Economic and Environmental Assessment of Olive Agroforestry Practices in Northern Greece

Abstract

:1. Introduction

2. Materials and Methods

2.1. Study Area

- (i)

- open-spaced olive trees intercropped with barley (BOT)

- (ii)

- open-spaced olive trees intercropped with a mixture of barley and common vetch (VBOT)

- (iii)

- olive orchards (OT)

- (iv)

- monocultures of cereals (barley) (BF),

2.2. LCA Background

2.3. Goal and Scope Definition

2.4. Life Cycle Inventory (LCI)

2.5. Life Cycle Impact Assessment

3. Results

3.1. Emissions and Energy Consumed

3.2. Economic Outcome

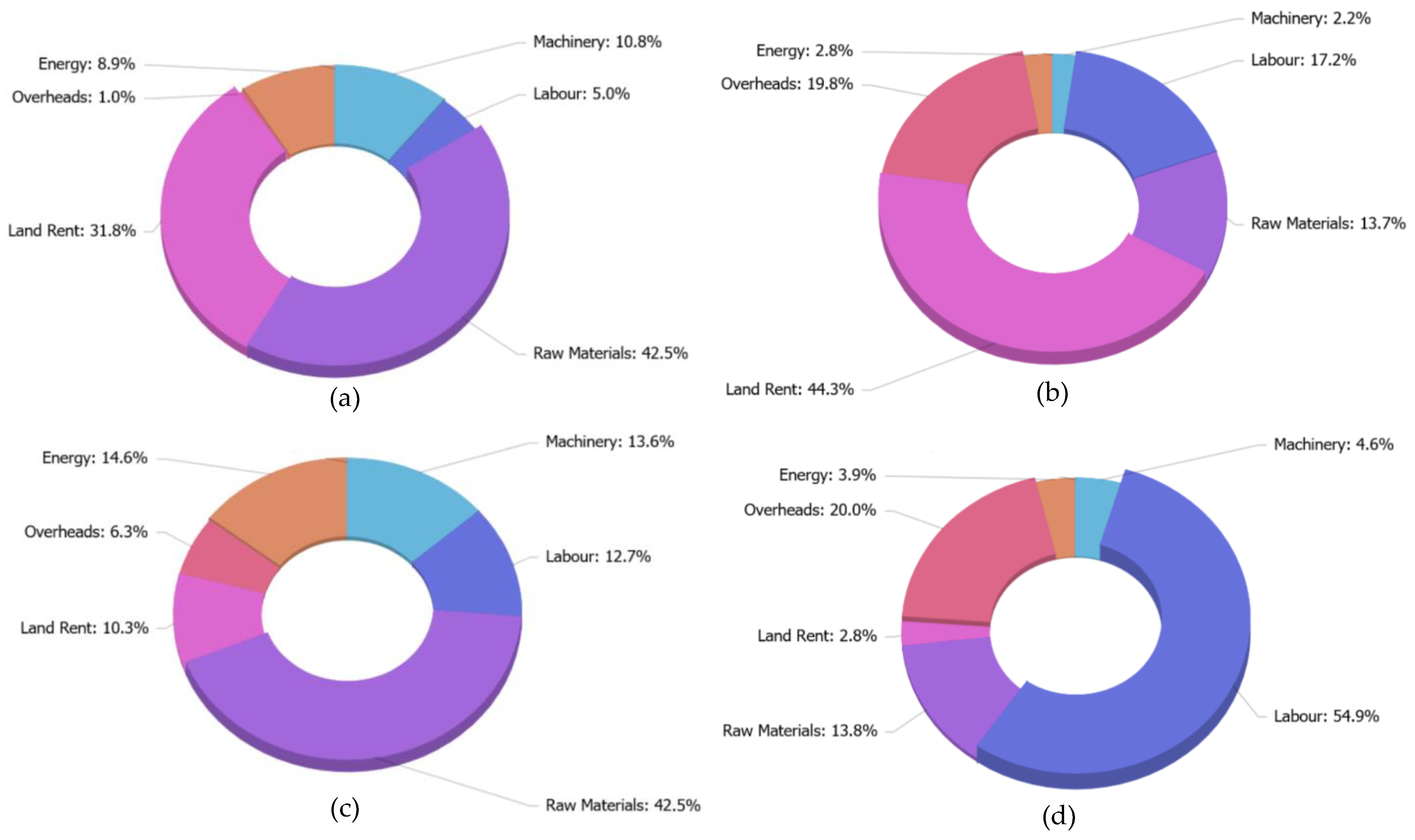

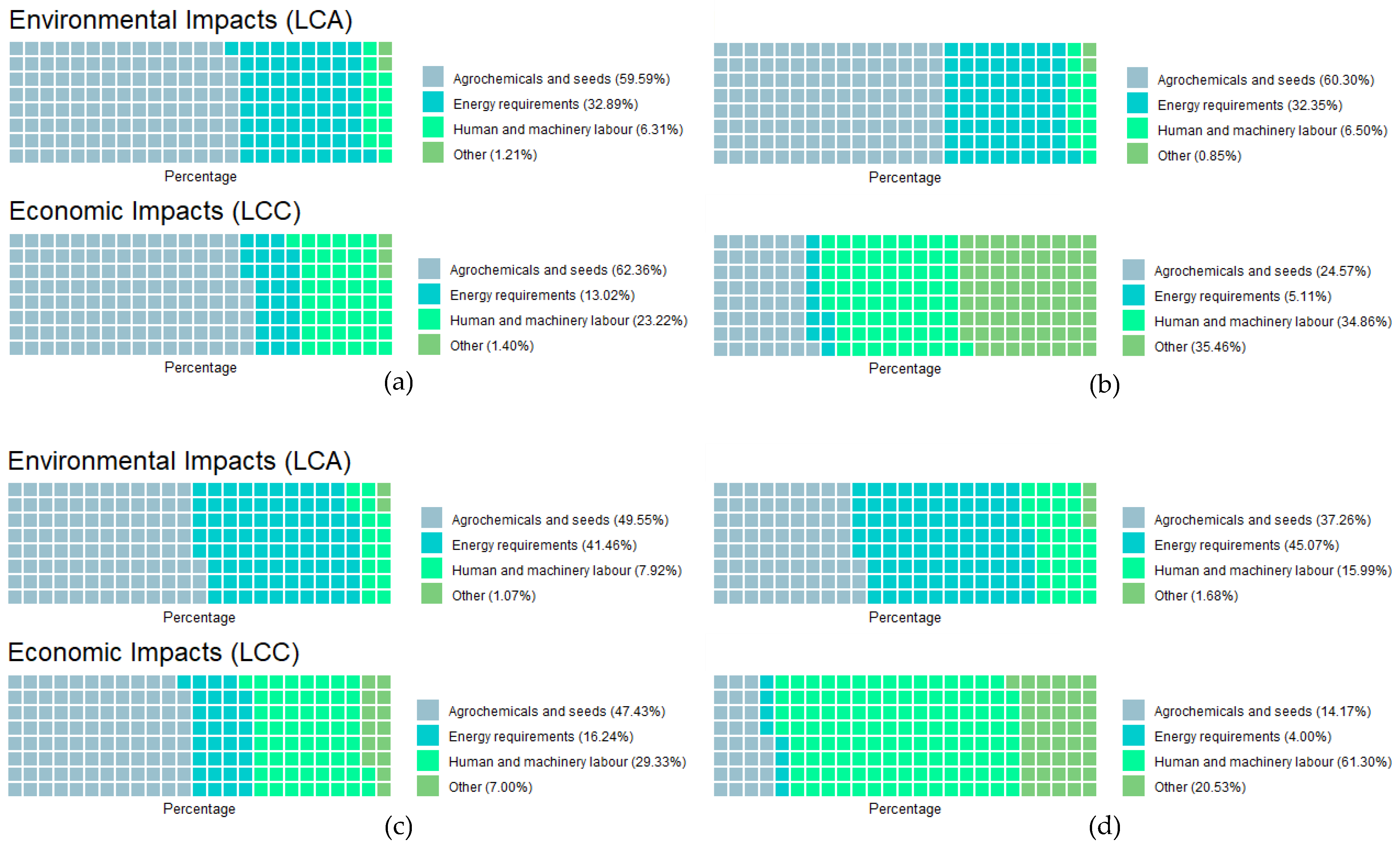

3.3. LCA and LCC Evaluation

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- FAO. The Future of Food and Agriculture—Trends and Challenges; FAO: Rome, Italy, 2017. [Google Scholar]

- FAO. World Food and Agriculture—Statistical Pocketbook 2018; FAO: Rome, Italy, 2018; p. 254, Licence: CC BY-NC-SA 3.0 IGO. [Google Scholar]

- IPES-Food. From Uniformity to Diversity: A Paradigm Shift from Industrial Agriculture to Diversified Agroecological Systems. International Panel of Experts on Sustainable Food Systems, 2016. Available online: www.ipes-food.org (accessed on 1 March 2022).

- European Commission. EU Agriculture and Climate Change Factsheet; European Commission: Brussels, Belgium, 2015. [Google Scholar]

- Lehmann, L.M.; Borzęcka, M.; Żyłowska, K.; Pisanelli, A.; Russo, G.; Ghaley, B.B. Environmental Impact Assessments of Integrated Food and Non-Food Production Systems in Italy and Denmark. Energies 2020, 13, 849. [Google Scholar] [CrossRef] [Green Version]

- Martineau, H.; Wiltshire, J.; Webb, J.; Hart, K.; Keenleyside, C.; Baldock, D.; Bell, H.; Watterson, J. Effective Performance of Tools for Climate Action Policy—Meta-Review of Common Agricultural Policy (CAP) Mainstreaming; Ricardo-AEA & IEEP: Didcot, UK, 2016. [Google Scholar]

- Moreno, G.; Aviron, S.; Berg, S.; Crous-Duran, J.; Franca, A.; de Jalón, S.G.; Hartel, T.; Mirck, J.; Pantera, A.; Palma, J.H.N.; et al. Agroforestry systems of high nature and cultural value in Europe: Provision of commercial goods and other ecosystem services. Agrofor. Syst. 2018, 92, 877–891. [Google Scholar] [CrossRef] [Green Version]

- Bastin, J.F.; Finegold, Y.; Garcia, C.; Mollicone, D.; Rezende, M.; Routh, D.; Zohner, C.M.; Crowther, T.W. The global tree restoration potential. Science 2019, 365, 76–79. [Google Scholar] [CrossRef]

- European Commission. Towards an EU Research and Innovation Policy Agenda for Nature-Based Solutions & Re-Naturing Cities; European Commission: Brussels, Belgium, 2015. [Google Scholar]

- Mantzanas, K.; Pantera, A.; Koutsoulis, D.; Papadopoulos, A.; Kapsalis, D.; Ispikoudis, S.; Fotiadis, G.; Sidiropoulou, A.; Papanastasis, V.P. Intercrop of olive trees with cereals and legumes in Chalkidiki, Northern Greece. Agroforest. Syst. 2021, 95, 895–905. [Google Scholar] [CrossRef]

- Papanastasis, V.P.; Mantzanas, K.; Dini-Papanastasi, O.; Ispikoudis, I. Traditional Agroforestry Systems and Their Evolution in Greece. In Agroforestry in Europe: Current Status and Future Prospects; Rigueiro-Rodrigez, A., McAdam, J., Mosquera-Losada, M.R., Eds.; Springer: Berlin/Heidelberg, Germany, 2009; pp. 89–109. [Google Scholar]

- Pantera, A.; Burgess, P.J.; Mosquera-Losada, R.; Moreno, G.; Lopez-Dıaz, M.L.; Corroyer, N.; McAdam, J.; Rosati, A.; Papadopoulos, A.M.; Graves, A.; et al. Agroforestry for high value tree systems in Europe. Agrofor. Syst. 2018, 92, 945–959. [Google Scholar]

- Pantera, A.; Papadopoulos, A.; Kitsikopoulos, D.; Mantzanas, K.; Papanastasis, V.; Fotiadis, G. System report: Olive agroforestry in Molos, Central Greece. AGFORWARD Deliv. 2016, 1–9. Available online: https://www.agforward.eu/documents/WP3_GR_Olives_Molos_system_description.pdf (accessed on 25 May 2022).

- Ponisio, L.C.; M’gonigle, L.K.; Mace, K.C.; Palomino, J.; De Valpine, P.; Kremen, C. Diversification Practices Reduce Organic to Conventional Yield Gap. Proc. R. Soc. B Biol. Sci. 2015, 282, 20141396. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tziolas, E.; Manos, B.; Bournaris, T. Planning of Agro-Energy Districts for Optimum Farm Income and Biomass Energy from Crops Residues. Oper. Res. 2017, 17, 535–546. [Google Scholar] [CrossRef]

- Ramachandran Nair, P.K.; Nair, V.D.; Mohan Kumar, B.; Showalter, J.M. Chapter Five—Carbon Sequestration in Agroforestry Systems. In Advances in Agronomy; Sparks, D.L., Ed.; Academic Press: Cambridge, MA, USA, 2010; Volume 108, pp. 237–307. [Google Scholar]

- Torralba, M.; Fagerholm, N.; Burgess, P.J.; Moreno, G.; Plieninger, T. Do European Agroforestry Systems Enhance Biodiversity and Ecosystem Services? A Meta-Analysis. Agric. Ecosyst. Environ. 2016, 230, 150–161. [Google Scholar] [CrossRef] [Green Version]

- Do Carmo Martinelli, G.; Schlindwein, M.M.; Padovan, M.P.; Vogel, E.; Ruviaro, C.F. Environmental Performance of Agroforestry Systems in the Cerrado Biome, Brazil. World Dev. 2019, 122, 339–348. [Google Scholar] [CrossRef]

- Recanati, F.; Arrigoni, A.; Scaccabarozzi, G.; Marveggio, D.; Melià, P.; Dotelli, G. LCA Towards Sustainable Agriculture: The Case Study of Cupuaçu Jam from Agroforestry. Procedia CIRP 2018, 69, 557–561. [Google Scholar] [CrossRef]

- Bessou, C.; Basset-Mens, C.; Tran, T.; Benoist, A. LCA Applied to Perennial Cropping Systems: A Review Focused on the Farm Stage. Int. J. Life Cycle Assess. 2013, 18, 340–361. [Google Scholar] [CrossRef] [Green Version]

- Brentrup, F.; Küsters, J.; Kuhlmann, H.; Lammel, J. Environmental Impact Assessment of Agricultural Production Systems Using the Life Cycle Assessment Methodology: I. Theoretical Concept of a LCA Method Tailored to Crop Production. Eur. J. Agron. 2004, 20, 247–264. [Google Scholar] [CrossRef]

- Notarnicola, B.; Sala, S.; Anton, A.; McLaren, S.J.; Saouter, E.; Sonesson, U. The Role of Life Cycle Assessment in Supporting Sustainable Agri-Food Systems: A Review of the Challenges. J. Clean. Prod. 2017, 140, 399–409. [Google Scholar] [CrossRef]

- Avraamides, M.; Fatta, D. Resource Consumption and Emissions from Olive Oil Production: A Life Cycle Inventory Case Study in Cyprus. J. Clean. Prod. 2008, 16, 809–821. [Google Scholar] [CrossRef]

- Maesano, G.; Chinnici, G.; Falcone, G.; Bellia, C.; Raimondo, M.; D’amico, M. Economic and Environmental Sustainability of Olive Production: A Case Study. Agronomy 2021, 11, 1753. [Google Scholar] [CrossRef]

- Tziolas, E.; Bournaris, T. Economic and Environmental Assessment of Agro-Energy Districts in Northern Greece: A Life Cycle Assessment Approach. BioEnergy Res. 2019, 12, 1145–1162. [Google Scholar] [CrossRef]

- Heyl, K.; Döring, T.; Garske, B.; Stubenrauch, J.; Ekardt, F. The Common Agricultural Policy beyond 2020: A Critical Review in Light of Global Environmental Goals. Rev. Eur. Comp. Int. Environ. Law 2021, 30, 95–106. [Google Scholar] [CrossRef]

- Kay, S.; Graves, A.; Palma, J.H.N.; Moreno, G.; Roces-Díaz, J.V.; Aviron, S.; Chouvardas, D.; Crous-Duran, J.; Ferreiro-Domínguez, N.; García de Jalón, S.; et al. Agroforestry Is Paying off—Economic Evaluation of Ecosystem Services in European Landscapes with and without Agroforestry Systems. Ecosyst. Serv. 2019, 36, 100896. [Google Scholar] [CrossRef] [Green Version]

- Kadigi, W.R.; Ngaga, Y.M.; Kadigi, R.M.J. Economic Viability of Smallholder Agroforestry and Beekeeping Projects in Uluguru Mountains, Tanzania: A Cost Benefit Analysis. Open J. For. 2021, 11, 83. [Google Scholar] [CrossRef]

- Doddabasawa; Chittapur, B.M.; Mahadeva Murthy, M. Economics and Energy Potential of Traditional Agroforestry Systems under Contrasting Ecosystems in Semi Arid Tropics. Agrofor. Syst. 2020, 94, 2237–2247. [Google Scholar] [CrossRef]

- Lehmann, L.M.; Smith, J.; Westaway, S.; Pisanelli, A.; Russo, G.; Borek, R.; Sandor, M.; Gliga, A.; Smith, L.; Ghaley, B.B. Productivity and Economic Evaluation of Agroforestry Systems for Sustainable Production of Food and Non-Food Products. Sustainability 2020, 12, 5429. [Google Scholar] [CrossRef]

- Soldatos, P. Economic Aspects of Bioenergy Production from Perennial Grasses in Marginal Lands of South Europe. Bioenergy Res. 2015, 8, 1562–1573. [Google Scholar] [CrossRef]

- Guinée, J.; Van Oers, L.; De Koning, A.; Tamis, W. Life Cycle Approaches for Conservation Agriculture; Leiden University: Leiden, The Netherlands, 2006; ISBN 9051911483. [Google Scholar]

- Mantzanas, K.; Papadimitriou, M.; Sidiropoulou, A.; Sklavou, P.; Chouvardas, D. Agrosilvopastoral systems with olive trees in Chalkidiki Greece. In Proceedings of the 9th Hellenic Range and Pasture Congress, Thessaloniki, Greece, 19–23 May 2012; pp. 401–408. [Google Scholar]

- Rebitzer, G.; Ekvall, T.; Frischknecht, R.; Hunkeler, D.; Norris, G.; Rydberg, T.; Schmidt, W.-P.; Suh, S.; Weidema, B.P.; Pennington, D.W. Life Cycle Assessment: Part 1: Framework, Goal and Scope Definition, Inventory Analysis, and Applications. Environ. Int. 2004, 30, 701–720. [Google Scholar] [CrossRef] [PubMed]

- ISO. ISO 14040: Life Cycle Assessment—Principles and Framework. Environ. Manag. 2006, 3, 28. [Google Scholar] [CrossRef]

- Muralikrishna, I.V.; Manickam, V. Chapter Five—Life Cycle Assessment. In Environmental Management; Muralikrishna, I.V., Manickam, V., Eds.; Butterworth-Heinemann: Oxford, UK, 2017; pp. 57–75. ISBN 978-0-12-811989-1. [Google Scholar]

- Gluch, P.; Baumann, H. The Life Cycle Costing (LCC) Approach: A Conceptual Discussion of Its Usefulness for Environmental Decision-Making. Build. Environ. 2004, 39, 571–580. [Google Scholar] [CrossRef] [Green Version]

- Di Vita, G.; D’Amico, M.; Bracco, S. Economic Performances of Smallholders PDO Viticulture in Eastern Sicily. Qual. Access Success 2013, 14, 99. [Google Scholar]

- European Commission. CAP Explained: Direct Payments for Farmers 2015–2020; Publications Office of the European Union: Luxembourg, 2018. [Google Scholar]

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent Developments in Life Cycle Assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef]

- Sonnemann, G.; Vigon, B.; Broadbent, C.; Curran, M.A.; Finkbeiner, M.; Frischknecht, R.; Inaba, A.; Schanssema, A.; Stevenson, M.; Ugaya, C.M.L.; et al. Process on “Global Guidance for LCA Databases. Int. J. Life Cycle Assess. 2011, 16, 95–97. [Google Scholar] [CrossRef] [Green Version]

- Corrado, S.; Castellani, V.; Zampori, L.; Sala, S. Systematic Analysis of Secondary Life Cycle Inventories When Modelling Agricultural Production: A Case Study for Arable Crops. J. Clean. Prod. 2018, 172, 3990–4000. [Google Scholar] [CrossRef]

- Edwards, R.; Padella, M.; Giuntoli, J.; Koeble, R.; O’Connell, A.; Bulgheroni, C.; Marelli, L. Definition of Input Data to Assess GHG Default Emissions from Biofuels in EU Legislation, Version 1c; Office for Official Publications of the European Communities: Luxembourg, 2017. [Google Scholar]

- Martin-Gorriz, B.; Maestre-Valero, J.F.; Almagro, M.; Boix-Fayos, C.; Martínez-Mena, M. Carbon Emissions and Economic Assessment of Farm Operations under Different Tillage Practices in Organic Rainfed Almond Orchards in Semiarid Mediterranean Conditions. Sci. Hortic. 2020, 261, 108978. [Google Scholar] [CrossRef]

- Baran, M.F. Energy Analysis of Summery Vetch Production in Turkey: A Case Study for Kırklareli Province. Am. Eurasian J. Agric. Environ. Sci. 2016, 16, 209–215. [Google Scholar] [CrossRef]

- Hernánz, J.L.; Girón, V.S.; Cerisola, C. Long-Term Energy Use and Economic Evaluation of Three Tillage Systems for Cereal and Legume Production in Central Spain. Soil Tillage Res. 1995, 35, 183–189. [Google Scholar] [CrossRef]

- Biograce, I.I. Harmonised Greenhouse Gas Calculations for Electricity, Heating and Cooling from Biomass, Calculation Rules 4a; Neeft, J., Ed.; Enterprise Agency (RVO), Formerly Agency NL: Den Haag, The Netherlands, 2021. [Google Scholar]

- Havrysh, V.; Kalinichenko, A.; Brzozowska, A.; Stebila, J. Life Cycle Energy Consumption and Carbon Dioxide Emissions of Agricultural Residue Feedstock for Bioenergy. Appl. Sci. 2021, 11, 2009. [Google Scholar] [CrossRef]

- Soni, P.; Sinha, R.; Perret, S.R. Energy Use and Efficiency in Selected Rice-Based Cropping Systems of the Middle-Indo Gangetic Plains in India. Energy Rep. 2018, 4, 554–564. [Google Scholar] [CrossRef]

- Janulevičius, A.; Juostas, A.; Čipliene, A. Estimation of Carbon-Oxide Emissions of Tractors during Operation and Correlation with the Not-to-Exceed Zone. Biosyst. Eng. 2016, 147, 117–129. [Google Scholar] [CrossRef]

- Sørensen, C.G.; Halberg, N.; Oudshoorn, F.W.; Petersen, B.M.; Dalgaard, R. Energy Inputs and GHG Emissions of Tillage Systems. Biosyst. Eng. 2014, 120, 2–14. [Google Scholar] [CrossRef]

- Mantoam, E.J.; Romanelli, T.L.; Gimenez, L.M. Energy Demand and Greenhouse Gases Emissions in the Life Cycle of Tractors. Biosystems Engineering 2016, 151, 158–170. [Google Scholar] [CrossRef]

- Gemtos, T.A.; Cavalaris, C.; Karamoutis, C.; Tagarakis, A.; Fountas, S. Energy Analysis of Three Energy Crops in Greece. Agric. Eng. Int. CIGR J. 2013, 15, 52–66. [Google Scholar]

- Smart Freight Centre. Cefic Calculating GHG Transport and Logistics Emissions for the European Chemical Industry; Smart Freight Centre: Amsterdam, The Netherlands, 2021. [Google Scholar]

- EC Directive (EU). 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources. Off. J. Eur. Union 2018, 328, 1–28. [Google Scholar]

- Litskas, V.D.; Mamolos, A.P.; Kalburtji, K.L.; Tsatsarelis, C.A.; Kiose-Kampasakali, E. Energy Flow and Greenhouse Gas Emissions in Organic and Conventional Sweet Cherry Orchards Located in or Close to Natura 2000 Sites. Biomass Bioenergy 2011, 35, 1302–1310. [Google Scholar] [CrossRef]

- Wang, J.J.; Yang, K.; Xu, Z.L.; Fu, C.; Li, L.; Zhou, Z.K. Combined Methodology of Optimization and Life Cycle Inventory for a Biomass Gasification Based BCHP System. Biomass Bioenergy 2014, 67, 32–45. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change (IPCC). IPCC: Climate Change 2021: The Physical Science Basis; IPCC: Geneva, Switzerland, 2021.

- Balafoutis, A.T.; Papageorgiou, E.; Dikopoulou, Z.; Fountas, S.; Papadakis, G. Sunflower Oil Fuel for Diesel Engines: An Experimental Investigation and Optimum Engine Setting Evaluation Using a Multi-Criteria Decision Making Approach. Int. J. Green Energy 2014, 11, 642–673. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A Harmonised Life Cycle Impact Assessment Method at Midpoint and Endpoint Level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Pennington, D.W.; Potting, J.; Finnveden, G.; Lindeijer, E.; Jolliet, O.; Rydberg, T.; Rebitzer, G. Life Cycle Assessment Part 2: Current Impact Assessment Practice. Environ. Int. 2004, 30, 721–739. [Google Scholar] [CrossRef] [PubMed]

- Myhre, G.; Shindell, D.; Pongratz, J. Anthropogenic and Natural Radiative Forcing. In Climate Change 2013 the Physical Science Basis: Working Group I Contribution to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2013; ISBN 9781107415324. [Google Scholar]

- Cain, M.; Lynch, J.; Allen, M.R.; Fuglestvedt, J.S.; Frame, D.J.; Macey, A.H. Improved Calculation of Warming-Equivalent Emissions for Short-Lived Climate Pollutants. Npj Clim. Atmos. Sci. 2019, 1, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Smith, M.A.; Cain, M.; Allen, M.R. Further Improvement of Warming-Equivalent Emissions Calculation. Npj Clim. Atmos. Sci. 2021, 4, 19. [Google Scholar] [CrossRef]

- Lynch, J.; Cain, M.; Pierrehumbert, R.; Allen, M. Demonstrating GWP: A Means of Reporting Warming-Equivalent Emissions That Captures the Contrasting Impacts of Short—A Nd Long-Lived Climate Pollutants. Environ. Res. Lett. 2020, 15, 044023. [Google Scholar] [CrossRef]

- World Resources Institute. GHG Protocol Agricultural Guidance Interpreting the Corporate Accounting and Reporting Standard for the Agricultural Sector; World Resources Institute (WRI) and the World Business Council for Sustainable Development (WBCSD). Available online: https://ghgprotocol.org/sites/default/files/standards/GHG%20Protocol%20Agricultural%20Guidance%20%28April%2026%29_0.pdf (accessed on 15 March 2022).

- Rozakis, S.; Haque, M.I.; Natsis, A.; Borzecka-Walker, M.; Mizak, K. Cost-Effectiveness of Bioethanol Policies to Reduce Carbon Dioxide Emissions in Greece. Int. J. Life Cycle Assess. 2013, 18, 306–318. [Google Scholar] [CrossRef] [Green Version]

- Forleo, M.B.; Palmieri, N.; Suardi, A.; Coaloa, D.; Pari, L. The Eco-Efficiency of Rapeseed and Sunflower Cultivation in Italy. Joining Environmental and Economic Assessment. J. Clean. Prod. 2018, 172, 3138–3153. [Google Scholar] [CrossRef]

- Portugal-Pereira, J.; Soria, R.; Rathmann, R.; Schaeffer, R.; Szklo, A. Agricultural and Agro-Industrial Residues-to-Energy: Techno-Economic and Environmental Assessment in Brazil. Biomass Bioenergy 2015, 81, 521–533. [Google Scholar] [CrossRef]

- ISO 15686-5:2017(E); Buildings and Constructed Assets—Service Life Planning. ISO: Geneva, Switzerland, 2017.

- Woodward, D.G. Life Cycle Costing—Theory, Information Acquisition and Application. Int. J. Proj. Manag. 1997, 15, 335–344. [Google Scholar] [CrossRef]

- Eversheim, W.; Neuhausen, J.; Sesterhenn, M. Design-to-Cost for Production Systems. Ann. Manuf. Technol. 1998, 47, 357–360. [Google Scholar] [CrossRef]

- Ben-Arieh, D.; Qian, L. Activity-Based Cost Management for Design and Development Stage. Int. J. Prod. Econ. 2003, 83, 169–183. [Google Scholar] [CrossRef]

- Emblemsvag, J. Activity-Based Life-Cycle Costing. Manag. Audit. J. 2001, 16, 17–27. [Google Scholar] [CrossRef]

- Durairaj, S.K.; Ong, S.K.; Nee, A.Y.C.; Tan, R.B.H. Evaluation of Life Cycle Cost Analysis Methodologies. Corp. Environ. Strategy 2002, 9, 30–39. [Google Scholar] [CrossRef]

- Studio, R.S. Integrated Development Environment for R; Studio Inc.: Boston, MA, USA, 2020. [Google Scholar]

- Tamburini, E.; Pedrini, P.; Marchetti, M.G.; Fano, E.A.; Castaldelli, G. Life Cycle Based Evaluation of Environmental and Economic Impacts of Agricultural Productions in the Mediterranean Area. Sustainability 2015, 3, 2915–2935. [Google Scholar] [CrossRef] [Green Version]

- Romero-Gámez, M.; Castro-Rodríguez, J.; Suárez-Rey, E.M. Optimization of Olive Growing Practices in Spain from a Life Cycle Assessment Perspective. J. Clean. Prod. 2017, 149, 25–37. [Google Scholar] [CrossRef]

- De Luca, A.I.; Falcone, G.; Stillitano, T.; Iofrida, N.; Strano, A.; Gulisano, G. Evaluation of Sustainable Innovations in Olive Growing Systems: A Life Cycle Sustainability Assessment Case Study in Southern Italy. J. Clean. Prod. 2018, 171, 1187–1202. [Google Scholar] [CrossRef]

- Konieczna, A.; Roman, K.; Roman, M.; Śliwiński, D.; Roman, M. Energy Efficiency of Maize Production Technology: Evidence from Polish Farms. Energies 2021, 14, 170. [Google Scholar] [CrossRef]

- Konieczna, A.; Roman, K.; Borek, K.; Grzegorzewska, E. GHG and NH3 Emissions vs. Energy Efficiency of Maize Production Technology: Evidence from Polish Farms; A Further Study. Energies 2021, 14, 5574. [Google Scholar] [CrossRef]

| Inputs | Unit | Primary Energy | GHG unit | GHGs | Remarks |

|---|---|---|---|---|---|

| Seeds | |||||

| Barley seeds | MJ/kg | 2.95 | gCO2eq/kg | 300.85 | [43] |

| Vetch seeds | MJ/kg | 10 | gCO2eq/kg | 488.80 | [44,45,46] |

| Agrochemicals | |||||

| Ν | MJ/kg | 48.99 | gCO2eq/kg | 4524.41 | [47] |

| Ρ | MJ/kg | 15.23 | gCO2eq/kg | 541,67 | [47] |

| Κ | MJ/kg | 9.68 | gCO2eq/kg | 416.67 | [47] |

| Pesticides | MJ/kg | 268.40 | gCO2eq/kg | 12,003.33 | [47] |

| Energy | |||||

| Lubricants | MJ/kg | 53.28 | gCO2eq/kg | 947.00 | [47] |

| Diesel | MJ/kg | 56.80 | gCO2eq/MJ | 95.10 | [47,48] |

| Petrol | MJ/kg | 60.20 | gCO2eq/MJ | 93.30 | [47,48] |

| Electricity | MJ/MJ | 2.73 | gCO2eq/MJ | 243.49 | [47] |

| Operations, maintenance and manufacturing | |||||

| Tractor | MJ/h | 16.42 | gCO2eq/h | 9800 | [49,50] |

| Human | MJ/h | 1.80 | gCO2eq | - | [49] |

| Machinery | MJ/h | 11.90–35.05 | gCO2eq/h | 0.10–1.70 | [51,52] |

| Irrigation system | MJ/ha | 373.7 | gCO2eq | - | [53] |

| Use of diesel | MJ | - | gCO2eq/MJ | 0.9 | [47] |

| Transportation | |||||

| Supplies | MJ/t*km | 0.87 | gCO2eq/t.km | 71 | [47,54] |

| Biomass | MJ/t*km | 0.81 | gCO2eq/t.km | 71 | [47,54] |

| Inputs | BF | OT | BOT | VBOT |

|---|---|---|---|---|

| Agrochemicals and seeds | 430.65 | 970.40 | 308.91 | 301.12 |

| Energy (electricity, diesel, petrol and lubricants) | 346.67 | 744.60 | 380.57 | 364.21 |

| Machinery (direct and indirect) | 66.47 | 149.48 | 72.70 | 129.28 |

| Other (Transportation of inputs, indirect N2O, etc) | 210.30 | 436.94 | 155.69 | 13.57 |

| Total | 1054.08 | 2301.42 | 917.87 | 808.17 |

| Cropping System | BF | OT | BOT | VBOT | ||

|---|---|---|---|---|---|---|

| Barley | Olive Trees | Vetch-Barley | Olive Trees | |||

| Annual yield (ton/ha) | 2.50 | 3.56 | 2.00 | 0.20 | 150 | 0.55 |

| Gross revenue (EUR/ha) | 325.00 | 3312.80 | 260.00 | 800.00 | 375.00 | 2216.00 |

| Total cost (EUR/ha) | 628.44 | 2805.08 | 486.94 | 1776.49 | ||

| Subsidy (EUR/ha) | 250.00 | 355.00 | 470.00 | 680.00 | ||

| Profit (EUR/ha) | −53.44 | 862.72 | 1043.06 | 1494.51 | ||

| Activity | BF | OT | BOT | VBOT |

|---|---|---|---|---|

| Sowing | 140.55 | 99.64 | 78.19 | |

| Ploughing | 52.96 | 42.02 | 36.18 | |

| Fertilization | 113.55 | 240.43 | 85.25 | 64.41 |

| Herbiciding | 63.26 | 165.72 | 66.16 | 158.23 |

| Irrigation | 41.23 | |||

| Weed control | 346.53 | |||

| Prunning | 48.00 | 124.54 | ||

| Harvesting | 52.12 | 214.53 | 65.30 | 910.50 |

| Total | 422.44 | 1008.44 | 406.37 | 1372.05 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tziolas, E.; Ispikoudis, S.; Mantzanas, K.; Koutsoulis, D.; Pantera, A. Economic and Environmental Assessment of Olive Agroforestry Practices in Northern Greece. Agriculture 2022, 12, 851. https://doi.org/10.3390/agriculture12060851

Tziolas E, Ispikoudis S, Mantzanas K, Koutsoulis D, Pantera A. Economic and Environmental Assessment of Olive Agroforestry Practices in Northern Greece. Agriculture. 2022; 12(6):851. https://doi.org/10.3390/agriculture12060851

Chicago/Turabian StyleTziolas, Emmanouil, Stefanos Ispikoudis, Konstantinos Mantzanas, Dimitrios Koutsoulis, and Anastasia Pantera. 2022. "Economic and Environmental Assessment of Olive Agroforestry Practices in Northern Greece" Agriculture 12, no. 6: 851. https://doi.org/10.3390/agriculture12060851

APA StyleTziolas, E., Ispikoudis, S., Mantzanas, K., Koutsoulis, D., & Pantera, A. (2022). Economic and Environmental Assessment of Olive Agroforestry Practices in Northern Greece. Agriculture, 12(6), 851. https://doi.org/10.3390/agriculture12060851