The Impact of Traffic-Induced Compaction on Soil Bulk Density, Soil Stress Distribution and Key Growth Indicators of Maize in North China Plain

Abstract

:1. Introduction

2. Materials and Methods

2.1. The Soil Conditions

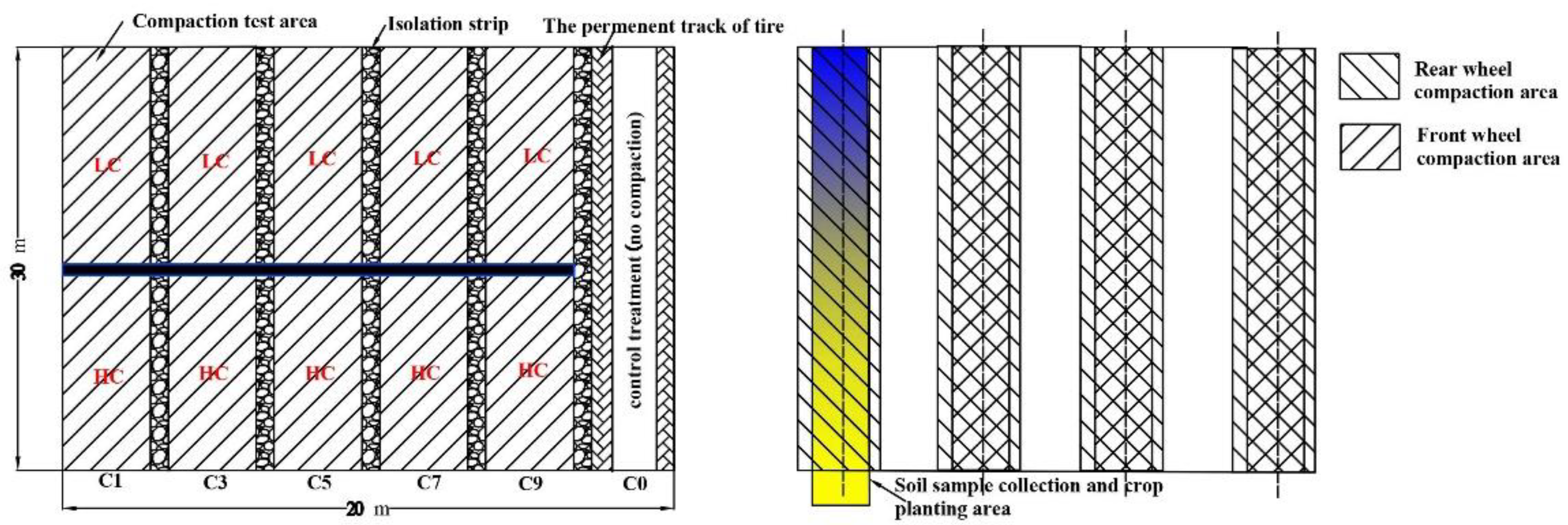

2.2. Experimental Treatments and Layout

2.3. Field Measurements and Soil Sampling

2.3.1. Soil Bulk Density

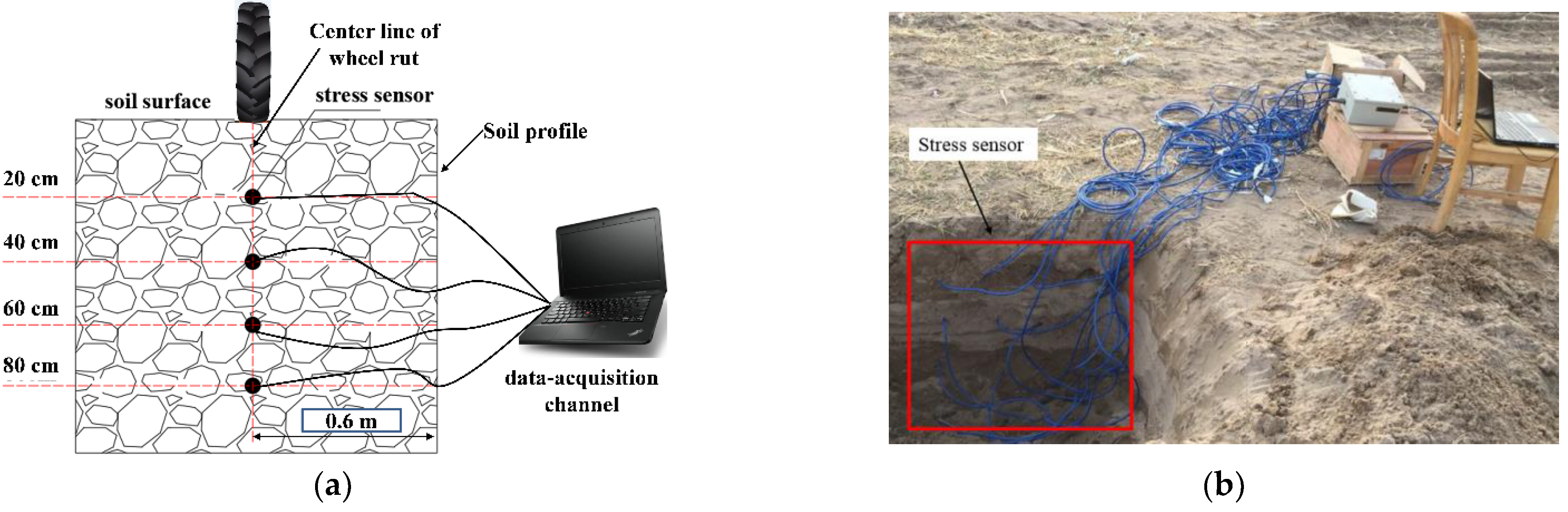

2.3.2. Soil Stress Measurement

2.3.3. Measurement of Maize Growth Indexes [33,34]

- The height and diameter of the maize stems

- 2.

- Dry matter weight

- 3.

- Leaf area index

- 4.

- Maize root distribution measurements

- 5.

- The yield of maize

2.4. The Data Analysis

3. Results

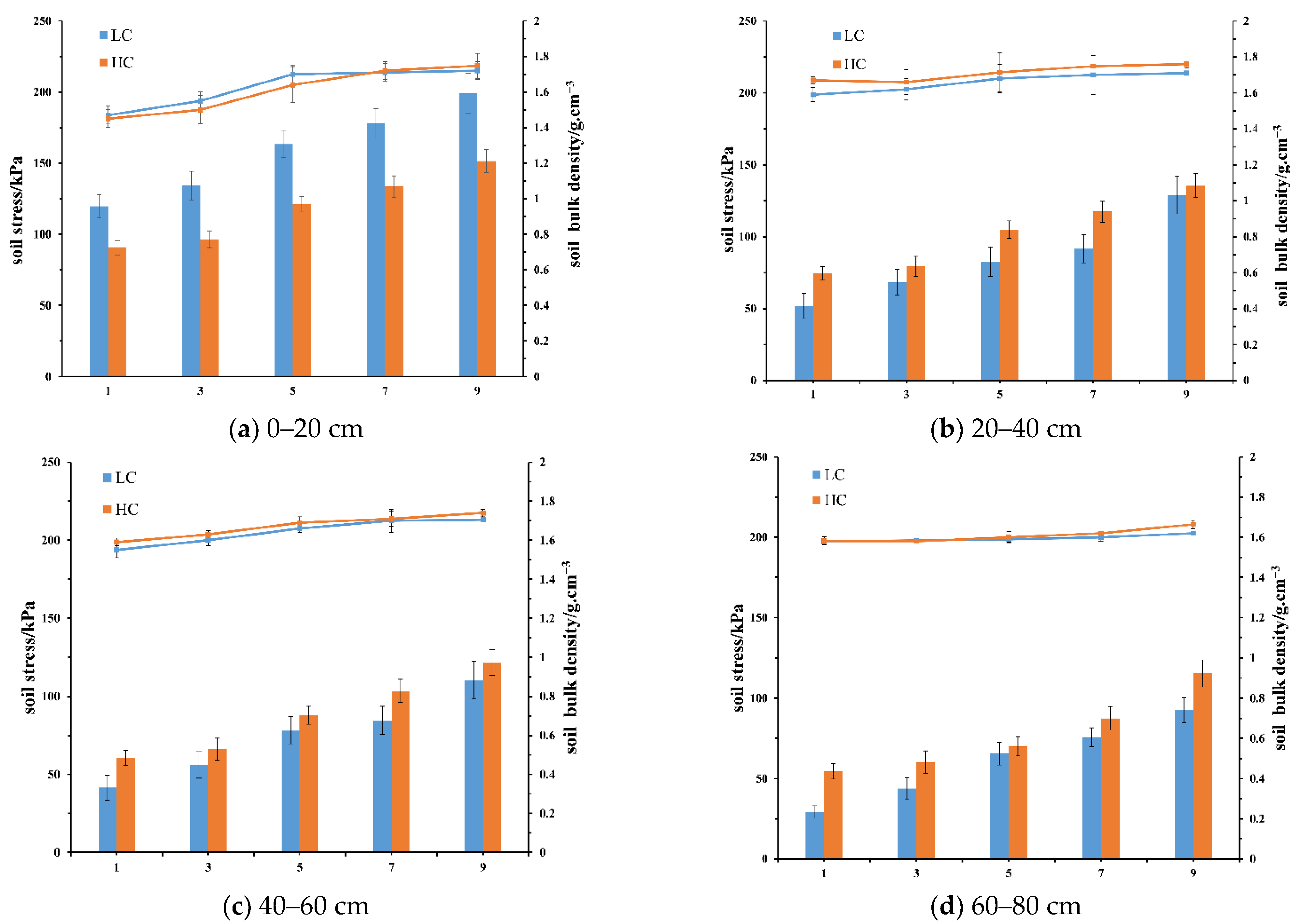

3.1. Effect of Tractor Load and Number of Passes on Spatial Distribution of Soil Stress

3.2. Effect of Tractor Load and Number of Passes on Soil Bulk Density

3.3. Effect of Tractor Mass and Number of Passes on Maize Growth

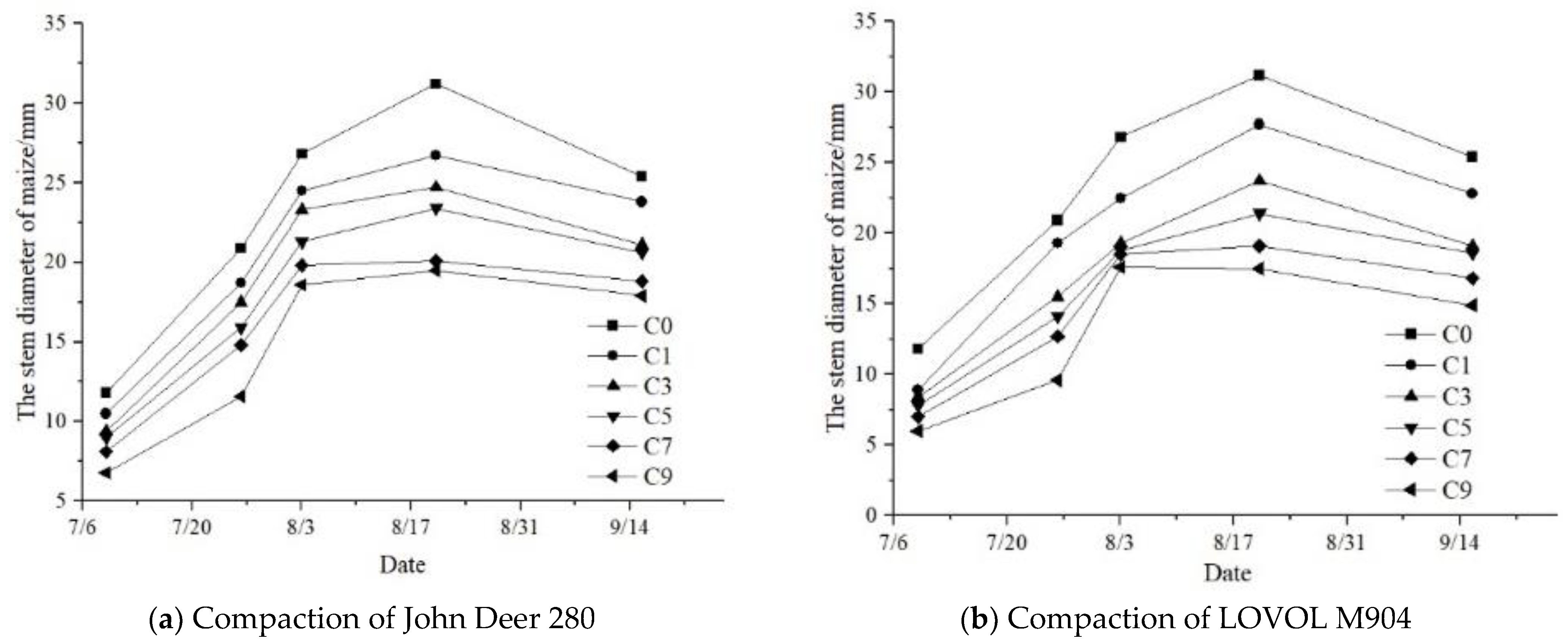

3.3.1. Effect of Soil Compaction on Height and Diameter of Maize Stems

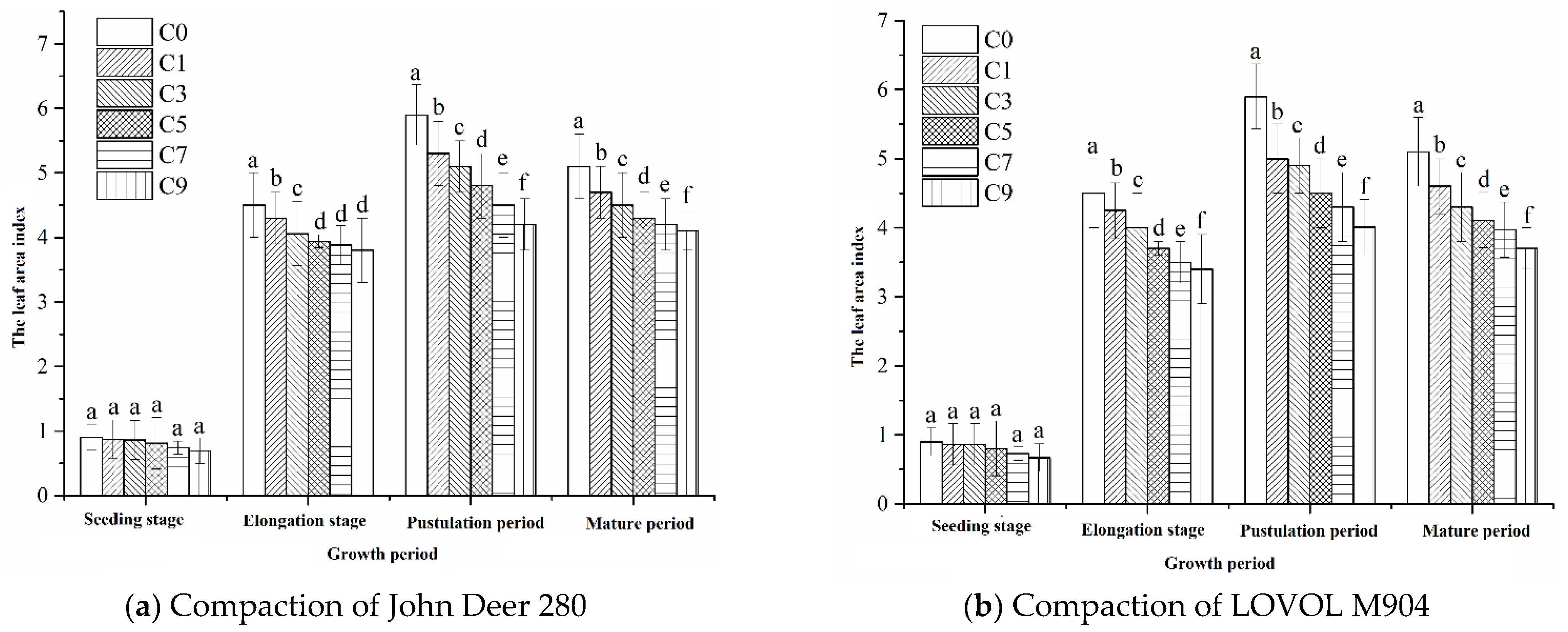

3.3.2. Effects of Soil Compaction on Leaf Area Index of Maize

3.3.3. Effects of Soil Compaction on Root Growth of Maize

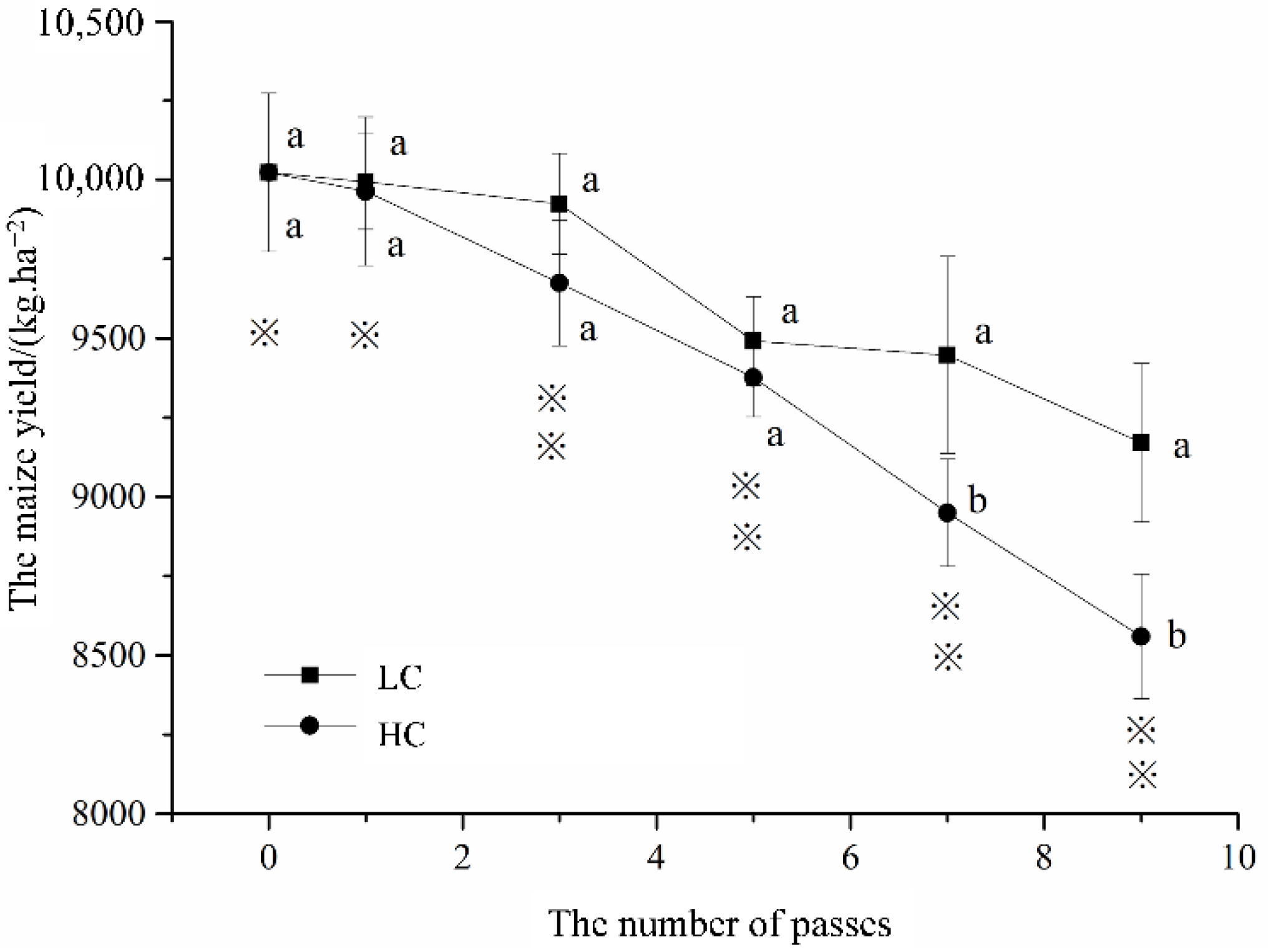

3.3.4. Effects of Soil Compaction on Maize Yield

4. Discussion

4.1. Effect of Tire Compaction on Soil Stress Distribution

4.2. Effect of Tire Compaction on Soil Bulk Density

4.3. The Effect of Tire Compaction on Crop Growth

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- He, C.; Wang, Y.-Q.; Yu, W.-B.; Kou, Y.-H.; N’dri Yves, B.; Zhao, X.; Zhang, H.-L. Comprehensive analysis of resource utilization efficiency under different tillage systems in North China Plain. J. Clean. Prod. 2022, 347, 131289. [Google Scholar] [CrossRef]

- Shaheb, R.; Ramarao, V.; Scott, A.S. A Review on the Effect of Soil Compaction and its Management for Sustainable Crop Production. J. Biosyst. Eng. 2021, 46, 417–439. [Google Scholar] [CrossRef]

- Richard, W.; Birl, L. Soil Compaction: Causes, Concerns, and Cures. 2008. Available online: https://soilsextension.qa.webhosting.cals.wisc.edu/wp-content/uploads/sites/68/2014/02/A3367.pdf (accessed on 15 August 2018).

- Kumar, V.; Jain, M.; Rani, V.; Kumar, A.; Kumar, S.; Naresh, J. A Review of Soil Compaction—Concerns, Causes and Alleviation. Int. J. Plant Soil Sci. 2008, 22, 1–9. [Google Scholar] [CrossRef]

- Nawaz, M.F.; Bourrié, G.; Trolard, F. Soil Compaction Impact and Modelling. A Review. Agron. Sustain. Dev. 2013, 33, 291–309. [Google Scholar] [CrossRef]

- Peter, B.O.; Ugarte, C.M. A meta-analysis of the impact of traffic-induced compaction on soil physical properties and grain yield. Soil Tillage Res. 2021, 211, 105019. [Google Scholar] [CrossRef]

- Gao, A.; Han, Z.; Wu, J. Experimental research on alfalfa soil compaction by mowing machine. Trans. CSAE 2007, 23, 101–105. [Google Scholar] [CrossRef]

- Li, R.; Lin, C.; Gao, H. Analysis of variances caused by agricultural machines for soil compaction. Agric. Mech. Res. 2001, 3, 84–87. [Google Scholar] [CrossRef]

- Gysi, M.; Fluhler, O.A. Influence of Single Passes with High Wheel Load on a Structured, Unploughed Sandy Loam Soil. Soil Tillage Res. 1999, 52, 141–151. [Google Scholar] [CrossRef]

- Schjønning, P.; Lamandé, M.; Tøgersen, F.A.; Arvidsson, J.; Keller, T. Modelling Effects of Tyre Inflation Pressure on the Stress Distribution Near the Soil–Tyre Interface. Biosyst. Eng. 2008, 99, 119–133. [Google Scholar] [CrossRef]

- Lamandé, M.; Schjønning, P. Transmission of Vertical Stress in a Real Soil Profile. Part Ii: Effect of Tyre Size, Inflation Pressure and Wheel Load. Soil Tillage Res. 2011, 114, 71–77. [Google Scholar] [CrossRef]

- Abebe, T.A.; Tanaka, T.; Yamaza, M. Soil Compaction by Multiple Passes of a Rigid Wheel Relevant for Optimization of Traffic. J. Terramechanics 1989, 26, 139–148. [Google Scholar] [CrossRef]

- Arvidsson, J.; Trautner, A.; Akker, J.J.; Schjønning, P. Subsoil Compaction Caused by Heavy Sugarbeet Harvesters in Southern Sweden. I. Soil Physical Properties and Crop Yield in Six Field Experiments. Soil Tillage Res. 2001, 60, 67–78. [Google Scholar] [CrossRef]

- Zhang, J.; Fu, W.; Ma, H. The Soil Compactive Characteristics and Their Application in Agricultural Production. Trans. CSAE 1995, 2, 17–20. [Google Scholar]

- Castioni, G.A.F.; de Lima, R.P.; Cherubin, M.R.; Bordonal, R.O.; Rolim, M.M.; Carnvalho, J.L.N. Machinery traffic in sugarcane straw removal operation: Stress transmitted and soil compaction. Soil Tillage Res. 2021, 213, 105122. [Google Scholar] [CrossRef]

- Liu, K.; Zhou, Q.; Wu, W. Comparison between multispectral and hyperspectral remote sensing for LAI estimation. Trans. Chin. Soc. Agric. Eng. 2016, 3, 155–162. [Google Scholar]

- Hamza, M.A.; Anderson, W.K. Soil Compaction in Cropping Systems a Review of the Nature, Causes and Possible Solutions. Soil Tillage Res. 2005, 82, 121–145. [Google Scholar] [CrossRef]

- Shaheb, M.R. A study on the Effect of Tyre Inflation Pressure on Soil Properties, Growth and Yield of Maize and Soybean in Central Illinois. Ph.D. Thesis, Harper Adams University, New Port, UK, 2020. [Google Scholar]

- Kirby, J.M.; Bengough, A.G. Influence of Soil Strength on Root Growth: Experiments and Analysis Using a Critical-State Model. Eur. J. Soil Sci. 2002, 53, 119–127. [Google Scholar] [CrossRef]

- Kristoffersen, A.O.; Riley, H. Effects of Soil Compaction and Moisture Regime on the Root and Shoot Growth and Phosphorus Uptake of Barley Plants Growing on Soils with Varying Phosphorus Status. Nutr. Cycl. Agroecosys. 2005, 72, 135–146. [Google Scholar] [CrossRef]

- Gerard, C.J.; Sexton, P.; Shaw, G. Physical Factors Influencing Soil Strength and Root Growth. Agron. J. 1982, 74, 875–879. [Google Scholar] [CrossRef]

- Guillermo, P.; Carina, R.A.; Miguel, Á.T. Soil compaction alleviation by deep non-inversion tillage and crop yield responses in no tilled soils of the Pampas region of Argentina. A meta-analysis. Soil Tillage Res. 2021, 211, 105022. [Google Scholar]

- Cid, P.; Carmona, I.; Murillo, J.M.; Gomez-Macpherson, H. No-Tillage Permanent Bed Planting and Controlled Traffic in a Maize-Cotton Irrigated System Under Mediterranean Conditions: Effects on Soil Compaction, Crop Performance and Carbon Sequestration. Eur. J. Agron. 2014, 61, 24–34. [Google Scholar] [CrossRef]

- Bouwman, L.; Arts, W.B.M. Effects of Soil Compaction on the Relationships Between Nematodes, Grass Production and Soil Physical Properties. Appl. Soil Ecol. 2000, 14, 213–222. [Google Scholar] [CrossRef]

- Botta, G.; Jorajurida, D.; Rosatto, H.; Ferrero, C. Light Tractor Traffic Frequency on Soil Compaction in the Rolling Pampa Region of Argentina. Soil Tillage Res. 2006, 86, 9–14. [Google Scholar] [CrossRef]

- Liu, X.; Liu, H.; Ren, D.; Liu, C.; Zhang, Y.; Wang, S.; Li, Z.; Zhang, M. Interlinkages between soil properties and keystone taxa under different tillage practices on the North China Plain. Appl. Soil Ecol. 2022, 178, 104551. [Google Scholar] [CrossRef]

- Hu, R.; Liu, Y.; Chen, T. Responses of soil aggregates, organic carbon, and crop yield to short-term intermittent deep tillage in Southern China. J. Clean. Prod. 2021, 298, 126767. [Google Scholar] [CrossRef]

- Zhang, H.; Shi, Y.; Dong, Y.; Lapen, D.R.; Liu, J.; Chen, W. Subsoiling and conversion to conservation tillage enriched nitrogen cycling bacterial communities in sandy soils under long-term maize monoculture. Soil Tillage Res. 2022, 215, 105197. [Google Scholar] [CrossRef]

- Wang, X. Study on the Evaluation of Soil Compaction by Agricultural Tire and Combination Shovel Loose Soil Technology. Master’s Thesis, China Agricultural University, Beijing, China, 2018. [Google Scholar]

- Yang, W.; Lan, H.; Li, M.; Meng, C. Prediction of Top Soil Layer Bulk Density Based on Image Processing and Gradient Boosting Regression Tree Model. Trans. Chin. Soc. Agric. Mach. 2020, 51, 193–200. [Google Scholar] [CrossRef]

- Lamande, M.; Schjønning, P.; Frede, A. Mechanical behaviour of an undisturbed soil subjected to loadings: Effects of load and contact area. Soil Tillage Res. 2007, 97, 91–106. [Google Scholar] [CrossRef]

- Keller, T.; Berli, M.; Ruiz, S. Transmission of vertical soil stress under agricultural tyres: Comparing measurements with simulations. Soil Tillage Res. 2014, 140, 106–117. [Google Scholar] [CrossRef]

- Cui, Z. Experimental Study on the Effects of Water-Saving Irrigation on Soil Water Salt and Nitrogen Dynamics and Maize Growth Yield. Master’s Thesis, China Agricultural University, Beijing, China, 2017. [Google Scholar]

- Cai, M. Effects of Water Deficit and Mulching on the Growth and Yield of Drip Maize in Chifeng Area. Master’s Thesis, China Agricultural University, Beijing, China, 2017. [Google Scholar]

- Lian, J. Distribution of Roots of Maize and Their Effects on Soil Physical Properties. Master’s Thesis, Northwest A&F University, Xiangyang, China, 2013. [Google Scholar]

- Hu, H. Design and Research of Targeted Hole-pricking and Deep-application Fertilizer Applicator between Maize Rows. Master’s Thesis, China Agricultural University, Beijing, China, 2017. [Google Scholar]

- Reichert, J.M.; Suzuki, L.E.A.S.; Reinert, D.J. Reference Bulk Density and Critical Degree-of-Compactness for No-Till Crop Production in Subtropical Highly Weathered Soils. Soil Tillage Res. 2009, 102, 242–254. [Google Scholar] [CrossRef]

- Arvidsson, J.; Håkansson, I. Response of Different Crops to Soil Compaction—Short-Term Effects in Swedish Field Experiments. Soil Tillage Res. 2014, 138, 56–63. [Google Scholar] [CrossRef]

- Jan, D.; Puea, M.L.; Wim, C. DEM simulation of stress transmission under agricultural traffic Part 2: Shear stress at the tyre-soil interface. Soil Tillage Res. 2020, 203, 104660. [Google Scholar] [CrossRef]

- Holthusena, D.; Anibal, A.; Reichert, M.; Horn, R. Soil porosity, permeability and static and dynamic strength parameters under native forest/grassland compared to no-tillage cropping. Soil Tillage Res. 2018, 177, 113–124. [Google Scholar] [CrossRef]

- Damme, L.; Stettler, M.; Pinet, M.; Vervaet, P.; Keller, T.; Munkholm, L.J.; Lamande, M. The contribution of tire evolution to the reduction of soil compaction risks. Soil Tillage Res. 2019, 194, 104283. [Google Scholar] [CrossRef]

- Taghavifar, H.; Mardani, A. Effect of Velocity, Wheel Load and Multipass on Soil Compaction. J. Saudi Soc. Agric. Sci. 2014, 13, 57–66. [Google Scholar] [CrossRef]

- Patel, S.K.; Mani, I. Effect of Multiple Passes of Tractor with Varying Normal Load on Subsoil Compaction. J. Terramech. 2011, 48, 277–284. [Google Scholar] [CrossRef]

- Botta, G.F.; Tolón-Becerra, A.; Rivero, D.; Laureda, D.; Ramirez-Roman, M.; Lastra-Bravo, X.; Agnes, D.; Flores-Parra, I.M.; Pelizzari, F.; Martiren, V. Compaction Produced by Combine Harvest Traffic: Effect on Soil and Soybean (Glycine max L.) Yields Under Direct Sowing in Argentinean Pampas. Eur. J. Agron. 2016, 74, 155–163. [Google Scholar] [CrossRef]

- Rücknagel, J.; Hofmann, B.; Deumelandt, P.; Reinicke, F.; Bauhardt, J.; Hulsbergen, K.-J. Indicator Based Assessment of the Soil Compaction Risk at Arable Sites Using the Model Repro. Ecol. Indic. 2015, 52, 341–352. [Google Scholar] [CrossRef]

- Arvidsson, J.; Hakansson, I. Do Effects of Soil Compaction Persist After Ploughing? Results from 21 Long-Term Field Experiments in Sweden. Soil Tillage Res. 1996, 39, 175–197. [Google Scholar] [CrossRef]

- Czyż, E.A. Effects of Traffic on Soil Aeration, Bulk Density and Growth of Spring Barley. Soil Tillage Res. 2004, 79, 153–166. [Google Scholar] [CrossRef]

- Li, D.; Gao, X.; Wang, D. Study on the effects of compaction on soil physical properties and crop emergence. Soils Fertil. Sci. China 1981, 5–6. [Google Scholar]

- Mari, G.R.; Ji, Y.; Zhou, J. Effect of different types of tractor traffic on soil physical properties and yield of winter wheat. Trans. CSAE 2007, 23, 132–140. [Google Scholar] [CrossRef]

| Soil Depth | Soil Type | Soil Texture/% | Weight Capacity/(g cm−3) | Organic Matter/(g kg−1) | pH Value | ||

|---|---|---|---|---|---|---|---|

| <0.002 mm | ≥0.002~0.02 mm | ≥0.02~2 mm | |||||

| 0~20 | Loamy soil | 10.6 | 40.1 | 49.3 | 1.22 | 11.5 | 7.6 |

| 20~40 | Loamy soil | 14.9 | 33.9 | 51.2 | 1.33 | 5.4 | 7.9 |

| 40~60 | Sandy loam soil | 9.8 | 32.8 | 57.4 | 1.42 | 5.1 | 7.5 |

| 60~80 | Sandy loam soil | 7.7 | 25.2 | 67.1 | 1.58 | 3.8 | 7.8 |

| Test Setup | Mass/kg | Tire Type | Axle-Load/kN | Tire Section Width/mm | Tire Pressure/kPa | Tire–Soil Contact Area/m2 | Contact Surface Stress/kPa | |

|---|---|---|---|---|---|---|---|---|

| John Deer 280 (LC) | 1225 | Front Wheel | 6.00–16 (R-1) | 5.75 | 152.4 | 150 | 0.036 | 160.4 |

| Rear Wheel | 9.5–24 (R-1) | 6.5 | 241.3 | 115 | 0.089 | 72.8 | ||

| LOVOLM904 (HC) | 4155 | Front Wheel | 12.4–24 | 20 | 315 | 85 | 0.15 | 133.3 |

| Rear Wheel | 16.9–34 | 21 | 430 | 100 | 0.339 | 61.9 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; He, J.; Bai, M.; Liu, L.; Gao, S.; Chen, K.; Zhuang, H. The Impact of Traffic-Induced Compaction on Soil Bulk Density, Soil Stress Distribution and Key Growth Indicators of Maize in North China Plain. Agriculture 2022, 12, 1220. https://doi.org/10.3390/agriculture12081220

Wang X, He J, Bai M, Liu L, Gao S, Chen K, Zhuang H. The Impact of Traffic-Induced Compaction on Soil Bulk Density, Soil Stress Distribution and Key Growth Indicators of Maize in North China Plain. Agriculture. 2022; 12(8):1220. https://doi.org/10.3390/agriculture12081220

Chicago/Turabian StyleWang, Xianliang, Jin He, Mingyue Bai, Lei Liu, Shang Gao, Kun Chen, and Haiyang Zhuang. 2022. "The Impact of Traffic-Induced Compaction on Soil Bulk Density, Soil Stress Distribution and Key Growth Indicators of Maize in North China Plain" Agriculture 12, no. 8: 1220. https://doi.org/10.3390/agriculture12081220

APA StyleWang, X., He, J., Bai, M., Liu, L., Gao, S., Chen, K., & Zhuang, H. (2022). The Impact of Traffic-Induced Compaction on Soil Bulk Density, Soil Stress Distribution and Key Growth Indicators of Maize in North China Plain. Agriculture, 12(8), 1220. https://doi.org/10.3390/agriculture12081220