A Decreased Nitrogen Rate with Increased Planting Density Facilitated Better Palatability of Conventional japonica Rice at High Yield Levels

Abstract

:1. Introduction

2. Materials and Methods

2.1. Plant Materials and Growth Conditions

2.2. Sampling and Measurements

2.2.1. Leaf Area Index, Shoot Biomass, N Concentration, NSC, and SPAD Values

2.2.2. Grain Yield and Grain Quality

2.2.3. Starch Granule Size Distribution, RVA Viscosity Parameters, and Thermal Properties

2.3. Calculation Methods and Statistical Analysis

3. Results

3.1. Grain Yield and N-Use Efficiency

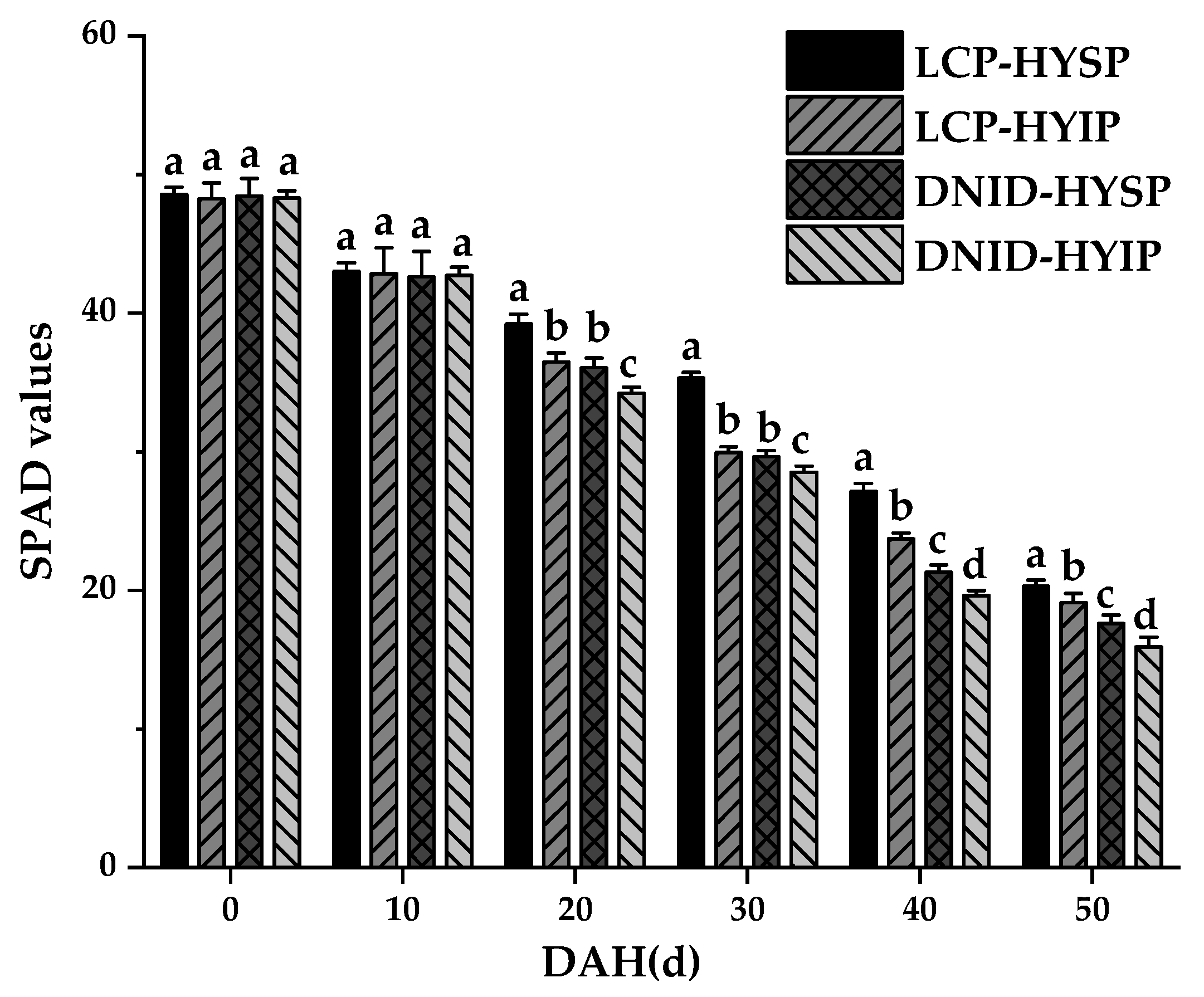

3.2. Shoot Biomass, Harvest Index, NSC, LAI, and SPAD Values

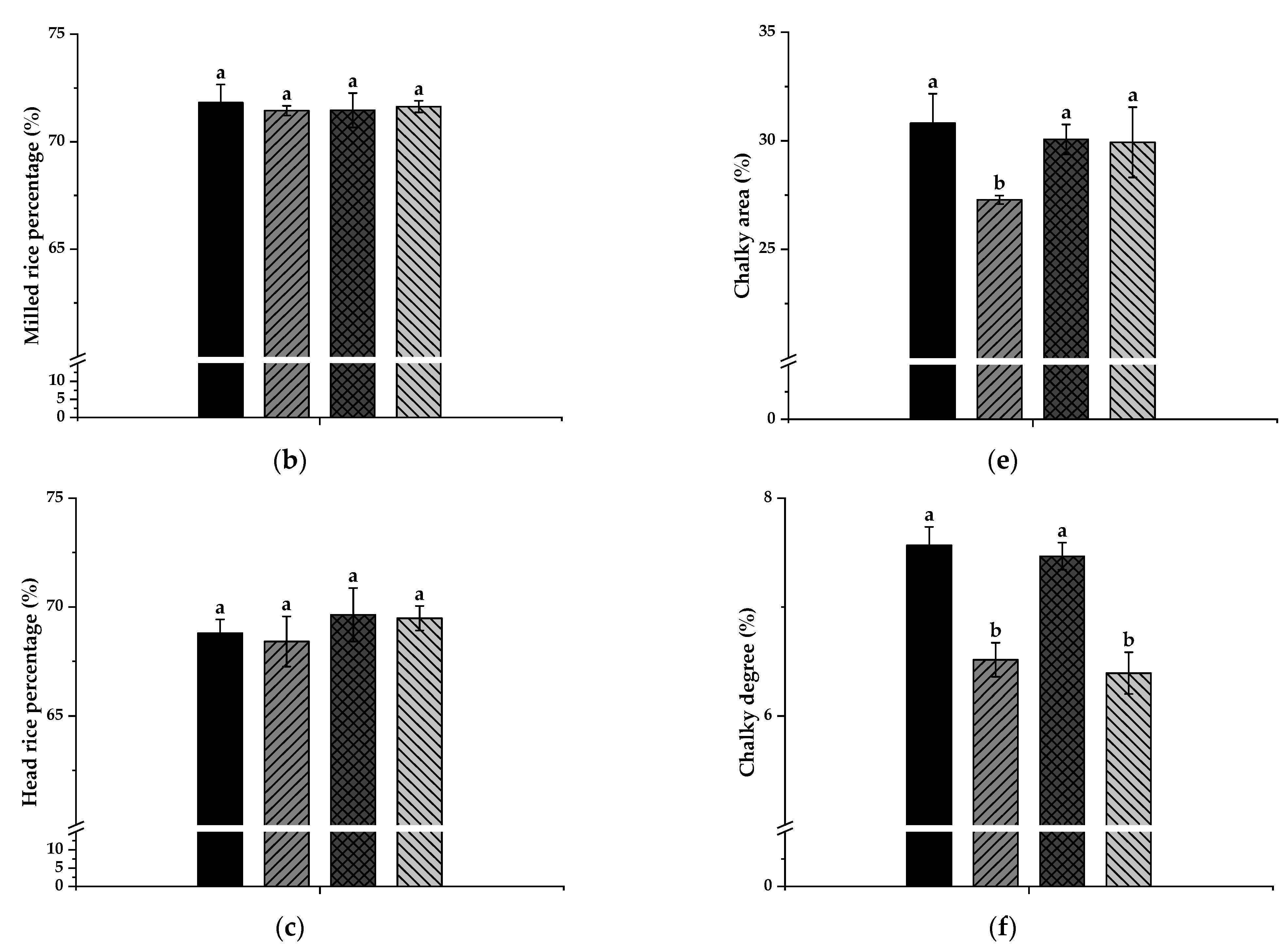

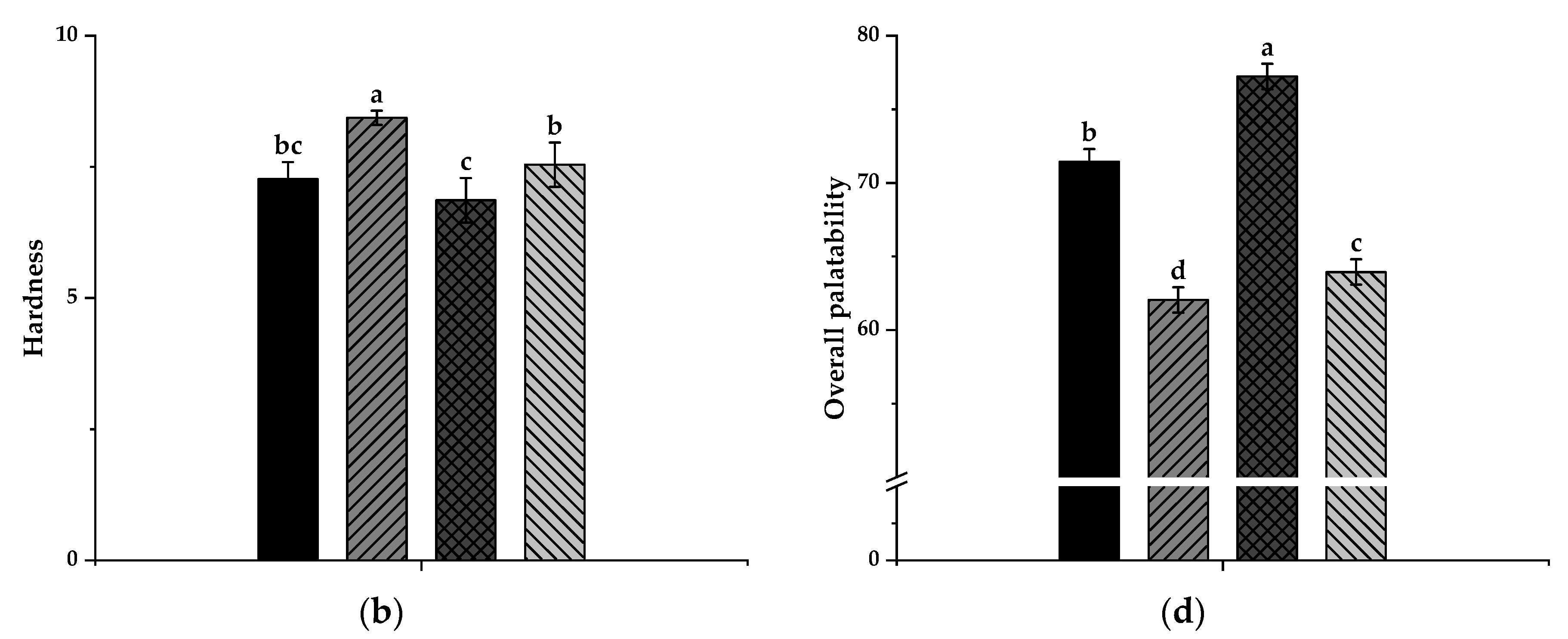

3.3. Milling, Appearance, Cooking and Eating, and Nutritional Qualities

3.4. Starch Granule Size Distribution and Pasting and Thermal Properties

3.5. Correlation Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ito, V.C.; Lacerda, L.G. Black rice (Oryza sativa L.): A review of its historical aspects, chemical composition, nutritional and functional properties, and applications and processing technologies. Food Chem. 2019, 301, 125304. [Google Scholar] [CrossRef] [PubMed]

- Miura, K.; Ashikari, M.; Matsuoka, M. The role of QTLs in the breeding of high-yielding rice. Trends Plant Sci. 2011, 16, 319–326. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Peng, S.B. Yield potential and nitrogen use efficiency of China’s super rice. J. Integr. Agr. 2017, 16, 1000–1008. [Google Scholar] [CrossRef]

- Zeng, D.L.; Tian, Z.X.; Rao, Y.C.; Dong, G.J.; Yang, Y.L.; Huang, L.C.; Leng, Y.J.; Xu, J.; Sun, C.; Zhang, G.H.; et al. Rational design of high-yield and superior-quality rice. Nat. Plants 2017, 3, 17031. [Google Scholar] [CrossRef] [PubMed]

- Buenafe, R.J.; Rathnam, A.; Añonuevoa, J.J.; Sundar, S.; Sreenivasulu, N. Application of classification models in screening superior rice grain quality in male sterile and pollen parents. J. Food Compos. Anal. 2021, 104, 104137. [Google Scholar] [CrossRef]

- Wang, C.L.; Zhang, Y.D.; Zhu, Z.; Chen, T.; Zhao, Q.Y.; Zhong, W.G.; Yang, J.; Yao, S.; Zhou, L.H.; Zhao, L.; et al. Research progress on the breeding of japonica super rice varieties in Jiangsu Province, China. J. Integr. Agric. 2017, 16, 992–999. [Google Scholar] [CrossRef]

- Jukanti, A.K.; Pautong, P.A.; Liu, Q.Q.; Sreenivasulu, N. Low glycemic index rice—A desired trait in starchy staples. Trends Food Sci. Technol. 2020, 106, 132–149. [Google Scholar] [CrossRef]

- Prom-u-thai, C.; Rerkasem, B. Rice quality improvement. A review. Agron. Sustain. Dev. 2020, 40, 28. [Google Scholar] [CrossRef]

- Okuda, M.; Aramaki, I.; Koseki, T.; Satoh, H.; Hashizume, K. Structural characteristics, properties, and in vitro digestibility of rice. Cereal Chem. 2005, 82, 361–368. [Google Scholar] [CrossRef]

- Chung, H.J.; Liu, Q.; Lee, L.; Wei, D.Z. Relationship between the structure, physicochemical properties and in vitro digestibility of rice starches with different amylose contents. Food Hydrocolloid. 2011, 25, 968–975. [Google Scholar] [CrossRef]

- Li, H.Y.; Prakash, S.; Nicholson, T.M.; Fitzgerald, M.A.; Gilbert, R.G. The importance of amylose and amylopectin fine structure for textural properties of cooked rice grains. Food Chem. 2016, 196, 702–711. [Google Scholar] [CrossRef]

- Balindong, J.L.; Ward, R.M.; Liu, L.; Rose, T.J.; Pallas, L.A.; Ovenden, B.W.; Snell, P.J.; Waters, D.L.E. Rice grain protein composition influences instrumental measures of rice cooking and eating quality. J. Cereal Sci. 2018, 79, 35–42. [Google Scholar] [CrossRef]

- Wood, R.M.; Dunn, B.W.; Balindong, J.L.; Waters, D.L.E.; Blanchard, C.L.; Mawson, A.J.; Oli, P. Effect of agronomic management on rice grain quality Part II: Nitrogen rate and timing. Cereal Chem. 2021, 98, 234–248. [Google Scholar] [CrossRef]

- Wei, H.H.; Meng, T.Y.; Ge, J.L.; Zhang, X.B.; Shi, T.Y.; Ding, E.H.; Lu, Y.; Li, X.Y.; Tao, Y.; Chen, Y.L.; et al. Reduced nitrogen application rate with dense planting improves rice grain yield and nitrogen use efficiency: A case study in east China. Crop J. 2021, 9, 954–961. [Google Scholar] [CrossRef]

- Xu, Q.; Chen, H.; Wang, C.H.; Yu, H.Y.; Yuan, X.P.; Wang, Y.P.; Feng, Y.; Tang, S.X.; Wei, X.H. Genetic diversity and structure of new inbred rice cultivars in China. J. Integr. Agric. 2012, 11, 1567–1573. [Google Scholar] [CrossRef]

- Mao, T.; Li, X.; Jiang, S.K.; Tang, L.; Wang, J.Y.; Xu, H.; Xu, Z.J. Discussion on strategy of grain quality improvement for super high yielding japonica rice in Northeast China. J. Integr. Agric. 2017, 16, 1075–1083. [Google Scholar] [CrossRef]

- Shan, Q.W.; Zhang, Y.; Chen, K.L.; Zhang, K.; Gao, C.X. Creation of fragrant rice by targeted knockout of the OsBADH2 gene using TALEN technology. Plant Biotechnol. J. 2015, 13, 791–800. [Google Scholar] [CrossRef]

- Zhao, Q.Y.; Yousaf, L.; Xue, Y.; Shen, Q. Changes in flavor of fragrant rice during storage under different conditions. J. Sci. Food Agric. 2020, 100, 3435–3444. [Google Scholar] [CrossRef]

- Bian, J.L.; Xu, F.F.; Han, C.; Qiu, S.; Ge, J.L.; Xu, J.; Zhang, H.C.; Wei, H.Y. Effects of planting methods on yield and quality of different types of japonica rice in northern Jiangsu plain, China. J. Integr. Agric. 2018, 17, 2624–2635. [Google Scholar] [CrossRef]

- Zhu, D.W.; Zhang, H.C.; Guo, B.W.; Xu, K.; Dai, Q.G.; Wei, C.X.; Zhou, G.S.; Huo, Z.Y. Effects of nitrogen level on structure and physicochemical properties of rice starch. Food Hydrocolloid. 2017, 63, 525–532. [Google Scholar] [CrossRef]

- Hu, Q.; Jiang, W.Q.; Qiu, S.; Xing, Z.P.; Hu, Y.J.; Guo, B.W.; Liu, G.D.; Gao, H.; Zhang, H.C.; Wei, H.Y. Effect of wide-narrow row arrangement in mechanical pot-seedling transplanting and plant density on yield formation and grain quality of japonica rice. J. Integr. Agric. 2020, 19, 1197–1214. [Google Scholar] [CrossRef]

- Wei, H.Y.; Zhu, Y.; Qiu, S.; Han, C.; Hu, L.; Xu, D.; Zhou, N.B.; Xing, Z.P.; Hu, Y.J.; Cui, P.Y.; et al. Combined effect of shading time and nitrogen level on grain filling and grain quality in japonica super rice. J. Integr. Agric. 2018, 17, 2405–2417. [Google Scholar] [CrossRef]

- Zhu, D.W.; Wei, H.Y.; Guo, B.W.; Dai, Q.G.; Wei, C.X.; Gao, H.; Hu, Y.J.; Cui, P.Y.; Li, M.; Huo, Z.Y.; et al. The effects of chilling stress after anthesis on the physicochemical properties of rice (Oryza sativa L) starch. Food Chem. 2017, 237, 936–941. [Google Scholar] [CrossRef] [PubMed]

- Zhou, T.Y.; Zhou, Q.; Li, E.P.; Yuan, L.M.; Wang, W.L.; Zhang, H.; Liu, L.J.; Wang, Z.Q.; Yang, J.C.; Gu, J.F. Effects of nitrogen fertilizer on structure and physicochemical properties of ‘super’ rice starch. Carbohyd. Polym. 2020, 239, 116237. [Google Scholar] [CrossRef]

- Chen, J.; Zhu, X.C.; Xie, J.; Deng, G.Q.; Tu, T.H.; Guan, X.J.; Yang, Z.; Huang, S.; Chen, X.M.; Qiu, C.F.; et al. Reducing nitrogen application with dense planting increases nitrogen use efficiency by maintaining root growth in a double-rice cropping system. Crop J. 2021, 9, 805–815. [Google Scholar] [CrossRef]

- Huang, M.; Chen, J.N.; Cao, F.B.; Zou, Y.B. Increased hill density can compensate for yield loss from reduced nitrogen input in machine-transplanted double-cropped rice. Field Crop. Res. 2018, 221, 333–338. [Google Scholar] [CrossRef]

- Hou, W.F.; Khan, M.R.; Zhang, J.L.; Lu, J.W.; Ren, T.; Cong, R.H.; Li, X.K. Nitrogen rate and plant density interaction enhances radiation interception, yield and nitrogen use efficiency of mechanically transplanted rice. Agric. Ecosyst. Environ. 2019, 269, 183–192. [Google Scholar] [CrossRef]

- Zheng, B.Q.; Fang, Q.; Zhang, C.X.; Mahmood, H.; Zhou, Q.; Li, W.Y.; Li, X.N.; Cai, J.; Wang, X.; Zhong, Y.X.; et al. Reducing nitrogen rate and increasing plant density benefit processing quality by modifying the spatial distribution of protein bodies and gluten proteins in endosperm of a soft wheat cultivar. Field Crop. Res. 2020, 253, 107831. [Google Scholar] [CrossRef]

- Peng, S.B.; Buresh, R.J.; Huang, J.L.; Zhong, X.H.; Zou, Y.B.; Yang, J.C.; Wang, G.H.; Liu, Y.Y.; Hu, R.F.; Tang, Q.Y.; et al. Improving nitrogen fertilization in rice by sitespecific N management. A review. Agron. Sustain. Dev. 2010, 30, 649–656. [Google Scholar] [CrossRef]

- Takai, T.; Matsuura, S.; Nishio, T.; Ohsumi, A.; Shiraiwa, T.; Hoire, T. Rice yield potential is closely related to crop growth rate during late reproductive period. Field Crop. Res. 2006, 96, 328–335. [Google Scholar] [CrossRef]

- Nkonge, C.; Ballance, G.M. A sensitive colorimetric procedure for nitrogen determination in micro-Kjeldahl digests. J. Agric. Food Chem. 1982, 30, 416–420. [Google Scholar] [CrossRef]

- Chen, X.; Xu, Y.; Hou, D.W.; Zhu, W.; Chen, X.Y.; Chen, P.R.; Du, X.F. Effect of heterogeneous protein distribution on in situ pasting properties of black rice starch. LWT-Food Sci. Technol. 2022, 153, 112388. [Google Scholar] [CrossRef]

- Laenoi, S.; Rerkasem, B.; Lordkaew, S.; Prom-u-thai, C. Seasonal variation in grain yield and quality in different rice varieties. Field Crop. Res. 2018, 221, 350–357. [Google Scholar] [CrossRef]

- Xu, Q.; Chen, W.F.; Xu, Z.J. Relationship between grain yield and quality in rice germplasms grown across different growing areas. Breeding Sci. 2015, 65, 226–232. [Google Scholar] [CrossRef]

- Hori, K.; Suzuki, K.; Lijima, K.; Ebana, K. Variation in cooking and eating quality traits in Japanese rice germplasm accessions. Breeding Sci. 2016, 66, 309–318. [Google Scholar] [CrossRef]

- Gayin, J.; Chandi, G.K.; Manful, J.; Seetharaman, K. Classification of rice based on statistical analysis of pasting properties and apparent amylose content: The case of Oryza glaberrima accessions from Africa. Cereal Chem. 2015, 92, 22–28. [Google Scholar] [CrossRef]

- Zhou, L.J.; Sheng, W.T.; Wu, J.; Zhang, C.Q.; Liu, Q.Q.; Deng, Q.Y. Differential expressions among five Waxy alleles and their effects on the eating and cooking qualities in specialty rice cultivars. J. Integr. Agric. 2015, 14, 1153–1162. [Google Scholar] [CrossRef]

- Huang, L.; Sreenivasulu, N.; Liu, Q.Q. Waxy editing: Olds meets new. Trends Plant Sci. 2020, 25, 963–966. [Google Scholar] [CrossRef]

- Hu, L.; Zhu, Y.; Xu, D.; Chen, Z.F.; Hu, B.Q.; Han, C.; Qiu, S.; Wu, P.; Zhang, H.C.; Wei, H.Y. Characteristics of good taste and high yield type of single cropping late japonica rice in southern China. Sci. Agric. Sin. 2019, 52, 215–227. (In Chinese) [Google Scholar]

- Nagarajan, S.; Jagadish, S.V.K.; Hari Prasad, A.S.; Thomar, A.K.; Anand, A.; Pal, M.; Agarwal, P.K. Local climate affects growth, yield and grain quality of aromatic and non-aromatic rice in northwestern India. Agric. Ecosyst. Environ. 2010, 138, 274–281. [Google Scholar] [CrossRef]

- Cui, Y.; Zhu, M.M.; Xu, Z.J.; Chen, W.F. The breeding of japonica rice in northern China: An 11-year study (2006–2016). J. Integr. Agric. 2020, 19, 1941–1946. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, H.; Feng, M.; Zhu, Y. Suppression of OsMADS7 in rice endosperm stabilizes amylose content under high temperature stress. Plant Biotechnol. J. 2017, 16, 18–26. [Google Scholar] [CrossRef]

- Zhu, Y.; Xu, D.; Hu, L.; Hua, C.; Chen, Z.F.; Zhang, Z.Z.; Zhou, N.B.; Liu, G.D.; Zhang, H.C.; Wei, H.Y. Characteristics of medium-maturity conventional japonica rice with good taste and high yield in Jianghuai area. Acta Agron. Sin. 2019, 45, 578–588. (In Chinese) [Google Scholar] [CrossRef]

- Meng, T.Y.; Zhang, X.B.; Ge, J.L.; Chen, X.; Yang, Y.L.; Zhu, G.L.; Chen, Y.L.; Zhou, G.S.; Wei, H.H.; Dai, Q.G. Agronomic and physiological traits facilitating better yield performance of japonica/indica hybrids in saline fields. Field Crop. Res. 2021, 271, 108255. [Google Scholar] [CrossRef]

- Yang, J.C.; Wang, Z.Q.; Liu, L.J.; Zhu, Q.S. Postanthesis water deficits enhance grain filling in two-line hybrid rice. Crop Sci. 2003, 43, 2099–2108. [Google Scholar] [CrossRef]

- Falade, K.O.; Semon, M.; Fadairo, O.S.; Oladunjoye, A.O.; Orou, K.K. Functional and physico-chemical properties of flours and starches of African rice cultivars. Food Hydrocolloid. 2014, 39, 41–50. [Google Scholar] [CrossRef]

- Feng, F.; Li, Y.; Qin, X.; Liao, Y.; Siddique, K.H.M. Changes in rice grain quality of indica and japonica type varieties released in China from 2000 to 2014. Front. Plant Sci. 2017, 8, 1863. [Google Scholar] [CrossRef]

- Zeng, Y.; Tan, X.; Zeng, Y.; Xie, X.; Pan, X.; Shi, Q.; Zhang, J. Changes in the rice grain quality of different high-quality rice varieties released in southern China from 2007 to 2017. J. Cereal Sci. 2019, 87, 111–116. [Google Scholar] [CrossRef]

- Meng, T.Y.; Zhang, X.B.; Chen, X.; Ge, J.L.; Zhou, G.S.; Wei, H.H.; Dai, Q.G. Trends in grain quality and responses to nitrogen application of japonica inbred rice released after the 1980s. Cereal Chem. 2022, 99, 503–519. [Google Scholar] [CrossRef]

- Huang, S.J.; Zhao, C.F.; Zhu, Z.; Zhou, L.H.; Zheng, Q.H.; Wang, C.L. Characterization of eating quality and starch properties of two Wx alleles japonica rice cultivars under different nitrogen treatments. J. Integr. Agric. 2020, 19, 988–998. [Google Scholar] [CrossRef]

- Bryant, R.J.; Anders, M.; McClung, A. Impact of production practices on physicochemical properties of rice grain quality. J. Sci. Food Agric. 2011, 92, 564–569. [Google Scholar] [CrossRef] [PubMed]

- Park, J.W.; Kim, S.S.; Kim, K.O. Effect of milling ratio on sensory properties of cooked rice and on physicochemical properties of milled and cooked rice. Cereal Chem. 2001, 78, 151–156. [Google Scholar] [CrossRef]

- Xu, Y.J.; Ying, Y.N.; Ouyang, S.H.; Duan, X.L.; Sun, H.; Jiang, S.K.; Sun, S.C.; Bao, J.S. Factors affecting sensory quality of cooked japonica rice. Rice Sci. 2018, 25, 330–339. [Google Scholar]

- Xiong, R.Y.; Xie, J.X.; Chen, L.M.; Yang, T.T.; Tan, X.M.; Zhou, Y.J.; Pan, X.H.; Zeng, Y.J.; Shi, Q.H.; Zhang, J.; et al. Water irrigation management affects starch structure and physicochemical properties of indica rice with different grain quality. Food Chem. 2021, 347, 129045. [Google Scholar] [CrossRef]

- Cheng, F.M.; Zhong, L.J.; Wang, F.; Zhang, G.P. Differences in cooking and eating properties between chalky and translucent parts in rice grains. Food Chem. 2005, 90, 39–46. [Google Scholar] [CrossRef]

- Zhu, L.; Wu, G.C.; Cheng, L.L.; Zhang, H.; Wang, L.; Qian, H.F.; Qi, X.G. Investigation on molecular and morphology changes of protein and starch in rice kernel during cooking. Food Chem. 2020, 316, 126262. [Google Scholar] [CrossRef] [PubMed]

| Year | Cultivation Treatment | Nitrogen Application Rate (kg ha−1) | Planting Density | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Total Rate | One Day before Transplanting | One Week after Transplanting | Panicle Initiation | Penultimate-Leaf Appearance | Hill Spacing | Seedling per Hill | Seeding per m2 | ||

| 2018 | LCP | 300 | 90 | 90 | 60 | 60 | 30 cm × 12 cm | 4 | 95 |

| DNID | 255 | 90 | 60 | 60 | 45 | 25 cm × 12 cm | 4 | 115 | |

| 2019 | LCP | 300 | 90 | 90 | 60 | 60 | 30 cm × 12 cm | 4 | 95 |

| DNID | 255 | 90 | 60 | 60 | 45 | 25 cm × 12 cm | 4 | 115 | |

| Source | df | Grain Yield | NUEg | 1000-Kernel Weight | Shoot Biomass Weight | NSC Content | LAI | Overall Palatability | Amylose Content | Protein Content | Peak Viscosity | Break-Down | Set-Back | Tp | ∆Hgel |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Maturity Stage | |||||||||||||||

| Year | 1 | ns | * | ns | ns | ns | ns | ns | ns | ns | ns | ns | ns | ns | ns |

| Cultivation treatment | 1 | ns | ** | * | ** | ** | ** | ** | ns | ** | ** | ** | ** | ** | ** |

| Cultivar type | 1 | ns | * | ** | ns | ** | ** | ** | ** | ns | ** | ** | ** | ** | ** |

| Year × Cultivation treatment | 3 | ns | ns | ns | ns | ns | ns | ns | ns | ns | ns | ns | ns | ns | ns |

| Year × Cultivar type | 3 | ns | ns | ns | ns | ns | ns | ns | ns | ns | ns | ns | ns | ns | ns |

| Cultivation treatment × Cultivar type | 3 | ns | ns | ns | ns | ns | ns | * | ns | ns | ns | * | * | ns | ns |

| Year × Cultivation treatment × Cultivar type | 7 | ns | ns | ns | ns | ns | ns | ns | ns | ns | ns | ns | ns | ns | ns |

| Total | 23 | ||||||||||||||

| Cultivation Treatment | Cultivar Type | Grain Yield (t ha−1) | Total N Accumulation (kg ha−1) | NUEg (kg kg−1) | PFPN (kg kg−1) |

|---|---|---|---|---|---|

| LCP | HYSP | 10.3 ± 0.1 a | 265 ± 7 a | 39.0 ± 1.1 c | 34.3 ± 0.4 b |

| HYIP | 10.3 ± 0.2 a | 252 ± 12 b | 40.8 ± 1.3 b | 34.1 ± 0.5 b | |

| DNID | HYSP | 10.2 ± 0.1 a | 232 ± 9 c | 44.0 ± 0.9 a | 40.0 ± 0.4 a |

| HYIP | 10.2 ± 0.2 a | 228 ± 9 c | 44.5 ± 1.2 a | 39.8 ± 0.7 a | |

| Analysis of variance (ANOVA) | |||||

| Cultivation treatment | ns | ** | ** | ** | |

| Cultivar type | ns | ns | * | ns | |

| Cultivation treatment × Cultivar type | ns | ns | ns | ns | |

| Cultivation Treatment | Cultivar Type | Panicles per m2 | Spikelets per Panicle | Spikelets per m2 (×103) | Filled-Grain PERCENTAGE (%) | 1000-Kernel Weight (g) |

|---|---|---|---|---|---|---|

| LCP | HYSP | 318 ± 10 b | 138 ±6 b | 43.8 ± 1.5 a | 89.5 ± 0.6 b | 25.4 ± 0.3 d |

| HYIP | 293 ± 7 c | 146 ± 7 a | 42.8 ± 1.2 a | 90.1 ± 0.3 ab | 26.6 ± 0.2 b | |

| DNID | HYSP | 330 ± 9 a | 132 ± 5 b | 43.6 ± 1.4 a | 90.8 ± 0.4 a | 26.1 ± 0.3 c |

| HYIP | 309 ± 8 b | 139 ± 5 b | 42.9 ± 1.1 a | 90.0 ± 1.3 ab | 27.0 ± 0.3 a | |

| Analysis of variance (ANOVA) | ||||||

| Cultivation treatment | ** | * | ns | * | * | |

| Cultivar type | ** | * | ** | ns | ** | |

| Cultivation treatment × Cultivar type | ns | ns | * | ns | ns | |

| Cultivation Treatment | Cultivar Type | Shoot Biomass Weight (t ha−1) | Shoot Biomass Accumulation (t ha−1) | Harvest Index | |||

|---|---|---|---|---|---|---|---|

| Jointing | Heading | Maturity | Jointing- Heading | Heading-Maturity | |||

| LCP | HYSP | 4.6 ± 0.2 b | 11.5 ± 0.2 a | 18.5 ± 0.2 a | 7.0 ± 0.3 a | 7.0 ± 0.2 a | 0.482 ± 0.005 b |

| HYIP | 4.9 ± 0.2 a | 11.5 ± 0.4 a | 18.1 ± 0.2 b | 6.6 ± 0.3 ab | 6.7 ± 0.3 b | 0.490 ± 0.004 a | |

| DNID | HYSP | 4.3 ± 0.2 c | 11.0 ± 0.3 b | 17.9 ± 0.2 bc | 6.7 ± 0.3 ab | 7.0 ± 0.2 ab | 0.494 ± 0.007 a |

| HYIP | 4.7 ± 0.2 b | 11.1 ± 0.3 b | 17.8 ± 0.2 c | 6.4 ± 0.2 b | 6.7 ± 0.1 b | 0.493 ± 0.004 a | |

| Analysis of variance (ANOVA) | |||||||

| Cultivation treatment | ** | ** | ** | ns | ns | ** | |

| Cultivar type | ** | ns | ** | * | ** | ns | |

| Cultivation treatment × Cultivar type | ns | ns | ns | ns | ns | ns | |

| Cultivation Treatment | Cultivar Type | NSC Content (g m−2) | NSC Remobilization Reserve (%) | |

|---|---|---|---|---|

| Heading | Maturity | |||

| LCP | HYSP | 334 ± 14 a | 180 ± 10 a | 46.3 ± 1.2 b |

| HYIP | 314 ± 10 b | 163 ± 6 b | 48.1 ± 1.1 c | |

| DNID | HYSP | 317 ± 13 b | 144 ± 9 c | 54.5 ± 1.5 a |

| HYIP | 278 ± 10 c | 131 ± 9 d | 52.8 ± 1.3 b | |

| Analysis of variance (ANOVA) | ||||

| Cultivation treatment | ** | ** | ** | |

| Cultivar type | ** | ** | ns | |

| Cultivation treatment × Cultivar type | ns | ns | * | |

| Cultivation Treatment | Cultivar Type | LAI (m2 m−2) | ||

|---|---|---|---|---|

| Jointing | Heading | Maturity | ||

| LCP | HYSP | 3.7 ± 0.2 a | 7.7 ± 0.3 a | 2.8 ± 0.2 a |

| HYIP | 3.7 ± 0.3 a | 7.7 ± 0.2 a | 2.5 ± 0.2 b | |

| DNID | HYSP | 3.5 ± 0.2 a | 7.5 ± 0.2 ab | 2.6 ± 0.2 b |

| HYIP | 3.7 ± 0.2 a | 7.4 ± 0.2 b | 2.2 ± 0.2 c | |

| Analysis of variance (ANOVA) | ||||

| Cultivation treatment | ns | ** | ** | |

| Cultivar type | ns | ns | ** | |

| Cultivation treatment × Cultivar type | ns | ns | ns | |

| Cultivation Treatment | Cultivar Type | Small Starch Granule Ratio (<2 µm) (%) | Medium Starch Granule Ratio (2–10 µm) (%) | Large Starch Granule Ratio (>10 µm) (%) |

|---|---|---|---|---|

| LCP | HYSP | 13.6 ± 0.4 a | 79.4 ± 0.5 b | 7.0 ± 0.5 a |

| HYIP | 14.0 ± 0.4 a | 79.4 ± 0.3 b | 6.5 ± 0.3 a | |

| DNID | HYSP | 14.4 ± 0.5 ab | 80.6 ± 0.4 a | 5.2 ± 0.5 b |

| HYIP | 14.8 ± 0.6 a | 80.5 ± 0.4 a | 4.8 ± 0.4 b | |

| Analysis of variance (ANOVA) | ||||

| Cultivation treatment | ns | ** | ** | |

| Cultivar type | ns | ns | ns | |

| Cultivation treatment × Cultivar type | ns | ns | ns | |

| Cultivation Treatment | Cultivar Type | Peak Viscosity (cP) | Hot Viscosity (cP) | Cool Viscosity (cP) | Breakdown (cP) | Setback (cP) |

|---|---|---|---|---|---|---|

| LCP | HYSP | 2679 ± 64 b | 1973 ± 76 b | 2485 ± 53 a | 706 ± 24 b | −176 ±29 c |

| HYIP | 2279 ± 18 d | 1868 ± 40 c | 2408 ± 77 b | 411 ± 44 d | 108 ± 52 a | |

| DNID | HYSP | 2945 ± 24 a | 2030 ± 30 ab | 2477 ± 15 a | 941 ± 31 a | −480 ± 44 d |

| HYIP | 2599 ± 49 c | 2047 ± 66 a | 2514 ± 58 a | 552 ± 43 c | −52 ± 21 b | |

| Analysis of variance (ANOVA) | ||||||

| Cultivation treatment | ** | ** | * | ** | ** | |

| Cultivar type | ** | ns | ns | ** | ** | |

| Cultivation treatment × Cultivar type | ns | ns | * | * | * | |

| Cultivation Treatment | Cultivar Type | To (°C) | Tp (°C) | Tc (°C) | ∆Hgel (J g−1) | ∆Hret (J g−1) | %R |

|---|---|---|---|---|---|---|---|

| LCP | HYSP | 64.1 ± 0.5 a | 68.5 ± 0.8 a | 73.9 ± 1.0 a | 11.4 ± 0.2 a | 1.4 ± 0.1 c | 12.1 ± 1.1 b |

| HYIP | 63.2 ± 0.9 ab | 66.8 ± 1.2 b | 72.5 ± 1.4 ab | 10.9 ± 0.2 b | 2.0 ± 0.1 a | 18.2 ± 1.2 a | |

| DNID | HYSP | 62.3 ± 0.7 b | 66.6 ± 0.9 b | 72.0 ± 1.1 b | 11.0 ± 0.1 b | 1.2 ± 0.1 d | 11.2 ± 1.0 b |

| HYIP | 61.1 ± 0.9 c | 63.6 ± 1.6 c | 70.2 ± 1.5 c | 10.5 ± 0.2 c | 1.8 ± 0.1 b | 17.4 ± 1.3 a | |

| Analysis of variance (ANOVA) | |||||||

| Cultivation treatment | * | ** | ** | ** | ns | ns | |

| Cultivar type | ** | ** | * | ** | ** | ** | |

| Cultivation treatment × Cultivar type | ns | ns | ns | ns | ns | * | |

| The Determined Parameters | LCP | DNID | ||

|---|---|---|---|---|

| Grain Yield | Overall Palatability | Grain Yield | Overall Palatability | |

| Panicle per m2 | 0.26 | 0.77 ** | 0.22 | 0.73 ** |

| Shoot biomass weight at maturity | 0.74 ** | 0.81 ** | 0.62 * | 0.68 * |

| Shoot biomass accumulation from heading to maturity | 0.68 * | 0.67 * | 0.68 * | 0.66 * |

| NSC at heading | 0.62 * | 0.88 ** | 0.62 * | 0.96 ** |

| NSC at maturity | 0.35 | 0.93 ** | 0.63 * | 0.82 ** |

| NSC remobilization reserve | 0.25 | −0.24 | 0.73 ** | 0.75 ** |

| LAI at heading | 0.54 | 0.56 | 0.07 | 0.60 * |

| LAI at maturity | 0.62 * | 0.89 ** | 0.66 * | 0.91 ** |

| SPAD at 40 DAH | 0.62 * | 0.94 ** | 0.56 | 0.92 ** |

| SPAD at 50 DAH | 0.65 * | 0.90 ** | 0.65 * | 0.93 ** |

| Amylose content | −0.30 | −0.89 ** | −0.32 | −0.92 ** |

| Amylopectin content | 0.43 | 0.83 ** | 0.34 | 0.87 ** |

| Total starch content | 0.51 | 0.53 | 0.29 | 0.60 * |

| Protein content | 0.30 | −0.68 * | 0.38 | −0.72 ** |

| Gel consistency | 0.14 | 0.79 ** | 0.19 | 0.91 ** |

| Hardness | −0.14 | −0.78 ** | −0.18 | −0.82 ** |

| Stickiness | 0.32 | 0.80 ** | 0.29 | 0.83 ** |

| Medium starch granule ratio (2–10 µm) | −0.24 | 0.55 | −0.05 | 0.66 * |

| Large starch granule ratio (>10 µm) | 0.16 | −0.50 | −0.03 | −0.62 * |

| Peak viscosity | 0.31 | 0.79 ** | 0.20 | 0.80 ** |

| Breakdown | 0.37 | 0.84 ** | 0.24 | 0.88 ** |

| Setback | −0.24 | −0.82 ** | −0.29 | −0.86 ** |

| To (°C) | 0.34 | 0.74 ** | 0.46 | 0.81 ** |

| Tp (°C) | 0.53 | 0.67 * | 0.43 | 0.71 ** |

| Tc (°C) | 0.44 | 0.72 ** | 0.51 | 0.62 * |

| ∆Hgel | −0.04 | 0.47 | 0.01 | 0.72 ** |

| ∆Hret | −0.36 | −0.97 ** | −0.26 | −0.96 ** |

| %R | −0.32 | −0.96 ** | −0.24 | −0.96 ** |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ge, J.; Zhang, X.; Wei, H.; Dai, Q. A Decreased Nitrogen Rate with Increased Planting Density Facilitated Better Palatability of Conventional japonica Rice at High Yield Levels. Agriculture 2022, 12, 1292. https://doi.org/10.3390/agriculture12091292

Ge J, Zhang X, Wei H, Dai Q. A Decreased Nitrogen Rate with Increased Planting Density Facilitated Better Palatability of Conventional japonica Rice at High Yield Levels. Agriculture. 2022; 12(9):1292. https://doi.org/10.3390/agriculture12091292

Chicago/Turabian StyleGe, Jialin, Xubin Zhang, Huanhe Wei, and Qigen Dai. 2022. "A Decreased Nitrogen Rate with Increased Planting Density Facilitated Better Palatability of Conventional japonica Rice at High Yield Levels" Agriculture 12, no. 9: 1292. https://doi.org/10.3390/agriculture12091292