Development of an Air-Recirculated Ventilation System for a Piglet House, Part 1: Analysis of Representative Problems through Field Experiment and Aerodynamic Analysis Using CFD Simulation for Evaluating Applicability of System

Abstract

:1. Introduction

1.1. Backgrounsd of the Study

1.2. Overall Aim of the Study

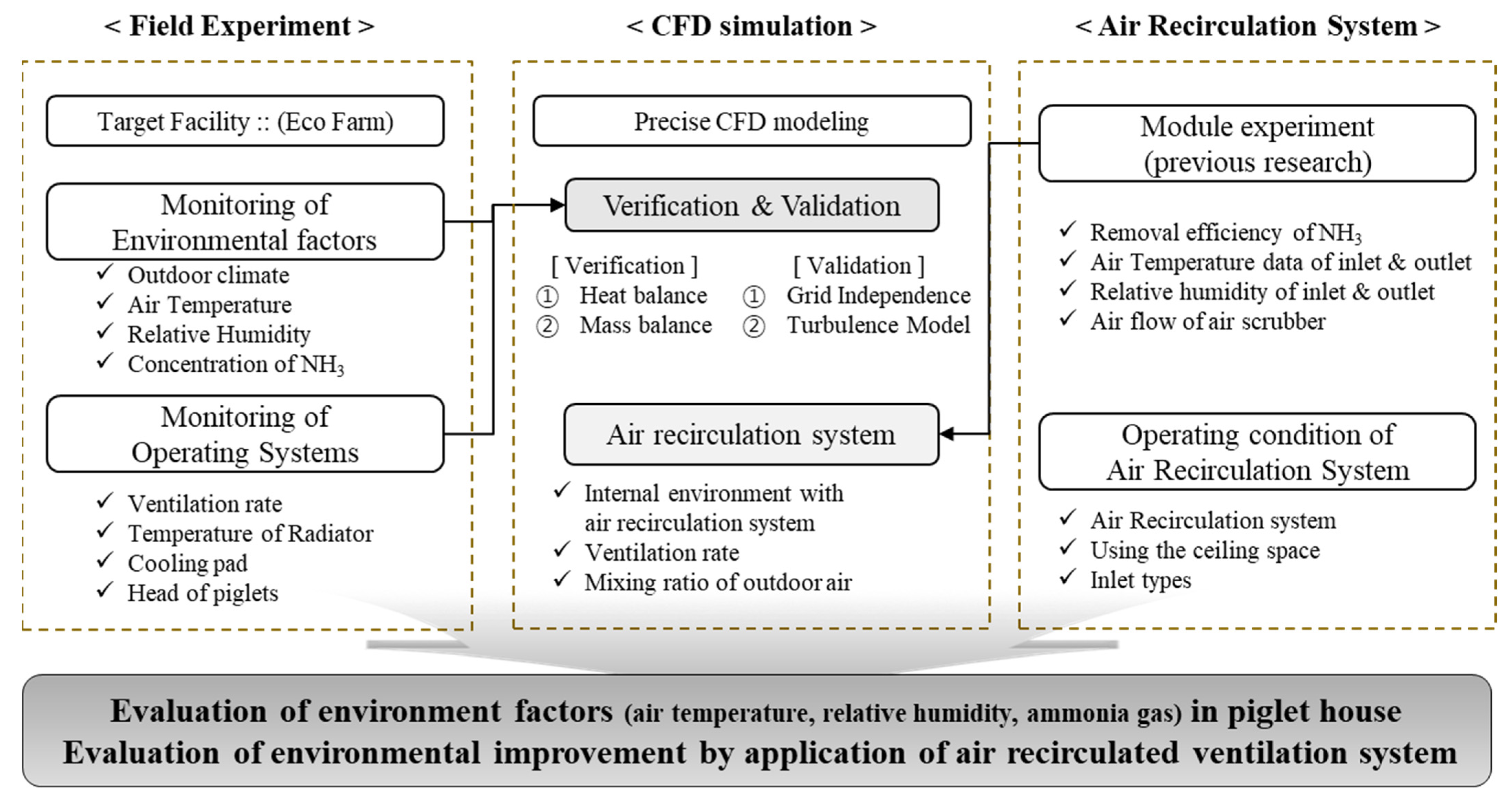

1.3. Scope and Objective of this Study

2. Materials and Methods

2.1. Target Facility

2.2. Field Experiment

2.3. Computational Fluid Dynamics

2.4. Experimental Procedure

2.4.1. Data Construction for Analysis of the Internal Environment of the Piglet House

2.4.2. Data Processing Method of Measured Data

2.4.3. Design and Validation of CFD Simulation Model

2.4.4. Boundary Conditions of CFD Simulation Model

2.4.5. Case Studies of CFD Simulation

3. Results and Discussion

3.1. Analysis of Internal Measurement Data of Piglet House in Suumer and Winter

3.1.1. Results of Summer Season

3.1.2. Results of Winter Season

3.2. Verification and Validation of CFD Simulation Model

3.2.1. Verification of Boundary Conditions

3.2.2. Validation of CFD Simulation Model for Computational Efficiency

3.2.3. Validation of CFD Simulation Model for Improvement of Uncertainty Variables

3.3. Analysis of the CFD Computed Results

3.3.1. CFD Computed Results According to the Outdoor Climate

3.3.2. Results of CFD Simulation for Internal Environment Improvement (Ventilation Rate and Radiator)

3.3.3. Results of CFD Simulation for Internal Environment Improvement (Ceiling Slots)

3.3.4. Analysis of the Air-Recirculated Ventilation System

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ministry of Agriculture Food and Rural Affairs. 2020. Available online: https://www.mafra.go.kr (accessed on 8 July 2020).

- Kwon, K.-s.; Lee, I.-b.; Ha, T. Identification of key factors for dust generation in a nursery pig house and evaluation of dust reduction efficiency using a CFD technique. Biosyst. Eng. 2016, 151, 28–52. [Google Scholar] [CrossRef]

- Godyń, D.; Herbut, P.; Angrecka, S.; Corrêa Vieira, F.M. Use of different cooling methods in pig facilities to alleviate the effects of heat stress—A review. Animals 2020, 10, 1459. [Google Scholar] [CrossRef] [PubMed]

- Korea Disease Control and Prevention Agency. 2020. Available online: https://www.kdca.go.kr (accessed on 8 July 2020).

- Huynh, T.; Aarnink, A.; Verstegen, M.; Gerrits, W.; Heetkamp, M.; Kemp, B.; Canh, T. Effects of increasing temperatures on physiological changes in pigs at different relative humidities. J. Anim. Sci. 2005, 83, 1385–1396. [Google Scholar] [CrossRef] [PubMed]

- Conti, C.; Bacenetti, J.; Costantini, M.; Lovarelli, D.; Orsi, L.; Ganzaroli, A.; Guarino, M. Life cycle assessment of pig production in Italy considering a wet scrubber ammonia abatement system. In Proceedings of the International Conference on Life Cycle Assessment of Food, Berlin/Heidelberg, Germany, 13–16 October 2020; pp. 136–140. [Google Scholar]

- Anthony, T.R.; Yang, A.Y.; Peters, T.M. Assessment of interventions to improve air quality in a livestock building. J. Agric. Saf. Health 2017, 23, 247–263. [Google Scholar] [CrossRef] [PubMed]

- Besant, R.W.; Simonson, C.J. Air-to-air energy recovery. ASHRAE J. 2000, 42, 31–43. [Google Scholar]

- Cortus, E.L.; Spronk, S.; Lanoue, C.; Nicolai, R.; Pohl, S. Heat and moisture balances for a new barn design with recirculated air. In ASABE/CSBE North Central Intersectional Meeting; The American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2006. [Google Scholar]

- Hall, A.; Saindon, J.; NEL, L.; Hardcastle, S. Feasibility of controlled recirculation of exhaust air to reduce heating costs at Ruttan Mine, Manitoba. In Proceedings of the Cim Bulletin, Edmonton, AB, Canada, 4–6 June 1987; p. 89. [Google Scholar]

- Lau, A.; Vizcarra, A.; Lo, K.; Luymes, J. Recirculation of filtered air in pig barns. Can. Agric. Eng. 1996, 38, 297–304. [Google Scholar]

- Partridge, L.J.; Nayak, P.R.; Stricoff, R.S.; Hagopian, J.H. Recommended Approach to Recirculation of Exhaust Air; Research Report. No. PB-90-195108/XAB; Little (Arthur D.), Inc.: Cambridge, MA, USA, 1978; pp. 78–124. [Google Scholar]

- Zhang, J.; Long, Z.; Liu, W.; Chen, Q. Strategy for studying ventilation performance in factories. Aerosol Air Qual. Res. 2016, 16, 442–452. [Google Scholar] [CrossRef]

- Ziegler, T.; Jubaer, H.; Schütz, M. Increasing the Energy Efficiency of Batch-Type Drying with Partial Air Recirculation. Chem. Ing. Tech. 2016, 88, 208–214. [Google Scholar] [CrossRef]

- American National Standards Institute. 2007. Available online: Webstore.ansi.org (accessed on 8 July 2020).

- Alvarado, A.C.; Predicala, B.Z. Control of Gas and Odor Levels in Swine Facilities Using Filters with Zinc Oxide Nanoparticles. Trans. ASABE 2017, 60, 943–956. [Google Scholar] [CrossRef]

- Anthony, T.R.; Altmaier, R.; Jones, S.; Gassman, R.; Park, J.H.; Peters, T.M. Use of recirculating ventilation with dust filtration to improve wintertime air quality in a swine farrowing room. J. Occup. Environ. Hyg. 2015, 12, 635–646. [Google Scholar] [CrossRef] [PubMed]

- Anthony, T.R.; Altmaier, R.; Park, J.H.; Peters, T.M. Modeled effectiveness of ventilation with contaminant control devices on indoor air quality in a swine farrowing facility. J. Occup. Environ. Hyg. 2014, 11, 434–449. [Google Scholar] [CrossRef] [PubMed]

- Park, C.; Lee, S.; Kim, C.; Choi, Y. A comparative study of lean burn and exhaust gas recirculation in an HCNG-fueled heavy-duty engine. Int. J. Hydrog. Energy 2017, 42, 26094–26101. [Google Scholar] [CrossRef]

- Wenke, C.; Pospiech, J.; Reutter, T.; Altmann, B.; Truyen, U.; Speck, S. Impact of different supply air and recirculating air filtration systems on stable climate, animal health, and performance of fattening pigs in a commercial pig farm. PLoS ONE 2018, 13, e0194641. [Google Scholar] [CrossRef] [PubMed]

- Peters, T.M.; Sawvel, R.A.; Park, J.H.; Anthony, T.R. Evaluation of a shaker dust collector for use in a recirculating ventilation system. J. Occup. Environ. Hyg. 2015, 12, D201–D210. [Google Scholar] [CrossRef] [PubMed]

- Park, J.H.; Peters, T.M.; Altmaier, R.; Jones, S.M.; Gassman, R.; Anthony, T.R. Simulation of air quality and operating cost to ventilate swine farrowing facilities in the midwest US during winter. Trans. ASABE 2017, 60, 465–477. [Google Scholar] [PubMed]

- Mostafa, E.; Hoelscher, R.; Diekmann, B.; Ghaly, A.; Buescher, W. Evaluation of two indoor air pollution abatement techniques in forced-ventilation fattening pig barns. Atmos. Pollut. Res. 2017, 8, 428–438. [Google Scholar] [CrossRef]

- Service, M.P. Swine Housing and Equipment Handbook; Midwest Plan Service: Ames, IA, USA, 1983. [Google Scholar]

- Park, G.; Lee, I.-b.; Yeo, U.-h.; Ha, T.; Kim, R.-w.; Lee, S.-y. Ventilation rate formula for mechanically ventilated broiler houses considering aerodynamics and ventilation operating conditions. Biosyst. Eng. 2018, 175, 82–95. [Google Scholar] [CrossRef]

- Liu, G.; Liu, M. Development of simplified in-situ fan curve measurement method using the manufacturers fan curve. Build. Environ. 2012, 48, 77–83. [Google Scholar] [CrossRef]

- CIGR. Heat and moisture production at animal and house levels. In 2002 ASAE Annual Meeting; The American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2002; pp. 37–40. [Google Scholar]

- Hayes, M.D.; Brown-Brandl, T.M.; Stinn, J.P.; Li, H.; Xin, H.; Nienaber, J.A.; Shepherd, T.A. House-level moisture production of modern swine by age, temperature and source. In Proceedings of the 2013, Kansas City, MO, USA, 21–24 July 2013; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2013; p. 1. [Google Scholar]

- Bjerg, B.; Zhang, G.; Kai, P. Porous media as boundary condition for air inlet, slatted floor and animal occupied zone in numerical simulation of airflow in a pig unit. In Proceedings of the Agricultural and Biosystems Engineering for a Sustainable World, International Conference on Agricultural Engineering, Hersonissos, Crete, Greece, 23–25 June 2008; p. 2008. [Google Scholar]

- Fuller, M. The Effects of Some Climatic Factors on the Growing Pig. Ph.D. Thesis, University of Cambridge, Cambridge, UK, 1965. [Google Scholar]

- Van Ouwerkerk, E.; Pedersen, S. Application of the carbon dioxide mass balance method to evaluate ventilation rates in livestock buildings. In Proceedings of the XII CIGR World Congress on Agricultural Engineering, Milano, Italy, 29 August–1 September 1994; pp. 516–529. [Google Scholar]

- Seo, I.-H.; Lee, I.-B.; Hong, S.-W.; Hwang, H.-S.; Bitog, J.P.; Yoo, J.-I.; Kwon, K.-S.; Ha, T.-H.; Kim, H.-T. Development of a CFD model to study ventilation efficiency of mechanically ventilated pig house. J. Korean Soc. Agric. Eng. 2008, 50, 25–37. [Google Scholar]

- Aarnink, A. Ammonia Emission from Houses for Growing Pigs as Affected by Pen Design, Indoor Climate and Behaviour. Ph.D. Thesis, Wageningen University, Wageningen, The Netherlands, 1997. [Google Scholar]

| Static Pressure (Pa) | Flow Rate (CMH) | Reduction Rate (%) | |

|---|---|---|---|

| Design | Actual | ||

| 0 | 8497 | 6835 | 19.6 |

| 10 | 8061 | 6499 | 19.4 |

| 20 | 7488 | 6046 | 19.3 |

| 30 | 6778 | 5478 | 19.2 |

| 40 | 5931 | 4787 | 19.3 |

| Types | Values | Units | |

|---|---|---|---|

| Outdoor temperature (TAC: 5%) | Winter | −8 | °C |

| Summer | 33 | ||

| Air temperature inside the corridor | Winter | 10 | °C |

| Summer | 31 | ||

| Heat production | Surface temperature of piglet | 39.7 | °C |

| Breathing capacity | 0.28 | m3·s−1 | |

| Moisture production of piglets | 1.7 | g·h−1·kg−1 | |

| Moisture generation rate of manure | 2.8 | g·h−1·kg−1 | |

| Ammonia generation rate of manure | 211.4 | g·h−1 | |

| Ventilation rate | Validation | 0.6 | min−1 |

| Winter | 0.12 | ||

| Summer | 0.92 | ||

| Solver | Pressure-based solver | - | |

| Numerical algorithm | SIMPLE algorithm | - | |

| Time condition | Steady state | - | |

| Operating pressure | 1.1325 | Pa | |

| Gravitational acceleration | 9.81 | m·s−2 | |

| Air density | 1.225 | kg·m−3 | |

| Air viscosity | 1.7894 × 10−5 | kg·m−1·s−1 | |

| Ammonia density | 0.6894 | kg·m−3 | |

| Ammonia viscosity | 1.015 × 10−5 | kg·m−1·s−1 | |

| H2O density | 0.5542 | kg·m−3 | |

| H2O viscosity | 1.34 × 10−5 | kg·m−1·s−1 | |

| Purpose | Experimental Variables | Cases |

|---|---|---|

| Analysis of the internal environment by season | Outdoor weather condition: winter & summer | 2 |

| Analysis of internal environment according to the increase of ventilation rate using radiator in winter season | Ventilation rate: 0.06, 0.12, 0.18, 0.24, 0.3 min−1 Radiant values of radiator: 0, 500, 600, 650 W | 20 |

| Analysis of internal environment according to the ceiling slot conditions | Open conditions of ceiling slots: 3 types Ventilation rate: 0.12, 0.24 min−1 | 6 |

| Analysis of the internal environment according to the operating conditions of the air recirculation system | Ventilation rate: 0.2, 0.6, 0.9 min−1 Mixing ratio of outdoor air: 25, 50, 75% | 9 |

| Conditions | Parameter | Heat Generation Rate | Unit |

|---|---|---|---|

| CFD computed data | (a) Breath of piglets | 26,567.6 | W |

| (b) Body heat of piglets | 9235.5 | W | |

| (a) + (b) Total | 35,803 | W | |

| Theoretical calculation | Total heat production | 94.8 | W·kg−1 |

| Latent heat production | 58.6 | W·kg−1 | |

| Sensible heat production | 36.2 | W·kg−1 | |

| 980 head × 20 kg × SHP | 35,476 | W |

| Conditions | Parameter | Gas Generation Rate | Unit |

|---|---|---|---|

| CFD computed data | Concentration of NH3 in pit slurry | 2.82 × 10−7 | kg·m−3·s−1 |

| Theoretical calculation | Emission factor of piglet | 2.98 × 10−7 | kg·m−3·s−1 |

| T-1 | T-2 | T-3 | T-4 | T-5 | T-6 | T-7 | T-8 | T-9 | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Measured data | Temp (°C) | 30.6 | 30.7 | 31.1 | 30.7 | 30.5 | 30.9 | 30.5 | 30.3 | 30.8 |

| Realizable k-e | Temp (°C) | 31.5 | 31.5 | 31.5 | 31.6 | 31.5 | 31.5 | 31.6 | 31.4 | 31.4 |

| Error (%) | 2.9 | 2.7 | 1.4 | 2.8 | 3.2 | 1.9 | 3.7 | 3.7 | 2.0 | |

| Standard k-e | Temp (°C) | 31.5 | 31.3 | 31.5 | 31.3 | 31.2 | 31.5 | 31.4 | 31.6 | 31.4 |

| Error (%) | 2.8 | 2.1 | 1.4 | 1.9 | 2.2 | 1.9 | 3.1 | 4.2 | 2.0 | |

| RNG k-e | Temp (°C) | 31.1 | 31.2 | 31.4 | 31.1 | 31.0 | 31.4 | 31.0 | 30.9 | 31.2 |

| Error (%) | 1.5 | 1.5 | 1.0 | 1.4 | 1.7 | 1.7 | 1.9 | 1.9 | 1.5 | |

| Standard k-w | Temp (°C) | 31.6 | 31.1 | 31.0 | 31.5 | 31.5 | 31.4 | 31.5 | 31.3 | 31.5 |

| Error (%) | 3.1 | 1.3 | 0.2 | 2.5 | 3.3 | 1.6 | 3.5 | 3.2 | 2.4 | |

| No. | Variable Factors of CFD Simulation (Ceiling Slot Conditions and Ventilation Rate) | Avg Temp (°C) | Avg Ammonia (ppm) |

|---|---|---|---|

| 1 | Ceiling slot (#6): closed Ventilation rate: 0.12 min−1 | 25.82 | 31.17 |

| 2 | Ceiling slot (#6, #7): closed Ventilation rate: 0.12 min−1 | 25.9 | 31.83 |

| 3 | Ceiling slot (#4): closed Ventilation rate: 0.12 min−1 | 25.57 | 31.67 |

| 4 | Ceiling slot (#6): closed Ventilation rate: 0.25 min−1 | 21.12 | 19.07 |

| 5 | Ceiling slot (#6, #7): closed Ventilation rate: 0.25 min−1 | 21.28 | 18.95 |

| 6 | Ceiling slot (#4): closed Ventilation rate: 0.25 min−1 | 20.91 | 17.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.-g.; Lee, I.-b.; Lee, S.-y.; Park, S.-j.; Jeong, D.-y.; Choi, Y.-b.; Decano-Valentin, C.; Yeo, U.-h. Development of an Air-Recirculated Ventilation System for a Piglet House, Part 1: Analysis of Representative Problems through Field Experiment and Aerodynamic Analysis Using CFD Simulation for Evaluating Applicability of System. Agriculture 2022, 12, 1139. https://doi.org/10.3390/agriculture12081139

Kim J-g, Lee I-b, Lee S-y, Park S-j, Jeong D-y, Choi Y-b, Decano-Valentin C, Yeo U-h. Development of an Air-Recirculated Ventilation System for a Piglet House, Part 1: Analysis of Representative Problems through Field Experiment and Aerodynamic Analysis Using CFD Simulation for Evaluating Applicability of System. Agriculture. 2022; 12(8):1139. https://doi.org/10.3390/agriculture12081139

Chicago/Turabian StyleKim, Jun-gyu, In-bok Lee, Sang-yeon Lee, Se-jun Park, Deuk-young Jeong, Young-bae Choi, Cristina Decano-Valentin, and Uk-hyeon Yeo. 2022. "Development of an Air-Recirculated Ventilation System for a Piglet House, Part 1: Analysis of Representative Problems through Field Experiment and Aerodynamic Analysis Using CFD Simulation for Evaluating Applicability of System" Agriculture 12, no. 8: 1139. https://doi.org/10.3390/agriculture12081139

APA StyleKim, J.-g., Lee, I.-b., Lee, S.-y., Park, S.-j., Jeong, D.-y., Choi, Y.-b., Decano-Valentin, C., & Yeo, U.-h. (2022). Development of an Air-Recirculated Ventilation System for a Piglet House, Part 1: Analysis of Representative Problems through Field Experiment and Aerodynamic Analysis Using CFD Simulation for Evaluating Applicability of System. Agriculture, 12(8), 1139. https://doi.org/10.3390/agriculture12081139