Review of Material Parameter Calibration Method

Abstract

:1. Introduction

2. Overview of the Test Methods Used for Parameter Calibration

3. Measurement Method of Material Intrinsic Parameters

3.1. Particle Size and Shape

3.2. Particle Density

3.3. Mechanical Properties of Particles

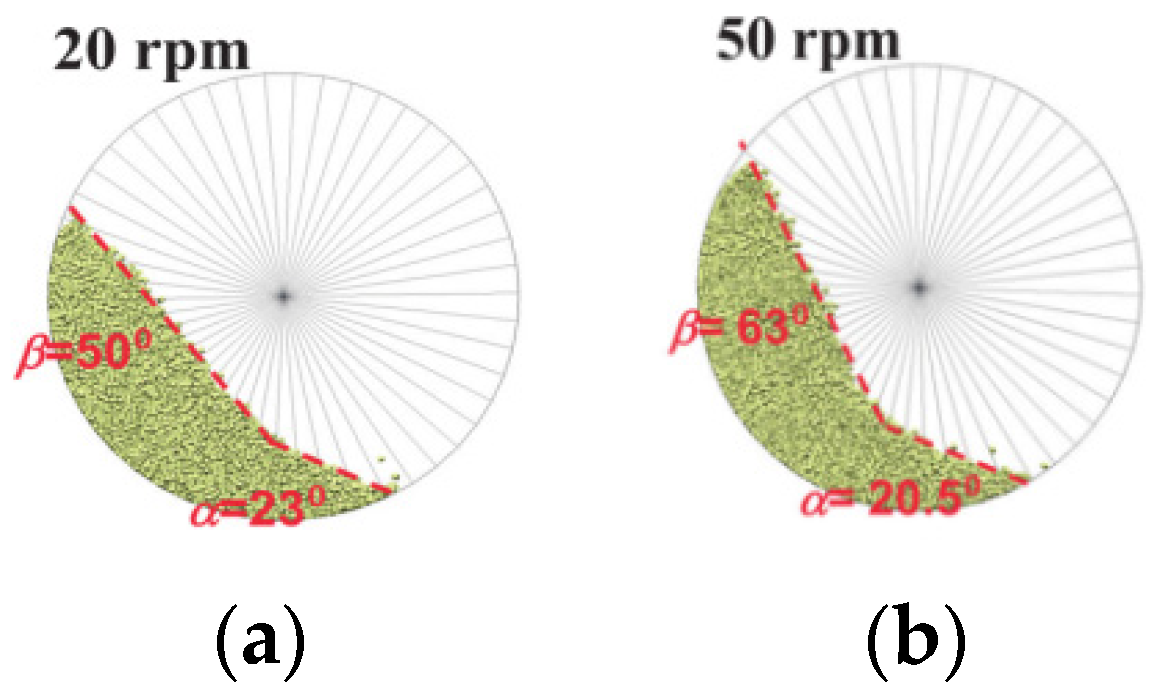

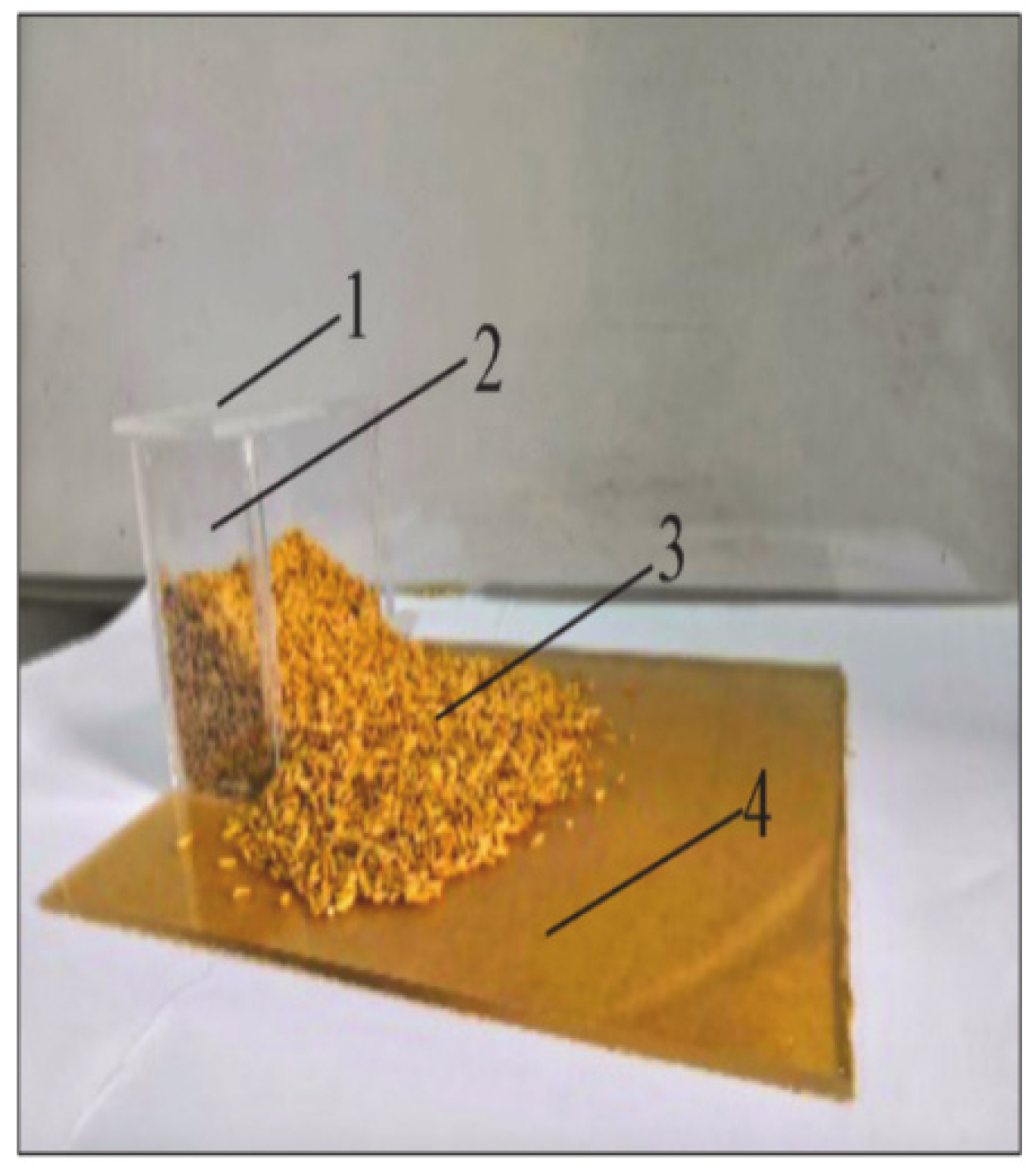

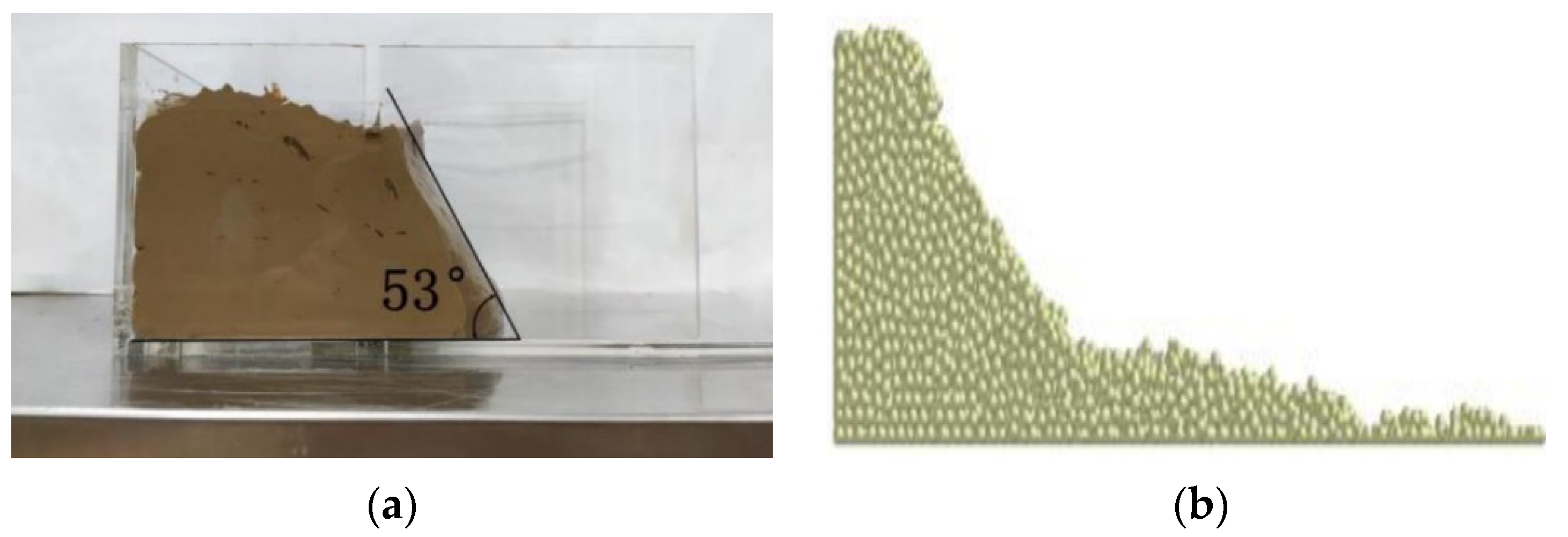

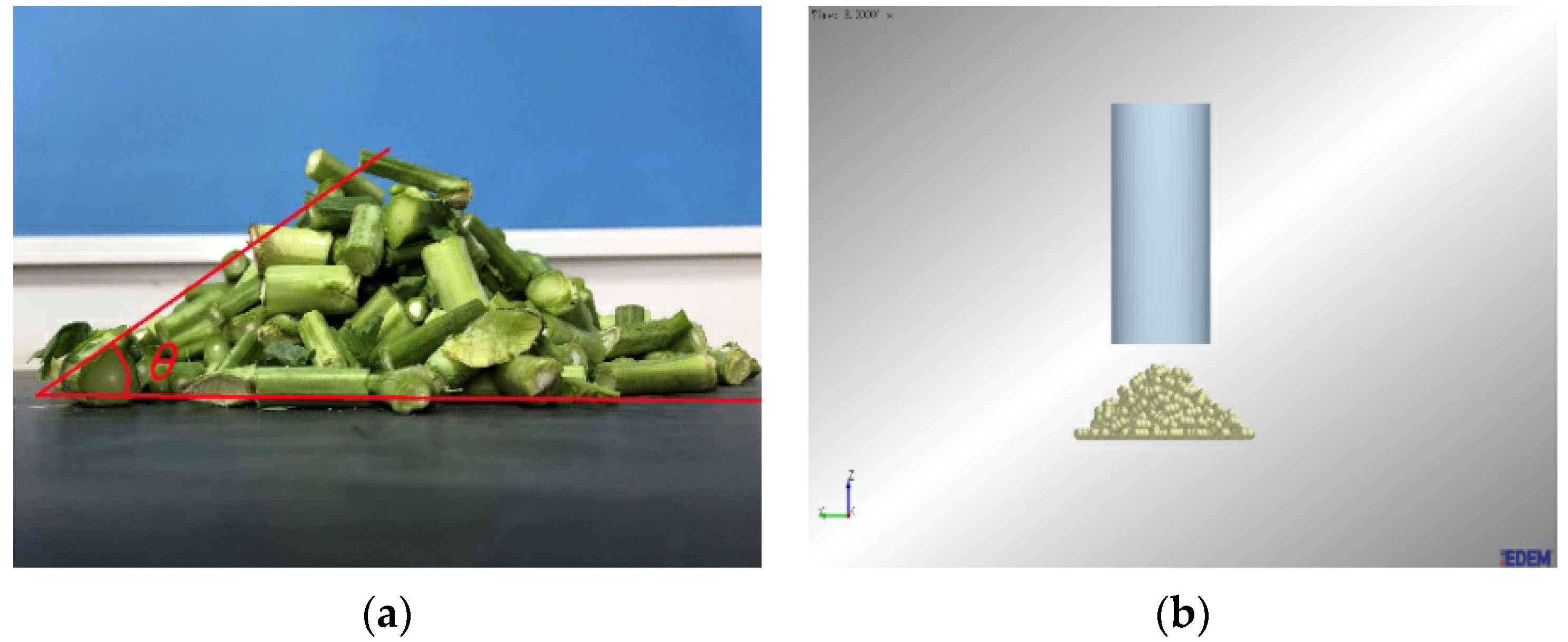

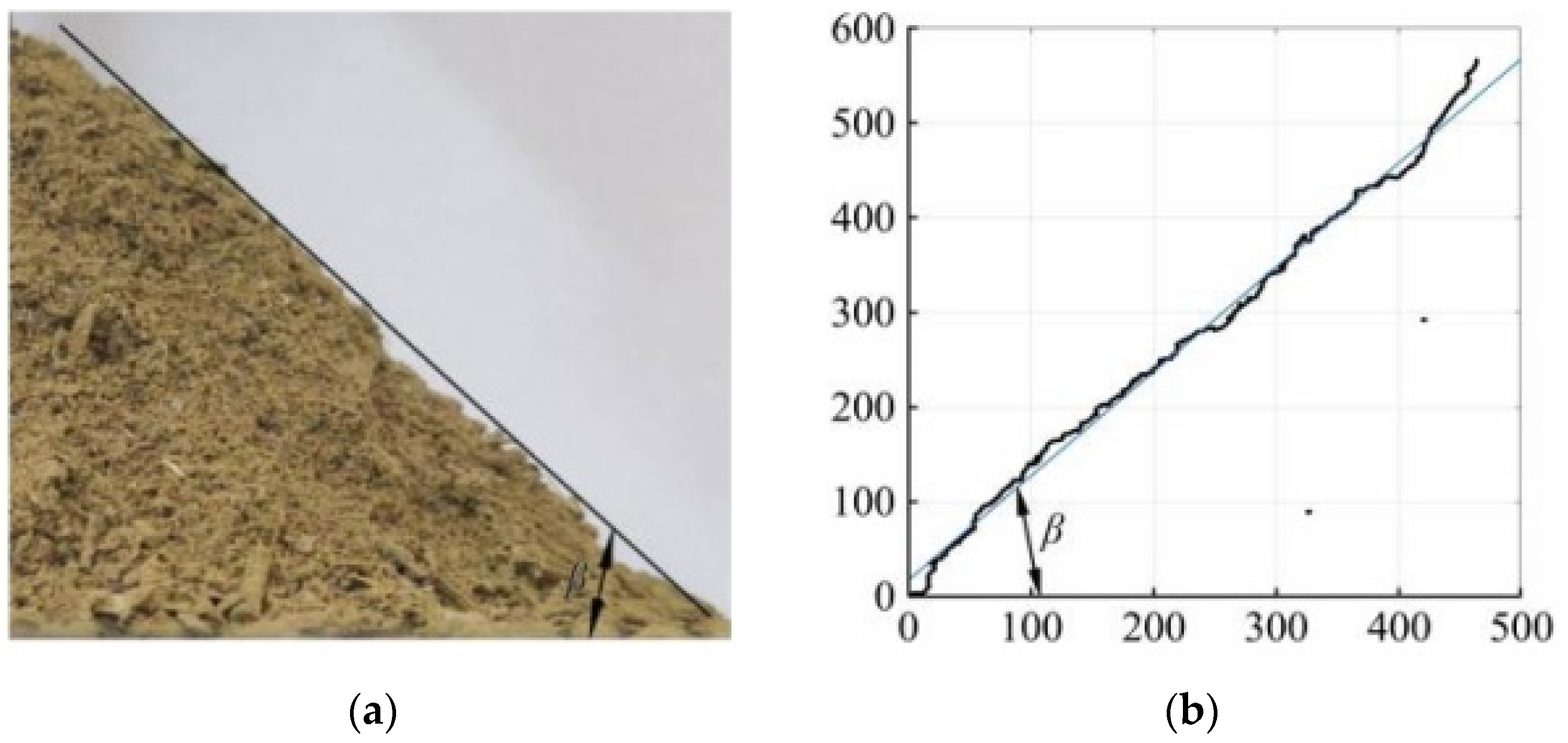

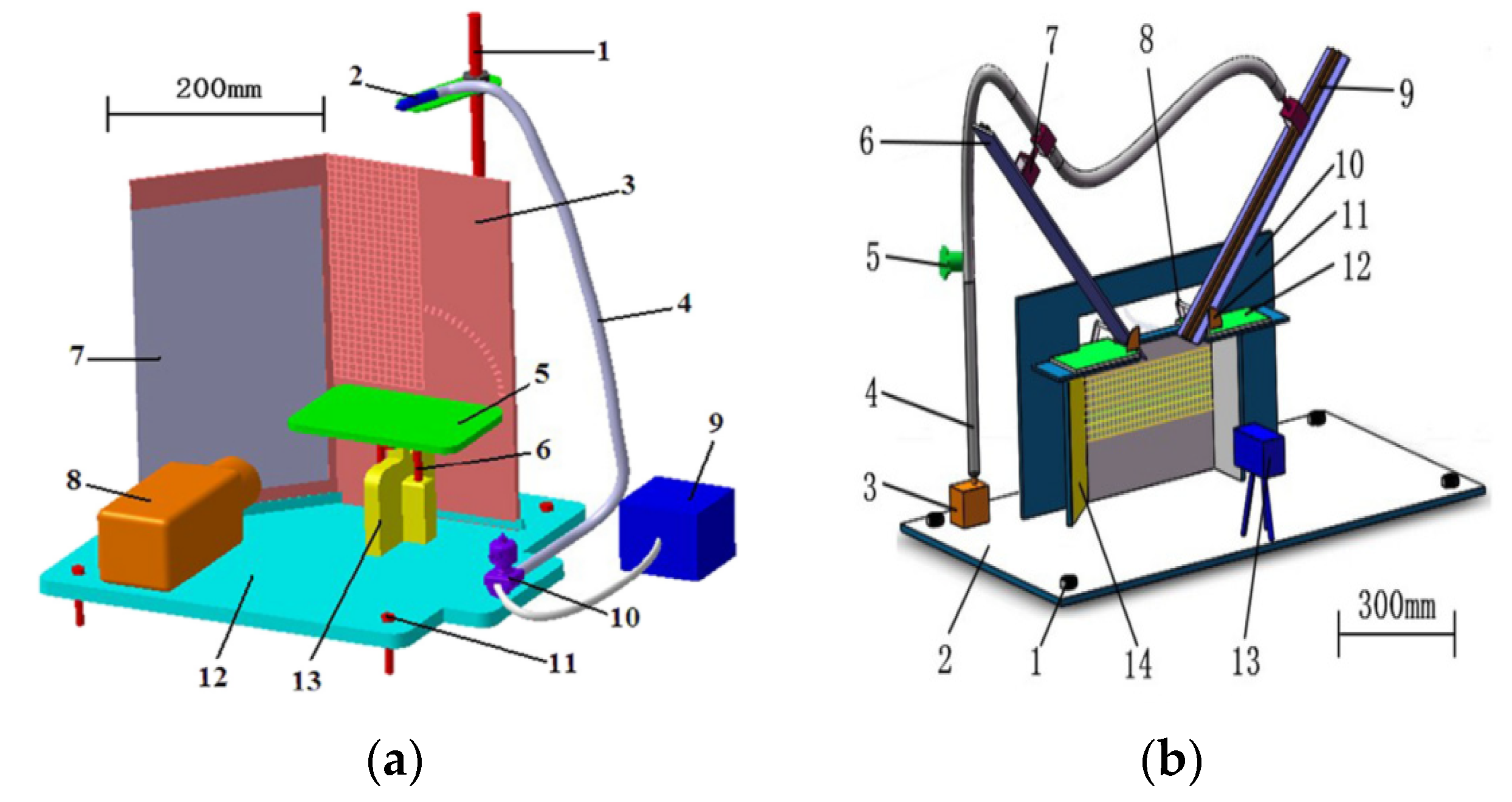

3.4. Measurement of Angle of Repose

4. Measurement Method of Material Contact Parameters

4.1. Contact Model

4.1.1. Particle–Particle

4.1.2. Particle–Rigid Body

4.2. Friction Coefficient

4.2.1. Static Friction Coefficient

- (1)

- Particle–Particle Static Friction Coefficient

- (2)

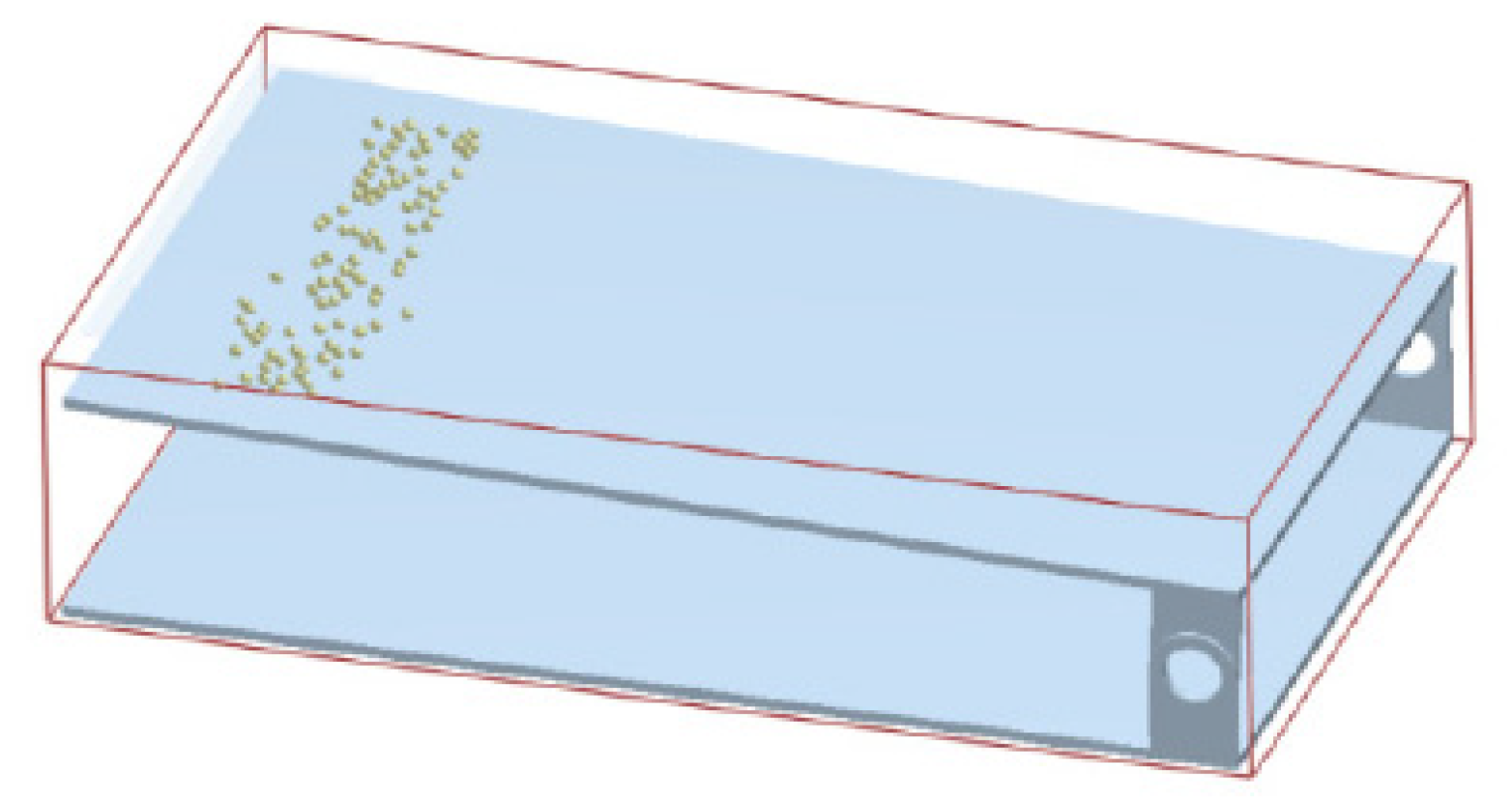

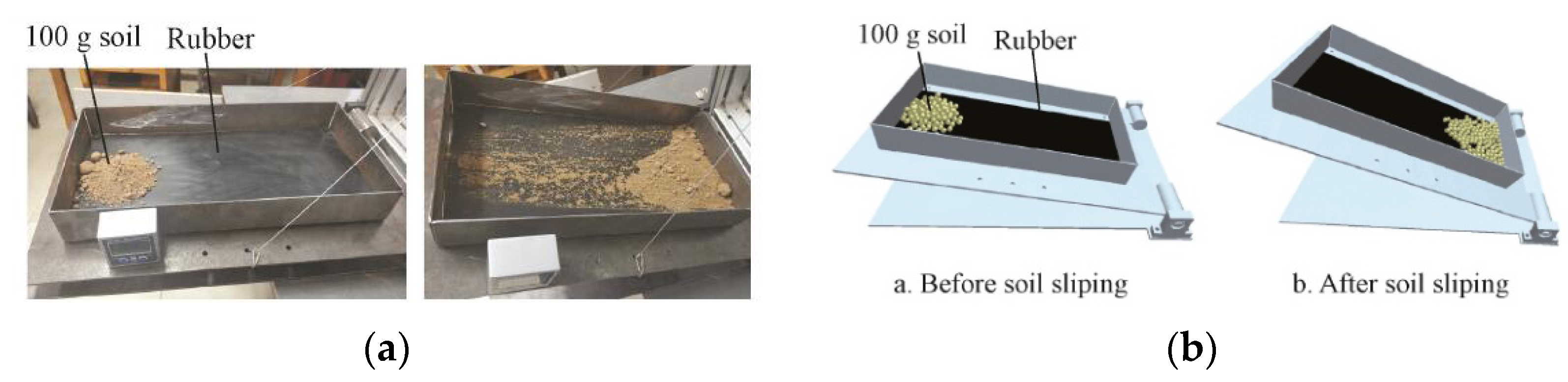

- Particle–Rigid Body Static Friction Coefficient

4.2.2. Dynamic Friction Coefficient

- (1)

- Particle–Particle Dynamic Friction Coefficient

- (2)

- Particle–Rigid Body Dynamic Friction Coefficient

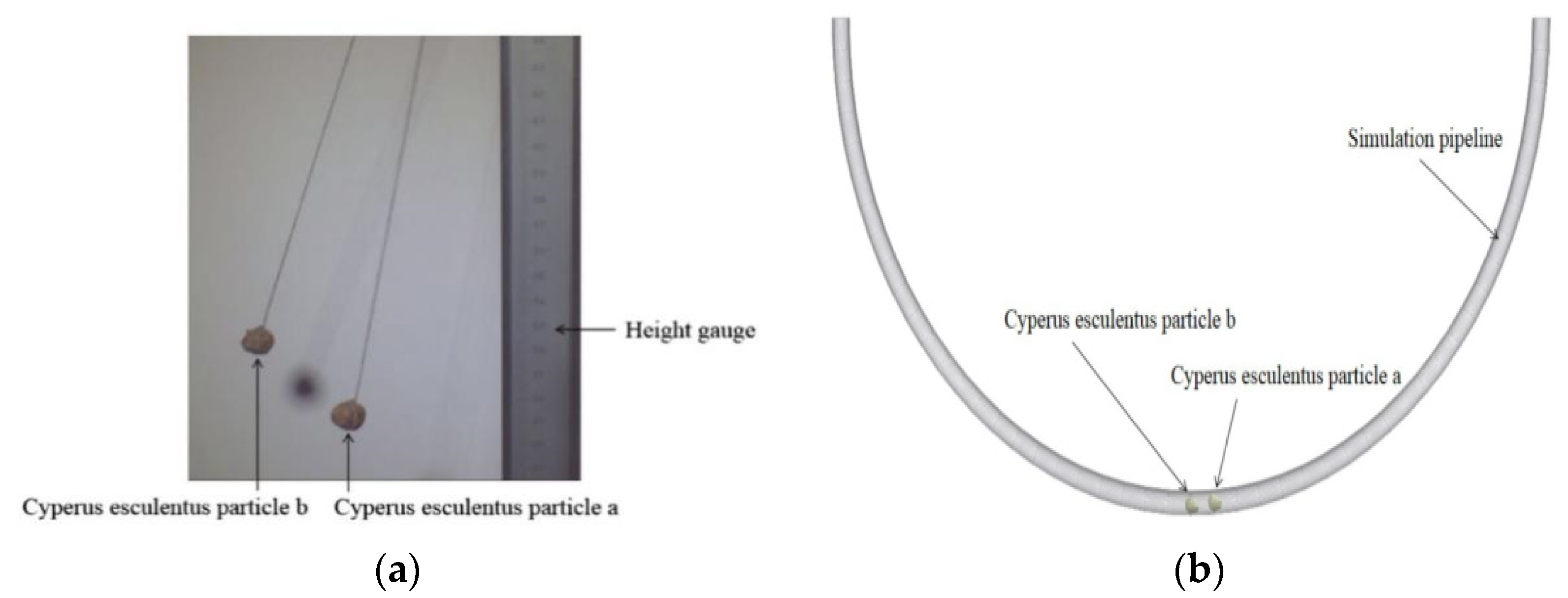

4.2.3. Collision Restitution Coefficient

- (1)

- Restitution Coefficient of Particle–Particle Collision

- (2)

- Restitution Coefficient of Particle–Rigid Body Collision

5. Summary of Current Research Status and Research Prospects

5.1. Summary of the Current Situation

- (1)

- Parameter calibration has become normative process, including the measurement of intrinsic parameters of materials and the method of parameter calibration through virtual simulation. The intrinsic parameters can often be directly measured by the test method before parameter calibration, and the contact parameters can be obtained by test measurement or parameter calibration through virtual simulation. Usually, the particle–particle static friction coefficient, particle–particle dynamic friction coefficient, and restitution coefficient of particle–particle collision can be obtained by virtual parameter calibration. The particle–rigid body static friction coefficient, particle–rigid body dynamic friction coefficient, restitution coefficient of particle–rigid body collision is usually measured experimentally. When the intrinsic properties of materials are difficult to obtain by direct measurement, they can also be obtained through parameter calibration. The particle–rigid body static friction coefficient is mainly measured by the sliding test method, and the particle–rigid body rolling friction coefficient is measured by the slope method.

- (2)

- Parameter calibration generally takes the angle of repose as the target parameter. The static angle of repose generally adopts the cylinder lifting method or the side wall lifting method, and the dynamic angle of repose is often measured by the drum method. Due to limitations in terms of computing power, the particle size is often enlarged by a certain number during simulation. Since the particle shape, size and other factors during simulation are slightly different from the actual factor values, and taking into account of the complexity of the actual application environment, the parameters obtained by calibration have some errors when compared with the actual parameters.

- (3)

- The Plackett–Burman test method or the rotating center combination test method are the commonly used measures to screen significant factors, and the steepest climbing test and the Box–Behnken test are usually used to calibrate the parameters.

- (4)

- By simulating the stacking angle test, slope test, sliding test, crash test, etc., and comparing the error with the test results, the purpose of parameter calibration and reliability verification is achieved. The software used for parameter calibration are EDEM, ROCKY DEM, etc. Function expansion of the software is usually carried out by means of the API program.

5.2. Prospects

- (1)

- When the parameters are calibrated, the tools used to measure the particle parameters are not uniform enough, and the differences in the tools easily cause errors in the parameter calibration. If the tools for material parameter measurement can be gradually formed into standards, the accuracy and efficiency of parameter calibration will be improved. If the common calculation theories of parameter calibration are summarized and shared in papers, the efficiency and convenience of parameter calibration will be improved.

- (2)

- The particle size has a greater impact on the simulation calculation time and simulation accuracy. Due to the computational limitations, the particle size is often enlarged by a certain multiple, but the simulation accuracy and the time saved after amplification need to be further compared to improve the simulation efficiency and simulation accuracy in order to quantify the impact of particle size on the time and simulation efficiency for easy analysis. With the improvement of computing performance, the shape and particle size of simulated particles will be more similar to the actual particles, and the contact situation will be closer to the real situation; then, the simulation’s accuracy will be further improved.

- (3)

- The functions of discrete element simulation software need improvement; many parameter calibration tools need to write an API to operate and the post-processing tools need to be further improved. With the continuous improvement of element simulation software functions, the convenience of discrete element simulation will be improved.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Li, C.; Yin, H.; Wu, C. Calibration of the Discrete Element Method and Modeling of Shortening Experiments. Front. Earth Sci. 2021, 9, 636512. [Google Scholar] [CrossRef]

- Syed, Z.; Tekeste, M.; White, D. A coupled sliding and rolling friction model for DEM calibration. J. Terramech. 2017, 72, 9–20. [Google Scholar] [CrossRef]

- Qu, T.; Feng, Y.; Zhao, T.; Wang, M. A hybrid calibration approach to Hertz-type contact parameters for discrete element models. Int. J. Numer. Anal. Methods Geomech. 2020, 44, 1281–1300. [Google Scholar] [CrossRef]

- Keppler, I.; Bablena, A.; Salman, N.D.; Kiss, P. Discrete element model calibration based on in situ measurements. Eng. Comput. 2021, 39, 1947–1961. [Google Scholar] [CrossRef]

- Wang, X.; Li, J. Simulation of triaxial response of granular materials by modified DEM. Sci. China-Phys. Mech. Astron. 2014, 57, 2297–2308. [Google Scholar] [CrossRef]

- Schramm, M.W.; Tekeste, M.Z.; Steward, B.L. Simulation of uniaxial compression for flexible fibers of wheat straw using the discrete element method. Trans. Asabe 2021, 64, 2025–2034. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, G.; Xue, D. An approach to calibration of BPM bonding parameters for iron ore. Powder Technol. 2021, 381, 245–254. [Google Scholar] [CrossRef]

- Mak, J.; Chen, Y.; Sadek, M.A. Determining parameters of a discrete element model for soil-tool interaction. Soil Tillage Res. 2012, 118, 117–122. [Google Scholar] [CrossRef]

- Wang, X.; Gao, P.; Yue, B.; Shen, H.; Fu, Z.; Zheng, Z.; Zhu, R.; Huang, Y. Optimization of installation parameters of subsoiler’ wing using the discrete element method. Comput. Electron. Agric. 2019, 162, 523–530. [Google Scholar] [CrossRef]

- Zhao, L.; Zhou, H.; Xu, L.; Song, S.; Zhang, C.; Yu, Q. Parameter calibration of coconut bran substrate simulation model based on discrete element and response surface methodology. Powder Technol. 2022, 395, 183–194. [Google Scholar] [CrossRef]

- Dai, Z.; Wu, M.; Fang, Z.; Qu, Y. Calibration and Verification Test of Lily Bulb Simulation Parameters Based on Discrete Element Method. Appl. Sci. 2021, 11, 10749. [Google Scholar] [CrossRef]

- Cheng, J.; Zheng, K.; Xia, J.; Liu, G.; Jiang, L.; Li, D. Analysis of adhesion between wet clay soil and rotary tillage part in paddy field based on discrete element method. Processes 2021, 9, 845. [Google Scholar] [CrossRef]

- Yang, Y.; Wen, B.; Ding, L.; Li, L.; Chen, X.; Li, J. Soil particle modeling and parameter calibration for use with discrete element method. Trans. Asabe 2021, 64, 2011–2023. [Google Scholar] [CrossRef]

- Refahi, A.; Aghazadeh Mohandesi, J.; Rezai, B. Comparison between bond crushing energy and fracture energy of rocks in a jaw crusher using numerical simulation. J. S. Afr. Inst. Min. Metall. 2009, 109, 709–717. [Google Scholar]

- Xie, C.; Yang, J.; Wang, B.; Zhuo, P.; Li, C.; Wang, L. Parameter calibration for the discrete element simulation model of commercial organic fertilizer. Int. Agrophys. 2021, 35, 107–117. [Google Scholar] [CrossRef]

- Peng, C.; Xu, D.; He, X.; Tang, Y.; Sun, S. Parameter calibration of discrete element simulation model for pig manure organic fertilizer treated with Hermetia illucen. Trans. Chin. Soc. Agric. Eng. 2020, 36, 212–218. [Google Scholar]

- Wang, L.; Fan, S.; Cheng, H. Calibration of contact parameters for pig manure based on EDEM. Trans. Chin. Soc. Agric. Eng. 2020, 36, 95–102. [Google Scholar]

- Shi, L.; Zhao, W.; Sun, W. Parameter calibration of soil particles contact model of farmland soil in northwest arid region based on discrete element method. Trans. Chin. Soc. Agric. Eng. 2017, 33, 181–187. [Google Scholar]

- Zhang, R.; Jiao, W.; Zhou, J.; Qi, B.; Liu, H.; Xia, Q. Parameter Calibration and Experiment of Rice Seeds Discrete Element Model with Different Filling Particle Radius. Trans. Chin. Soc. Agric. Mach. 2020, 51, 227–235. [Google Scholar]

- Shi, G.; Li, J.; Ding, L. Calibration and Tests for the Discrete Element Simulation Parameters of Fallen Jujube Fruit. Agriculture 2022, 12, 38. [Google Scholar] [CrossRef]

- Xiang, W.; Wu, M.; Lü, J.; Quan, W.; Ma, L.; Liu, J. Calibration of simulation physical parameters of clay loam based on soil accumulation test. Trans. Chin. Soc. Agric. Eng. 2019, 35, 116–123. [Google Scholar]

- Zhang, T.; Zhao, M.; Liu, F. A Discrete Element Method Model of Corn Stalk and Its Mechanical Characteristic Parameters. Bioresources 2020, 15, 9337–9350. [Google Scholar] [CrossRef]

- Zhang, S.; Tekeste, M.Z.; Li, Y.; Gaul, A.; Zhu, D.; Liao, J. Scaled-up rice grain modelling for DEM calibration and the validation of hopper flow. Biosyst. Eng. 2020, 194, 196–212. [Google Scholar] [CrossRef]

- Tekeste, M.Z.; Mousaviraad, M.; Rosentrater, K.A. Discrete element model calibration using multi-responses and simulation of corn flow in a commercial grain auger. Trans. Asabe 2018, 61, 1743–1755. [Google Scholar] [CrossRef]

- Rorato, R.; Arroyo, M.; Gens, A.; Ando, E.; Viggiani, G. Image-based calibration of rolling resistance in discrete element models of sand. Comput. Geotech. 2021, 131, 103929. [Google Scholar] [CrossRef]

- Binelo, M.O.; Lima, R.F.; Khatchatourian, O.A.; Stransky, J. Modelling of the drag force of agricultural seeds applied to the discrete element method. Biosyst. Eng. 2019, 178, 168–175. [Google Scholar] [CrossRef]

- Hanley, K.J.; Sullivan, C.; Byrne, E.P.; Cronin, K. Discrete element modelling of the quasi-static uniaxial compression of individual infant formula agglomerates. Particuology 2012, 10, 523–531. [Google Scholar] [CrossRef]

- Chen, J.; Gao, R.; Liu, Y. Numerical study of particle morphology effect on the angle of repose for coarse assemblies using DEM. Adv. Mater. Sci. Eng. 2019, 2019, 8095267. [Google Scholar] [CrossRef] [Green Version]

- Shulkin, V.M.; Strukov, A.Y. Particle-Size Analysis of Modern Bottom Sediments by the Laser Diffraction and Sieve Methods. Russ. J. Pac. Geol. 2020, 14, 378–386. [Google Scholar] [CrossRef]

- Qiu, W.; Hu, W.; Curtin, D.; Motoi, L. Soil particle size range correction for improved calibration relationship between the laser-diffraction method and sieve-pipette method. Pedosphere 2021, 31, 134–144. [Google Scholar] [CrossRef]

- Kursun, I. Particle size and shape characteristics of kemerburgaz quartz sands obtained by sieving, laser diffraction, and digital image processing method. Miner. Process. Extr. Metall. Rev. 2009, 30, 346–360. [Google Scholar] [CrossRef]

- Wang, W.P.; Liu, J.L.; Zhang, J.B. Evaluation of Laser Diffraction Analysis of Particle Size Distribution of Typical Soils in China and Comparison with the Sieve-Pipette Method. Soil Sci. 2013, 178, 194–204. [Google Scholar] [CrossRef]

- Boikov, A.; Savelev, R.; Payor, V.; Potapov, A. Universal approach for DEM parameters calibration of bulk materials. Symmetry 2021, 13, 1088. [Google Scholar] [CrossRef]

- Cabiscol, R.; Finke, J.H.; Kwade, A. Calibration and interpretation of DEM parameters for simulations of cylindrical tablets with multi-sphere approach. Powder Technol. 2018, 327, 232–245. [Google Scholar] [CrossRef]

- Coetzee, C.J. Particle upscaling: Calibration and validation of the discrete element method. Powder Technol. 2019, 344, 487–503. [Google Scholar] [CrossRef]

- Roessler, T.; Katterfeld, A. Scaling of the angle of repose test and its influence on the calibration of DEM parameters using upscaled particles. Powder Technol. 2018, 330, 58–66. [Google Scholar] [CrossRef]

- Rozbroj, J.; Zegzulka, J.; Necas, J.; Jezerska, L. Discrete element method model optimization of cylindrical pellet size. Processes 2019, 7, 101. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Zhang, S.; Pan, H.; Zheng, Z.; Huang, Y.; Zhu, R. Effect of soil particle size on soil-subsoiler interactions using the discrete element method simulations. Biosyst. Eng. 2019, 182, 138–150. [Google Scholar] [CrossRef]

- Combarros, M.; Feise, H.J.; Zetzener, H.; Kwade, A. Segregation of particulate solids: Experiments and DEM simulations. Particuology 2014, 12, 25–32. [Google Scholar] [CrossRef]

- Höhner, D.; Wirtz, S.; Scherer, V. Experimental and numerical investigation on the influence of particle shape and shape approximation on hopper discharge using the discrete element method. Powder Technol. 2013, 235, 614–627. [Google Scholar] [CrossRef]

- Just, S.; Toschkoff, G.; Funke, A.; Djuric, D.; Scharrer, G.; Khinast, J.; Knop, K.; Kleinebudde, P. Experimental analysis of tablet properties for discrete element modeling of an active coating process. AAPS PharmSciTech 2013, 14, 402–411. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ji, S.; Karlovsek, J. Calibration and uniqueness analysis of microparameters for DEM cohesive granular material. Int. J. Min. Sci. Technol. 2022, 32, 121–136. [Google Scholar] [CrossRef]

- Guo, W.; Hu, C.; He, X.; Wang, L.; Hou, S.; Wang, X. Construction of virtual mulch film model based on discrete element method and simulation of its physical mechanical properties. Int. J. Agric. Biol. Eng. 2020, 13, 211–218. [Google Scholar] [CrossRef]

- Liu, G.; Xia, J.; Zheng, K.; Cheng, J.; Du, J.; Li, D. Effects of moisture content and tillage methods on creep properties of paddy soil. PLoS ONE 2021, 16, e0253623. [Google Scholar] [CrossRef] [PubMed]

- Barrios, G.K.P.; Mde Carvalho, R.; Kwade, A.; Tavares, L.M. Contact parameter estimation for DEM simulation of iron ore pellet handling. Powder Technol. 2013, 248, 84–93. [Google Scholar] [CrossRef]

- Paulick, M.; Morgeneyer, M.; Kwade, A. Review on the influence of elastic particle properties on DEM simulation results. Powder Technol. 2015, 283, 66–76. [Google Scholar] [CrossRef]

- Zhou, L.; Gao, J.; Li, Q.; Hu, C.; Wang, R. Numerical simulation analysis of interaction model between track and sandy road based on discrete element method. In Proceedings of the International Conference on Automation and Computing (ICAC), Lancaster University, Lancaster, UK, 7 May 2019. [Google Scholar]

- Zeng, H.; Xu, W.; Zang, M.; Yang, P.; Guo, X. Calibration and validation of DEM-FEM model parameters using upscaled particles based on physical experiments and simulations. Adv. Powder Technol. 2020, 31, 3947–3959. [Google Scholar] [CrossRef]

- Mousaviraad, M.; Tekeste, M.; Rosentrater, K.A. calibration and validation of a discrete element model of corn using grain flow simulation in a commercial screw grain auger. Trans. Asabe 2017, 60, 1403–1416. [Google Scholar] [CrossRef] [Green Version]

- Liu, F.; Zhang, J.; Chen, J. Modeling of flexible wheat straw by discrete element method and its parameters calibration. Int. J. Agric. Biol. Eng. 2018, 11, 42–46. [Google Scholar] [CrossRef] [Green Version]

- Ghodki, B.M.; Kumar, K.C.; Goswami, T.K. Modeling breakage and motion of black pepper seeds in cryogenic mill. Adv. Powder Technol. 2018, 29, 1055–1071. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Y.; Yang, Y. Discrete element modelling of citrus fruit stalks and its verification. Biosyst. Eng. 2020, 200, 400–414. [Google Scholar] [CrossRef]

- Ding, Q.; Ren, J.; Adam, B.E.; Zhao, J.; Ge, S.; Li, Y. DEM analysis of subsoiling process in wet clayey paddy soil. Trans. Chin. Soc. Agric. 2017, 48, 38–48, (In Chinese with English abstract). [Google Scholar]

- Kim, Y.S.; Siddique, M.A.A.; Kim, W.S. DEM simulation for draft force prediction of moldboard plow according to the tillage depth in cohesive soil. Comput. Electron. Agric. 2021, 189, 106368. [Google Scholar] [CrossRef]

- Hoshishima, C.; Ohsaki, S.; Nakamura, H.; Watano, S. Parameter calibration of discrete element method modelling for cohesive and non-spherical particles of powder. Powder Technol. 2021, 386, 199–208. [Google Scholar] [CrossRef]

- Coetzee, C. Calibration of the discrete element method: Strategies for spherical and non-spherical particles. Powder Technol. 2020, 364, 851–878. [Google Scholar] [CrossRef]

- Marigo, M.; Stitt, E.H. Discrete Element Method (DEM) for Industrial Applications: Comments on Calibration and Validation for the Modelling of Cylindrical Pellets. Kona Powder Part. J. 2015, 32, 236–252. [Google Scholar] [CrossRef] [Green Version]

- Kanakabandi, C.K.; Goswami, T.K. Determination of properties of black pepper to use in discrete element modeling. J. Food Eng. 2019, 246, 111–118. [Google Scholar] [CrossRef]

- Roessler, T.; Richter, C.; Katterfeld, A.; Will, F. Development of a standard calibration procedure for the DEM parameters of cohesionless bulk materials—Part I: Solving the problem of ambiguous parameter combinations. Powder Technol. 2019, 343, 803–812. [Google Scholar] [CrossRef]

- Geng, L.; Zuo, J.; Lu, F.; Jin, X.; Sun, C.; Ji, J. Calibration and experiment validation of contact parameters for oat seeds for discrete element method simulation. Appl. Eng. Agric. 2021, 37, 605–614. [Google Scholar] [CrossRef]

- Petingco, M.C.; Casada, M.E.; Maghirang, R.G.; Fasina, O.O.; Chen, Z.; Ambrose, R.P.K. Influence of Particle Shape and Contact Parameters on DEM-Simulated Bulk Density of Wheat. Trans. Asabe 2020, 63, 1657–1672. [Google Scholar] [CrossRef]

- Zhu, B.; Liu, J.A.; Chen, X.; Yu, J.; Liu, M.; Zhang, Q. Parameter calibration of soil in the poyang lake region based on discrete element method. Am. J. Biochem. Biotechnol. 2020, 16, 538–548. [Google Scholar] [CrossRef]

- Liao, Y.; Wang, Z.; Liao, Q.; Liang, F.; Liu, J. Calibration of discrete element parameters of fodder rape crop stem at flowering stage. In Proceedings of the 2020 ASABE Annual International Virtual Meeting, St. Joseph, MI, USA, 13–15 July 2020. [Google Scholar]

- Liang, R.; Chen, X.; Jiang, P.; Zhang, B.; Meng, H.; Peng, X.; Kan, Z. Calibration of the simulation parameters of the particulate materials in film mixed materials. Int. J. Agric. Biol. Eng. 2020, 13, 29–36. [Google Scholar] [CrossRef]

- De Pue, J.; Di Emidio, G.; Flores, R.D.V.; Bezuijen, A.; Cornelis, W.M. Calibration of DEM material parameters to simulate stress-strain behaviour of unsaturated soils during uniaxial compression. Soil Tillage Res. 2019, 194, 104303. [Google Scholar] [CrossRef]

- Du, Y.; Cui, T.; Zhang, D.; Wei, Y.; Yang, R.; Wu, H. Establishment and parameter calibration of broad bean seeds simulation particles in EDEM. In Proceedings of the 2019 ASABE Annual International Meeting, St. Joseph, MI, USA, 7–10 July 2019. [Google Scholar]

- Roessler, T.; Katterfeld, A. DEM parameter calibration of cohesive bulk materials using a simple angle of repose test. Particuology 2019, 45, 105–115. [Google Scholar] [CrossRef]

- Zu, E.; Zhou, P.; Jiang, Z. Discrete element method of coke accumulation: Calibration of the contact Parameter. N. In Proceedings of the 5th IFAC Workshop on Mining, Mineral and Metal Processing (MMM), Shanghai, China, 23–25 August 2018. [Google Scholar]

- Giannis, K.; Schilde, C.; Finke, J.H.; Kwade, A. Modeling of high-density compaction of pharmaceutical tablets using multi-contact discrete element method. Pharmaceutics 2021, 13, 2194. [Google Scholar] [CrossRef] [PubMed]

- Mudarisov, S.; Farkhutdinov, I.; Khamaletdinov, R.; Khasanov, E.; Mukhametdinov, A. Evaluation of the significance of the contact model particle parameters in the modelling of wet soils by the discrete element method. Soil Tillage Res. 2022, 215, 105228. [Google Scholar] [CrossRef]

- Tian, X.; Cong, X.; Qi, J.; Guo, H.; Li, M.; Fan, X. Parameter calibration of discrete element model for corn straw-soil mixture in black soil areas. Trans. Chin. Soc. Agric. Mach. 2021, 52, 100–108+242. [Google Scholar]

- Zhang, S.; Zhang, R.; Chen, T.; Fu, J.; Yuan, H. Parameter calibration of mung bean seeds discrete element simulation and verification test of seeding. Trans. Chin. Soc. Agric. Eng. 2022, 53, 71–79. [Google Scholar]

- Yuan, Q.; Xu, L.; Ma, S.; Niu, C.; Wang, S.; Yuan, X. Design and test of sawtooth fertilizer block crushing blade of organic fertilizer deep applicator. Trans. Chin. Soc. Agric. Eng. 2020, 36, 44–51. [Google Scholar]

- Chen, G.; Schott, D.L.; Lodewijks, G. Sensitivity analysis of DEM prediction for sliding wear by single iron ore particle. Eng. Comput. 2017, 34, 2031–2053. [Google Scholar] [CrossRef] [Green Version]

- Liao, Y.; Liao, Q.; Zhou, Y.; Wang, Z.; Jiang, Y.; Liang, F. Parameters calibration of discrete element model of fodder rape crop harvest in bolting stage. Trans. Chin. Soc. Agric. Mach. 2020, 51, 73–82. [Google Scholar]

- Saunders, C.; Ucgul, M.; Godwin, R.J. Discrete element method (DEM) simulation to improve performance of a mouldboard skimmer. Soil Tillage Res. 2021, 205, 104764. [Google Scholar] [CrossRef]

- Zeng, Z.; Chen, Y.; Qi, L. Simulation of cotyledon-soil dynamics using the discrete element method (DEM). Comput. Electron. Agric. 2020, 174, 105505. [Google Scholar] [CrossRef]

- Ajmal, M.; Roessler, T.; Richter, C.; Katterfeld, A. Calibration of cohesive DEM parameters under rapid flow conditions and low consolidation stresses. Powder Technol. 2020, 374, 22–32. [Google Scholar] [CrossRef]

- Zeng, Z.; Ma, X.; Chen, Y.; Qi, L. Modelling residue incorporation of selected chisel ploughing tools using the discrete element method (DEM). Soil Tillage Res. 2020, 197, 104505. [Google Scholar] [CrossRef]

- Zhao, H.; Li, H.; Ma, S. The effect of various edge-curve types of plain-straight blades for strip tillage seeding on torque and soil disturbance using DEM. Soil Tillage Res. 2020, 202, 104674. [Google Scholar] [CrossRef]

- Han, Y.L.; Jia, F.G.; Tang, Y.R.; Liu, Y.; Zhang, Q. Influence of granular coefficient of rolling friction on accumulation characteristics. Acta Phys. Sin. 2014, 63, 173–179. [Google Scholar]

- Chen, Z.; Wassgren, C.; Veikle, E.; Ambrose, K. Determination of material and interaction properties of maize and wheat kernels for DEM simulation. Biosyst. Eng. 2020, 195, 208–226. [Google Scholar] [CrossRef]

- Song, S.; Tang, Z.; Zheng, X.; Liu, J.; Meng, X.; Liang, Y. Calibration of the discrete element parameters for the soil model of cotton field after plowing in Xinjiang of China. Trans. Chin. Soc. Agric. Eng. 2021, 37, 63–70. [Google Scholar]

- Liu, W.; Jin, H.E.; LI, H.; LI, X.; Zheng, K.; Wei, Z. Calibration of Simulation Parameters for Potato Minituber Based on EDEM. Trans. Chin. Soc. Agric. Mach. 2018, 49, 125–135, 142. [Google Scholar]

- Yu, Q.; Liu, Y.; Chen, X.; Sun, K.; Lai, Q. Calibration and experiment of simulation parameters for panax notoginseng seeds based on DEM. Trans. Chin. Soc. Agric. Mach. 2020, 51, 123–132. [Google Scholar]

- Hoseinian, S.H.; Hemmat, A.; Esehaghbeygi, A.; Shahgoli, G.; Baghbanan, A. Development of a dual sideway-share subsurface tillage implement: Part 1. Modeling tool interaction with soil using DEM. Soil Tillage Res. 2022, 215, 105201. [Google Scholar] [CrossRef]

- Jia, H.; Deng, J.; Deng, Y. Contact parameter analysis and calibration in discrete element simulation of rice straw. Int. J. Agric. Biol. Eng. 2021, 14, 72–81. [Google Scholar] [CrossRef]

- Coetzee, C.J.; Els, D.N.J. Calibration of discrete element parameters and the modelling of silo discharge and bucket filling. Comput. Electron. Agric. 2009, 65, 198–212. [Google Scholar] [CrossRef]

- Tripathi, A.; Kumar, V.; Agarwal, A. Quantitative DEM simulation of pellet and sinter particles using rolling friction estimated from image analysis. Powder Technol. 2021, 380, 288–302. [Google Scholar] [CrossRef]

- Wang, Y.; Liang, Z.; Zhang, D.; Cui, T.; Shi, S.; Li, K.; Yang, L. Calibration method of contact characteristic parameters for corn seeds based on EDEM. Trans. Chin. Soc. Agric. Eng. 2016, 32, 36–42. [Google Scholar]

- Ma, S.; Xu, L.; Yuan, Q.; Niu, C.; Zeng, J.; Chen, C.; Wang, S.; Yuan, X. Calibration of discrete element simulation parameters of grapevine antifreezing soil and its interaction with soil-cleaning components. Trans. Chin. Soc. Agric. Eng. 2020, 36, 40–49. [Google Scholar]

- Li, J.; Tong, J.; Hu, B.; Wang, H.; Mao, C.; Ma, Y. Calibration of parameters of interaction between clayey black soil with different moisture content and soil-engaging component in northeast China. Trans. Chin. Soc. Agric. Eng. 2019, 35, 130–140. [Google Scholar]

- Westbrink, F.; Elbel, A.; Schwung, A.; Ding, S.X. Optimization of DEM parameters using multi-objective reinforcement learning. Powder Technol. 2021, 379, 602–616. [Google Scholar] [CrossRef]

- Klejment, P. Application of supervised machine learning as a method for identifying DEM contact law parameters. Math. Biosci. Eng. 2021, 18, 7490–7505. [Google Scholar] [CrossRef]

- Benvenuti, L.; Kloss, C.; Pirker, S. Identification of DEM simulation parameters by Artificial Neural Networks and bulk experiments. Powder Technol. 2016, 291, 456–465. [Google Scholar] [CrossRef]

- Ye, F.; Wheeler, C.; Chen, B.; Hu, J.; Chen, K.; Chen, W. Calibration and verification of DEM parameters for dynamic particle flow conditions using a backpropagation neural network. Adv. Powder Technol. 2019, 30, 292–301. [Google Scholar] [CrossRef]

- Zhou, H.; Hu, Z.; Chen, J.; Lv, X.; Xie, N. Calibration of DEM models for irregular particles based on experimental design method and bulk experiments. Powder Technol. 2018, 332, 210–223. [Google Scholar] [CrossRef]

- Kotrocz, K.; Kerenyi, G. Investigation the effect of the model dimension in soil-cone penetometer discrete element simulation. In Proceedings of the 32nd European Conference on Modelling and Simulation (ECMS), Wilhelmshaven, Germany, 22–25 May 2018. [Google Scholar]

- Garcia, B.; Richefeu, V.; Baroth, J.; Daudon, D.; Villard, P. Collision of shaped boulders with sand substrate investigated by experimental, stochastic, and discrete approaches. J. Geophys. Res.-Earth Surf. 2020, 125, e2019JF005500. [Google Scholar] [CrossRef]

- Qi, J.; An, S.; Kan, Z.; Meng, H.; Li, Y.; Zhao, X. Discrete element-based calibration of simulation parameters of Cyperus esculentus L. (tiger nut) planted in sandy soil. J. Food Process. Preserv. 2021, 45, e15631. [Google Scholar] [CrossRef]

- Hlosta, J.; Zurovec, D.; Rozbroj, J.; Ramirez-Gomez, A.; Necas, J.; Zegzulka, J. Experimental determination of particle-particle restitution coefficient via double pendulum method. Chem. Eng. Res. Des. 2018, 135, 222–233. [Google Scholar] [CrossRef]

- Wang, L.; Wu, B.; Wu, Z.; Li, R.; Feng, X. Experimental determination of the coefficient of restitution of particle-particle collision for frozen maize grains. Powder Technol. 2018, 338, 263–273. [Google Scholar] [CrossRef]

- Wang, L.; Zheng, Z.; Yu, Y.; Liu, T.; Zhang, Z. Determination of the energetic coefficient of restitution of maize grain based on laboratory experiments and DEM simulations. Powder Technol. 2020, 362, 645–658. [Google Scholar] [CrossRef]

- Adilet, S.; Zhao, J.; Sayakhat, N.; Chen, J.; Nikolay, Z.; Bu, L.; Wang, Z. Calibration strategy to determine the interaction properties of fertilizer particles using two laboratory tests and DEM. Agriculture 2021, 11, 592. [Google Scholar] [CrossRef]

- Xia, R.; Li, B.; Wang, X.; Li, T.; Yang, Z. Measurement and calibration of the discrete element parameters of wet bulk coal. Measurement 2019, 142, 84–95. [Google Scholar] [CrossRef]

- Wang, L.; Zhou, W.; Ding, Z.; Li, X.; Zhang, C. Experimental determination of parameter effects on the coefficient of restitution of differently shaped maize in three-dimensions. Powder Technol. 2015, 284, 187–194. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, W.; Wang, X.; Han, D.; Chen, X. Review of Material Parameter Calibration Method. Agriculture 2022, 12, 706. https://doi.org/10.3390/agriculture12050706

Fang W, Wang X, Han D, Chen X. Review of Material Parameter Calibration Method. Agriculture. 2022; 12(5):706. https://doi.org/10.3390/agriculture12050706

Chicago/Turabian StyleFang, Weiquan, Xinzhong Wang, Dianlei Han, and Xuegeng Chen. 2022. "Review of Material Parameter Calibration Method" Agriculture 12, no. 5: 706. https://doi.org/10.3390/agriculture12050706

APA StyleFang, W., Wang, X., Han, D., & Chen, X. (2022). Review of Material Parameter Calibration Method. Agriculture, 12(5), 706. https://doi.org/10.3390/agriculture12050706