Stability Analysis of a Sprayer UAV with a Liquid Tank with Different Outer Shapes and Inner Structures

Abstract

:1. Introduction

1.1. Motivation

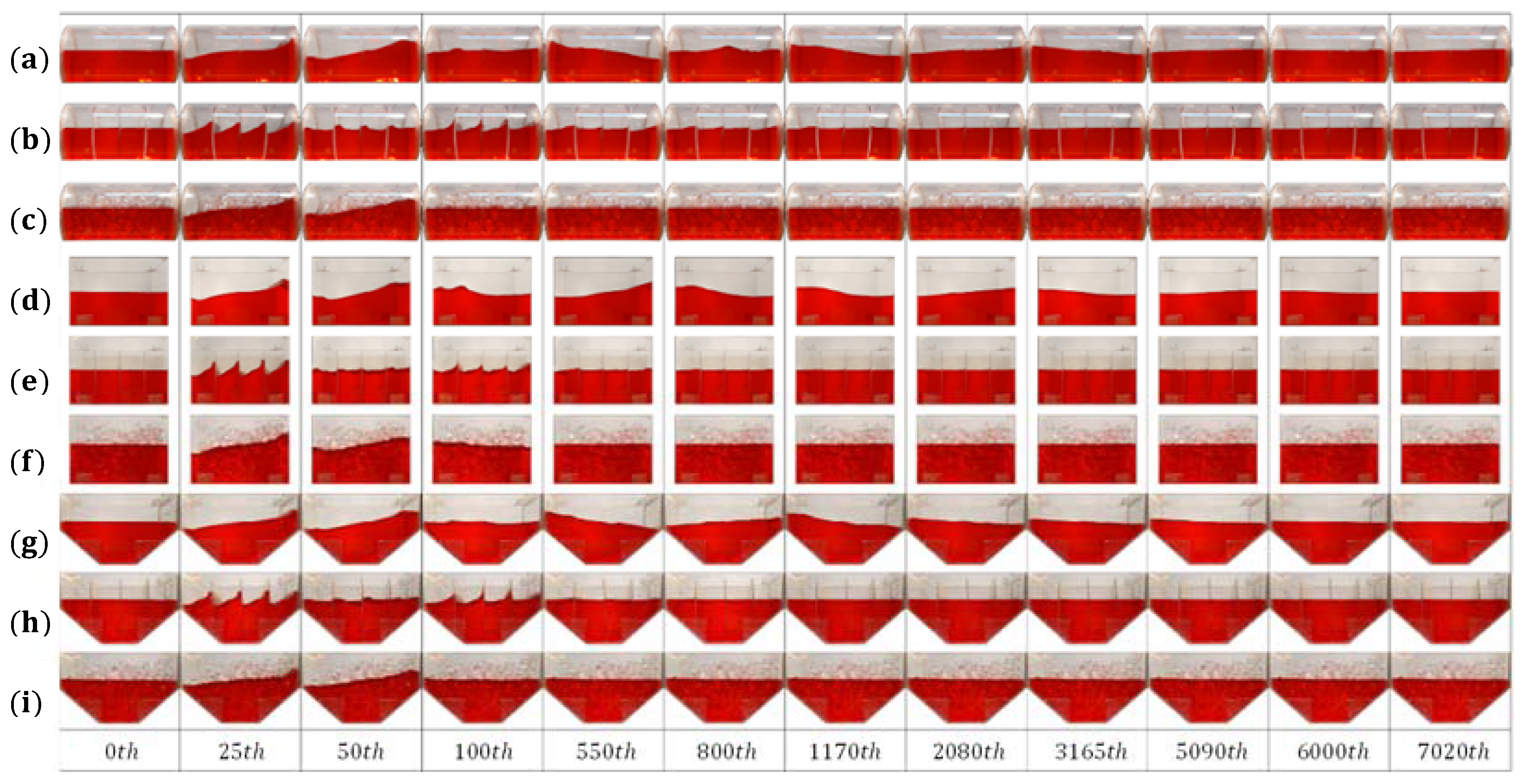

- An experimental study of the slosh effect using different shaped tanks, inner baffle systems, and different liquid levels using a linear-guided motion machine and a high-speed camera.

- An aircraft principal axes analysis of a model-sized sprayer rotorcraft UAV carrying a select tank setup.

- A time and height evaluation of water sloshing for a better effective tanker system.

- A flight inconsistency evaluation to prove the system’s effectiveness for rotorcraft UAVs.

1.2. Contributions

- Three primary shaped-tank effectiveness tests and a result comparison.

- Multiple water-level experiments and analyses with a high-speed camera.

- Two inner baffle system tests and effectiveness comparisons.

- A new baffle ball introduced for universal use in commercial UAV tanks.

- An aircraft principal axes evaluation for an efficiency check.

1.3. Implications

1.4. Organization of the Article

2. Background and Related Work

3. System Architecture

3.1. Tank, Baffle Wall, and Baffle Ball Designs

3.2. Guided Linear-Motion Frame

3.3. Quadrotor Frame and Flight Controller

4. Experiment Methods

4.1. Indoor Tank Experiment

4.2. Outdoor UAV Flight Experiment

5. Result Comparison and Discussion

5.1. Slosh Height and Impact Duration Comparison

5.2. UAV Flight-Record Comparison during the Mission

5.3. Comprehensive Results Check of Lab Tank Results and Flight Results

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sanca, A.S.; Alsina, P.J.; Jés de Jesus, F.C. Dynamic modelling of a quadrotor aerial vehicle with nonlinear inputs. In Proceedings of the 2008 IEEE Latin American Robotic Symposium, Salvador, Brazil, 29–30 October 2008; IEEE: Piscataway, NJ, USA, 2008; pp. 143–148. [Google Scholar] [CrossRef]

- Ryll, M.; Bülthoff, H.H.; Giordano, P.R. A novel overactuated quadrotor unmanned aerial vehicle: Modeling, control, and experimental validation. IEEE Trans. Control Syst. Technol. 2014, 23, 540–556. [Google Scholar] [CrossRef] [Green Version]

- Marino, S.; Alvino, A. Detection of Spatial and Temporal Variability of Wheat Cultivars by High-Resolution Vegetation Indices. Agronomy 2019, 9, 226. [Google Scholar] [CrossRef] [Green Version]

- Surový, P.; Almeida Ribeiro, N.; Panagiotidis, D. Estimation of positions and heights from UAV-sensed imagery in tree plantations in agrosilvopastoral systems. Int. J. Remote Sens. 2018, 39, 4786–4800. [Google Scholar] [CrossRef]

- Cilia, C.; Panigada, C.; Rossini, M.; Meroni, M.; Busetto, L.; Amaducci, S.; Boschetti, M.; Picchi, V.; Colombo, R. Nitrogen Status Assessment for Variable Rate Fertilization in Maize through Hyperspectral Imagery. Remote Sens. 2014, 6, 6549–6565. [Google Scholar] [CrossRef] [Green Version]

- Zaman-Allah, M.; Vergara, O.; Araus, J.L.; Tarekegne, A.; Magorokosho, C.; Zarco-Tejada, P.J.; Hornero, A.; Alba, A.H.; Das, B.; Craufurd, P.; et al. Unmanned aerial platform-based multi-spectral imaging for field phenotyping of maize. Plant Methods 2015, 11, 35. [Google Scholar] [CrossRef] [Green Version]

- Chang, A.; Jung, J.; Maeda, M.M.; Landivar, J. Crop height monitoring with digital imagery from Unmanned Aerial System (UAS). Comput. Electron. Agric. 2017, 141, 232–237. [Google Scholar] [CrossRef]

- Honkavaara, E.; Kaivosoja, J.; Mäkynen, J.; Pellikka, I.; Pesonen, L.; Saari, H.; Salo, H.; Hakala, T.; Marklelin, L.; Rosnell, T. Hyperspectral reflectance signatures and point clouds for precision agriculture by light weight UAV imaging system. ISPRS Ann. Photogramm. Remote Sens. Spat. Inf. Sci 2012, 7, 353–358. [Google Scholar] [CrossRef] [Green Version]

- Pflanz, M.; Nordmeyer, H.; Schirrmann, M. Weed Mapping with UAS Imagery and a Bag of Visual Words Based Image Classifier. Remote Sens. 2018, 10, 1530. [Google Scholar] [CrossRef] [Green Version]

- Rasmussen, J.; Nielsen, J.; Garcia-Ruiz, F.; Christensen, S.; Streibig, J.C.; Lotz, B. Potential uses of small unmanned aircraft systems (UAS) in weed research. Weed Res. 2013, 53, 242–248. [Google Scholar] [CrossRef]

- Rahnemoonfar, M.; Sheppard, C. Deep Count: Fruit Counting Based on Deep Simulated Learning. Sensors 2017, 17, 905. [Google Scholar] [CrossRef] [Green Version]

- Lou, Z.; Xin, F.; Han, X.; Lan, Y.; Duan, T.; Fu, W. Effect of Unmanned Aerial Vehicle Flight Height on Droplet Distribution, Drift and Control of Cotton Aphids and Spider Mites. Agronomy 2018, 8, 187. [Google Scholar] [CrossRef] [Green Version]

- Xiao, Q.; Xin, F.; Lou, Z.; Zhou, T.; Wang, G.; Han, X.; Lan, Y.; Fu, W.J.A. Effect of aviation spray adjuvants on defoliant droplet deposition and cotton defoliation efficacy sprayed by unmanned aerial vehicles. Agronomy 2019, 9, 217. [Google Scholar] [CrossRef] [Green Version]

- Liu, A.; Zhang, H.; Llao, C.; Zhang, Q.; Cenglin, X.; Juying, H.; Zhang, J.; Yan, H.; Ll, J.; Xiwen, L.J.A.S. Technology, Effects of Supplementary Pollination by Single-rotor Agricultural Unmanned Aerial Vehicle in Hybrid Rice Seed Production. Agric. Sci. Technol. 2017, 18, 543–552. [Google Scholar]

- Chen, S.; Lan, Y.; Li, J.; Xu, X.; Wang, Z.; Peng, B. Evaluation and test of effective spraying width of aerial spraying on plant protection UAV. Trans. Chin. Soc. Agric. Eng. 2017, 33, 82–90. [Google Scholar]

- Wang, C.; He, X.; Wang, X.; Wang, Z.; Pan, H.; He, Z. Testing method of spatial pesticide spraying deposition quality balance for unmanned aerial vehicle. Trans. Chin. Soc. Agric. Eng. 2016, 32, 54–61. [Google Scholar] [CrossRef] [Green Version]

- Ahmed, S.; Qiu, B.; Ahmad, F.; Kong, C.-W.; Xin, H. A State-of-the-Art Analysis of Obstacle Avoidance Methods from the Perspective of an Agricultural Sprayer UAV’s Operation Scenario. Agronomy 2021, 11, 1069. [Google Scholar] [CrossRef]

- Ming, D. Study on the Equivalent Mechanical Model for Large Amplitude Slosh. J. Astronaut. 2016, 37, 631. [Google Scholar]

- JIYI K++ Flight Controller. 16 June 2021. Available online: https://support.jiyiuav.com/docs/skning/skning-1c8jtpfthji51 (accessed on 12 December 2021).

- Wei, C.; Wang, L.; Shabana, A.A. A total Lagrangian ANCF liquid sloshing approach for multibody system applications. J. Comput. Nonlinear Dyn. 2015, 10. [Google Scholar] [CrossRef]

- Chen, W.; Haroun, M.A.; Liu, F. Large amplitude liquid sloshing in seismically excited tanks. Earthq. Eng. Struct. Dyn. 1996, 25, 653–669. [Google Scholar] [CrossRef]

- Wang, Q.-Y.; Jiang, L.; Chai, M.; Huang, H.; Tang, J.-H. Numerical and experimental analysis of the effect of elastic membrane on liquid sloshing in partially filled tank vehicles. Mech. Based Des. Struct. Mach. 2021, 1–17. [Google Scholar] [CrossRef]

- Sanapala, V.; Sajish, S.; Velusamy, K.; Ravisankar, A.; Patnaik, B. An experimental investigation on the dynamics of liquid sloshing in a rectangular tank and its interaction with an internal vertical pole. J. Sound Vib. 2019, 449, 43–63. [Google Scholar] [CrossRef]

- Xue, M.-A.; Chen, Y.; Zheng, J.; Qian, L.; Yuan, X. Fluid dynamics analysis of sloshing pressure distribution in storage vessels of different shapes. Ocean Eng. 2019, 192, 106582. [Google Scholar] [CrossRef]

- Liu, D.; Lin, P. A numerical study of three-dimensional liquid sloshing in tanks. J. Comput. Phys. 2008, 227, 3921–3939. [Google Scholar] [CrossRef]

- Kolaei, A.; Rakheja, S.; Richard, M.J. Effects of tank cross-section on dynamic fluid slosh loads and roll stability of a partly-filled tank truck. Eur. J. Mech. B/Fluids 2014, 46, 46–58. [Google Scholar] [CrossRef]

- Deng, M.-L.; Yue, B.-Z. Attitude dynamics and control of liquid filled spacecraft with large amplitude fuel slosh. J. Mech. 2017, 33, 125–136. [Google Scholar] [CrossRef]

- Xue, M.-A.; Zheng, J.; Lin, P.; Yuan, X. Experimental study on vertical baffles of different configurations in suppressing sloshing pressure. Ocean Eng. 2017, 136, 178–189. [Google Scholar] [CrossRef]

- Arif, U.G.M.; Loo, C.-Y.; Kang, H.-S.; Punurai, W.; Quen, L.K.; Lai, G.N.-Y.; Chong, W.-T. Suppression of Hydrodynamic Sloshing in Liquefied Natural Gas Tank with Floating Baffle: Experimental and Numerical Studies. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bangkok, Thailand, 2020; p. 012111. [Google Scholar] [CrossRef]

- George, A.; Cho, I. Anti-sloshing effects of a vertical porous baffle in a rolling rectangular tank. Ocean Eng. 2020, 214, 107871. [Google Scholar] [CrossRef]

- Zhang, C.; Su, P.; Ning, D. Hydrodynamic study of an anti-sloshing technique using floating foams. Ocean Eng. 2019, 175, 62–70. [Google Scholar] [CrossRef]

- Qin, H.; Mu, L.; Tang, W.; Hu, Z. Numerical study on structural response of anti-sloshing baffles of different configurations in a sloshing tank considering hydroelasticity. Ocean Eng. 2019, 188, 106290. [Google Scholar] [CrossRef]

- Wang, W.; Guo, Z.; Peng, Y.; Zhang, Q. A numerical study of the effects of the T-shaped baffles on liquid sloshing in horizontal elliptical tanks. Ocean Eng. 2016, 111, 543–568. [Google Scholar] [CrossRef]

- Hasheminejad, S.M.; Mohammadi, M. Effect of anti-slosh baffles on free liquid oscillations in partially filled horizontal circular tanks. Ocean Eng. 2011, 38, 49–62. [Google Scholar] [CrossRef]

- Liu, G.; Lin, Y.; Guan, G.; Yu, Y.-Y. Numerical research on the anti-sloshing effect of a ring baffle in an independent type C LNG tank. J. Zhejiang Univ. Sci. A 2018, 19, 758–773. [Google Scholar] [CrossRef]

- Maleki, A.; Ziyaeifar, M. Sloshing damping in cylindrical liquid storage tanks with baffles. J. Sound Vib. 2008, 311, 372–385. [Google Scholar] [CrossRef]

- Hu, Q.; Li, Y.; Liu, J.; Liang, J. Research on liquid sloshing performance in vane type tank under microgravity. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Hangzhou, China, 2016; p. 012016. [Google Scholar] [CrossRef] [Green Version]

- Taylor, G.L. Anti-Slosh Devices for Damping Oscillation of Liquids in Tanks. Google Patent US 7,648,749 B1, 19 January 2010. [Google Scholar]

- Dodson, G.M.; Hill, W.F. Water Tank Baffle. U.S. Patent 5,960,981, 5 October 1999. [Google Scholar]

- Spickelmire, J. Liquid Stabilizing Baffle System. U.S. Patent 5,890,618, 6 April 1999. [Google Scholar]

- Bambacigno, J.A. Liquid Stabilizing Deflector Baffle. U.S. Patent 6,848,472 B2, 19 January 2005. [Google Scholar]

- Zang, Y.; Zang, Y.; Zhou, Z.; Gu, X.; Jiang, R.; Kong, L.; He, X.; Luo, X.; Lan, Y. Design and anti-sway performance testing of pesticide tanks in spraying UAVs. Int. J. Agric. Biol. Eng. 2019, 12, 10–16. [Google Scholar] [CrossRef] [Green Version]

- Pro, X. XRotor Pro X8 Series—Industrial/Commercial Use. Available online: https://www.hobbywingdirect.com/collections/xrotor-x8-series (accessed on 12 December 2021).

- Holybro Pixhawk 4. 16 June 2021. Available online: https://docs.px4.io/master/en/flight_controller/pixhawk4.html (accessed on 12 December 2021).

- ArduPilot Mission Planner Flight PLAN. Available online: https://ardupilot.org/planner/docs/mission-planner-flight-plan.html (accessed on 12 December 2021).

- Krejčí, J.; Stoklasa, J. Aggregation in the analytic hierarchy process: Why weighted geometric mean should be used instead of weighted arithmetic mean. Expert Syst. Appl. 2018, 114, 97–106. [Google Scholar] [CrossRef]

- Bracke, M.B.; Zonderland, J.J.; Bleumer, E.J. Expert consultation on weighting factors of criteria for assessing environmental enrichment materials for pigs. Appl. Anim. Behav. Sci. 2007, 104, 14–23. [Google Scholar] [CrossRef]

- Leng, Y.; Chen, Y.; Fu, Q.; Chen, Z. Constructing empowerment method based on index independence. Stat. Decis. 2016, 19, 9–11. [Google Scholar]

- Brar, L.S.; Elsayed, K. Analysis and optimization of cyclone separators with eccentric vortex finders using large eddy simulation and artificial neural network. Sep. Purif. Technol. 2018, 207, 269–283. [Google Scholar] [CrossRef]

- Shan, M.-Q.; Qian, Y.; Yu, S.; Guo, S.-C.; Zhang, L.; Ding, A.-W.; Wu, Q.-N. Anti-inflammatory effect of volatile oil from Schizonepeta tenuifolia on carrageenin-induced pleurisy in rats and its application to study of appropriate harvesting time coupled with multi-attribute comprehensive index method. J. Ethnopharmacol. 2016, 194, 580–586. [Google Scholar] [CrossRef]

- Hyun-Soo, K.; Young-Shin, L. Optimization design technique for reduction of sloshing by evolutionary methods. J. Mech. Sci. Technol. 2008, 22, 25–33. [Google Scholar] [CrossRef]

- OpenStreetMap. In InMeteo: VentuSky. 2021. Available online: https://www.ventusky.com/?p=32.178;119.497;10&l=wind-10m&t=20210821/1200 (accessed on 12 December 2021).

- Khorsandi, F.; Ayers, P.D.; Freeland, R.S.; Wang, X. Modeling the effect of liquid movement on the center of gravity calculation of agricultural vehicles. J. Terramech. 2018, 75, 37–48. [Google Scholar] [CrossRef]

- Pomeau, Y.; Villermaux, E. Two hundred years of capillarity research. Phys. Today 2006, 59, 39. Available online: https://hal.archives-ouvertes.fr/hal-00094659 (accessed on 12 December 2021). [CrossRef] [Green Version]

| Liquid Amount (L) | Standard Surface Height (cm) | Normal Surface-to-Peak Distance (cm) | |||

|---|---|---|---|---|---|

| No Baffle | Baffle Wall | Baffle Ball | |||

| Rectangular | 3 | 5.2 | 3.1 | 2.7 | 4.0 |

| 4 | 6.5 | 3.4 | 2.6 | 4.7 | |

| 5 | 8.5 | 3.8 | 3.0 | 3.6 | |

| 6 | 9.8 | 3.7 | 2.9 | 3.5 | |

| 7 | 11.3 | 4.1 | 3.4 | 4.0 | |

| Hexagonal | 3 | 8.1 | 2.5 | 3.0 | 2.0 |

| 4 | 9.5 | 3.2 | 2.7 | 2.1 | |

| 5 | 10.9 | 3.2 | 2.7 | 2.4 | |

| 6 | 12.4 | 3.1 | 2.6 | 2.8 | |

| 7 | 14 | 3.3 | 2.7 | 3.1 | |

| Cylindrical | 3 | 5.3 | 2.9 | 2.3 | 3.5 |

| 4 | 6.9 | 3.3 | 2.1 | 3.6 | |

| 5 | 8.4 | 3.5 | 2.3 | 3.4 | |

| 6 | 10 | 4.1 | 2.2 | 3.6 | |

| 7 | 11.6 | 4.9 | 2.3 | 4.2 | |

| Liquid Amount (L) | Normal Surface Height (cm) | Impact Durations and Reductions | |||||

|---|---|---|---|---|---|---|---|

| No Baffle | Baffle Wall | Baffle Ball | |||||

| Time (s) | Time (s) | Reduction (%) | Time (s) | Reduction (%) | |||

| Rectangular | 3 | 5.2 | 31.3 | 5.5 | 82.3 | 1.4 | 95.4 |

| 4 | 6.5 | 32.4 | 5.7 | 82.5 | 1.3 | 95.9 | |

| 5 | 8.5 | 42.3 | 5.4 | 87.3 | 1.5 | 96.4 | |

| 6 | 9.8 | 35.0 | 4.1 | 88.4 | 1.3 | 96.3 | |

| 7 | 11.3 | 28.3 | 3.6 | 87.3 | 1.7 | 94.1 | |

| Hexagonal | 3 | 8.1 | 34.7 | 3.2 | 90.8 | 1.6 | 95.4 |

| 4 | 9.5 | 30.6 | 4.2 | 86.3 | 1.6 | 94.9 | |

| 5 | 10.9 | 32.0 | 5.0 | 84.3 | 1.5 | 95.2 | |

| 6 | 12.4 | 46.3 | 5.0 | 89.2 | 1.7 | 96.3 | |

| 7 | 14 | 41.4 | 4.5 | 89.2 | 1.6 | 96.2 | |

| Cylindrical | 3 | 5.3 | 30.7 | 6.0 | 80.6 | 1.1 | 96.4 |

| 4 | 6.9 | 37.4 | 7.6 | 79.7 | 1.0 | 97.2 | |

| 5 | 8.4 | 41.9 | 8.3 | 80.1 | 1.4 | 96.6 | |

| 6 | 10 | 42.9 | 8.9 | 79.2 | 1.4 | 96.8 | |

| 7 | 11.6 | 44.8 | 7.6 | 83.0 | 1.7 | 96.3 | |

| Condition | Tank Type | Sloshing Impact Time | Slosh Height Change | Pitch-Inconsistency Difference with Reference | Roll-Inconsistency Difference with Reference |

|---|---|---|---|---|---|

| Without Baffle | Rectangular | Very High | Medium | Highest | Highest |

| Hexagonal | Very High | Highest | Highest | Highest | |

| Cylindrical | Very High | Highest | Highest | Highest | |

| With Baffle Wall | Rectangular | Low | Lowest | Medium | Medium |

| Hexagonal | Low | Medium | Medium | Medium | |

| Cylindrical | Low | Lowest | Medium | Medium | |

| With Baffle Ball | Rectangular | Very Low | Highest | Lowest | Lowest |

| Hexagonal | Very Low | Lowest | Lowest | Lowest | |

| Cylindrical | Very Low | Highest | Lowest | Lowest |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmed, S.; Xin, H.; Faheem, M.; Qiu, B. Stability Analysis of a Sprayer UAV with a Liquid Tank with Different Outer Shapes and Inner Structures. Agriculture 2022, 12, 379. https://doi.org/10.3390/agriculture12030379

Ahmed S, Xin H, Faheem M, Qiu B. Stability Analysis of a Sprayer UAV with a Liquid Tank with Different Outer Shapes and Inner Structures. Agriculture. 2022; 12(3):379. https://doi.org/10.3390/agriculture12030379

Chicago/Turabian StyleAhmed, Shibbir, Huang Xin, Muhammad Faheem, and Baijing Qiu. 2022. "Stability Analysis of a Sprayer UAV with a Liquid Tank with Different Outer Shapes and Inner Structures" Agriculture 12, no. 3: 379. https://doi.org/10.3390/agriculture12030379

APA StyleAhmed, S., Xin, H., Faheem, M., & Qiu, B. (2022). Stability Analysis of a Sprayer UAV with a Liquid Tank with Different Outer Shapes and Inner Structures. Agriculture, 12(3), 379. https://doi.org/10.3390/agriculture12030379