Leverage of Essential Oils on Faeces-Based Methane and Biogas Production in Dairy Cows

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Methodology of In Vivo Research

2.2. Methodology of Laboratory Physical Analysis

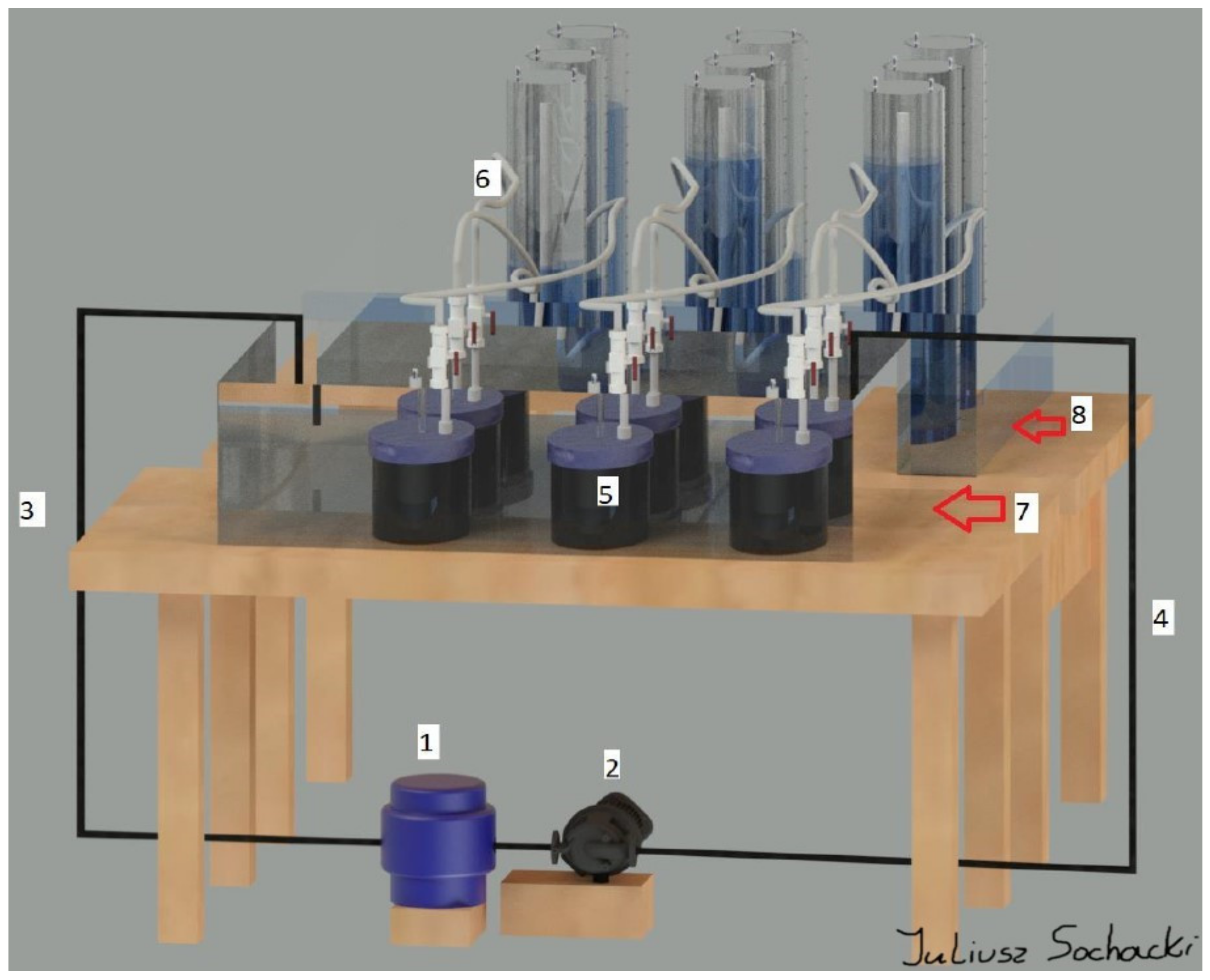

2.3. Methodology of Laboratory Methane Fermentation Tests

3. Results

3.1. Physical Analysis Results

3.2. Methane Fermentation Tests Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Eisen, M.B.; Brown, P.O. Rapid Global Phaseout of Animal Agriculture Has the Potential to Stabilize Greenhouse Gas Levels for 30 Years and Offset 68 Percent of CO2 Emissions This Century. PLoS Clim. 2022, 1, e0000010. [Google Scholar] [CrossRef]

- Hayek, M.N.; Harwatt, H.; Ripple, W.J.; Mueller, N.D. The Carbon Opportunity Cost of Animal-Sourced Food Production on Land. Nat. Sustain. 2021, 4, 21–24. [Google Scholar] [CrossRef]

- Twine, R. Emissions from Animal Agriculture—16.5% Is the New Minimum Figure. Sustainability 2021, 13, 6276. [Google Scholar] [CrossRef]

- Xu, X.; Sharma, P.; Shu, S.; Lin, T.-S.; Ciais, P.; Tubiello, F.N.; Smith, P.; Campbell, N.; Jain, A.K. Global Greenhouse Gas Emissions from Animal-Based Foods Are Twice Those of Plant-Based Foods. Nat. Food 2021, 2, 724–732. [Google Scholar] [CrossRef] [PubMed]

- MacLeod, M.J.; Vellinga, T.; Opio, C.; Falcucci, A.; Tempio, G.; Henderson, B.; Makkar, H.; Mottet, A.; Robinson, T.; Steinfeld, H.; et al. Invited Review: A Position on the Global Livestock Environmental Assessment Model (GLEAM). Animal 2018, 12, 383–397. [Google Scholar] [CrossRef] [PubMed]

- Gerber, P.J.; Steinfeld, H.; Henderson, B.; Organization, (FAO) Food and Agriculture; Gerber, P.J. Tackling Climate Change through Livestock: A Global Assessment of Emissions and Mitigation Opportunities; FAO: Rome, Italy, 2013. [Google Scholar]

- Ritchie, H.; Rosado, P.; Roser, M. Meat and Dairy Production. Our World Data. Available online: https://ourworldindata.org/meat-production#citation (accessed on 23 October 2022).

- Poland. 2022 National Inventory Report (NIR)|UNFCCC. Available online: https://unfccc.int/documents/461818 (accessed on 30 July 2023).

- Measuring Emissions: Detailed Guide 2020. Available online: https://environment.govt.nz/publications/measuring-emissions-detailed-guide-2020/ (accessed on 23 October 2022).

- United States Envitonmental Protection Agency. Overview of Greenhouse Gases. Available online: https://www.epa.gov/ghgemissions/overview-greenhouse-gases (accessed on 23 October 2022).

- Sommer, S.G.; Feilberg, A. Gaseous Emissions of Ammonia and Malodorous Gases. In Animal Manure Recycling; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2013; pp. 131–151. ISBN 978-1-118-67667-7. [Google Scholar]

- Zhang, X.; Lassaletta, L. Manure Management Benefits Climate with Limits. Nat. Food 2022, 3, 312–313. [Google Scholar] [CrossRef] [PubMed]

- Köninger, J.; Lugato, E.; Panagos, P.; Kochupillai, M.; Orgiazzi, A.; Briones, M.J.I. Manure Management and Soil Biodiversity: Towards More Sustainable Food Systems in the EU. Agric. Syst. 2021, 194, 103251. [Google Scholar] [CrossRef]

- Anacleto, T.M.; Oliveira, H.R.; Diniz, V.L.; de Oliveira, V.P.; Abreu, F.; Enrich-Prast, A. Boosting Manure Biogas Production with the Application of Pretreatments: A Meta-Analysis. J. Clean. Prod. 2022, 362, 132292. [Google Scholar] [CrossRef]

- De Vries, J.W.; Groenestein, C.M.; De Boer, I.J.M. Environmental Consequences of Processing Manure to Produce Mineral Fertilizer and Bio-Energy. J. Environ. Manag. 2012, 102, 173–183. [Google Scholar] [CrossRef]

- Peterson, C.B.; Mitloehner, F.M. Sustainability of the Dairy Industry: Emissions and Mitigation Opportunities. Front. Anim. Sci. 2021, 2, 760310. [Google Scholar] [CrossRef]

- Sandars, D.L.; Audsley, E.; Cañete, C.; Cumby, T.R.; Scotford, I.M.; Williams, A.G. Environmental Benefits of Livestock Manure Management Practices and Technology by Life Cycle Assessment. Biosyst. Eng. 2003, 84, 267–281. [Google Scholar] [CrossRef]

- Chadwick, D.R. Emissions of Ammonia, Nitrous Oxide and Methane from Cattle Manure Heaps: Effect of Compaction and Covering. Atmos. Environ. 2005, 39, 787–799. [Google Scholar] [CrossRef]

- Oenema, O.; Oudendag, D.; Velthof, G.L. Nutrient Losses from Manure Management in the European Union. Livest. Sci. 2007, 112, 261–272. [Google Scholar] [CrossRef]

- Re-Evaluating the Cost of Compaction from Manure Application—Manure ManagerManure Manager. Available online: https://www.manuremanager.com/re-evaluating-the-cost-of-compaction-from-manure-application-30480/ (accessed on 26 August 2023).

- United States Envitonmental Protection Agency. Practices to Reduce Methane Emissions from Livestock Manure Management. Available online: https://www.epa.gov/agstar/practices-reduce-methane-emissions-livestock-manure-management (accessed on 23 October 2022).

- Using Separated Manure Solids for Compost Bedding|Ontario.Ca. Available online: http://www.ontario.ca/page/using-separated-manure-solids-compost-bedding (accessed on 26 August 2023).

- Reducing Nutrient Losses during Storage of Manure by Improvement of Storage Conditions or Composting. BovINE. Available online: https://www.bovine-eu.net/reducing-nutrient-losses-during-storage-of-manure-by-improvement-of-storage-conditions-or-composting/ (accessed on 26 August 2023).

- Van Zanten, H.H.E.; Simon, W.; van Selm, B.; Wacker, J.; Maindl, T.I.; Frehner, A.; Hijbeek, R.; van Ittersum, M.K.; Herrero, M. Circularity in Europe Strengthens the Sustainability of the Global Food System. Nat. Food 2023, 4, 320–330. [Google Scholar] [CrossRef] [PubMed]

- Bai, M.; Flesch, T.; Trouvé, R.; Coates, T.; Butterly, C.; Bhatta, B.; Hill, J.; Chen, D. Gas Emissions during Cattle Manure Composting and Stockpiling. J. Environ. Qual. 2020, 49, 228–235. [Google Scholar] [CrossRef] [PubMed]

- Boniecki, P.; Dach, J.; Mueller, W.; Koszela, K.; Przybyl, J.; Pilarski, K.; Olszewski, T. Neural Prediction of Heat Loss in the Pig Manure Composting Process. Appl. Therm. Eng. 2013, 58, 650–655. [Google Scholar] [CrossRef]

- Ahn, H.K.; Mulbry, W.; White, J.W.; Kondrad, S.L. Pile Mixing Increases Greenhouse Gas Emissions during Composting of Dairy Manure. Bioresour. Technol. 2011, 102, 2904–2909. [Google Scholar] [CrossRef]

- Czekała, W.; Malińska, K.; Cáceres, R.; Janczak, D.; Dach, J.; Lewicki, A. Co-Composting of Poultry Manure Mixtures Amended with Biochar—The Effect of Biochar on Temperature and C-CO2 Emission. Bioresour. Technol. 2016, 200, 921–927. [Google Scholar] [CrossRef]

- Janczak, D.; Malińska, K.; Czekała, W.; Cáceres, R.; Lewicki, A.; Dach, J. Biochar to Reduce Ammonia Emissions in Gaseous and Liquid Phase during Composting of Poultry Manure with Wheat Straw. Waste Manag. 2017, 66, 36–45. [Google Scholar] [CrossRef]

- Żukowska, G.; Mazurkiewicz, J.; Myszura, M.; Czekała, W. Heat Energy and Gas Emissions during Composting of Sewage Sludge. Energies 2019, 12, 4782. [Google Scholar] [CrossRef]

- Cow Manure Anaerobic Digestion or Composting—Energetic and Economic Analysis|IEEE Conference Publication|IEEE Xplore. Available online: https://ieeexplore.ieee.org/document/9077550 (accessed on 2 November 2022).

- Czekała, W.; Janczak, D.; Cieślik, M.; Mazurkiewicz, J.; Pulka, J. Food Waste Management Using Hermetia Illucens Insect. J. Ecol. Eng. 2020, 21, 214–216. [Google Scholar] [CrossRef] [PubMed]

- Romaniuk, W.; Mazur, K.; Borek, K.; Borusiewicz, A.; Wardal, W.J.; Tabor, S.; Kuboń, M. Biomass Energy Technologies from Innovative Dairy Farming Systems. Processes 2021, 9, 335. [Google Scholar] [CrossRef]

- Mazur, K.; Roman, K.; Wardal, W.J.; Borek, K.; Barwicki, J.; Kierończyk, M. Emission of Harmful Gases from Animal Production in Poland. Environ. Monit. Assess. 2021, 193, 341. [Google Scholar] [CrossRef] [PubMed]

- Setoguchi, A.; Oishi, K.; Kimura, Y.; Ogino, A.; Kumagai, H.; Hirooka, H. Carbon Footprint Assessment of a Whole Dairy Farming System with a Biogas Plant and the Use of Solid Fraction of Digestate as a Recycled Bedding Material. Resour. Conserv. Recycl. Adv. 2022, 15, 200115. [Google Scholar] [CrossRef]

- Gerber, P.J.; Hristov, A.N.; Henderson, B.; Makkar, H.; Oh, J.; Lee, C.; Meinen, R.; Montes, F.; Ott, T.; Firkins, J.; et al. Technical Options for the Mitigation of Direct Methane and Nitrous Oxide Emissions from Livestock: A Review. Animal 2013, 7, 220–234. [Google Scholar] [CrossRef]

- Mazurkiewicz, J. Loss of Energy and Economic Potential of a Biogas Plant Fed with Cow Manure Due to Storage Time. Energies 2023, 16, 6686. [Google Scholar] [CrossRef]

- Mazurkiewicz, J. The Impact of Manure Use for Energy Purposes on the Economic Balance of a Dairy Farm. Energies 2023, 16, 6735. [Google Scholar] [CrossRef]

- Holm-Nielsen, J.B.; Al Seadi, T.; Oleskowicz-Popiel, P. The Future of Anaerobic Digestion and Biogas Utilization. Bioresour. Technol. 2009, 100, 5478–5484. [Google Scholar] [CrossRef]

- Cornelissen, S.; Koper, M.; Deng, Y.Y. The Role of Bioenergy in a Fully Sustainable Global Energy System. Biomass Bioenergy 2012, 41, 21–33. [Google Scholar] [CrossRef]

- Burg, V.; Bowman, G.; Haubensak, M.; Baier, U.; Thees, O. Valorization of an Untapped Resource: Energy and Greenhouse Gas Emissions Benefits of Converting Manure to Biogas through Anaerobic Digestion. Resour. Conserv. Recycl. 2018, 136, 53–62. [Google Scholar] [CrossRef]

- Nwuche, C.O.; Gupta, S.; Akor, J.; Nweze, J.E.; Nweze, J.A.; Unah, V.U. Biogas from Manure: The Future of Renewable Natural Gas and Its Implications. In Climate Changes Mitigation and Sustainable Bioenergy Harvest Through Animal Waste: Sustainable Environmental Implications of Animal Waste; Arshad, M., Ed.; Springer Nature Switzerland: Cham, Switzerland, 2023; pp. 171–214. ISBN 978-3-031-26224-1. [Google Scholar]

- Teymoori Hamzehkolaei, F.; Amjady, N. A Techno-Economic Assessment for Replacement of Conventional Fossil Fuel Based Technologies in Animal Farms with Biogas Fueled CHP Units. Renew. Energy 2018, 118, 602–614. [Google Scholar] [CrossRef]

- Krausmann, F.; Erb, K.-H.; Gingrich, S.; Lauk, C.; Haberl, H. Global Patterns of Socioeconomic Biomass Flows in the Year 2000: A Comprehensive Assessment of Supply, Consumption and Constraints. Ecol. Econ. 2008, 65, 471–487. [Google Scholar] [CrossRef]

- Burg, V.; Troitzsch, K.G.; Akyol, D.; Baier, U.; Hellweg, S.; Thees, O. Farmer’s Willingness to Adopt Private and Collective Biogas Facilities: An Agent-Based Modeling Approach. Resour. Conserv. Recycl. 2021, 167, 105400. [Google Scholar] [CrossRef]

- Biogas from Manure. Available online: https://extension.psu.edu/biogas-from-manure (accessed on 25 August 2023).

- Ahlberg-Eliasson, K.; Westerholm, M.; Isaksson, S.; Schnürer, A. Anaerobic Digestion of Animal Manure and Influence of Organic Loading Rate and Temperature on Process Performance, Microbiology, and Methane Emission From Digestates. Front. Energy Res. 2021, 9, 740314. [Google Scholar] [CrossRef]

- Kucharska, K.; Hołowacz, I.; Konopacka-Łyskawa, D.; Rybarczyk, P.; Kamiński, M. Key Issues in Modeling and Optimization of Lignocellulosic Biomass Fermentative Conversion to Gaseous Biofuels. Renew. Energy 2018, 129, 384–408. [Google Scholar] [CrossRef]

- Surendra, K.C.; Ogoshi, R.; Reinhardt-Hanisch, A.; Oechsner, H.; Zaleski, H.M.; Hashimoto, A.G.; Khanal, S.K. Anaerobic Digestion of High-Yielding Tropical Energy Crops for Biomethane Production: Effects of Crop Types, Locations and Plant Parts. Bioresour. Technol. 2018, 262, 194–202. [Google Scholar] [CrossRef] [PubMed]

- Usman Khan, M.; Kiaer Ahring, B. Improving the Biogas Yield of Manure: Effect of Pretreatment on Anaerobic Digestion of the Recalcitrant Fraction of Manure. Bioresour. Technol. 2021, 321, 124427. [Google Scholar] [CrossRef] [PubMed]

- Mazurkiewicz, J. Energy and Economic Balance between Manure Stored and Used as a Substrate for Biogas Production. Energies 2022, 15, 413. [Google Scholar] [CrossRef]

- Mazurkiewicz, J. Analysis of the Energy and Material Use of Manure as a Fertilizer or Substrate for Biogas Production during the Energy Crisis. Energies 2022, 15, 8867. [Google Scholar] [CrossRef]

- Czekała, W.; Jasiński, T.; Dach, J. Profitability of the Agricultural Biogas Plants Operation in Poland, Depending on the Substrate Use Model. Energy Rep. 2023, 9, 196–203. [Google Scholar] [CrossRef]

- Czubaszek, R.; Wysocka-Czubaszek, A.; Banaszuk, P. Importance of Feedstock in a Small-Scale Agricultural Biogas Plant. Energies 2022, 15, 7749. [Google Scholar] [CrossRef]

- Benchaar, C.; Hassanat, F.; Martineau, R.; Gervais, R. Linseed Oil Supplementation to Dairy Cows Fed Diets Based on Red Clover Silage or Corn Silage: Effects on Methane Production, Rumen Fermentation, Nutrient Digestibility, N Balance, and Milk Production. J. Dairy. Sci. 2015, 98, 7993–8008. [Google Scholar] [CrossRef]

- Hassanat, F.; Benchaar, C. Methane Emissions of Manure from Dairy Cows Fed Red Clover- or Corn Silage-Based Diets Supplemented with Linseed Oil. J. Dairy. Sci. 2019, 102, 11766–11776. [Google Scholar] [CrossRef] [PubMed]

- An Evaluation of Evidence for Efficacy and Applicability of Methane Inhibiting Feed Additives for Livestock. Available online: https://www.climatelinks.org/resources/evaluation-evidence-efficacy-and-applicability-methane-inhibiting-feed-additives (accessed on 28 August 2023).

- PN-C-04616-01:1975; Wersja Polska. Polski Komitet Normalizacyjny: Warszawa, Poland, 1975. Available online: https://sklep.pkn.pl/pn-c-04616-01-1975p.html (accessed on 27 August 2023).

- Mazurkiewicz, J.; Marczuk, A.; Pochwatka, P.; Kujawa, S. Maize Straw as a Valuable Energetic Material for Biogas Plant Feeding. Materials 2019, 12, 3848. [Google Scholar] [CrossRef] [PubMed]

- PN-Z-15011-3:2001; Wersja Polska. Polski Komitet Normalizacyjny: Warszawa, Poland, 2001. Available online: https://sklep.pkn.pl/pn-z-15011-3-2001p.html (accessed on 27 August 2023).

- PN-C-04540-01:1990; Wersja Polska. Polski Komitet Normalizacyjny: Warszawa, Poland, 1990. Available online: https://sklep.pkn.pl/pn-c-04540-01-1990p.html (accessed on 27 August 2023).

- Pracownia Ekotechnologii. Available online: https://ekolab.up.poznan.pl/en (accessed on 1 August 2023).

- DIN 38414-8; German Standard Methods for the Examination of Water, Waste Water and Sludge; Sludge and Sediments (Group S); Determination of the Amenability to Anaerobic Digestion (S 8). DIN: Berlin, Germany, 1985. Available online: https://www.en-standard.eu/din-38414-8-german-standard-methods-for-the-examination-of-water-waste-water-and-sludge-sludge-and-sediments-group-s-determination-of-the-amenability-to-anaerobic-digestion-s-8/ (accessed on 1 August 2023).

- VDI 4630; Fermentation of Organic Materials - Characterization of the Substrate, Sampling, Collection of Material Data, Fermentation Tests. VDI: Düsseldorf, Germany, 2016. Available online: https://www.vdi.de/richtlinien/details/vdi-4630-fermentation-of-organic-materials-characterization-of-the-substrate-sampling-collection-of-material-data-fermentation-tests (accessed on 1 August 2023).

- European Union Methane Action Plan—Policies. Available online: https://www.iea.org/policies/17024-european-union-methane-action-plan (accessed on 1 October 2023).

- Agar, D.A.; Athanassiadis, D.; Pavelka, B.J. The CO2 Cutting Cost of Biogas from Humanure and Livestock Manure. Sustain. Energy Technol. Assess. 2022, 53, 102381. [Google Scholar] [CrossRef]

- Banks, C.J.; Salter, A.M.; Chesshire, M. Potential of Anaerobic Digestion for Mitigation of Greenhouse Gas Emissions and Production of Renewable Energy from Agriculture: Barriers and Incentives to Widespread Adoption in Europe. Water Sci. Technol. 2007, 55, 165–173. [Google Scholar] [CrossRef]

- Jenkins, J. The Humanure Handbook: Sh** in a Nutshell, 4th ed.; Joseph Jenkins, Inc.: Grove City, PA, USA, 2019; Available online: https://bookstore.acresusa.com/products/the-humanure-handbook-shit-in-a-nutshell-4th-edition (accessed on 27 August 2023).

- Vedrenne, F.; Béline, F.; Dabert, P.; Bernet, N. The Effect of Incubation Conditions on the Laboratory Measurement of the Methane Producing Capacity of Livestock Wastes. Bioresour. Technol. 2008, 99, 146–155. [Google Scholar] [CrossRef]

- Matos, C.F.; Paes, J.L.; Pinheiro, É.F.M.; Campos, D.V.B.D. Biogas production from dairy cattle manure, under organic and conventional production systems. Eng. Agríc. 2017, 37, 1081–1090. [Google Scholar] [CrossRef]

- Pochwatka, P.; Kowalczyk-Juśko, A.; Sołowiej, P.; Wawrzyniak, A.; Dach, J. Biogas Plant Exploitation in a Middle-Sized Dairy Farm in Poland: Energetic and Economic Aspects. Energies 2020, 13, 6058. [Google Scholar] [CrossRef]

- Aili Hamzah, A.F.; Hamzah, M.H.; Che Man, H.; Jamali, N.S.; Siajam, S.I.; Ismail, M.H. Effect of Organic Loading on Anaerobic Digestion of Cow Dung: Methane Production and Kinetic Study. Heliyon 2023, 9, e16791. [Google Scholar] [CrossRef]

- Kafle, G.K.; Chen, L. Comparison on Batch Anaerobic Digestion of Five Different Livestock Manures and Prediction of Biochemical Methane Potential (BMP) Using Different Statistical Models. Waste Manag. 2016, 48, 492–502. [Google Scholar] [CrossRef] [PubMed]

- Ramin, M.; Chagas, J.C.C.; Pal, Y.; Danielsson, R.; Fant, P.; Krizsan, S.J. Reducing Methane Production from Stored Feces of Dairy Cows by Asparagopsis Taxiformis. Front. Sustain. Food Syst. 2023, 7, 1187838. [Google Scholar] [CrossRef]

- Belanche, A.; Newbold, C.J.; Morgavi, D.P.; Bach, A.; Zweifel, B.; Yáñez-Ruiz, D.R. A Meta-Analysis Describing the Effects of the Essential Oils Blend Agolin Ruminant on Performance, Rumen Fermentation and Methane Emissions in Dairy Cows. Animals 2020, 10, 620. [Google Scholar] [CrossRef] [PubMed]

- Miller, G.; Eory, V.; Duthie, C.-A.; Newbold, J. Existing and Near-to-Market Methane Reducing Feed Additives and Technologies: Evidence of Efficacy, Regulatory Pathways to Market and Mechanisms to Incentivise Adoption. Available online: https://pure.sruc.ac.uk/en/publications/existing-and-near-to-market-methane-reducing-feed-additives-and-tedition (accessed on 27 August 2023).

| TMR Ingredients | g/kg Dry Matter | Chemical Composition | g/kg Dry Matter |

|---|---|---|---|

| Corn silage | 388 | Dry matter g/kg as fed | 432 |

| Alfalfa silage | 82 | Organic matter | 906 |

| Meadow grass silage | 91 | aNDF | 367 |

| Beet pulp | 103 | Crude protein | 159 |

| Brewer’s grain | 95 | Ether extract | 26.3 |

| Concentrate | 119 | VEM | 943 |

| Rapeseed meal | 108 | ||

| Mineral vitamin premix | 14 | ||

| Forage:concentrate ratio | 76:24 |

| Parameters | pH [-] | Dry Matter [%] | Dry Organic Matter [%] |

|---|---|---|---|

| Control group–“CON” | |||

| Average value and standard deviation | 7.01 ± 0.05 | 13.19 ± 0.83 | 84.23 ± 2.83 |

| Experimental group (with CA)–“CA” | |||

| Average value and standard deviation | 7.06 ± 0.012 | 13.88 ± 1.77 | 82.54 ± 4.05 |

| CON vs. CA | −0.6 | −0.69 | 1.70 |

| p-value from a t-test | 0.19 | 0.30 | 0.32 |

| Parameters/Test No. | CH4 Content (%) | CH4 m3/Mg FM | Biogas m3/Mg FM | CH4 m3/Mg DM | Biogas m3/Mg DM | CH4 m3/Mg DOM | Biogas m3/Mg DOM |

|---|---|---|---|---|---|---|---|

| Control group–“CON” | |||||||

| Average value and standard deviation | 59.38 ± 0.7 | 19.46 ± 2.3 | 32.75 ± 3.11 | 147.22 ± 11.24 | 247.79 ± 16.86 | 175.21 ± 15.84 | 294.91 ± 23.88 |

| Experimental group (with CA)–“CA” | |||||||

| Average value and standard deviation | 59.98 ± 0.7 | 22.95 ± 1.15 | 38.28 ± 2.06 | 166.70 ± 17.66 | 278.24 ± 32.69 | 201.51 ± 13.99 | 336.21 ± 27.06 |

| CON vs. CA | 1.0% | 15.2% | 14.4% | 11.7% | 10.9% | 13.1% | 12.3% |

| p value * | 0.09 | 0.001 | 0.001 | 0.01 | 0.02 | 0.001 | 0.001 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mazurkiewicz, J.; Sidoruk, P.; Dach, J.; Szumacher-Strabel, M.; Lechniak, D.; Galama, P.; Kuipers, A.; Antkowiak, I.R.; Cieslak, A. Leverage of Essential Oils on Faeces-Based Methane and Biogas Production in Dairy Cows. Agriculture 2023, 13, 1944. https://doi.org/10.3390/agriculture13101944

Mazurkiewicz J, Sidoruk P, Dach J, Szumacher-Strabel M, Lechniak D, Galama P, Kuipers A, Antkowiak IR, Cieslak A. Leverage of Essential Oils on Faeces-Based Methane and Biogas Production in Dairy Cows. Agriculture. 2023; 13(10):1944. https://doi.org/10.3390/agriculture13101944

Chicago/Turabian StyleMazurkiewicz, Jakub, Pola Sidoruk, Jacek Dach, Malgorzata Szumacher-Strabel, Dorota Lechniak, Paul Galama, Abele Kuipers, Ireneusz R. Antkowiak, and Adam Cieslak. 2023. "Leverage of Essential Oils on Faeces-Based Methane and Biogas Production in Dairy Cows" Agriculture 13, no. 10: 1944. https://doi.org/10.3390/agriculture13101944

APA StyleMazurkiewicz, J., Sidoruk, P., Dach, J., Szumacher-Strabel, M., Lechniak, D., Galama, P., Kuipers, A., Antkowiak, I. R., & Cieslak, A. (2023). Leverage of Essential Oils on Faeces-Based Methane and Biogas Production in Dairy Cows. Agriculture, 13(10), 1944. https://doi.org/10.3390/agriculture13101944