Analysis of Operating Conditions for Vibration of a Self-Propelled Monorail Branch Chipper

Abstract

:1. Introduction

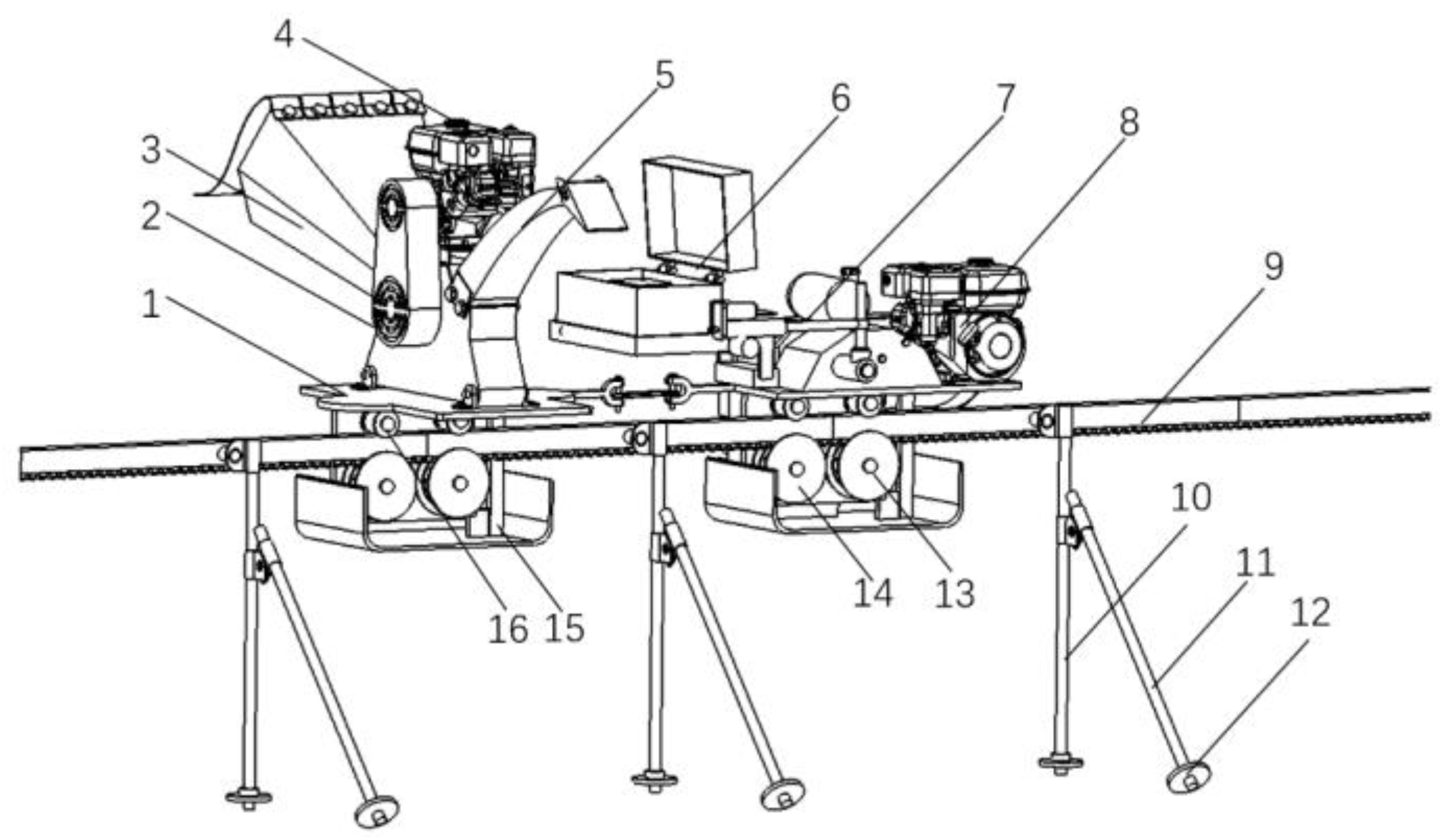

2. Overall Structure and Working Principle

2.1. Overall Structure

2.2. Working Principle

3. Modal Analysis of Rail Systems

3.1. Principles of Modal Analysis

- ——quality matrix;

- ——damping matrix;

- ——stiffness matrix;

- {}——force vector;

- ——displacement vector;

- ——speed vector;

- ——acceleration vector.

3.2. Rail System Modal Analysis

3.3. Analysis of the Results

- ——speed of gasoline engine, r/min;

- ——gasoline engine’s number of cylinders;

- ——number of strokes of gasoline engine.

4. Vibration Test of the Chipper under Different Working Conditions

4.1. Vibration Test at No-Load

4.2. Vibration Test under Crushing Operation

4.3. Multi-Stage Vibration Test

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Song, Y.; Zhang, H. Development status and trend of domestic orchard transportation machinery in hilly and mountainous areas. J. Chin. Agric. Mech. 2019, 40, 50. [Google Scholar]

- Zheng, Y.; Jiang, S.; Chen, B.; LÜ, H.; Wan, C.; Kang, F. Review on Technology and Equipment of Mechanization in Hilly Orchard. Trans. Chin. Soc. Agric. Mach. 2020, 51, 1–20. [Google Scholar]

- Liu, H.; Liu, J.; Li, J. Comprehensive Utilization Technology of Orchard Pruning Branches. J. Agric. Mech. Res. 2011, 33, 218–221. [Google Scholar]

- Feng, H.; Yang, D.; Bai, S.; Xie, H.; Liu, X.; Pei, H. Characteristics of Degradation of Lignocellulose and Microbial Community Diversity during Fermentation of Wolfberry Branches Substrate. Trans. Chin. Soc. Agric. Mach. 2017, 48, 313–319. [Google Scholar]

- Feng, H.; Yang, Z.; Yang, D.; Qu, J.; Wang, C.; Guo, W. Parameter optimization of fermented substrate from wolfberry shoots. Trans. Chin. Soc. Agric. Eng. 2015, 31, 252–260. [Google Scholar]

- Shi, L.; Gu, J.; Pan, H.; Zhang, K.; Yin, Y.; Zhao, T.; Wang, X.; Gao, H. Improving enzyme activity by compound microbial agents in compost with mixed fruit tree branches and pig manure during composting. Trans. Chin. Soc. Agric. Eng. 2015, 31, 244–251. [Google Scholar]

- Guo, A.; Li, J.; Li, F.; Zhao, J.; Lu, Y. Process Optimization of Biomass Cushion Packaging Products and Its Properties. J. Mech. Eng. 2013, 49, 178–183. [Google Scholar] [CrossRef]

- Florkowski, W.J.; Nouve, Y.D.E.; Bauske, E.M.; Norton, N. Wood chip production and disposal choices: Landfill or recycle? J. Clean. Prod. 2022, 357, 131947. [Google Scholar] [CrossRef]

- He, Y.; Qian, W.; Wang, J.; Xiong, Y.; Song, P.; Wang, R. High value-added reutilization approach for waste biomass materials. Trans. Chin. Soc. Agric. Eng. 2016, 32, 1–8. [Google Scholar]

- Wang, F.; Liu, X.; Chen, L. Research status and development prospect of energy and high value utilization of biomass resources. Trans. Chin. Soc. Agric. Eng. 2021, 37, 219–231. [Google Scholar]

- Pang, Q.; Shi, T. Discussion of basic issues of drum chipper design. For. Grassl. Mach. 1997, 5–10. [Google Scholar]

- Micheletti Cremasco, M.; Giustetto, A.; Caffaro, F.; Colantoni, A.; Cavallo, E.; Grigolato, S. Risk assessment for musculoskeletal disorders in forestry: A comparison between RULA and REBA in the manual feeding of a wood-chipper. Int. J. Environ. Res. Public Health 2019, 16, 793. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Manzone, M. Energy consumption and CO2 analysis of different types of chippers used in wood biomass plantations. Appl. Energy 2015, 156, 686–692. [Google Scholar] [CrossRef] [Green Version]

- Facello, A.; Cavallo, E.; Magagnotti, N.; Paletto, G.; Spinelli, R. The effect of knife wear on chip quality and processing cost of chestnut and locust fuel wood. Biomass Bioenergy 2013, 59, 468–476. [Google Scholar] [CrossRef]

- Acuna, M.; Mirowski, L.; Ghaffariyan, M.R.; Brown, M. Optimising transport efficiency and costs in Australian wood chipping operations. Biomass Bioenergy 2012, 46, 291–300. [Google Scholar] [CrossRef]

- Guerrini, L.; Tirinnanzi, A.; Guasconi, F.; Fagarazzi, C.; Baldi, F.; Masella, P.; Parenti, A. A Plackett-Burman design to optimize wood chipper settings. Croat. J. For. Eng. 2019, 40, 81–87. [Google Scholar]

- Wang, Q.; He, L.; Zhou, Y.; Pan, Y.; Song, L.; Song, Z. Development status and trend of control system of the orchard branches crushing machinery. J. Chin. Agric. Mech. 2022, 43, 238–244. [Google Scholar]

- Wang, S. Design and Experiment of Orchard Branch Shredder; Northwest A&F University: Xianyang, China, 2021. [Google Scholar]

- Shen, X.; Liu, J.; Zhu, Z.; Yang, L. Parameter Optimization and Test of 9ZFS-350 Crawler Self-propelled Pruning Crusher. J. Agric. Mech. Res. 2022, 44, 78–82. [Google Scholar]

- Zhan, L.; Feng, X.; Ma, Y. Design and Experimental Study on the Crushing Mechanism of Crawler-type Pulverizers. J. Agric. Mech. Res. 2018, 40, 97–101. [Google Scholar]

- Gong, Y.; Song, Y.; Ren, L.; Zhang, H.; Han, Y. Design and field test of self-propelled branch crusher based on transportation track system in hilly orchard. J. Shandong Agric. Univ. 2021, 52, 692–696. [Google Scholar]

- Zhang, H. Development and Experiment of Frost Protection Smoke Machine Based on Transportation Track of Hilly Orchard Abstract; Shandong Agricultural University: Taian, China, 2021. [Google Scholar]

- Li, H.; Geni, M. Numerical analysis method and vibration characteristics analysis of complex composite structure de cotton rotor. J. Vib. Shock 2020, 39, 114–121. [Google Scholar]

- Li, X.; Zhao, G.; Yang, H. Nonlinear pre-stressed modal analysis for a composite beam considering influence of joint surface. J. Vib. Shock 2014, 33, 17–21. [Google Scholar]

- Xiao, X.; Li, H.; Li, X.; Wang, M. Modal and Transient Analysis of Threshing Cylinder Based on ANSYS Workbench. J. Agric. Mech. Res. 2016, 38, 46–50. [Google Scholar]

- Zhang, C. Vibration Test and Modal Analysis of Compartment of Monorail Transport Truck; Jiangsu University: Zhejiang, China, 2019. [Google Scholar]

- Lei, X.; Xing, C.; Wu, S. Mid-and high-frequency vibration characteristics of track structures. J. Vib. Eng. 2020, 33, 1245–1252. [Google Scholar]

- Chou, S.; Hu, Y.; Zhang, C. Vibration test and analysis of orchard monorail truck under multiple working conditions. J. Jiangsu Univ. 2021, 42, 207–214+228. [Google Scholar]

- Pelloso, M.F.; Pelloso, B.F.; de Lima, A.A.; Ortiz, A.H.T. Influence of harvester and rotation of the primary extractor speed in the agroindustrial performance of sugarcane. Sugar Tech 2021, 23, 692–696. [Google Scholar] [CrossRef]

- Wang, F.L.; Ma, S.C.; Xing, H.N.; Bai, J.; Ma, J.Z.; Wang, M.L. Effect of Contra-Rotating Basecutter Parameters on Basecutting Losses. Sugar Tech 2021, 23, 278–285. [Google Scholar] [CrossRef]

- Ma, L.; Wei, J.; Huang, X.; Zong, W.Y.; Zhan, G.C. Analysis of Harvesting Losses of Rapeseed Caused by Vibration of Combine Harvester Header during Field Operation. Trans. Chin. Soc. Agric. Mach. 2020, 51, 134–138. [Google Scholar]

- Zhao, X.; Li, X. Vibration analysis of chippers-pulverize. J. Inn. Mong. Agric. Univ. 2011, 32, 194–196. [Google Scholar]

- Ma, H.; Cui, H.; An, Z. Low-Frequency Vibration Characteristics in the Working Process of the Salix psammophila Chipper. Sci. Silvae Sin. 2018, 54, 177–190. [Google Scholar]

- Zhu, D.; Xue, R.; Cao, X. Vehicle random vibration analysis using a SDOF parametric excitation model. J. Vib. Shock 2022, 41, 79–86. [Google Scholar]

- Xu, W.; Li, B.; Liu, B.; Wang, S.; Li, Y.; Jia, L.; Zhao, Q. Shaking table test on multi-dimensional seismic response of nuclear power equipment considering different fixed conditions. World Earthq. Eng. 2022, 38, 89–95. [Google Scholar]

- Zak, G.; Wylomanska, A.; Zimroz, R. Alpha-stable distribution based methods in the analysis of the crusher vibration signals for fault detection. IFAC PapersOnLine 2017, 50, 4696–4701. [Google Scholar] [CrossRef]

- Ning, L.; Wang, H. Numerical Simulation Study on Cutting Parameters of Drum Chipper. China For. Prod. Ind. 2019, 56, 26–30. [Google Scholar]

- Hao, X.; Yu, C.; Liu, J.; Han, Q.; Zhai, J. Thermal-induced Bearing Stiffness and Clearance Variation Characteristics and its Effect on Vibration Response of Rotor System. J. Mech. Eng. 2022, 58, 147–165. [Google Scholar]

| Parameters | Numerical |

|---|---|

| Whole machine size (L × W × H)/(cm × cm × cm) | 150 × 80 × 100 |

| Operation slope/(°) | ≥25 |

| Operation speed/(m/s) | 0.5~1 |

| Chipper supported power/(Kw) | 2.94 |

| Operation efficiency/(m3/h) | 1.1~2.1 |

| Material | Density (kg/m3) | Modulus of Elasticity (Pa) | Poisson’s Ratio |

|---|---|---|---|

| Q235 | 7860 | 2.12 × 1011 | 0.288 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gong, Y.; Ren, L.; Han, X.; Gao, A.; Jing, S.; Feng, C.; Song, Y. Analysis of Operating Conditions for Vibration of a Self-Propelled Monorail Branch Chipper. Agriculture 2023, 13, 101. https://doi.org/10.3390/agriculture13010101

Gong Y, Ren L, Han X, Gao A, Jing S, Feng C, Song Y. Analysis of Operating Conditions for Vibration of a Self-Propelled Monorail Branch Chipper. Agriculture. 2023; 13(1):101. https://doi.org/10.3390/agriculture13010101

Chicago/Turabian StyleGong, Yanchen, Longlong Ren, Xiang Han, Ang Gao, Shuaijie Jing, Chunliang Feng, and Yuepeng Song. 2023. "Analysis of Operating Conditions for Vibration of a Self-Propelled Monorail Branch Chipper" Agriculture 13, no. 1: 101. https://doi.org/10.3390/agriculture13010101

APA StyleGong, Y., Ren, L., Han, X., Gao, A., Jing, S., Feng, C., & Song, Y. (2023). Analysis of Operating Conditions for Vibration of a Self-Propelled Monorail Branch Chipper. Agriculture, 13(1), 101. https://doi.org/10.3390/agriculture13010101