An Experimental Study of Axial Poisson’s Ratio and Axial Young’s Modulus Determination of Potato Stems Using Image Processing

Abstract

:1. Introduction

2. Materials and Methods

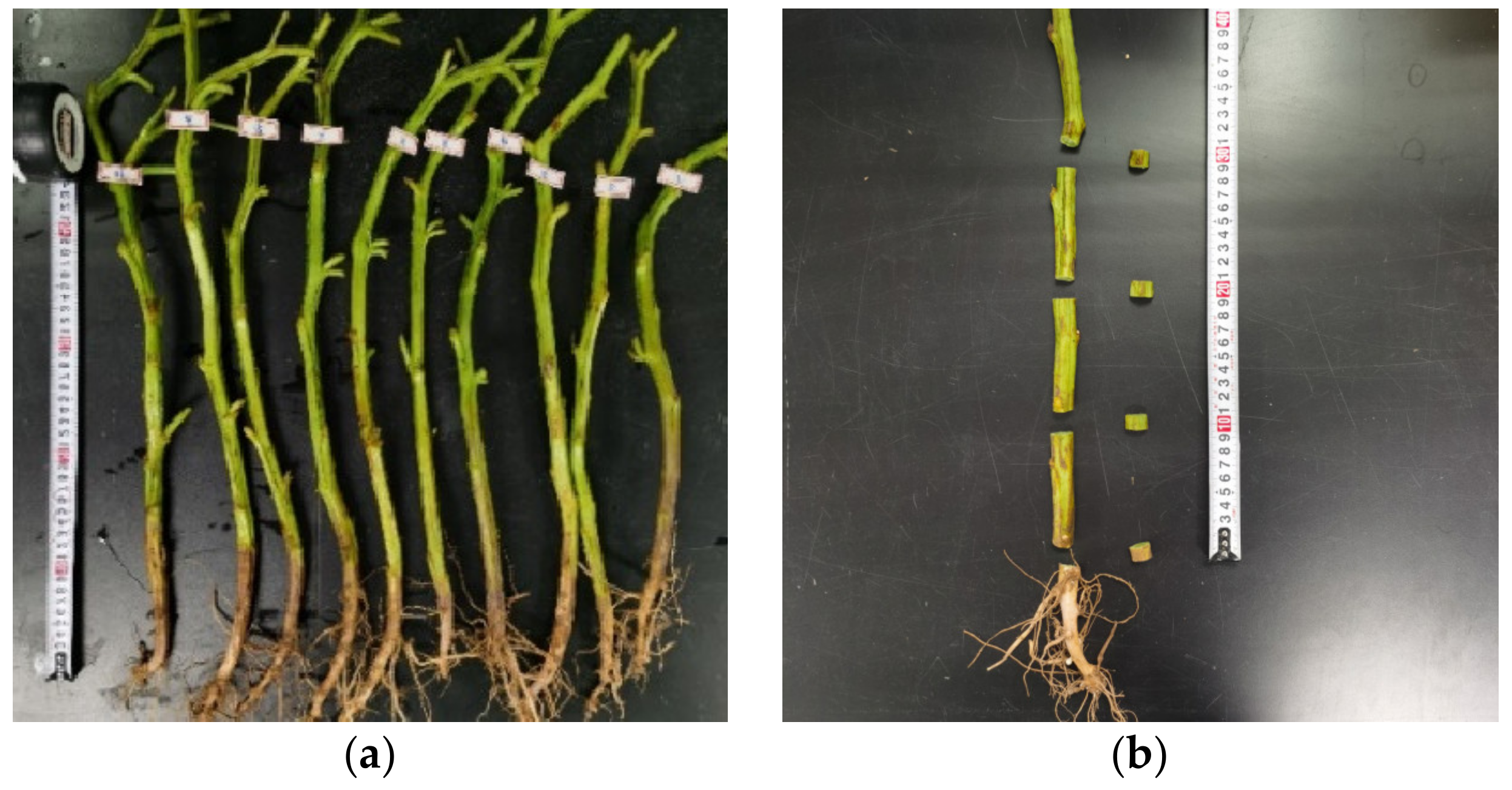

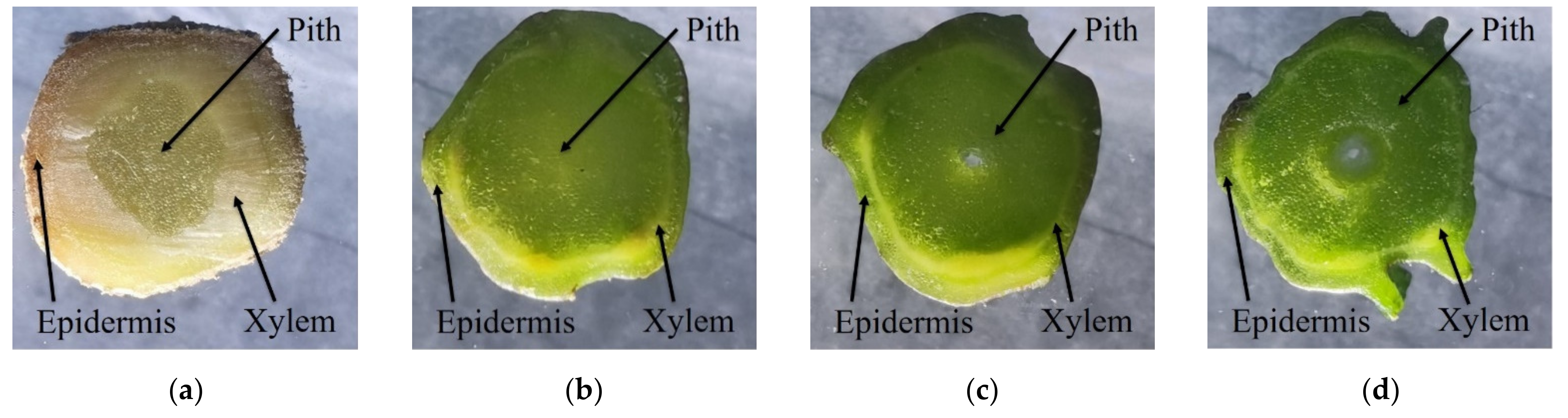

2.1. Preparation of Potato Main Stem Specimens

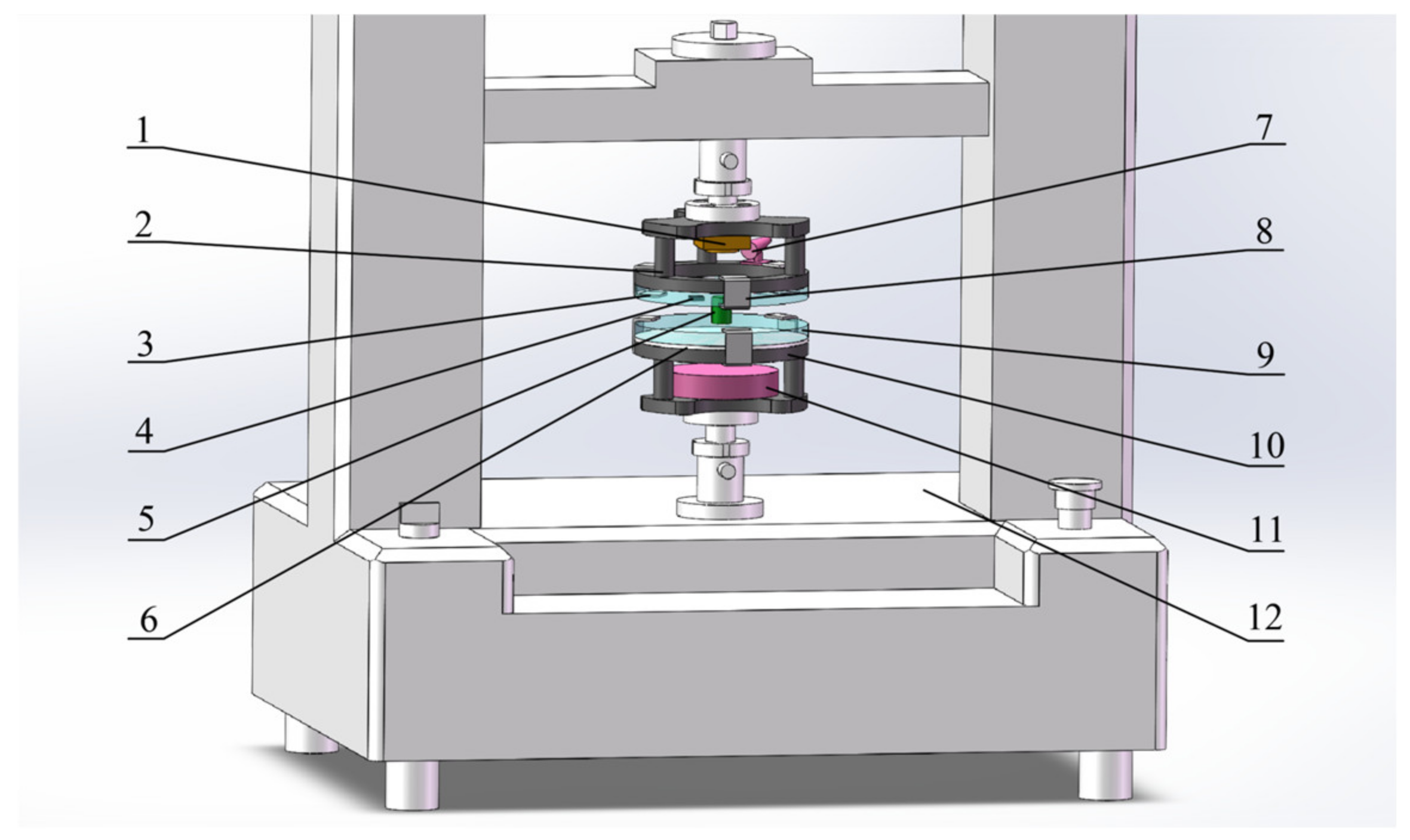

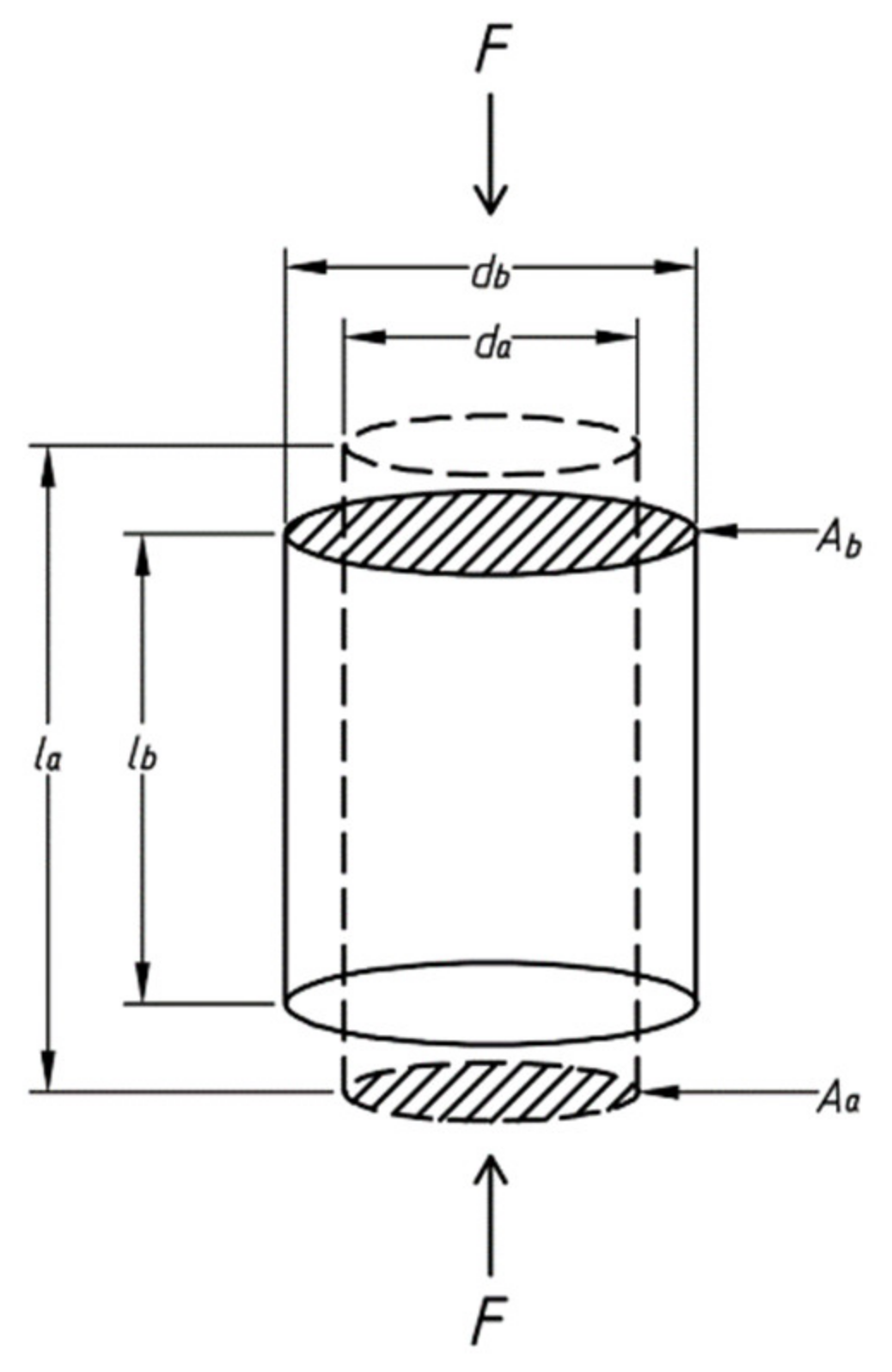

2.2. Introduction of the Poisson’s Ratio and Young’s Modulus Measurement Test Bench

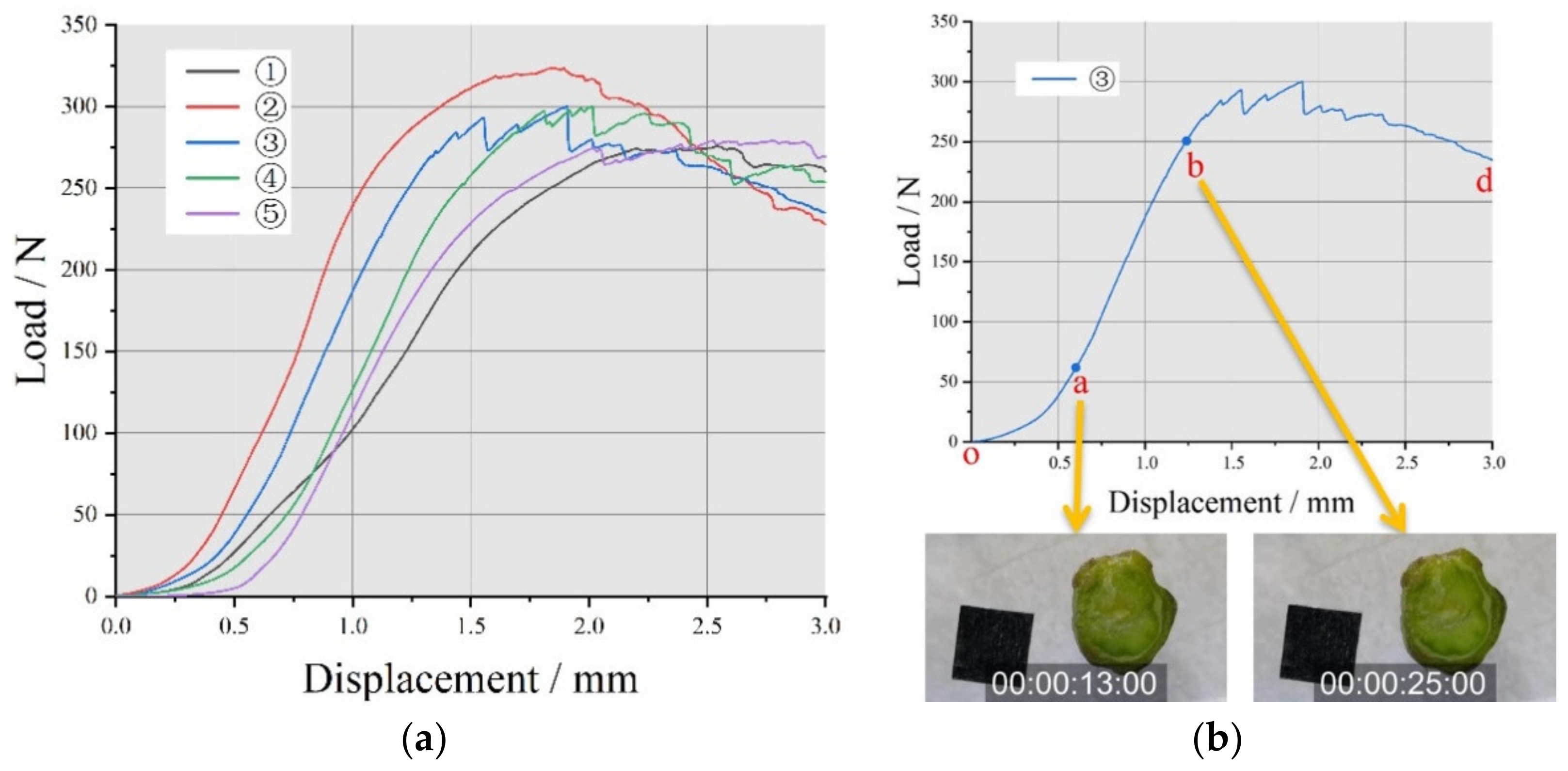

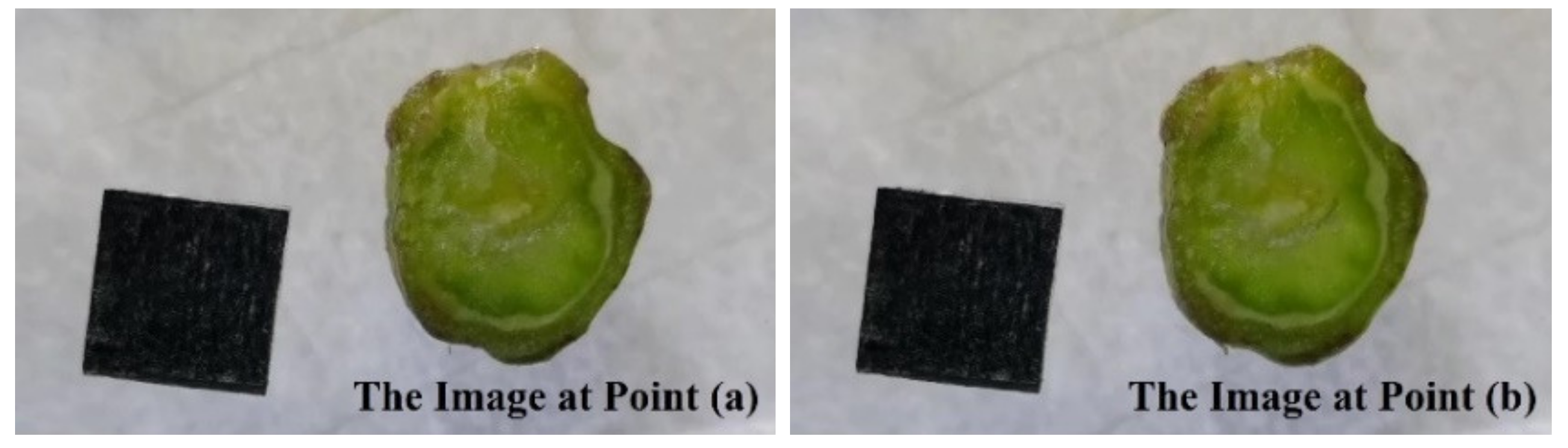

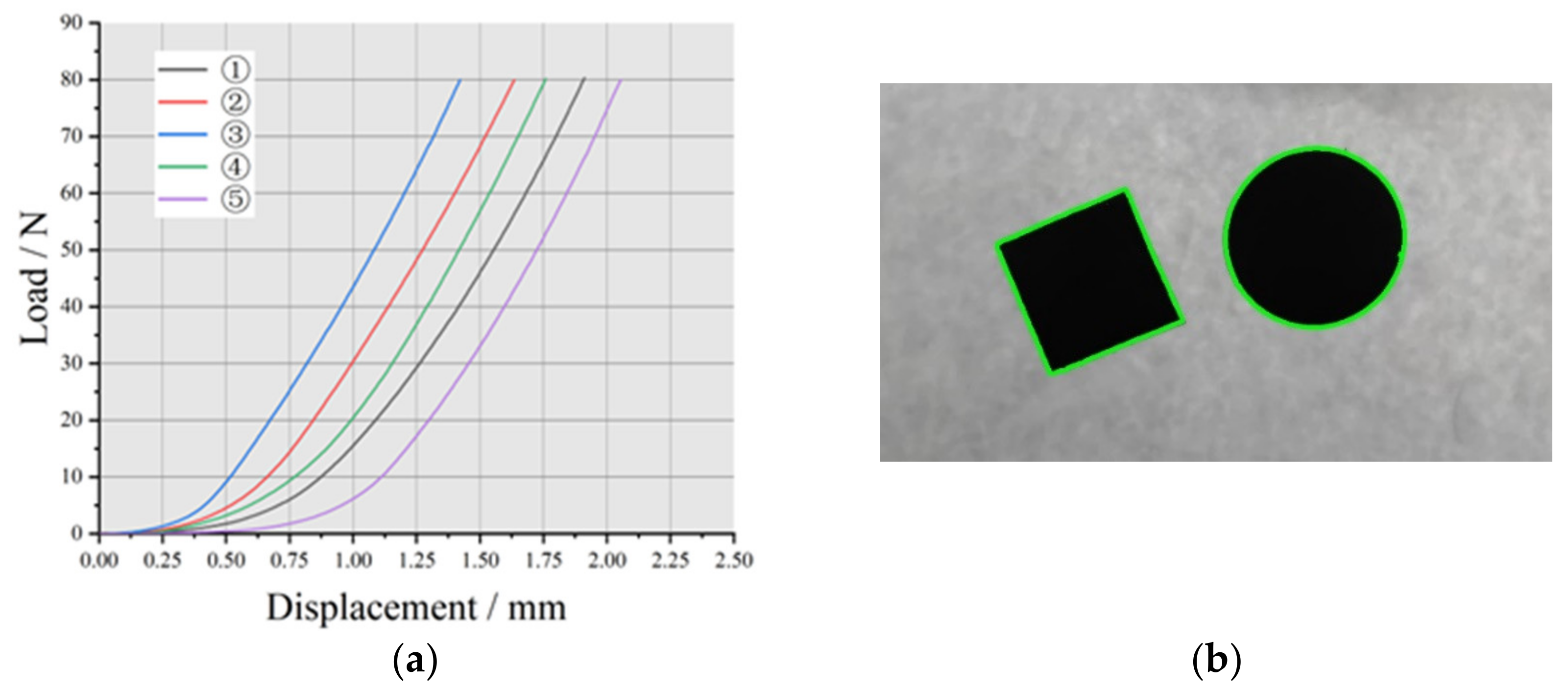

2.3. Determination of the Elastic Limit of Potato Stems during Compression

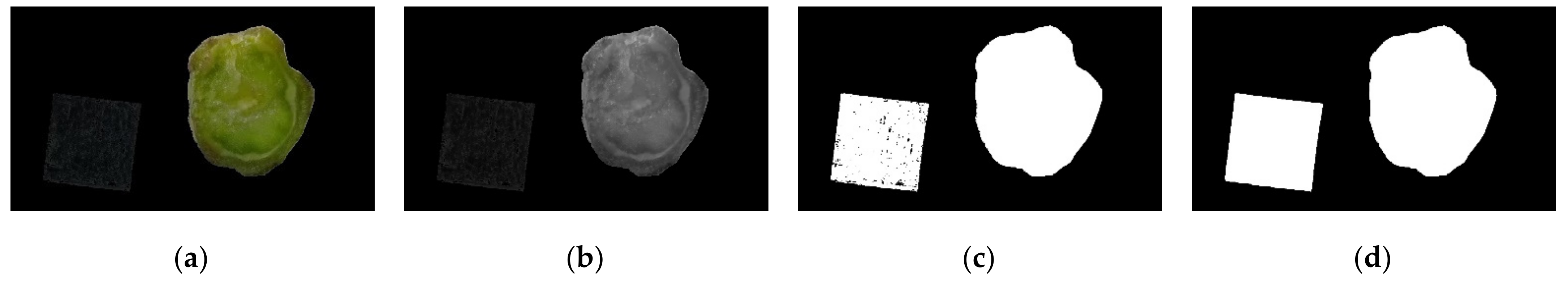

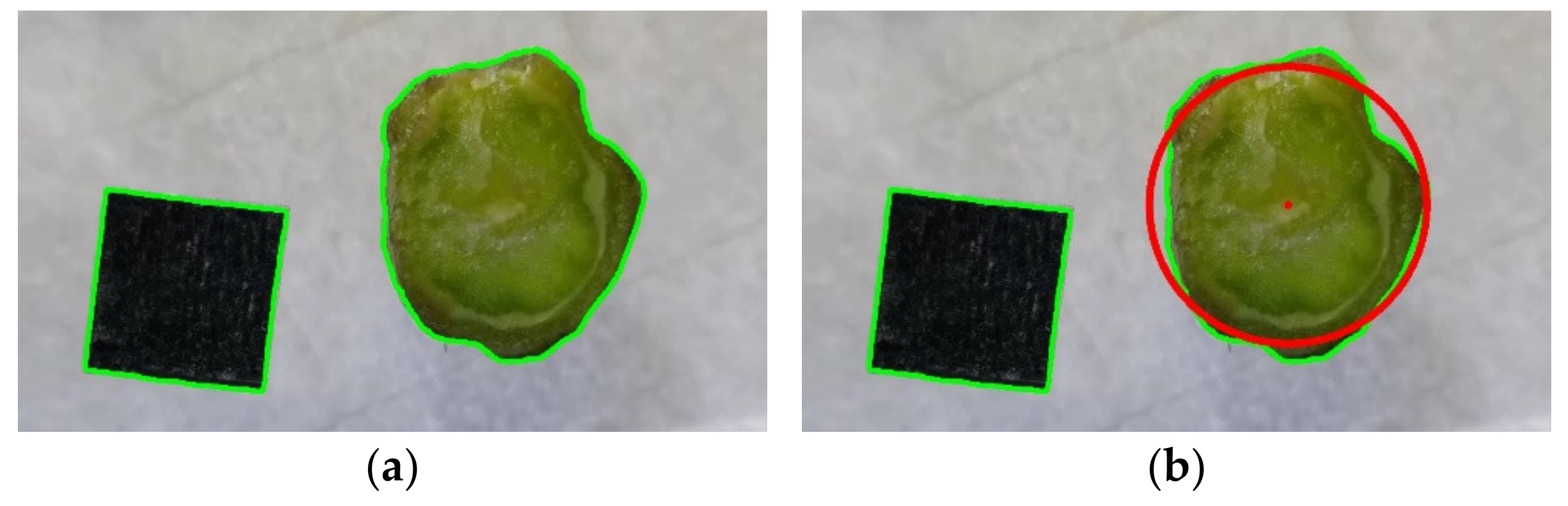

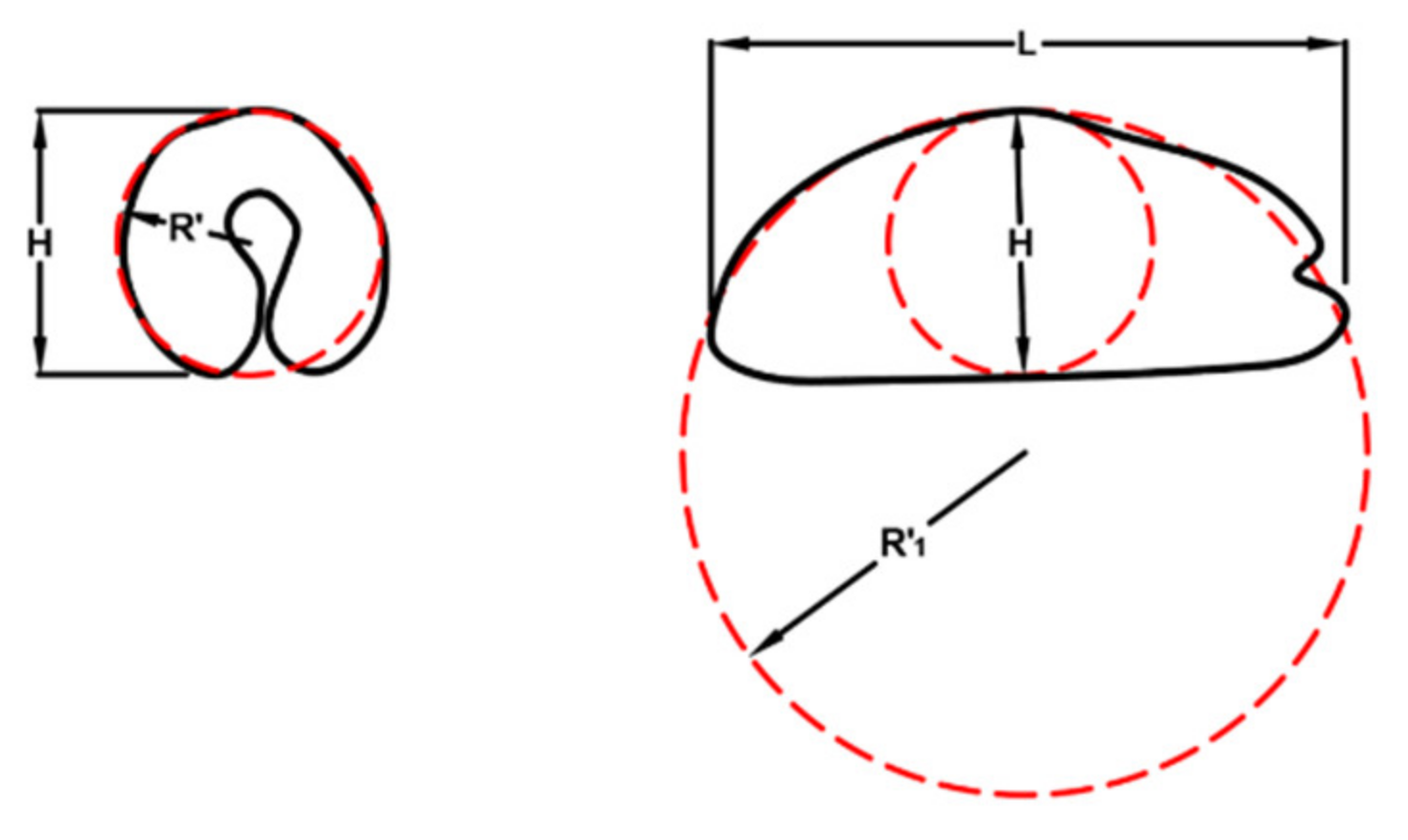

2.4. Measurement of the Cross-Sectional Area and the Fitted Circle Diameter of the Potato Stem

2.5. Equations of Calculating the Poisson’s Ratio and the Young’s Modulus

3. Results

3.1. The Feasibility Verification of Poisson’s Ratio and Young’s Modulus Measurement Methods

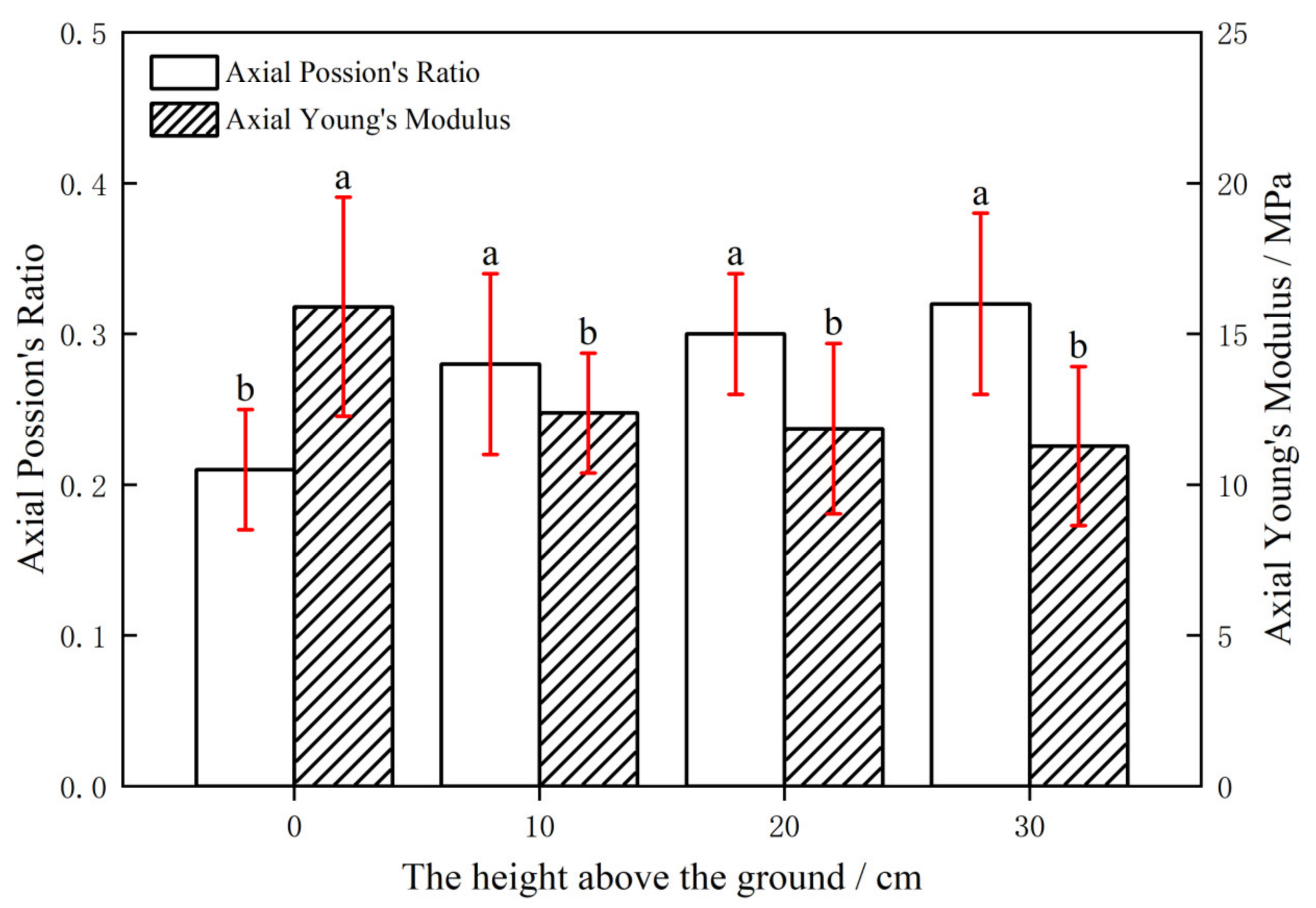

3.2. Measurement Results and Analysis of the Axial Poisson’s Ratio and the Axial Young’s Modulus of Potato Main Stems

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, H.; Xu, F.; Wu, Y.; Hu, H.H.; Dai, X.F. Progress of potato staple food research and industry development in China. J. Integr. Agric. 2017, 16, 2924–2932. [Google Scholar] [CrossRef]

- FAOSTAT. Available online: http://faostat.fao.org (accessed on 4 June 2020).

- Lu, J.; Shang, Q.; Yang, Y.; Li, Z.; Li, J.; Liu, Z. Design optimization and experiment on potato haulm cutter. Trans. Chin. Soc. Agric. Mach. 2016, 47, 106–114. [Google Scholar] [CrossRef]

- Lu, J.; Wang, P.; Liu, Z.; Li, Z.; Zou, F.; Yang, D. Design and Experiment of Potato Harvester Potato Stem Separation Equipment. Trans. Chin. Soc. Agric. Mach. 2019, 50, 100–109. [Google Scholar] [CrossRef]

- Lv, J.; Yu, J.; Feng, X.; Dui, H.; Liu, Z.; Wang, P. Design optimization and experiment of flail roll system of potato haulm cutter. Int. Agric. Eng. J. 2019, 28, 27–38. [Google Scholar]

- Sun, J.; Li, X.; Li, S.; Wang, X.; Wang, L.; Yang, F. Design Optimization and Experiment of Four-Row Potato Seedling-Cutting Machine. Appl. Eng. Agric. 2021, 37, 1155–1167. [Google Scholar] [CrossRef]

- Wang, T.; Liu, Z.; Yan, X.; Mi, G.; Liu, S.; Chen, K.; Zhang, S.; Wang, X.; Zhang, S.; Wu, X. Finite Element Model Construction and Cutting Parameter Calibration of Wild Chrysanthemum Stem. Agriculture 2022, 12, 894. [Google Scholar] [CrossRef]

- Wang, W.; Song, J.; Zhou, G.; Quan, L.; Zhang, C.; Chen, L. Development and Numerical Simulation of a Precision Strip-Hole Layered Fertilization Subsoiler While Sowing Maize. Agriculture 2022, 12, 938. [Google Scholar] [CrossRef]

- Xie, L.; Wang, J.; Cheng, S.; Zeng, B.; Yang, Z. Optimisation and dynamic simulation of a conveying and top breaking system for whole-stalk sugarcane harvesters. Biosyst. Eng. 2020, 197, 156–169. [Google Scholar] [CrossRef]

- Canet, W.; Alvarez, M.D.; Gil, M.J. Fracture behaviour of potato samples (cv. Desiree) under uniaxial compression. J. Food Eng. 2007, 82, 427–435. [Google Scholar] [CrossRef]

- Bentini, M.; Caprara, C.; Martelli, R. Physico-mechanical properties of potato tubers during cold storage. Biosyst. Eng. 2009, 104, 25–32. [Google Scholar] [CrossRef]

- Feng, B.; Sun, W.; Shi, L.; Sun, B.; Zhang, T.; Wu, J. Determination of restitution coefficient of potato tubers collision in harvest and analysis of its influence factors. Nongye Gongcheng Xuebao Trans. Chin. Soc. Agric. Eng. 2017, 33, 50–57. [Google Scholar] [CrossRef]

- Feng, B.; Sun, W.; Sun, B.; Zhang, T.; Wu, J.; Shi, L. A study on dropping impact characteristics and damage regularity of potato tubers during harvest. Zhendong Yu Chongji J. Vib. Shock. 2019, 38, 267–274. [Google Scholar] [CrossRef]

- Deng, W.; Wang, Y.; Liu, C.; Li, P.; Xie, S.; Wang, C. Frictional collision acceleration and damage of potato peel: An experimental study. Int. J. Food Prop. 2021, 24, 646–655. [Google Scholar] [CrossRef]

- Gong, Z.; Sun, W.; Wu, J.; Wang, F.; Guo, W. Potato stalk buds compression characteristic test. In Proceedings of the 2015 International Conference on Applied Science and Engineering Innovation, Jinan, China, 30–31 August 2015; pp. 1367–1370. [Google Scholar]

- ASTME E132-17; ASTM Standards: Standard Test Method for Poisson’s Ratio at Room Temperature. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM E111-17; ASTM Standards: Standard Test Method for Young’s Modulus, Tangent Modulus, and Chord Modulus. ASTM International: West Conshohocken, PA, USA, 2017.

- Shan, G.; Yang, W.; Feng, J.; Yang, M. Advances in test methods for Poisson’s ratio of materials. Mater. Rev. 2006, 20, 15–20. [Google Scholar]

- GB/T3354-2014; General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. Test Method for Tensile Properties of Orientation Fiber Reinforced Polymer Matrix Composite Materials. Standardization Administration of the People’s Republic of China: Beijing, China, 2014.

- Carlotti, G. Elastic Characterization of Transparent and Opaque Films, Multilayers and Acoustic Resonators by Surface Brillouin Scattering: A Review. Appl. Sci. 2018, 8, 124. [Google Scholar] [CrossRef] [Green Version]

- Kumar, M.; Gaur, K.K.; Shakher, C. Measurement of material constants (Young’s modulus and Poisson’s ratio) of polypropylene using digital speckle pattern interferometry (DSPI). J. Jpn. Soc. Exp. Mech. 2015, 15, s87–s91. [Google Scholar]

- Seebacher, S.; Osten, W.; Baumbach, T.; Jüptner, W. The determination of material parameters of microcomponents using digital holography. Opt. Lasers Eng. 2001, 36, 103–126. [Google Scholar] [CrossRef]

- Chappell, T.W.; Hamann, D.D. Poisson’s Ratio and Young’s Modulus for Apple Flesh Under Compressive Loading. Trans. ASAE 1968, 11, 608–610. [Google Scholar] [CrossRef]

- Kiani, M.K.D.; Maghsoudi, H.; Minaee, S. Determination of poisson’s ratio and young’s modulus of red bean grains. J. Food Process Eng. 2011, 34, 1573–1583. [Google Scholar] [CrossRef]

- Liao, Q.; Liao, Y.; Shu, C.; Tian, B. Research on the physical mechanics properties of the Rape Stalk. In Proceedings of the 2007 ASAE Annual Meeting, Minneapolis, MN, USA, 17–20 June 2007. [Google Scholar]

- An, Y.; Riaz, M.; Park, J. CBIR Based on Adaptive Segmentation of HSV Color Space. In Proceedings of the 2010 12th International Conference on Computer Modelling and Simulation, Cambridge, UK, 24–26 March 2010; pp. 248–251. [Google Scholar]

- Gere, J.M.; Goodno, B.J. Mechanics of Materials; Cengage Learning: Boston, MA, USA, 2012; pp. 28–29. [Google Scholar]

- Figura, L.; Teixeira, A.A. Food Physics: Physical Properties-Measurement and Applications; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2007; p. 121. [Google Scholar]

- Sotomayor-del-Moral, J.A.; Pascual-Francisco, J.B.; Susarrey-Huerta, O.; Resendiz-Calderon, C.D.; Gallardo-Hernández, E.A.; Farfan-Cabrera, L.I. Characterization of Viscoelastic Poisson’s Ratio of Engineering Elastomers via DIC-Based Creep Testing. Polymers 2022, 14, 1837. [Google Scholar] [CrossRef]

- Murali Manohar, D.; Chakraborty, B.C.; Shamshath Begum, S. Hardness-Elastic Modulus Relationship for Nitrile Rubber and Nitrile Rubber-Polyvinyl Chloride Blends. In Advances in Design and Thermal Systems; Springer: Berlin/Heidelberg, Germany, 2021; pp. 301–314. [Google Scholar]

- Boudet, A.-M. Lignins and lignification: Selected issues. Plant Physiol. Biochem. 2000, 38, 81–96. [Google Scholar] [CrossRef]

- Gibson, L.J. The hierarchical structure and mechanics of plant materials. J. R. Soc. Interface 2012, 9, 2749–2766. [Google Scholar] [CrossRef] [PubMed]

- Malekabadi, A.J.; Khojastehpour, M.; Emadi, B.; Golzarian, M. Determination of elasticity modulus and Poisson ratio of two onion varieties under different loading conditions. J. Agric. Mach. 2016, 6, 376–378. [Google Scholar]

- ASAE S368.4 DEC2000 (R2008); ASABE Standards: Compression Test of Food Materials of Convex Shape. American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2008.

- Voicu, G.; Tudosie, E.-M.; Ungureanu, N.; Constantin, G.-A. Some mechanical characteristics of wheat seeds obtained by uniaxial compression tests. Univ. Politeh. Buch. Sci. Bull. D 2013, 75, 265–278. [Google Scholar]

- Shelef, L.; Mohsenin, N.N. Evaluation of the modulus of elasticity of wheat grain. Cereal. Chem. 1967, 44, 392–402. [Google Scholar]

| Specimen No. | ν | E/MPa | la/mm | lb/mm | Aa/mm2 | Aa/mm2 | da/mm | db/mm | Fa/N | Fb/N |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.42 | 7.16 | 11.17 | 10.25 | 116.08 | 124.26 | 12.16 | 12.58 | 7.23 | 75.38 |

| 2 | 0.41 | 7.00 | 11.04 | 10.22 | 118.19 | 125.43 | 12.27 | 12.64 | 17.64 | 79.09 |

| 3 | 0.40 | 7.29 | 10.60 | 9.98 | 119.19 | 124.88 | 12.32 | 12.61 | 27.81 | 78.60 |

| 4 | 0.42 | 6.54 | 10.72 | 10.13 | 118.30 | 123.84 | 12.27 | 12.56 | 24.17 | 66.78 |

| 5 | 0.42 | 6.63 | 10.37 | 9.69 | 121.03 | 127.71 | 12.41 | 12.75 | 20.07 | 72.66 |

| Levin Statistics | df 1 | df2 | Sig. | |

|---|---|---|---|---|

| axial Poisson’s ratio | 0.720 | 3 | 36 | 0.547 |

| axial Young’s modulus | 1.408 | 3 | 36 | 0.256 |

| Sum of Squares | df | Mean Square | F | Sig. | ||

|---|---|---|---|---|---|---|

| axial Poisson’s ratio | Between Groups | 0.067 | 3 | 0.022 | 8.547 | 0.000 |

| Within Groups | 0.093 | 36 | 0.003 | |||

| Total | 0.160 | 39 | ||||

| axial Young’s modulus | Between Groups | 129.457 | 3 | 43.152 | 5.367 | 0.004 |

| Within Groups | 289.428 | 36 | 8.040 | |||

| Total | 418.885 | 39 |

| The Height above the Ground | Number of Samples | Axial Poisson’s Ratio | Axial Young’s Modulus |

|---|---|---|---|

| 0 cm | 10 | 0.21 ± 0.04 b | 15.90 ± 3.63 a |

| 10 cm | 10 | 0.28 ± 0.06 a | 12.38 ± 1.99 b |

| 20 cm | 10 | 0.30 ± 0.04 a | 11.86 ± 2.83 b |

| 30 cm | 10 | 0.32 ± 0.06 a | 11.28 ± 2.64 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, J.; Li, Y.; Wang, B.; Gu, F.; Wu, F.; Yang, H.; Yu, Z.; Hu, Z. An Experimental Study of Axial Poisson’s Ratio and Axial Young’s Modulus Determination of Potato Stems Using Image Processing. Agriculture 2022, 12, 1026. https://doi.org/10.3390/agriculture12071026

Fan J, Li Y, Wang B, Gu F, Wu F, Yang H, Yu Z, Hu Z. An Experimental Study of Axial Poisson’s Ratio and Axial Young’s Modulus Determination of Potato Stems Using Image Processing. Agriculture. 2022; 12(7):1026. https://doi.org/10.3390/agriculture12071026

Chicago/Turabian StyleFan, Jiali, Yuyao Li, Bing Wang, Fengwei Gu, Feng Wu, Hongguang Yang, Zhaoyang Yu, and Zhichao Hu. 2022. "An Experimental Study of Axial Poisson’s Ratio and Axial Young’s Modulus Determination of Potato Stems Using Image Processing" Agriculture 12, no. 7: 1026. https://doi.org/10.3390/agriculture12071026

APA StyleFan, J., Li, Y., Wang, B., Gu, F., Wu, F., Yang, H., Yu, Z., & Hu, Z. (2022). An Experimental Study of Axial Poisson’s Ratio and Axial Young’s Modulus Determination of Potato Stems Using Image Processing. Agriculture, 12(7), 1026. https://doi.org/10.3390/agriculture12071026