Abstract

Aiming at the problems of the poor passing capacity of machines and low cleaning rate of seed strip during wheat no-tillage sowing in annual double cropping areas of North China, a spiral discharge anti-blocking and row-sorting device (SDARD) was designed and is reported in this paper. After the straw was cut and chopped by the high-velocity rotating no-till anti-blocking knife group (NAKG), the straw was thrown into the spiral discharging mechanism (SDM) behind the NAKG. The chopped straw was discharged to the non-sowing area to reach the effect of seed strip cleaning through the interaction between the SDM and the row-sorting of straw mechanism (RSM). Based on a theoretical analysis for determining the parameters of crucial components, the quadratic rotation orthogonal combination test method was adopted, and the operating velocity of machines (OVM), the rotary velocity of the spiral shaft (RVSS), and the height of the holding hopper from the ground (HHHG) were selected as the test factors. The straw cleaning rate (SCR) was taken as the test index. The discrete element simulation test was carried out, the regression model of the SCR was established, and parameters optimization and field test were carried out. The results show that the significant order of the three influencing factors on the SCR was HHHG > OVM > RVSS. The optimal combination of operating parameters was that OVM was 5 km/h, RVSS was 80 r/min, and HHHG was 10 mm. Under the optimal parameter combination, the average SCR was 84.49%, which was 15.5% higher than the no-till planter without the device, and the passing capacity of machines was great, which met the agronomic requirements of no-tillage sowing of wheat in annual double cropping areas. This study could provide a reference for the design of no-tillage machines.

1. Introduction

Conservation tillage is an advanced agricultural tillage technology that implements no/minimum tillage on farmland covered with crop straw. It can effectively reduce soil wind and water erosion, improve soil fertility level and drought resistance, avoid straw burning, and alleviate ecological pressure. It is an important measure for achieving sustainable agricultural development [1,2,3,4]. When winter wheat is no-tillage sown in annual double cropping areas of North China, the straw is chopped and returned to the field, and a large amount of the straw on the soil surface is covered, which causes the no-till planter to be easily blocked during operation. The problems of the poor passing capacity of the machine and poor furrowing effect are severe [5,6,7,8,9], and if the straw or stubble falls on the seeding row during operation, it will affect the contact degree between the seed and the soil and reduce the seed implantation quality [10,11,12,13,14,15]. Therefore, timely and effective separation of the straw from the planter and its working parts and discharge of the straw residue to the non-sowing area are crucial problems for solving the blockage of the wheat no-till planter and improving the sowing quality [16,17].

Existing research mainly focuses on the anti-blocking performance of no-till planters—that is, the passing capacity of the machines. Wang et al. [18] studied the telescopic lever furrowing and anti-blocking unit, which used the telescopic lever to collect the straw in front of the furrowing opener and release it to the row, which greatly affected anti-blocking ability when furrowing. Lin et al. [19,20] designed and studied an Archimedes spiral type notched disc knife based on the Archimedean spiral, which improved the stubble-breaking performance of the disc knife. Lu et al. [21,22,23,24] studied a rotary cutting anti-blocking device with a slide plate pressing straw and the friction characteristics of straw during operation. Compared with a zonal rotary and strip chopping no-till planter, this device had better passing capacity, even emergence, and lower rotary velocity.

Although the currently developed anti-blocking device can meet the requirements of the passing capacity of machines, a part of the straw remains in the sowing strip after the operation, and the cleaning effect of the sowing strip is still difficult to guarantee. Straw falling on the seed row will affect the seed implantation quality, then affect the seed emergence, and even reduce the grain yield. Improving the cleaning effect of seed strips is becoming another research hotspot of no-tillage anti-blocking devices. For example, Yuan et al. [25] studied a straw cleaning device for wide-narrow maize no-tillage sowing strip in the drip irrigation area. They put forward the seed strip cleaning method to meet the agronomic requirements of no-tillage sowing of wide-narrow maize in the drip irrigation area. Yu et al. [26] studied and designed a spiral-split sowing strip cleaning device to solve the problems of straw blockage during no-tillage sowing in Northeast China. These studies mainly focus on the no-tillage sowing of maize in annual once cropping areas in the northeast and northwest, while few studies exist on the seed strip cleaning of wheat no-tillage sowing in annual double cropping areas in the Huang-Huai-Hai. Mainly because the row spacing of wheat no-tillage sowing in annual double cropping areas in the Huang-Huai-Hai is narrow, there is no leisure period between the harvest of the last crop and the sowing of the next crop. The straw has strong deformation resistance during the sowing period, and it is difficult to row-sort the straw and carry out seed strip cleaning.

This paper proposes an SDARD of wheat no-till planter for solving these above problems. It can efficiently discharge the straw to the non-sowing area on both sides of the machine and between the seed strips, while ensuring passing capacity, playing the role of straw cleaning, effectively reducing the furrowing opener’s blockage, and concentrating the straw in the non-sowing area. Through theoretical analysis, the parameters of the critical components of the SDARD are determined. The quadratic rotation orthogonal combination test determines the optimal structure and working parameters through a discrete element simulation test. Finally, a field test on the optimized SDARD was conducted to verify the above theoretical analysis and discrete element simulation experiments.

2. Materials and Methods

2.1. Machine Structure and Working Principle of the SDARD

2.1.1. Structure of the SDARD

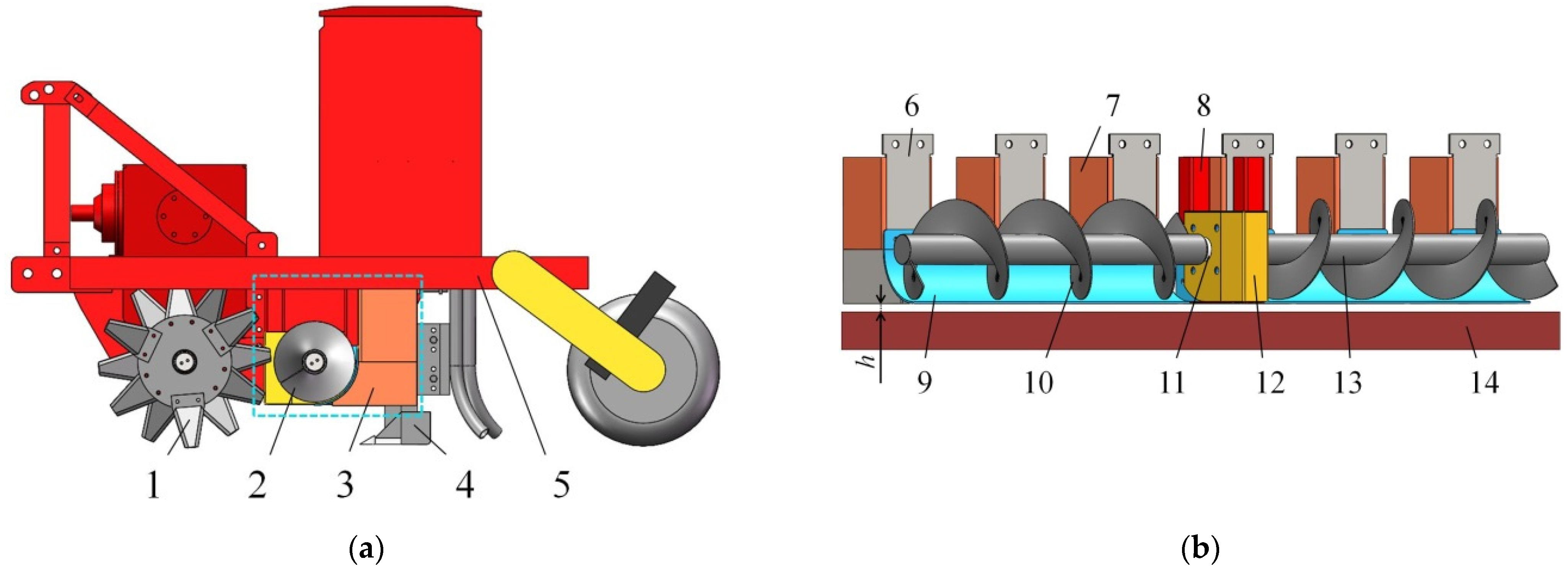

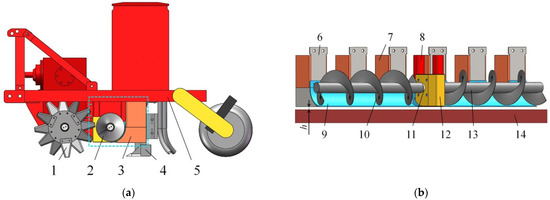

As shown in Figure 1a, the SDARD was installed between the NAKG (1) and the furrowing opener (4) of the wheat no-till planter. Moreover, it was composed of the SDM (2) and the RSM (3). Its overall structure is shown in Figure 1b.

Figure 1.

SDARD with its specific position. (a) Installation position of SDARD of wheat no-till planter; (b) the structure of SDARD. Note: 1, NAKG; 2, SDM; 3, RSM; 4, furrowing opener; 5, frame; 6, seed strip baffle; 7, side baffle; 8, support-connecting; 9, holding hopper; 10, spiral blade; 11, rolling bearing; 12, inclined anti-winding plate; 13, spiral shaft; 14, soil. h is the height of the hopper above the ground, mm. h also indicates a gap between the hopper (9) and the soil (14). Moreover, there is no contact. h > 0.

The SDM (2) comprised spiral shaft (13), spiral blade (10), holding hopper (9), support-connecting frame (8), rolling bearing (11), and inclined anti-winding plate (12). Wherein the spiral blade (10) was integrally formed with the spiral shaft (13), combined with the helix direction of the spiral blade (10), the two spiral shafts (13) were reversely installed in the rolling bearing (11), fixed on the support-connecting frame (8) through the inclined anti-winding plate (12), and the support-connecting frame (8) was welded on the frame (5). Holding hopper (9) was located directly below the spiral blade (10), and there was a gap between the bottom of the holding hopper (9) and the soil surface (14) (essential position parameter h), which was not in contact with the soil.

The RSM (3) comprised seed strip baffle (6) and side baffle (7). Seed strip baffle (6) was installed in front of the furrowing opener (4), and the top was connected with frame (5) through bolts. Both sides of the seed strip baffle (6) were equipped with a side baffle (7) that was integrally formed. Furthermore, the top of the holding hopper (9) was fixed at the bottom of the seed strip baffle (6) by bolts.

2.1.2. Working Principle

The power of the SDARD was provided by the rear output shaft of the tractor. When working, the high-velocity rotating NAKG was achieved by cutting and chopping the soil and straw, reaching the power-driven anti-blocking effect and guaranteeing the passing capacity.

Under the action of high-velocity rotation of the NAKG, most of the straw was thrown directly into the holding hopper, alternatively, to the front side of the seed strip baffle, and fell on the hopper through free-fall motion. The SDM accumulated and transported the straw falling into the hopper to both sides of the planter, playing roles of collection and diversion. When the spiral blade transported the straw in the hopper to the gap between adjacent seed strip baffles, the position corresponded to the no-sowing areas, the straw tended to move backward, and it would fall from the gap to the non-sowing area between the seed strips, achieving the effect of straw-cleaning in the seed strips.

A small part of the straw was directly thrown into the gap between the adjacent seed strip baffles by the NAKG and directly fell, or was rebounded by the side baffle, to the non-sowing area, playing the role of row-sorting the straw.

2.2. Parameter Design of the SDM

The relationship between the material bearing limit of the SDM and the straw feeding amounts (SFA) was an important index for evaluating the device’s conveying performance stability and straw discharge effect. When designing, in order to ensure that the actual SFA was within the limit of the material bearing capacity of the mechanism, the minimum material bearing capacity of a device should be greater than the maximum SFA to ensure the stable and reliable conveying performance of the device and good straw conveying effect.

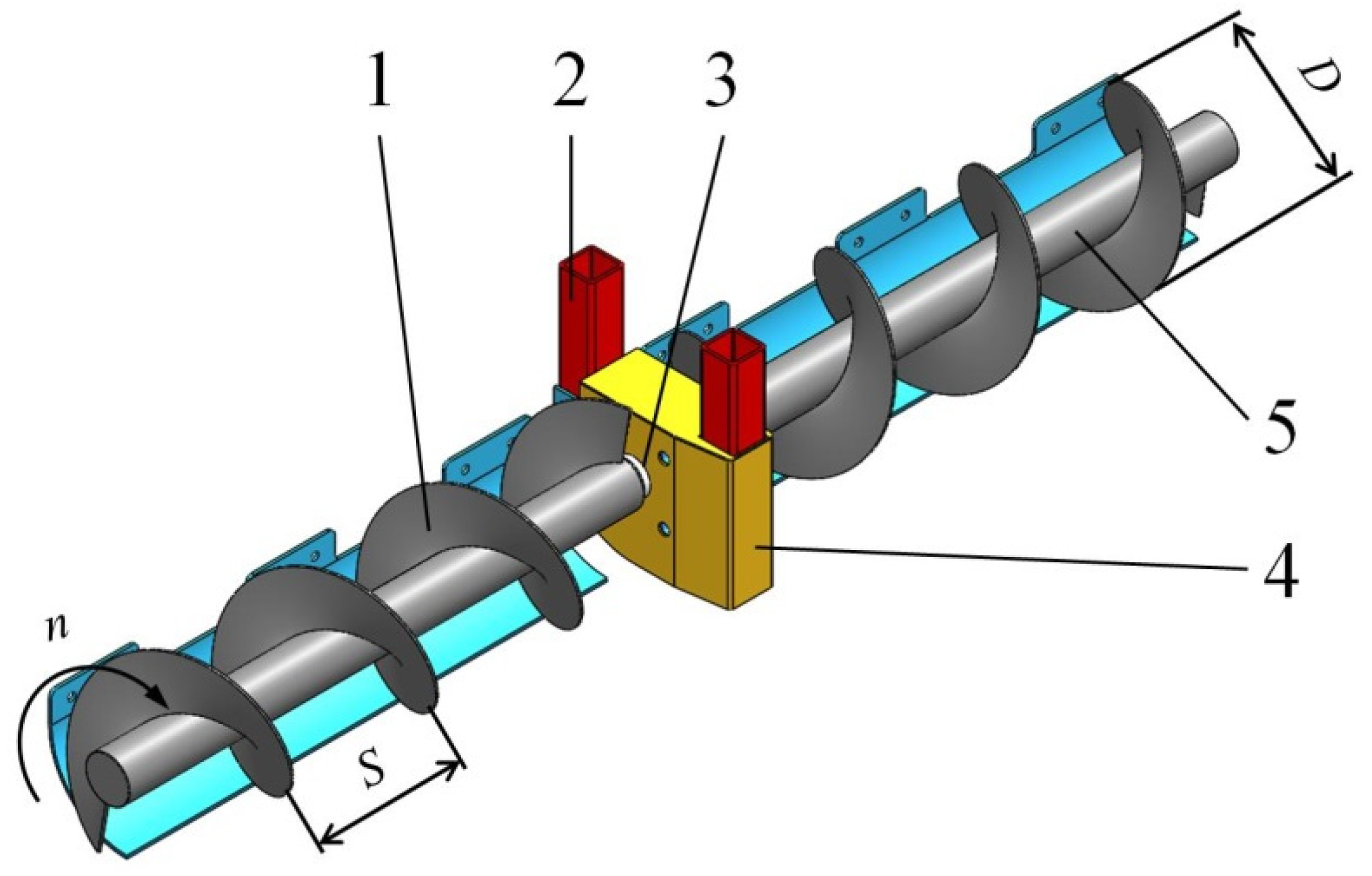

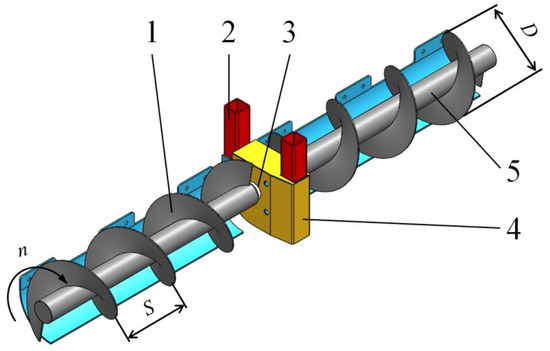

Therefore, this research calculated the maximum SFA Qs according to the actual operating environment of the annual double cropping areas in North China, and then designed and calculated the critical structural dimensions (spiral blade outer diameter D, pitch S, and HHHG h) and operating parameters (RVSS n) according to the SFA Qs (Figure 1 and Figure 2).

Figure 2.

Critical parameters of SDM. 1, Spiral blade; 2, support-connecting frame; 3, rolling bearing; 4, inclined anti-winding plate; 6, spiral shaft; 5, holding hopper. D is the outer diameter of the spiral blade, m; S is pitch, m; n is the RVSS, r/min.

2.2.1. The SFA Qs

The SFA Qs referred to in this paper was the maximum value of the total mass of straw residues thrown into the holding hopper of the SDM by the NAKG in unit time, which was the total mass of disappeared straw in the sowing strip, while these straws were all from stover and stubble of maize on the surface before the operation. Its size was mainly determined by the straw mulching quantity (SMQ), the seed strip cleaning area of no-till planter per-unit time, and the seed strip cleaning rate. The area was determined by the width of machines, operation velocity, and time. Therefore, to obtain quantitative data of SFA, a mathematical model of the SFA and the above-mentioned related factors was constructed.

In order to simplify the model, it was assumed that: (1) the straw was covered evenly on the ground surface before operation; (2) considering the cutting effect of the NAKG on soil and the gap between the bottom of the hopper and soil surface, the soil would be discharged from the gap in preference to the straw under gravity. Thus, the influence of the soil on the SFA was not considered in the modeling process.

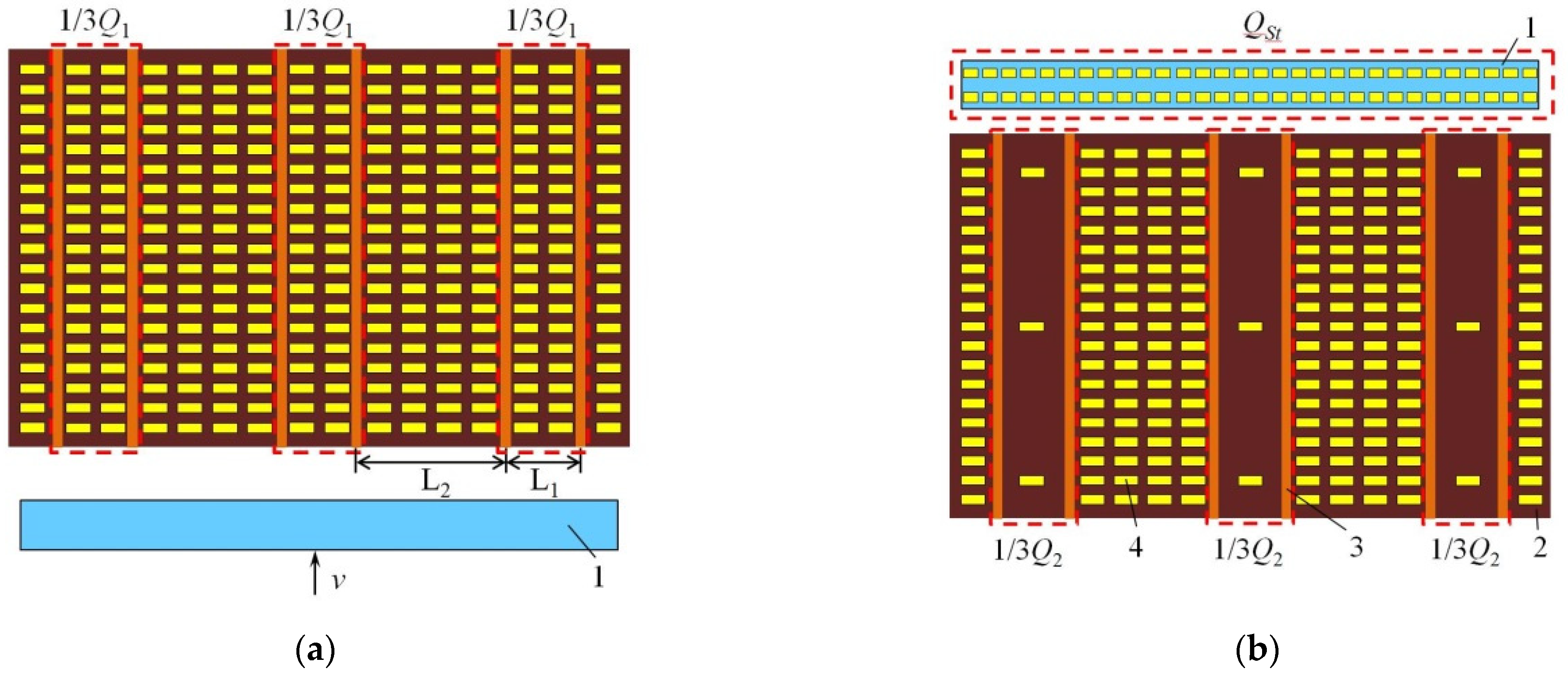

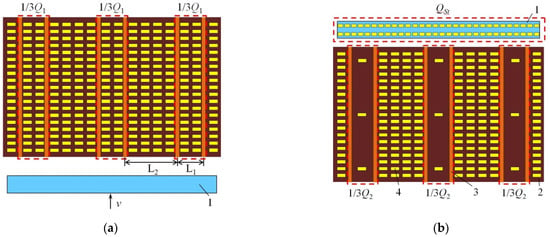

As shown in Figure 3, the mathematical model could be described as an ideal process: within a specific time t, the total mass QSt of straw thrown into the hopper by the NAKG was equal to the mass difference of straw that disappeared in the sowing strip before and after the operation, that was, QSt = (Q1 − Q2). The mass difference per unit time could be determined by SMQ CS, OVM v, the number of sowing strips z, the total width of sowing strip cleaning L1, and SCR λ. The conversion from the SMQ CS to the SFA Qs was realized. The mathematical model of the relationship between SFA and SMQ established by the mathematical induction and the quotient-remaining method was as the following equation:

where Qs is the SFA; QSt is the total feeding mass of straw in the hopper after a specific operation time, kg; t is the operation time of no-till planter, min; Q1 is the mass of straw before sowing strip operation, kg; Q2 is the residual mass of straw after sowing strip operation, kg; CS is the SMQ, kg/m2; v is the OVM, km/h; z is the number of corresponding sowing strips; L1 is the total cleaning width of the sowing strip, mm; λ is the SCR,%.

Figure 3.

Mathematical model of the relationship between the SFA and the SMQ. (a) Theoretical model before no-tillage operation; (b) theoretical model after a no-tillage operation. Note: 1, the hopper of SDM; 2, no-tillage surface of the field; 3, seed line; 4, straw residue. Q1 is the mass of straw on the sowing strip before an operation, kg; Q2 is the residual mass of straw on the sowing strip after an operation, kg; QSt is the total mass of straw fed into the hopper after a certain period of operation, kg; v is the OVM, km/h; L1 is the total cleaning width of sowing strip, mm; L2 is the total width of non-sowing area, mm.

Through the quadrat method [27], the maximum value of the SMQ CS on the ground surface of pre-operated maize was 1.72 kg/m2, the typical operating velocity of 2BMQF-6/12A wheat no-till planter was 3~5 km/h, the maximum OVM v was 5 km/h, each side of the SDM corresponded to 3 sowing strips, z was 3, the width L1 of the sowing strip was 150 mm, and the SCR λ took the maximum value of 1. According to Equation (1), the SFA Qs of the SDM was 64.5 kg/min.

2.2.2. Outer Diameter of the Spiral Blade D

The outer diameter of the spiral blade was an essential parameter in the design of SDM, which was directly related to the straw discharged capacity and structural size of the mechanism. Referring to the Darnell–Mol solid conveying theory [28] proposed by Darnell and Mol, the calculation equation of the spiral blade outer diameter [29,30] was as follows:

where D is the outer diameter of the spiral blade, m; K is the material characteristic coefficient; Qs is the SFA, kg/min; ψ is the filling factor; ρ is the material density, kg/m3; C is the inclination coefficient.

By consulting the literature [29,30,31,32,33], the material characteristic coefficient K was 0.05, filling coefficient ψ took 0.3, straw density ρ took 240 kg/m3, and when the SDM was in the horizontal state during operation, the inclination coefficient C was taken as 1. According to Equation (2), the minimum value of the spiral blade outer diameter D was 0.246 m, and D was 0.250 m after rounding.

2.2.3. Pitch S

When the pitch increased, the axial conveying velocity increased, but the conveying stability decreased. The conveying stability was great when the pitch decreased, but the conveying velocity slowed down. The pitch calculation equation was as follows:

where S is the pitch of the spiral blade, m; K1 is the pitch coefficient; D is the outer diameter of the spiral blade, m.

Referring to the transportation machinery design and selection manual [30], when the pitch coefficient K1 was taken as 1, the pitch value S calculated by Equation (3) was 0.250 m.

2.2.4. The HHHG h

The hopper should have a suitable height from the ground. On the one hand, it could reduce the disturbance of the hopper to the soil and let part of the soil pass through the gap. The HHHG h should be greater than 0 to avoid contact with the soil surface. On the other hand, combined with the dropping track of straw under the action of NAKG, the value of the HHHG would affect the amount of straw falling into the hopper and also impact the SCR λ, so the relationship between h and λ should be determined according to the simulation test.

2.2.5. The RVSS n

When the spiral shaft rotated, the straw was affected by the normal thrust of the spiral blade, and the radial component of the thrust and a frictional force of the spiral blade acting on the straw would carry some straw to rotate around the spiral shaft [31]. When the RVSS was too low, the straw discharge velocity was slow, which was accessible to lead to the blockage of the SDM. When the RVSS increased, the centrifugal force would gradually replace the blade’s thrust and play a leading role. When the RVSS exceeded a specific limit value, the straw would be thrown outward due to excessive centrifugal force so that it could not be transported, thus reducing the transportation stability of straw [32,33]. The calculation equation of RVSS was as follows:

where n is the RVSS, r/min; Qs is the SFA, kg/min; D is the outer diameter of spiral blade, m; S is the pitch of the spiral blade, m; ψ is the filling factor; ρ is the material density, kg/m3; C is the inclination coefficient.

Substituting the above-mentioned calculated and selected parameters into Equation (4), it was calculated that the minimum RVSS was 73.2 r/min. In order to ensure that its maximum bearing capacity could adapt to the SMQ in annual double cropping areas, the minimum value of n was 80 r/min. Considering that the impact of RVSS n on the SCR was unknown and that the RVSS was the main factor affecting the stability of material transportation [32], follow-up was based on discrete element simulation experiments for analyzing the variation law of n and λ.

2.3. Parameter Design of the RSM

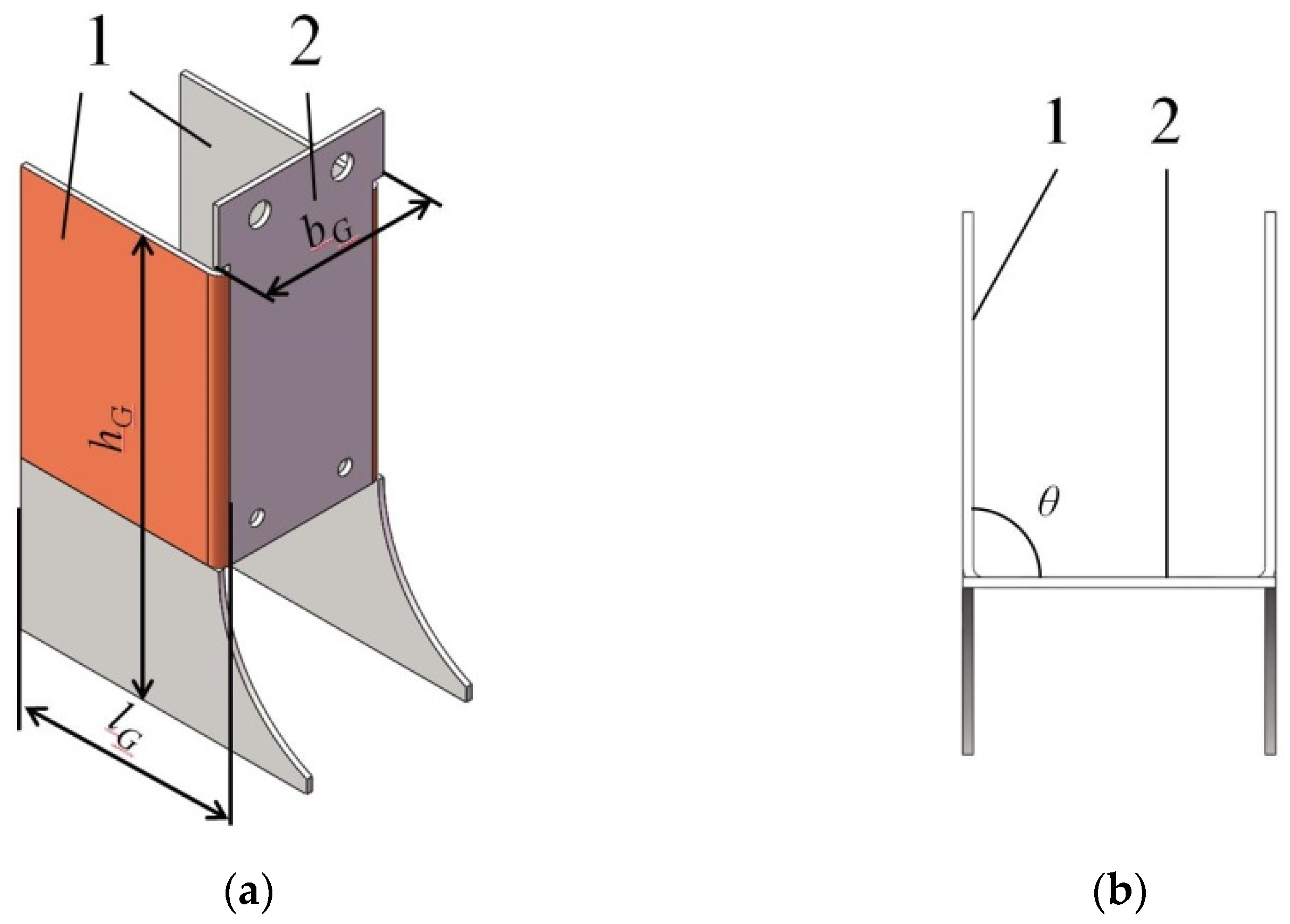

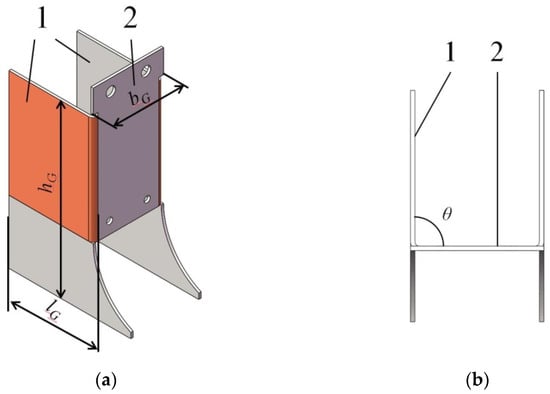

The RSM could discharge the straw residue to the non-sowing area on both sides of the sowing strip and directly prevent the straw from falling into the sowing strip, improving the cleaning effect of the seed strip. The critical parameters of RSM are shown in Figure 4, including width bB, height hG, length lG, and included angle θ.

Figure 4.

Critical parameters of the RSM. (a) Oblique view; (b) top view. Note: 1, side baffle; 2, seed strip baffle. bG is the width of the RSM, mm; hG is the height of the RSM, mm; lG is the length of the side baffle, mm; θ is the included angle between the strip baffle and the side baffle.

2.3.1. The Width of the RSM bG

Agronomic conditions had specific requirements for the width of the no-tillage sowing seed strip and the gap between the adjacent sowing strips. When designing the RSM, first of all, it had to be ensured that the straw could not fall into the sowing strip, so the width between the side baffles on both sides of the same RSM had to be greater than the row spacing of narrow rows. Secondly, considering that the row spacing of no-tillage sowing of wheat was narrow and the number of corn stalks in the field at the sowing date was large, there needed to be enough space to place straw, so the spacing between adjacent RSMs had to be maximized.

As shown in Figure 3a, the width and narrow rows of no-tillage wheat in annual double cropping areas in northern China required the row spacing of two adjacent sowing strips to be L = 340 mm, the total cleaning width of sowing strip L1 ≥ 150 mm, and the total width of non-sowing area L2 ≤ L − L1 = 190 mm. In order to meet the above requirements, the width of the RSM bG = L1 = 150 mm was determined.

2.3.2. The Height of the RSM hG

In the RSM, the function of the seed strip baffle and the side baffle was to prevent the straw from falling into the sowing strip from the front and side. If the height of the RSM was short, the straw could fly into the sowing strip across its top or fall into the seed strip along the gap at the bottom, and the cleaning effect of the seed strip would be weakened.

Combined with the installation position of the no-till planter, the optimum range of height threshold of RSM was 350~370 mm. In order to improve the effect of preventing straw from falling into the seed strip, the height of RSM hG was selected as 370 mm.

2.3.3. The Length of the Side Baffle lG

The side baffle would guide the straw to the non-sowing area. The reasonable length design would avoid the straw blocking the furrowing openers and ensure the seed strip cleaning effect. Considering the above factors, the length of the side baffle lG was 180 mm.

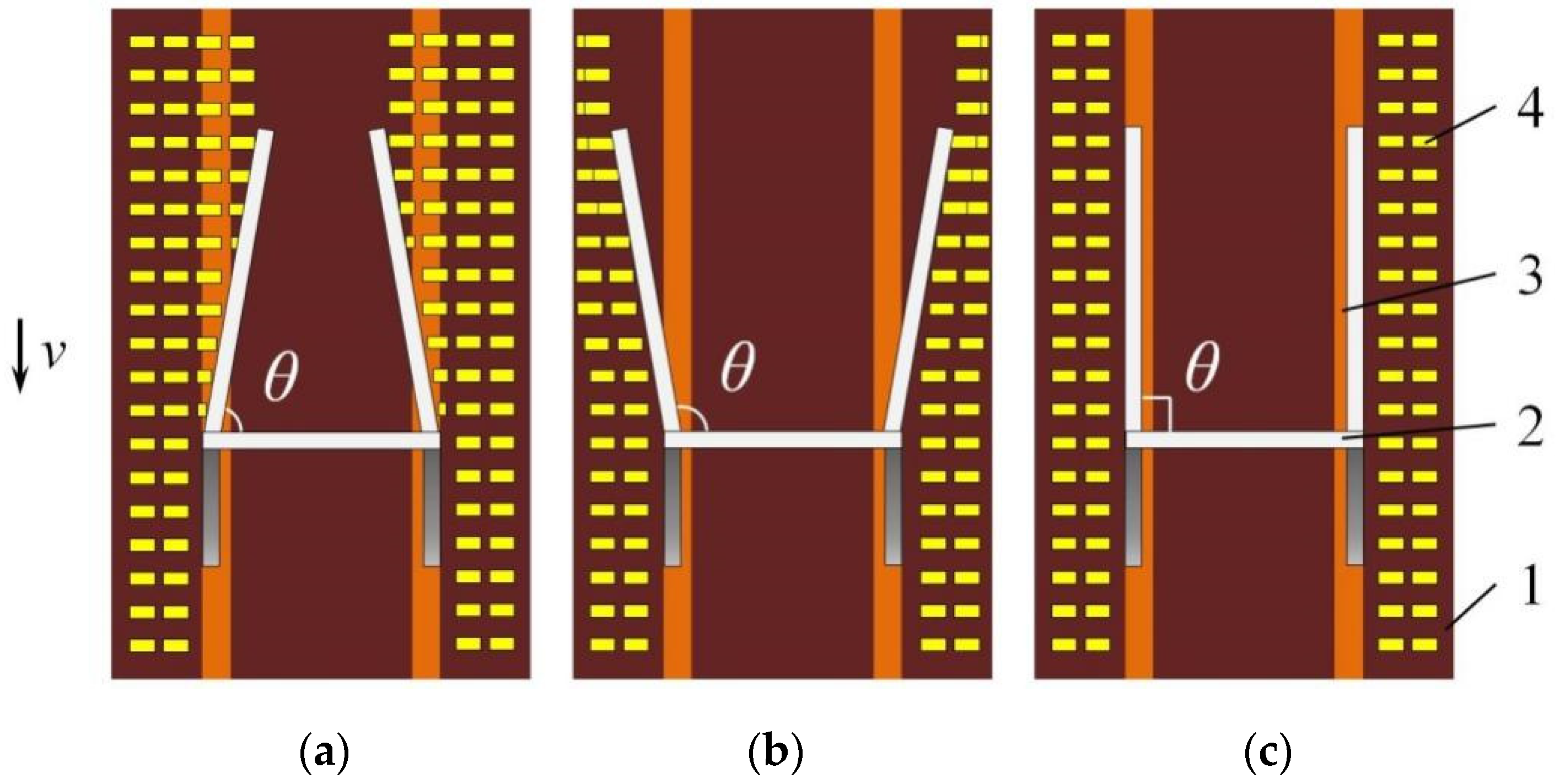

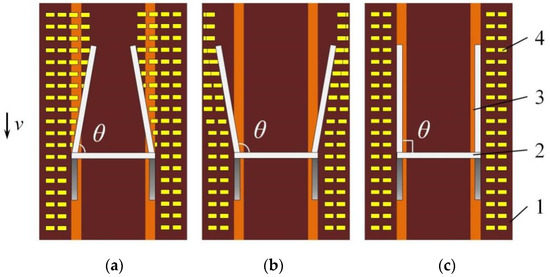

2.3.4. The Included Angle between the Seed Strip Baffle and the Side Baffle θ

In order to ensure that all straw fell in the non-sowing area and was distributed evenly, the included angle θ between the seed strip baffle and the side baffle had to be designed. As shown in Figure 5, when θ < 90°, the function area of the side baffle could not completely cover the sowing strip, which increased the probability of straw falling into the seed row. When θ > 90°, most straw was concentrated in the centerline of the non-sowing area, and the uniformity of straw distribution was poor. To sum up, the included angle was taken θ = 90°.

Figure 5.

Effect of θ on cleaning effect of seed strip. (a) θ < 90°; (b) θ > 90°; (c) θ = 90°. Note: 1, no-tillage surface of the field; 2, RSM; 3, seed line; 4, straw.

2.4. Rational and Reasonable Parameters of the SDARD by EDEM Optimization Method

The discrete element method was often used to study the relationship between working parts and multi-granular media such as soil. In this research, the discrete element simulation software EDEM was used to establish the computer simulation model between the SDARD and its operation object (straw and soil) and to simulate the actual operating conditions of the SDARD. The SCR in the sowing strip was selected as the test index in the simulation process, and OVM, RVSS, and HHHG were taken as the primary test factors. The influence of various factors on the SCR was analyzed through a discrete element simulation test to provide the basis for the optimal structure and operating parameters and to lay the foundation for the subsequent prototype trial production and field test.

2.4.1. Establishment of the Discrete Element Simulation Model

Because the computer’s computing power and simulation efficiency were considered, spherical particles with a radius of 7 mm were selected as soil particles. The mechanical relationship model between soil particles was a coupled contact model consisting of the Hertz–Mindlin with bonding model and the Hertz–Mindlin (no slip) model [25,26], and the shear modulus was 1.0 × 106 Pa, soil density 1850 kg/m3, Poisson’s ratio 0.38. They were combined with the actual situation of straw in the field. An extended linear model with a length of 88 mm composed of a diameter of 16 mm and a ball center interval of 4 mm was used as the straw particle model. The Hertz–Mindlin (no slip) model was selected as the mechanical relationship model of the straw model, and the shear modulus was 1.0 × 106 Pa, straw density 240 kg/m3, Poisson’s ratio 0.4, and the basic contact parameters of the discrete element simulation [34,35] are shown in Table 1.

Table 1.

Parameter settings for EDEM simulation.

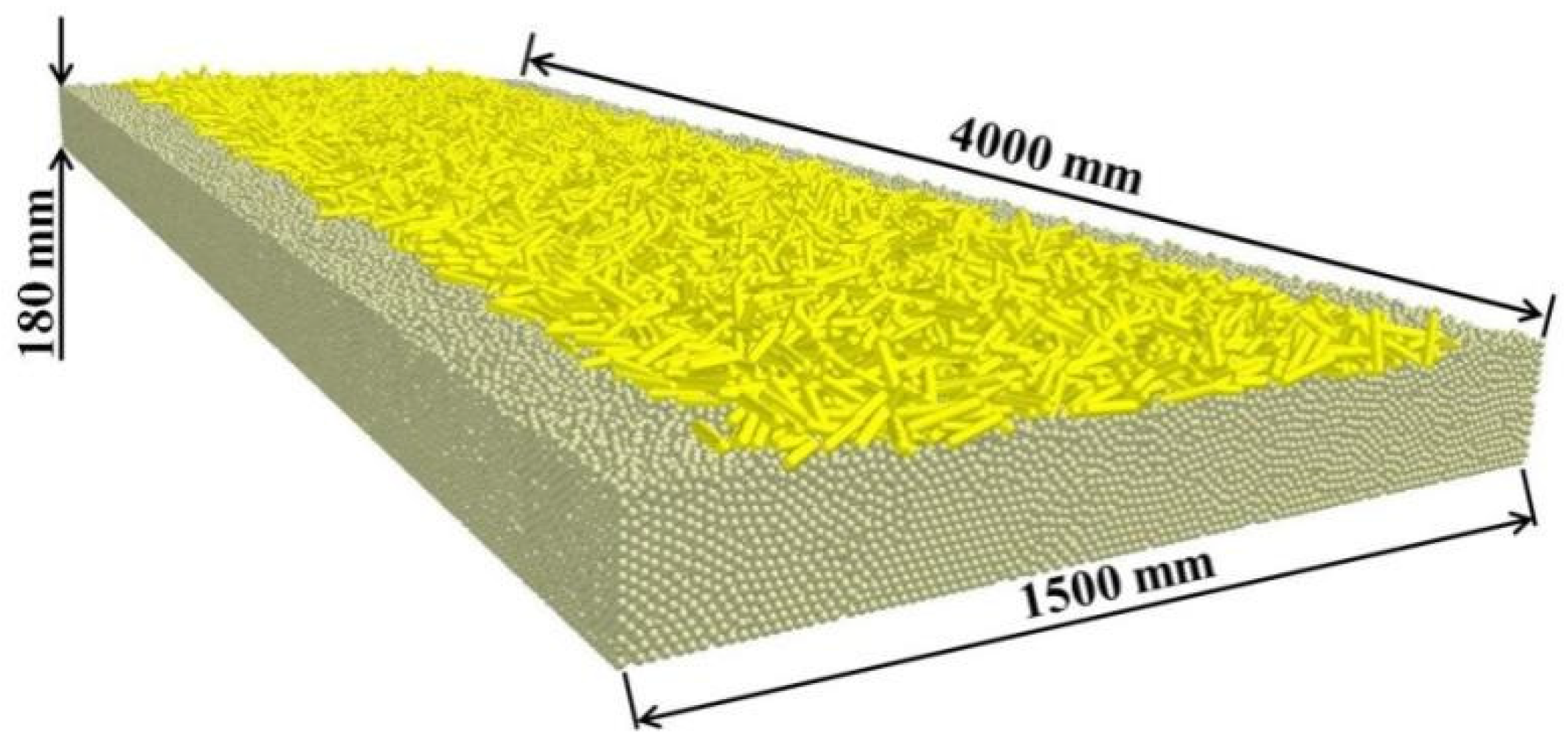

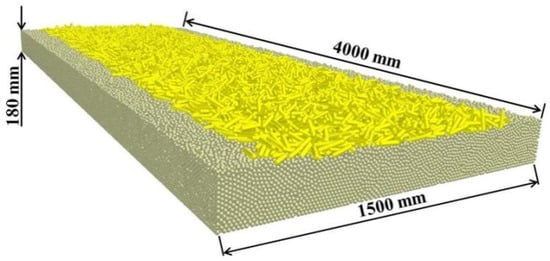

In EDEM, a virtual soil bin suitable for SDRAD of wheat no-till planter was established. Firstly, the soil particles were generated to make the soil particles settle naturally under gravity, and by appropriately extending the simulation time, it was ensured that stable bonding bonds were formed between soil particles and that they were as static as possible. After the soil was settled, the straw was dropped, and the straw particles were dropped above the soil particles to make the model as close as possible to the actual soil and straw conditions. The actual size of the soil bin (length × wide × height) was set at 4000 mm × 1500 mm × 220 mm, with a 180 mm thick soil layer and 40 mm thick straw layer. Figure 6 shows the built virtual soil bin model.

Figure 6.

Virtual soil bin model.

After the soil bin was established, the SOLIDWORKS 3D model of SDARD with a scale of 1:1 was imported into the EDEM software in a STEP format file. The material property of the SDARD was 45 steel, the density was 7800 kg/m3, the Poisson’s ratio was 0.31, and the shear modulus was 7.0 × 1010 Pa.

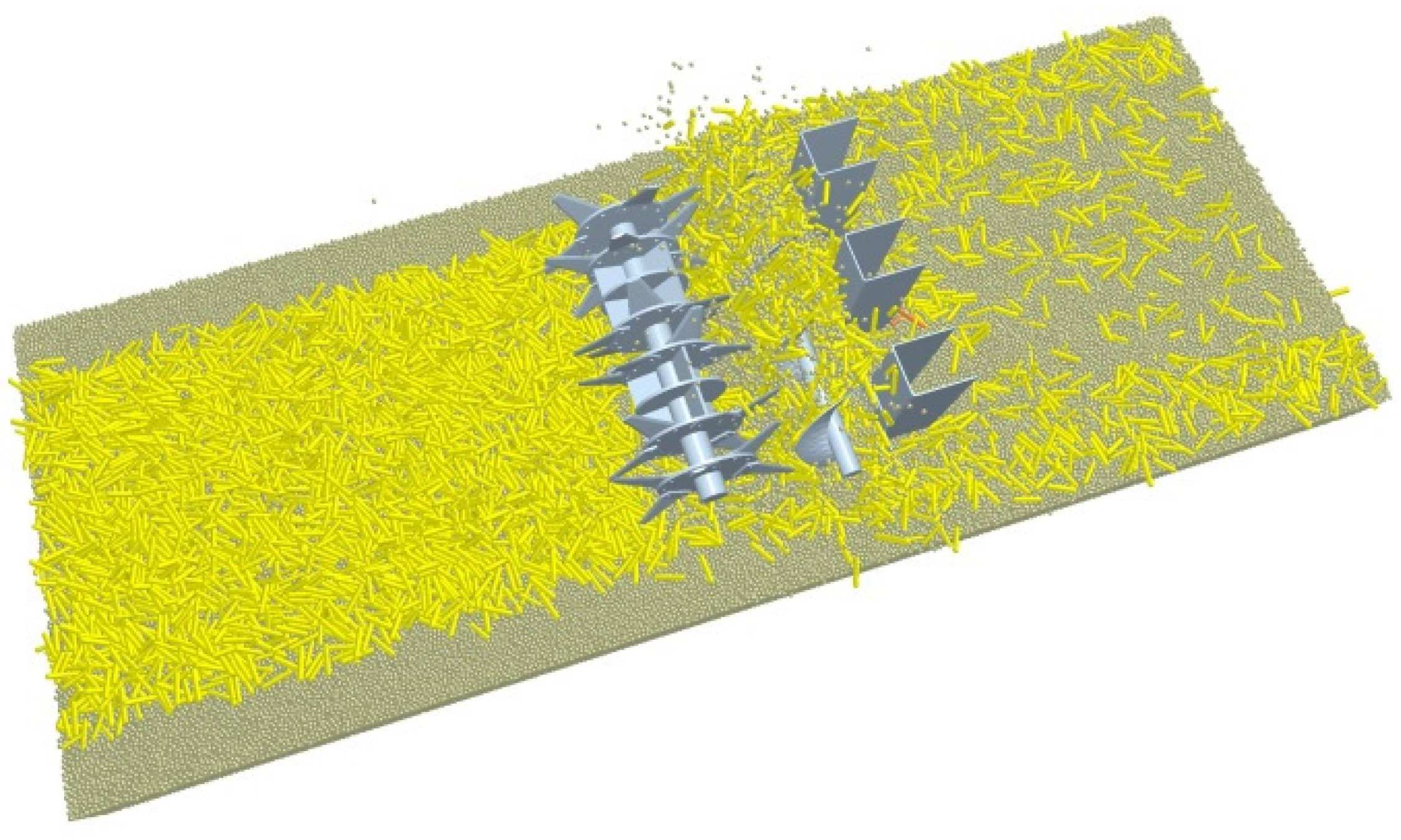

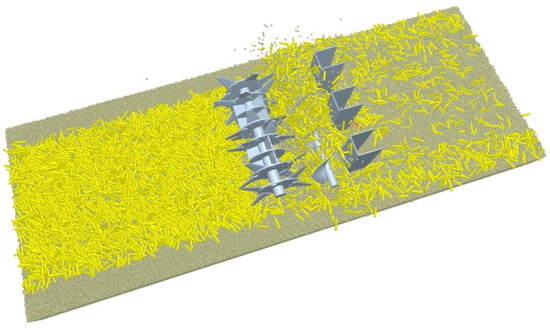

2.4.2. Simulation Process

The SDARD was set at one end of the soil bin and started. In order to ensure the continuity of the operation process of the SDARD and the movement of soil and straw particles, the minimum step size was set as 0.0001 s, the total simulation time was 5.0 s, and the grid size was set as 2.5 times of the minimum soil particle size—i.e., 17.5 mm. The simulation operation process of SDARD is shown in Figure 7.

Figure 7.

Simulation operation process of the SDARD.

2.4.3. Simulation Experimental Design

Comprehensively considering the theoretical analysis and results of the design of critical components, taking the SCR as the evaluation index, and selecting OVM, RVSS, and HHHG as the test factors, the quadratic regression combined simulation test was carried out in EDEM. According to the main technical parameters, theoretical analysis, and pre-test of the device, it was determined that the value range of the OVM was 3~5 km/h, the value range of RVSS was 80~160 r/min, and the value range of HHHG was 10~30 mm. The Box–Behnken method in Design Expert 10.0.7 software was used to determine the test factors and codes, as shown in Table 2.

Table 2.

Test factors and coding.

3. Results and Discussion

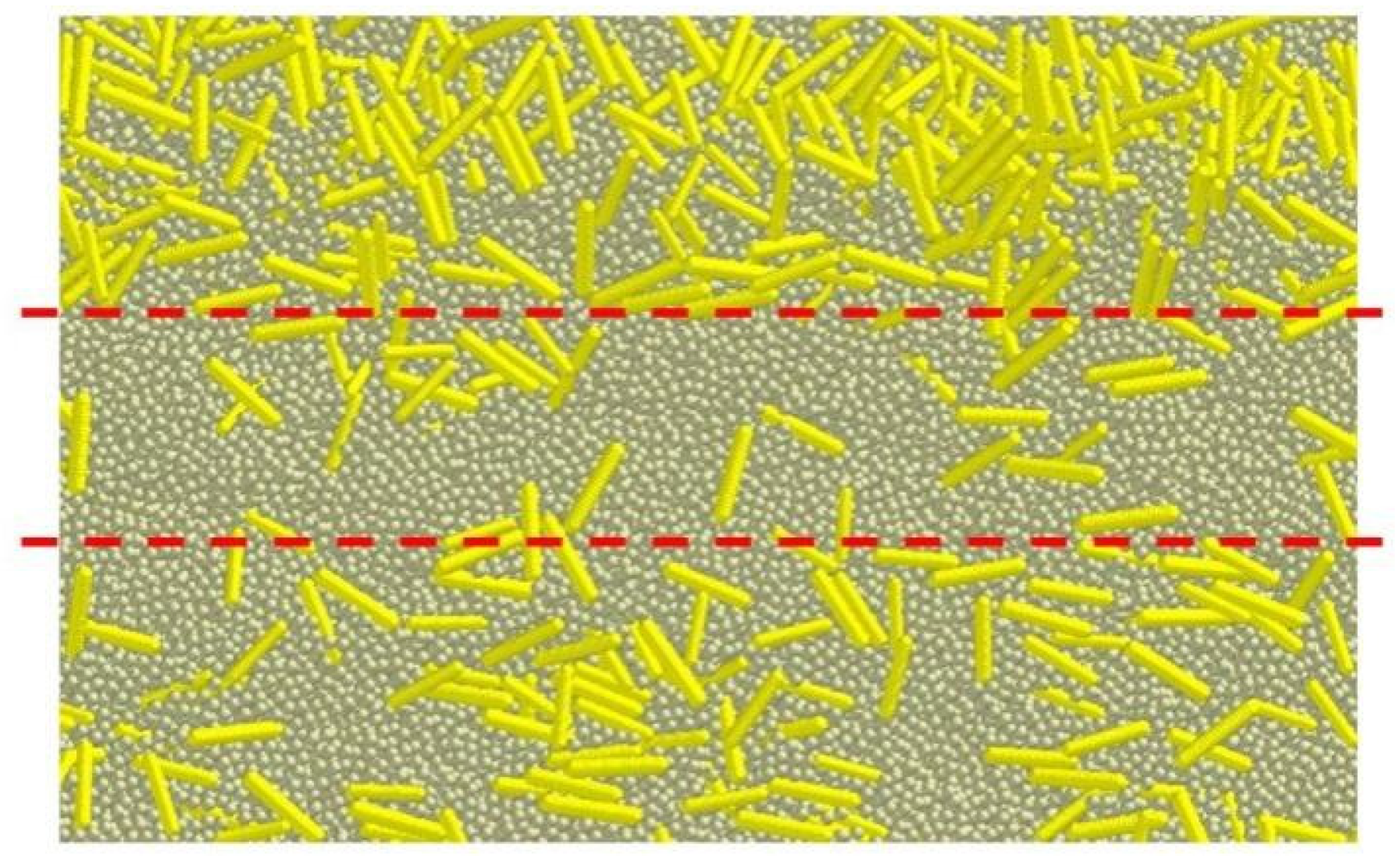

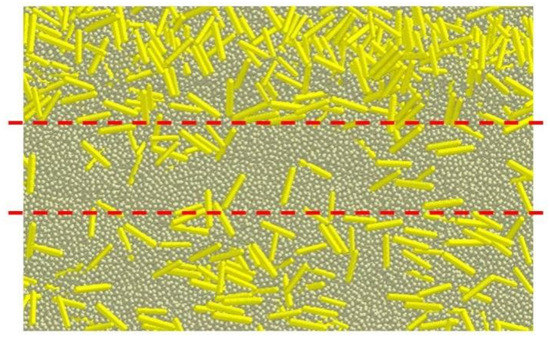

The Selection option in the Analyst module of EDEM software was used to establish a Total Mass Sensor grid area (mass sensor) with a length and width of 2000 × 150 mm at the corresponding sowing strip position. The corresponding SCR was obtained by calculating the straw quality change before and after the operation of the SDARD in the area. The local straw cleaning effect of the sowing strip is shown in Figure 8.

Figure 8.

Test area of sowing strip straw cleaning effect. Note: The red dotted line area is the sowing strip after the operation of the SDARD.

The calculation equation of SCR was as follows:

where λ is the SCR, %; m1 is the mass of straw before the operation, kg; m2 is the mass of straw after the operation, kg.

3.1. Regression Model Construction

The test results are shown in Table 3. According to the test data in Table 3, the quadratic regression analysis of the straw cleaning test results of the sowing strip was carried out through the Design Expert software, and a quadratic response surface regression model was established with the test index as the SCR and the test factors as the OVM, the RVSS, and the HHHG; the equation was as follows:

Table 3.

Experimental design and results.

The results of the analysis of significant variance (Table 4) show that in the regression model, the y model, which is representative of the SCR, is p < 0.01; the regression model is highly significant; and the influence of X1, X2, X3, and X1 × 3 is highly significant (p < 0.01). X32 has a significant effect (0.01 < p < 0.05). The effect of X12 is relatively significant (0.05 < p < 0.1). The other items are not significant. The significant order of the three influencing factors on the SCR is X3 > X1 > X2—that is, the HHHG, the OVM, and the RVSS. The lack of fit test p > 0.1, the regression model is highly significant, the lack of fit is insignificant, and the coefficient of determination R2 of the equations was 0.9453, demonstrating that the regression models could explain more than 85% of the response values. Moreover, the regression model is effective.

Table 4.

Experimental design and results.

3.2. Analysis of the Influence of Particular Factor Numerical Change on Indicator

Changes in either factor will have an impact on the results. It can be seen from Equation (6) that when the value range of X1 is 3~5 km/h, X1 and y are positively correlated, so when X1 increases, the value of y will also increase. When the value range of X2 is 80~160 r/min, X2 is negatively correlated with y, and when X2 increases, the value of y will decrease slightly. When the value range of X3 is 10~30 mm, X3 and y are also negatively correlated, so when X3 increases, the value of y will decrease sharply. Furthermore, because the coefficient of X1 is 2.55, the coefficient of X2 is −1.05, and the coefficient of X3 is −3.52. The more significant the absolute value of the coefficient, the more significant the influence on y. The significant order is X3 > X1 > X2. The conclusion of the above analysis is the same.

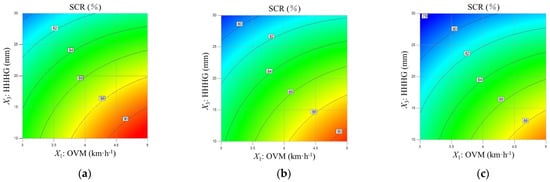

3.3. Basic Theoretical Analysis of the Influence of Interaction Factors on Indicator

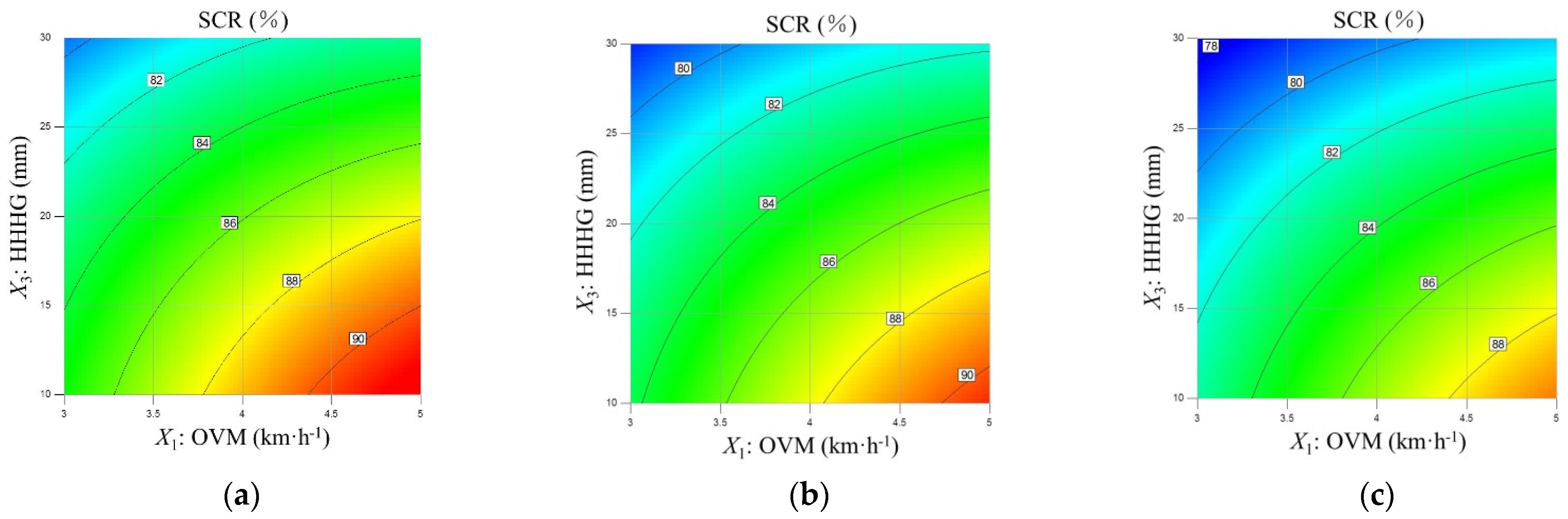

Based on the experimental design and results (Table 4), this study separately analyzed the influences of the interactive factors X1, X3, and X1X3 on y. It can be seen that X1 and X3 have an interactive effect on y, and the response surface of the two interactions is shown in Figure 9. X2 is fixed at 120 r/min. When X1 is constant, y decreases with the increase in X3, and the two factors are negatively correlated. When X3 is within 10~30 mm, the smaller the gap between the bottom of the holding hopper and the ground surface and the less straw that can pass directly through the gap when the planter is operating, which can effectively improve the operation effect and y of the planter.

Figure 9.

Effects of interaction factors on the SCR. (a) X2 = 80 r/min; (b) X2 = 120 r/min; (c) X2 = 160 r/min.

When X3 is constant, y increases with the increase in X1. Thus, y is positively correlated with X1. Considering a greater X1, the greater the soil cutting pitch during the operation of the NAKG and the fewer times the soil and straw are effectively cut and chopped within the same distance. In addition, the amount of soil beyond a certain depth is more significant than the amount of straw, X1 is increased, the amount of soil thrown into the holding hopper within the same distance is reduced, the decline degree of soil surface level is reduced, the amount of straw that can pass through the gap between the bottom of the holding hopper and the surface is reduced, and y is improved. X1 is low, the amount of soil cut by the NAKG is large, and the decline in the surface soil level will increase the gap, resulting in more straw staying in the sowing strip, which has a specific impact on the straw cleaning effect in the seed strip.

It can be seen from Figure 9 that with the increase in X2 (increasing from 80 to 160 in numerical value), the model shows a gradually falling trend. It is more evident that the vertices in the red area of the model in Figure 9a are above y = 90%, while the red vertices of the model in Figure 9c are below y = 90%. However, with the change in X2, the model’s shape is basically unchanged, which shows that the overall trend of the model for the test index y is unchanged, and it also shows that the model is stable and effective. Moreover, as X2 decreases, the area of the red area is getting more minor, and the area of the blue area is getting more evident. Further, the more significant the red area, the higher the value of y, the more significant the blue area, the lower the value of y.

3.4. Discussion

Based on the above analysis, it can be concluded that the relationship between OVM and SCR is such that when OVM gradually increases, SCR will decrease when OVM is at 3~5 km/h—on the premise that OVM interacts with HHHG. It is because the more significant the soil cutting pitch during the operation of the NAKG, the fewer times the soil and straw are effectively cut and chopped within the same distance, the soil level drops less, and only less straw can pass through the gap between the bottom of the holding hopper and the surface. This viewpoint is similar to Yu’s [26] discrete element simulation analysis viewpoint.

In terms of RVSS, this research concludes that when RVSS is in the range of 80–160 r/min, RVSS is negatively correlated with SCR, and SCR will decrease with the increase in RVSS. The reason is that when the RVSS increases, the centrifugal force would gradually replace the blade’s thrust and play a leading role, the axial conveying effect of the blade is weakened, and the efficiency of conveying straw is reduced, thereby reducing the SCR. This point of view is consistent with Wulantuya’s point of view [31,32,33] in the theoretical analysis.

According to the interaction between HHHG and OVM, when HHHG is at 10~30 mm, there is a negative correlation between SCR and HHHG. The smaller the gap between the bottom of the holding hopper and the ground surface, the less straw can pass directly through the gap when the planter is operating, effectively improving the operation effect and the SCR of the planter.

4. Optimization and Verification

4.1. Parameter Optimization

In order to obtain the optimal parameter combination of the SDARD, the Optimization module in Design Expert software was used to optimize and solve the above-established regression model. Taking the maximum SCR as the goal, the objective function was established as follow:

The optimization results to obtain the parameter values of the three experimental factors were as follows: the OVM was 5 km/h, the RVSS was 80 r/min, the HHHG was 10 mm, and the optimal SCR was 91.72%. The best parameters obtained by optimization were used for simulation experiments in EDEM, and the SCR was 90.87%, which was basically consistent with the optimization results.

4.2. Field Test Verification

4.2.1. Field Test Conditions

The test was carried out on 26 October 2021 at the Machines Trial Production Base of the Conservation Tillage Research Center of the Ministry of Agriculture and Rural Affairs of China Agricultural University, Baimasi Town, Luolong District, Luoyang City, Henan Province (112°35′27″ E longitude, 34°43′19″ N latitude, 133 m above sea level, air pressure 1006.4 hPa). The test field was a crop field covered with corn stalks that had been chopped and returned to the field, and the previous crop was autumn maize planted in June of the same year. The soil texture of the test site was brown clay, and the average daily temperature during the test period was 9~21 °C without precipitation. Affected by the continuous rainfall in Zhengzhou, the water content of soil and straw in the field was relatively high. The main parameters of the experimental area are shown in Table 5.

Table 5.

Main parameters of field tests.

4.2.2. Test Method and Result Analysis

The Passing Capacity of No-Till Planter

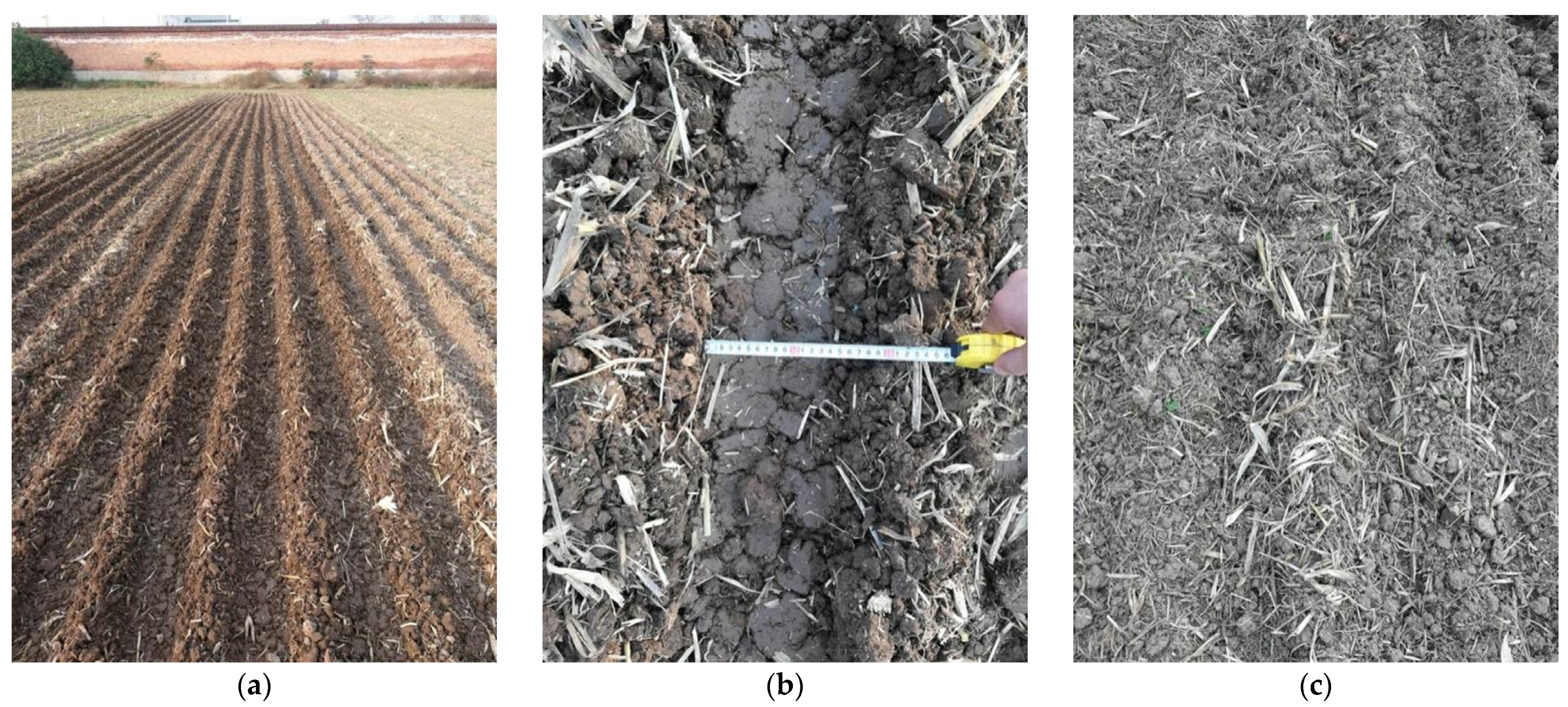

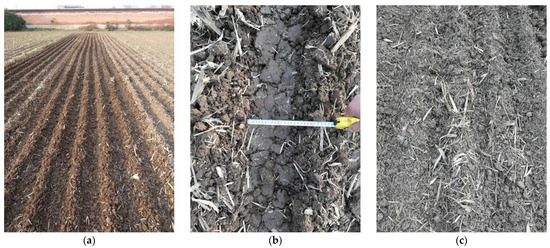

According to the technical requirements in NY/T 1768–2009 “Technical Specifications for Quality Evaluation of No-till planters”, the no-till planter would make a round trip in the test area with a length of 60 m at a conventional operating velocity, and the number of shutdowns caused by blockage during the planter operation was observed and recorded. No blockage or a slight blockage was considered qualified. The SDARD was installed on a 2BMQF-6/12A no-tillage fertilizer planter. The field test site is shown in Figure 10.

Figure 10.

Field verification test.

The test results show that the no-till planter with the SDARD operated smoothly without blocking. By observing the actual operation effect, compared with the no-till planter without the SDARD, the passing capacity performance of the planter had been improved.

The SCR of the Sowing Strip

On the field test day, a 0.25 m2 square metal frame and an electronic balance were used to randomly sample and weigh the SMQ in the field by the five-point sampling method [36]. After the operation, the straw in the area of 15 × 15 cm2 of sowing strip was weighed, and the quantity of straw remaining on the strip was calculated. The measurement points were the data of 10 consecutive weighing positions with an interval of 1 m in the stable operation area. The 10 sets of data were then averaged. The SCR in the sowing strip after the operation was calculated by Equation (5).

According to the optimized operation parameters, the OVM was set to 5 km/h, the RVSS was 80 r/min, and the HHHG was 10 mm. The cleaning effect of the seed strip after the operation is shown in Figure 11, and the field test results of the SCR of the sowing strip are shown in Table 6.

Figure 11.

Straw cleaning effect in seed strip after the operation. (a) The overall effect with SDARD after operation; (b) seed strip cleaning effect with SDARD; (c) seed strip cleaning effect without SDARD.

Table 6.

Field test results of straw cleaning effect of sowing strip.

It can be seen from Table 6 that the average SCR of the planter equipped with the SDARD is 84.49%, which is increased by 15.5% compared with the no-till planter without the SDARD, as shown in Figure 11, meeting the agronomic requirements of no-tillage sowing of wheat in an annual double cropping area in China.

5. Conclusions

(1) In this paper, an SDARD was designed. During the operation of the no-till planter, the straw was cut and chopped by the high-velocity rotating NAKG and then thrown to the SDM. Through the interaction between the SDM and the RSM, the chopped straw was transported to the non-sowing area, which could effectively reduce the blockage of the furrowing opener, concentrate the straw in the non-sowing area, and realize the cleaning of the seed strip.

(2) The relationship between the material bearing limit of the SDM and the SFA was an important index for evaluating the conveying performance stability and straw discharge effect of the device. Therefore, the mathematical model of the relationship between SFA and SMQ was established by mathematical induction and quotient-remaining method, which provided a theoretical basis for the parameter design of SDM and RSM. On this basis, the specific numerical values and the ranges of the critical structural dimensions and working parameters of the SDM and the RSM were determined.

(3) Using the quadratic rotation orthogonal combination test method—selecting OVM, RVSS, and HHHG as the test factors and SCR as the test index—the discrete element simulation test was carried out, the regression model of SCR was established, and the parameter optimization and field test were carried out. The results show that the significant factors affecting the SCR in the sowing strip from high to low were HHHG, OVM, and RVSS. The optimal combination of operating parameters was that the OVM was 5 km/h, the RVSS was 80 r/min, and the HHHG was 10 mm. Under the optimal parameter combination, the average SCR of the planter equipped with the SDARD was 84.49%, 15.5% higher than that of the no-till planter without the device. The passing capacity of the machines was great, which meets the agronomic requirements of no-tillage sowing of wheat in the annual double cropping area.

The SDARD designed in this paper might provide a new design idea for the anti-blocking and row-sorting device of no-till planters for wheat in the annual double cropping area in northern China. Further, it had the potential to improve the passing capacity of no-till planters and sowing quality to increase grain production in this area. However, this paper mainly conducted parameters design and discrete element simulation experiments for a new mechanism for determining the rational and reasonable values of critical parameters. However, it is essential to assess how much the indicator of reliability, durability, maintainability has changed compared with the control device. Moreover, it is also imperative and meaningful to evaluate the preservation ability of agricultural machinery for theoretical analysis and further exploration. In addition, we will conduct in-depth research on the above issues to improve further the operational reliability of the anti-blocking and row-sorting device.

Author Contributions

Conceptualization, Y.L. and C.L.; methodology, Y.L., C.L., S.H. and P.Y.; software, Y.L., S.H. and Z.G.; writing—original draft preparation, Y.L. and X.W.; writing—review and editing, C.L.; H.L., J.H., Q.W. and H.Z.; funding acquisition, H.L. and C.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the China Agriculture Research System of MOF and MARA (Grant No.CARS-03), Innovative Research Team in University of China (Grant No.IRT13039), and the 2115 Talent Development Program of China Agricultural University and Chinese Universities Scientific Fund (Grant No.2021TC105).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| SDARD | Spiral discharge anti-blocking and row-sorting device |

| NAKG | No-till anti-blocking knife group |

| SDM | Spiral discharging mechanism |

| RSM | Row-sorting of straw mechanism |

| OVM/v | Operating velocity of machines |

| RVSS/n | Rotary velocity of the spiral shaft |

| HHHG/h | Height of the holding hopper from the ground |

| SCR/λ | Straw cleaning rate |

| SFA/Qs | Straw feeding amounts |

| SMQ/CS | Straw mulching quantity |

| Q1 | Mass of straw on the sowing strip before an operation |

| Q2 | Residual mass of straw on the sowing strip after an operation |

| QSt | Total mass of straw fed into the hopper after a certain period of operation |

| L1 | Total cleaning width of sowing strip |

| L2 | Total width of non-sowing area |

| D | Outer diameter of the spiral blade |

| S | Pitch |

| z | Number of corresponding sowing strips |

| K | Material characteristic coefficient |

| ψ | Filling factor |

| ρ | Material density |

| C | Inclination coefficient |

| K1 | Pitch coefficient |

| bG | Width of the RSM |

| hG | Height of the RSM |

| lG | Length of the side baffle |

| θ | Included angle between the strip baffle and the side baffle |

| m1 | Mass of straw before the operation |

| m2 | Mass of straw after the operation |

References

- He, J.; Li, H.; Chen, H.; Lu, C.; Wang, Q. Research progress of conservation tillage technology and machine. Trans. Chin. Soc. Agric. Mach. 2018, 49, 1–19. [Google Scholar] [CrossRef]

- Cao, X.; Wang, Q.; Li, H.; He, J.; Lu, C. Design and experiment of active rotating collective straw-cleaner. Trans. Chin. Soc. Agric. Eng. 2021, 37, 26–34. [Google Scholar] [CrossRef]

- Cao, X.; Wang, Q.; Li, H.; He, J.; Lu, C. Combined row cleaners research with side cutter and stubble clean disk of corn no-till seeder. Trans. Chin. Soc. Agric. Mach. 2021, 52, 9. [Google Scholar] [CrossRef]

- Wang, Q.; Cao, X.; Wang, C.; Li, H.; He, J.; Lu, C. Research progress of no/minimum tillage corn seeding technology and machine in northeast black soil regions of China. Trans. Chin. Soc. Agric. Mach. 2021, 52, 1–15. [Google Scholar]

- Jia, H.; Zhao, J.; Jiang, X.; Jiang, T.; Wang, Y.; Guo, H. Design and experiment of anti-blocking mechanism for inter-row no-tillage seeder. Trans. Chin. Soc. Agric. Eng. 2013, 29, 16–25. [Google Scholar] [CrossRef]

- Yao, Z.; Gao, H.; Wang, X.; Li, H.; Li, W. Design and experiment on 2BMX-5 no-till wheat-maize seeder. Trans. Chin. Soc. Agric. Mach. 2008, 39, 64–68. [Google Scholar]

- Fallahi, S.; Raoufat, M.H. Row-crop planter attachments in a conservation tillage system: A comparative study. Soil Tillage Res. 2008, 98, 27–34. [Google Scholar] [CrossRef]

- He, J.; Li, H.W.; Wang, Q.J.; Gao, H.W.; Li, W.Y.; Zhang, X.M.; McGiffen, M. The adoption of conservation tillage in China. Ann. N. Y. Acad. Sci. 2010, 1195, E96–E106. [Google Scholar] [CrossRef]

- He, J.; Zhang, Z.; Li, H.; Wang, Q. Development of small/medium size no-till and minimum-till seeders in Asia: A review. Int. J. Agric. Biol. Eng. 2014, 7, 1–12. [Google Scholar] [CrossRef]

- Siemens, M.C.; Wilkins, D.E.; Correa, R.F. Development and evaluation of a residue management wheel for hoe-type no-till drills. Trans. ASAE 2003, 47, 397–404. [Google Scholar] [CrossRef]

- Tourn, M.; Soza, E.; Botta, G.; Mete, A. Direct corn seedling. Effects of residue clearance on implant efficiency. Span. J. Agric. Res. 2003, 1, 99–103. [Google Scholar] [CrossRef] [Green Version]

- Morris, N.L.; Miller, P.C.H.; Orson, J.H.; Froud-Williams, R.J. The adoption of non-inversion tillage systems in the United Kingdom and the agronomic impact on soil, crops and the environment—A review. Soil Tillage Res. 2010, 108, 1–15. [Google Scholar] [CrossRef]

- Celik, A.; Altikat, S.; Way, T.R. Strip tillage width effects on sunflower seed emergence and yield. Soil Tillage Res. 2013, 131, 20–27. [Google Scholar] [CrossRef]

- Li, H.; Liu, H.; Zhou, J.; Wei, G.; Shi, S.; Zhang, X.; Zhang, R.; Zhu, H.; He, T. Development and first results of a no-till pneumatic seeder for maize precise sowing in Huang-Huai-Hai plain of China. Agriculture 2021, 11, 1023. [Google Scholar] [CrossRef]

- Wang, C.; Li, H.; He, J.; Wang, Q.; Lu, C.; Yang, H. Optimization design of a pneumatic wheat-shooting device based on numerical simulation and field test in rice–wheat rotation areas. Agriculture 2022, 12, 56. [Google Scholar] [CrossRef]

- Zhao, H. Study on Driven Seedbed-Cleaning and Anti-Blocking Device of Residue Inter-Row Side-Throwing for Minimum till Wheat Seeding; China Agricultural University: Beijing, China, 2019. [Google Scholar]

- Zheng, Z. Study on Corn Straw Pickup-Chopping and Ditch-Burying Returning Field Machine; China Agricultural University: Beijing, China, 2017. [Google Scholar]

- Wang, Q.; He, J.; Li, H.; Lu, C.; Rasaily, R.G.; Su, Y. Design and experiment on furrowing and anti-blocking unit for no-till planter. Trans. Chin. Soc. Agric. Eng. 2012, 28, 27–31. [Google Scholar] [CrossRef]

- Lin, J.; Li, B.; Li, H. Design and experiment of Archimedes spiral type stubble breaking ditching device and stubble breaking anti blocking device. Trans. Chin. Soc. Agric. Eng. 2015, 31, 10–19. [Google Scholar] [CrossRef]

- Lin, J.; Li, B.; Li, B.; Niu, J.; Qian, W. Parameter optimization and experiment on archimedes spiral type of gap cutting disc. Trans. Chin. Soc. Agric. Mach. 2014, 45, 118–124. [Google Scholar] [CrossRef]

- Lu, C. Study on Anti-Blocking Technology and Device of Rotary Cutting with Slide Plate Pressing Straw for No-Till Planter; China Agricultural University: Beijing, China, 2014. [Google Scholar]

- Lu, C.; Zhao, C.; Meng, Z.; Wang, X.; Wu, G.; Gao, N. Straw friction characteristic based on rotary cutting anti-blocking device with slide plate pressing straw. Trans. Chin. Soc. Agric. Eng. 2016, 32, 83–89. [Google Scholar] [CrossRef]

- Lu, C.; Li, H.; He, J.; Zhu, H.; Xu, D. Floated support anti-blocking device of wheat no-till seeder. Trans. Chin. Soc. Agric. Eng. 2013, 44, 52–55, 153. [Google Scholar] [CrossRef]

- Lu, C.; He, J.; Li, H.; Wang, Q.; Zhang, X.; Liu, J. Finite element analysis and experiment on anti-blocking device based on support cutting. Trans. Chin. Soc. Agric. Mach. 2013, 44, 61–66. [Google Scholar] [CrossRef]

- Yuan, P.; Li, H.; Jiang, G.; He, J.; Lu, C.; Huang, S. Design and experiment of straw cleaning device for wide narrow maize no-tillage sowing strip in drip irrigation area. Trans. Chin. Soc. Agric. Mach. 2021, 52, 43–52. [Google Scholar] [CrossRef]

- Yu, C.; Wang, Q.; Li, H.; He, J.; Lu, C. Design and experiment of spiral-split sowing strip cleaning device. Trans. Chin. Soc. Agric. Eng. 2020, 51, 212–219. [Google Scholar]

- Zhou, H. The Application of Quadrat Method in Parameters of Forest Spatial Structure Investigation; Chinese Academy of Forestry: Beijing, China, 2009. [Google Scholar] [CrossRef]

- Darnell, W.H. Solid Conveying in Extruders. SPE J. 1956, 12, 20–29. [Google Scholar]

- Yuan, Q.; Xu, L.; Niu, C.; Ma, S.; Yan, C.; Zhao, S.; Liu, F.; Wang, K. Development of soil-fertilizer mixing layered backfiller for organic fertilizer deep applicator in orchard. Trans. Chin. Soc. Agric. Eng. 2021, 37, 11–19. [Google Scholar] [CrossRef]

- “Transportation Machinery Design and Selection Manual” Committee. Transport Machinery Design and Selection Manual, the Next Volume; Chemical Industry Press: Beijing, China, 1999. [Google Scholar]

- Wang, C.; Zhao, F.; Wang, X. Experiment and optimization of screw conveyor parameters for rubbing and breaking corn straw. J. China Agric. Univ. 2019, 24, 115–122. [Google Scholar] [CrossRef]

- Wang, C.; Qi, S.; Yan, J.; Wang, J. Test and analysis of performance of screw conveyor for rubbing and breaking corn straw. Trans. Chin. Soc. Agric. Eng. 2015, 31, 51–59. [Google Scholar] [CrossRef]

- Study on the Mechanism of Screw Conveying Theory for Rubbing and Breaking Corn Straw; Inner Mongolia Agricultural University: Hohhot, China, 2016.

- Wang, X.; Hu, H.; Wang, Q.; Li, H.; He, J.; Chen, W. Calibration method of soil contact characteristic parameters based on DEM theory. Trans. Chin. Soc. Agric. Eng. 2017, 48, 78–85. [Google Scholar] [CrossRef]

- Fang, H.; Ji, C.; Ahmed, A.T.; Zhang, Q.; Guo, J. Simulation analysis of straw movement in straw soil rotary blade system. Trans. Chin. Soc. Agric. Mach. 2016, 47, 60–67. [Google Scholar] [CrossRef]

- Ni, H.; Lu, F.; Luo, X.; Tian, H.; Wang, J.; Guan, Y.; Chen, S.; Luo, X.; Zeng, E. Assessment of sampling designs to measure riverine fluxes from the pearl river delta, china to the south china sea. Environ. Monit. Assess. 2008, 143, 291–301. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).