An Overview of End Effectors in Agricultural Robotic Harvesting Systems

Abstract

:1. Introduction

- The examination of recent works from 2016 up to date. In [7], reported research spans from 1987 to 2017, including only three reviewed research papers after 2016.

- The examination of end effectors developed for ground harvesting applications and for UAV harvesting systems. UAV manipulation systems were revised in [9]; however, the emphasis was on grasping and picking tasks rather than on mounted end effectors targeted for aerial harvesting operations.

- The evaluation of end effectors in real-world harvesting applications. In [11], the focus is on fresh market fruit picking rather than on harvesting end effectors, and consequently, no in-field evaluation performance of the revised end effectors is provided.

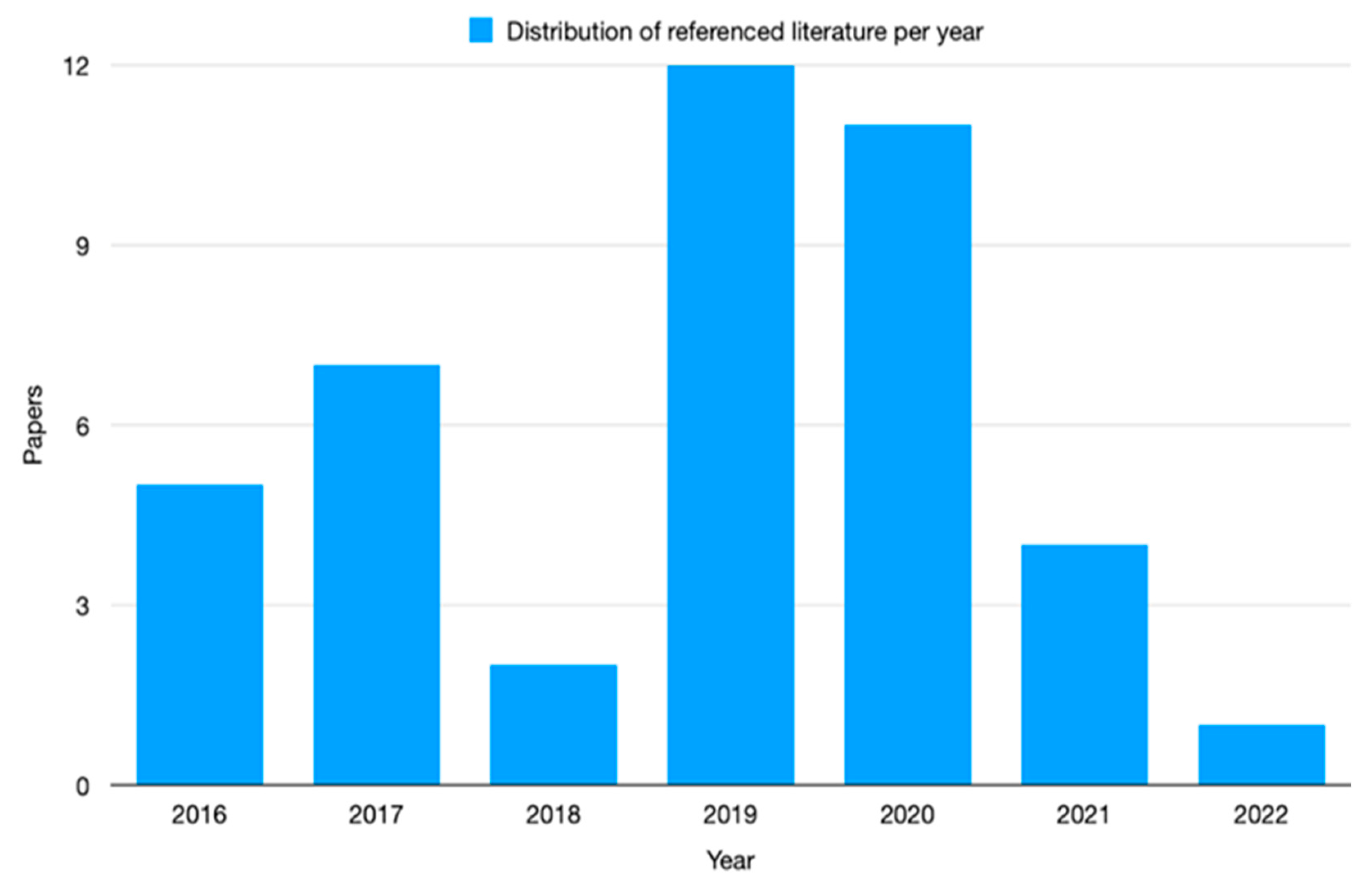

2. Materials and Methods

- Extensive literature research. It has been suggested that in all areas, Google Scholar citation data are a superset of Web of Science and Scopus, with significant extra coverage [13]. Therefore, the database of Google Scholar was selected as the source of the literature for the scope of this review article. Combinations of keywords, such as “end-effector”, “harvesting robot”, and “manipulation”, were applied for the initial research.

- All extracted papers were reviewed for their relevance to the subject. The papers that did not provide information regarding the in-field used end effectors were excluded.

- The third step of the method included examination of the references in the papers of step 2, towards a more thorough review.

- In the final step, all research papers dated up to 2015 were excluded from the research, keeping the recent literature from 2016 to date.

3. End Effectors in Agricultural Robotic Harvesting Systems

3.1. Detachment Methods

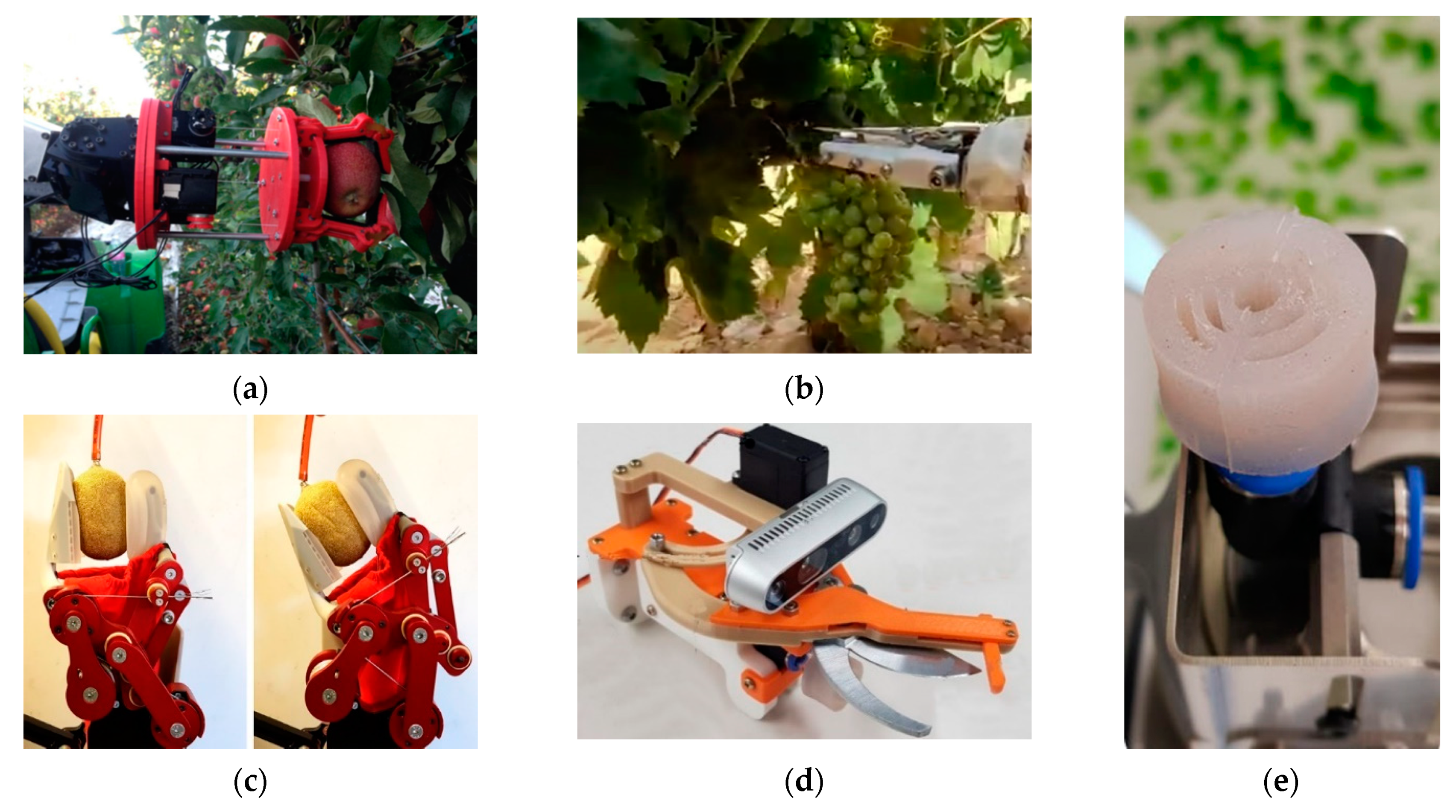

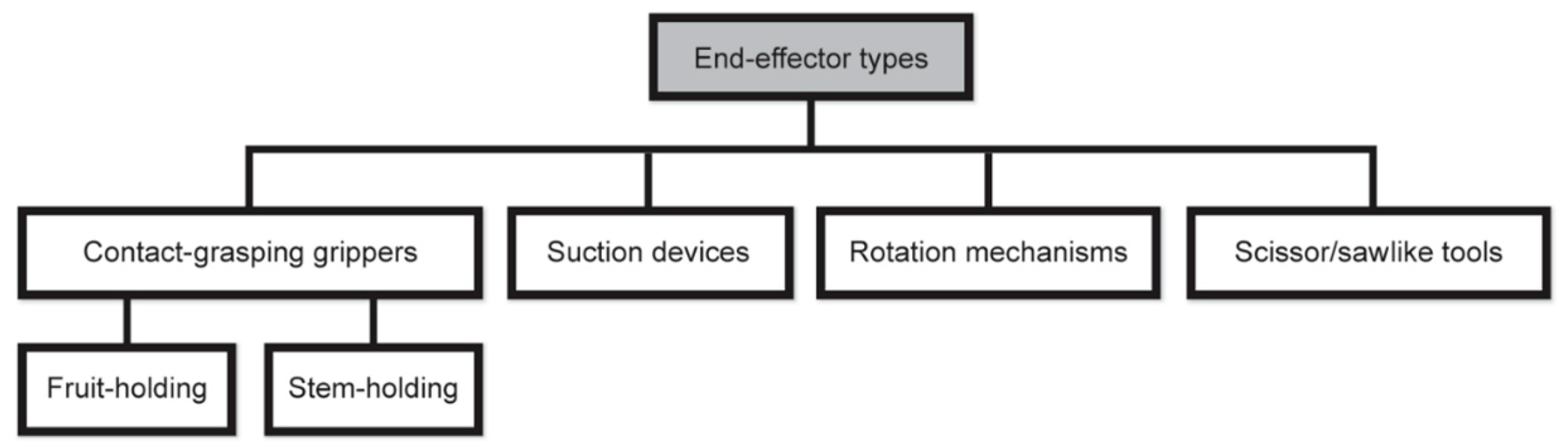

3.2. End-Effector Types

3.3. Additional Sensors

3.4. Operating Requirements for Agricultural End Effectors

- The maximum load they can lift. This load ranges from a few tens of grams up to a few kilograms depending on the weight of the fruit. It should be clarified that it is not enough to consider only the end effector’s load capacity, but also the robotic system’s load capacity on which the end effector is mounted on. In addition, depending on how the product is detached (e.g., suction, rotation, or cut), this maximum load should be increased so that the additional forces required for the fruit’s detachment could be applied for the final detachment of the harvested product from a branch on which it is usually connected [44].

- The power exerted by the mechanism. To hold the product before it is removed from the branch, an appropriate force should be applied, which should not deform the product. In this case, depending on the product, the end effector may have sensors that control the applied force or have properly configured fingers with soft interior surfaces for holding smoothly agricultural products. In the former case, continuous control of the applied forces with the help of appropriate algorithms is required, whereas in the latter case, no sensors are often required, and end effectors have smaller control problems [8,45].

- The geometry and dimensions of the end effectors directly related to the geometry and dimensions of the products collected each time. Depending on the product, fingers with different geometries and dimensions can be adapted to the same gripper to serve this purpose [46].

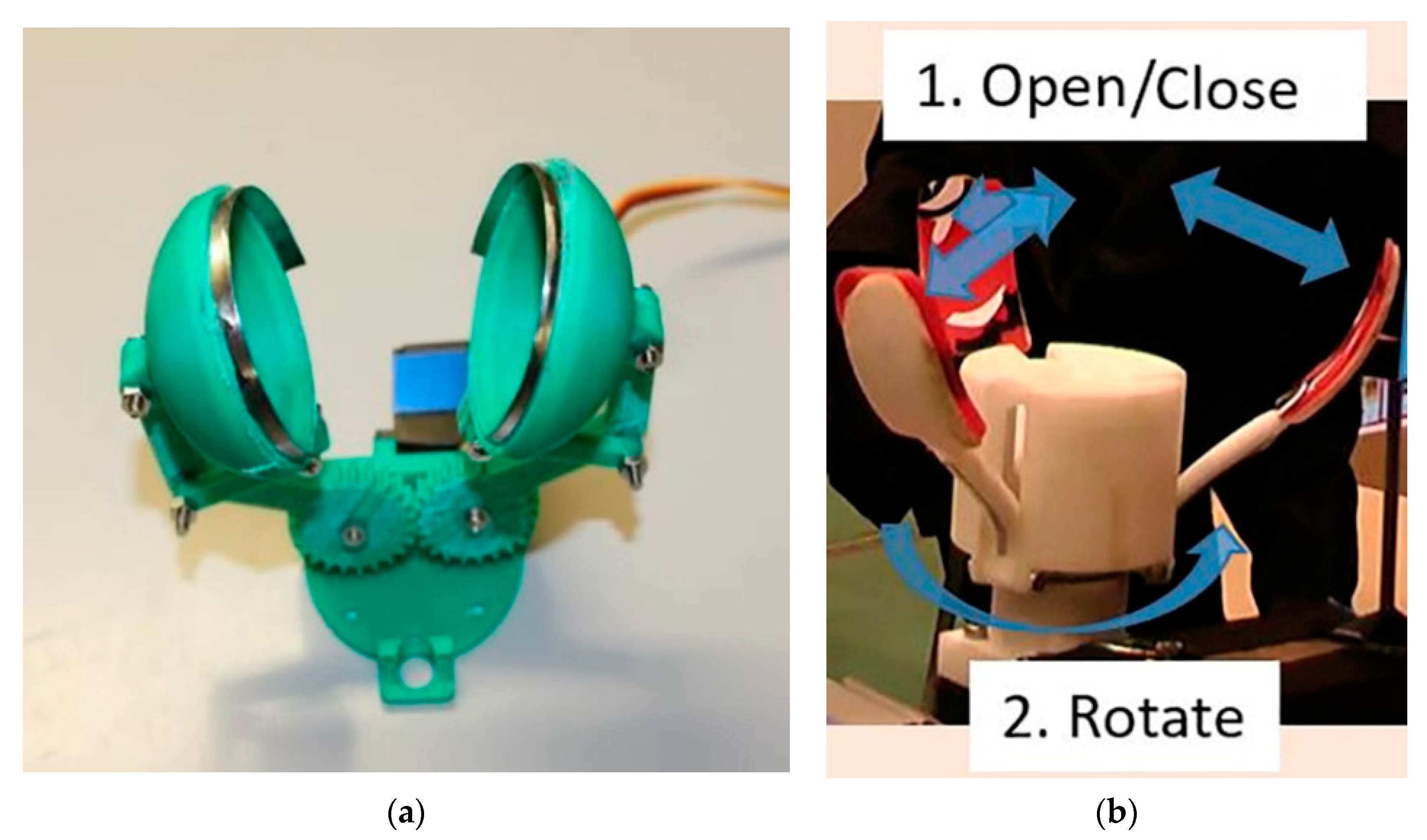

- The type of movement to perform a particular task. In most cases of end effectors for the harvesting of agricultural products, the movement of the gripper is limited to opening and closing operations. However, the trajectory of the robotic system should be properly planned so that the end effector can approach, catch, and hold the product and remove it from the branch, for example, by moving towards a specific direction and orientation and by employing a rotational movement until the product is detached or cut off with the help of an appropriate cutting mechanism [47].

- The type of actuators required. Most end effectors are based on electric actuators that permit accurate control. The required power is small (some watts or a few dozens of watts), so it could be provided by the moving robotic system on which they are mounted. However, in recent years, implementations with soft actuators have appeared that allow the handling of sensitive products with much higher safety and less manufacturing costs. These actuators mainly operate with air and only limited by the accuracy of their movement and control [48].

- The time of action completing a movement to harvest a product. The end effector, depending on its complexity (e.g., use of sensors, control software, etc.) requires some time to complete a processing cycle of holding and detaching the harvested fruit from the crop. This picking time concerns: (a) the time to detect the fruit with the help of a detection system, which in most cases is a vision system with one camera (monocular), stereoscopic camera, or 3D camera; (b) the design of the trajectory that the robotic system should follow toward the desired goal; (c) the navigation to the desired goal; (d) the time required to grasp the product; (e) the detachment of the fruit from the branch; and (f) the transfer of the harvested product to a predetermined collection location. The grasping time of an end effector may be in the range of a few tenths of a second to a few seconds [7].

- The characteristics of contact with the product. Depending on the type of product, as mentioned above, the final configuration of the fingers of the end effector should be carefully determined. If the product is very sensitive, such as a strawberry, then the fingers should have soft surfaces and additional force or pressure sensors to regulate the holding force. If the product has medium hardness, such as an apple, then the use of only soft surfaces on the fingers (and control of the power with the current in the actuator–electric grippers) is generally sufficient to hold without damaging the product. To hold a product from the stem and detach it with an appropriate stem-cutting mechanism, such as in grape harvest, no sensors or control approaches are required [10].

- The tolerances and accuracy of the system. The end effector and the robotic navigation system towards the desired goal should at all times have the required precision so that the target could be detected and approached accurately. If the robotic system does not have the required accuracy by construction, then accuracy improvement techniques should be developed and applied as the end effector approaches the final target, for example, with the sensory feedback of a vision system mounted on the end effector and a visual servoing application [49].

3.5. Basic Agricultural End-Effector Development Principles

3.5.1. Research and Requirements

- Bibliography. Research in the bibliography is the first step toward effective end-effector development. First, traditional manual harvesting and selective harvesting methods need to be reviewed. Selective harvesting is the segmented picking of a fruit at harvest based on different yield or quality criteria in order to exploit any observed variations [50]. By studying the human hand patterns, imitation detachment techniques and appropriate tools could be developed. Research on automation and end effectors used can also provide useful insights; a detailed design and evaluation of end-effector systems could be used as a guide for system development, modification, or improvement toward enhancing performance.

- Functional and nonfunctional requirements. According to the study of the bibliography, the system requirements need to be extracted. System requirements that need to be addressed, summarized in Section 3.4, include the maximum payload, grip force, geometry, and dimensions of the end effector in relation to the harvesting product, type of harvesting movement, type of actuators, picking time, detachment method, definition of product contact surface, material selection, tolerance, and accuracy of the system.

- Evaluation based on requirements. Evaluation of the development process and cost estimation is essential after specifying the operational requirements so as to ensure that the proposed design idea is feasible to fabricate and cost-effective.

3.5.2. Design

- Hardware design. The study and selection of all hardware components and materials takes place, such as plastics, metals, motors, cutters, and all the remaining necessary mechanical components, sensors, batteries, and so on. The design of necessary components with the help of known computer-aided design (CAD) software applications (AutoCAD, SolidWorks, FreeCAD, etc.) follows. The way that the hardware will be connected, installed, and assembled and the design of appropriate driving and control electronic circuits for all devices (schematic and printed circuit board (PCB) design) are also included. Energy and payload requirements also need to be considered.

- Software design. For effective control of the end-effector system, driving algorithms, navigation, and control strategies based on software engineering principles need to be developed. Unified Modeling Language (UML) diagrams could be used for the visual representation of the system design. Effective data—as well as knowledge—representations should also be considered.

- System simulation. End-effector manufacturers try hard to realize true system performance until it is too late in the design process; mechanical and electrical subsystems need to be validated against the identified requirements. However, testing and validation of the entire system is usually delayed, leading to potential redesign or changes to the initial design of the end effector, which is costly, time-consuming, and risky. In order to improve engineering efficiency and reduce product development challenges, early system design validation is considered necessary, enabled by simulation. In this phase, if the appropriate software tools exist (for example, Robot Operating System (ROS), Gazebo simulation suite), a virtual model of the end-effector system can be constructed (e.g., a Unified Robot Description Format (URDF) file), and the operation of the end effector can be evaluated in a simulation environment. In ROS, with the help of the Gazebo simulation environment, an important number of parameters can be tested. For example, in the simulated environment, simulated sensors’ values can be read, and simulated actuators can change their state depending on sensor values. Contacts, forces implemented, torques, pressures, light variation, and so on, as responses of sensors, change the state as well as the behavior of the end effector. However, if an extensive analysis of the end-effector operation is required, more specific simulation applications are adopted. For example, Adams and Simulia multibody dynamic simulation environments can evaluate and manage the complex interactions of a system, including motion, structures, actuation, and controls, to better optimize product designs for performance and safety.

3.5.3. Prototype Development

3.5.4. Testing

- Testing of the prototype system. The evaluation of fabrication time and estimation of the final cost of the prototype is required. The testing of the effectiveness of the prototype through an experimental procedure; recording of material behavior, applied forces, payload, pressure control, energy requirements, sensory feedback, control algorithm performance, and so on; and measurement of selected performance metrics (damage rate, picking time, etc.).

- Optimization and fine-tuning. Optimization of the design of the end effector, re-experimentation and measurement of performance metrics, decision on an acceptable minimum/maximum performance for the prototype so as to be considered potentially viable are suggested. If the required changes are significant, then a new full cycle is repeated (design, prototype development, and testing).

- Alternative designs and comparison. Prototype development, evaluation, and optimization of alternative end-effector designs toward comparison and final selection.

4. Applications of End Effectors in Agricultural Robotic Harvesting Systems

4.1. Ground Harvesting End Effectors

4.1.1. Heavy Crops

4.1.2. Tomatoes

4.1.3. Strawberries

4.1.4. Apples

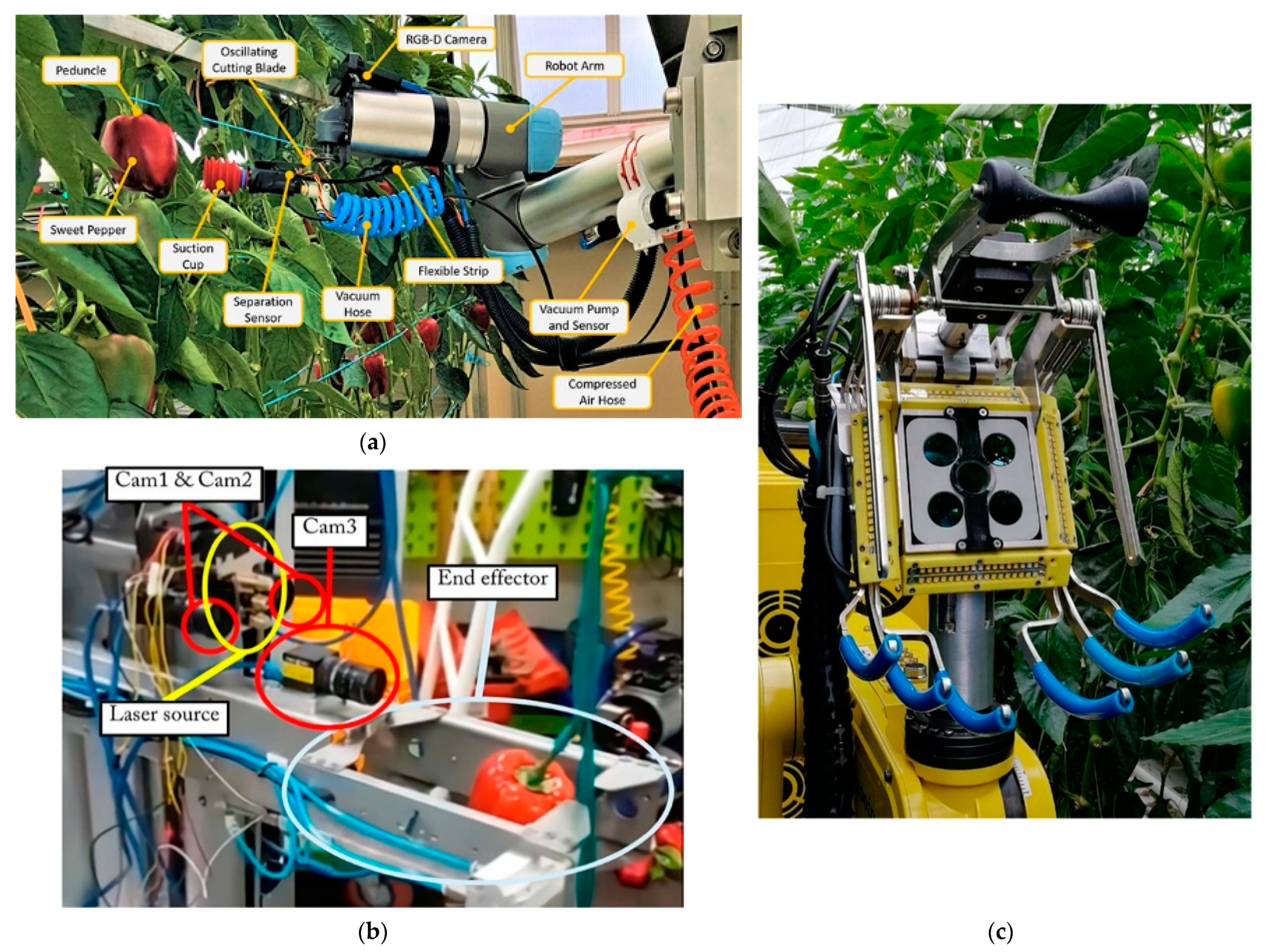

4.1.5. Sweet Peppers

4.1.6. Kiwifruits

4.1.7. Other Agricultural Products

4.2. Aerial Harvesting End Effectors

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- United Nations Department of Economics and Social Affairs. Population Dynamics World Population Prospects; United Nations: San Francisco, CA, USA, 2019. [Google Scholar]

- Berners-Lee, M.; Kennelly, C.; Watson, R.; Hewitt, C.N. Current global food production is sufficient to meet human nutritional needs in 2050 provided there is radical societal adaptation. Elem. Sci. Anthr. 2018, 6, 52. [Google Scholar] [CrossRef]

- Sharma, D.; Malhotra, H.; Mittal, R. Post-harvest Management Practice (PHMP): A Systematic Program to Attain Food Security. In Sustainable Agriculture for Food Security; Apple Academic Press: New York, NY, USA, 2021; pp. 179–207. [Google Scholar]

- Oliveira, L.F.P.; Moreira, A.P.; Silva, M.F. Advances in Agriculture Robotics: A State-of-the-Art Review and Challenges Ahead. Robotics 2021, 10, 52. [Google Scholar] [CrossRef]

- Morar, C.A.; Doroftei, I.A.; Doroftei, I.; Hagan, M.G. Robotic applications on agricultural industry. A review. IOP Conf. Ser. Mater. Sci. Eng. 2020, 997, 012081. [Google Scholar] [CrossRef]

- Arikapudi, R.; Vougioukas, S.G. Robotic Tree-Fruit Harvesting With Telescoping Arms: A Study of Linear Fruit Reachability Under Geometric Constraints. IEEE Access 2021, 9, 17114–17126. [Google Scholar] [CrossRef]

- Davidson, J.; Bhusal, S.; Mo, C.; Karkee, M.; Zhang, Q. Robotic Manipulation for Specialty Crop Harvesting: A Review of Manipulator and End-Effector Technologies. Glob. J. Agric. Allied Sci. 2020, 2, 25–41. [Google Scholar] [CrossRef]

- Navas, E.; Fernández, R.; Sepúlveda, D.; Armada, M.; Gonzalez-de-Santos, P. Soft Grippers for Automatic Crop Harvesting: A Review. Sensors 2021, 21, 2689. [Google Scholar] [CrossRef]

- Mohiuddin, A.; Tarek, T.; Zweiri, Y.; Gan, D. A Survey of Single and Multi-UAV Aerial Manipulation. Unmanned Syst. 2020, 08, 119–147. [Google Scholar] [CrossRef]

- Tinoco, V.; Silva, M.F.; Santos, F.N.; Rocha, L.F.; Magalhaes, S.; Santos, L.C. A Review of Pruning and Harvesting Manipulators. In Proceedings of the 2021 IEEE International Conference on Autonomous Robot Systems and Competitions (ICARSC), Santa Maria da Feira, Portugal, 28–29 April 2021; pp. 155–160. [Google Scholar]

- Feng, Q. End-Effector Technologies. In Agriculture Automation and Control; Spinger: Berlin/Heidelberg, Germany, 2021; pp. 191–212. [Google Scholar]

- Zhang, B.; Xie, Y.; Zhou, J.; Wang, K.; Zhang, Z. State-of-the-art robotic grippers, grasping and control strategies, as well as their applications in agricultural robots: A review. Comput. Electron. Agric. 2020, 177, 105694. [Google Scholar] [CrossRef]

- Martín-Martín, A.; Orduna-Malea, E.; Thelwall, M.; Delgado López-Cózar, E. Google Scholar, Web of Science, and Scopus: A systematic comparison of citations in 252 subject categories. J. Informetr. 2018, 12, 1160–1177. [Google Scholar] [CrossRef]

- Láng, Z. A simple model for fruit tree shaking harvest. Int. J. Hortic. Sci. 2007, 13, 33–36. [Google Scholar] [CrossRef]

- Fantoni, G.; Santochi, M.; Dini, G.; Tracht, K.; Scholz-Reiter, B.; Fleischer, J.; Kristoffer Lien, T.; Seliger, G.; Reinhart, G.; Franke, J.; et al. Grasping devices and methods in automated production processes. CIRP Ann. 2014, 63, 679–701. [Google Scholar] [CrossRef]

- Taqi, F.; Al-Langawi, F.; Abdulraheem, H.; El-Abd, M. A cherry-tomato harvesting robot. In Proceedings of the 2017 18th International Conference on Advanced Robotics (ICAR), Hong Kong, China, 10–12 July 2017; pp. 463–468. [Google Scholar]

- Tejada, V.F.; Stoelen, M.F.; Kusnierek, K.; Heiberg, N.; Korsaeth, A. Proof-of-concept robot platform for exploring automated harvesting of sugar snap peas. Precis. Agric. 2017, 18, 952–972. [Google Scholar] [CrossRef]

- Yeshmukhametov, A.; Koganezawa, K.; Buribayev, Z.; Amirgaliyev, Y.; Yamamoto, Y. Development of Continuum Robot Arm and Gripper for Harvesting Cherry Tomatoes. Appl. Sci. 2022, 12, 6922. [Google Scholar] [CrossRef]

- Bac, C.W.; Hemming, J.; van Tuijl, B.A.J.; Barth, R.; Wais, E.; van Henten, E.J. Performance Evaluation of a Harvesting Robot for Sweet Pepper. J. Field Robot. 2017, 34, 1123–1139. [Google Scholar] [CrossRef]

- Williams, H.A.M.; Jones, M.H.; Nejati, M.; Seabright, M.J.; Bell, J.; Penhall, N.D.; Barnett, J.J.; Duke, M.D.; Scarfe, A.J.; Ahn, H.S.; et al. Robotic kiwifruit harvesting using machine vision, convolutional neural networks, and robotic arms. Biosyst. Eng. 2019, 181, 140–156. [Google Scholar] [CrossRef]

- Vu, Q.; Ronzhin, A. A. A Model of Four-Finger Gripper with a Built-in Vacuum Suction Nozzle for Harvesting Tomatoes. In Smart Innovation, Systems and Technologies; Spinger: Berlin/Heidelberg, Germany, 2020; pp. 149–160. ISBN 9789811392665. [Google Scholar]

- Silwal, A.; Davidson, J.R.; Karkee, M.; Mo, C.; Zhang, Q.; Lewis, K. Design, integration, and field evaluation of a robotic apple harvester. J. Field Robot. 2017, 34, 1140–1159. [Google Scholar] [CrossRef]

- Vrochidou, E.; Tziridis, K.; Nikolaou, A.; Kalampokas, T.; Papakostas, G.A.; Pachidis, T.P.; Mamalis, S.; Koundouras, S.; Kaburlasos, V.G. An Autonomous Grape-Harvester Robot: Integrated System Architecture. Electronics 2021, 10, 1056. [Google Scholar] [CrossRef]

- Jun, J.; Kim, J.; Seol, J.; Kim, J.; Son, H. Il Towards an Efficient Tomato Harvesting Robot: 3D Perception, Manipulation, and End-Effector. IEEE Access 2021, 9, 17631–17640. [Google Scholar] [CrossRef]

- Li, S.; Stampfli, J.J.; Xu, H.J.; Malkin, E.; Diaz, E.V.; Rus, D.; Wood, R.J. A Vacuum-driven Origami “Magic-ball” Soft Gripper. In Proceedings of the 2019 International Conference on Robotics and Automation (ICRA), Montreal, QC, Canada, 20–24 May 2019; pp. 7401–7408. [Google Scholar]

- Monkman, G.J.; Hesse, S.; Steinmann, R.; Schunk, H. Robot Grippers; Wiley: New York, NY, USA, 2006; ISBN 9783527406197. [Google Scholar]

- Mao, Y.; Yuan, S.; Wang, J.; Zhang, J.; Song, S. Modeling and Control of an Untethered Magnetic Gripper. In Proceedings of the 2021 IEEE International Conference on Robotics and Automation (ICRA), Xi′an, China, 30 May–5 June 2021; pp. 7274–7280. [Google Scholar]

- Kim, Y.; Cha, Y. Soft Pneumatic Gripper With a Tendon-Driven Soft Origami Pump. Front. Bioeng. Biotechnol. 2020, 8, 461. [Google Scholar] [CrossRef]

- Chin, L.; Yuen, M.C.; Lipton, J.; Trueba, L.H.; Kramer-Bottiglio, R.; Rus, D. A Simple Electric Soft Robotic Gripper with High-Deformation Haptic Feedback. In Proceedings of the 2019 International Conference on Robotics and Automation (ICRA), Montreal, QC, Canada, 20–24 May 2019; pp. 2765–2771. [Google Scholar]

- Șerdean, M.; Șerdean, F.; Mândru, D. An Overview of Grippers in Agriculture Robotic Systems. In Mechanisms and Machine Science; Spinger: Berlin/Heidelberg, Germany, 2021; pp. 212–225. [Google Scholar]

- Wolf, A.; Schunk, H. Grippers in Motion. In Grippers in Motion; Carl Hanser Verlag GmbH & Co. KG: München, Germany, 2018; pp. 1–13. [Google Scholar]

- Davidson, J.R.; Hohimer, C.J.; Mo, C.; Karkee, M. Dual Robot Coordination for Apple Harvesting. In Proceedings of the 2017 American Society of Agricultural and Biological Engineers International Meeting, Spokane, WA, USA, 16–19 July 2017. [Google Scholar]

- Roshanianfard, A.; Noguchi, N. Pumpkin harvesting robotic end-effector. Comput. Electron. Agric. 2020, 174, 105503. [Google Scholar] [CrossRef]

- Navarro, S.E.; Marufo, M.; Ding, Y.; Puls, S.; Goger, D.; Hein, B.; Worn, H. Methods for safe human-robot-interaction using capacitive tactile proximity sensors. In Proceedings of the 2013 IEEE/RSJ International Conference on Intelligent Robots and Systems, Tokyo, Japan, 3–7 November 2013; pp. 1149–1154. [Google Scholar]

- Muji, S.Z.M.; Wahab, M.H.A.; Ambar, R.; Loo, W.K. Design and implementation of electronic chess set. In Proceedings of the 2016 International Conference on Advances in Electrical, Electronic and Systems Engineering (ICAEES), Putrajaya, Malaysia, 14–16 November 2016; pp. 451–456. [Google Scholar]

- Jamshidi, M. Sensors and interfacing in robotics and manufacturing. Robot. Comput. Integr. Manuf. 1990, 7, 243–253. [Google Scholar] [CrossRef]

- Edward, R. Hall-Effect Sensors: Theory and Application, 2nd ed.; Newnes: Oxford, UK, 2011. [Google Scholar]

- Dahiya, R.S.; Cattin, D.; Adami, A.; Collini, C.; Barboni, L.; Valle, M.; Lorenzelli, L.; Oboe, R.; Metta, G.; Brunetti, F. Towards Tactile Sensing System on Chip for Robotic Applications. IEEE Sens. J. 2011, 11, 3216–3226. [Google Scholar] [CrossRef]

- Shaw, J.; Cheng, K.Y. Object identification and 3-D position calculation using eye-in-hand single camera for robot gripper. In Proceedings of the 2016 IEEE International Conference on Industrial Technology (ICIT), Taipei, Taiwan, 14–17 March 2016; pp. 1622–1625. [Google Scholar]

- Jiang, L.-T.; Smith, J.R. Seashell effect pretouch sensing for robotic grasping. In Proceedings of the 2012 IEEE International Conference on Robotics and Automation, Saint Paul, MN, USA, 14–18 May 2012; pp. 2851–2858. [Google Scholar]

- Dollar, A.M.; Howe, R.D. A robust compliant grasper via shape deposition manufacturing. IEEE/ASME Trans. Mechatron. 2006, 11, 154–161. [Google Scholar] [CrossRef]

- Zhang, J.; Ye, Z.; Li, K. Multi-sensor information fusion detection system for fire robot through back propagation neural network. PLoS ONE 2020, 15, e0236482. [Google Scholar] [CrossRef]

- Rodriguez, A.S.-M.; Hosseini, M.; Paik, J. Hybrid Control Strategy for Force and Precise End Effector Positioning of a Twisted String Actuator. IEEE/ASME Trans. Mechatron. 2021, 26, 2791–2802. [Google Scholar] [CrossRef]

- Dai, Y.; Xiang, C.; Qu, W.; Zhang, Q. A Review of End-Effector Research Based on Compliance Control. Machines 2022, 10, 100. [Google Scholar] [CrossRef]

- Huang, S.-J.; Chang, W.-H.; Su, J.-Y. Intelligent robotic gripper with adaptive grasping force. Int. J. Control. Autom. Syst. 2017, 15, 2272–2282. [Google Scholar] [CrossRef]

- Russo, M.; Ceccarelli, M.; Corves, B.; Hüsing, M.; Lorenz, M.; Cafolla, D.; Carbone, G. Design and test of a gripper prototype for horticulture products. Robot. Comput. Integr. Manuf. 2017, 44, 266–275. [Google Scholar] [CrossRef]

- Li, K.; Qi, Y. Motion Planning of Robot Manipulator for Cucumber Picking. In Proceedings of the 2018 3rd International Conference on Robotics and Automation Engineering (ICRAE), Guangzhou, China, 17–19 November 2018; pp. 50–54. [Google Scholar]

- Hines, L.; Petersen, K.; Lum, G.Z.; Sitti, M. Soft Actuators for Small-Scale Robotics. Adv. Mater. 2017, 29, 1603487. [Google Scholar] [CrossRef]

- Ribeiro, E.G.; de Queiroz Mendes, R.; Grassi, V. Real-time deep learning approach to visual servo control and grasp detection for autonomous robotic manipulation. Rob. Auton. Syst. 2021, 139, 103757. [Google Scholar] [CrossRef]

- Kootstra, G.; Wang, X.; Blok, P.M.; Hemming, J.; van Henten, E. Selective Harvesting Robotics: Current Research, Trends, and Future Directions. Curr. Robot. Rep. 2021, 2, 95–104. [Google Scholar] [CrossRef]

- Roshanianfard, A.; Noguchi, N. Kinematics Analysis and Simulation of A 5DOF Articulated Robotic Arm Applied to Heavy Products Harvesting. Tarım Bilim. Derg. 2018, 24, 91–104. [Google Scholar] [CrossRef]

- Roshanianfard, A.; Noguchi, N.; Kamata, T. Design and performance of a robotic arm for farm use. Int. J. Agric. Biol. Eng. 2019, 12, 146–158. [Google Scholar] [CrossRef]

- Roshanianfard, A.; Noguchi, N. Designing of pumpkin harvester robotic end-effector. In Proceedings of the 3rd International Conference on Control, Automation and Robotics (ICCAR 2017), Nagoya, Japan, 24–26 April 2017. [Google Scholar]

- Feng, Q.; Zou, W.; Fan, P.; Zhang, C.; Wang, X. Design and test of robotic harvesting system for cherry tomato. Int. J. Agric. Biol. Eng. 2018, 11, 96–100. [Google Scholar] [CrossRef]

- Yaguchi, H.; Nagahama, K.; Hasegawa, T.; Inaba, M. Development of an autonomous tomato harvesting robot with rotational plucking gripper. In Proceedings of the 2016 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Daejeon, Korea, 9–14 October 2016; pp. 652–657. [Google Scholar]

- Lili, W.; Bo, Z.; Jinwei, F.; Xiaoan, H.; Shu, W.; Yashuo, L.; Qiangbing, Z.; Chongfeng, W. Development of a tomato harvesting robot used in greenhouse. Int. J. Agric. Biol. Eng. 2017, 10, 140–149. [Google Scholar] [CrossRef]

- Zhao, Y.; Gong, L.; Liu, C.; Huang, Y. Dual-arm Robot Design and Testing for Harvesting Tomato in Greenhouse. IFAC-Pap. 2016, 49, 161–165. [Google Scholar] [CrossRef]

- Ling, X.; Zhao, Y.; Gong, L.; Liu, C.; Wang, T. Dual-arm cooperation and implementing for robotic harvesting tomato using binocular vision. Rob. Auton. Syst. 2019, 114, 134–143. [Google Scholar] [CrossRef]

- Xiong, Y.; Peng, C.; Grimstad, L.; From, P.J.; Isler, V. Development and field evaluation of a strawberry harvesting robot with a cable-driven gripper. Comput. Electron. Agric. 2019, 157, 392–402. [Google Scholar] [CrossRef]

- Xiong, Y.; Ge, Y.; Grimstad, L.; From, P.J. An autonomous strawberry-harvesting robot: Design, development, integration, and field evaluation. J. Field Robot. 2020, 37, 202–224. [Google Scholar] [CrossRef]

- De Preter, A.; Anthonis, J.; De Baerdemaeker, J. Development of a Robot for Harvesting Strawberries. IFAC-PapersOnLine 2018, 51, 14–19. [Google Scholar] [CrossRef]

- Davidson, J.R.; Silwal, A.; Hohimer, C.J.; Karkee, M.; Mo, C.; Zhang, Q. Proof-of-concept of a robotic apple harvester. In Proceedings of the IEEE International Conference on Intelligent Robots and Systems, Daejeon, Korea, 9–14 October 2016. [Google Scholar]

- Hohimer, C.J.; Wang, H.; Bhusal, S.; Miller, J.; Mo, C.; Karkee, M. Design and Field Evaluation of a Robotic Apple Harvesting System with a 3D-Printed Soft-Robotic End-Effector. Trans. ASABE 2019, 62, 405–414. [Google Scholar] [CrossRef]

- Onishi, Y.; Yoshida, T.; Kurita, H.; Fukao, T.; Arihara, H.; Iwai, A. An automated fruit harvesting robot by using deep learning. Robomech J. 2019, 6, 13. [Google Scholar] [CrossRef]

- Bu, L.; Hu, G.; Chen, C.; Sugirbay, A.; Chen, J. Experimental and simulation analysis of optimum picking patterns for robotic apple harvesting. Sci. Hortic. (Amst.) 2020, 261, 108937. [Google Scholar] [CrossRef]

- Lehnert, C.; English, A.; McCool, C.; Tow, A.W.; Perez, T. Autonomous Sweet Pepper Harvesting for Protected Cropping Systems. IEEE Robot. Autom. Lett. 2017, 2, 872–879. [Google Scholar] [CrossRef]

- Lehnert, C.; McCool, C.; Sa, I.; Perez, T. Performance improvements of a sweet pepper harvesting robot in protected cropping environments. J. Field Robot. 2020, 37, 1197–1223. [Google Scholar] [CrossRef]

- Lee, B.; Kam, D.; Min, B.; Hwa, J.; Oh, S. A Vision Servo System for Automated Harvest of Sweet Pepper in Korean Greenhouse Environment. Appl. Sci. 2019, 9, 2395. [Google Scholar] [CrossRef]

- Arad, B.; Balendonck, J.; Barth, R.; Ben-Shahar, O.; Edan, Y.; Hellström, T.; Hemming, J.; Kurtser, P.; Ringdahl, O.; Tielen, T.; et al. Development of a sweet pepper harvesting robot. J. Field Robot. 2020, 37, 1027–1039. [Google Scholar] [CrossRef]

- Mu, L.; Cui, G.; Liu, Y.; Cui, Y.; Fu, L.; Gejima, Y. Design and simulation of an integrated end-effector for picking kiwifruit by robot. Inf. Process. Agric. 2020, 7, 58–71. [Google Scholar] [CrossRef]

- Mu, L.; Liu, Y.; Cui, Y.; Liu, H.; Chen, L.; Fu, L.; Gejima, Y. Design of End-effector for Kiwifruit Harvesting Robot Experiment. In Proceedings of the 2017 American Society of Agricultural and Biological Engineers, Spokane, WA, USA, 16–19 July 2017. [Google Scholar]

- Wang, Y.; Yang, Y.; Yang, C.; Zhao, H.; Chen, G.; Zhang, Z.; Fu, S.; Zhang, M.; Xu, H. End-effector with a bite mode for harvesting citrus fruit in random stalk orientation environment. Comput. Electron. Agric. 2019, 157, 454–470. [Google Scholar] [CrossRef]

- You, K.; Burks, T. Development of A Robotic Fruit Picking End Effector and An Adaptable Controller. In Proceedings of the 2016 ASABE International Meeting; American Society of Agricultural and Biological Engineers, Orlando, FL, USA, 17–20 July 2016. [Google Scholar]

- Sepulveda, D.; Fernandez, R.; Navas, E.; Armada, M.; Gonzalez-De-Santos, P. Robotic Aubergine Harvesting Using Dual-Arm Manipulation. IEEE Access 2020, 8, 121889–121904. [Google Scholar] [CrossRef]

- Dubey, A.P.; Pattnaik, S.M.; Banerjee, A.; Sarkar, R.; Kumar R, S. Autonomous Control and Implementation of Coconut Tree Climbing and Harvesting Robot. Procedia Comput. Sci. 2016, 85, 755–766. [Google Scholar] [CrossRef]

- Brown, J.; Sukkarieh, S. Design and evaluation of a modular robotic plum harvesting system utilizing soft components. J. Field Robot. 2021, 38, 289–306. [Google Scholar] [CrossRef]

- Anh, N.P.T.; Hoang, S.; Van Tai, D.; Quoc, B.L.C. Developing Robotic System for Harvesting Pineapples. In Proceedings of the 2020 International Conference on Advanced Mechatronic Systems (ICAMechS), Hanoi, Vietnam, 10–13 December 2020; pp. 39–44. [Google Scholar]

- Birrell, S.; Hughes, J.; Cai, J.Y.; Iida, F. A field-tested robotic harvesting system for iceberg lettuce. J. Field Robot. 2020, 37, 225–245. [Google Scholar] [CrossRef]

- Gharakhani, H.; Thomasson, J.A.; Lu, Y. An end-effector for robotic cotton harvesting. Smart Agric. Technol. 2022, 2, 100043. [Google Scholar] [CrossRef]

- Xie, T.; Li, J.; Yang, C.; Jiang, Z.; Chen, Y.; Guo, L.; Zhang, J. Crop height estimation based on UAV images: Methods, errors, and strategies. Comput. Electron. Agric. 2021, 185, 106155. [Google Scholar] [CrossRef]

- Mazzia, V.; Comba, L.; Khaliq, A.; Chiaberge, M.; Gay, P. UAV and Machine Learning Based Refinement of a Satellite-Driven Vegetation Index for Precision Agriculture. Sensors 2020, 20, 2530. [Google Scholar] [CrossRef]

- Das, S.; Christopher, J.; Apan, A.; Choudhury, M.R.; Chapman, S.; Menzies, N.W.; Dang, Y.P. Evaluation of water status of wheat genotypes to aid prediction of yield on sodic soils using UAV-thermal imaging and machine learning. Agric. For. Meteorol. 2021, 307, 108477. [Google Scholar] [CrossRef]

- Kelly, J.; Kljun, N.; Olsson, P.-O.; Mihai, L.; Liljeblad, B.; Weslien, P.; Klemedtsson, L.; Eklundh, L. Challenges and Best Practices for Deriving Temperature Data from an Uncalibrated UAV Thermal Infrared Camera. Remote Sens. 2019, 11, 567. [Google Scholar] [CrossRef]

- Qiu, Z.; Ma, F.; Li, Z.; Xu, X.; Ge, H.; Du, C. Estimation of nitrogen nutrition index in rice from UAV RGB images coupled with machine learning algorithms. Comput. Electron. Agric. 2021, 189, 106421. [Google Scholar] [CrossRef]

- Tetila, E.C.; Machado, B.B.; Menezes, G.K.; Da Silva Oliveira, A.; Alvarez, M.; Amorim, W.P.; De Souza Belete, N.A.; Da Silva, G.G.; Pistori, H. Automatic Recognition of Soybean Leaf Diseases Using UAV Images and Deep Convolutional Neural Networks. IEEE Geosci. Remote Sens. Lett. 2020, 17, 903–907. [Google Scholar] [CrossRef]

- Apolo-Apolo, O.E.; Martínez-Guanter, J.; Egea, G.; Raja, P.; Pérez-Ruiz, M. Deep learning techniques for estimation of the yield and size of citrus fruits using a UAV. Eur. J. Agron. 2020, 115, 126030. [Google Scholar] [CrossRef]

- Meng, Y.; Su, J.; Song, J.; Chen, W.-H.; Lan, Y. Experimental evaluation of UAV spraying for peach trees of different shapes: Effects of operational parameters on droplet distribution. Comput. Electron. Agric. 2020, 170, 105282. [Google Scholar] [CrossRef]

- TEVEL Flying Autonomous Robots (FAV). Available online: https://www.tevel-tech.com/ (accessed on 18 April 2022).

- Kusha, S.N.; Monisha, H.G.; Manasa, J.S.; Maniesh, M.V.; Aparanji, V.M. Fruit harvesing drone. Int. J. Adv. Res. Rev. 2020, 5, 49–55. [Google Scholar]

- Jagadeeswaran, P.; Duraisamy, R.; Elavarasan, M.; Tamilarasu, P.; Yogeshwaran, P. A smart coconut and palm cutting drone. Inf. Technol. Ind. 2021, 9, 204–208. [Google Scholar]

- Varadaramanujan, S.; Sreenivasa, S.; Pasupathy, P.; Calastawad, S.; Morris, M.; Tosunoglu, S. Design of a drone with a robotic end-effector. In Proceedings of the 30th Florida Conference on Recent Advances in Robotics, Boca Raton, FL, USA, 11–12 May 2017; pp. 1–8. [Google Scholar]

- Birglen, L.; Schlicht, T. A statistical review of industrial robotic grippers. Robot. Comput. Integr. Manuf. 2018, 49, 88–97. [Google Scholar] [CrossRef]

- Robotics Soft Choosing the (Right) Number of Fingers. Available online: https://www.softroboticsinc.com/knowledgebase/how-many-fingers/ (accessed on 20 April 2022).

- Radoglou-Grammatikis, P.; Sarigiannidis, P.; Lagkas, T.; Moscholios, I. A compilation of UAV applications for precision agriculture. Comput. Netw. 2020, 172, 107148. [Google Scholar] [CrossRef]

- Kaburlasos, V.G. The Lattice Computing (LC) Paradigm. In Proceedings of the 15th International Conference on Concept Lattices and Their Applications CLA, Tallinn, Estonia, 20–22 June 2020; pp. 1–8. [Google Scholar]

- Kaburlasos, V.G.; Lytridis, C.; Vrochidou, E.; Bazinas, C.; Papakostas, G.A.; Lekova, A.; Bouattane, O.; Youssfi, M.; Hashimoto, T. Granule-Based-Classifier (GbC): A Lattice Computing Scheme Applied on Tree Data Structures. Mathematics 2021, 9, 2889. [Google Scholar] [CrossRef]

- Kaburlasos, V.G. Robot intelligence technology for skillful viniculture based on the lattice computing paradigm. In Proceedings of the International Meet & Expo on Robot Intelligence Technology and Applications (ROBOTMEET2022), Edinburgh, Scotland, 18–20 August 2022; p. 12. [Google Scholar]

| Manipulator | Detachment Method | End Effector | Evaluation | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ref. | Year | Crop | DOF | Type | Grasp | Vacuum | Rotate | Cut | DOF | Type | Time | Accuracy |

| Heavy Crops | ||||||||||||

| [51] | 2018 | Pumpkin, cabbage | 5 | RAVebots-1 | ✓ | - | - | ✓ | 2 | 5-finger gripper/cutter [53] | - | - |

| [52] | 2019 | Pumpkin, watermelon | 5 | RAVeBots-1 | ✓ | - | - | ✓ | 2 | 5-finger gripper/cutter [53] | 33 s | Up to 2.06 nm |

| [33] | 2020 | Pumpkin | 5 | RAVeBots-1 | ✓ | - | - | ✓ | 2 | 5-finger gripper | - | Up to 92% |

| Tomatoes | ||||||||||||

| [16] | 2017 | Cherry tomato | 3 | Custom | ✓ | - | - | - | 1 | 2-finger gripper | 30 s | 100% |

| [54] | 2018 | Cherry tomato | 6 | Denso VS-6556G | ✓s | - | - | ✓ | 1 | 2-finger gripper/cutter | 8 s | 83% |

| [18] | 2019 | Cherry tomato | - | TakoBot arm | ✓ | - | - | ✓ | 1 | Semispherical gripper/cutter | - | - |

| [55] | 2016 | Tomato | 6 | UR5 | ✓ | - | ✓ | - | 2 | 3-finger gripper | 23 s | 60% |

| [56] | 2017 | Tomato | 4 | Custom | ✓ | - | - | ✓ | 1 | Shear-type gripper | 15 s | 86% |

| [57] | 2016 | Tomato | 3 | Custom (×2) | - | ✓ | - | ✓ | 1 | Saw-type cutter | - | - |

| 1 | Suction device | |||||||||||

| [58] | 2019 | Tomato | 3 | Custom (×2) | - | ✓ | - | ✓ | 1 | Cutting gripper | 30 s | 87.5% |

| 1 | Suction cup | |||||||||||

| [21] | 2020 | Tomato | - | - | ✓ | ✓ | - | - | 1 | 4-finger gripper/suction | - | - |

| [24] | 2021 | Tomato | 6 | UR3 | - | ✓ | - | ✓ | 1 | Suction/cutter | 5.9 s | - |

| Strawberries | ||||||||||||

| [59] | 2019 | Strawberry | 5 | RV-2AJ | ✓ | - | - | ✓ | 1 | 6-finger gripper/cutter | 7.5 s | 96.8% |

| [60] | 2020 | Strawberry | 3 | Rail multiarm (×2) | ✓ | - | - | - | 1 | 3-clamp gripper | 4.6 s | Up to 97.1% |

| [61] | 2019 | Strawberry | 3 | Custom | ✓ | - | ✓ | - | 1 | Soft finger gripper | 4s | - |

| Apples | ||||||||||||

| [22] | 2017 | Apple | 6 | Custom | ✓ | - | - | - | 1 | 3-finger gripper | 6 s | 84% |

| [32] | 2017 | Apple | 6 | Custom | ✓ | - | - | - | 1 | 3-finger gripper | 1.5 s | - |

| 1 | Catching device | |||||||||||

| [63] | 2019 | Apple | 5 | Custom | ✓ | - | - | - | 1 | 3 soft-robotic pneumatic actuators | 7.3 s | 67% |

| [64] | 2019 | Apple | 6 | UR3 | ✓ | - | ✓ | - | 2 | 4-finger gripper | 16 s | 90% |

| [65] | 2020 | Apple | - | - | ✓ | - | ✓ | - | 1 | Bowl-shaped gripper | - | - |

| Sweet peppers | ||||||||||||

| [19] | 2017 | Sweet pepper | 9 | Custom | ✓ | - | - | ✓ | 1 | 4-finger gripper/cutter | 94 s | 29% |

| [66] | 2017 | Sweet pepper | 6 | UR10 | - | ✓ | - | ✓ | 1 | Suction/cutter | 40 s | 92% |

| [67] | 2020 | Sweet pepper | 6 | UR10 | - | ✓ | - | ✓ | 1 | Suction/cutter | 40 s | 76.5% |

| [68] | 2019 | Sweet pepper | 3 | Custom | - | - | - | ✓ | 1 | Pose-control/cutter | 51.1 s | 70% |

| [69] | 2020 | Sweet pepper | 6 | Fanuc LR Mate 200iD | - | - | - | ✓ | 1 | Stem-fix device/cutter | 15–24 s | Up to 61% |

| Kiwifruit | ||||||||||||

| [20] | 2019 | Kiwifruit | 3 | Custom | ✓ | - | ✓ | - | 2 | Soft 2-finger gripper | 5.5 s | 51% |

| [70] | 2020 | Kiwifruit | 3 | CF3-3 | ✓ | - | - | - | 1 | Soft bionic fingers | 4–5 s | 94.2% |

| Other | ||||||||||||

| [17] | 2017 | Sugar pea pods | 5 | WidowX Mark II | ✓s | - | - | - | 1 | 2-finger gripper | 15 s | - |

| [23] | 2021 | Grape | 7 | Jaco 2 Kinova | ✓s | - | - | ✓ | 1 | 2-finger gripper/cutter | - | - |

| [73] | 2016 | Orange | 6 | ARC Mate | ✓ | ✓ | ✓ | - | 2 | 4-finger gripper/suction | - | Up to 95% |

| [72] | 2019 | Citrus | 6 | AUBO-i5 | ✓ | - | - | ✓ | 1 | Bite-mode scissors | - | 78% |

| [74] | 2020 | Aubergine | 6 | MICO Kinova (x2) | ✓ | - | - | - | 1 | 3-finger gripper (KG-3 Kinova) (×2) | 26 s | 91.67% |

| [75] | 2016 | Coconut | - | - | - | - | - | ✓ | 3 | Arm/cutter | - | - |

| [76] | 2021 | Plum | 6 | UR5 CB3 | ✓ | - | - | - | 1 | Soft 4-finger pneumatic gripper | - | 42% |

| [77] | 2020 | Pineapple | 3 | Custom (×2) | ✓ | - | - | ✓ | 1 | 2-finger gripper/cutter | 12 s | 95.56% |

| [78] | 2019 | Iceberg | 6 | UR10 | ✓ | - | - | ✓ | 1 | Soft gripper/cutter | 31.7 s | 88% |

| [79] | 2022 | Cotton | 3 | Custom | ✓ | - | - | - | 1 | 3-finger gripper | 4–18 s | 66–85% |

| Manipulator | Detachment Method | End Effector | Evaluation | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ref. | Year | Crop | DOF | Type | Grasp | Vacuum | Rotate | Cut | DOF | Type | Time | Accuracy |

| [88] | 2019 | Apple | 3 | Solid arm | ✓ | - | - | - | 1 | Cup-shaped gripper | - | - |

| 2021 | 3-finger gripper | |||||||||||

| [89] | 2020 | Pomegranates | 3 | Solid arm | ✓ | - | - | ✓ | 1 | 3-finger gripper/cutter | - | - |

| [90] | 2021 | Coconut | - | - | - | - | - | ✓ | 1 | Cutting blade slider crank mechanism | - | - |

| [91] | 2017 | - | 2 | Custom | ✓ | ✓ | ✓ | - | 1 | 2-finger gripper cups/suction | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vrochidou, E.; Tsakalidou, V.N.; Kalathas, I.; Gkrimpizis, T.; Pachidis, T.; Kaburlasos, V.G. An Overview of End Effectors in Agricultural Robotic Harvesting Systems. Agriculture 2022, 12, 1240. https://doi.org/10.3390/agriculture12081240

Vrochidou E, Tsakalidou VN, Kalathas I, Gkrimpizis T, Pachidis T, Kaburlasos VG. An Overview of End Effectors in Agricultural Robotic Harvesting Systems. Agriculture. 2022; 12(8):1240. https://doi.org/10.3390/agriculture12081240

Chicago/Turabian StyleVrochidou, Eleni, Viktoria Nikoleta Tsakalidou, Ioannis Kalathas, Theodoros Gkrimpizis, Theodore Pachidis, and Vassilis G. Kaburlasos. 2022. "An Overview of End Effectors in Agricultural Robotic Harvesting Systems" Agriculture 12, no. 8: 1240. https://doi.org/10.3390/agriculture12081240

APA StyleVrochidou, E., Tsakalidou, V. N., Kalathas, I., Gkrimpizis, T., Pachidis, T., & Kaburlasos, V. G. (2022). An Overview of End Effectors in Agricultural Robotic Harvesting Systems. Agriculture, 12(8), 1240. https://doi.org/10.3390/agriculture12081240