 | 1.92 |

| 3 | 1.21 | 3 | 1.68 |

| 4 | 1.34 | 4 | 1.77 |

| 5 | 1.41 | 5 | 1.67 |

| 6 | 1.28 | 6 | 1.88 |

| (Speed Match) Test Number | Loss Ratio (%) | (Random Speed) Test Number | Loss Ratio (%) |

|---|---|---|---|

| 1 | 1.25 | 1 | 1.71 |

| 2 | 1.19 | 2 | 1.68 |

| 3 | 1.33 | 3 | 1.76 |

| 4 | 1.29 | 4 | 1.81 |

| 5 | 1.27 | 5 | 2.06 |

| 6 | 1.31 | 6 | 1.94 |

| (Speed Match) Test Number | Loss Ratio (%) | (Random Speed) Test Number | Loss Ratio (%) |

|---|---|---|---|

| 1 | 1.15 | 1 | 1.76 |

| 2 | 1.23 | 2 | 1.84 |

| 3 | 1.16 | 3 | 1.81 |

| 4 | 1.19 | 4 | 1.78 |

| 5 | 1.33 | 5 | 1.69 |

| 6 | 1.28 | 6 | 1.78 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, K.; Li, Y.; Liang, Z.; Liu, Y.; Cheng, J.; Wang, H.; Zhu, R.; Xia, S.; Zheng, G. Device and Method Suitable for Matching and Adjusting Reel Speed and Forward Speed of Multi-Crop Harvesting. Agriculture 2022, 12, 213. https://doi.org/10.3390/agriculture12020213

Ji K, Li Y, Liang Z, Liu Y, Cheng J, Wang H, Zhu R, Xia S, Zheng G. Device and Method Suitable for Matching and Adjusting Reel Speed and Forward Speed of Multi-Crop Harvesting. Agriculture. 2022; 12(2):213. https://doi.org/10.3390/agriculture12020213

Chicago/Turabian StyleJi, Kuizhou, Yaoming Li, Zhenwei Liang, Yanbin Liu, Junhui Cheng, Hanhao Wang, Ruiheng Zhu, Shengbo Xia, and Guoqiang Zheng. 2022. "Device and Method Suitable for Matching and Adjusting Reel Speed and Forward Speed of Multi-Crop Harvesting" Agriculture 12, no. 2: 213. https://doi.org/10.3390/agriculture12020213

APA StyleJi, K., Li, Y., Liang, Z., Liu, Y., Cheng, J., Wang, H., Zhu, R., Xia, S., & Zheng, G. (2022). Device and Method Suitable for Matching and Adjusting Reel Speed and Forward Speed of Multi-Crop Harvesting. Agriculture, 12(2), 213. https://doi.org/10.3390/agriculture12020213