Effect of Gamma Radiation and Storage Time on the Microbial and Physicochemical Properties of Dried Byadgi Chili (Capsicum annuum)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Collection

2.2. Analysis of Moisture and Water Activity

2.3. Surface Color Measurement

2.4. Determination of Aflatoxin B1, B2, G1, and G2

2.5. Determination of Capsaicin and Dihydrocapsaicin

2.6. Microbiological Analysis

2.7. Statistical Analysis

3. Results and Discussion

3.1. Moisture and Water Activity Content

3.2. Effect on Surface Color (L*, a*, b*, C* and h*)

3.3. Capsaicin and Dihydrocapsaicin Content

3.4. Microbial Content

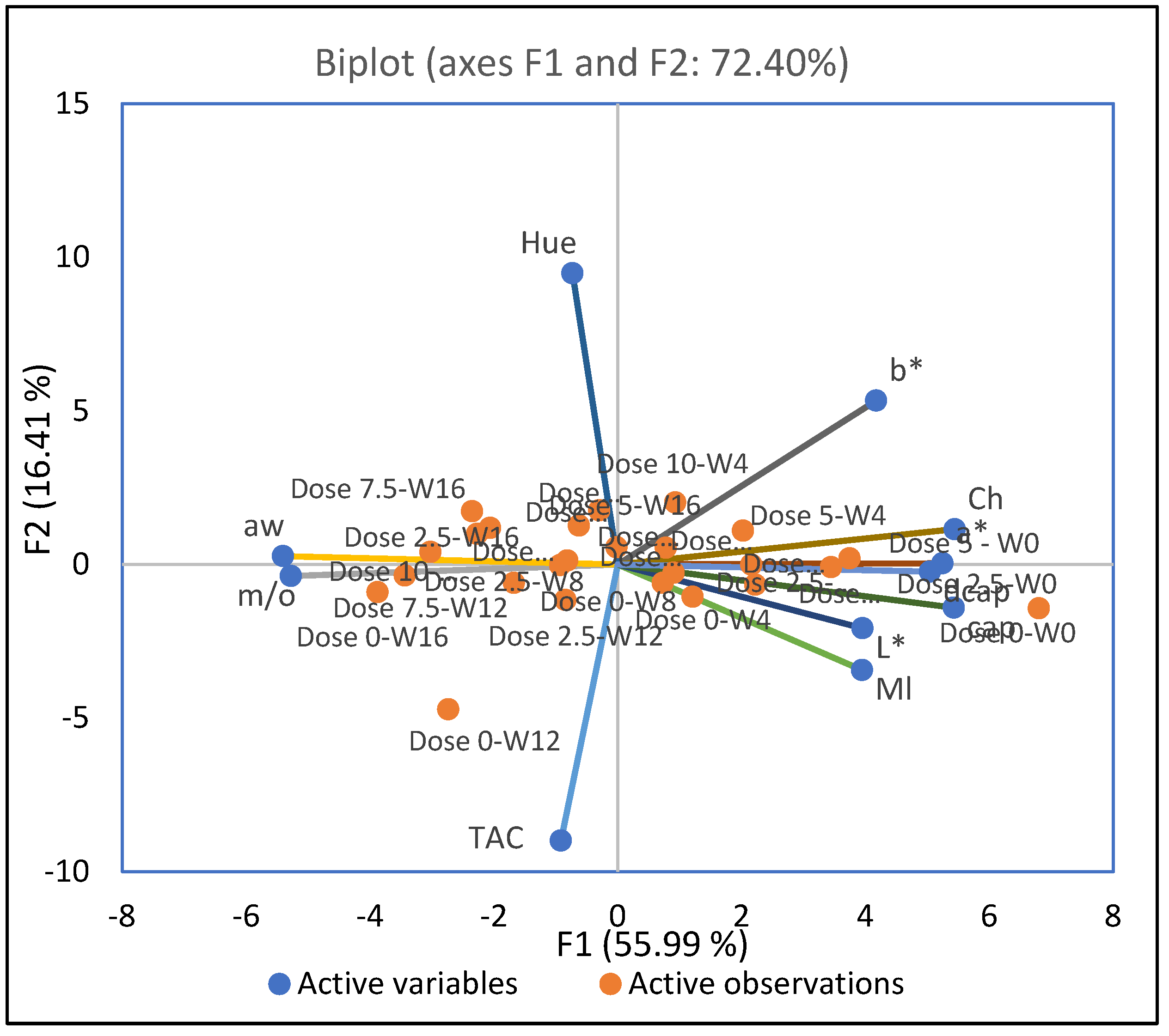

3.5. Relationship between Dried Byadgi chili Quality Characteristics as Affected by Irradiation Doses and Storage Times

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Conflicts of Interest

References

- Topuz, A.; Feng, H.; Kushad, M. The effect of drying method and storage on color characteristics of paprika. Food Sci. Technol. 2009, 42, 1667–1673. [Google Scholar] [CrossRef]

- Iqbal, S.Z.; Bhatti, I.A.; Sheikh, M.A.; Bhatti, H.N. Aflatoxin B1 in chillies from Punjab Region, Pakistan. Mycotoxin Res. 2010, 26, 205–209. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ahene, R.E.; Odamtten, G.T.; Owusu, E. Fungal and bacterial contaminants of six spices and spice products in Ghana. Afr. J. Environ. Sci. Technol. 2011, 5, 633–640. [Google Scholar]

- Eliasson, L.; Isaksson, S.; Lovenklev, M.; Ahrne, L. A comparative study of infrared and microwave heating for microbial decontamination of paprika powder. Front. Microbiol. 2015, 6, 1071. [Google Scholar] [CrossRef] [Green Version]

- Staack, N.; Ahrné, L.; Borch, E.; Knorr, D. Effect of infrared heating on quality and microbial decontamination in paprika powder. J. Food Eng. 2008, 86, 17–24. [Google Scholar] [CrossRef]

- Verma, V.P.; Petwal, V.C.; Gothwal, P.; Seema, M.; Malviya, K.K.; Jishnu, D. Effect of electron bean irradiation on microbial decontamination & phytochemical contents of spices. Int. J. Trop. Agric. 2015, 33, 2999–3003. [Google Scholar]

- Parveen, S.; Das, S.; Begum, A.; Sultana, N.; Hoque, M.M.; Ahmad, I. Microbiological quality assessment of three selected spices in Bangladesh. Int. Food Res. J. 2014, 21, 1327–1330. [Google Scholar]

- Cho, S.-H.; Lee, C.-H.; Jang, M.-R.; Son, Y.-W.; Lee, S.-M.; Choi, I.-S.; Kim, S.-H.; Kim, D.-B. Aflatoxins contamination in spices and processed spice products commercialized in Korea. Food Chem. 2008, 107, 1283–1288. [Google Scholar] [CrossRef]

- Youssuf, A.G.; Yassmin, M.S.; Helal, A. Aspergilli and Their Aflatoxins Contamination of Poultry and Animal Feedstuff Samples in Western Region of Saudi Arabia. Sains Malays. 2019, 48, 765–771. [Google Scholar]

- Rajarajan, P.N.; Rajasekaran, K.M.; Asha Devi, N.K. Aflatoxin Contamination in Agricultural Commodities. Indian J. Pharm. Biol. Res. (IJPBR) 2013, 1, 148–151. [Google Scholar] [CrossRef]

- Golge, O.; Hepsag, F.; Kabak, B. Incidence and level of aflatoxin contamination in chilli commercialised in Turkey. Food Control 2013, 33, 514–520. [Google Scholar] [CrossRef]

- Jalili, M.; Jinap, S. Natural occurrence of aflatoxins and ochratoxin A in commercial dried chili. Food Control 2012, 24, 160–164. [Google Scholar] [CrossRef]

- Set, E.; Erkmen, O. The aflatoxin contamination of ground red pepper and pistachio nuts sold in Turkey. Food Chem. Toxicol. 2010, 48, 2532–2537. [Google Scholar] [CrossRef] [PubMed]

- Cotty, P.J.; Jaime-Garcia, R. Influences of climate on aflatoxin producing fungi and aflatoxin contamination. Int. J. Food Microbiol. 2007, 119, 109–115. [Google Scholar] [CrossRef] [PubMed]

- Ongoma, V. A review of the effects of climate change on occurrence of aflatoxin and its impacts on food security in semi-arid areas of Kenya. Int. J. Agric. Sci. Res. 2013, 2, 307–311. [Google Scholar]

- Prelle, A.; Spadaro, D.; Garibaldi, A.; Gullino, M.L. Co-occurrence of aflatoxins and ochratoxin A in spices commercialized in Italy. Food Control 2014, 39, 192–197. [Google Scholar] [CrossRef]

- Kiran, D.R.; Narayana, K.J.; Vijayalakshmi, M. Aflatoxin B1 production in chillies (Capsicum annuum L.) kept in cold stores. Afr. J. Biotechnol. 2005, 4, 791–795. [Google Scholar]

- Muhammad, A.; Faqir, M.A.; Tahir, Z.; Haq, N. Effect of Storage Period and Irradiation Doses on Red Chillies. Pak. J. Nutr. 2009, 8, 1287–1291. [Google Scholar]

- Loh, S.H.; Iryani, N.; How, M.L. Determination of Aflatoxins B1 and B2 in Peanuts and Corn Based Products. Sains Malays. 2010, 39, 731–735. [Google Scholar]

- Norrakiah, A.S.; Ong, K.Y.; Ayom, M.K.; Muhammad, S.Y.; Abdul, S.B.; Nazaruddin, R. Effects of Gamma Irradiation on Microbiological Quality, Protein and Amino Acid Profile of Edible Bird Nest Powder. Kasetsart J. (Nat. Sci.) 2015, 49, 880–894. [Google Scholar]

- Balakrishnan, N.; Yusop, S.M.; Rahman, I.A.; Dauqan, E.; Abdullah, A. Efficacy of Gamma Irradiation in Improving the Microbial and Physical Quality Properties of Dried Chillies (Capsicum annuum L.): A Review. Foods 2022, 11, 91. [Google Scholar] [CrossRef] [PubMed]

- Robert, L.S. Introducing Food Science; CRC Press: London, UK, 2009. [Google Scholar]

- AOAC. AOAC 978.18 Water Activity; AOAC: Rockville, MD, USA, 1995. [Google Scholar]

- VICAM. AflaTest Instruction Manual (for HPLC Use); VICAM: Watertown, MA, USA, 2007; Volume 715001733 REV B. [Google Scholar]

- Barbero, G.F.; Liazid, A.; Palma, M.; Barroso, C.G. Ultrasound-assisted extraction of capsaicinoids from peppers. Talanta 2008, 75, 1332–1337. [Google Scholar] [CrossRef] [PubMed]

- Promila, D.; Binoo, S. Comparative study between different storage practices on the basis of infestation in spices. Ann. Biol. Res. 2013, 4, 16–22. [Google Scholar]

- Rico, C.W.; Kim, G.R.; Ahn, J.J.; Kim, H.K.; Furuta, M.; Kwon, J.H. The comparative effect of steaming and irradiation on the physicochemical and microbiological properties of dried red pepper (Capsicum annum L.). Food Chem. 2010, 119, 1012–1016. [Google Scholar] [CrossRef]

- Iqbal, Q.; Amjad, M.; Asi, M.R.; Arino, A. Mold and aflatoxin reduction by gamma radiation of packed hot peppers and their evolution during storage. J. Food Prot. 2012, 75, 1528–1531. [Google Scholar] [CrossRef]

- Daood, H.; Kapitány, J.; Biacs, P.; Albrecht, K. Drying temperature, endogenous antioxidants and capsaicinoids affect carotenoid stability in paprika (red pepper spice). J. Sci. Food Agric. 2006, 86, 2450–2457. [Google Scholar] [CrossRef]

- Chatterjee, S.; Padwal-Desai, S.R.; Thomas, P. Effect of γ-irradiation on the colour power of turmeric (Curcuma longa) and red chillies (Capsicum annum) during storage. Food Res. Int. 1998, 31, 625–628. [Google Scholar] [CrossRef]

- Kispéter, J.; Bajúsz-Kabók, K.; Fekete, M.; Szabó, G.; Fodor, E.; Páli, T. Changes induced in spice paprika powder by treatment with ionizing radiation and saturated steam. Radiat. Phys. Chem. 2003, 68, 893–900. [Google Scholar] [CrossRef]

- Jose MN, S.; Luis, A.; Jose AF, L.; Munoz, J.A. Effect of irradiation on colour and microbial bioburden of red paprika. J. Food Prot. 2000, 63, 633–637. [Google Scholar]

- Lee, J.H.; Sung, T.H.; Lee, K.T.; Kim, M.R. Effect of gamma-irradiation on color, pungency, and volatiles of Korean red pepper powder. J. Food Sci. 2004, 69, C585–C592. [Google Scholar] [CrossRef]

- Lee, D.S.; Chung SU, N.; Kim, H.; Yam, K. Nonenzymatic browning in dried red pepper products. J. Food Qual. 2007, 14, 153–163. [Google Scholar] [CrossRef]

- Helga, M.; Bata-Vidács, I.; Baka, E.; Cserhalmi, Z.; Ferenczi, S.; Tömösközi-Farkas, R.; Adányi, N.; Székács, A. The effect of different decontamination methods on the microbial load, bioactive components, aroma and colour of spice paprika. Food Control 2018, 83, 131–140. [Google Scholar]

- Iqbal, Q.; Amjad, M.; Asi, M.R.; Nawaz, A.; Khan, S.M.; Arino, A.; Ahmad, T. Irradiation maintains functional components of dry hot peppers (Capsicum annuum L.) under ambient storage. Foods 2016, 5, 63. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fontana, A.J. Understanding the importance of water activity in food. Cereal Foods World 2000, 45, X-10. [Google Scholar]

- Kennao, E.; Kumari, A.; Singh, M.; Hossain, S.A.; Das, A.; Wasnik, P.K.; Bharti, B.K. Effect of drying on physicochemical characteristics of bhutjolokia (chilli pepper). J. Food Process. Technol. 2020, 11, 823. [Google Scholar]

- Calucci, L.; Pinzino, C.; Zandomeneghi, M.; Capocchi, A.; Ghiringhelli, S.; Saviozzi, F.; Tozzi, S.; Galleschi, L. Effects of γ-Irradiation on the Free Radical and Antioxidant Contents in Nine Aromatic Herbs and Spices. J. Agric. Food Chem. 2003, 51, 927–934. [Google Scholar] [CrossRef]

- Kwon, J.H.; Byun, M.W.; Cho, H.O. Effect of gamma irradiation on the sterilization of red pepper powder. J. Korean Soc. Food Sci. Nutr. 1984, 13, 188–192. [Google Scholar]

- Odai, B.T.; Tano-Debrah, K.; Addo, K.K.; Saalia, F.K.; Akyeh, L.M. Effect of gamma radiation and storage at 4 °C on the inactivation of Listeria monocytogenes, Escherichia coli and Salmonella enterica Typhimurium in Legon-18 pepper (Capsicum annuum) powder. Food Qual. Saf. 2019, 3, 265–272. [Google Scholar] [CrossRef]

- Ayob, O.; Hussain, P.R.; Suradkar, P.; Naqash, F. Gamma irradiation and storage effects on quality and safety of Himalayan paprika (Waer). LWT 2021, 147, 111667. [Google Scholar] [CrossRef]

- Topuz, A.; Ozdemir, F. Influences of gamma irradiation and storage on the capsaicinoids of sun-dried and dehydrated paprika. Food Chem. 2004, 86, 509–515. [Google Scholar] [CrossRef]

- Iqbal, Q.; Amjad, M.; Asi, M.R.; Arino, A.; Ziaf, K.; Nawaz, A.; Ahmad, T. Stability of Capsaicinoids and antioxidants in dry hot peppers under different packaging and storage temperatures. Foods 2015, 4, 51–64. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, Y.; Xia, Y.; Wang, J.; Luo, F.; Huang, Y. Capsaicinoids in chili pepper (Capsicum annuum L.) powder as affected by heating and storage methods. Trans. Am. Soc. Agric. Biol. Eng. (ASABE) 2009, 52, 2007–2010. [Google Scholar] [CrossRef]

- Napia, L.M.A.; Rahman, I.A.; Hamzah, M.Y.; Mohamed, F.; Mohd, H.M.K.; Bastamam, I.S.A.; Sharin, S.; Hidzir, N.M.; Radiman, S. Effect of Gamma Irradiation on the Physical Stability of DPPC Liposomes. Sains Malays. 2018, 47, 1235–1240. [Google Scholar]

- Alam, M.K.; Choudhury, N.; Chowdhury, N.A.; Youssouf, Q.M. Decontamination of spices by gamma radiation. Appl. Microbiol. 1992, 14, 199–202. [Google Scholar] [CrossRef]

- Dikkala, P.; Hymavathi, T.V.; Roberts, P.; Sujatha, M. Effect of heat treatment and gamma irradiation on the total bacterial count of selected millet grains (Jowar, Bajra and Foxtail). Int. J. Curr. Microbiol. Appl. Sci. 2018, 7, 1293–1300. [Google Scholar] [CrossRef] [Green Version]

- Lado, B.H.; Yousef, A.E. Alternative food preservation technologies: Efficacy and mechanism. Microbes Infect. 2002, 4, 433–440. [Google Scholar] [CrossRef]

- Desouky, O.; Ding, N.; Zhou, G. Targeted and non-targeted effects of ionizing radiation. J. Radiat. Res. Appl. Sci. 2015, 8, 247–254. [Google Scholar] [CrossRef] [Green Version]

- Deng, W.; Wu, G.; Guo, L.; Long, M.; Li, B.; Liu, S.; Cheng, L.; Pan, X.; Zou, L. Effect of Gamma Radiation on Escherichia coli, Salmonella enterica Typhimurium and Aspergillus niger in Peppers. Food Sci. Technol. Res. 2015, 21, 241–245. [Google Scholar] [CrossRef] [Green Version]

- Song, W.J.; Sung, H.J.; Kim, S.Y.; Kim, K.P.; Ryu, S.; Kang, D.H. Inactivation of Escherichia coli O157:H7 and Salmonella Typhimurium in black pepper and red pepper by gamma irradiation. Int. J. Food Microbiol. 2014, 172, 125–129. [Google Scholar] [CrossRef]

- Yu, W.J.; Liu, H.P.; Zhang, X.W.; Dong, D.; Jiang, Y.; Sun, N.X.; Liu, Y.K.; Yuan, J.F. Postirradiation changes of the microbiological quality, aflatoxin, capsinoids, volatile oils, and the color of red pepper powder. J. Food Process. Preserv. 2017, 42, e13522. [Google Scholar] [CrossRef]

- Jung, K.; Song, B.S.; Kim, M.J.; Moon, B.G.; Go, S.M.; Kim, J.K.; Lee, Y.J.; Park, J.H. Effect of X-ray, gamma ray, and electron beam irradiation on the hygienic and physicochemical qualities of red pepper powder. Food Sci. Technol. 2015, 63, 846–851. [Google Scholar] [CrossRef]

- Wissanee, P.; Sumiko, S.; Varit, S.; Chalermchai, W.-A.; Songsin, P. Color appearance and physico-chemical changes in dried chili as affected by modified atmosphere packaging and temperature during storage. J. Food Process. Preserv. 2021, 45, 11. [Google Scholar]

- Topuz, A.; Ozdemir, F. Influences of γ-Irradiation and Storage on the Carotenoids of Sun-Dried and Dehydrated Paprika. J. Agric. Food Chem. 2003, 51, 4972–4977. [Google Scholar] [CrossRef] [PubMed]

| Storage (Weeks) | 0 kGy | 2.5 kGy | 5.0 kGy | 7.5 kGy | 10.0 kGy | |

|---|---|---|---|---|---|---|

| 0 | Moisture | 14.87 ± 0.45 cB | 15.31 ± 0.02 dAB | 15.54 ± 0.08 eA | 15.66 ± 0.35 cA | 15.33 ± 0.14 cAB |

| Water activity | 0.6047 ± 0.0026 dE | 0.6163 ± 0.0005 eD | 0.6241 ± 0.0009 eC | 0.6276 ± 0.0007 cB | 0.6307 ± 0.0011 bA | |

| 4 | Moisture | 16.24 ± 0.05 bA | 15.76 ± 0.3 cB | 15.97 ± 0.05 dAB | 16.16 ± 0.02 bA | 15.72 ± 0.2 bB |

| Water activity | 0.6571 ± 0.0018 bA | 0.6293 ± 0.0004 dD | 0.6317 ± 0.0015 dD | 0.6495 ± 0.0021 bB | 0.6430 ± 0.0009 cC | |

| 8 | Moisture | 16.27 ± 0.13 bA | 16.24 ± 0.06 bA | 16.17 ± 0.09 cAB | 16.00 ± 0.16 bcBC | 15.90 ± 0.09 bC |

| Water activity | 0.6505 ± 0.0004 cA | 0.6502 ± 0.0010 cAB | 0.6477 ± 0.0016 cC | 0.6480 ± 0.0012 bBC | 0.6309 ± 0.0016 bD | |

| 12 | Moisture | 16.37 ± 0.17 bB | 16.38 ± 0.1 bB | 16.71 ± 0.05 aA | 16.72 ± 0.05 aA | 16.41 ± 0.12 aB |

| Water activity | 0.6562 ± 0.0065 bcA | 0.6589 ± 0.0053 bA | 0.6586 ± 0.0006 aA | 0.6560 ± 0.0015 aA | 0.6595 ± 0.0008 aA | |

| 16 | Moisture | 17.60 ± 0.05 aA | 16.74 ± 0.08 aB | 16.34 ± 0.14 bC | 16.39 ± 0.25 abC | 16.29 ± 0.17 aC |

| Water activity | 0.6684 ± 0.0008 aA | 0.6647 ± 0.0012 aB | 0.6562 ± 0.0007 bC | 0.6561 ± 0.0014 aC | 0.6547 ± 0.0011 bC |

| Storage (Weeks) | Parameters | 0 kGy | 2.5 kGy | 5.0 kGy | 7.5 kGy | 10.0 kGy |

|---|---|---|---|---|---|---|

| 0 | L* | 24.16 ± 1.01 Aa | 24.11 ± 0.47 Aa | 24.24 ± 0.3 Aa | 23.50 ± 0.46 Aa | 23.91 ± 1.35 Aa |

| a* | 20.85 ± 0.69 Aa | 18.04 ± 0.13 Ca | 19.18 ± 0.34 Ba | 16.54 ± 0.10 Dab | 16.76 ± 0.06 Da | |

| b* | 9.85 ± 0.05 Ba | 9.03 ± 0.09 Ca | 10.43 ± 0.07 Aab | 8.01 ± 0.13 Eb | 8.40 ± 0.02 Db | |

| 4 | L* | 22.87 ± 0.09 Ab | 21.91 ± 0.67 BCb | 22.23 ± 0.34 ABb | 21.21 ± 0.09 Cb | 21.92 ± 0.45 BCb |

| a* | 16.16 ± 0.12 Cc | 13.97 ± 0.06 Ec | 18.00 ± 0.21 Ab | 15.39 ± 0.10 Db | 16.69 ± 0.08 Ba | |

| b* | 8.63 ± 0.11 Cb | 9.17 ± 0.06 Ba | 9.64 ± 0.06 Ab | 8.24 ± 0.10 Db | 9.76 ± 0.26 Aa | |

| 8 | L* | 22.71 ± 0.04 Ab | 20.24 ± 0.23 Cb | 20.39 ± 0.07 Cc | 19.55 ± 0.22 Dc | 21.67 ± 0.12 Bb |

| a* | 17.82 ± 0.13 Ab | 15.84 ± 0.20 Db | 16.26 ± 0.05 Cc | 16.97 ± 0.08 Ba | 17.04 ± 0.19 Ba | |

| b* | 8.51 ± 0.11 Bb | 8.05 ± 0.13 Cb | 7.10 ± 0.11 Dc | 9.62 ± 0.12 Aa | 8.20 ± 0.07 Cb | |

| 12 | L* | 21.59 ± 0.25 Dc | 21.96 ± 0.33 Cb | 19.74 ± 0.09 Ed | 23.20 ± 0.08 Aa | 22.38 ± 0.02 Bb |

| a* | 12.44 ± 0.78 Bd | 15.70 ± 0.41 Ab | 12.89 ± 0.98 Bd | 13.16 ± 0.27 Bc | 12.89 ± 0.46 Bb | |

| b* | 5.22 ± 0.41 Cd | 7.56 ± 0.80 Ab | 6.83 ± 0.69 ABc | 6.34 ± 0.17 BCc | 6.61 ± 0.77 ABc | |

| 16 | L* | 21.34 ± 0.06 Bc | 22.50 ± 0.57 Ab | 22.58 ± 0.24 Ab | 21.43 ± 0.50 Bb | 21.17 ± 0.59 Bb |

| a* | 11.40 ± 0.84 ABd | 13.11 ± 0.43 Ad | 11.24 ± 0.93 Be | 10.99 ± 1.63 Bd | 10.88 ± 0.35 Bc | |

| b* | 6.76 ± 1.41 CDc | 7.79 ± 0.25 BCb | 10.82 ± 0.87 Aa | 8.37 ± 0.55 Bb | 5.47 ± 0.34 Dd |

| Storage (Weeks) | Parameters | 0 kGy | 2.5 kGy | 5.0 kGy | 7.5 kGy | 10.0 kGy |

|---|---|---|---|---|---|---|

| 0 | C* | 22.69 ± 0.17 Aa | 20.17 ± 0.03 Ba | 19.60 ± 0.05 Ca | 17.55 ± 0.03 Ea | 18.91 ± 0.10 Db |

| h* | 25.85 ± 0.07 Ca | 26.31 ± 0.05 Bb | 26.74 ± 0.22 Aa | 25.62 ± 0.23 Cd | 26.15 ± 0.06 Bc | |

| 4 | C* | 18.41 ± 0.40 Bb | 15.42 ± 0.10 Cc | 20.49 ± 1.03 Aa | 17.72 ± 0.20 Ba | 19.78 ± 0.39 Aa |

| h* | 26.25 ± 1.00 CDa | 25.93 ± 0.41 Db | 28.20 ± 0.41 Ba | 27.21 ± 0.18 BCc | 30.61 ± 0.43 Aa | |

| 8 | C* | 15.91 ± 0.10 Bc | 13.83 ± 0.11 De | 14.86 ± 0.14 Cb | 17.27 ± 0.11 Aa | 16.04 ± 0.25 Bc |

| h* | 26.63 ± 1.35 Ba | 26.47 ± 0.69 Bb | 26.82 ± 2.39 Ba | 29.35 ± 0.25 Ab | 27.63 ± 0.68 ABb | |

| 12 | C* | 13.50 ± 0.88 Bd | 17.15 ± 0.19 Ab | 11.98 ± 1.30 Cc | 14.61 ± 0.28 Bb | 14.43 ± 0.11 Bd |

| h* | 22.73 ± 0.32 Db | 22.55 ± 0.50 Dc | 27.69 ± 0.47 Ba | 25.94 ± 0.36 Cd | 30.98 ± 0.14 Aa | |

| 16 | C* | 12.83 ± 0.73 Bd | 14.36 ± 0.59 Ad | 14.77 ± 0.85 Ab | 14.74 ± 0.58 Ab | 12.23 ± 0.35 Be |

| h* | 25.92 ± 0.33 Ca | 29.70 ± 0.43 ABa | 28.24 ± 1.45 Ba | 31.09 ± 0.66 Aa | 26.57 ± 1.10 Cbc |

| Storage (Weeks) | 0 kGy | 2.5 kGy | 5.0 kGy | 7.5 kGy | 10.0 kGy | |

|---|---|---|---|---|---|---|

| 0 | Cap | 359.9 ± 3.4 Aa | 313.5 ± 1.3 Ca | 340.1 ± 10.2 Ba | 321.2 ± 0.6 Ca | 288.9 ± 8.3 Da |

| DHC | 170.4 ± 1.6 Aa | 138.7 ± 2.7 Ca | 124.0 ± 2.1 Eb | 131.1 ± 1.0 Db | 143.4 ± 2.8 Ba | |

| 4 | Cap | 316.6 ± 2.3 Ab | 312.4 ± 3.0 Aa | 296.4 ± 5.7 Bb | 278.4 ± 2.4 Cb | 271.5 ± 0.9 Db |

| DHC | 109.5 ± 2.1 Dc | 123.4 ± 2.2 Cb | 142.3 ± 2.1 Aa | 135.6 ± 1.8 Ba | 121.8 ± 2.1 Cc | |

| 8 | Cap | 288.7 ± 4.3 Ac | 267.9 ± 1.6 Cb | 287.5 ± 3.9 Ab | 276.3 ± 4.1 Bb | 287.4 ± 3.1 Aa |

| DHC | 127.1 ± 0.3 Bb | 112.5 ± 0.4 Dc | 115.5 ± 0.4 Cb | 107.4 ± 1.7 Ec | 136.3 ± 1.9 Ab | |

| 12 | Cap | 268.5 ± 1.1 BCd | 271.9 ± 4.2 ABb | 263.2 ± 2.4 Cc | 275.1 ± 3.9 Ab | 253.3 ± 3.8 Dc |

| DHC | 93.6 ± 1.6 Dd | 104.2 ± 1.1 Bd | 98.4 ± 1.5 Cc | 105.1 ± 1.5 Bc | 110.0 ± 1.1 Ad | |

| 16 | Cap | 233.6 ± 7.7 De | 269.8 ± 7.0 Cb | 290.7 ± 10.0 Ab | 271.4 ± 11.9 Bb | 254.5 ± 3.3 Cc |

| DHC | 107.7 ± 0.9 Ac | 83.6 ± 1.7 Be | 113.7 ± 15.2 Ab | 72.6 ± 0.1 BCd | 66.1 ± 0.8 Ce |

| Storage (Weeks) | Irradiation Dose (kGy) | |||||

|---|---|---|---|---|---|---|

| 0 kGy | 2.5 kGy | 5.0 kGy | 7.5 kGy | 10.0 kGy | ||

| 0 | TAC | 8.9 × 103 ± 8.1 × 102 Ab | 6.3 × 102 ± 4.1 × 101 Bc | 2.1 × 102 ± 1.8 × 101 Ba | 6.7 ± 5.8 Bab | 0 Bb |

| Mold | 11 ± 1.7 aA | 2.0 ± 1.7 bA | 3.3 ± 5.8 bA | 3.3 ± 5.8 bA | 0 bA | |

| 4 | TAC | 7.7 × 103 ± 5.8 × 102 Ab | 5.2 × 103 ± 3.3 × 101 Ba | 1.8 × 102 ± 2.0 × 101 Cb | 1.7 × 101 ± 9.1 Ca | 3.0 Cb |

| Mold | 7.7 ± 4 aAB | 1 ± 1.7 bA | 0 bA | 0 bA | 0 bA | |

| 8 | TAC | 6.8 × 103 ± 3.5 × 102 Ab | 1.1 × 103 ± 3.0 × 101Bb | 2.0 × 102 ± 2.0 × 101 Cab | 1.1 × 101 ± 1.7 Cab | 4.0 × 101 ± 8.9 Ca |

| Mold | 4.3 ± 2.3 aB | 3.3 ± 3.5 abA | 0 bA | 0 bA | 0 bA | |

| 12 | TAC | 4.7 × 104 ± 4.9 × 103 Aa | 1.1 × 103 ± 1.2 × 101 Bb | 4.3 × 101 ± 5.8 Bc | 5.7 ± 2.3 Bb | 0 Bb |

| Mold | 0 aC | 0 aA | 0 aA | 0 aA | 0 aA | |

| 16 | TAC | 1.0 × 104 ± 1.7 × 102 Ab | 6.1 × 102 ± 8.1 Bc | 3.8 × 101 ± 6.8 Cc | 1.0 × 101 ± 3.0 Cab | 5.7 ± 2.3 Cb |

| Mold | 0 aC | 0 aA | 0 aA | 0 aA | 0 aA | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Balakrishnan, N.; Yusop, S.M.; Rahman, I.A.; Dauqan, E.; Abdullah, A. Effect of Gamma Radiation and Storage Time on the Microbial and Physicochemical Properties of Dried Byadgi Chili (Capsicum annuum). Agriculture 2022, 12, 639. https://doi.org/10.3390/agriculture12050639

Balakrishnan N, Yusop SM, Rahman IA, Dauqan E, Abdullah A. Effect of Gamma Radiation and Storage Time on the Microbial and Physicochemical Properties of Dried Byadgi Chili (Capsicum annuum). Agriculture. 2022; 12(5):639. https://doi.org/10.3390/agriculture12050639

Chicago/Turabian StyleBalakrishnan, Naleene, Salma Mohamad Yusop, Irman Abdul Rahman, Eqbal Dauqan, and Aminah Abdullah. 2022. "Effect of Gamma Radiation and Storage Time on the Microbial and Physicochemical Properties of Dried Byadgi Chili (Capsicum annuum)" Agriculture 12, no. 5: 639. https://doi.org/10.3390/agriculture12050639

APA StyleBalakrishnan, N., Yusop, S. M., Rahman, I. A., Dauqan, E., & Abdullah, A. (2022). Effect of Gamma Radiation and Storage Time on the Microbial and Physicochemical Properties of Dried Byadgi Chili (Capsicum annuum). Agriculture, 12(5), 639. https://doi.org/10.3390/agriculture12050639