Simulation and Experimental Study of a Split High-Speed Precision Seeding System

Abstract

:1. Introduction

2. Materials and Methods

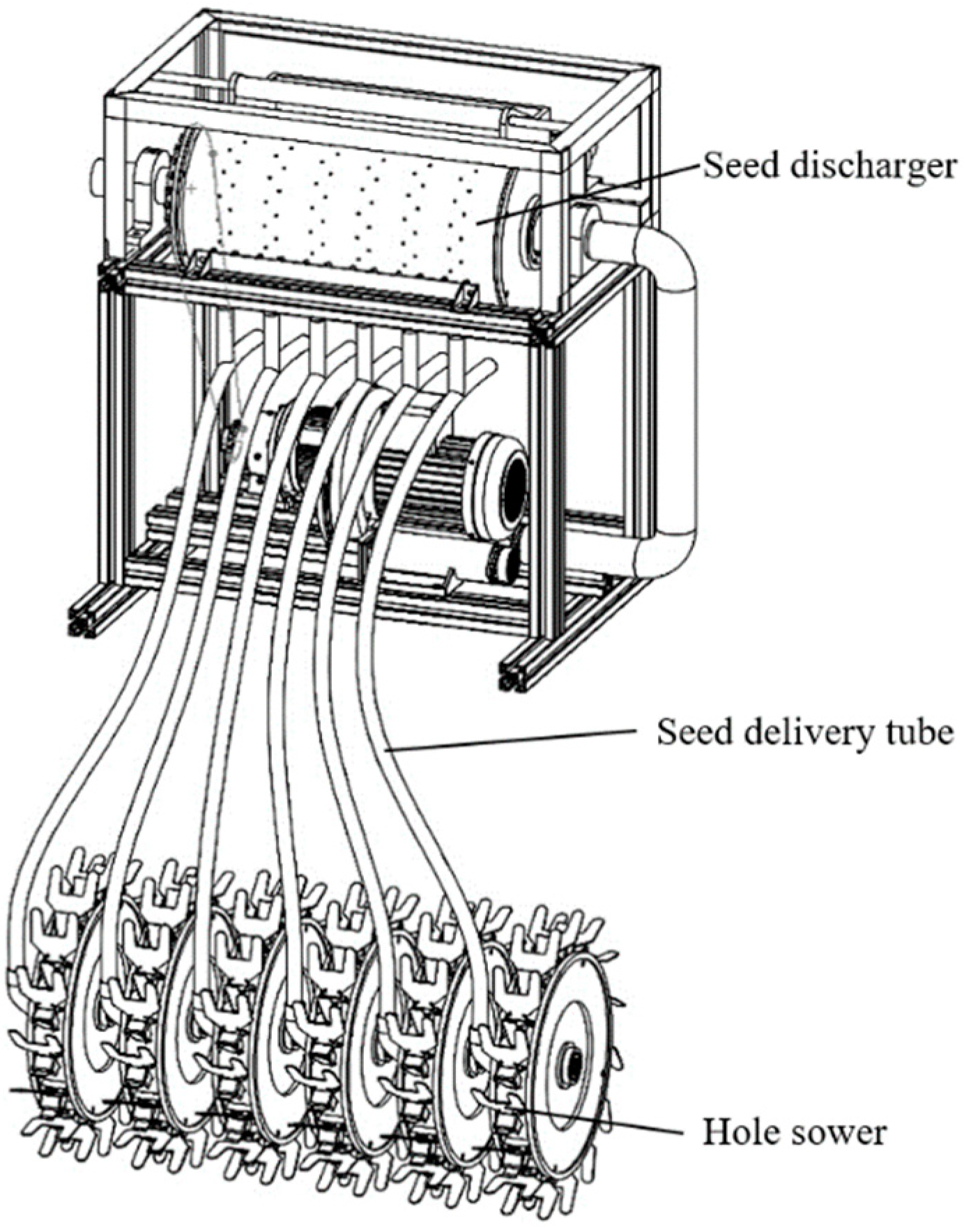

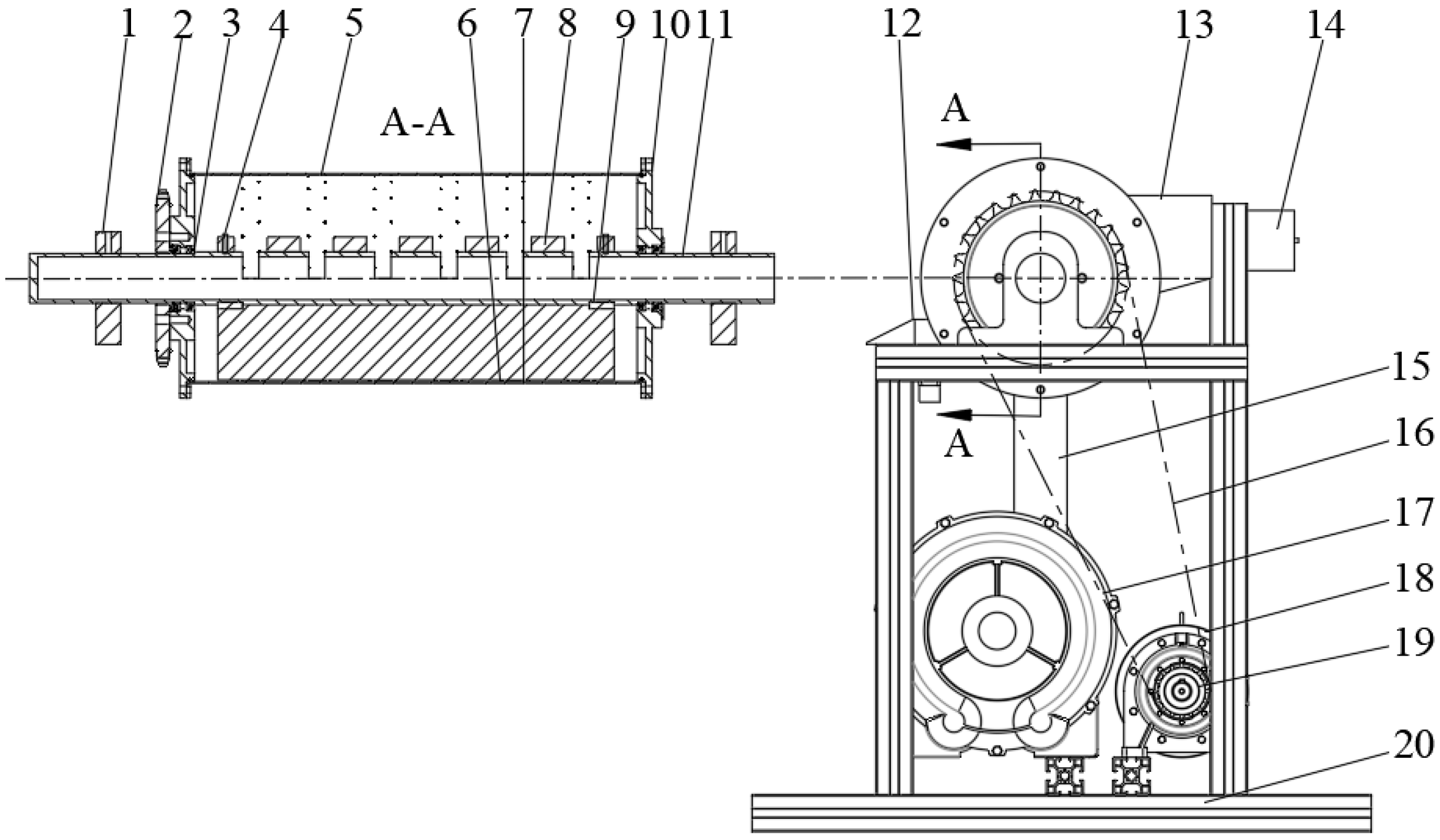

2.1. Overall Structure of the Split Seeding System

2.2. Working Principle of Each Part

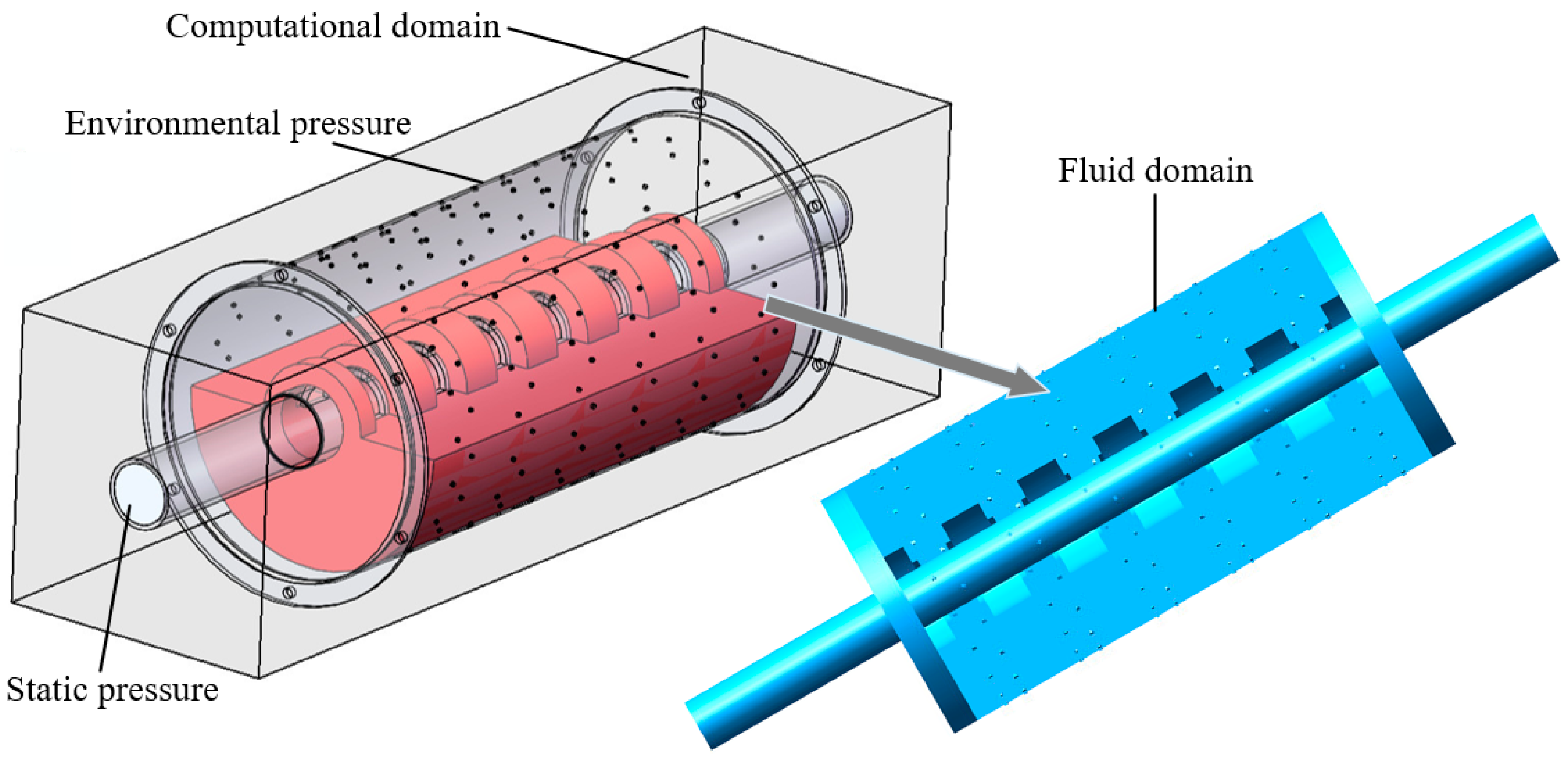

2.3. Simulation of the Seed Dispenser Flow Field

2.3.1. Seed Discharger Simulation Model and Parameter Settings

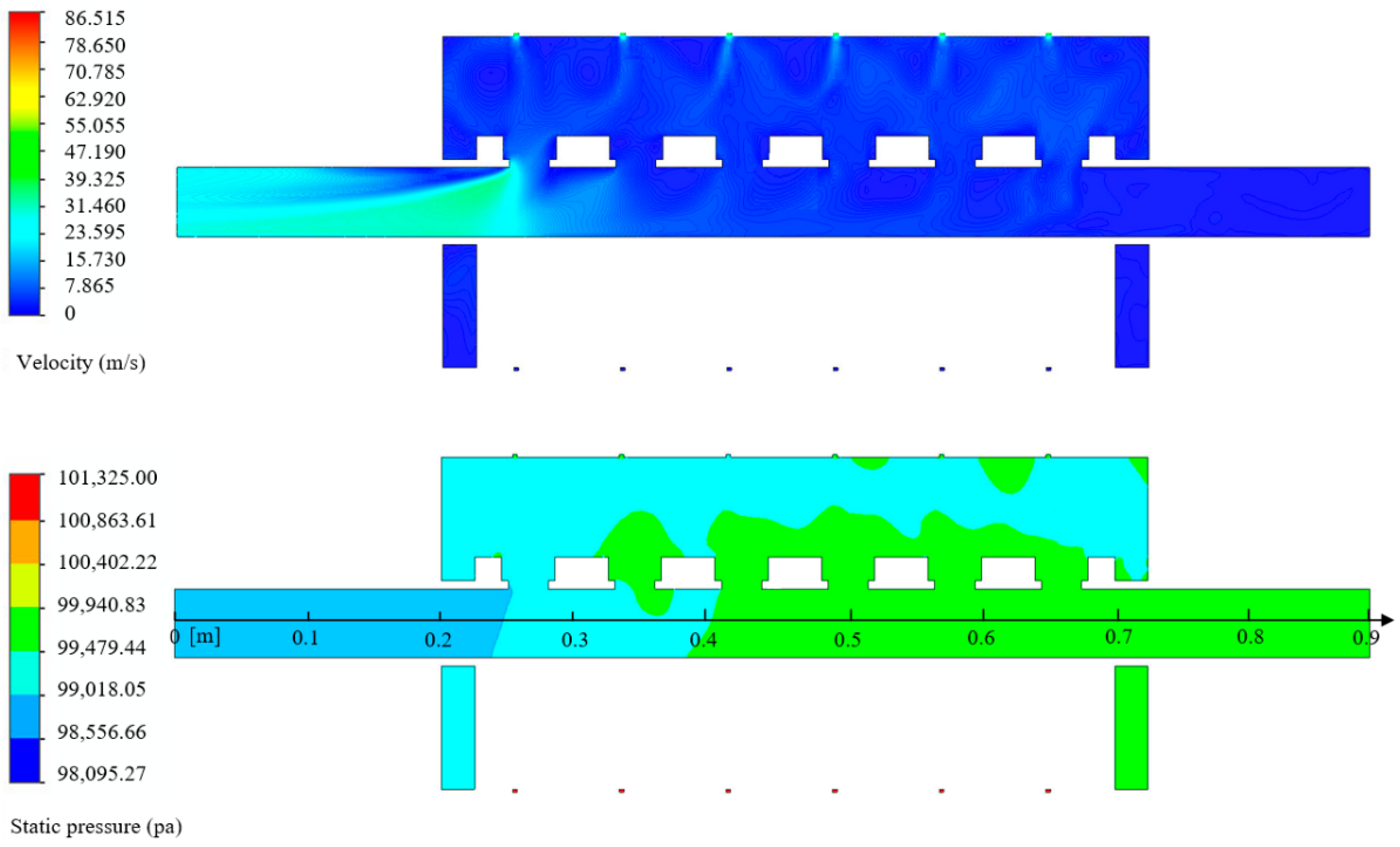

2.3.2. Simulation Results and Analysis of the Seed Dispenser

2.4. Coupled Simulation of Seed Transport in the Seed Transfer Tube

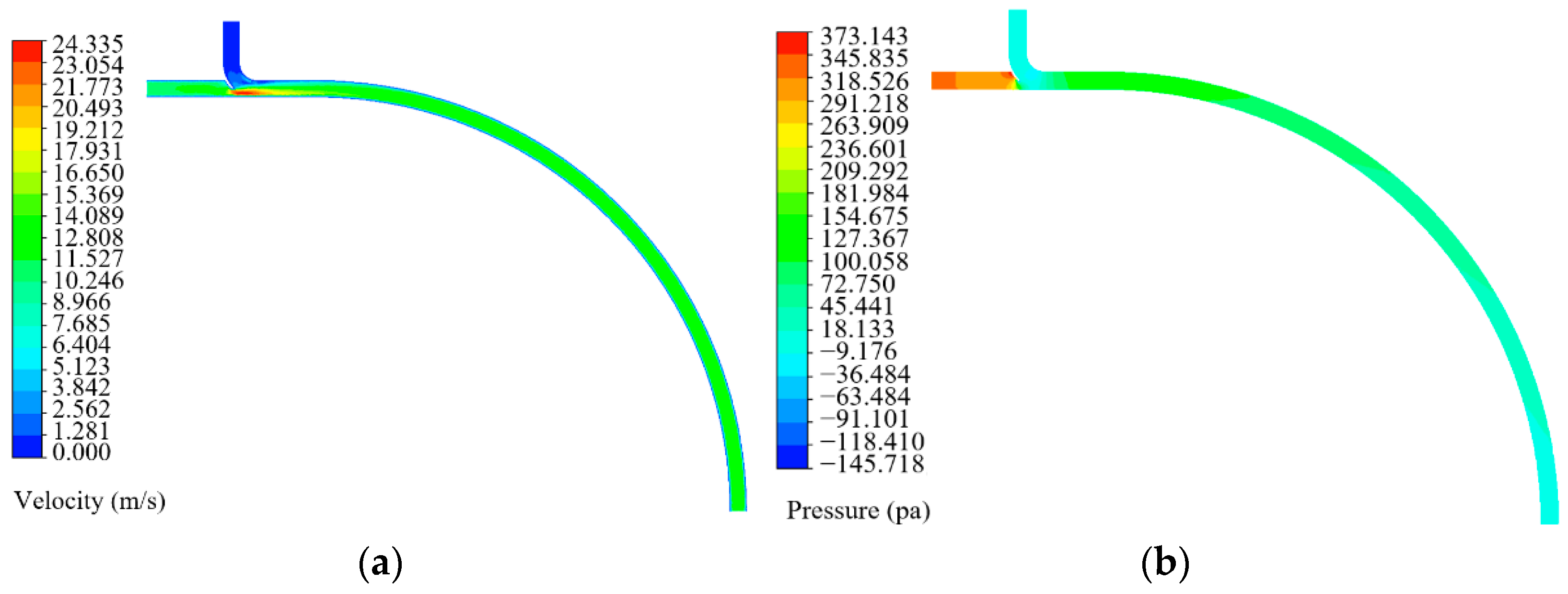

2.4.1. Simulation Analysis of the Flow Field of the Seed Delivery Tube

2.4.2. Simulation Analysis of Cotton Seed Transport

2.5. Simulation of the Hole Seeder and Analysis of the Seed Dispersal Process

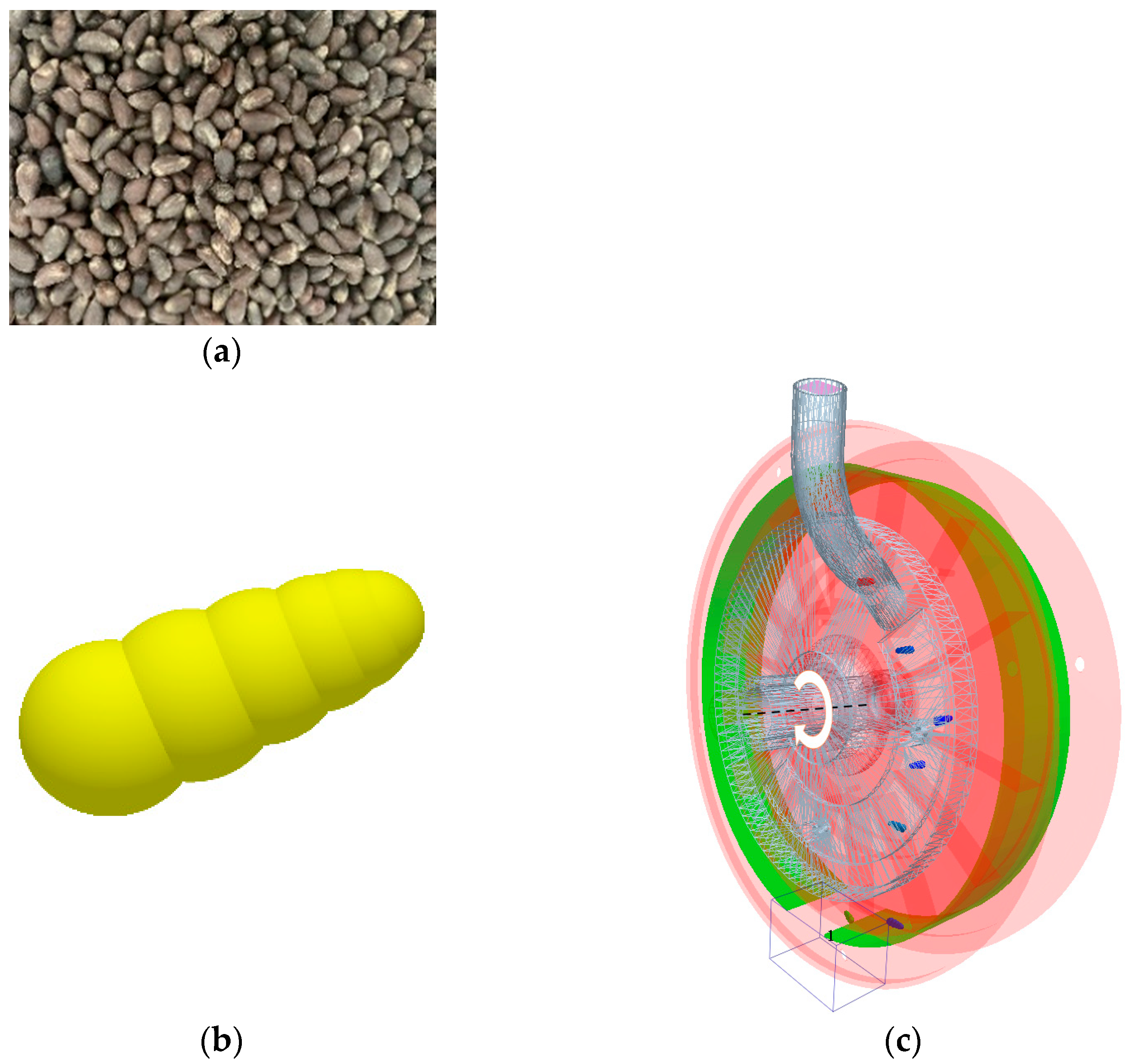

2.5.1. Modeling and Parameterization of the Hole Seeder

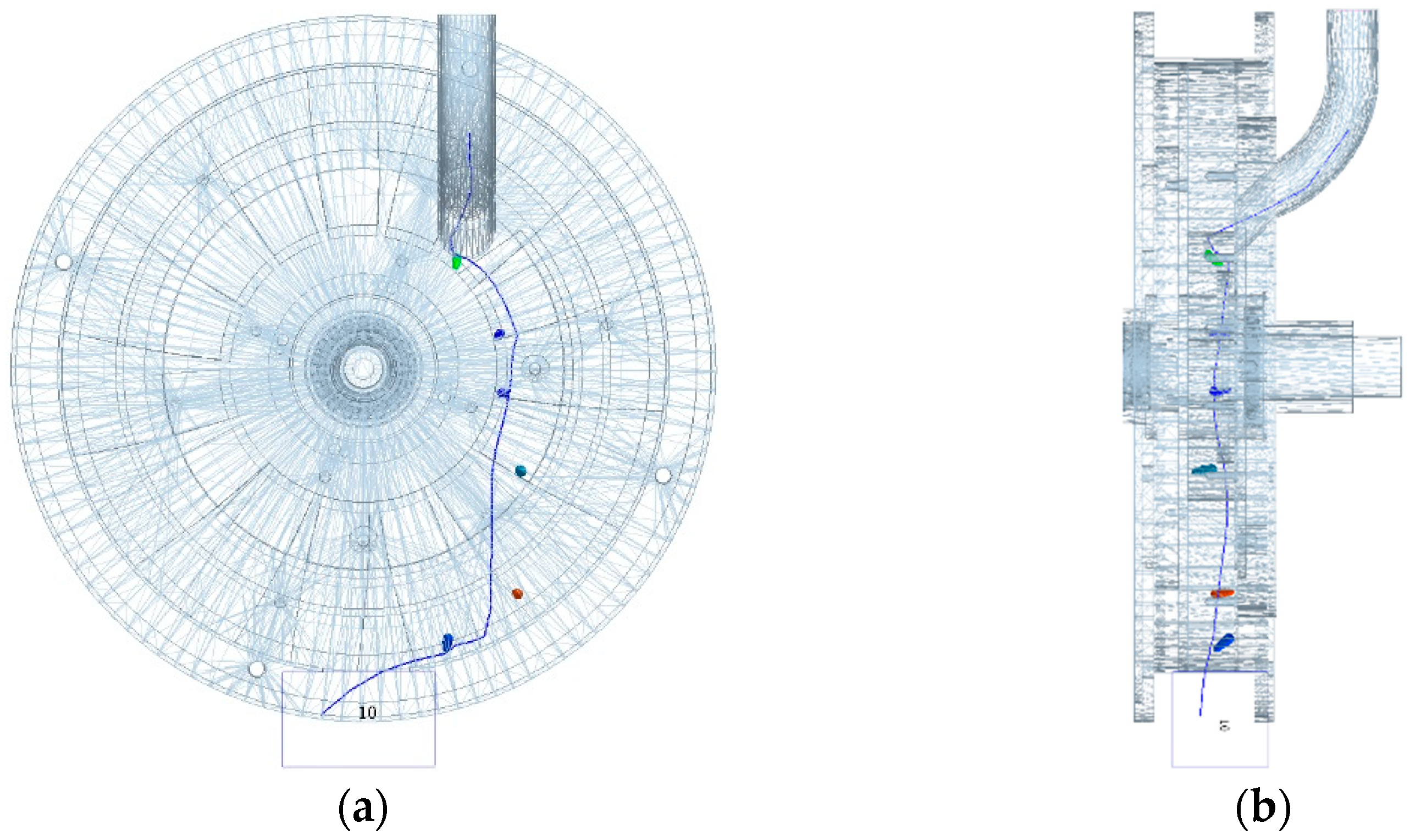

2.5.2. Seed Transport Trajectory Analysis

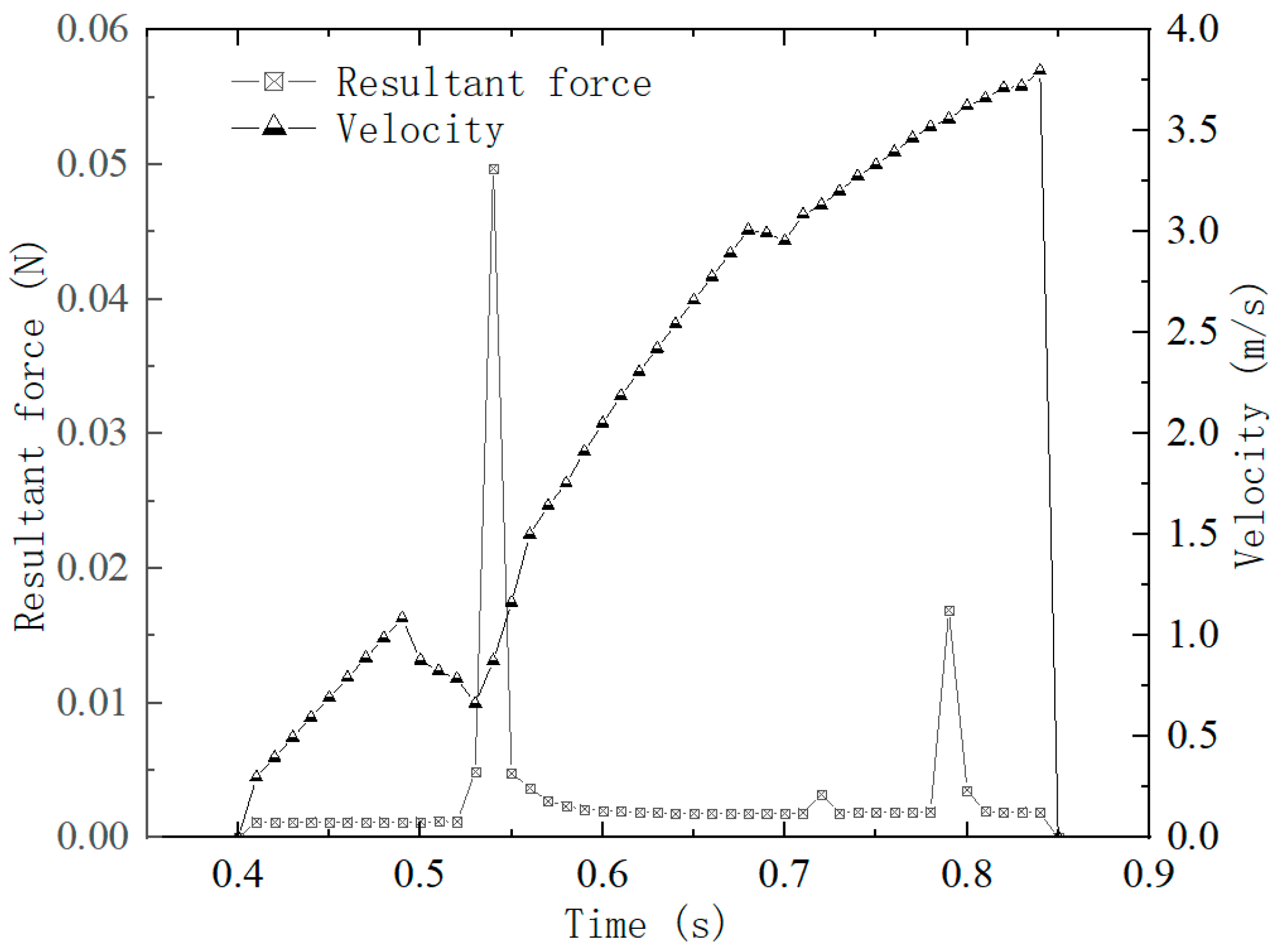

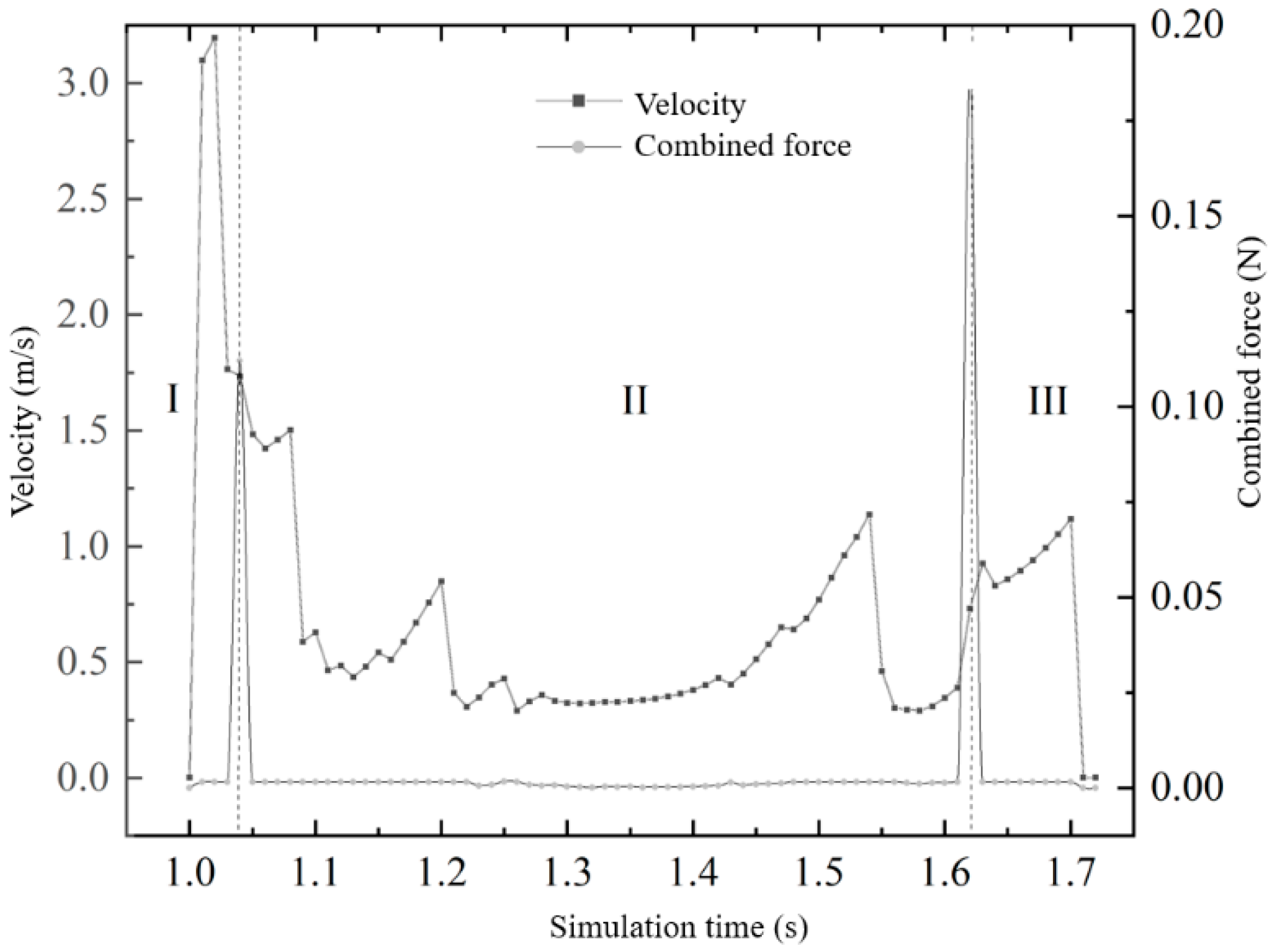

2.5.3. Analysis of the Combined Seed Force and Velocity Variation

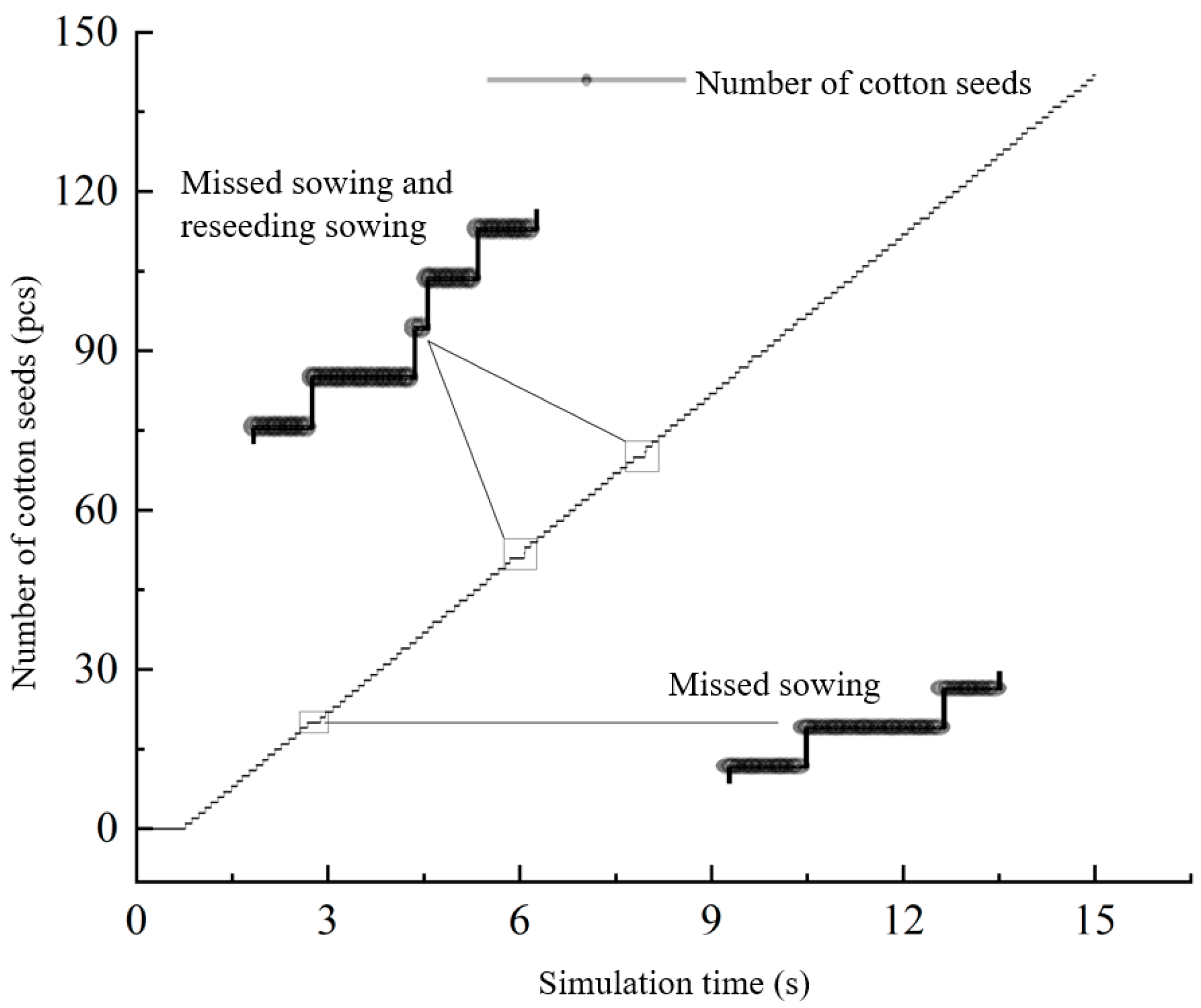

2.5.4. Seeding Performance Analysis

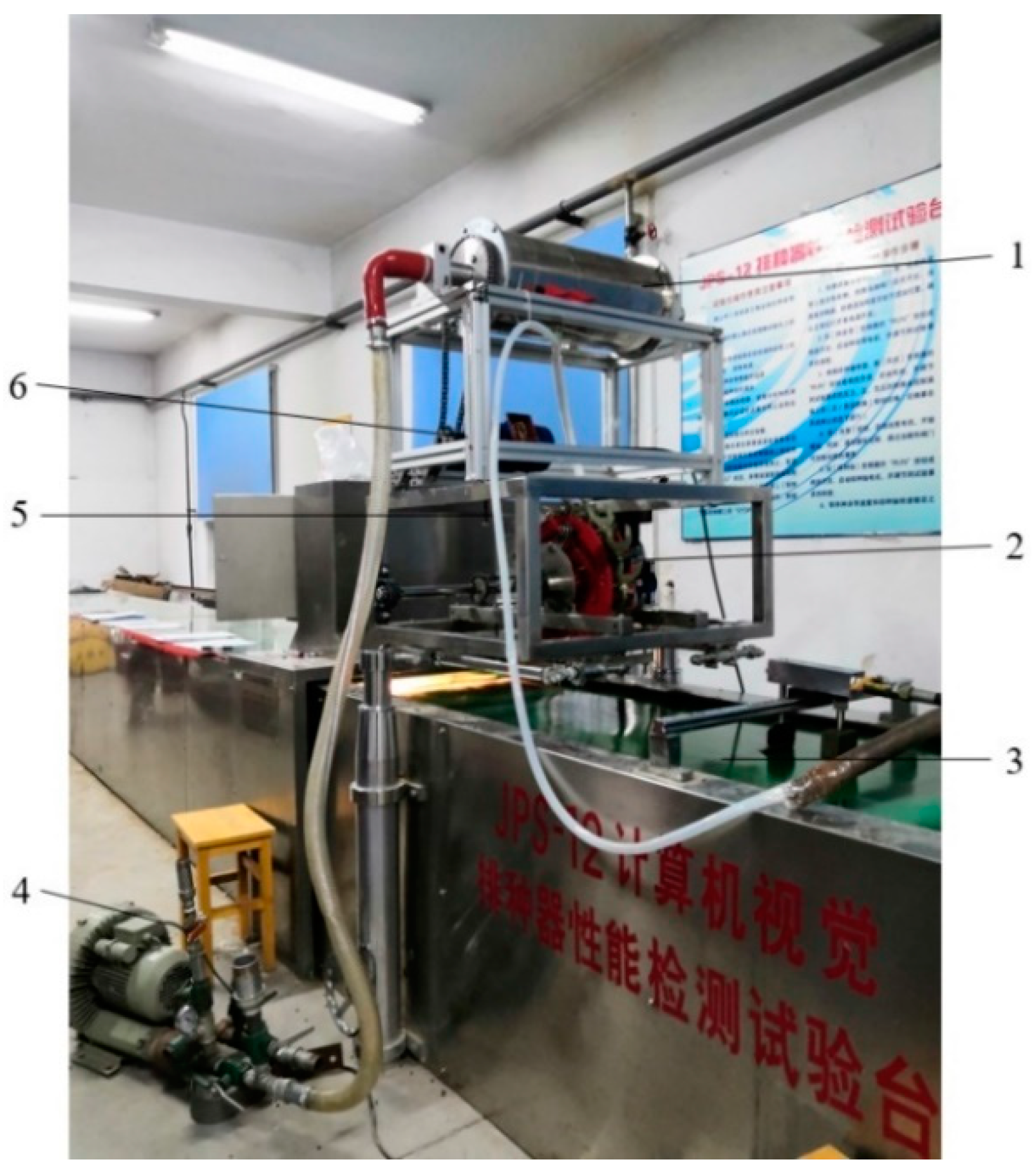

2.6. Bench Test

2.6.1. Test Conditions

2.6.2. Selection of Test Factors and Evaluation Indicators

2.6.3. Central Composite Design

3. Results and Discussion

3.1. Analysis of Test Results

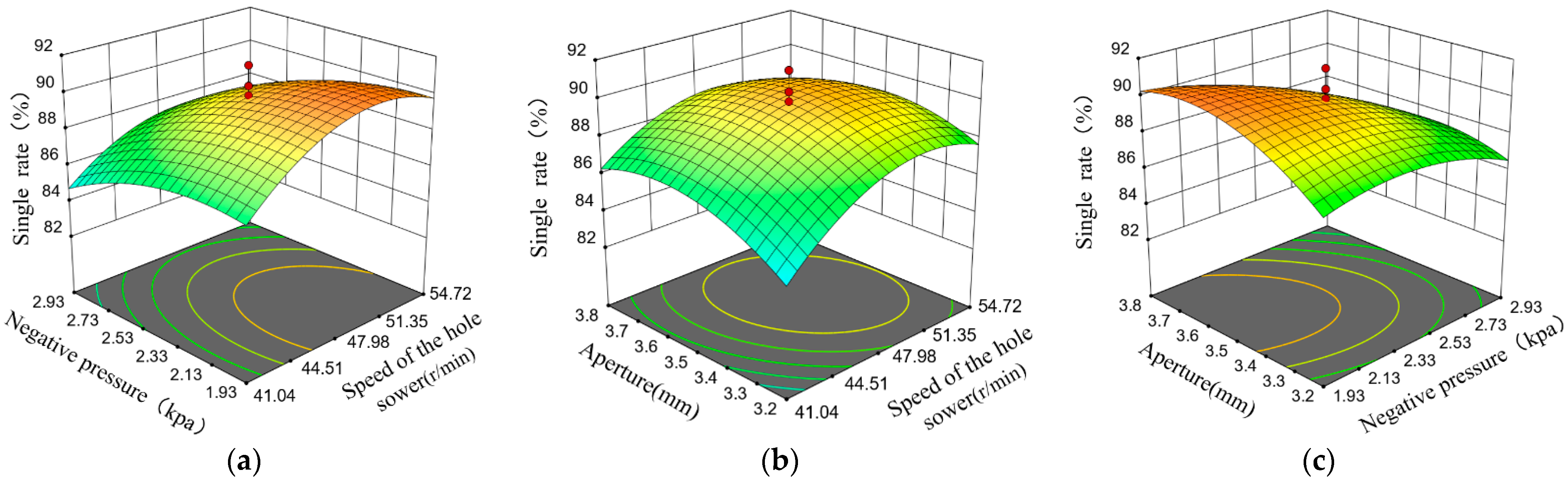

3.2. Analysis of the Impact of Experimental Factors on Evaluation Indicators

3.3. Parameter Optimization and Verification

3.4. Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dun, G.; Mao, N.; Gao, Z.; Wu, X.; Liu, W.; Zhou, C. Model construction of soybean average diameter and hole parameters of seed-metering wheel based on DEM. Int. J. Agric. Biol. Eng. 2021, 14, 101–110. [Google Scholar] [CrossRef]

- Han, D.; Zhang, D.; Jing, H.; Yang, L.; Cui, T.; Ding, Y.; Wang, Z.; Wang, Y.; Zhang, T. DEM-CFD coupling simulation and optimization of an inside-filling air-blowing maize precision seed-metering device. Comput. Electron. Agric. 2018, 150, 426–438. [Google Scholar] [CrossRef]

- Bourges, G.; Medina, M. Air-seeds flow analysis in a distributor head of an “air drill” seeder. In Proceedings of the 1st International Symposium on CFD Applications in Agriculture 1008, Valencia, Spain, 9–10 July 2012; pp. 259–264. [Google Scholar]

- Hu, M.; Xia, J.; Zhou, Y.; Luo, C.; Zhou, M.; Liu, Z. Measurement and Calibration of the Discrete Element Parameters of Coated Delinted Cotton Seeds. Agriculture 2022, 12, 286. [Google Scholar] [CrossRef]

- Huang, X.; Zhang, S.; Luo, C.; Li, W.; Liao, Y. Design and Experimentation of an Aerial Seeding System for Rapeseed Based on an Air-Assisted Centralized Metering Device and a Multi-Rotor Crop Protection UAV. Appl. Sci. 2020, 10, 8854. [Google Scholar] [CrossRef]

- Lu, F.; Chi, B.-J.; Dong, H.-Z. Cotton cultivation technology with Chinese characteristics has driven the 70-year development of cotton production in China. J. Integr. Agric. 2022, 21, 597–609. [Google Scholar]

- Tejaswi, T.; Talekar, N. Appraisal of precision farming: A review. Pharma Inov. J. 2022, 11, 232–234. [Google Scholar]

- Ding, Y.; Wang, K.; Liu, X.; Liu, W.; Chen, L.; Liu, W.; Du, C. Research progress on sowing detection technology of small and medium-sized seeds. Trans. Chin. Soc. Agric. Eng. 2021, 37, 30–41. [Google Scholar] [CrossRef]

- Zhang, K.; Zhang, L.; Ding, Y.; Liu, X.; Zhao, X. Design and Test of Air-Suction Pepper Seed Metering Device Based on Air Supply and Quantitative Seed Supply. INMATEH Agric. Eng. 2021, 64, 345–354. [Google Scholar] [CrossRef]

- Bagherpour, H. Modeling and evaluation of a vacuum-cylinder precision seeder for chickpea seeds. Agric. Eng. Int. CIGR J. 2019, 21, 75–82. [Google Scholar]

- Li, J.; Lai, Q.; Zhang, H.; Zhang, Z.; Zhao, J.; Wang, T. Suction force on high-sphericity seeds in an air-suction seed-metering device. Biosyst. Eng. 2021, 211, 125–140. [Google Scholar] [CrossRef]

- Abdolahzare, Z.; Abdanan Mehdizadeh, S. Real time laboratory and field monitoring of the effect of the operational parameters on seed falling speed and trajectory of pneumatic planter. Comput. Electron. Agric. 2018, 145, 187–198. [Google Scholar] [CrossRef]

- Hu, H.; Zhou, Z.; Wu, W.; Yang, W.; Li, T.; Chang, C.; Ren, W.; Lei, X. Distribution characteristics and parameter optimisation of an air-assisted centralised seed-metering device for rapeseed using a CFD-DEM coupled simulation. Biosyst. Eng. 2021, 208, 246–259. [Google Scholar] [CrossRef]

- Lei, X.; Hu, H.; Wu, W.; Liu, H.; Liu, L.; Yang, W.; Zhou, Z.; Ren, W. Seed motion characteristics and seeding performance of a centralised seed metering system for rapeseed investigated by DEM simulation and bench testing. Biosyst. Eng. 2021, 203, 22–33. [Google Scholar] [CrossRef]

- Gao, X.; Zhou, Z.; Xu, Y.; Yu, Y.; Su, Y.; Cui, T. Numerical simulation of particle motion characteristics in quantitative seed feeding system. Powder Technol. 2020, 367, 643–658. [Google Scholar] [CrossRef]

- Guzman, L.; Chen, Y.; Landry, H. Coupled CFD-DEM Simulation of Seed Flow in an Air Seeder Distributor Tube. Processes 2020, 8, 1597. [Google Scholar] [CrossRef]

- Hongxin, L.; Lifeng, G.; Lulu, F.; Shifa, T. Study on multi-size seed-metering device for vertical plate soybean precision planter. Int. J. Agric. Biol. Eng. 2015, 8, 1–8. [Google Scholar]

- Wang, C.; Li, H.; He, J.; Wang, Q.; Lu, C.; Yang, H. Optimization Design of a Pneumatic Wheat-Shooting Device Based on Numerical Simulation and Field Test in Rice–Wheat Rotation Areas. Agriculture 2022, 12, 56. [Google Scholar] [CrossRef]

- Wang, Y.; Li, H.; Wang, Q.; He, J.; Lu, C.; Yang, Q.; Liu, P. Experiment and Parameters Optimization of Seed Distributor of Mechanical Wheat Shooting Seed-Metering Device. INMATEH Agric. Eng. 2021, 63, 29–40. [Google Scholar] [CrossRef]

- Xiong, D.; Wu, M.; Xie, W.; Liu, R.; Luo, H. Design and Experimental Study of the General Mechanical Pneumatic Combined Seed Metering Device. Appl. Sci. 2021, 11, 7223. [Google Scholar] [CrossRef]

- Yatskul, A.; Lemiere, J.-P. Establishing the conveying parameters required for the air-seeders. Biosyst. Eng. 2018, 166, 1–12. [Google Scholar] [CrossRef]

- Yazgi, A.; Degirmencioglu, A. Measurement of seed spacing uniformity performance of a precision metering unit as function of the number of holes on vacuum plate. Measurement 2014, 56, 128–135. [Google Scholar] [CrossRef]

- Yazgi, A.; Demİr, V.; DeĞİRmencİOĞLu, A. Comparison of computational fluid dynamics-based simulations and visualized seed trajectories in different seed tubes. Turk. J. Agric. For. 2020, 44, 599–611. [Google Scholar] [CrossRef]

- Lei, X.; Wu, W.; Chang, C.; Li, T.; Zhou, Z.; Guo, J.; Zhu, P.; Hu, J.; Cheng, H.; Zhou, W.; et al. Seeding Performance Caused by Inclination Angle in a Centralized Seed-Metering Device for Rapeseed. Agriculture 2022, 12, 590. [Google Scholar] [CrossRef]

- Chen, Y.; Cheng, Y.; Chen, J.; Zheng, Z.; Hu, C.; Cao, J. Design and Experiment of the Buckwheat Hill-Drop Planter Hole Forming Device. Agriculture 2021, 11, 85. [Google Scholar] [CrossRef]

- Gorobets, V.; Trokhaniak, V.; Masiuk, M.; Spodyniuk, N.; Blesnyuk, O.; Marchishina, Y. Cfd Modeling of Aerodynamic Flow in a Wind Turbine with Vertical Rotational Axis and Wind Flow Concentrator. INMATEH Agric. Eng. 2021, 64, 159–166. [Google Scholar] [CrossRef]

- Jiajia, Y.; Yitao, L.; Jinling, C.; Song, Y.; Qingxi, L. Simulation analysis and match experiment on negative and positive pressures of pneumatic precision metering device for rapeseed. Int. J. Agric. Biol. Eng. 2014, 7, 1–12. [Google Scholar]

- Liu, Z.; Meng, Z.; Han, J.; Zhuang, Y.; Yin, X.; Chen, Y. Effect of Seed Filling and Releasing Angles on the Performance of Compound Vacuum Seed Metering Device. INMATEH Agric. Eng. 2021, 65, 153–162. [Google Scholar] [CrossRef]

- Hai, N.T.; Chosa, T.; Tojo, S.; Thi-Hien, N. Application of a Similarity Measure Using Fuzzy Sets to Select the Optimal Plan for an Air-Assisted Rice Seeder. Appl. Sci. 2021, 11, 6715. [Google Scholar] [CrossRef]

- Lei, X.; Liao, Y.; Liao, Q. Simulation of seed motion in seed feeding device with DEM-CFD coupling approach for rapeseed and wheat. Comput. Electron. Agric. 2016, 131, 29–39. [Google Scholar] [CrossRef]

- Mudarisov, S.; Badretdinov, I.; Rakhimov, Z.; Lukmanov, R.; Nurullin, E. Numerical simulation of two-phase “Air-Seed” flow in the distribution system of the grain seeder. Comput. Electron. Agric. 2020, 168, 105151. [Google Scholar] [CrossRef]

- Li, H.; Zeng, S.; Luo, X.; Fang, L.; Liang, Z.; Yang, W. Design, DEM Simulation, and Field Experiments of a Novel Precision Seeder for Dry Direct-Seeded Rice with Film Mulching. Agriculture 2021, 11, 378. [Google Scholar] [CrossRef]

- Shen, H.; Zhang, J.; Chen, X.; Dong, J.; Huang, Y.; Shi, J. Development of a guiding-groove precision metering device for high-speed planting of soybean. Trans. ASABE 2021, 64, 1113–1122. [Google Scholar] [CrossRef]

- Zhang, X.; Zhu, D.; Xue, K.; Li, L.; Zhu, J.; Zhang, S.; Liao, J. Parameter Optimization and Experiment of Slider-Hole-Wheel Seed-Metering Device Based on Discrete Element Method. INMATEH Agric. Eng. 2021, 65, 410–420. [Google Scholar] [CrossRef]

- Bai, S.; Yuan, Y.; Niu, K.; Zhou, L.; Zhao, B.; Wei, L.; Liu, L.; Xiong, S.; Shi, Z.; Ma, Y.; et al. Simulation Parameter Calibration and Experimental Study of a Discrete Element Model of Cotton Precision Seed Metering. Agriculture 2022, 12, 870. [Google Scholar] [CrossRef]

- Xing, H.; Zang, Y.; Wang, M.Z.; Luo, W.X.; Zhang, H.M.; Ma, X.Y.; Fang, Y.L. Design and Experimental Analysis of a Stirring Device for a Pneumatic Precision Rice Seed Metering Device. Trans. ASABE 2020, 63, 799–808. [Google Scholar] [CrossRef]

- Gao, X.; Cui, T.; Zhou, Z.; Yu, Y.; Xu, Y.; Zhang, D.; Song, W. DEM study of particle motion in novel high-speed seed metering device. Adv. Powder Technol. 2021, 32, 1438–1449. [Google Scholar] [CrossRef]

- Cheng, Q.; Wang, J.; Liu, K.; Chao, J.; Liu, D. Design of Rice Straw Fiber Crusher and Evaluation of Fiber Quality. Agriculture 2022, 12, 729. [Google Scholar] [CrossRef]

- Guo, H.; Cao, Y.; Song, W.; Zhang, J.; Wang, C.; Wang, C.; Yang, F.; Zhu, L. Design and Simulation of a Garlic Seed Metering Mechanism. Agriculture 2021, 11, 1239. [Google Scholar] [CrossRef]

- Lai, Q.; Sun, K.; Yu, Q.; Qin, W. Design and experiment of a six-row air-blowing centralized precision seed-metering device for Panax notoginseng. Int. J. Agric. Biol. Eng. 2020, 13, 111–122. [Google Scholar] [CrossRef]

- Li, B.; Ahmad, R.; Qi, X.; Li, H.; Nyambura, S.M.; Wang, J.; Chen, X.; Li, S. Design Evaluation and Performance Analysis of a Double-Row Pneumatic Precision Metering Device for Brassica chinensis. Sustainability 2021, 13, 1374. [Google Scholar] [CrossRef]

- Liquan, T.; Yongsen, X.; Zhao, D.; Zhan, S. Design and Performance Test of Direct Seed Metering Device for Rice Hill. INMATEH Agric. Eng. 2021, 64, 257–268. [Google Scholar] [CrossRef]

- Wang, B.; Luo, X.; Wang, Z.; Zheng, L.; Zhang, M.; Dai, Y.; Xing, H. Design and field evaluation of hill-drop pneumatic central cylinder direct-seeding machine for hybrid rice. Int. J. Agric. Biol. Eng. 2018, 11, 33–40. [Google Scholar] [CrossRef]

- Wang, J.; Qi, X.; Xu, C.; Wang, Z.; Jiang, Y.; Tang, H. Design Evaluation and Performance Analysis of the Inside-Filling Air-Assisted High-Speed Precision Maize Seed-Metering Device. Sustainability 2021, 13, 5483. [Google Scholar] [CrossRef]

| Parameters | Value |

| Poisson’s ratio of cotton seed | 0.25 |

| Shear modulus of cotton seed (Pa) | 1.0 × 106 |

| The density of cotton seed (kg/m3) | 664.6 |

| Collision recovery coefficient between cotton seed and cotton seed | 0.3 |

| Coefficient of static friction between cotton seed and cotton seed | 0.56 |

| Coefficient of rolling friction between cotton seed and cotton seed | 0.15 |

| Poisson’s ratio of ABS | 0.5 |

| Shear modulus of ABS (Pa) | 1.77 × 106 |

| The density of ABS (kg/m3) | 1180 |

| Collision recovery coefficient between ABS and cotton seed | 0.6 |

| Coefficient of static friction between ABS and cotton seed | 0.48 |

| Coefficient of rolling friction between ABS and cotton seed | 0.1 |

| Poisson’s ratio of steel | 0.28 |

| Shear modulus of steel (Pa) | 8.2 × 1010 |

| The density of steel (kg/m3) | 7890 |

| Collision recovery coefficient between steel and cotton seed | 0.52 |

| Coefficient of static friction between steel and cotton seed | 0.5 |

| Coefficient of rolling friction between steel and cotton seed | 0.1 |

| Gravitational acceleration (m/s2) | 9.8 |

| Fixed time step (s) | 7.51 × 10−6 |

| Total simulation time (s) | 15 |

| Code Value | Test Factors | ||

|---|---|---|---|

| Speed of the Hole Sower X1/(r/min) | Negative Pressure X2/(kPa) | Aperture X3/(mm) | |

| −1.682 | 36.31 | 1.59 | 3.0 |

| −1 | 41.04 | 1.93 | 3.2 |

| 0 | 47.98 | 2.43 | 3.5 |

| 1 | 54.72 | 2.93 | 3.8 |

| 1.682 | 59.45 | 3.27 | 4.0 |

| Test Serial Number | Test Factors | Evaluation Indicators | |||

|---|---|---|---|---|---|

| X1 | X2 | X3 | Single Grain Rate y1/% | Missed Seeding Rate y0/% | |

| 1 | 0 | 0 | −1.682 | 85.6 | 7.2 |

| 2 | −1 | −1 | −1 | 83.2 | 13.6 |

| 3 | 1 | −1 | −1 | 87.5 | 7.9 |

| 4 | −1 | 1 | −1 | 83.4 | 9.9 |

| 5 | 1 | 1 | −1 | 85.2 | 6.0 |

| 6 | 0 | −1.682 | 0 | 89.2 | 5.4 |

| 7 | −1.682 | 0 | 0 | 82.3 | 12.2 |

| 8 | 0 | 0 | 0 | 89.1 | 7.5 |

| 9 | 0 | 0 | 0 | 89.8 | 7.0 |

| 10 | 0 | 0 | 0 | 89.6 | 5.4 |

| 11 | 0 | 0 | 0 | 88.8 | 6.9 |

| 12 | 0 | 0 | 0 | 90.4 | 4.1 |

| 13 | 0 | 0 | 0 | 89.9 | 5.1 |

| 14 | 0 | 0 | 0 | 91.5 | 4.5 |

| 15 | 0 | 0 | 0 | 89.0 | 5.7 |

| 16 | 0 | 0 | 0 | 90.4 | 4.0 |

| 17 | 1.682 | 0 | 0 | 86.5 | 3.7 |

| 18 | 0 | 1.682 | 0 | 84.9 | 8.1 |

| 19 | −1 | −1 | 1 | 88.0 | 5.5 |

| 20 | 1 | −1 | 1 | 89.1 | 6.9 |

| 21 | −1 | 1 | 1 | 83.1 | 10.3 |

| 22 | 1 | 1 | 1 | 83.8 | 11.2 |

| 23 | 0 | 0 | 1.682 | 86.1 | 7.5 |

| Source of Variance | Single Grain Rate | Missed Seeding Rate | ||||||

|---|---|---|---|---|---|---|---|---|

| Sum of Squares | Freedom | F-Value | p-Value | Sum of Squares | Freedom | F-Value | p-Value | |

| Model | 165.42 | 9 | 32.05 | <0.0001 ** | 126.42 | 9 | 5.89 | 0.0022 ** |

| X1 | 16.40 | 1 | 28.59 | 0.0001 ** | 34.05 | 1 | 14.32 | 0.0023 ** |

| X2 | 27.93 | 1 | 48.71 | <0.0001 ** | 4.73 | 1 | 1.99 | 0.1823 |

| X3 | 2.25 | 1 | 3.92 | 0.0693 | 0.6570 | 1 | 0.2755 | 0.6085 |

| X1 × 2 | 1.05 | 1 | 1.83 | 0.1988 | 0.2112 | 1 | 0.0886 | 0.7707 |

| X1 × 3 | 2.31 | 1 | 4.03 | 0.0659 | 17.70 | 1 | 7.42 | 0.0174 * |

| X2 × 3 | 8.20 | 1 | 14.30 | 0.0023 ** | 27.01 | 1 | 11.33 | 0.0051 ** |

| X12 | 60.00 | 1 | 104.63 | <0.0001 ** | 20.66 | 1 | 8.67 | 0.0114 * |

| X22 | 16.09 | 1 | 28.06 | 0.0001 ** | 8.15 | 1 | 3.42 | 0.0874 |

| X32 | 32.52 | 1 | 56.71 | <0.0001 ** | 13.69 | 1 | 5.74 | 0.0323 * |

| Residual | 7.45 | 13 | 31.00 | 13 | ||||

| Misfit | 1.67 | 5 | 0.4636 | 0.7936 | 17.43 | 5 | 2.05 | 0.1745 |

| Error | 5.78 | 8 | 13.58 | 8 | ||||

| Sum | 172.87 | 22 | 157.42 | 22 | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, B.; Ni, X.; Li, S.; Li, K.; Qi, Q. Simulation and Experimental Study of a Split High-Speed Precision Seeding System. Agriculture 2022, 12, 1037. https://doi.org/10.3390/agriculture12071037

Lu B, Ni X, Li S, Li K, Qi Q. Simulation and Experimental Study of a Split High-Speed Precision Seeding System. Agriculture. 2022; 12(7):1037. https://doi.org/10.3390/agriculture12071037

Chicago/Turabian StyleLu, Bo, Xiangdong Ni, Shufeng Li, Kezhi Li, and Qingzheng Qi. 2022. "Simulation and Experimental Study of a Split High-Speed Precision Seeding System" Agriculture 12, no. 7: 1037. https://doi.org/10.3390/agriculture12071037

APA StyleLu, B., Ni, X., Li, S., Li, K., & Qi, Q. (2022). Simulation and Experimental Study of a Split High-Speed Precision Seeding System. Agriculture, 12(7), 1037. https://doi.org/10.3390/agriculture12071037